Patents

Literature

34results about How to "Implement preliminary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

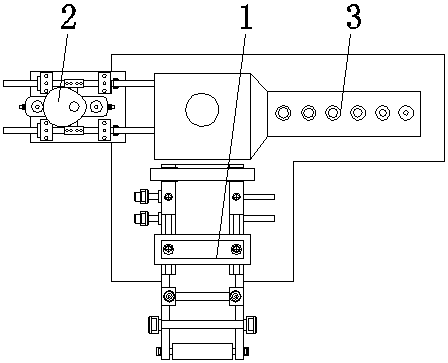

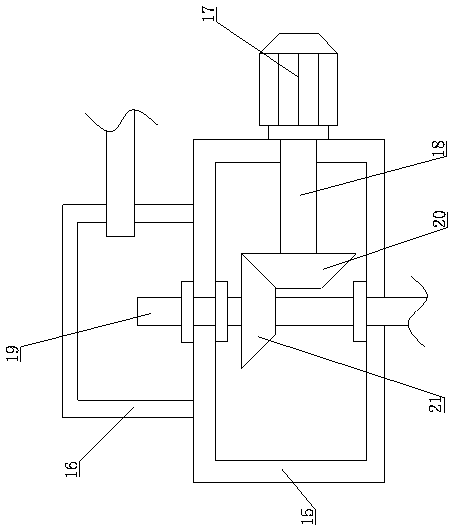

Pressure battery shell mechanism

InactiveCN107661915AAchieve clampingIncrease the clamping degreeShaping toolsMetal-working feeding devicesDrive shaftUtilization rate

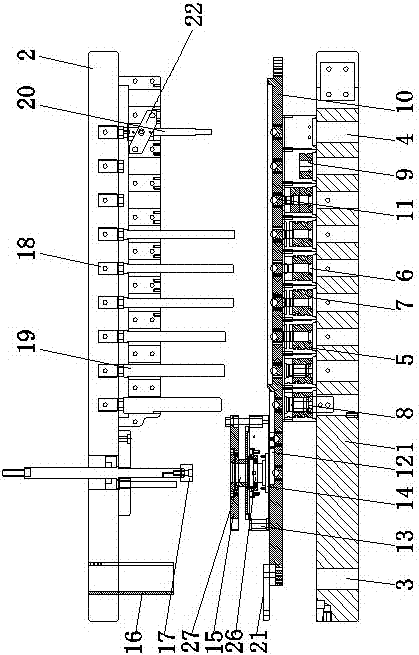

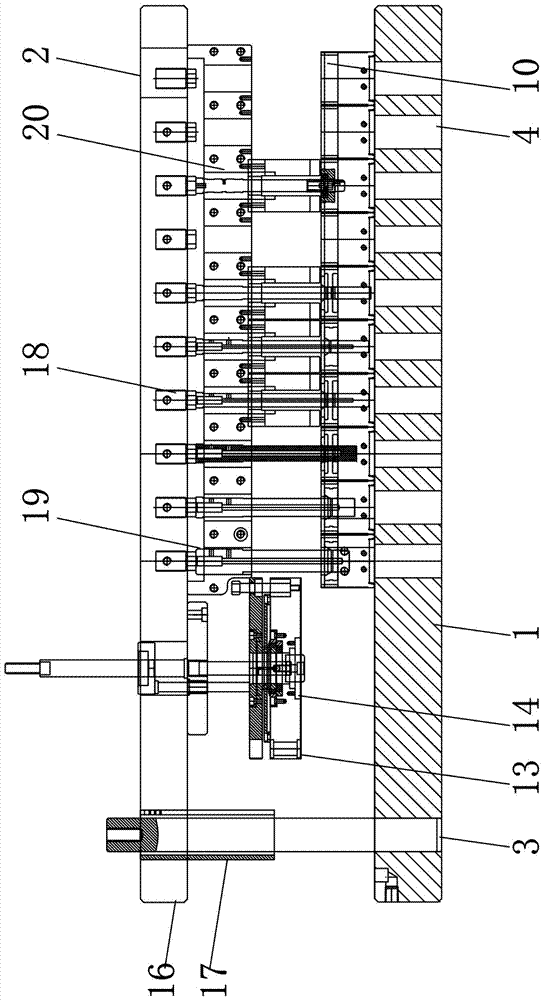

The invention discloses a pressing battery shell mechanism, which includes a feeding mechanism, a transmission mechanism and a stamping mechanism. The feeding mechanism is provided with a base, and a horizontal sliding platform A is arranged at a middle position above the base. The horizontal sliding platform A is distributed laterally on the base, first mounts are symmetrically arranged at the front and rear positions above the transverse slide A, and slide rails are installed on the two first mounts. The invention solves the problems of low material utilization rate and material deviation during the production process of the battery case by setting the cylinder, the transverse sliding table A, the feeding table and the feeding auxiliary table; by setting the motor, the guide seat, the first The first transmission shaft, the second bevel gear, the second transmission shaft and the operation box solve the problem that the transmission and feeding structure is complicated and the processing and feeding of the battery case are not synchronized with the stamping; by setting the upper mold, the lower mold, the punch and the battery case fixture, It solves the problems of complicated steps, low continuity and low yield in the production process of the battery case.

