Movable hazardous chemical substance decontamination and dust removal method

A hazardous chemical, mobile technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problem of not being able to deal with the leakage of gas, liquid and powder hazardous chemicals at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

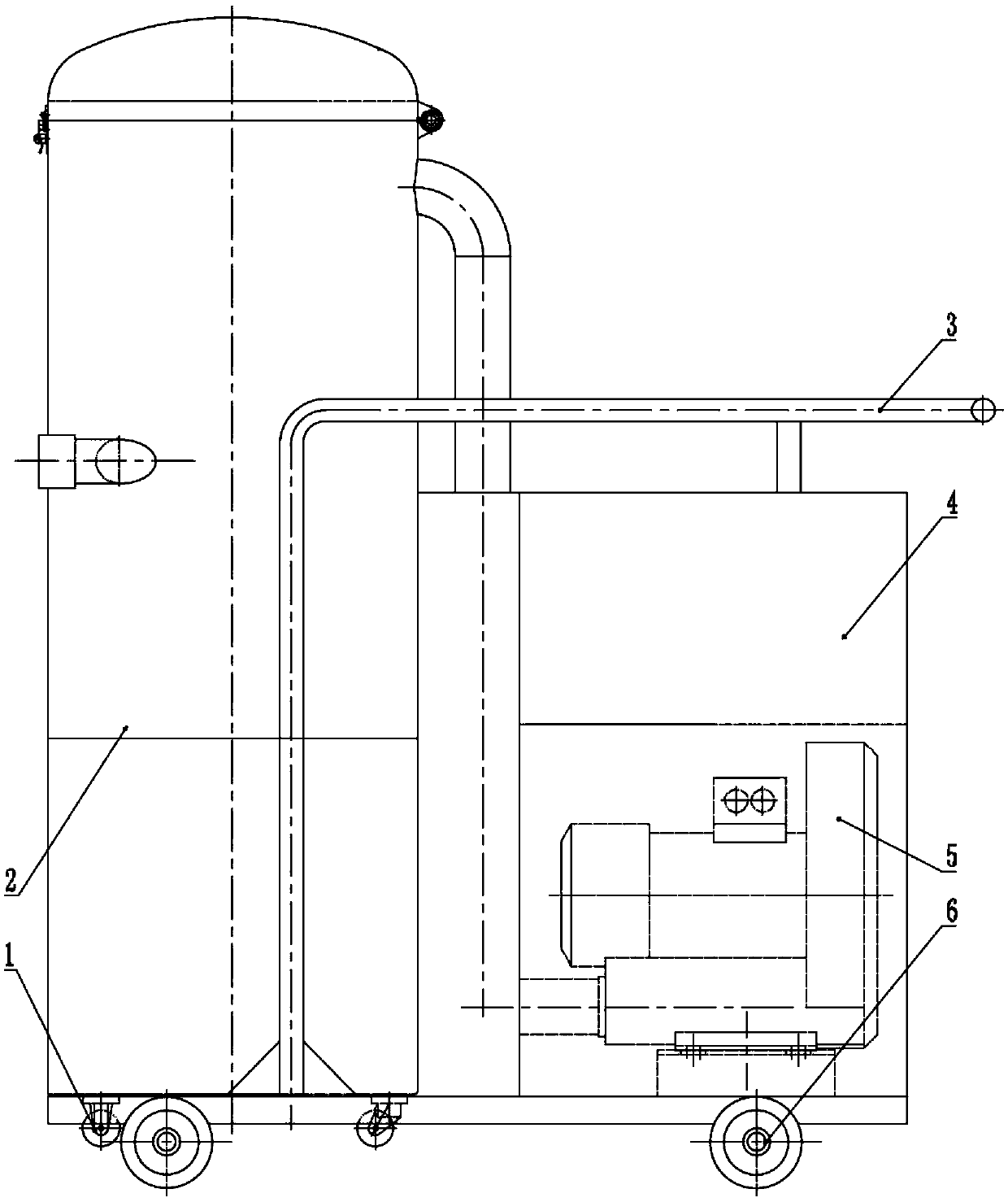

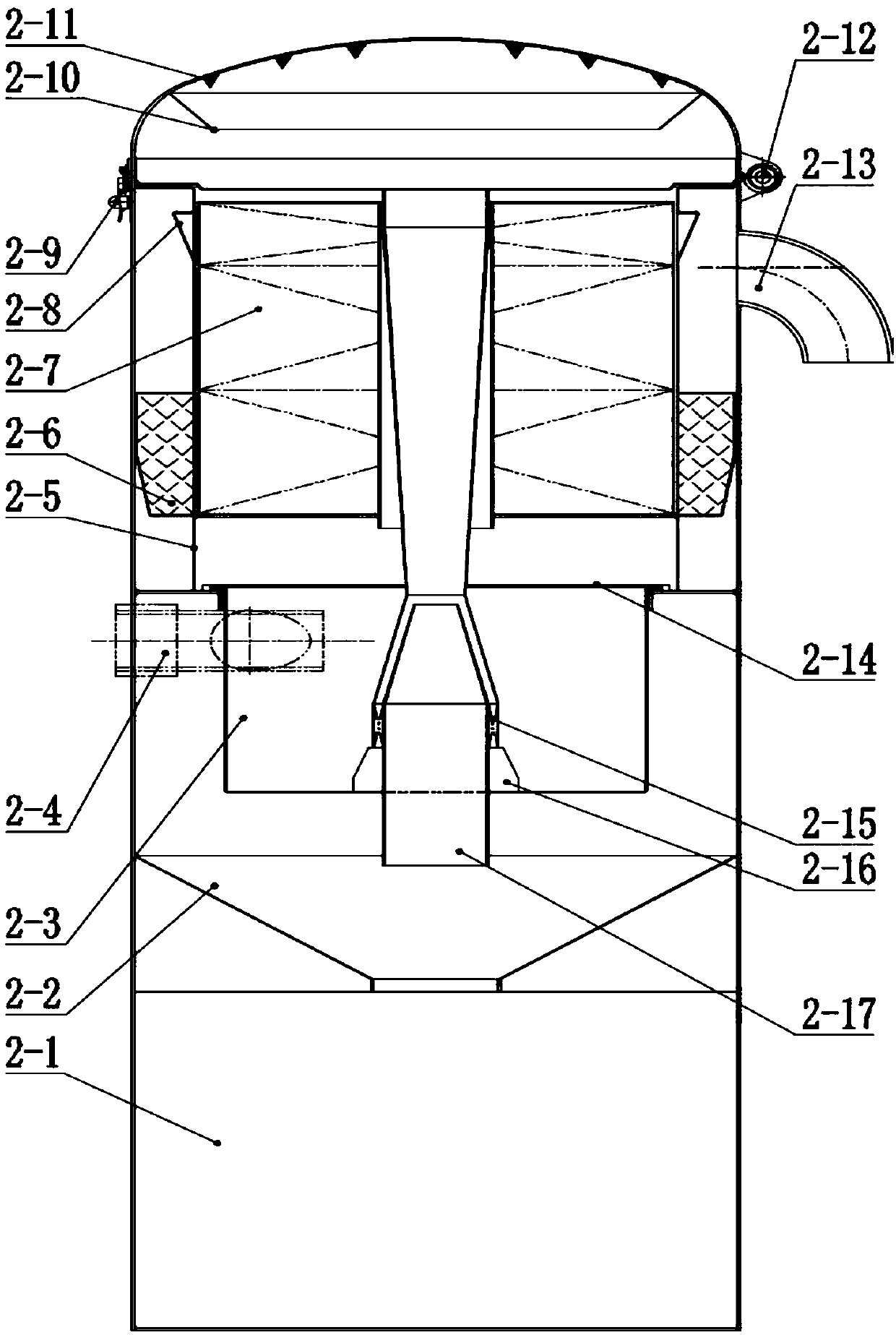

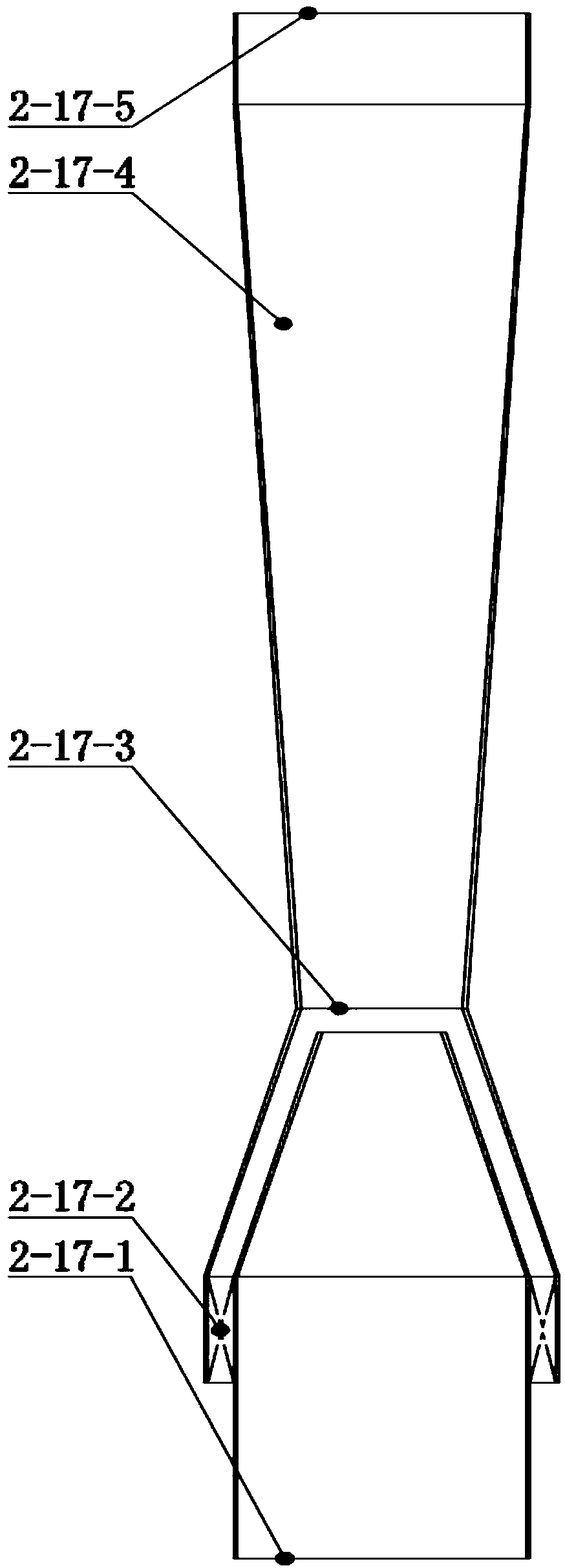

[0021] A mobile hazardous chemical washing and dust removal method, such as figure 1 As shown, its pressure-resistant and airtight wall is provided with a suction port 2-4 and a discharge port 2-13, the suction port 2-4 is connected to the suction head through a suction pipe, and the discharge port 2-13 is directly connected to the fan 5 In the same way, the mobile hazardous chemical cleaning and dust removal method is placed on a flexible mobile cart. The device can effectively treat the leaked hazardous chemical gas, liquid and powder substances. The container is divided into a three-phase cyclone collection section Four functional sections: gas-liquid decontamination section, separation section and collection section;

