Patents

Literature

132results about How to "Rotate at a constant speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

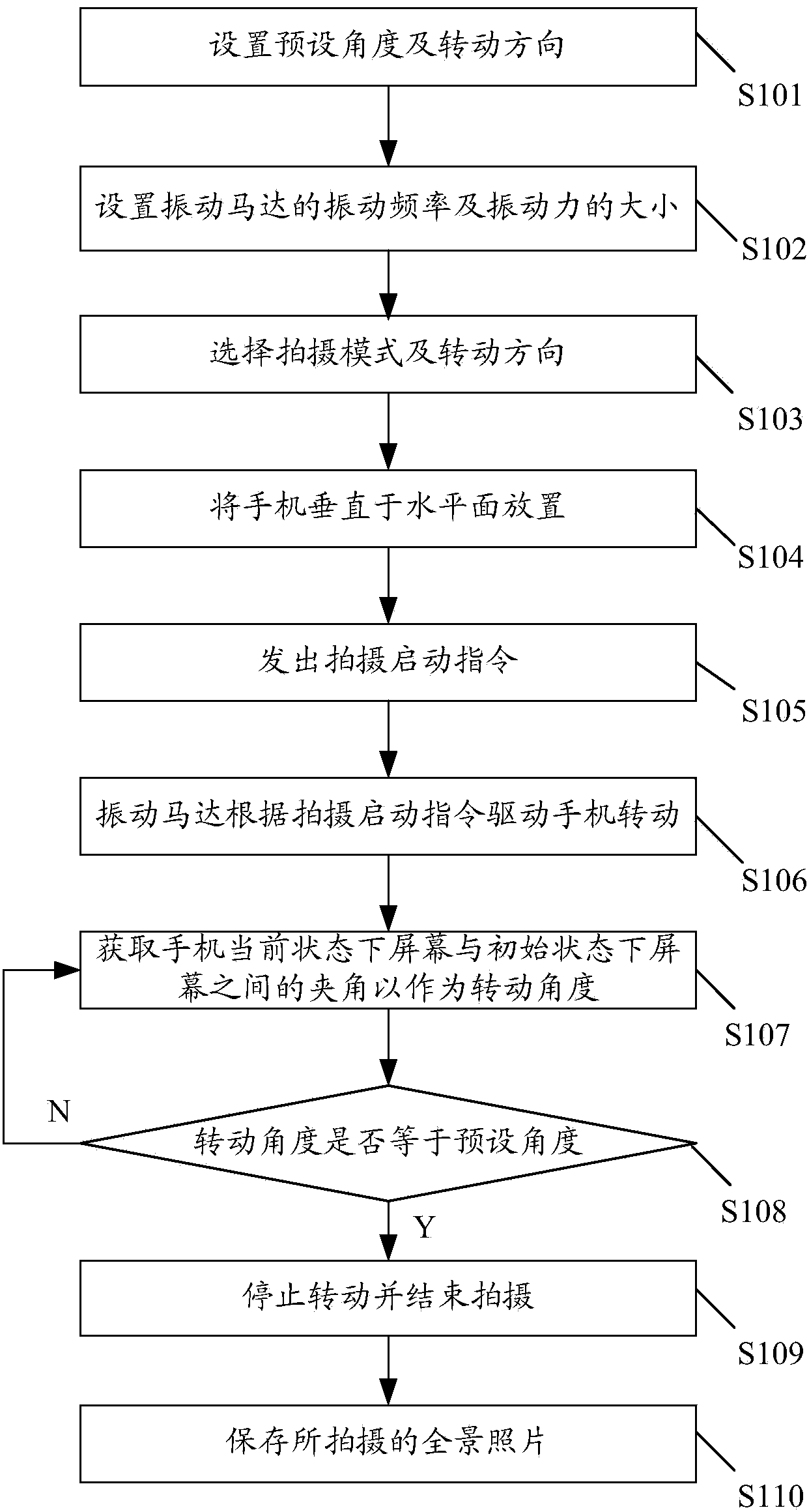

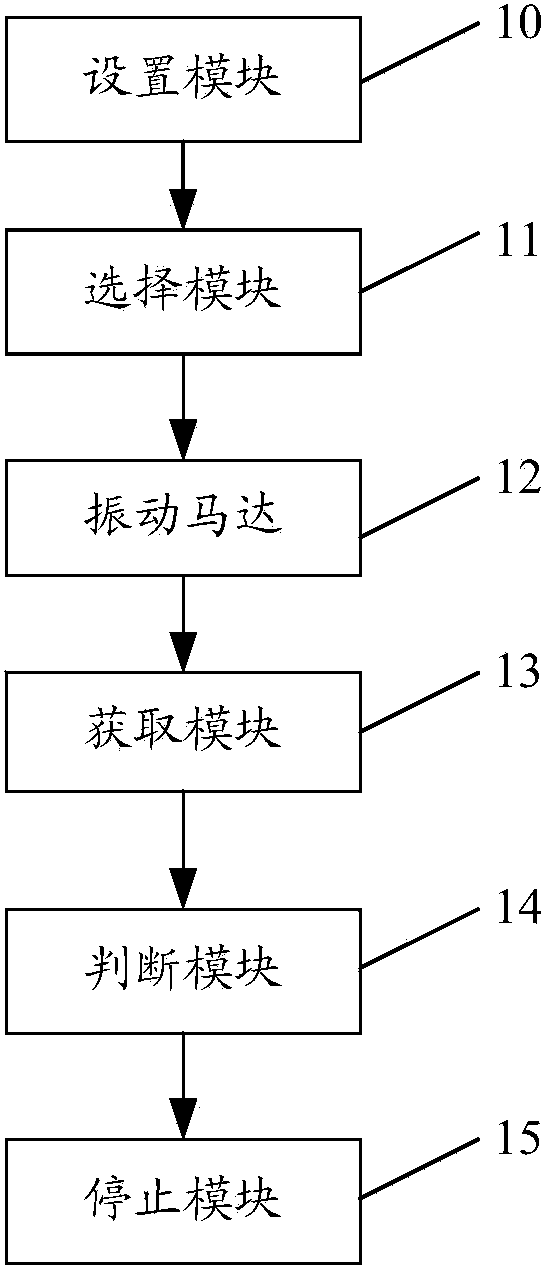

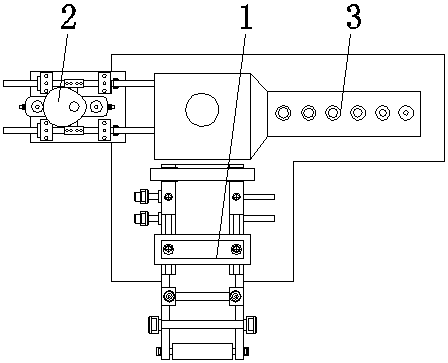

Method for shooting panoramic photos or videos based on mobile terminal and mobile terminal

InactiveCN103561209AQuality assuranceRotate at a constant speedTelevision system detailsColor television detailsComputer terminalComputer science

The invention discloses a method for shooting panoramic photos or videos based on a mobile terminal. The method includes the steps a vibration motor drives the mobile terminal to rotate according to shooting starting instructions; whether a rotating angle is equal to a preset angle is judged; the mobile terminal stops rotating and shooting according to the judgment result. Compared with the prior art, the motor of the mobile terminal drives the mobile terminal to rotate, vertical swaying generated when the terminal is moved by hand in the shooting process is avoided, the mobile terminal can be effectively rotated at constant speed, and therefore the quality of the shot panoramic photos or videos is guaranteed. The invention further discloses the mobile terminal for shooting the panoramic photos or videos.