Owner:新乡市盛达电源科技有限公司

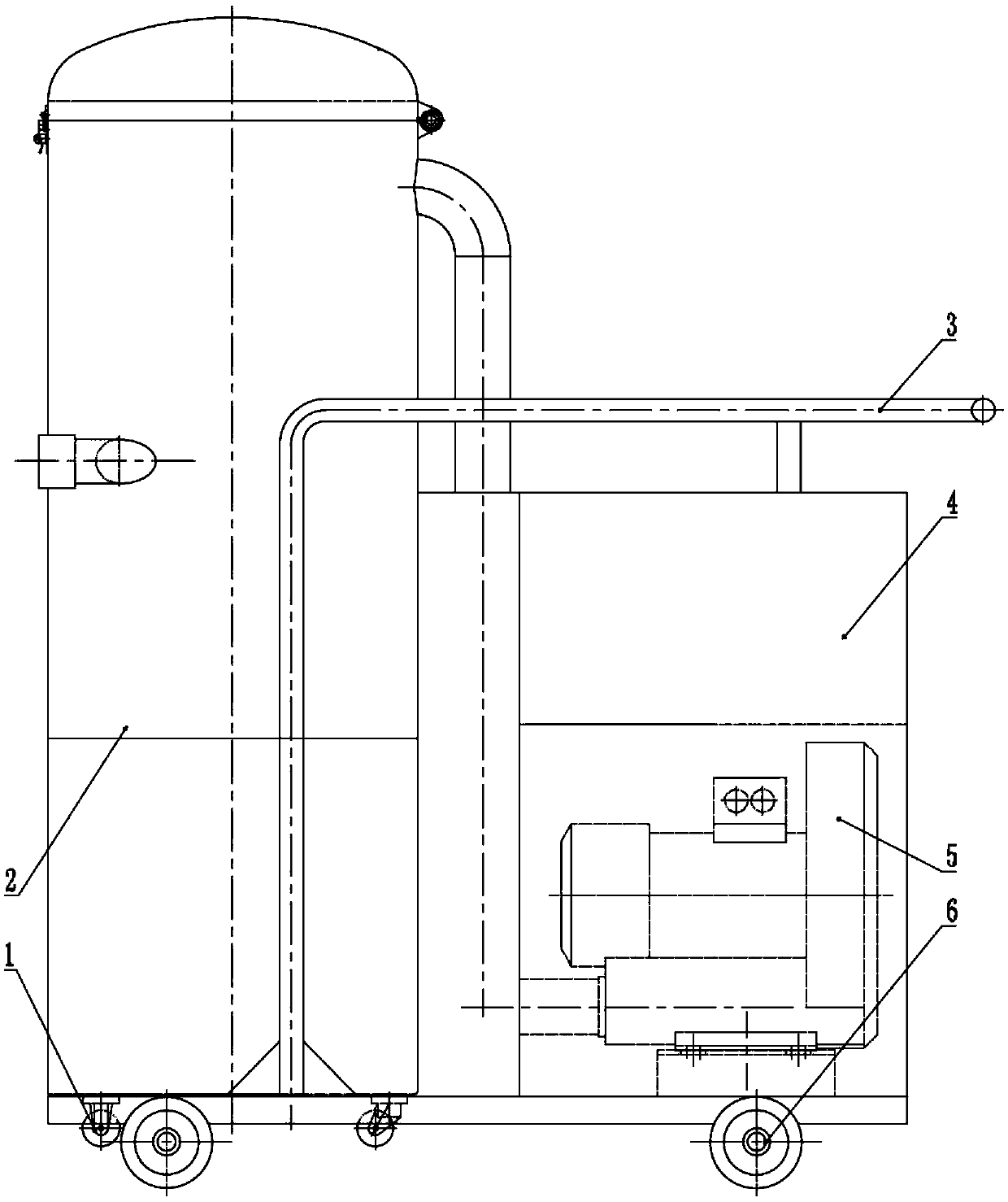

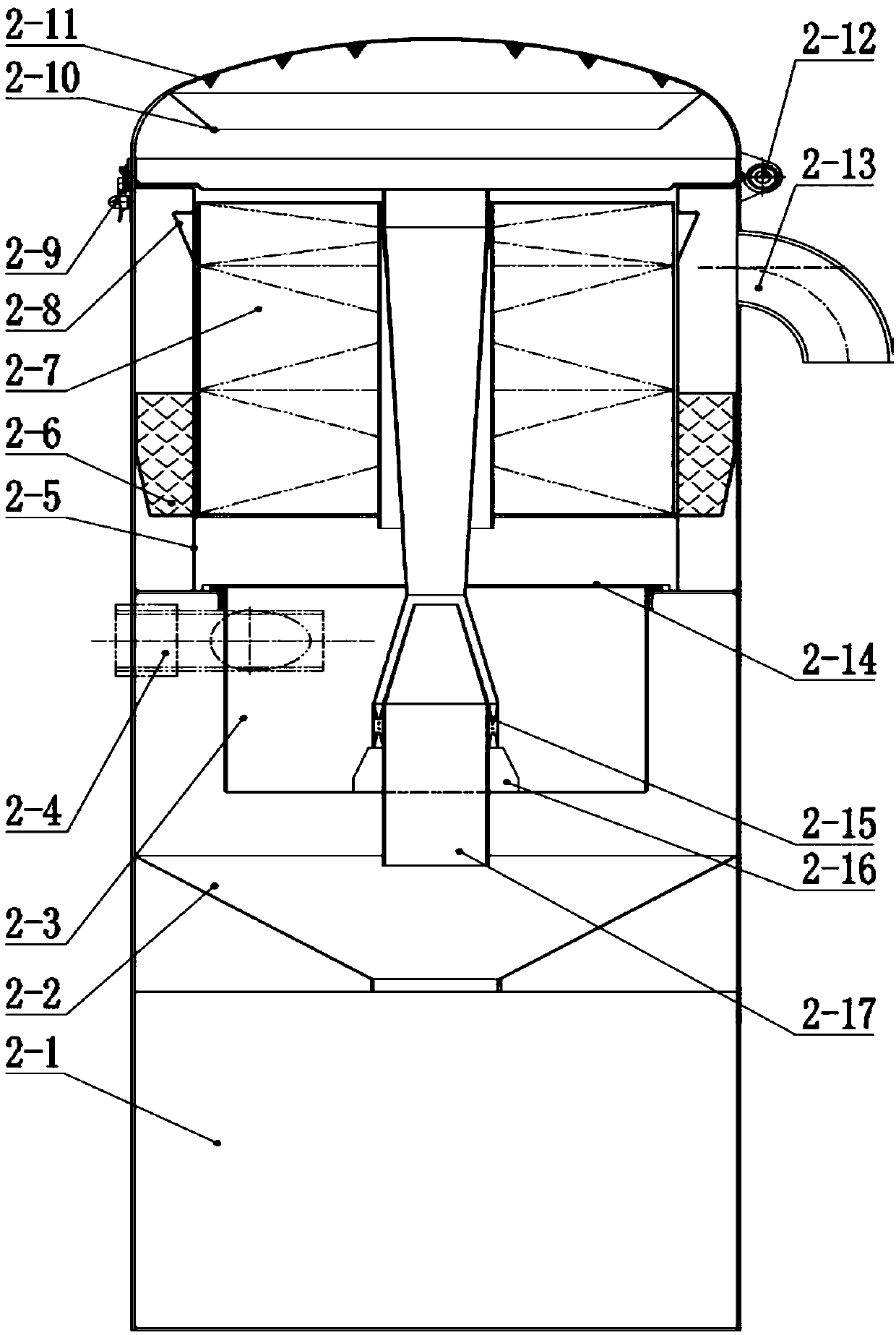

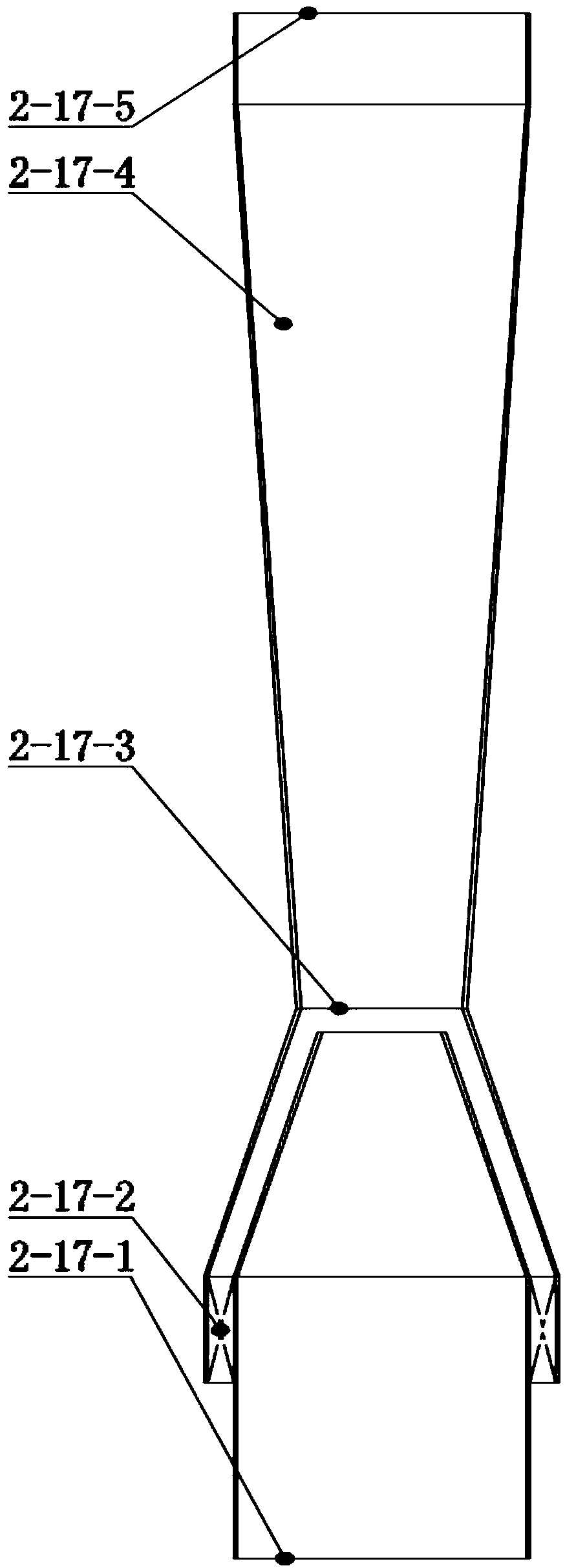

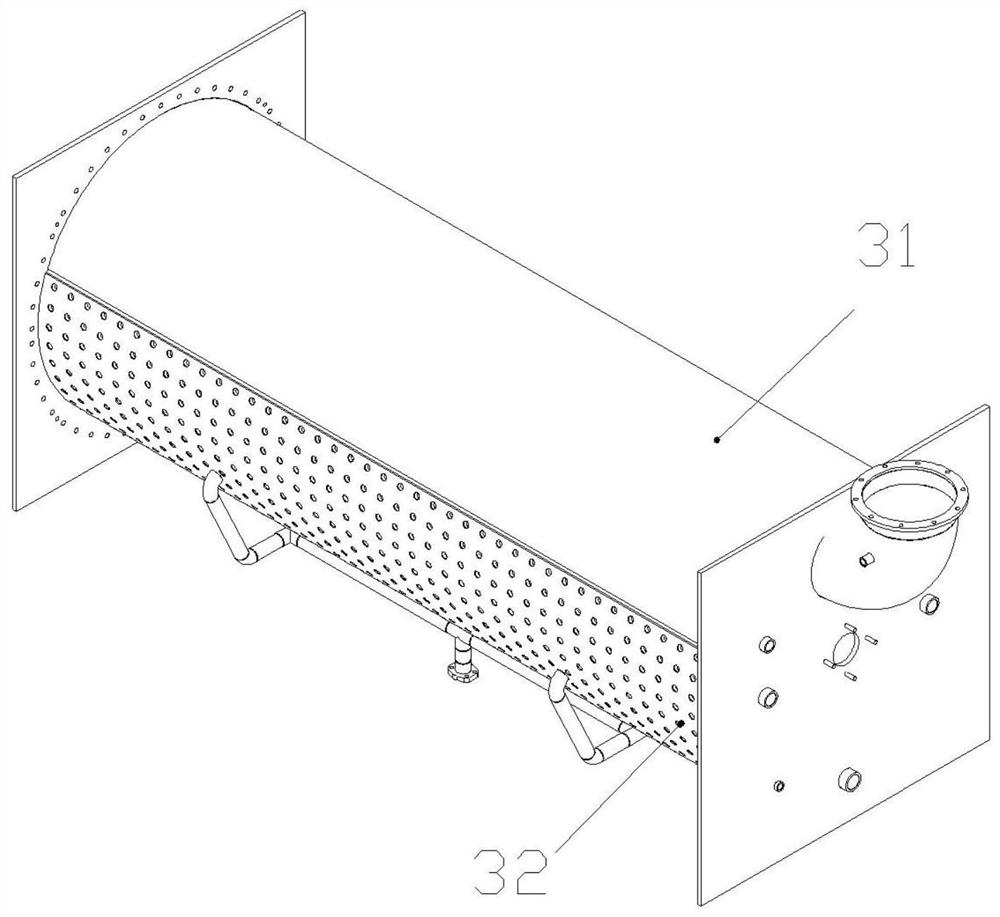

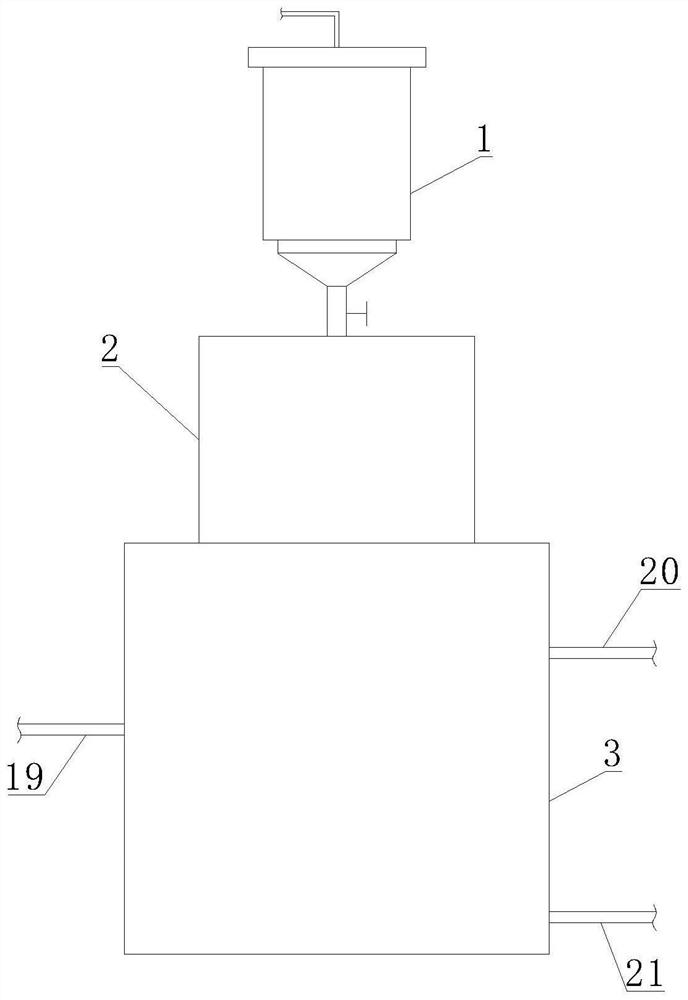

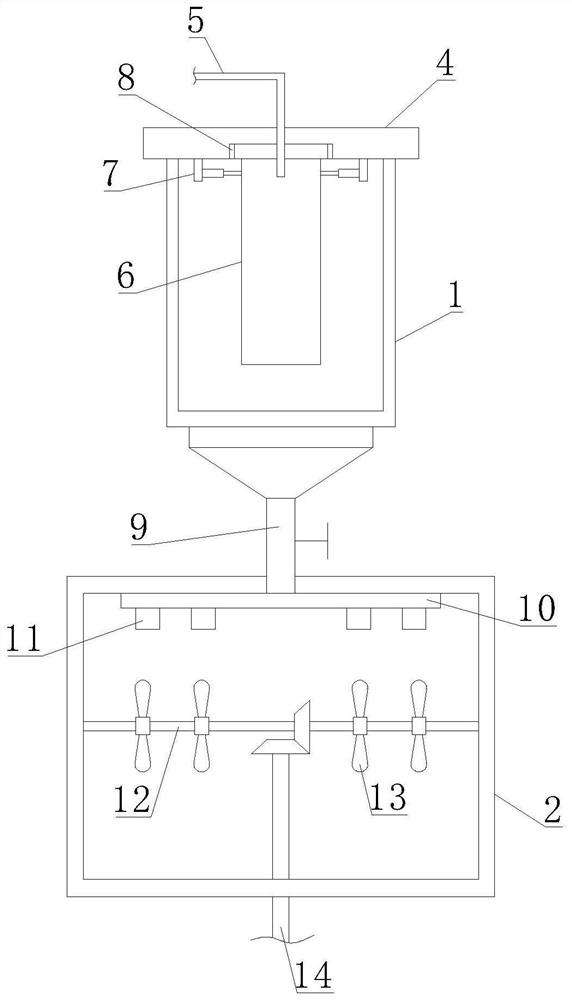

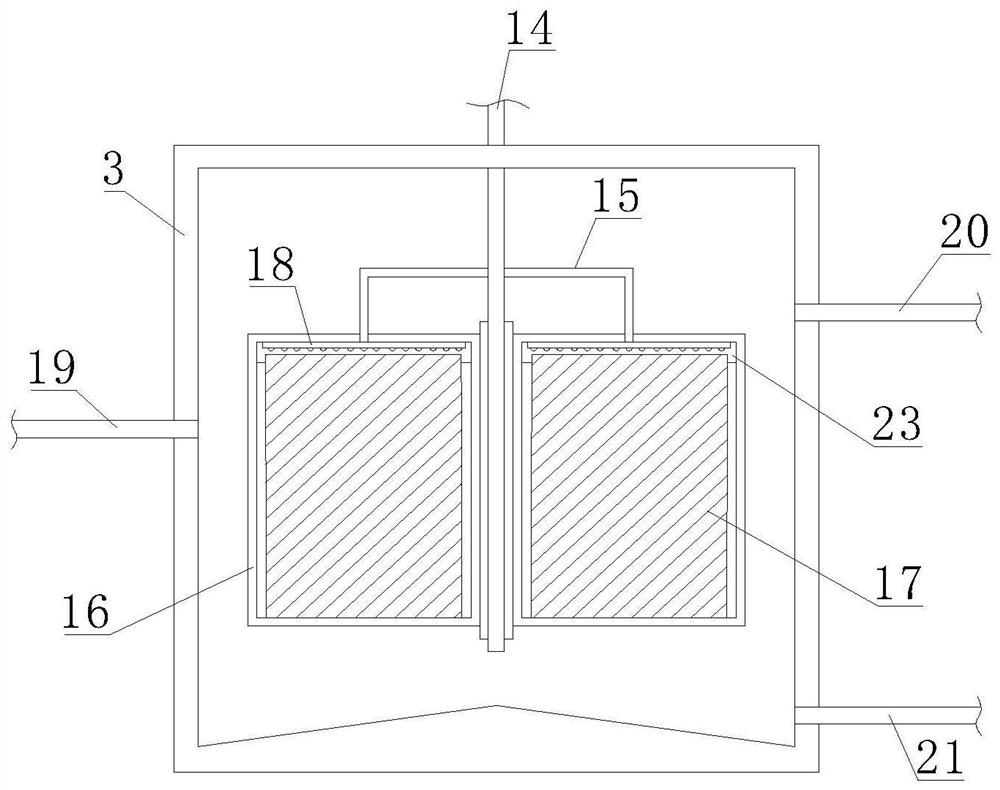

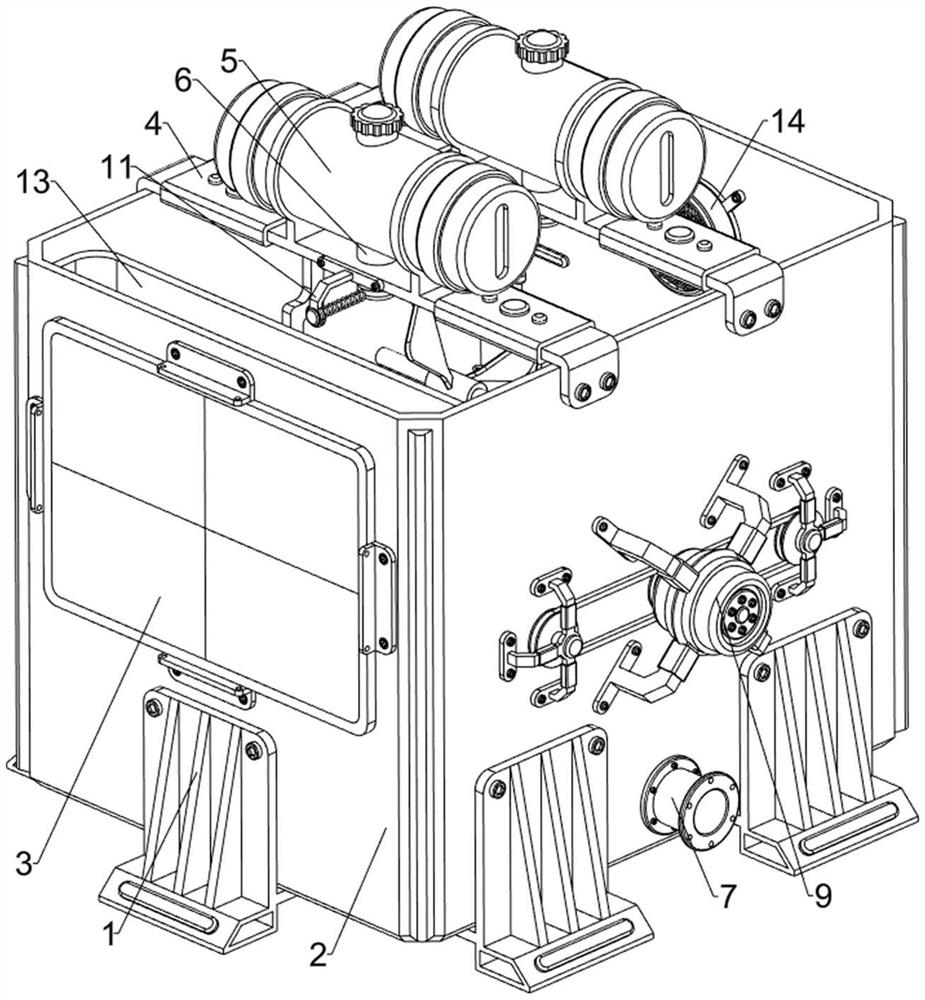

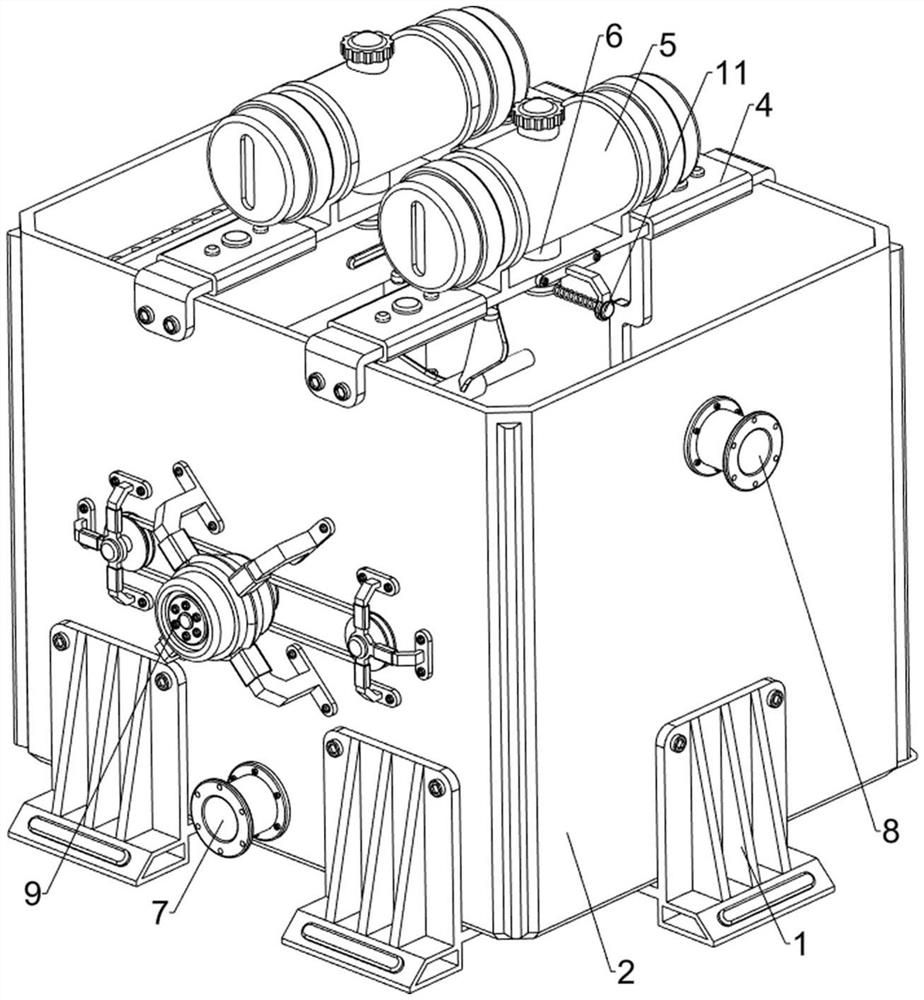

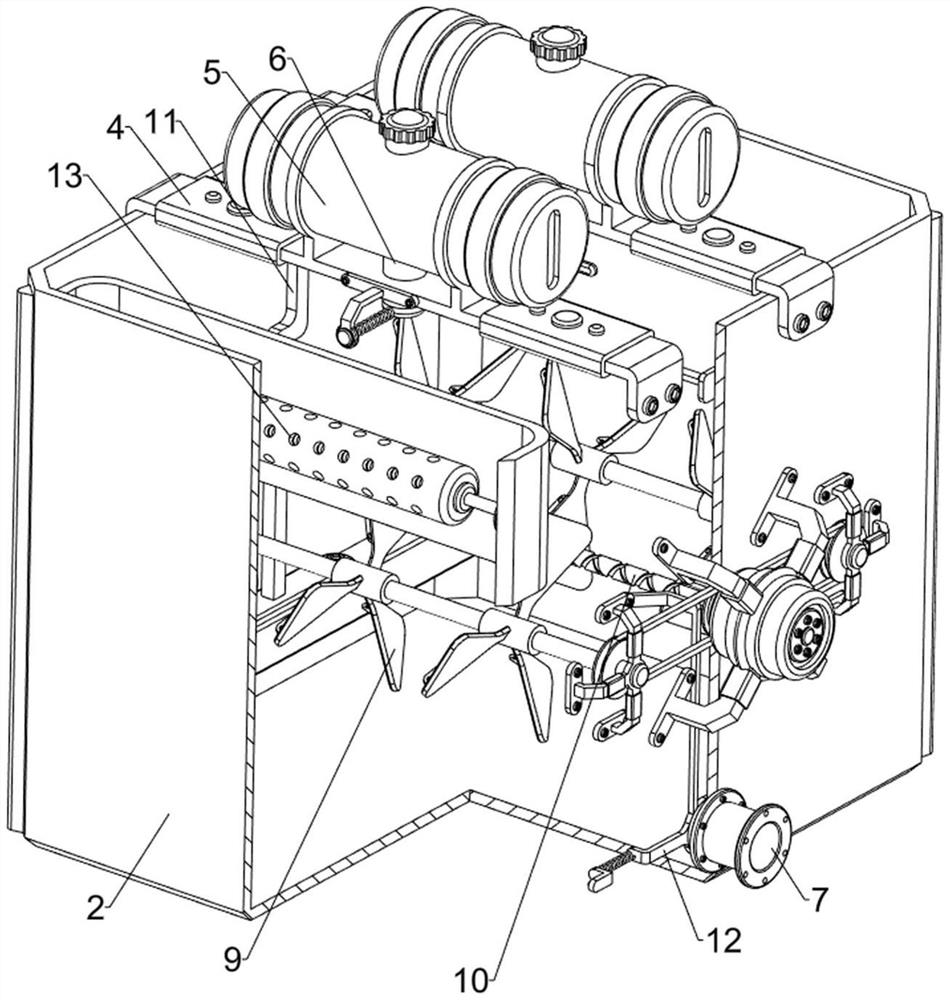

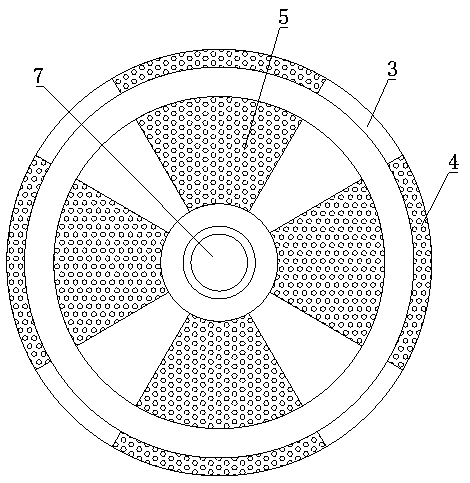

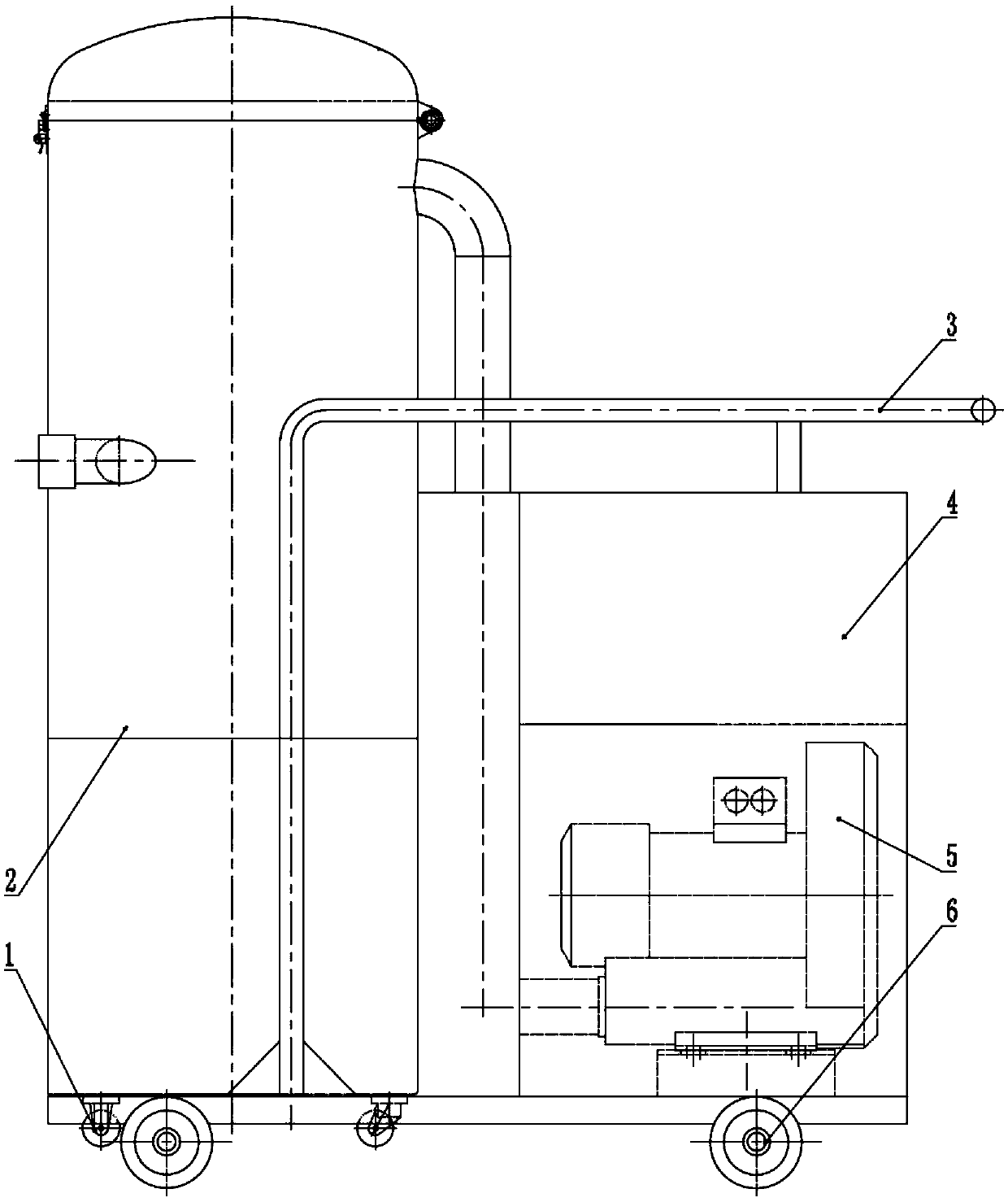

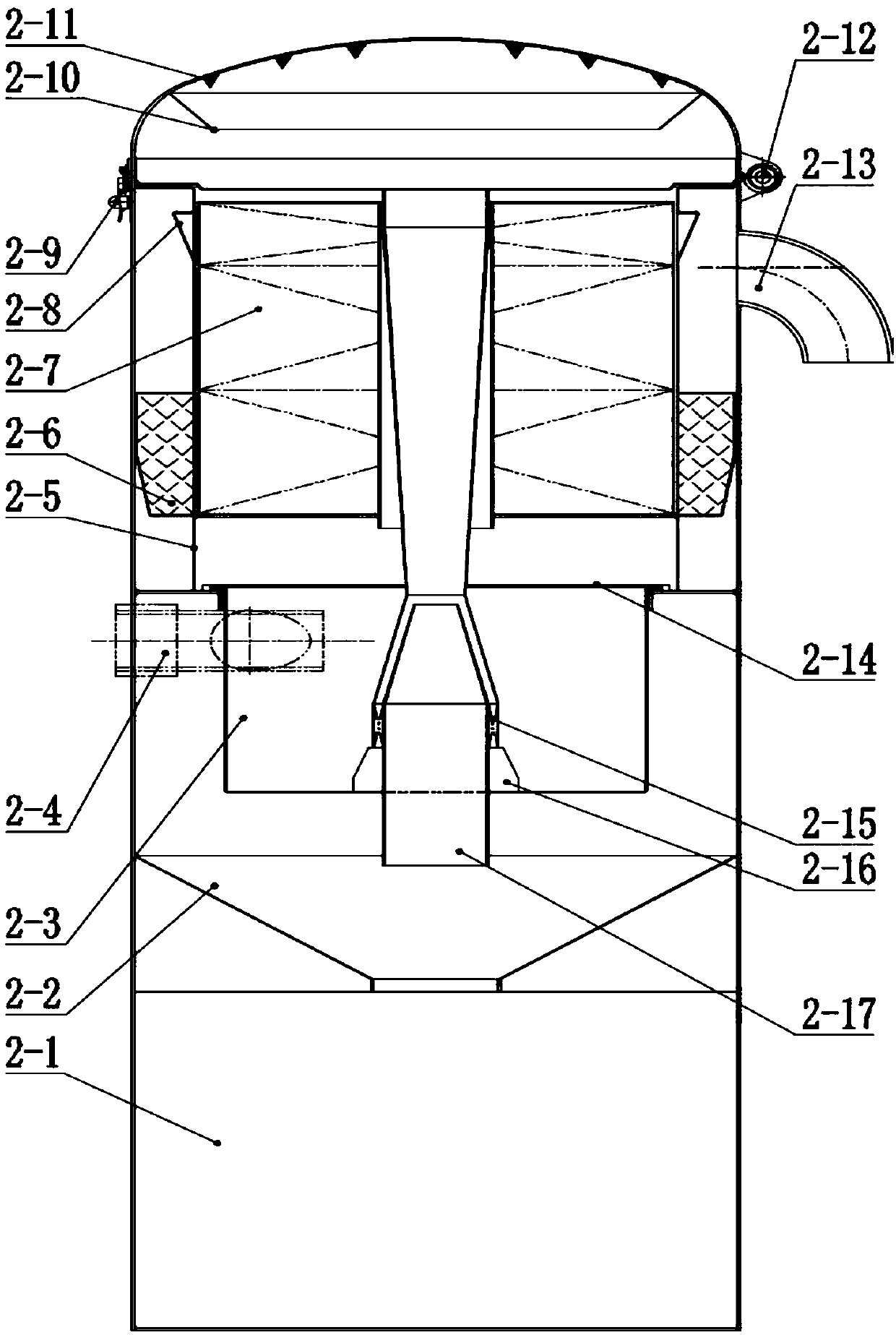

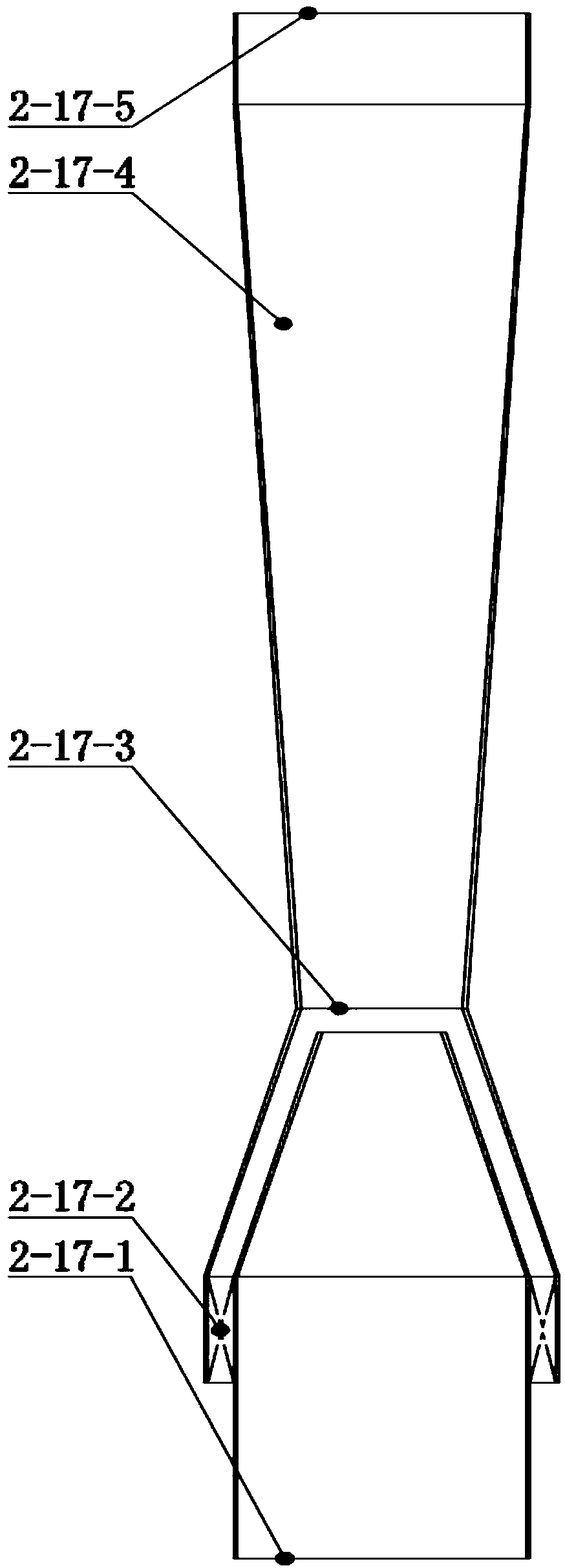

Movable hazardous chemical substance decontamination and dust removal device and applications thereof

InactiveCN110871004AImplement preliminary processingUsing liquid separation agentDust controlEngineering

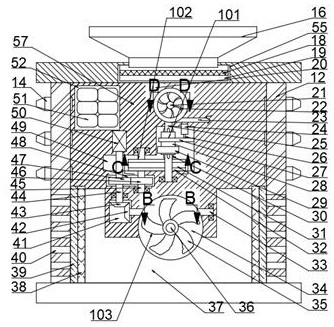

The invention relates to a movable hazardous chemical substance decontamination and dust removal device and applications thereof, and mainly solves the problems that hazardous chemical substance leakage of gas, liquid and powder cannot be treated simultaneously in the prior art. In the method, the movable hazardous chemical substance decontamination and dust removal device includes a hazardous chemical substance decontamination and dust removal cabin, a controller, a movable platform, and a fan, wherein the hazardous chemical substance decontamination and dust removal cabin, the controller andthe fan are all fixed to the movable platform. The hazardous chemical substance decontamination and dust removal cabin includes a three-phase cyclone collection section, a gas-liquid decontaminationsection, a separation section, and a collection section. By means of the technical scheme, the problems are solved well. The device can be used for treatment on the gas, liquid and powdery hazardous chemical substances due to leakage of a workshop.

