Whole membrane treatment method of electroplating chromeplating waste water

A treatment method, the technology of the full-membrane method, is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the negative impact on the environment, and it is difficult to solve the problem that it cannot meet the zero discharge standard. Secondary pollution and other problems, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

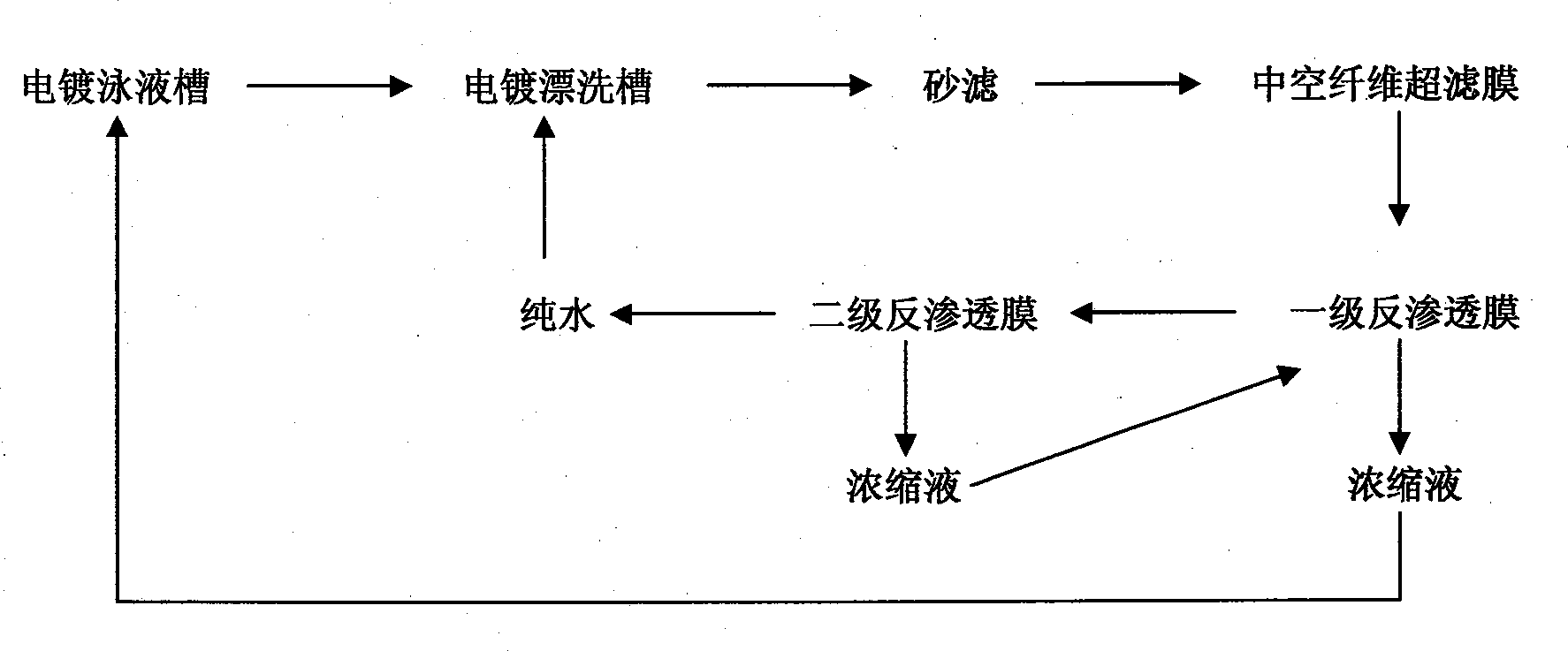

[0018] Example: The electroplating wastewater project of the 38th Research Institute of Hefei, Anhui Province, China Electronics Technology Group Corporation; the project adopts the full-membrane treatment method of electroplating chromium-plating wastewater, combined with a set of hollow fiber membrane equipment and a set of first-level reverse osmosis concentrated membrane equipment And a set of two-stage reverse osmosis concentrated membrane equipment, the internal operation of the entire system is stable, and the effluent index still meets the user's requirement that the conductivity of the effluent is lower than that of municipal tap water. The entire rinse water and hexavalent chromium ions have been circulating inside the system. There is no discharge out of the system, which meets the requirements of zero discharge of the whole membrane method. The specific operation steps of the whole process are as follows:

[0019] (1) Rinse: The electroplated chrome-plated parts are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com