Owner:GUANG DONG MING CHUANG SOFTWARE TECH CORP

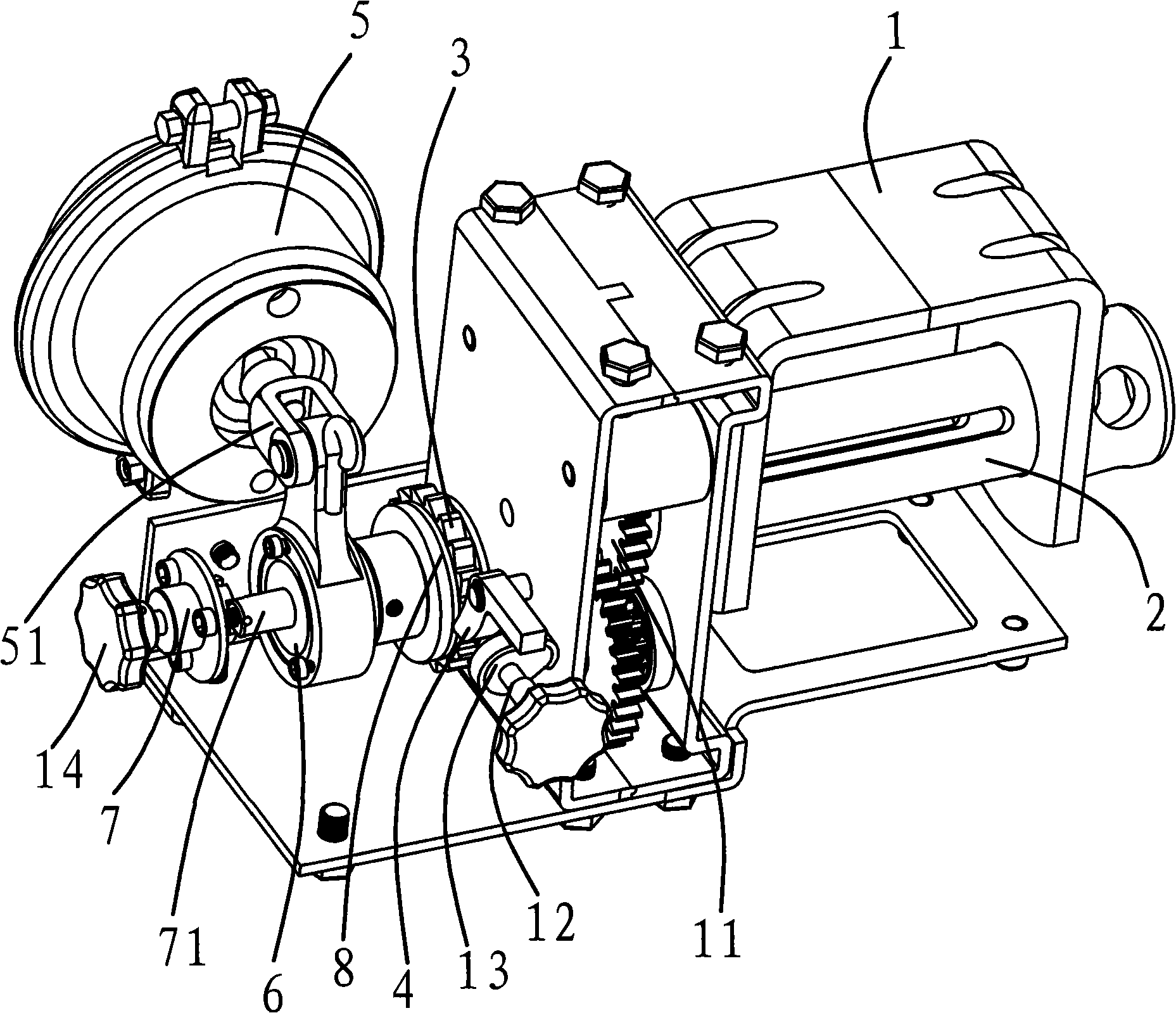

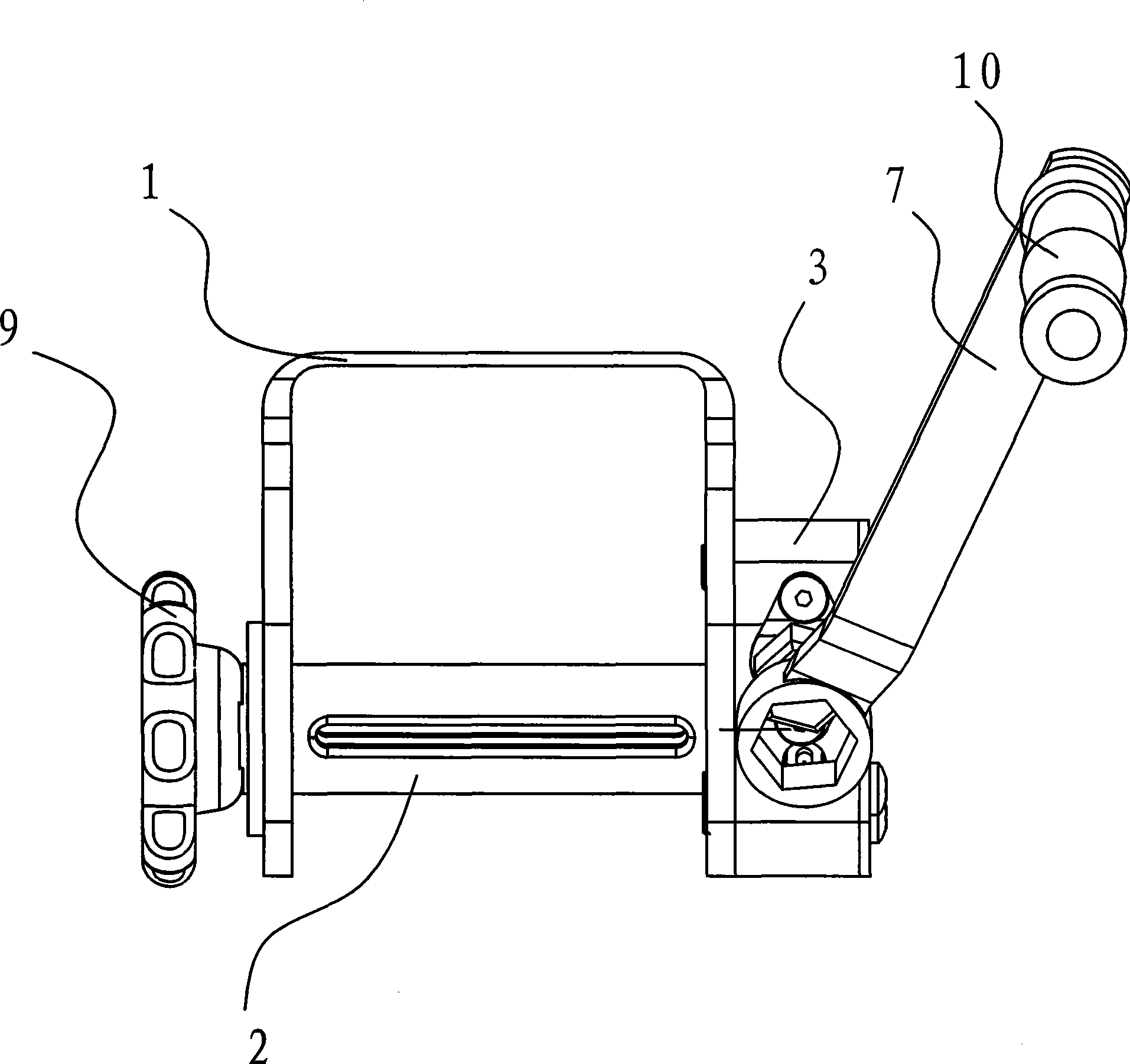

Belt deploying and retracting device of winch

ActiveCN101318565ARotate at a constant speedImprove stabilityLoad securingBundling machine detailsEngineeringSelf locking

The invention provides a belt deploying and retracting device of a winch, belonging to the technical field of machinery. The belt deploying and retracting device solves the problems of low operational security and stability, high application cost and poor commonality in the fast binding device of the existing winch. The belt deploying and retracting device of the winch is arranged at a support of the winch and is connected with a take-up spool of the winch; the device comprises a worm gear, a worm and a driving mechanism, wherein the worm gear and the worm are mutually meshed, the worm is connected with the driving mechanism, the worm gear is connected with the take-up spool and can drive the take-up spool to do corotation or contrarotation under the action of the driving mechanism. The belt deploying and retracting device of the winch is characterized in that the device can lead to fast, time-saving and labor-saving binding of the winch, has self-locking function and can conveniently realize unidirectional continuous rotation no matter in corotation or contrarotation.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