Owner:CHINA PETROLEUM & CHEM CORP +1

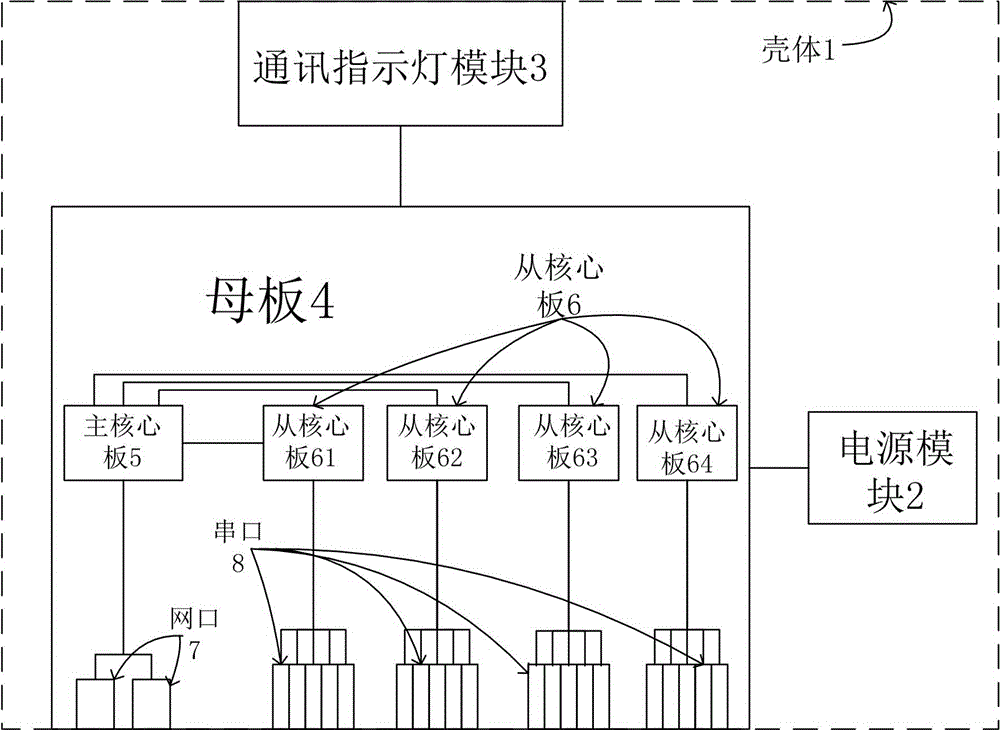

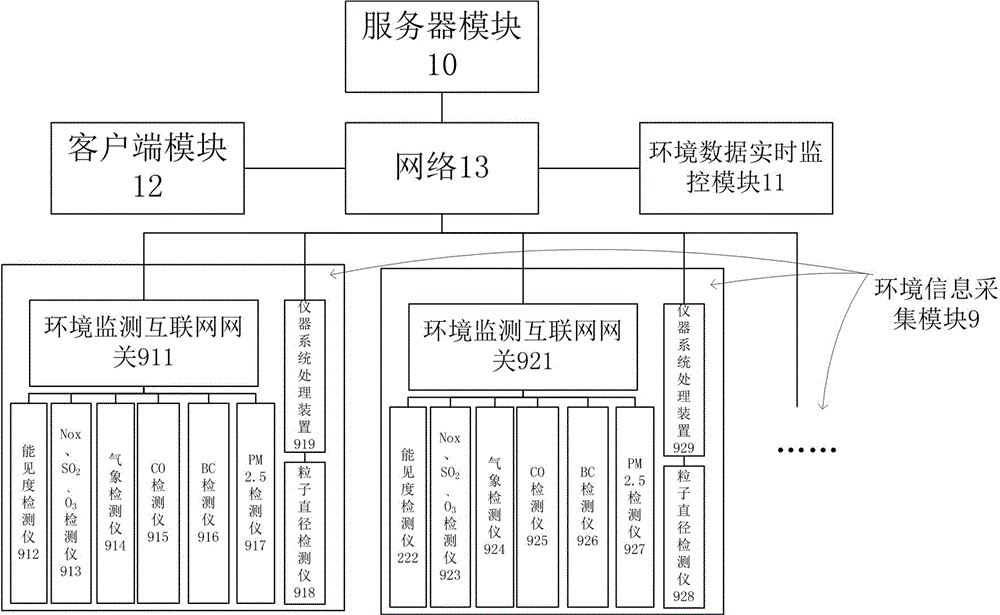

Environment monitoring Internet of Things gateway and system thereof

InactiveCN105282018AReal-time acquisitionImplement preliminary processingTransmission systemsNetwork connectionsNetwork connectionThe Internet

The invention provides an environment monitoring Internet of Things gateway. The environment monitoring Internet of Things gateway comprises a shell, a power supply module, a communication indication lamp module and a mother board; the mother board is provided with a main core board and at least one sub core board, the sum core boards are connected with the main core board, each sub core board is provided with five serial ports, the main core board is provided with two Ethernet ports, and the sub core boards enable the serial ports to be mapped onto the main core board through a RPC protocol. The invention further provides an Internet of Things environment monitoring system. The Internet of Things environment monitoring system comprises a server module, at least one environment information acquisition module, a client side module and an environment data real-time monitoring module; and the environment information acquisition module is connected with the server module through the internet, and the server module is connected with the client side module and the environment data real-time monitoring module through the internet. The environment monitoring Internet of Things gateway can achieve real-time acquisition and environment information preliminary processing for environment information, and the Internet of Things environment monitoring system improves modern management level of an environment monitoring network.