[0022] For the treatment of gaseous, liquid and powder hazardous chemicals in the factory workshop, after the fan 5 is started, after negative pressure suction, the air carrying gaseous, liquid and powder hazardous chemicals is drawn from the suction port 2-...

Embodiment 2

[0026] A mobile hazardous chemical washing and dust removal method, such as figure 1 As shown, its pressure-resistant and airtight wall is provided with a suction port 2-4 and a discharge port 2-13, the suction port 2-4 is connected to the suction head through a suction pipe, and the discharge port 2-13 is directly connected to the fan 5 In the same way, the mobile hazardous chemical cleaning and dust removal method is placed on a flexible mobile cart. The device can effectively treat the leaked hazardous chemical gas, liquid and powder substances. The container is divided into a three-phase cyclone collection section Four functional sections: gas-liquid decontamination section, separation section and collection section;

[0027]For the treatment of gaseous, liquid and powder hazardous chemicals in the factory workshop, after the fan 5 is started, after negative pressure suction, the air carrying gaseous, liquid and powder hazardous chemicals is drawn from the suction port 2- ...

Embodiment 3

[0031] A mobile hazardous chemical washing and dust removal method, such as figure 1 As shown, its pressure-resistant and airtight wall is provided with a suction port 2-4 and a discharge port 2-13, the suction port 2-4 is connected to the suction head through a suction pipe, and the discharge port 2-13 is directly connected to the fan 5 In the same way, the mobile hazardous chemical cleaning and dust removal method is placed on a flexible mobile cart. The device can effectively treat the leaked hazardous chemical gas, liquid and powder substances. The container is divided into a three-phase cyclone collection section Four functional sections: gas-liquid decontamination section, separation section and collection section;

[0032] For the treatment of gaseous, liquid and powder hazardous chemicals in the factory workshop, after the fan 5 is started, after negative pressure suction, the air carrying gaseous, liquid and powder hazardous chemicals is drawn from the suction port 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com