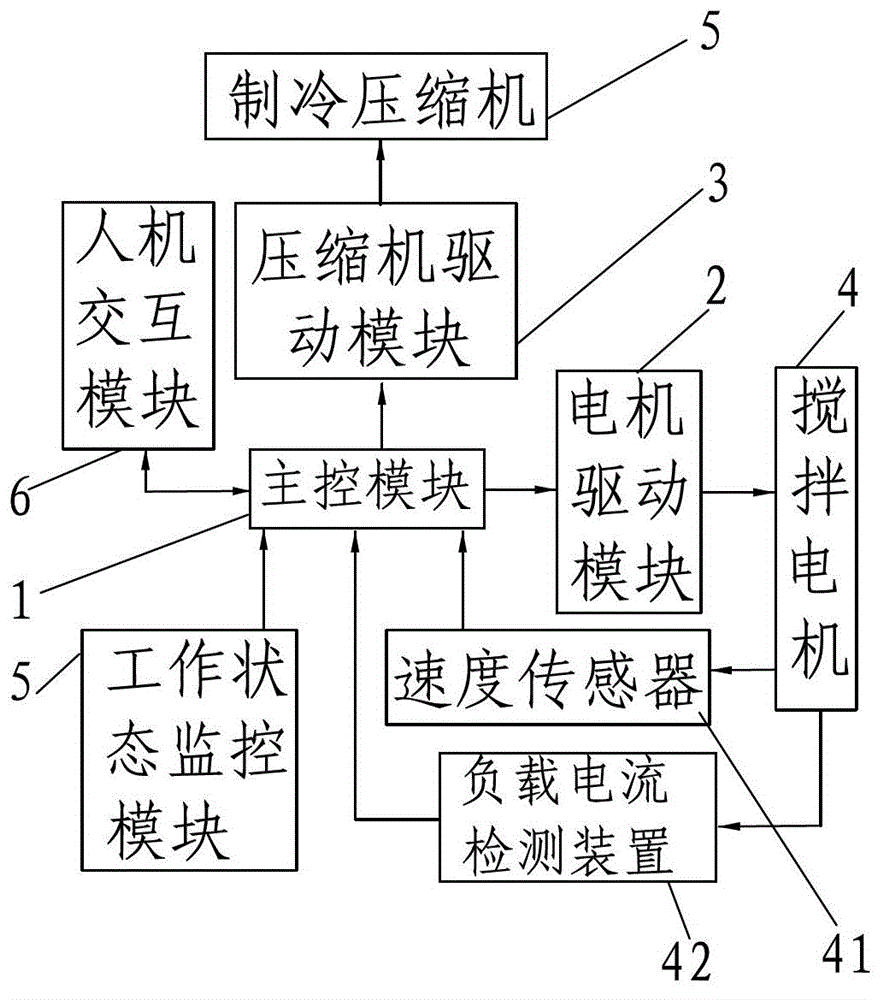

Refrigerating equipment based on hardness control

InactiveCN102972613APrecise Hardness ControlQuality assuranceMilk preparationFrozen sweetsElectric machineryHardness

The invention relates to the technical field of refrigerating equipment, in particular to the refrigerating equipment based on hardness control. The refrigerating equipment based on the hardness control comprises a main control module, and a motor driver module and a compressor driver module are arranged on the main control module and controlled by the main control module. In a preparation process of frozen foods, when the hardness of frozen products is changed slightly, the load of a mixing motor is changed accordingly, mixing speed is affected by the load and changed, when a speed variation transmitted by a speed sensor is accepted by the main control module, a motor is driven to be at a setting speed through the motor driver module by the main control module, and uniform rotation all the time is achieved. On the other side, a working current which can be detected by a load current detecting device is changed, further the actual hardness of the products can be obtained through current-hardness analysis arranged in the main control module, and start-up and shut-down of a refrigerating compressor is driven through the compressor driver module, so that accurate hardness control of the frozen products is achieved, and frozen product quality is exactly ensured.

Owner:DG HUST MFG ENG RES INST +2

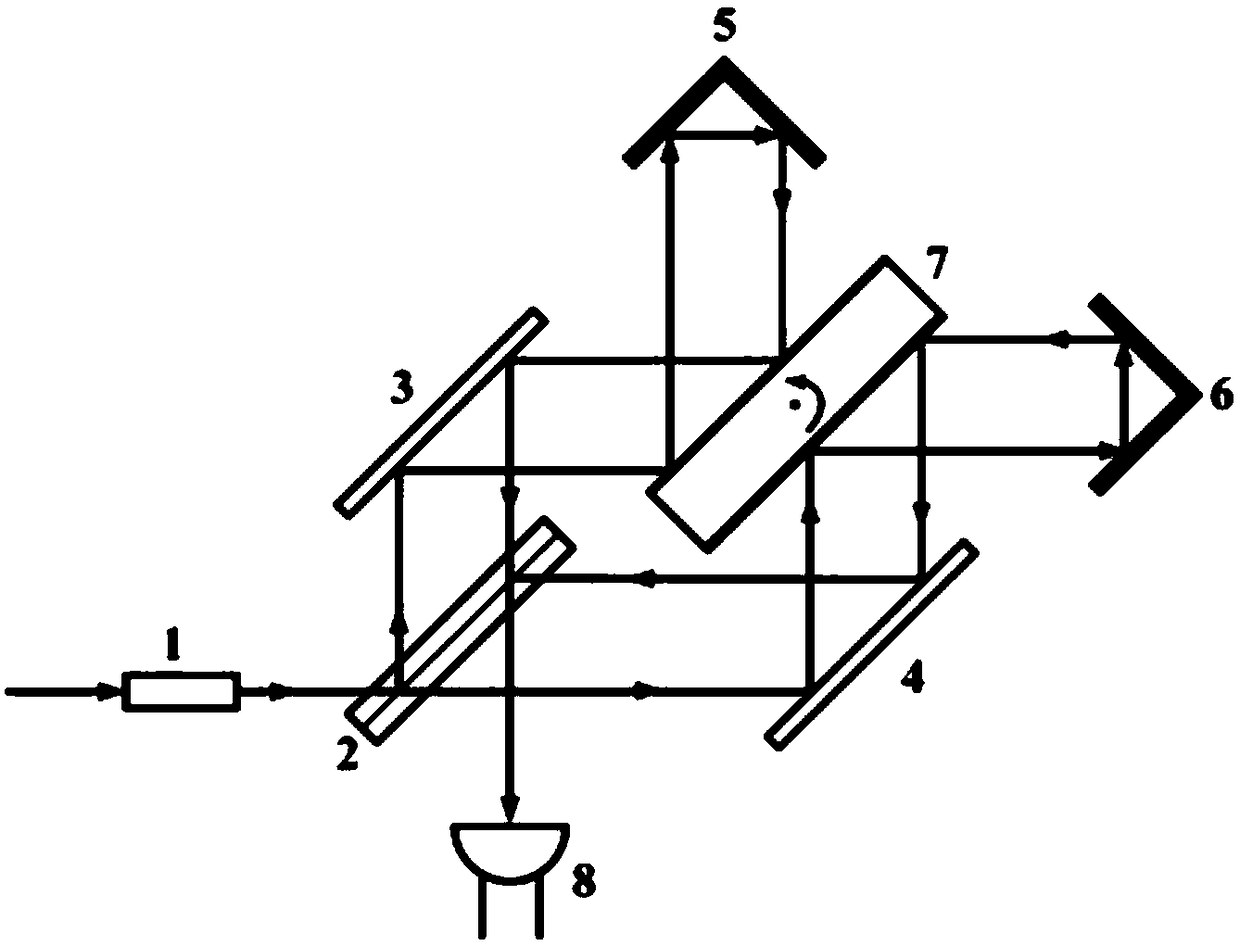

Fourier transform hyperspectral imaging device based on high speed double reflection rotating mirror