Owner:山东厚德测控技术股份有限公司

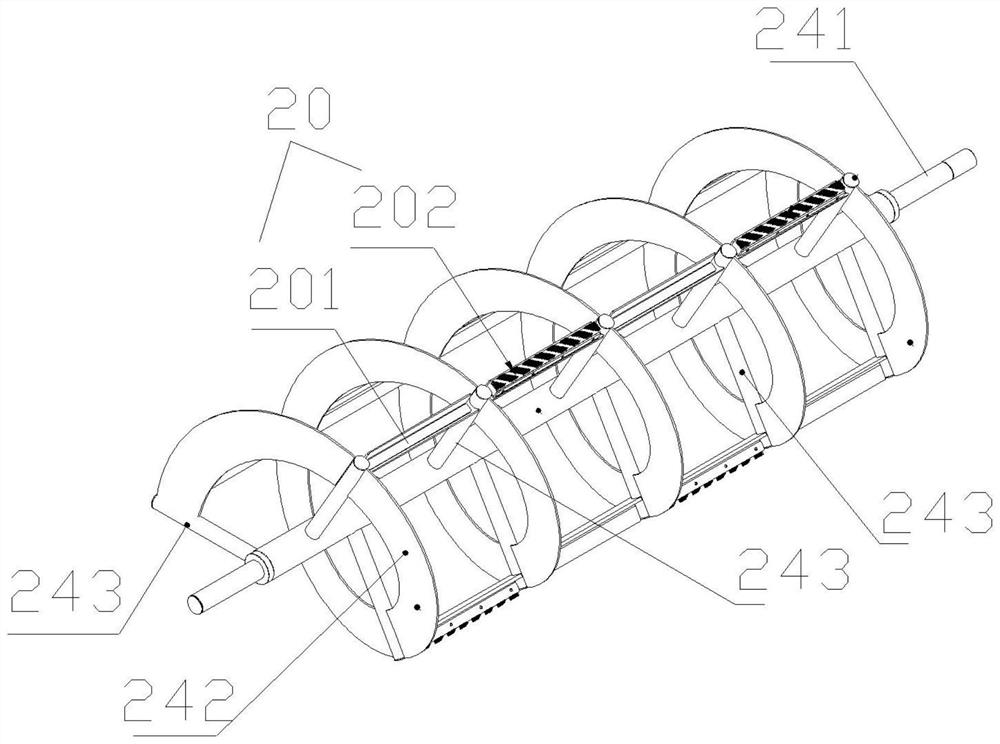

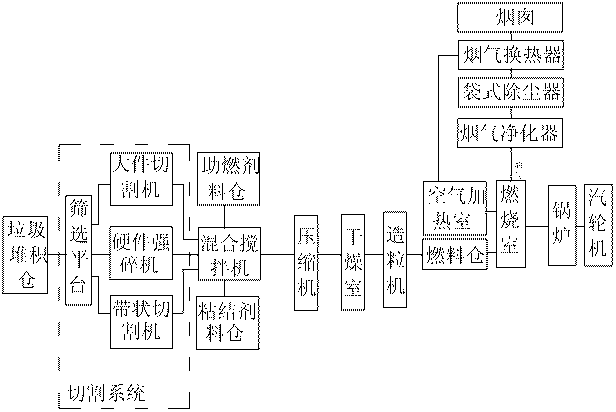

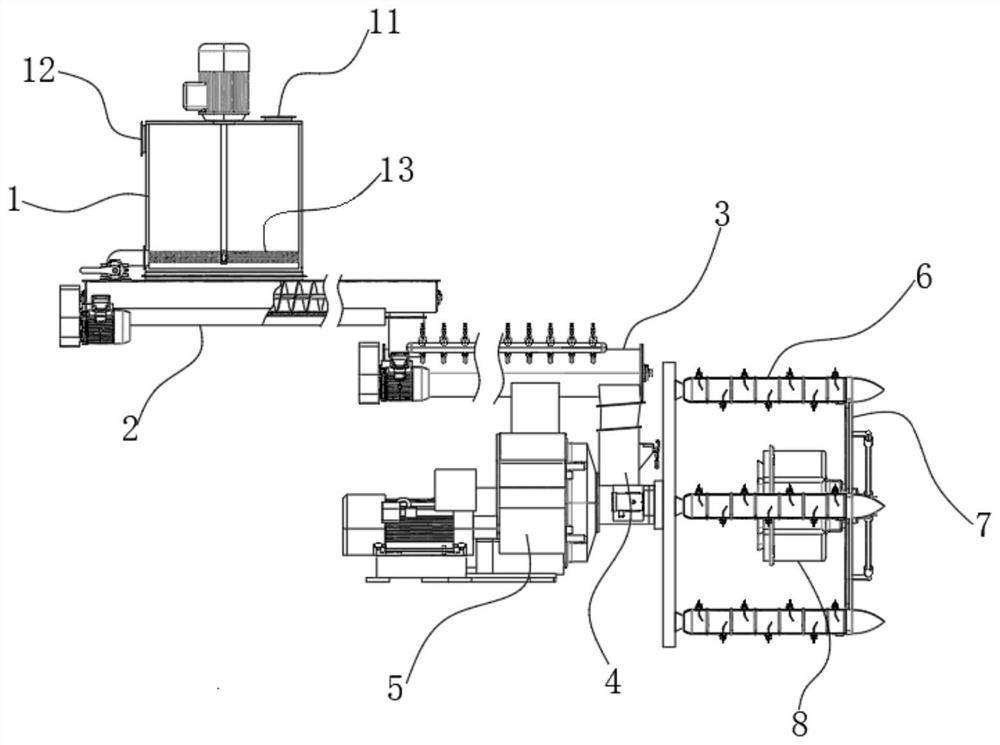

Low-temperature stirring evaporation equipment

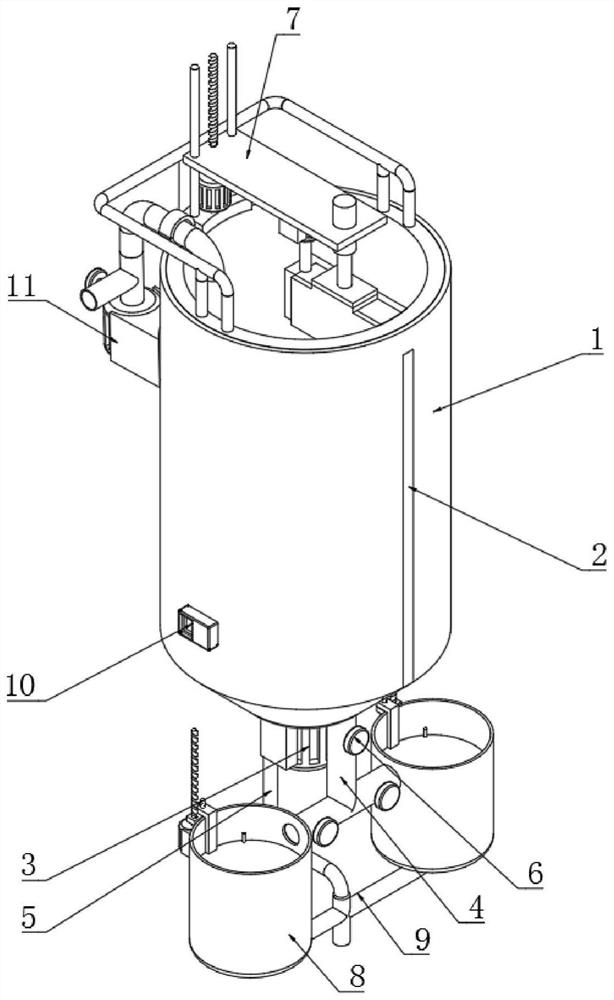

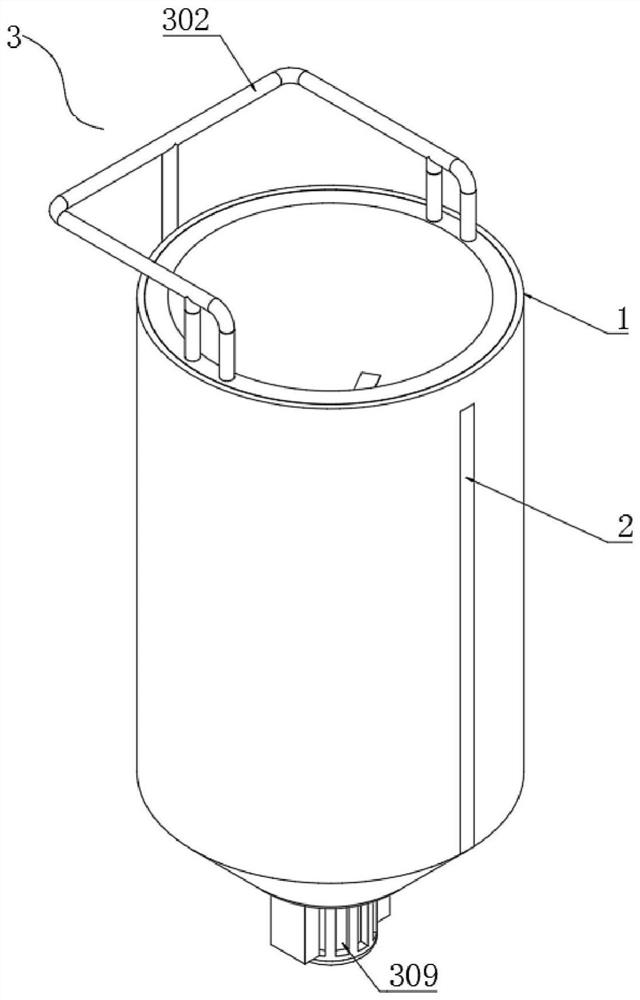

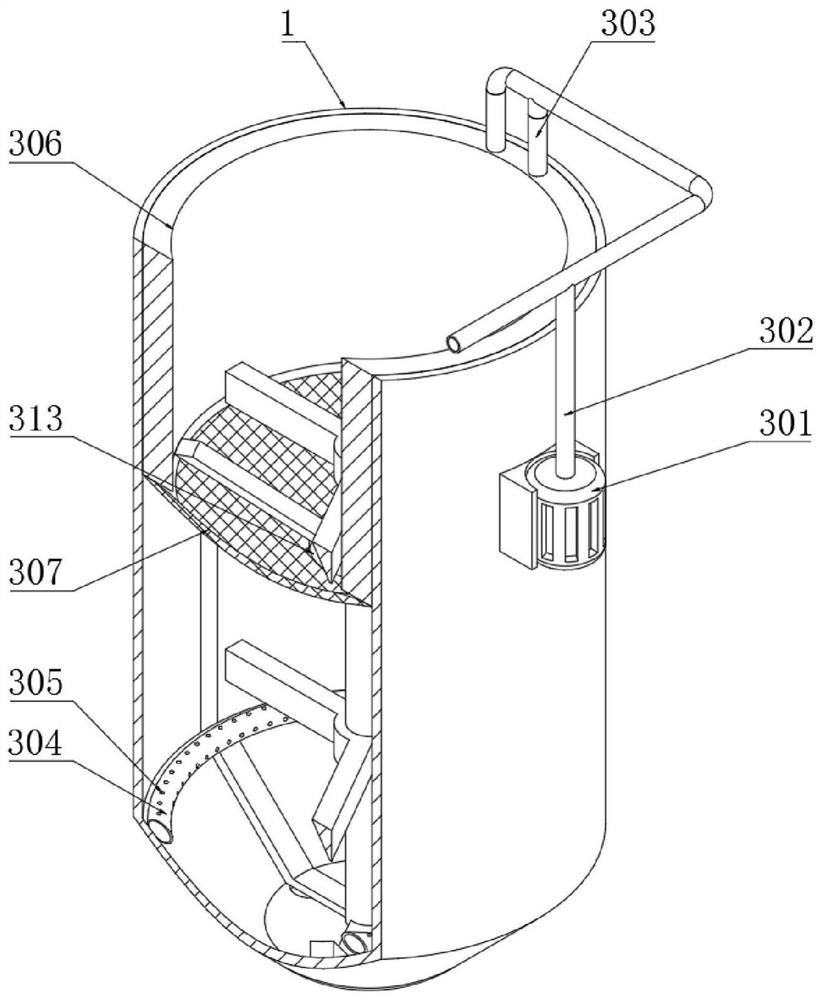

PendingCN112897616AImplement preliminary processingEvenly heatedRotary stirring mixersTransportation and packagingHelical bladeEngineering

The invention relates to low-temperature stirring evaporation equipment which comprises an evaporator, a steam input pipe, a steam output pipe, a pressure reducing device, a stirring device and a heat pump system; the evaporator is used for evaporating waste liquid and comprises an outer wall and a heat insulation plate arranged on at least part of the outer wall, and a steam gap is formed between the heat insulation plate and the outer wall; the steam input pipe and the steam output pipe are connected with the steam gap so as to input and output steam into and out of the steam gap; the pressure reducing device is connected with the evaporator so as to vacuumize the interior of the evaporator; the stirring device comprises a stirring shaft at least partially arranged in the evaporator and a spiral blade arranged on the stirring shaft; the stirring shaft and the spiral blade are internally provided with communicated hollow structures, and a heat exchange medium enters from one end of the stirring shaft, passes through the spiral blade and flows out from the other end of the stirring shaft; and the heat pump system is connected with the steam input pipe and the steam output pipe. The low-temperature stirring evaporation equipment is low in energy consumption and large in heating area, and waste liquid in the evaporator can be uniformly heated, so that the heating efficiency of equipment is improved.

