A system for aseptic treatment of water surface garbage in hydropower stations

A technology for surface garbage and treatment systems, applied in waste fuels, fuels, biofuels, etc., can solve problems such as difficult disposal and rapid spread of bacteria, and achieve environmental protection, strong pertinence, broad social value and economic value. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

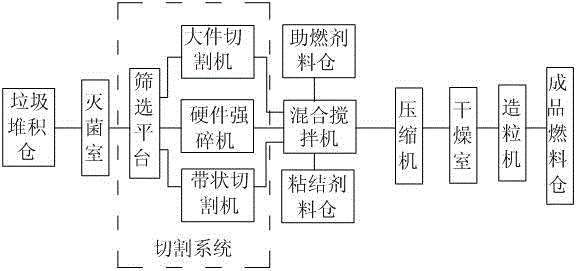

[0016] like figure 1 As shown in the figure, the present invention is a hydropower station water surface garbage aseptic treatment system, including a garbage accumulation bin, a sterilization chamber, a cutting system, a mixing mixer, a compressor, a drying chamber, a granulator, and a finished fuel bin connected in sequence by a conveyor belt. , the garbage is transported to the sterilization room, and the garbage is subjected to compulsory sterilization and disinfection in the sterilization room. After the quarantine reaches the standard, the garbage is transported to the cutting system through the conveyor belt. The cutting system includes a screening platform. For the garbage sent from the bacteria room, the three output ports of the screening platform are respectively connected to the large-size cutting machine, the hardware crusher, and the belt cutting machine, and the large-volume objects in the garbage, such as tree trunks, waste tires and other objects are sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com