PendingCN109297600ASame intensityGood interferenceInterferometric spectrometryBeam splitterOptoelectronics

The invention relates to an overspeed detection hyperspectral imaging technique, and provides a Fourier transform hyperspectral imaging device based on a high-speed double reflection rotating mirror to solve the problem of nonlinearity caused by an optical path difference of a high-speed rotating mirror transmission type interference spectrometer. The device comprises a collimating mirror, a beamsplitting mirror, a first reflecting mirror, a second reflecting mirror, a first hollow retro-reflector, a second hollow retro-reflector, a detector and the double reflection rotating mirror. Incidentlight is incident on a beam splitter and is divided into reflected light and transmitted light. The reflected light enters the first hollow retro-reflector after being reflected by the first reflecting mirror and the double reflection rotating mirror. Then the reflected light returns back to the double reflection rotating mirror at 180 degrees, and is then reflected to the beam splitter by the double reflection rotating mirror and the first reflecting mirror. The transmitted light enters the second hollow retro-reflector after being reflected by the second reflecting mirror and the double reflection rotating mirror. Then the reflected light returns back to the double reflection rotating mirror at 180 degrees, and is then reflected to the beam splitter by the double reflection rotating mirror and the second reflecting mirror. The interference light generated by the reflected light and the transmitted light is received by the detector.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

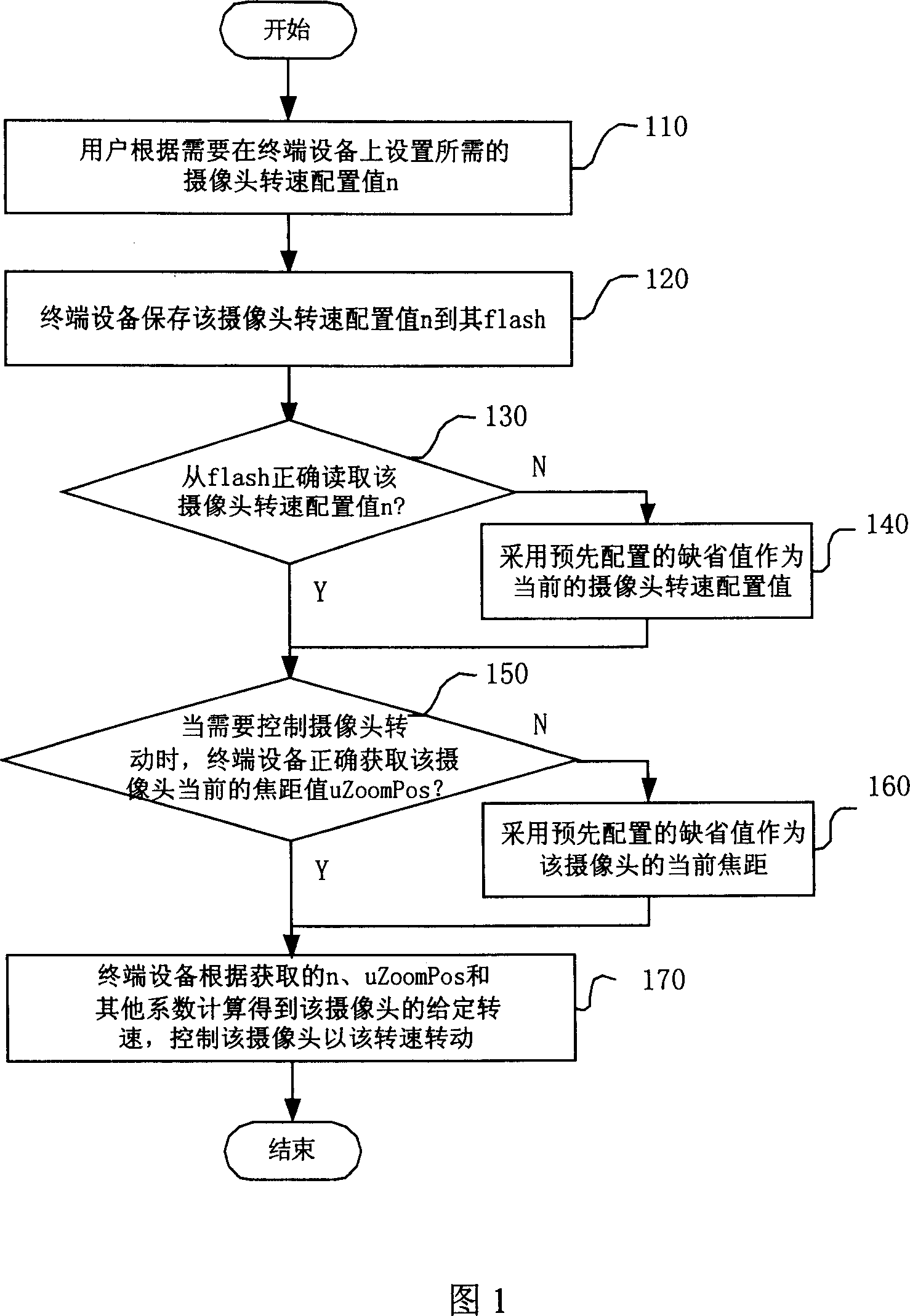

Method for flexible control of rotary speed of cam through terminal device

ActiveCN1972383AControl rotation speedRotate at a constant speedTelevision system detailsTelevision conference systemsCommunication interfaceTerminal equipment

This invention relates to one method to control cameral head rotation speed by terminal device, which comprises the following steps: user sets needed cameral head align value and stores the set by needs; the said terminal device is started to get the align value; in rotating of cameral head, the terminal device gets the cameral head rotation speed according to the cameral head speed and informs the speed to the cameral head through said communication interface to control cameral head rotation speed.

