Magnetic core heat treatment clamp

A magnetic core and fixture technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problem of low magnetic core occupancy, and achieve the effects of good molding quality, high strength and good heat treatment quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and realized through the following technical solutions.

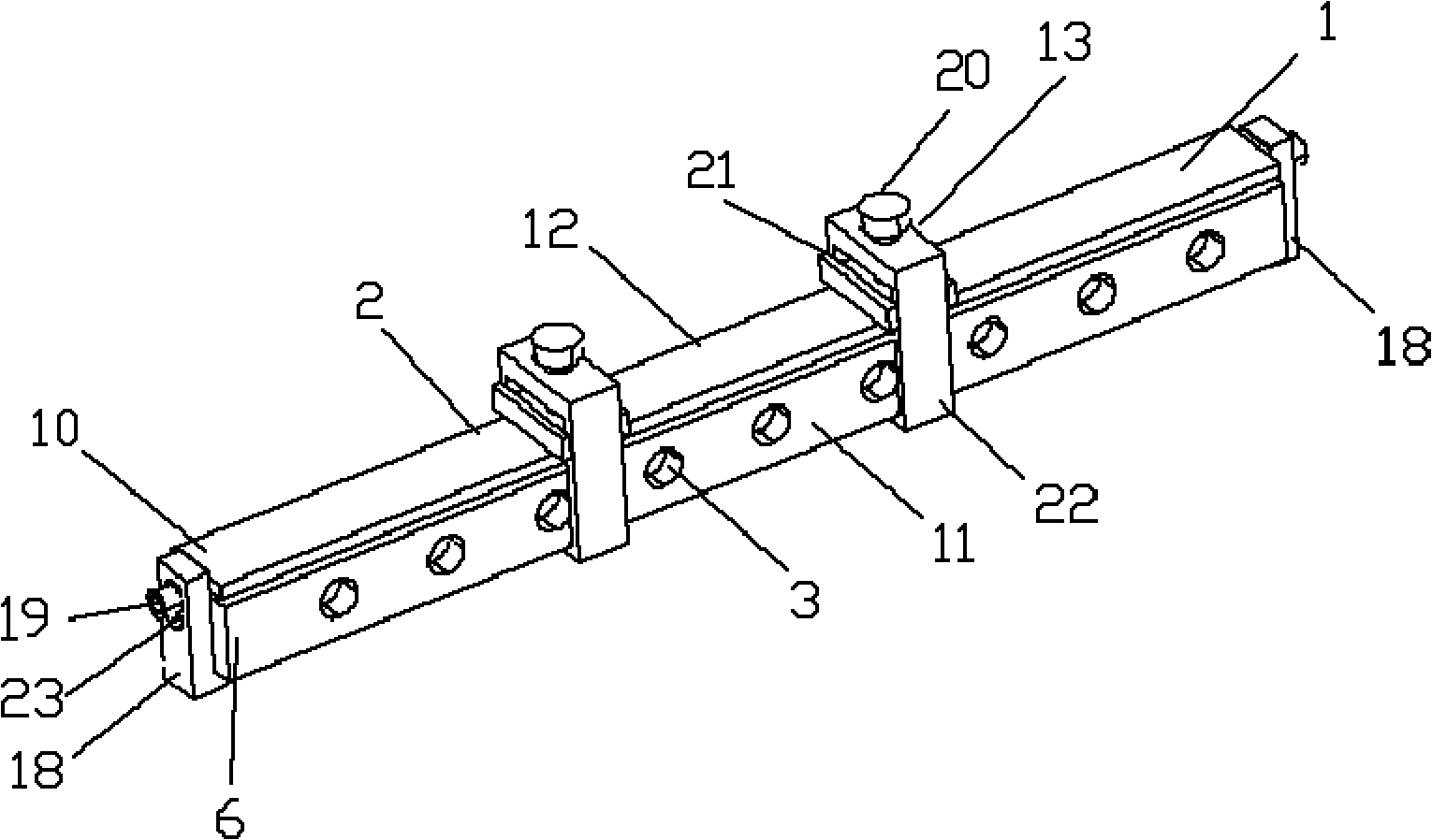

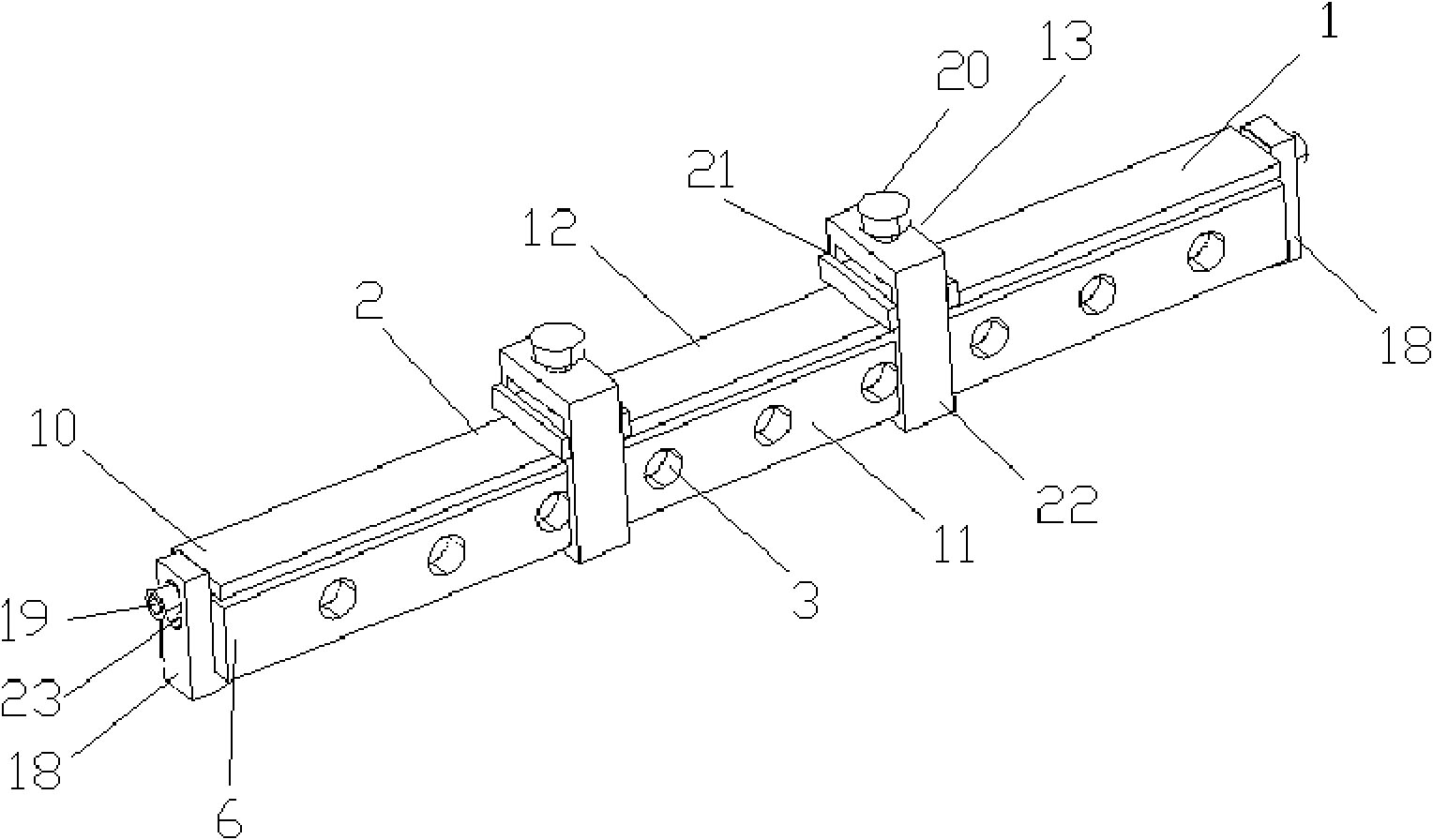

[0032] Such as figure 1 As shown, a magnetic core heat treatment jig of the present invention includes: a magnetic core heat treatment molding die 1 and a fastening fixture 14; The groove pressing part 12 includes a pressing plate 2 and an L-shaped fastener 18 fixed on the end of the pressing plate. The main body of the fastening fixture 14 is a combination of locking fixtures 13, and the combination of locking fixtures 13 is composed of a rectangular locking ring 22, an I-shaped The pressing plate 21 and the fastening knob 20 are composed.