Owner:昆山威胜达环保设备有限公司

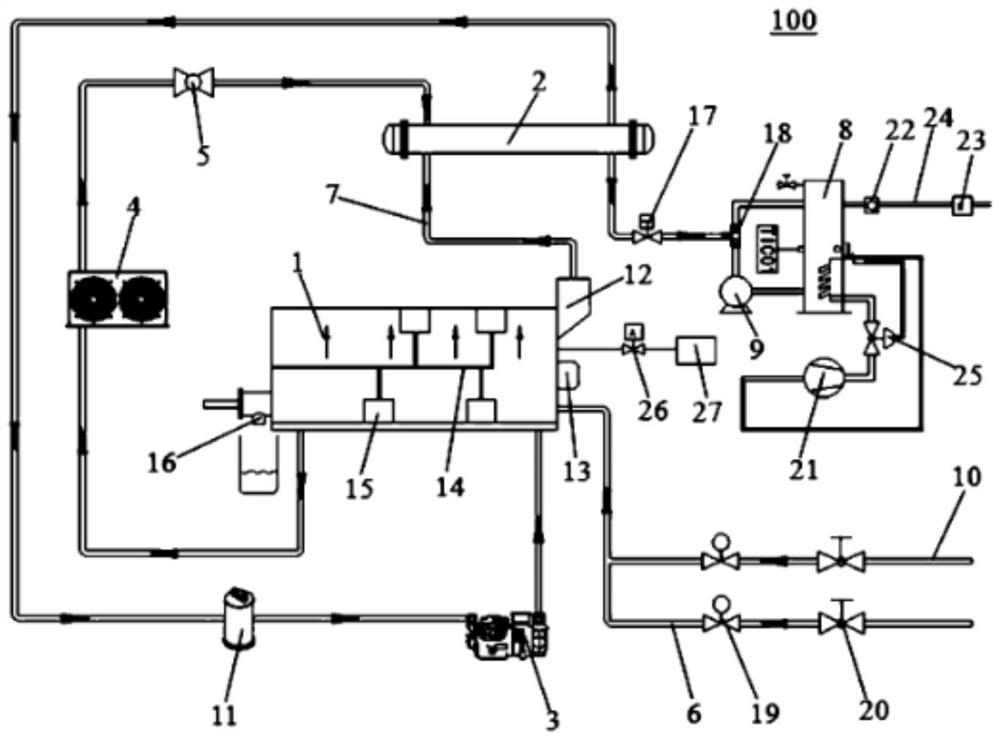

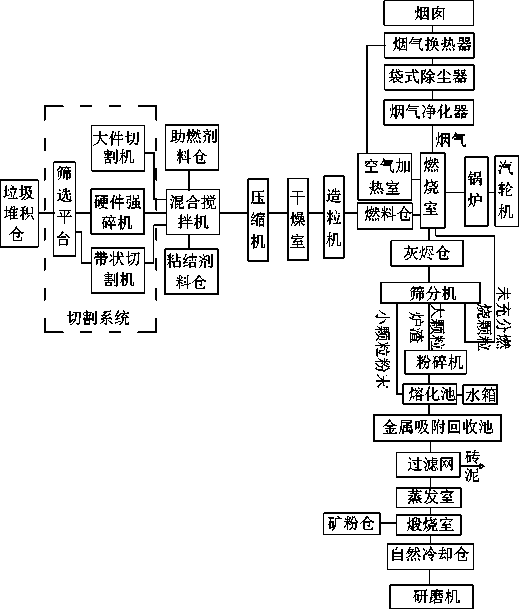

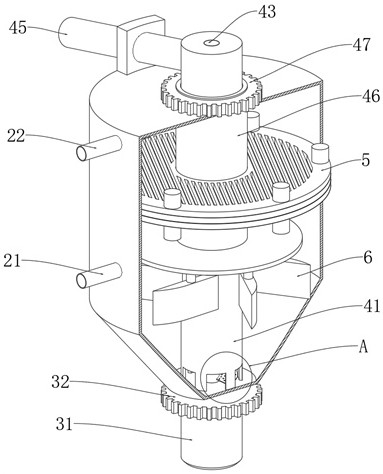

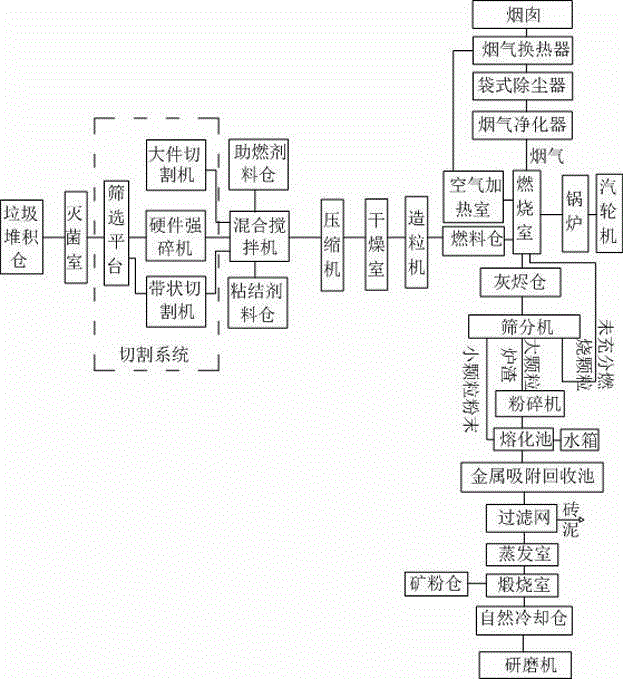

Processing system for generating power by burning refuse on water surface of hydropower station

ActiveCN104070055ASolve problems such as secondary pollutionImprove protectionSolid waste disposalIncinerator apparatusCombustion chamberEngineering

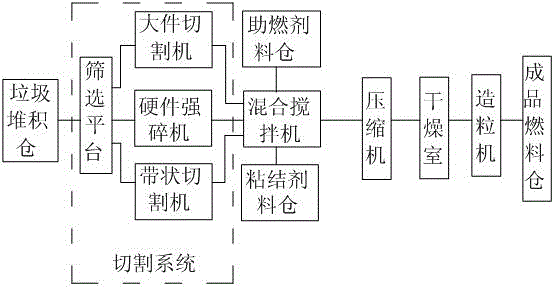

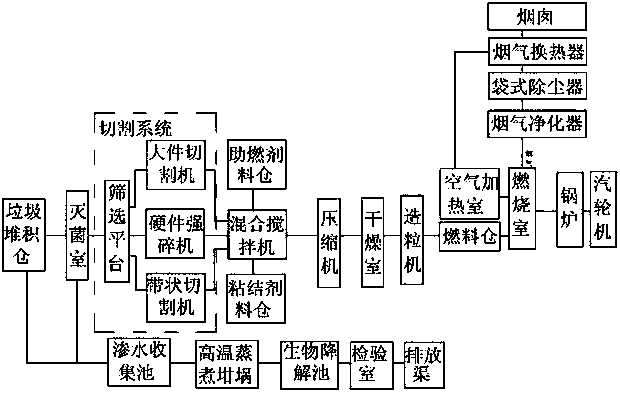

The invention discloses a processing system for generating power by burning refuse on the water surface of a hydropower station. The processing system comprises a refuse stacking bin, a cutting system, a mixing-stirring machine, a compressor, a drying chamber, a granulator, a fuel bin, a combustion chamber, a combustion improver stock bin, a binding material stock bin, a boiler and a steam turbine, wherein smoke is exhausted through a chimney, and an ash bin is arranged under the combustion chamber and is sequentially connected with a sieving machine, a crushing machine, a melting pool, a metal adsorbing-recycling pool, a filter net, an evaporation chamber, calcining chamber, a natural cooling bin, a grinding machine, a water tank and a mineral powder bin. According to the processing system, the refuse is converted into a new fuel and is fed into the combustion chamber in a certain feeding speed, the steam is generated by the boiler by virtue of heat generated after the combustion of the fuel, and the steam turbine is driven to generate the power by virtue of the steam, so that the considerable energy source is obtained; the combusted ash can be converted into a cement additive with high utilization, economic and social values by virtue of reasonable processes and equipment.

Owner:STATE GRID SICHUAN ELECTRIC POWER

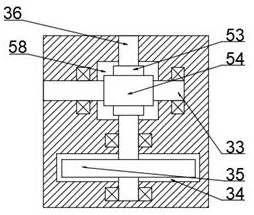

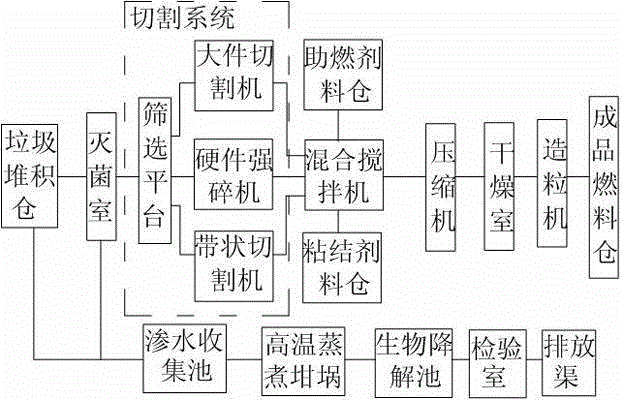

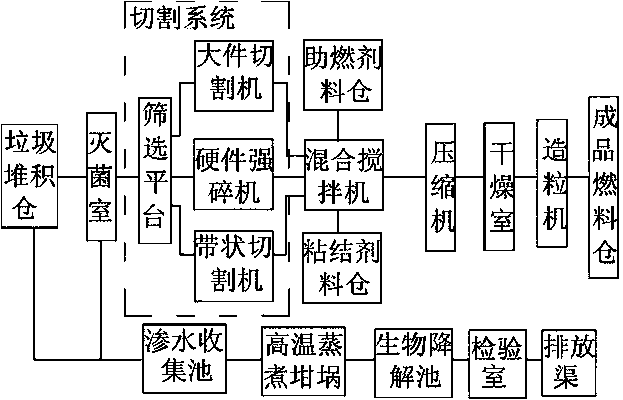

A water surface waste treatment system for a hydropower station

ActiveCN104028539BSolve problems such as secondary pollutionImprove protectionSolid waste disposalBiofuelsCombustionPollution

The invention discloses a hydropower station water surface rubbish treating system. The treating system comprises a rubbish heaping bin, a cutting system, a mixing agitator, a compressor, a drying chamber, a granulator and a finished product fuel bin which are sequentially connected with one another by a conveying belt, as well as a combustion improver bin and an adhesive bin which are respectively connected with the mixing agitator. By virtue of the treating system, rubbish can be transformed into new fine fuel with unified specification, waste is made profitable, and the problems such as secondary pollution caused by rubbish heaping are solved, so that the treating system not only brings benefits for environment protection, but also generates sustainable fuel resources, and has extensive social and economic values.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

Anti-pollution environment-friendly electroplating wastewater treatment device

InactiveCN112340886AScientific and reasonable structureSafe to useWater/sewage treatment by centrifugal separationTreatment involving filtrationAir pumpWastewater disposal

The invention discloses an anti-pollution environment-friendly electroplating wastewater treatment device which is characterized in that an air pump is mounted at one end of the outer side of a separation tank, the air outlet end of the air pump is connected with the air inlet end of an air inlet pipe, one side of the air inlet pipe is connected with an air outlet pipe, and the bottom end of the air outlet pipe is mounted at the top end of an annular air pipe; one end of the air outlet pipe and the side end of the annular air pipe are provided with air outlet holes, a decelerating cylinder isplaced on the inner side of the separation tank, a decelerating net is welded to the bottom end of the decelerating cylinder, a stirring fan is welded to the side end of a transmission rod, an inclined scraping plate is welded to the side end of the transmission rod, the air outlet speed is changed through the air outlet holes, the bubble generation speed is increased, the aeration efficiency is improved, and meanwhile part of metal ions can be subjected to redox reaction, and thus the precipitate of metal compounds is generated, and the speed of flocculate is reduced through the deceleratingcylinder and the decelerating net so that metal impurities can be separated from flocculate and fall to the bottom end of the separation tank, and the wastewater treatment effect and efficiency are guaranteed.

Owner:孟娜妮

Waste disposal system and waste disposal method

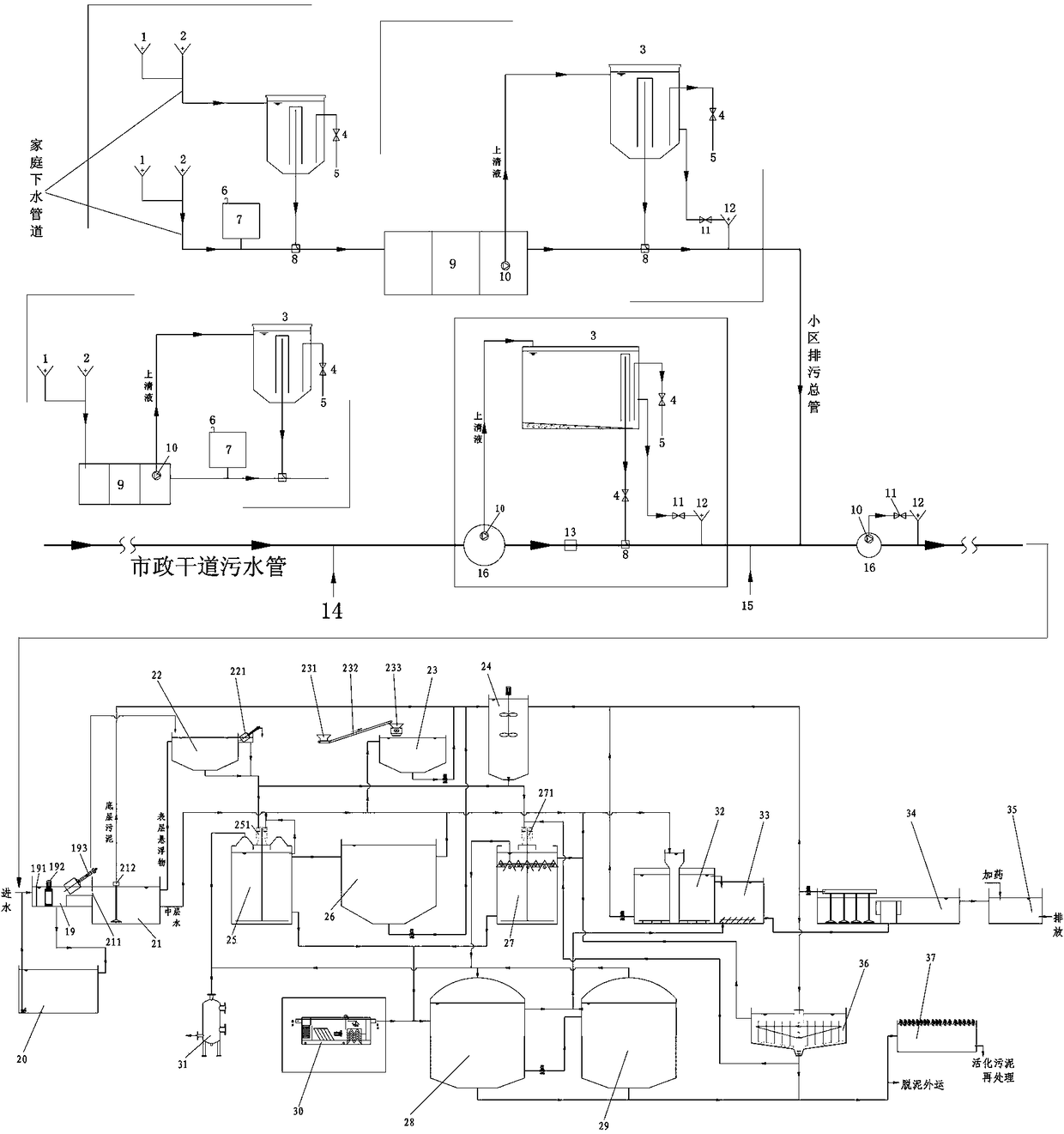

ActiveCN107008730BImplement preliminary processingAvoid cloggingSolid waste disposalSpecific water treatment objectivesSiphonHydrogen

The invention relates to a rubbish treatment system and method in order to solve the problem that low-cost rubbish treatment cannot be effectively conducted easily in the prior art. When the rubbish treatment method is used for treating rubbish, the rubbish manufactured by citizens is directly discharged into a municipal sewage pipe network after being smashed and is further scoured continuously by an intermittent siphon scouring and silting device, and accordingly pipeline silting can be prevented. The smashed rubbish is mixed into original municipal sewage and then is conveyed to a service reservoir through the municipal sewage pipe network, the rubbish is matched with farmer market rubbish collected to be made into sewage with the COD content and power of hydrogen being suitable for meeting the growing requirements of methane bacteria, part of organic matter in the sewage can be decomposed into biogas quickly after the sewage passes through a fast biogas digester, and biogas slurry which is not decomposed in the fast biogas digester is then conveyed into a low-speed biogas digester to be fully decomposed to produce a large amount of biogas in the low-speed biogas digester together with collected food waste. By means of the rubbish treatment system and method, the municipal rubbish and sewage can be recovered and treated to the greatest degree, and meanwhile the blocking problem of city sewer lines can be solved.