Owner:ZTE CORP

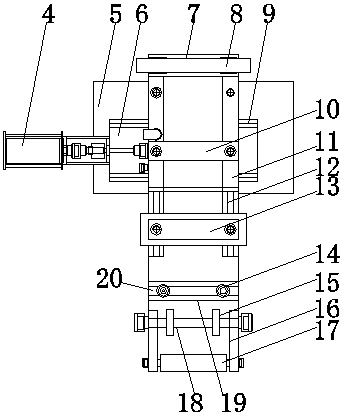

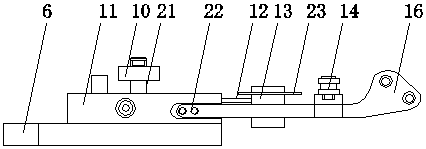

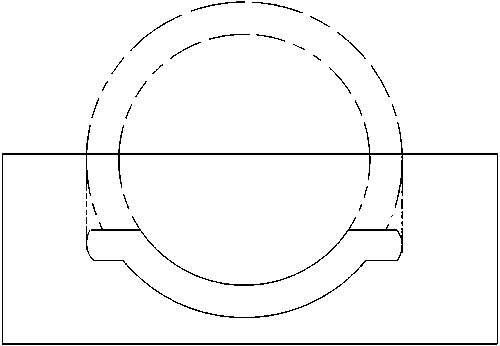

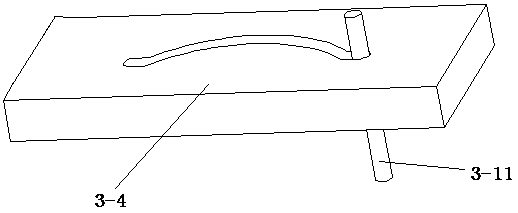

Pressure battery shell mechanism

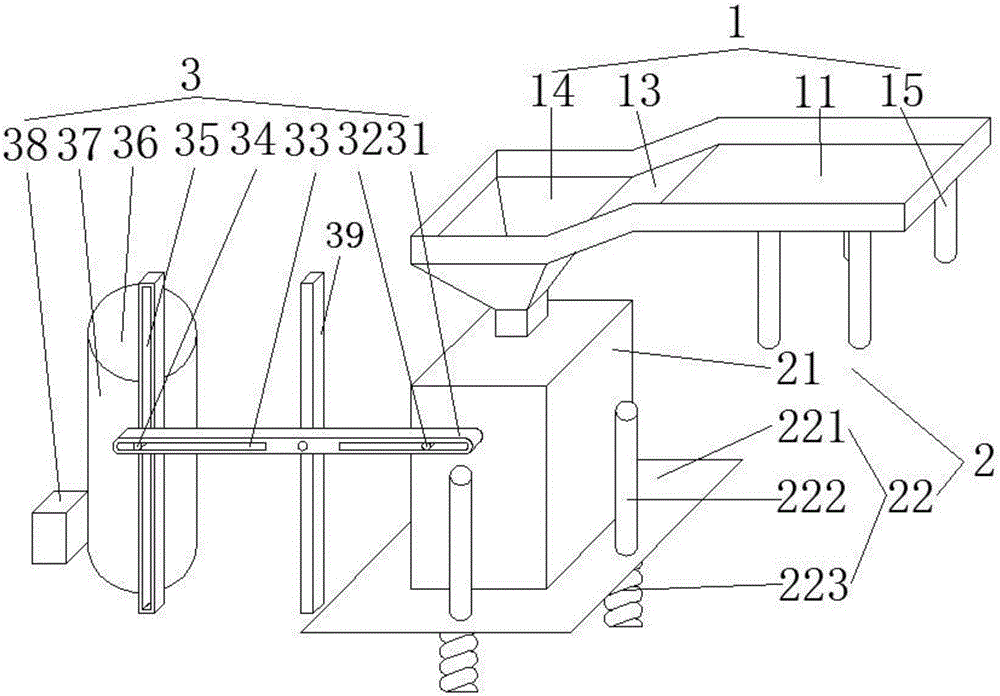

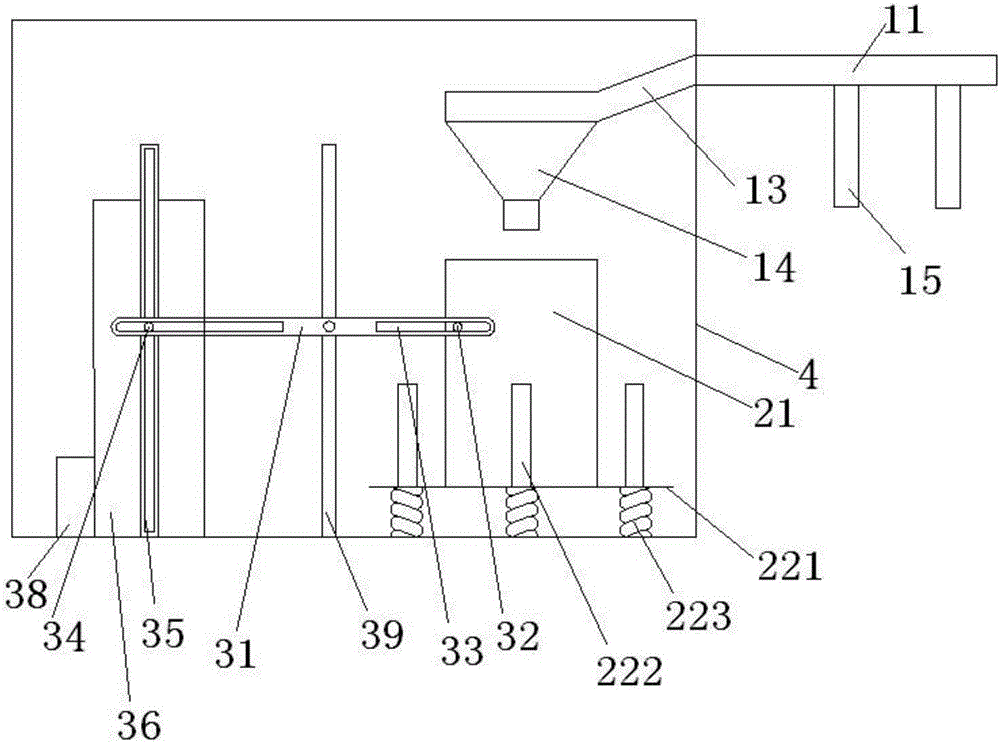

InactiveCN107661915AAchieve clampingIncrease the clamping degreeShaping toolsMetal-working feeding devicesDrive shaftUtilization rate

The invention discloses a pressing battery shell mechanism, which includes a feeding mechanism, a transmission mechanism and a stamping mechanism. The feeding mechanism is provided with a base, and a horizontal sliding platform A is arranged at a middle position above the base. The horizontal sliding platform A is distributed laterally on the base, first mounts are symmetrically arranged at the front and rear positions above the transverse slide A, and slide rails are installed on the two first mounts. The invention solves the problems of low material utilization rate and material deviation during the production process of the battery case by setting the cylinder, the transverse sliding table A, the feeding table and the feeding auxiliary table; by setting the motor, the guide seat, the first The first transmission shaft, the second bevel gear, the second transmission shaft and the operation box solve the problem that the transmission and feeding structure is complicated and the processing and feeding of the battery case are not synchronized with the stamping; by setting the upper mold, the lower mold, the punch and the battery case fixture, It solves the problems of complicated steps, low continuity and low yield in the production process of the battery case.