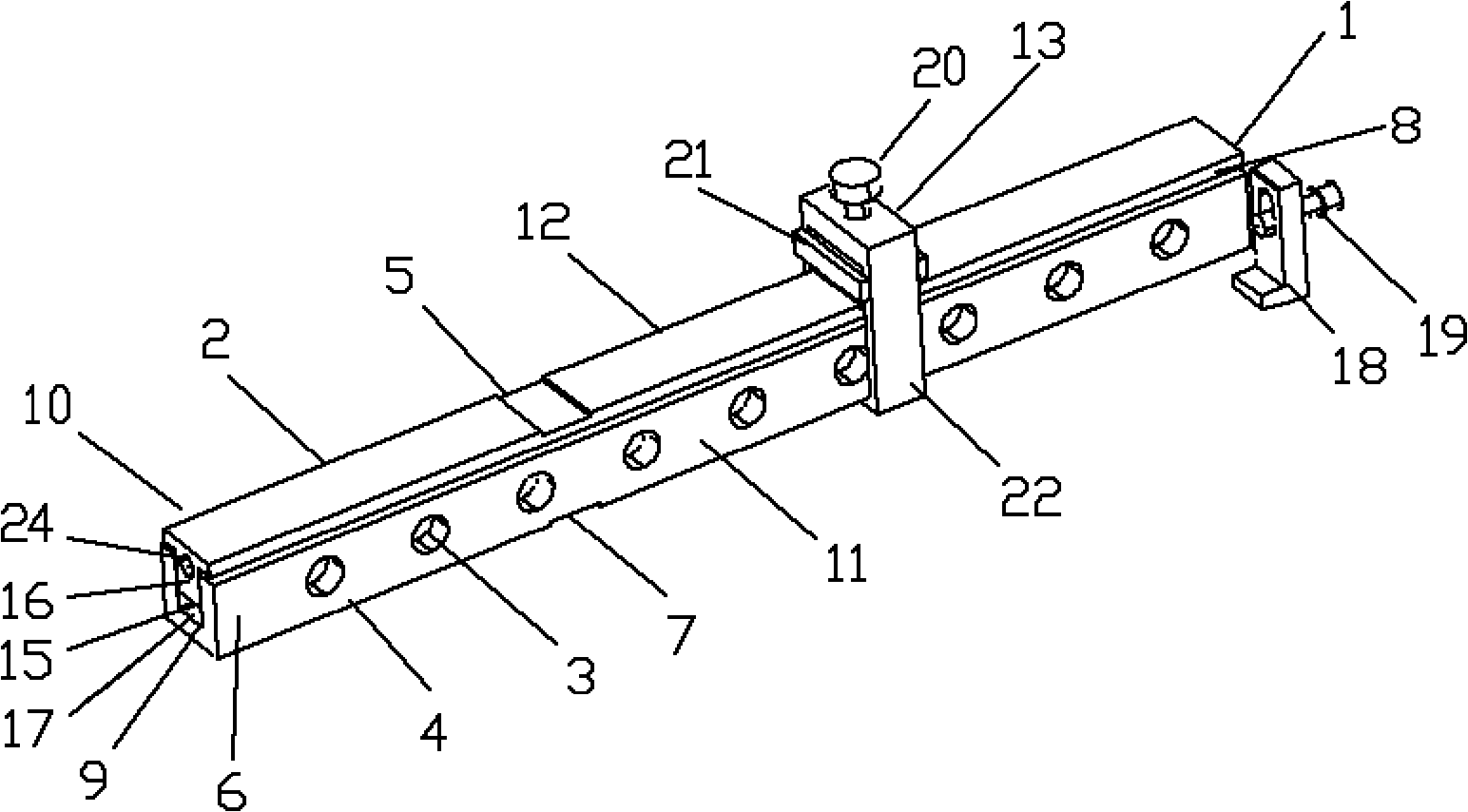

[0033] Among them, such as figure 2 Described, described pressing plate 2 is the straight bar of T-shaped cross section, and described section becomes the pressing plate 2 of T-shaped cross section, and the lower half 8 of pressing plate on the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com