Owner:郑州鹤鹏精密机械设备有限公司

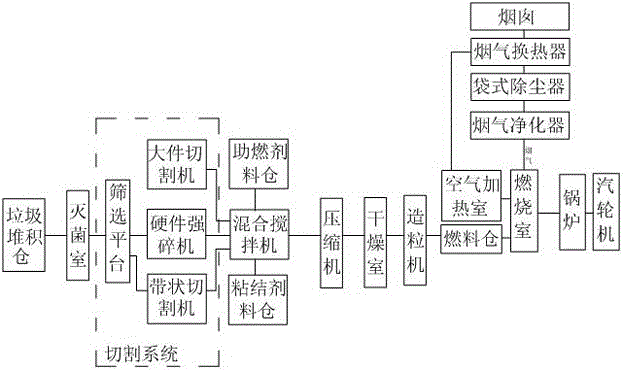

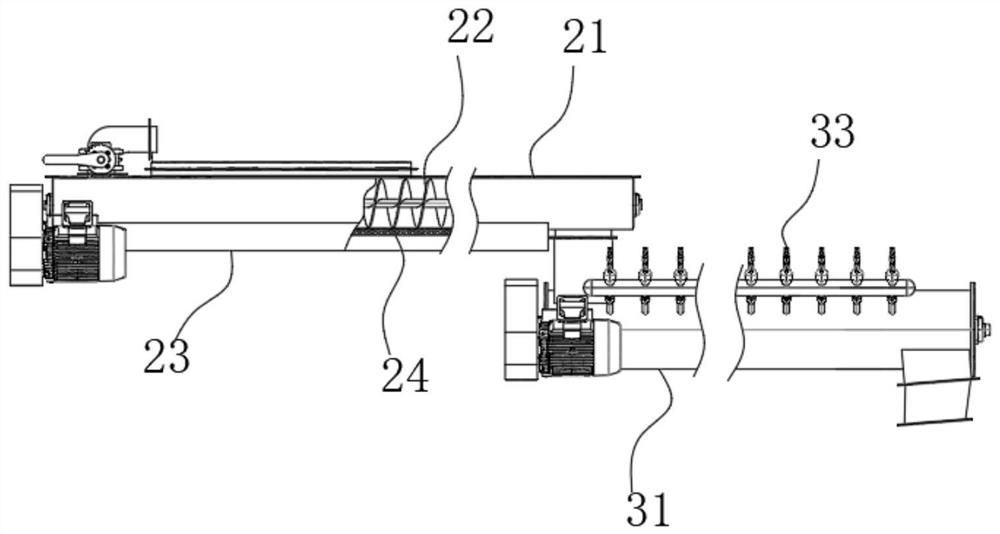

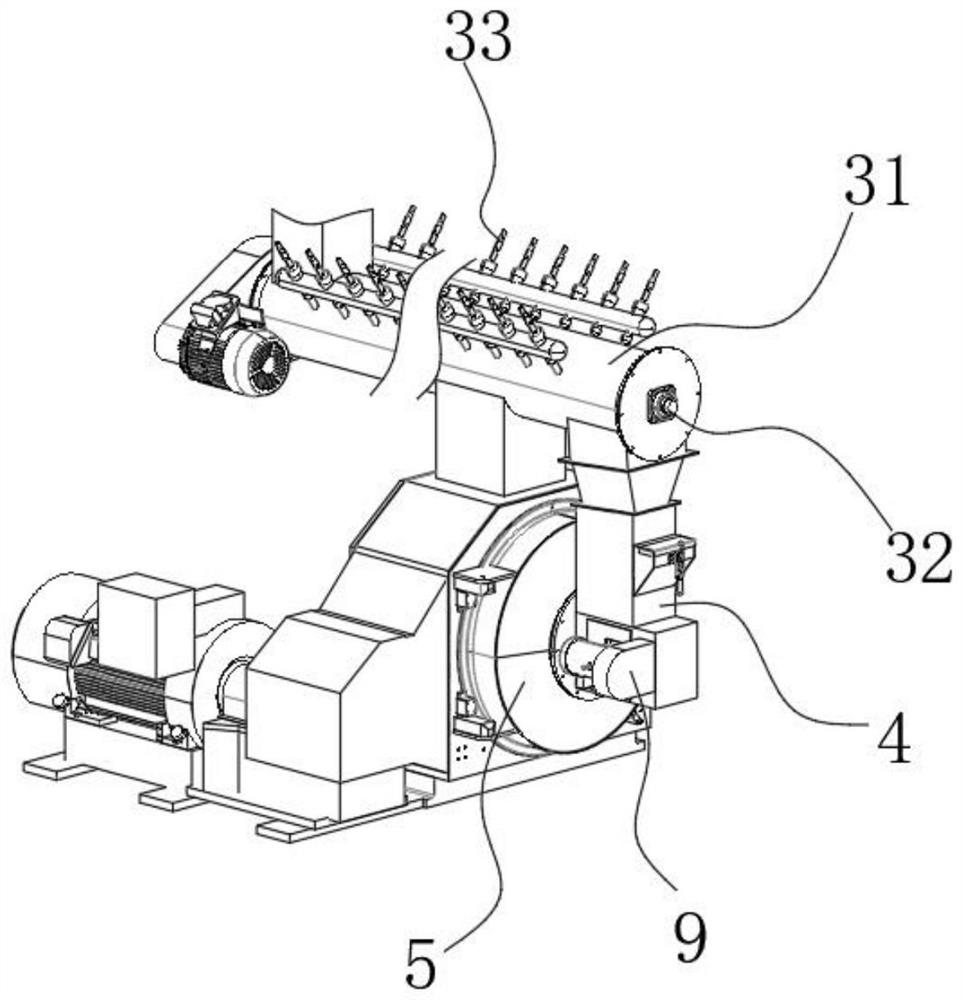

Detachable waste cutting machine

InactiveCN108714461AEasy to disassembleImplement preliminary processingGrain treatmentsPulp and paper industry

The invention discloses a detachable waste cutting machine. The detachable waste cutting machine comprises a cutting machine body. A supporting plate is arranged on the upper portion of the cutting machine body. A waste box and waste passages arranged on the two sides of the waste box are arranged on the upper portion of the supporting plate. A cutting device is arranged below the supporting plate. The cutting device comprises a cutting base fixedly arranged at the bottom of the supporting plate, a cutting bar arranged on the lower portion of the cutting base and a cutter body arranged at oneend of the cutting bar. Receiving sliding grooves provided with receiving devices are arranged on the lower portions of the waste passages. Each receiving device comprises receiving ropes and a receiving basket. The detachable waste cutting machine is simple in structure. The receiving baskets and the cutter bodies are convenient to dismantle. The detachable waste cutting machine implements initial draining treatment on waste, is stable in material receiving, also achieves fast cutting on the waste, improves the cutting efficiency through multiple cutting knife edges and further improves the cutting effect. The service life of the detachable waste cutting machine can be prolonged through an arranged cutting disk, and the cutting cost is lowered.

Owner:盱眙效阳农业开发有限公司

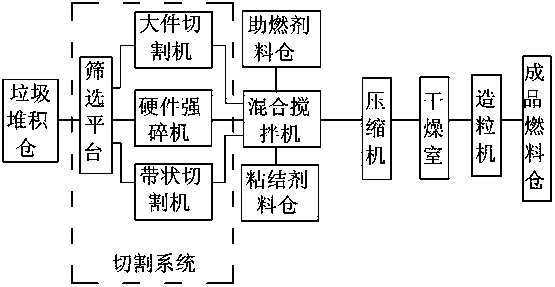

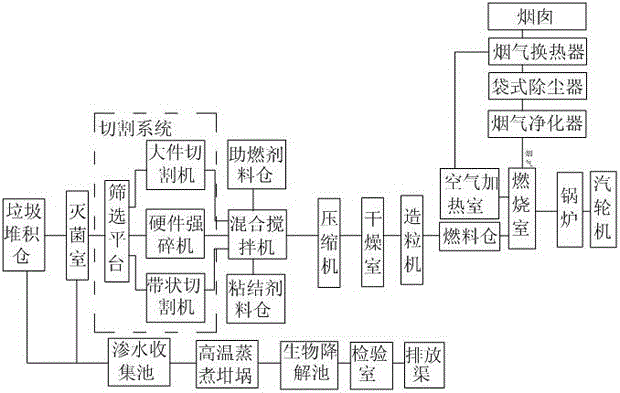

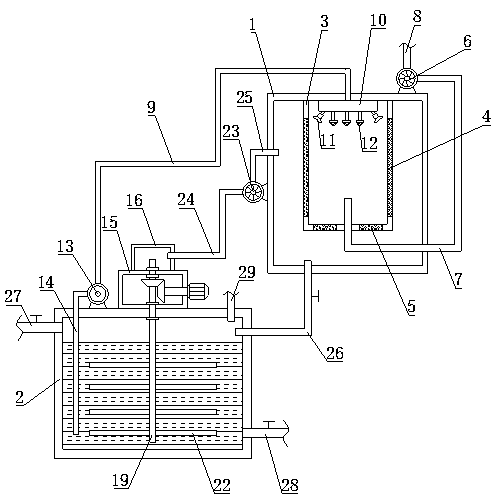

Environment-friendly overwater garbage combustion power generation system for hydropower station

ActiveCN104033907ASolve processing problemsSolve the problem of secondary pollution of water seepageSolid waste disposalIndirect carbon-dioxide mitigationCombustion chamberAdhesive

The invention discloses an environment-friendly overwater garbage combustion power generation system for a hydropower station. The environment-friendly overwater garbage combustion power generation system comprises a garbage stacking warehouse, a sterilization chamber, a cutting system, a mix blender, a compressor, a drying chamber, a pelletizer, a fuel bin, a combustion chamber, a combustion improver bunker, an adhesives bunker, a boiler and a turbine which are all connected sequentially through transmission belts. Fuel gas is discharged through a chimney. The environment-friendly overwater garbage combustion power generation system further comprises a water seepage collection pool, a high-temperature cooking crucible, a biodegradation pool, a checkout chamber and a discharge channel. By the arrange, garbage is changed into new fuel, subsequent environment of garbage treatment is purified, the garbage polluting the environment is converted into the fuel for combustion, the problem about garbage treatment is greatly solved, the environment is favorably protected, sustainable fuel resources are obtained, a wide range of social and economic values is achieved, accumulated water seepage and water seepage in the sterilization room can be handled, and the problem about secondary environmental pollution can be solved.

Owner:STATE GRID SICHUAN ELECTRIC POWER

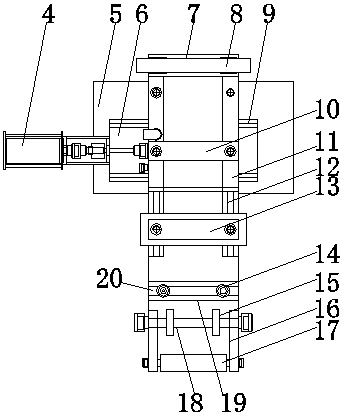

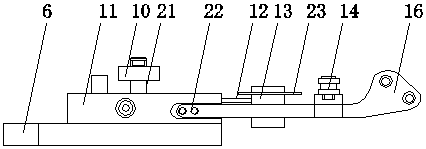

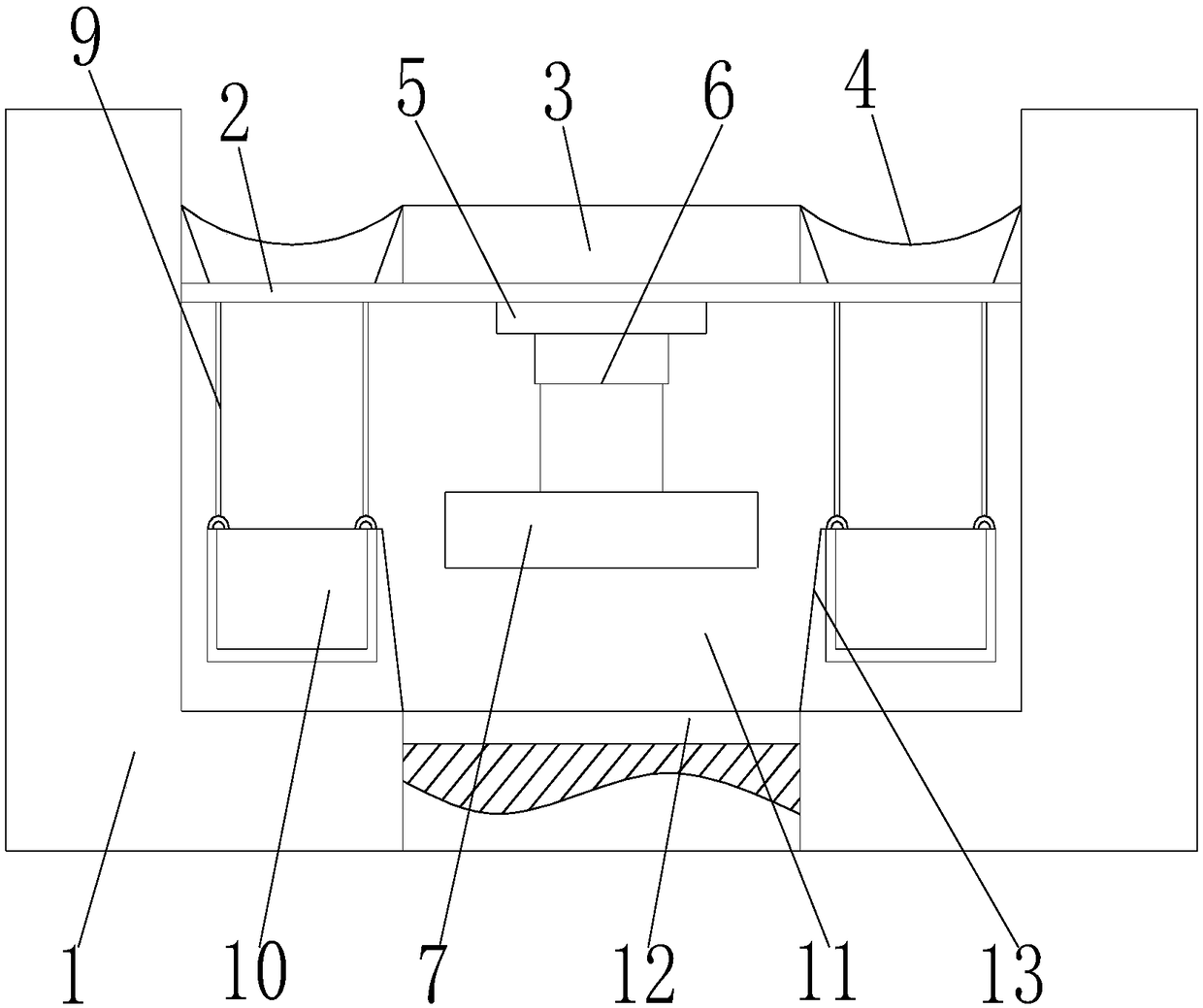

Punching press mechanism for battery case production

InactiveCN107570598AImplement preliminary processingFast initial processingShaping toolsMetal-working feeding devicesPunch pressFixed frame

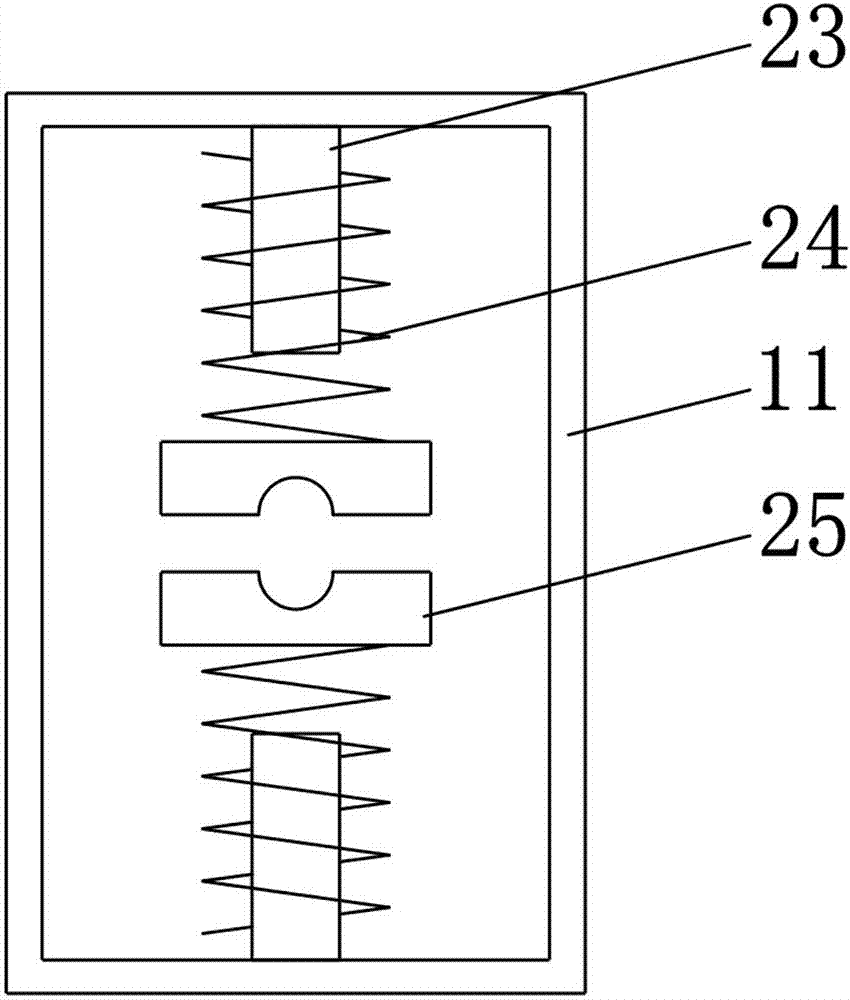

The invention discloses a punching press mechanism for battery case production. The punching press mechanism comprises a mold fixed frame and a punching head installing seat, wherein a first round through hole is formed in one end of the mold fixed frame; a second round through hole is formed in the other end of the mold fixed frame; a continuous mold is arranged on the upper surface of the mold fixed frame; a third round through hole is formed in the continuous mold; a force return column is arranged inside the third round through hole by a force return spring; a first blanking hole is formedin one side of the third round through hole of the continuous mold; a return platform is arranged at the outer side of the upper surface of the continuous mold by guide rails; a battery case fixtureis arranged at the inner side of the return platform; a groove is formed in one end, close to the first round through hole, of the return platform; a raw material permanent seat is arranged at the outer side of the groove of the return platform; and a lower mold is arranged below the inner side of the raw material permanent seat. The punching press mechanism can complete the blanking and punchingpress of raw materials and makes the raw materials into finished products directly.

