Anti-pollution environment-friendly electroplating wastewater treatment device

A technology for electroplating wastewater and pollution prevention, which is applied in metallurgical wastewater treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc. A lot of time and other problems, to achieve the effect of easy replacement, safe and convenient use, and accelerated efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

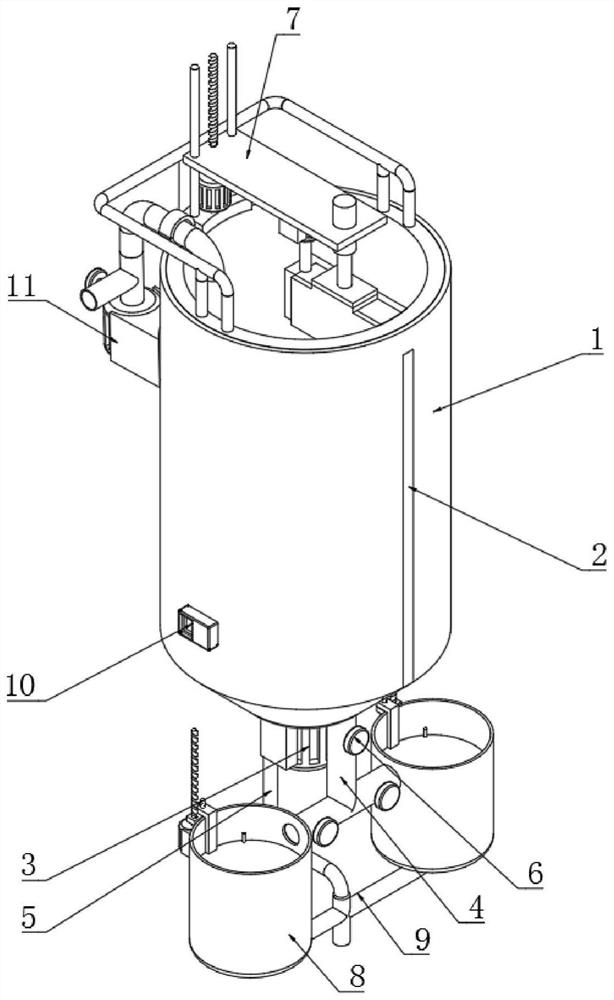

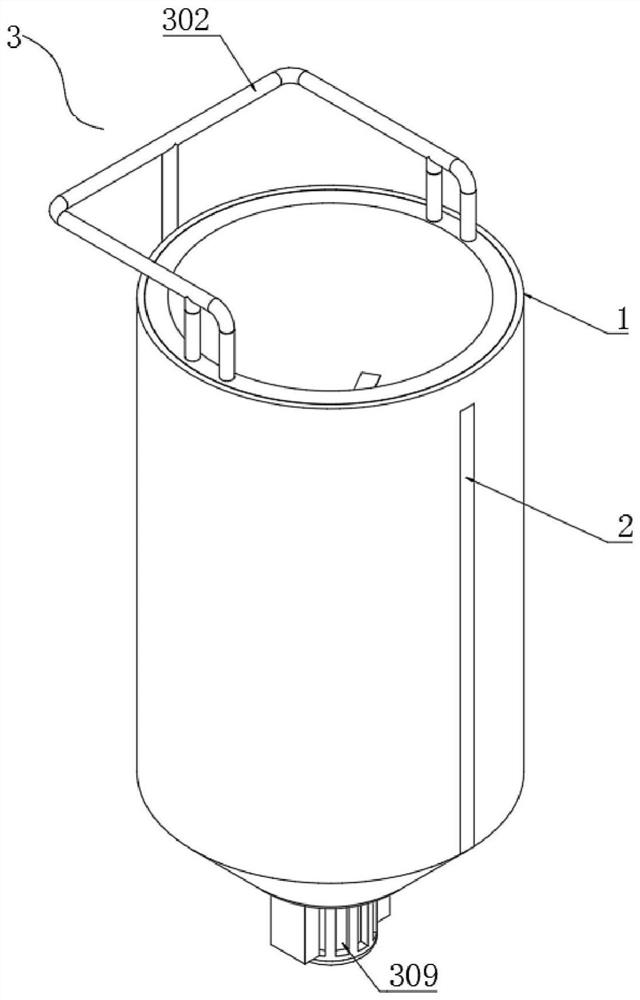

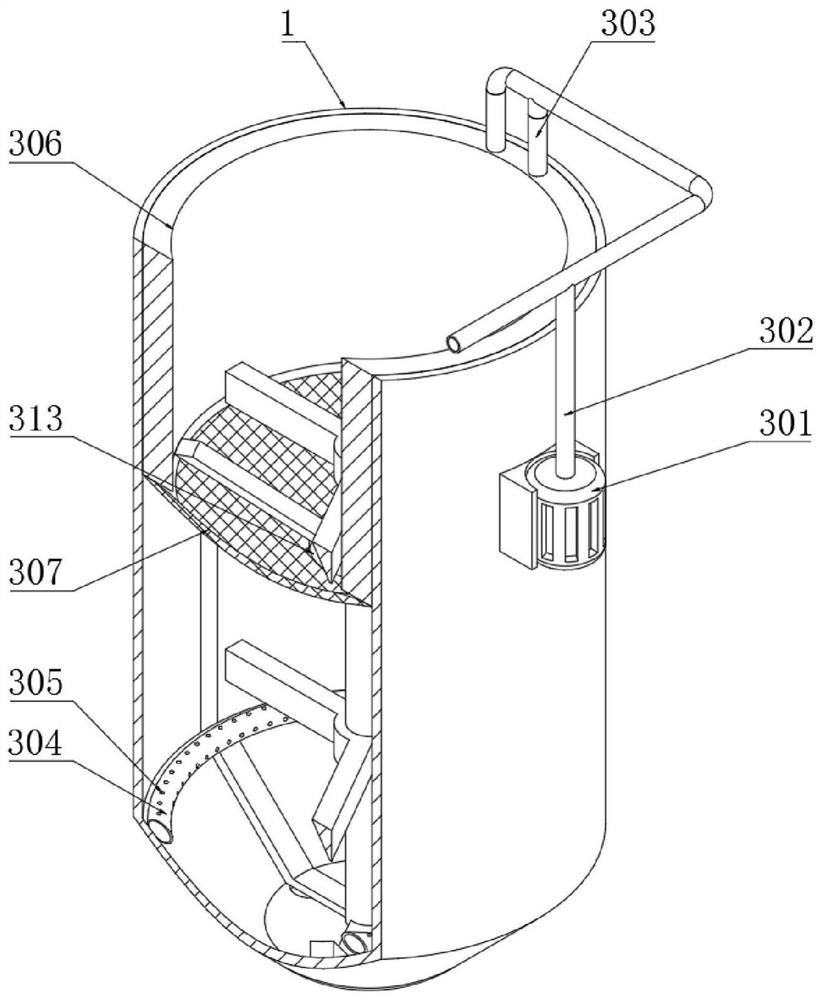

[0054] Example: such as Figure 1-9 As shown, the present invention provides a technical solution for an environmentally friendly electroplating wastewater treatment device that prevents pollution. An environmentally friendly electroplating wastewater treatment device that prevents pollution includes a separation tank 1. One end of the separation tank 1 is embedded with an observation window 2, and an aeration component 3 is installed on the inside of the separation tank 1, and the aeration component 3 is used to aerate it, so that the impurities contained in the wastewater are in the bubbles. Separation and generation of flocs under the action, so as to purify them, and set up interception of flocs, so as to separate metal substances from flocs;

[0055] A collection assembly 7 is installed on the top of the separation tank 1, and the flocs floating on the water surface are collected by the collection assembly 7, which prevents the substance from re-merging into the water aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com