Combined water purification equipment for mine water treatment

A kind of water purification equipment and combined technology, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high treatment cost and poor purification quality, and ensure the precipitation quality, effect of reducing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

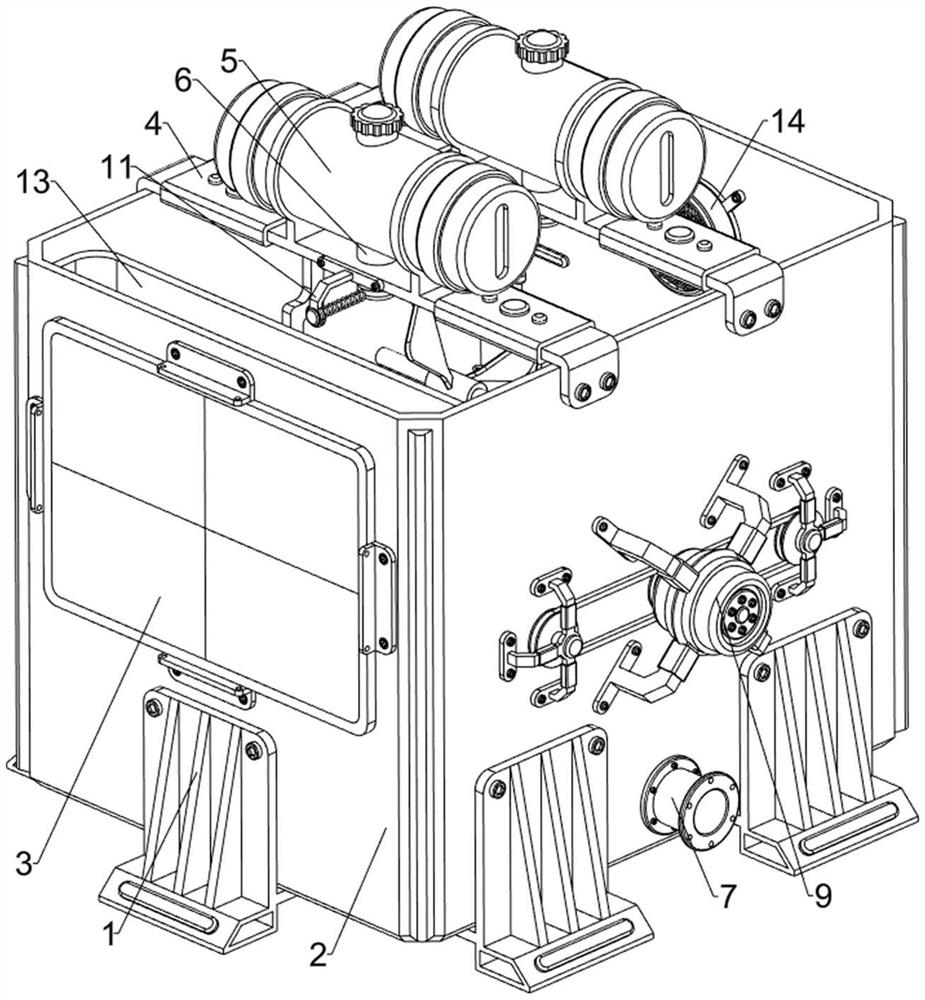

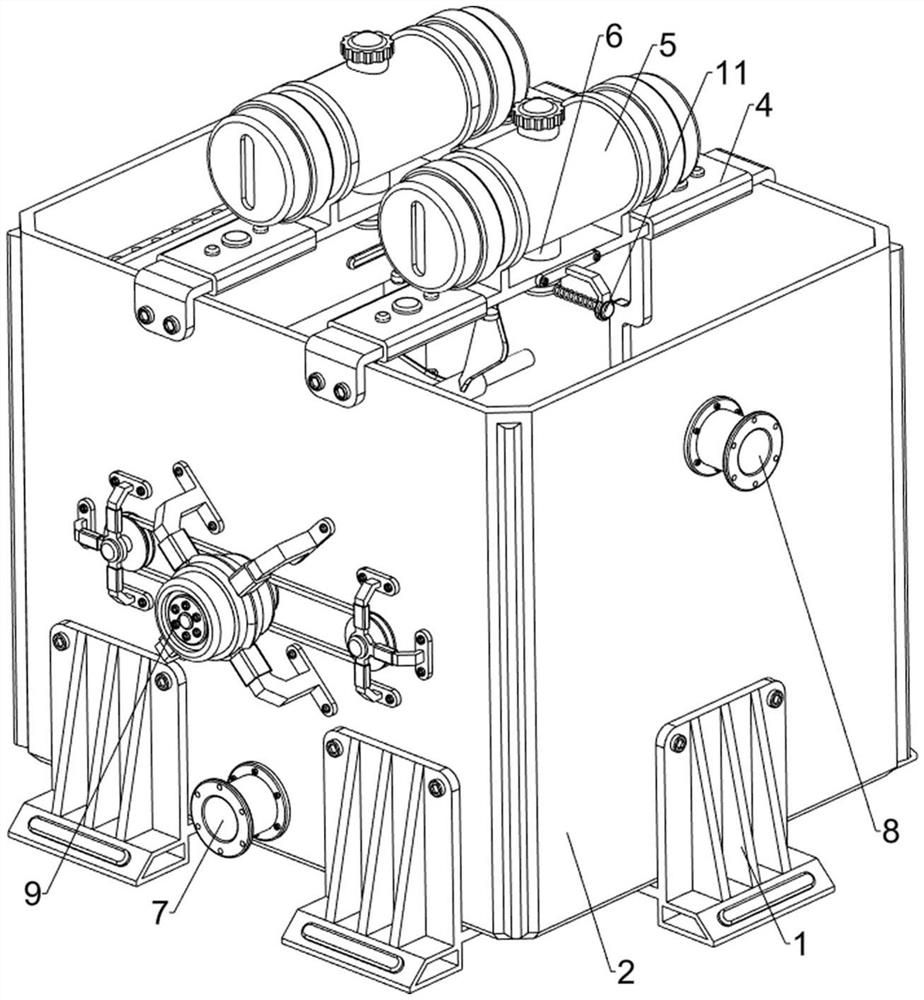

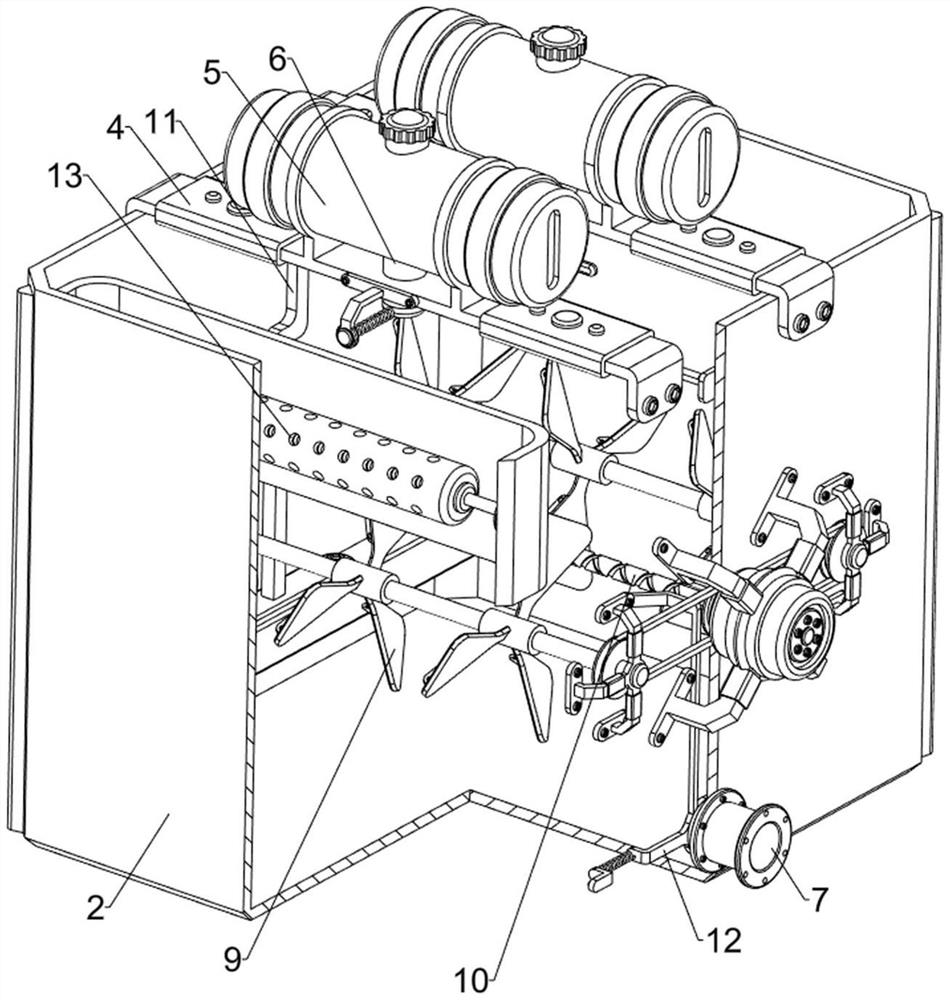

[0035] A combined water purification equipment for mine water treatment, such as Figure 1 to Figure 5 As shown, it includes a base 1, a water purification tank 2, an observation window 3, a base 4, a water purification agent placing tank 5, an outflow pipe 6, a sediment outflow output pipe 7, a purified water output pipe 8, a mixing mechanism 9 and a bottom The sediment push-out mechanism 10, a water purification tank 2 is installed on the top of the base 1, an observation window 3 is embedded in the front side of the water purification tank 2, and the observation window 3 is made of acrylic plate, which is transparent and easy to check the degradation situation. The base 4 is symmetrically