Owner:新乡市盛达电源科技有限公司

Method for generating electricity through environmental garbage

InactiveCN105222135AImprove protectionSolve problems such as secondary pollutionSteam generation plantsIncinerator apparatusElectricityCombustion chamber

The invention discloses a method for generating electricity through environmental garbage. A garbage accumulation bin, a cutting system, a mixing stirrer, a compressor, a drying chamber, a pelletizer, a fuel bin, a combustion chamber, an accelerant bin, an adhesive bin, a boiler and a turbine are included. Smoke is exhausted through a chimney. According to the method for generating electricity through the environmental garbage, the garbage is converted into novel fuel, fine fuel of the uniform specification is formed and conveyed to the fuel bin, the fuel bin feeds fuel particles into the combustion chamber according to a certain feeding speed, and heat is generated after combustion of the fuel and enables the boiler to generate steam, so that the turbine is pushed to rotate and generate electricity. By converting garbage polluting the environment into fuel to be combusted, treatment of the garbage is achieved to a great extent, and considerable energy is obtained.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Energy-saving and environment-friendly sewage recycling device

PendingCN113371878AImplement preliminary processingFully contactedSpecific water treatment objectivesTreatment involving filtrationWater filterSewage

The invention belongs to the technical field of sewage treatment, and particularly relates to an energy-saving and environment-friendly sewage recycling device, so as to solve the problems that a filtering part of an existing sewage recycling device is inconvenient to disassemble and assemble, a filtering structure is difficult to clean or replace, and filtered sewage cannot be effectively disinfected. The device comprises a water filtering tank, a fixing tank, a disinfection tank, a cover plate and a sewage input pipe, the fixing tank is installed at the top of the disinfection tank, the top of the fixing tank is fixedly connected with the water filtering tank, the cover plate is installed at the top of the water filtering tank, the sewage input pipe is installed on the cover plate, a water filtering mechanism is arranged in the water filtering tank, and a positioning mechanism is arranged at the bottom of the cover plate. The positioning mechanism fixes the water filtering mechanism, and the sewage input pipe extends into the water filtering mechanism. Sewage is filtered by arranging the water filtering mechanism, the contact area of the sewage and disinfection gas can be increased by arranging the water curtain, the disinfection efficiency and the disinfection effect are remarkably improved, and the water filtering mechanism is convenient to replace and clean by arranging the positioning mechanism.

Owner:亳州洁能电力有限公司

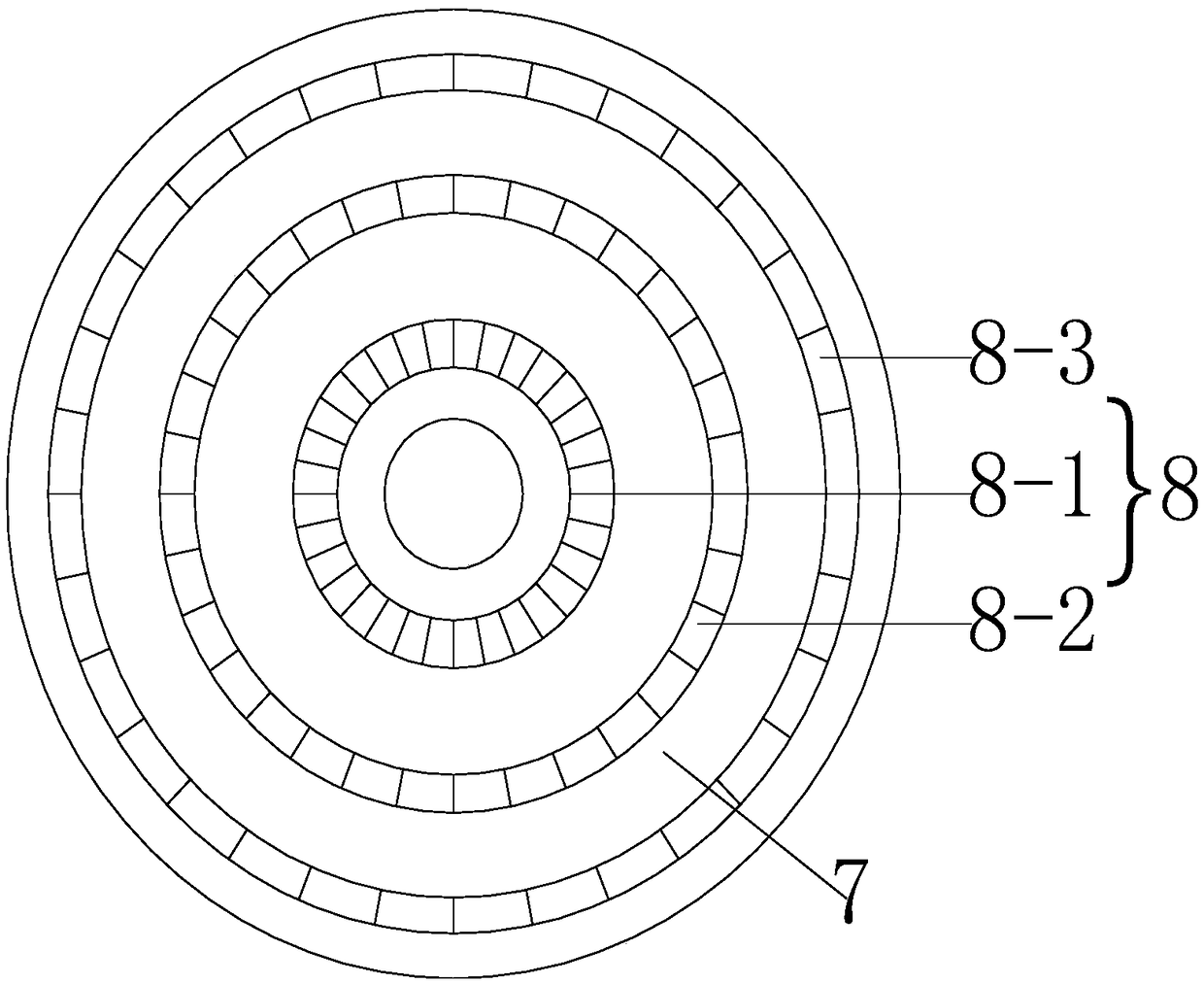

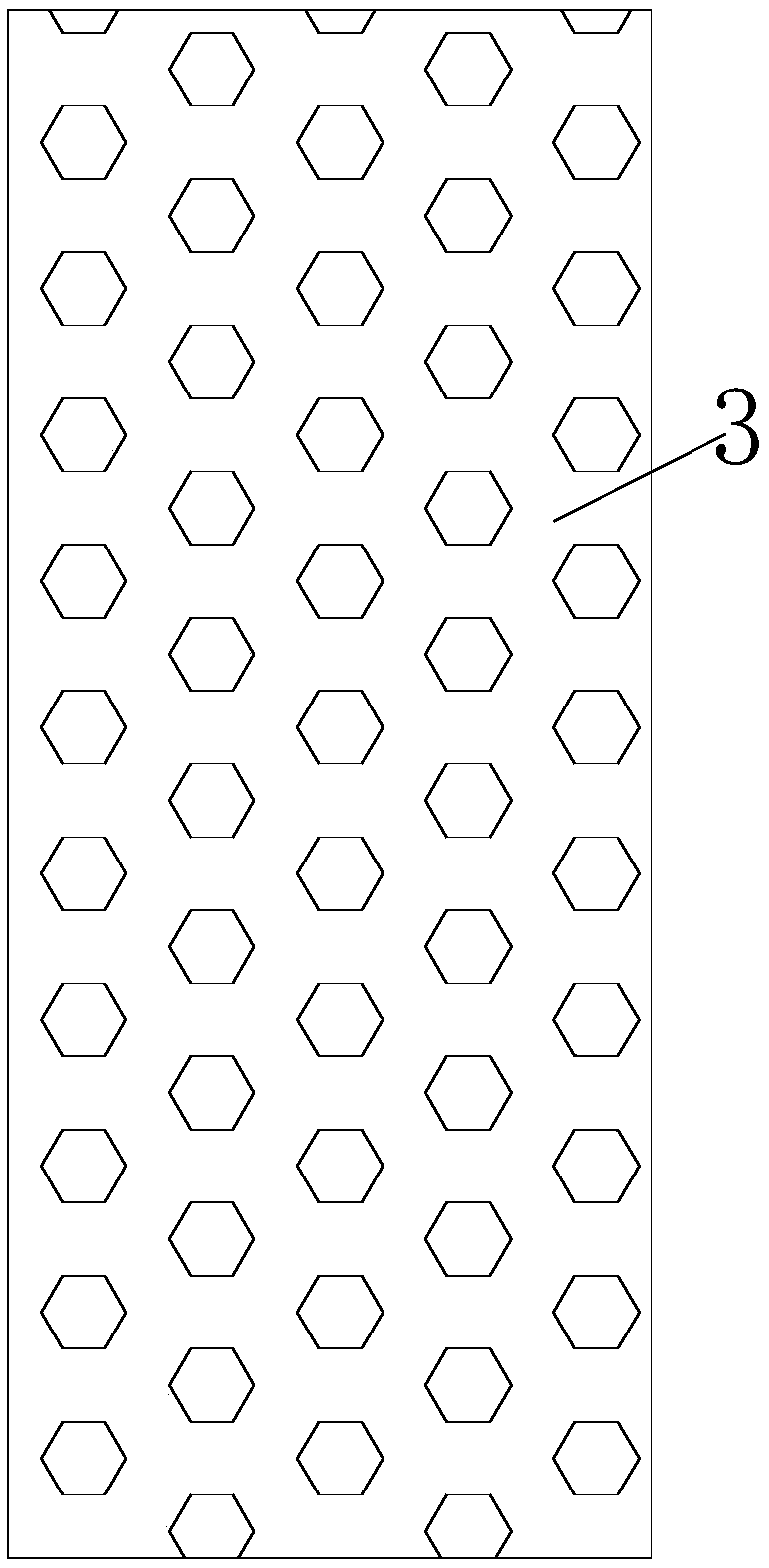

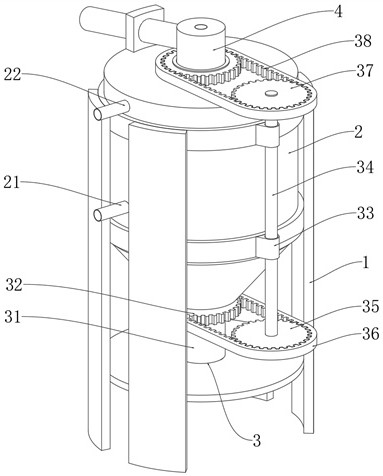

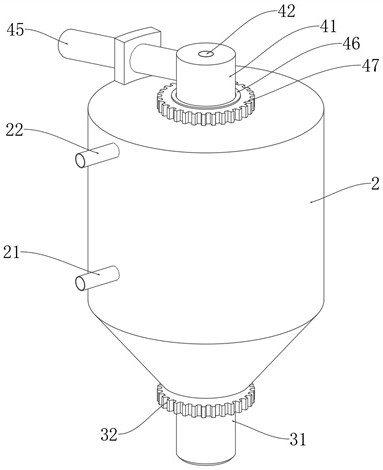

A variable filter element sewage preliminary treatment equipment

ActiveCN113318514BImplement preliminary processingReduce wasteWater/sewage treatment by centrifugal separationSpecific water treatment objectivesFiltrationMechanical engineering

The invention discloses a variable filter element sewage preliminary treatment equipment, which comprises a frame, a conical tank is installed on the frame, a power mechanism is installed on the frame, a sewage discharge mechanism is installed on the conical tank, The variable-pitch filter element and the swirl mechanism are installed on the sewage discharge mechanism respectively, and the variable-pitch filter element includes a main filter piece fixed on the inner wall of the conical tank. As for the electromagnetic string, the two ends of the plurality of electromagnetic strings are symmetrically slidably sleeved and installed with two secondary filters. The larger impurities in the sewage are settled and removed by means of centrifugal swirl, and the fine impurities are filtered out by the variable-pitch filter element, and the variable-pitch filter element is washed by the variable-pitch flushing method to make the washing impurities swirl and settle , realize the preliminary treatment of sewage, high treatment efficiency, reduce the consumption of consumables, reduce the waste of water, more environmentally friendly and lower cost.

Owner:JIANGSU BANGTEC ENVIRONMENTAL SCI TECH CO LTD

Overwater garbage burning and power generating system for hydropower station

ActiveCN104033906ASolve processing problemsImprove protectionSolid waste disposalSteam generation plantsPower stationCombustion

The invention discloses an overwater garbage burning and power generating system for a hydropower station. The overwater garbage burning and power generating system comprises a garbage accumulation bin, a cutting system, a mixing and stirring machine, a compressor, a drying chamber, a pelletizer, a fuel bin, a burning chamber, a combustion improver bin, an adhesive bin, a boiler and a steam turbine, and smoke is discharged through a chimney. Garbage turns into new fuel and is small fuel with unified specifications and conveyed to the fuel bin. The fuel bin feeds fuel particles into the burning chamber at certain feed speed, heat generated after the fuel is burned and heats the boiler to generate steam, and the steam pushes the steam turbine to generate power. Accordingly, garbage polluting the environment is converted into the fuel and burned, problems about garbage treatment are greatly solved, and considerable energy resources are obtained.

Owner:STATE GRID SICHUAN ELECTRIC POWER

Road guardrail equipment capable of purifying air

InactiveCN112323686AImplement preliminary processingPhotovoltaic supportsDispersed particle filtrationWater storage tankStormwater

The invention relates to the field of air purifiers, in particular to road guardrail equipment capable of purifying air, which comprises supporting columns in bilateral symmetry, a base is fixedly arranged on the bottom walls of the two supporting columns, a bottom plate is fixedly arranged between the two supporting columns, and fixing plates are symmetrically arranged on the bottom plate front and back, fixing plates used for absorbing solar energy for power generation are arranged on the bottom plate in a front-back symmetry mode, a top plate is fixedly arranged on the top walls of the fixing plates, and a water storage tank is arranged in the top plate. According to the road guardrail equipment capable of purifying air provided by the invention, preliminary treatment of harmful gases such as automobile exhaust on a road can be realized, The air quality is improved to a certain extent, and meanwhile, rainwater can be filtered and stored and sprayed to cool the photovoltaic panel andreduce dust in air in hot weather.

Owner:磐安德宗电子科技有限公司

Hydropower station water surface rubbish treating system

ActiveCN104028539ASolve secondary pollutionConducive to the protection of the environmentSolid waste disposalBiofuelsRefuse DisposalsCombustion

The invention discloses a hydropower station water surface rubbish treating system. The treating system comprises a rubbish heaping bin, a cutting system, a mixing agitator, a compressor, a drying chamber, a granulator and a finished product fuel bin which are sequentially connected with one another by a conveying belt, as well as a combustion improver bin and an adhesive bin which are respectively connected with the mixing agitator. By virtue of the treating system, rubbish can be transformed into new fine fuel with unified specification, waste is made profitable, and the problems such as secondary pollution caused by rubbish heaping are solved, so that the treating system not only brings benefits for environment protection, but also generates sustainable fuel resources, and has extensive social and economic values.