Owner:新乡市盛达电源科技有限公司

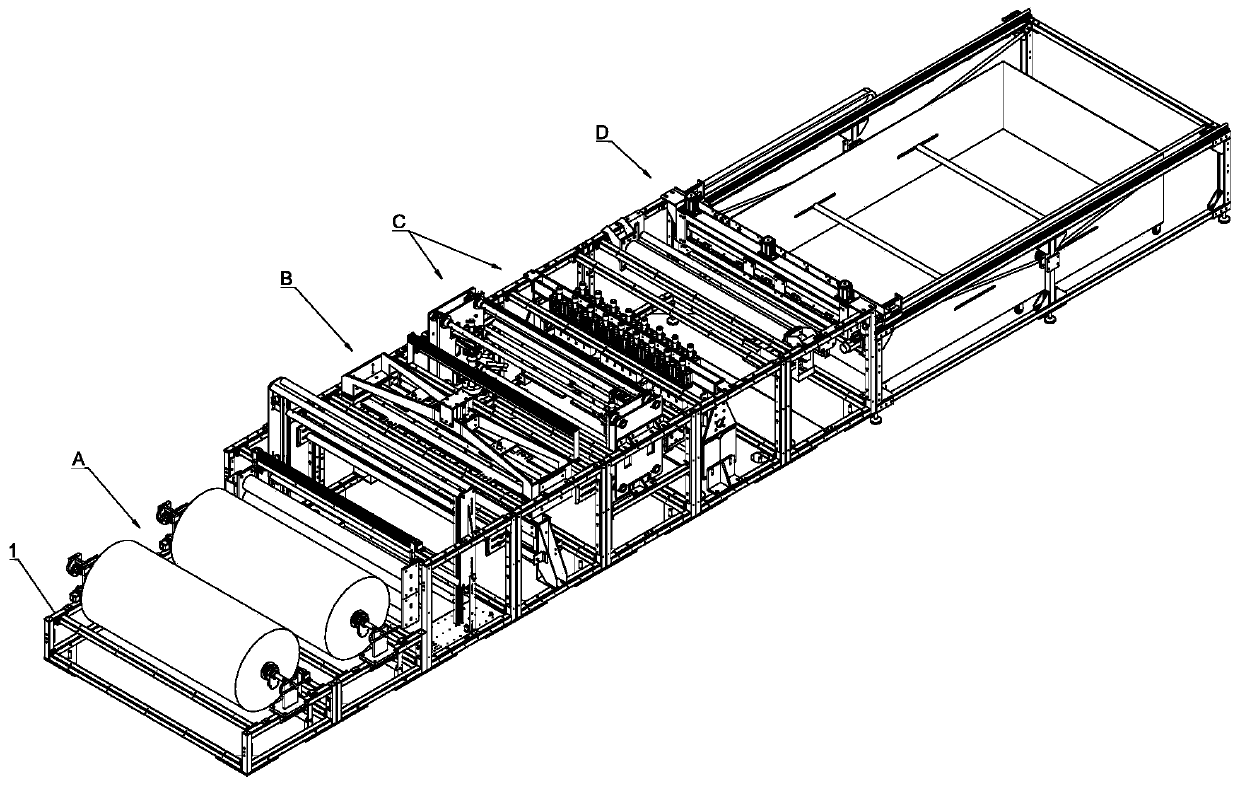

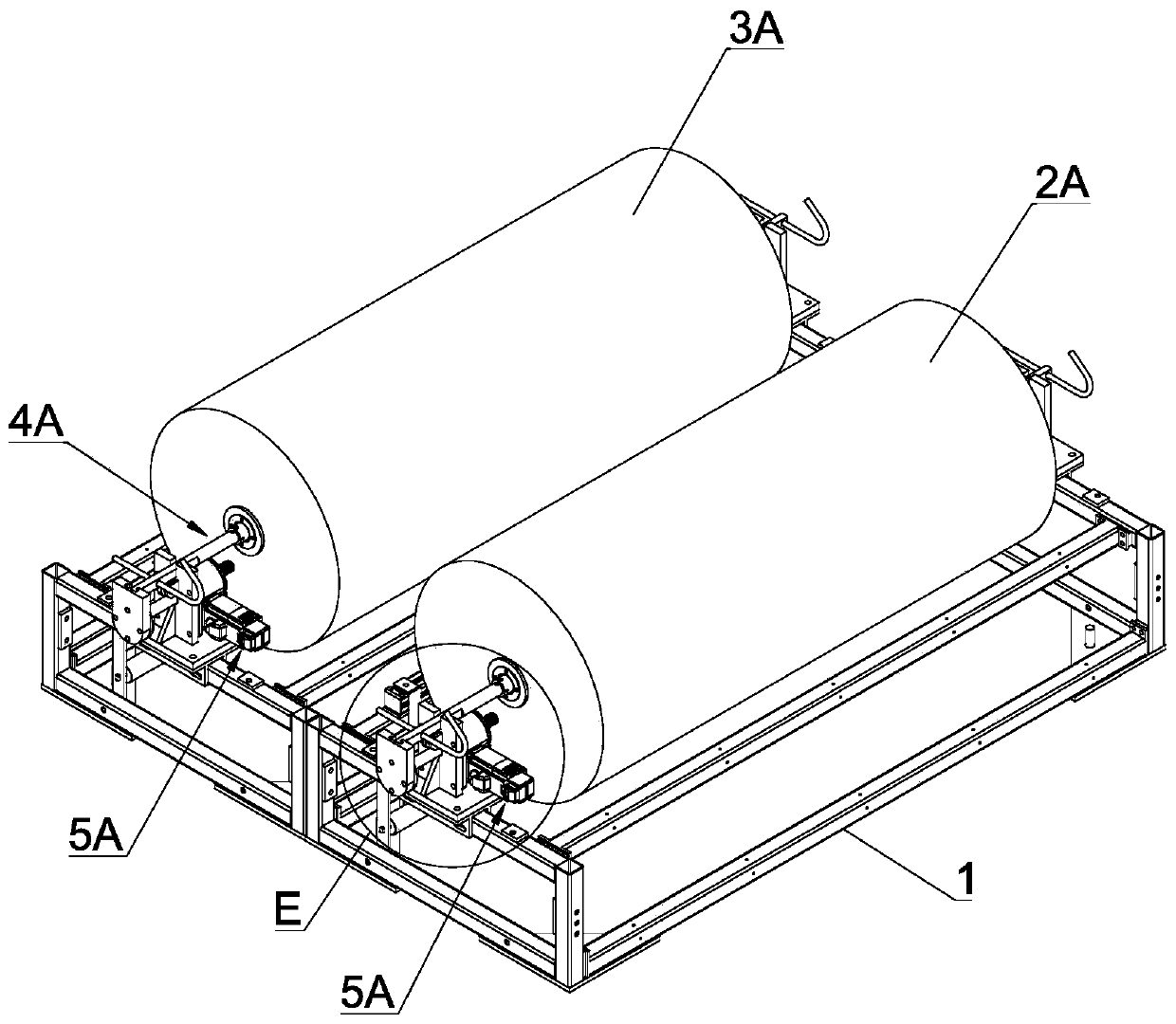

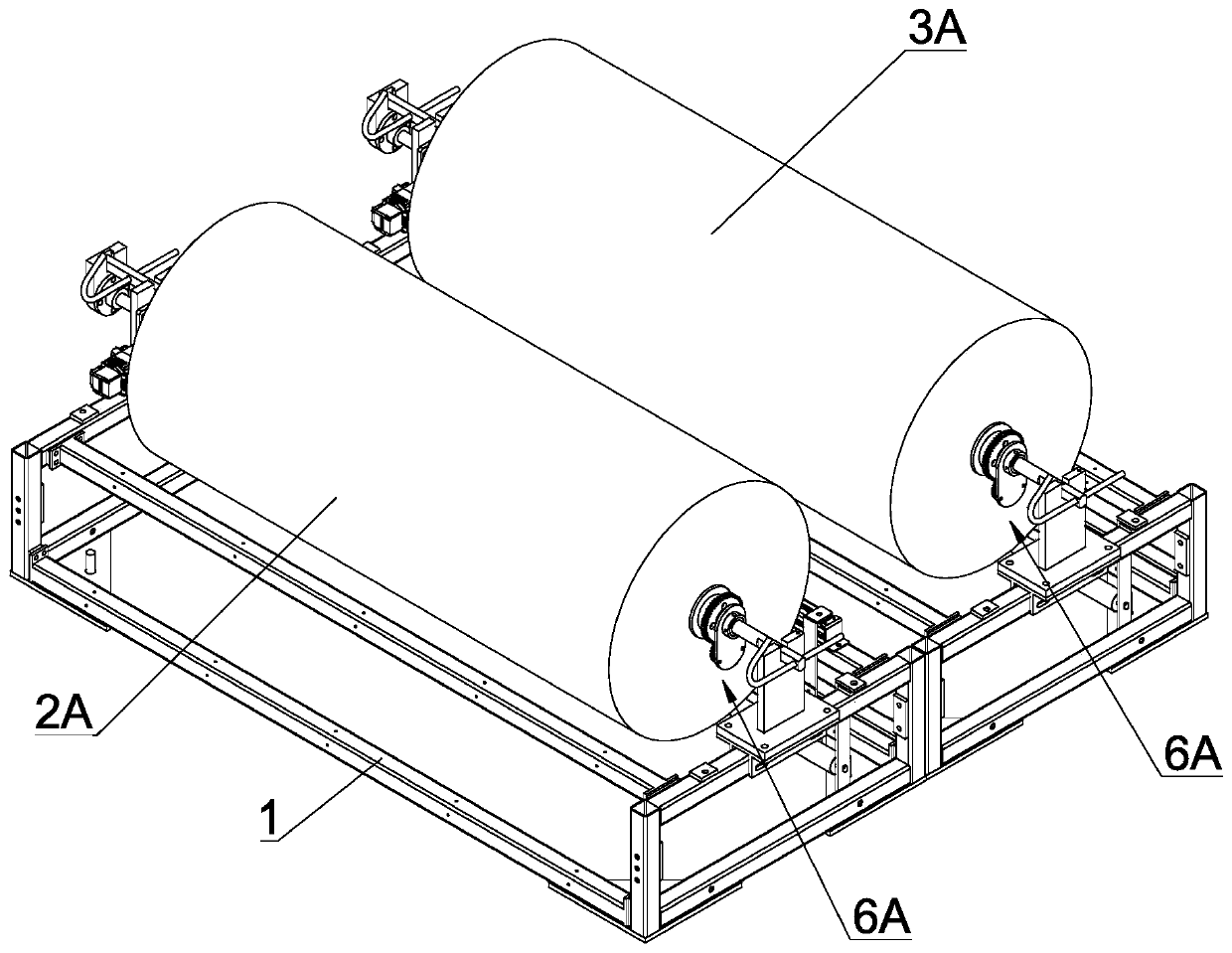

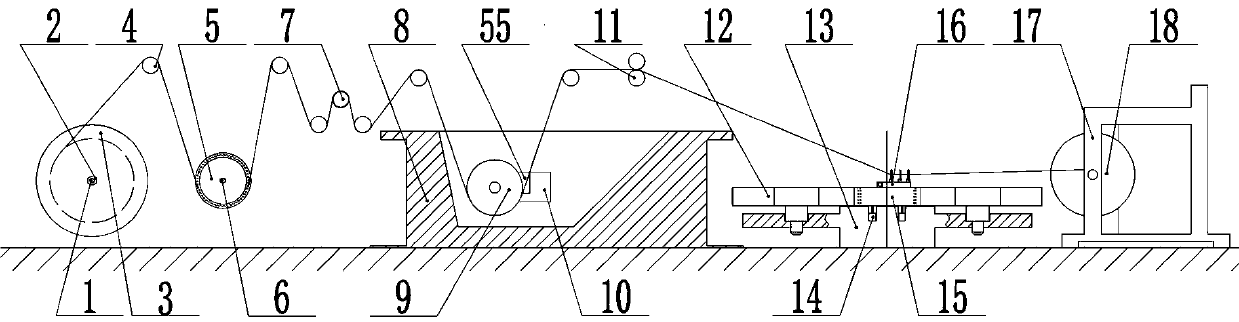

Full automatic production line for medical operating coat

ActiveCN110731563ARealize the normal trendIncrease the feeding speedProtective garmentClothes making applicancesRotational axisPunching

The invention discloses a full automatic production line for a medical operating coat. The production line comprises a rack, and a discharge device, a punching device, a composite device and a cuttingdevice arranged on the rack, wherein the discharge device comprises an upper-layer non-woven fabric roll, a lower-layer non-woven fabric roll, a deviation correction drive mechanism and a damping anti-rotating mechanism arranged on the rack; the composite device comprises a lateral side welding module and a middle part welding module; the lateral side welding module comprises a roll welding mechanism; the roll welding mechanism comprises a welding head and a rotation shaft adaptive separation mechanism used for separating a non-woven fabric body from lateral side margin wastes; the cutting device comprises a cutting mechanism, a fabric pressing mechanism and an adaptive material pulling mechanism arranged on the rack; the fabric pressing mechanism comprises a fixed mount, a movable mountand a compression drive mechanism; and the cutting mechanism comprises a cutter and a cutting drive mechanism. The production line can improve production efficiency and production quality of the operating coats.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