provided, the top of the base 4 is provided with a water purifying agent placing tank 5, and the bottom of the water purifying agent placing tank 5 is connected with outflow pipes 6, and the outflow pipes 6 all pass through the base 4, and the lower part of the water purification tank 2 Th...

Embodiment 2

[0040] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 6 to Figure 12 As shown, it also includes a mechanism 11 for intermittently feeding water purifying agent, and the mechanism 11 for intermittently feeding water purifying agent includes a mounting frame 111, a first return spring 112, a blocking plate 113, a contact plate 114, a mounting bracket 115, a cam 116, a torsion spring 117. The force-receiving rod 118 and the push rod 119, the outside of the base 4 is connected with a mounting frame 111, and the mounting frame 111 is slidably connected with a blocking plate 113 through the first return spring 112, and the blocking plate 113 can block the outflow pipe 6 The inner side of the blocking plate 113 is provided with a contact plate 114, and a mounting bracket 115 is connected between the left and right sides of the upper inner wall of the water purification tank 2. The mounting bracket 115 is rotatably connected with a cam 116 through a torsion ...

Embodiment 3

[0044] On the basis of Example 2, as figure 1 , image 3 , Figures 13 to 15 As shown, it also includes a preliminary purification mechanism 13. The preliminary purification mechanism 13 includes a guide plate 131, a mounting plate 132 and an activated carbon placement groove plate 133. The upper inner front side of the clean water tank 2 is provided with a guide plate 131, and the inner wall of the guide plate 131 is left and right. Mounting plates 132 are provided on both sides, and an activated carbon placing slot plate 133 is connected between the mounting plates 132, and the activated carbon placing slot plate 133 places the activated carbon to realize preliminary purification.

[0045] It also includes a mechanism 14 for preventing sediment outflow. The mechanism 14 for preventing sediment outflow includes a connecting plate 141, a guide pipe 142 and a dividing net 143. There is a guide duct 142 , and the front side of the guide duct 142 is provided with a separating n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com