Owner:STATE GRID SICHUAN ELECTRIC POWER

A power generation system for aseptic combustion of water surface garbage in hydropower stations

ActiveCN104028540BSolve processing problemsSolve problems such as secondary pollutionSolid waste disposalMachines/enginesCombustion chamberAdhesive

The invention discloses an aseptic combustion power generation system for water surface garbage in a hydropower station, which includes a garbage storage bin, a sterilization room, a cutting system, a mixing mixer, a compressor, a drying room, a granulator, a fuel bin, a combustion chamber, and a fuel bin , adhesive silos, boilers, and steam turbines, and the flue gas is discharged through the chimney. The invention turns garbage into new fuel, which not only meets the requirements of hygienic production, but also purifies the follow-up environment of garbage treatment, turns garbage into new fuel, forms fine fuel with uniform specifications, and transports it to the fuel bunker. A certain feed rate puts fuel particles into the combustion chamber. After the fuel is burned, it generates heat and makes the boiler generate steam, which drives the steam turbine to rotate and generate electricity, and converts the garbage that pollutes the environment into fuel for combustion. Considerable energy.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

Process for conducting environment-friendly electricity generation treatment through environmental garbage

InactiveCN105258129ASolve processing problemsSolve the problem of secondary pollution of water seepageIncinerator apparatusCombined combustion mitigationCombustion chamberFlue gas

The invention discloses a process for conducting environment-friendly electricity generation treatment through environmental garbage. According to the process, a garbage heaping bin, a sterilization room, a cutting system, a mixing and stirring machine, a compressor, a drying chamber, a granulating machine, a fuel bin, a combustion chamber, a combustion improver bin, an adhesive bin, a boiler and a steam turbine are sequentially connected through a conveyor belt; and flue gas is discharged through a chimney, the combustion improver bin, the adhesive bin, a seepage water collection pool, a high-temperature steaming crucible, a biodegradation pool, an inspection chamber and a discharging drain are further arranged. Garbage is transformed into new fuel, the environment for follow-up garbage treatment is purified, the garbage polluting the environment is transformed into the new fuel for combustion, and therefore the garbage treatment problem is solved greatly; environment protection is facilitated, and sustainable fuel is obtained; the method has very high social value and economic value, seepage water generated by heaping and seepage water of the sterilization room can be treated, and the problem of secondary pollution to the environment caused by seepage water is solved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

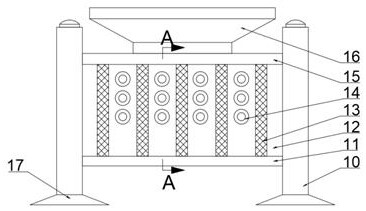

Combined water purification equipment for mine water treatment

PendingCN114735856AImplement preliminary processingNo manual post-processing requiredWaste water treatment from quariesRotary stirring mixersWater treatmentWater tanks

The invention relates to water purification equipment, in particular to combined water purification equipment for mine water treatment. The invention provides the combined water purification equipment for mine water treatment, which accelerates the settling speed, controls the treatment cost and ensures the purification quality at the same time. Combined water purification equipment for mine water treatment comprises a base, a water purification tank is mounted at the top of the base, and a transparent observation window convenient for checking degradation conditions is embedded in the front side of the water purification tank; the bases are symmetrically arranged on the top of the water purifying tank front and back, water purifying agent placing tanks are arranged on the tops of the bases, outflow pipelines are connected to the bottoms of the water purifying agent placing tanks, and the outflow pipelines penetrate through the bases; and the right side of the lower part of the water purifying tank is communicated with the sediment flow-out output pipeline. The mixing blades rotate to accelerate the fusion of the wastewater and the water purifying agent, so that internal metal elements are converted into solids which are settled at the bottom of the water purifying tank, and the primary treatment of the mine water is realized.

Owner:宿州学院

Landfill leachate treatment equipment

ActiveCN113501626AImplement preliminary processingRealize the collectionSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSludgeLeachate

The invention discloses landfill leachate treatment equipment, and relates to the technical field of landfill leachate treatment. The landfill leachate treatment equipment comprises a concentration tank used for receiving landfill leachate subjected to secondary precipitation; a feeding mechanism of which the feeding end is communicated with the sludge discharging end of the concentration tank; a mixing and drying mechanism which has a feeding end communicated with the discharging end of the feeding mechanism, and can further dry sludge; and at least one guiding drying bin of which the feeding end is communicated with the discharging end of the mixing and drying mechanism through a discharging bin, the interior of the discharging bin being further communicated with a high-pressure pumping machine which can pump high-temperature and high-pressure gas into the guiding drying bin.

Owner:马宁

An environment-friendly water surface waste combustion power generation system for hydropower stations

ActiveCN104033907BSolve processing problemsSolve the problem of secondary pollution of water seepageSolid waste disposalIndirect carbon-dioxide mitigationCombustion chamberAdhesive

The invention discloses an environment-friendly overwater garbage combustion power generation system for a hydropower station. The environment-friendly overwater garbage combustion power generation system comprises a garbage stacking warehouse, a sterilization chamber, a cutting system, a mix blender, a compressor, a drying chamber, a pelletizer, a fuel bin, a combustion chamber, a combustion improver bunker, an adhesives bunker, a boiler and a turbine which are all connected sequentially through transmission belts. Fuel gas is discharged through a chimney. The environment-friendly overwater garbage combustion power generation system further comprises a water seepage collection pool, a high-temperature cooking crucible, a biodegradation pool, a checkout chamber and a discharge channel. By the arrange, garbage is changed into new fuel, subsequent environment of garbage treatment is purified, the garbage polluting the environment is converted into the fuel for combustion, the problem about garbage treatment is greatly solved, the environment is favorably protected, sustainable fuel resources are obtained, a wide range of social and economic values is achieved, accumulated water seepage and water seepage in the sterilization room can be handled, and the problem about secondary environmental pollution can be solved.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

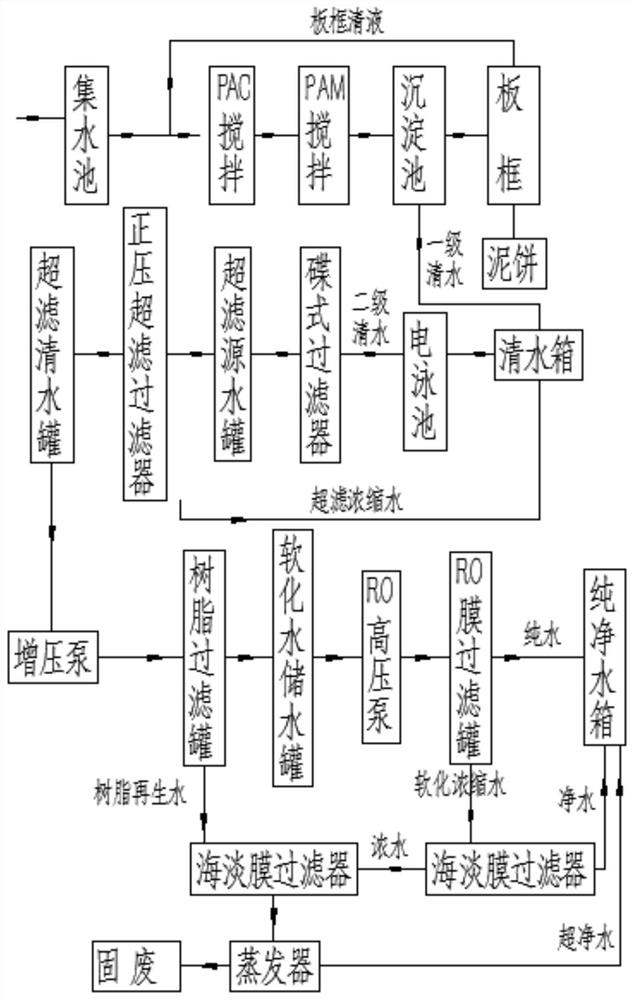

Zero-discharge sewage treatment process in nano-powder industry

PendingCN114524568ARealize zero discharge of sewageZero emissionTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisSoftened waterUltrafiltration

The invention discloses a zero-discharge sewage treatment process in the nano-powder industry. The zero-discharge sewage treatment process comprises a flocculation tank, a sedimentation tank, an electrophoresis tank, a disc filter, a positive pressure ultrafiltration filter, a resin filtering tank, an RO (Reverse Osmosis) membrane filtering tank, a sea light membrane filter and an evaporator, the flocculation tank is used for flocculating and settling nano-powder in the sewage; then passing through a settling pond to obtain settled sludge and primary clear water; the primary clear water enters an electrophoresis pool to remove most of superfine powder, and then is filtered by a disc filter and a positive pressure ultrafiltration filter to obtain ultrafiltration clear water and ultrafiltration concentrated water; enabling the ultrafiltration clear water to pass through a resin filtering tank to obtain softened water; enabling the softened water to pass through an RO membrane filtering tank and a sea fresh water membrane filter to obtain purified water and concentrated water, and enabling the concentrated water to pass through an evaporator to obtain ultra-purified water; according to the zero-discharge sewage treatment process in the nano-powder industry, primary treatment is achieved through flocculation and sedimentation, solid waste and pure water which are completely separated are obtained through multi-stage filtration and concentration, and zero discharge of sewage is achieved.

Owner:HEFEI YUWANG MEMBRANE ENG TECH

A system for making fuel from waste on the water surface of a hydropower station

ActiveCN104031712BImprove protectionSolve problems such as secondary pollutionBiofuelsSolid fuelsPower stationCombustion

The invention discloses a system for preparing fuel from water surface garbage in water power stations, which comprises a garbage accumulation bin, a sterilizing chamber, a cutting system, a stirrer, a compressor, a drying chamber, a granulator and a finished fuel bin which are sequentially connected through a transmission band, and also comprises a combustion improver bin, an adhesive bin, a seeping water collecting tank, a high-temperature steaming crucible, a biodegradation tank, an inspection chamber and a discharge trench. By converting the garbage into the new fuel, the system satisfies the requirement of hygienic production, purifies the subsequent environment for garbage treatment, forms the uniform-standard fine fuel, changes wastes into valuable substances, solves the problems of secondary pollution and the like caused by garbage accumulation, is beneficial to environmental protection, obtains a sustainable fuel resource, has wide social value and economic value, can treat the accumulated seeping water and the seeping water in the sterilizing chamber, and solves the problem of secondary environmental pollution.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

Comprehensive utilization method for generating electricity through environmental garbage

InactiveCN105258130AImprove protectionSolve processing problemsIncinerator apparatusCombined combustion mitigationElectricityCombustion chamber

The invention discloses a comprehensive utilization method for generating electricity through environmental garbage. According to the comprehensive utilization method, a garbage heaping bin, a sterilization room, a cutting system, a mixing and stirring machine, a compressor, a drying chamber, a granulating machine, a fuel bin, a combustion chamber, a combustion improver bin, an adhesive bin, a boiler and a steam turbine are included; and flue gas is discharged through a chimney. Garbage is transformed into new fuel, the sanitary production requirement is met, the environment for follow-up garbage treatment is purified, the garbage is transformed into the new fuel to form tiny fuel of the unified specification to be conveyed to the fuel bin, fuel particles are thrown into the combustion chamber at a certain feeding speed by means of the fuel bin, heat is generated after fuel is combusted, steam is generated in the boiler, the steam turbine is pushed to rotate so as to generate electricity, the garbage polluting the environment is converted into the fuel for combustion, the garbage treatment problem is solved greatly, and quite considerable energy is obtained.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Waste gas collecting apparatus in decolorant production process

InactiveCN110743332AAchieve purificationEasy to handleDispersed particle separationExhaust fumesProcess engineering

The invention discloses a waste gas collection apparatus in the decolorant production process. The apparatus comprises a first waste gas treatment box and a second waste gas treatment box, wherein a connecting cylinder is arranged in the first waste gas treatment box, first filter cloths are arranged on the outer peripheral surface of the connecting cylinder, second filter cloths are arranged on the bottom of the connecting cylinder, a connecting part is arranged in the connecting cylinder, the connecting part is provided with liquid spraying heads and mist spraying heads, a gas supply pipe extends into the connecting cylinder, a rotating part is rotationally connected with the second waste gas treatment box, the top end of the rotating part extends into a second connecting box, a gas suction pipe is arranged on a second gas extractor and communicates with the first waste gas treatment box, a gas conveying pipe is arranged on the second gas extractor and communicates with the second connecting box, a transmission shaft is arranged on a driving apparatus and is connected with the rotating part in a transmission manner, gas discharge holes are arranged on stirring parts, the inside of each stirring part is provided with a second gas conveying channel, and a first gas conveying channel is arranged on the rotating part. The apparatus has the advantages of simple operation and convenient use, can effectively absorb and treat the waste gas generated during the decolorant production process, has good purification effects and high purification efficiency, and significantly reducesthe pollution to the atmospheric environment.

Owner:九江市美景水处理科技有限公司

A comprehensive treatment system for waste combustion and power generation on the water surface of a sterile hydropower station

ActiveCN104056846BSolve problems such as secondary pollutionSolve processing problemsSolid waste disposalMelting tankCombustion chamber

The invention discloses a comprehensive processing system for generating power by sterilely burning garbage on the surface of water in a hydropower station. The comprehensive processing system comprises a garbage accumulation bin, a sterilization chamber, a cutting system, a mixing and stirring machine, a compressor, a drying chamber, a pelleting machine, a fuel bin, a burning chamber, a combustion improver bin, a binding agent bin, a boiler and a turbine, wherein an ash bin is arranged below the burning chamber, and is sequentially connected with a sieving machine, a crushing machine, a melting tank, a metal adsorbing and recycling tank, a filter net, an evaporation chamber, a calcining chamber, a natural cooling bin, a grinding machine, a water tank and a mineral powder bin. According to the comprehensive processing system, garbage is sterilely treated to form a new fuel for burning, the fuel is brunt to generate heat and the boiler is enabled to generate vapor to push the turbine to rotate to generate power, a considerable energy is obtained, and the burnt ash can be converted into a cement additive with high utilization value and economic value through reasonable process and equipment; the comprehensive processing system has a very high social value.

Owner:STATE GRID SICHUAN ELECTRIC POWER CO

System for preparing fuel from water surface garbage in water power stations

ActiveCN104031712AImprove protectionSolve problems such as secondary pollutionBiofuelsSolid fuelsCombustionPower station

The invention discloses a system for preparing fuel from water surface garbage in water power stations, which comprises a garbage accumulation bin, a sterilizing chamber, a cutting system, a stirrer, a compressor, a drying chamber, a granulator and a finished fuel bin which are sequentially connected through a transmission band, and also comprises a combustion improver bin, an adhesive bin, a seeping water collecting tank, a high-temperature steaming crucible, a biodegradation tank, an inspection chamber and a discharge trench. By converting the garbage into the new fuel, the system satisfies the requirement of hygienic production, purifies the subsequent environment for garbage treatment, forms the uniform-standard fine fuel, changes wastes into valuable substances, solves the problems of secondary pollution and the like caused by garbage accumulation, is beneficial to environmental protection, obtains a sustainable fuel resource, has wide social value and economic value, can treat the accumulated seeping water and the seeping water in the sterilizing chamber, and solves the problem of secondary environmental pollution.

Owner:STATE GRID SICHUAN ELECTRIC POWER

Process for conducting fuel reproduction on environment trash

InactiveCN105255537AImprove protectionSolve problems such as secondary pollutionBiofuelsSolid fuelsCombustionEnvironmental engineering

The invention discloses a process for conducting fuel reproduction on environment trash. The process involves a trash accumulating bin, a sterilizing chamber, a cutting system, a mixing stirrer, a compressor, a drying chamber, a granulating machine and a finished product fuel bin which are sequentially connected through a conveying belt, and further involves a combustion improver material bin, an adhesive material bin, a seepage water collecting pool, a high-temperature cooking crucible, a biological degradation pool, a detecting chamber and a discharge channel. By converting trash into new fuel, the requirement for sanitary production is met, the subsequence environment of trash treatment is purified, fine fuel of uniform specification is formed, waste is turned into wealth, the problems of secondary pollution and the like caused by trash accumulation are solved, the environment protection is facilitated, sustainable fuel resources are obtained, wide social value and economic value are achieved, accumulated seepage water and seepage water of the sterilizing chamber can be processed, and the problem of seepage water secondary pollution to the environment is solved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

Movable hazardous chemical substance decontamination and dust removal method

InactiveCN110871009AImplement preliminary processingCombination devicesSeparation devicesDust controlEnvironmental engineering

The invention relates to a movable hazardous chemical substance decontamination and dust removal method and mainly solves the problem that hazardous chemical substance leakage of gas, liquid and powder cannot be treated simultaneously in the prior art. In the method, a movable hazardous chemical substance decontamination and dust removal device is employed, wherein air carrying gas, liquid and powdery hazardous chemical substances is fed into a three-phase cyclone collection section, a Venturi washing device, and a packing decontamination and dust removal unit for treatment and then is discharged into atmosphere, so that the technical problems are solved well. The method can be used for treatment on the gas, liquid and powdery hazardous chemical substances due to leakage of a workshop.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com