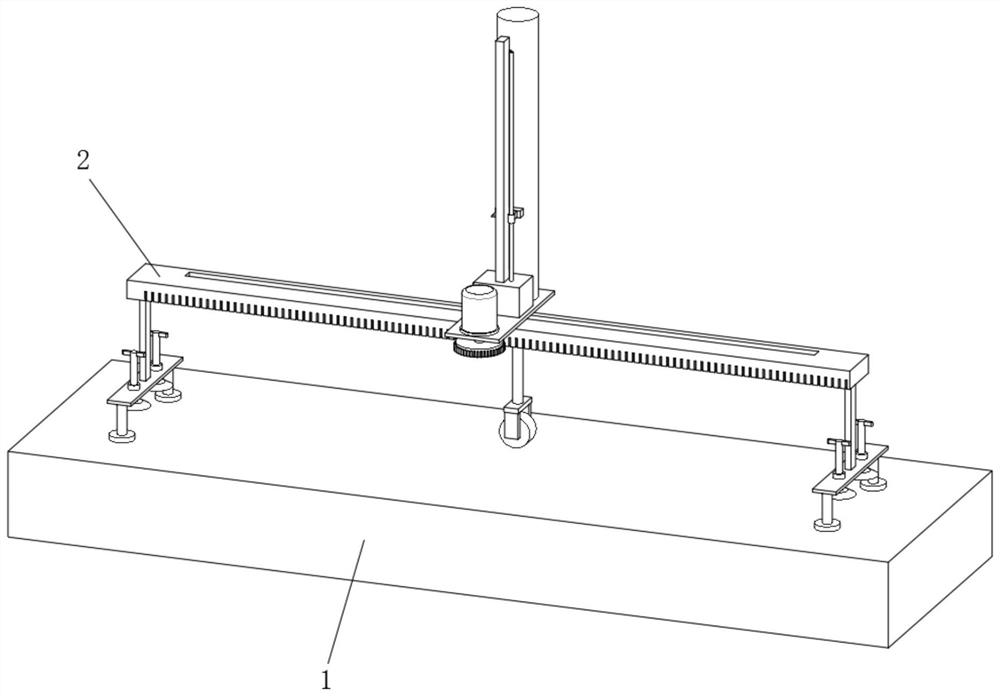

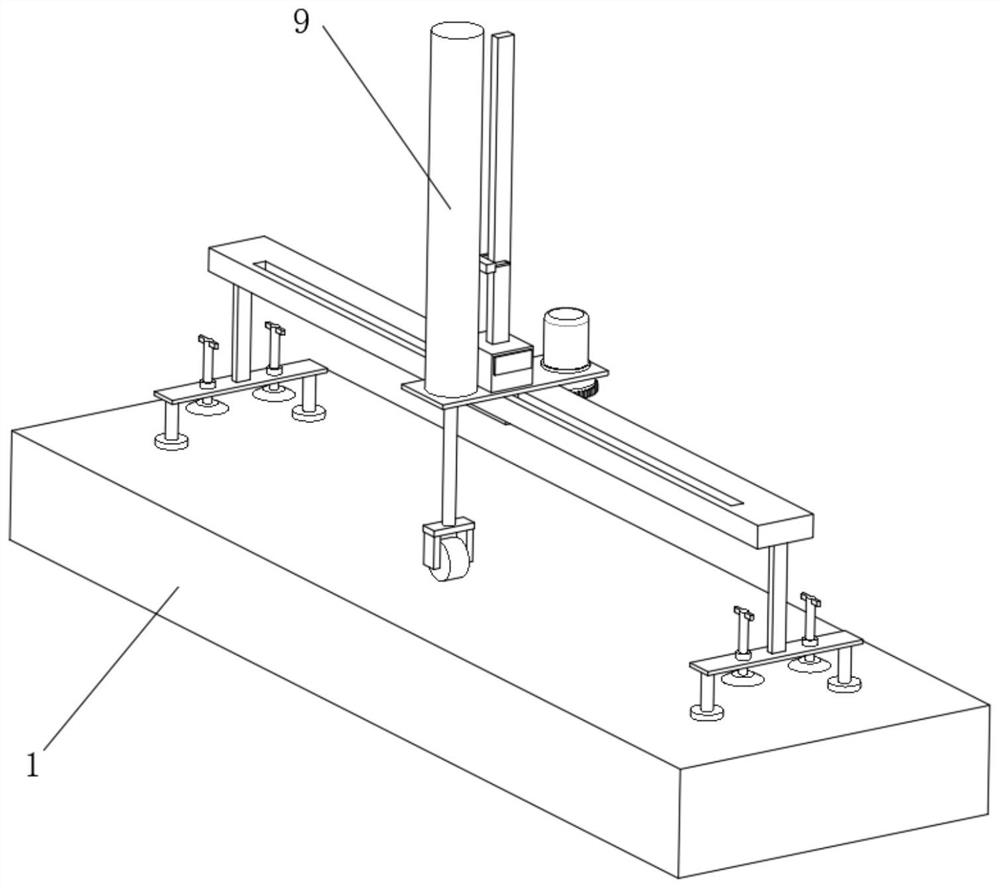

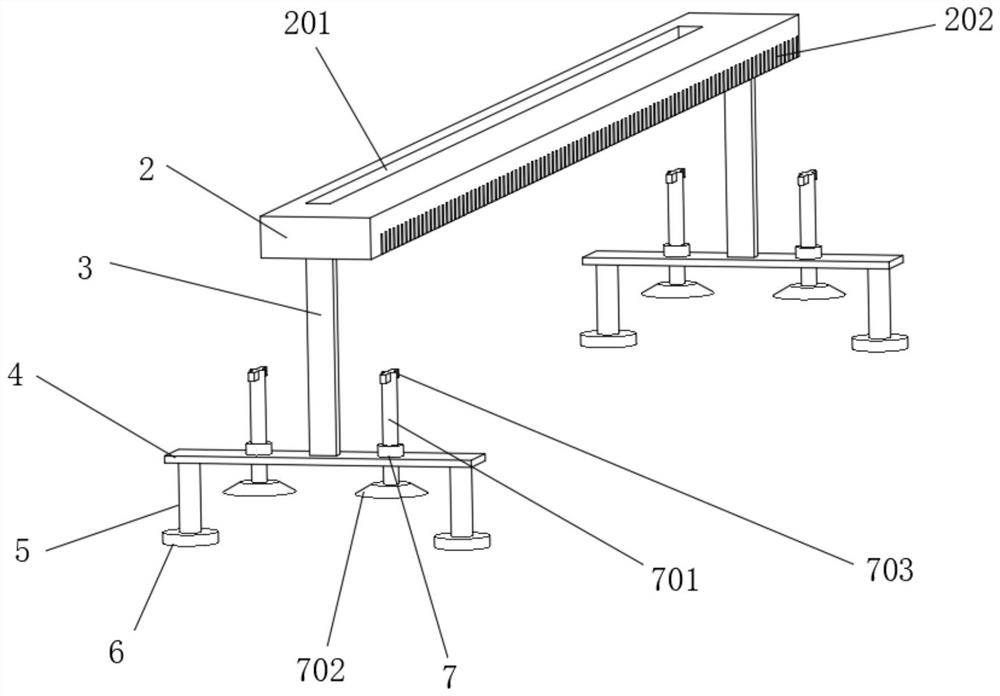

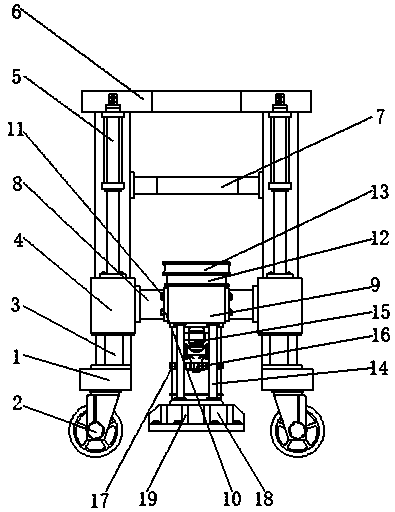

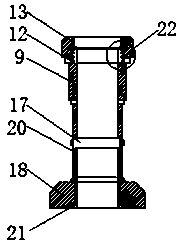

Pavement flatness detection device for road and bridge construction

InactiveCN112458849ACheck flatnessFlatness judgmentBridge structural detailsRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a pavement flatness detection device for road and bridge construction, and relates to the field of road and bridge construction. The pavement flatness detection device for roadand bridge construction comprises a to-be-detected ground and a support plate, supporting strip blocks are fixedly connected to the two sides of the bottom of the support plate, a supporting flat plate is fixedly connected to the bottoms of the supporting strip blocks, supporting columns are fixedly connected to the two sides of the bottom of the supporting flat plate, and a reinforcing mechanismcorresponding to the to-be-detected ground is arranged on the supporting flat plate. A rubber block is attached to the to-be-detected ground, a sliding plate is slidably connected to the upper surface of the support plate, a power mechanism corresponding to the support plate is arranged on the sliding plate, a hollow cylinder is fixedly connected to the top of the sliding plate, an inner cavity is formed in the hollow cylinder, a lifting block is slidably connected into the inner cavity of the hollow cylinder, and an abutting spring is arranged in the inner cavity of the hollow cylinder. Thepavement flatness detection device for road and bridge construction is convenient to use for detecting the flatness of the to-be-detected ground, is not easy to damage, and is low in use cost.

Owner:尚福涛

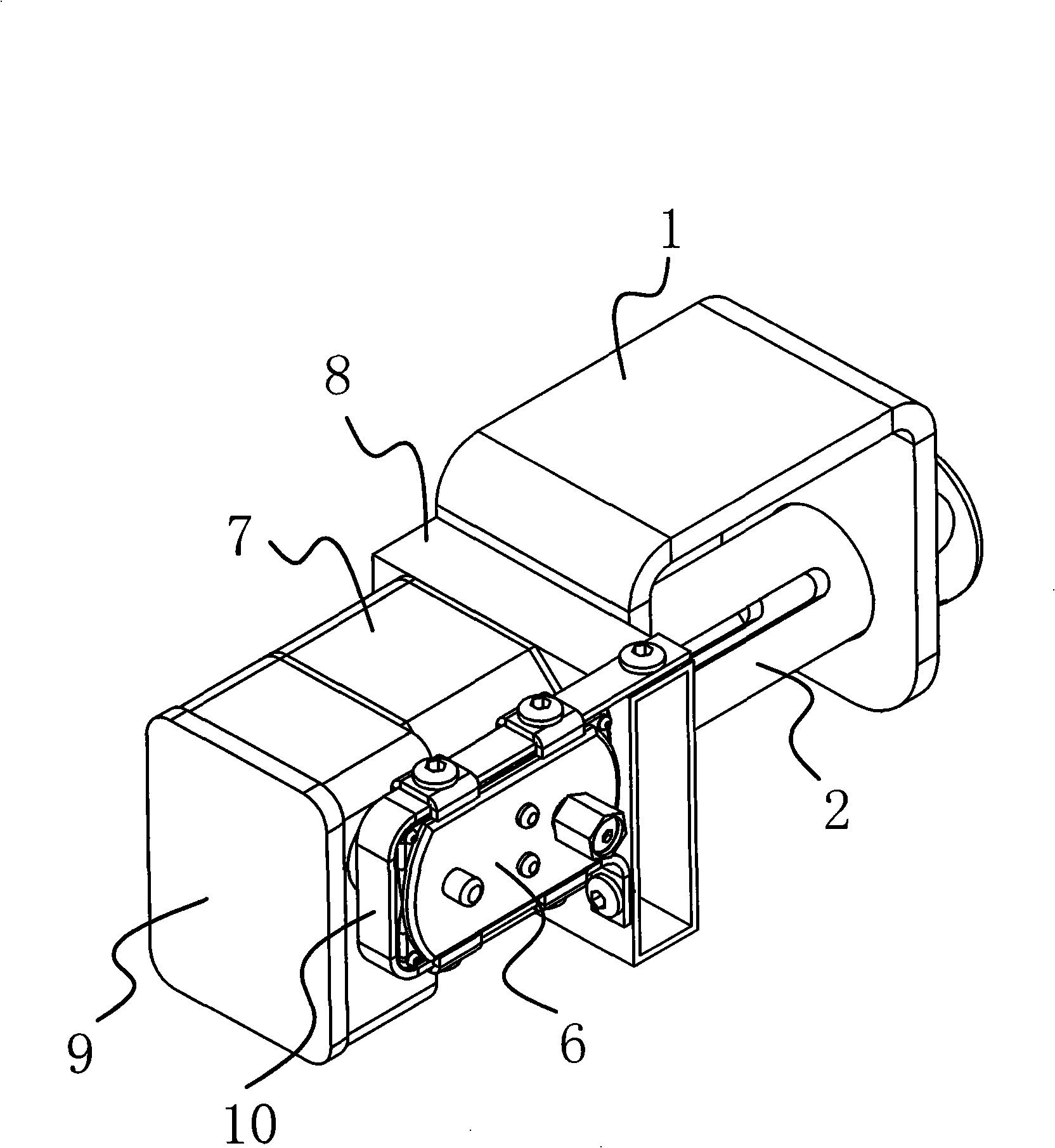

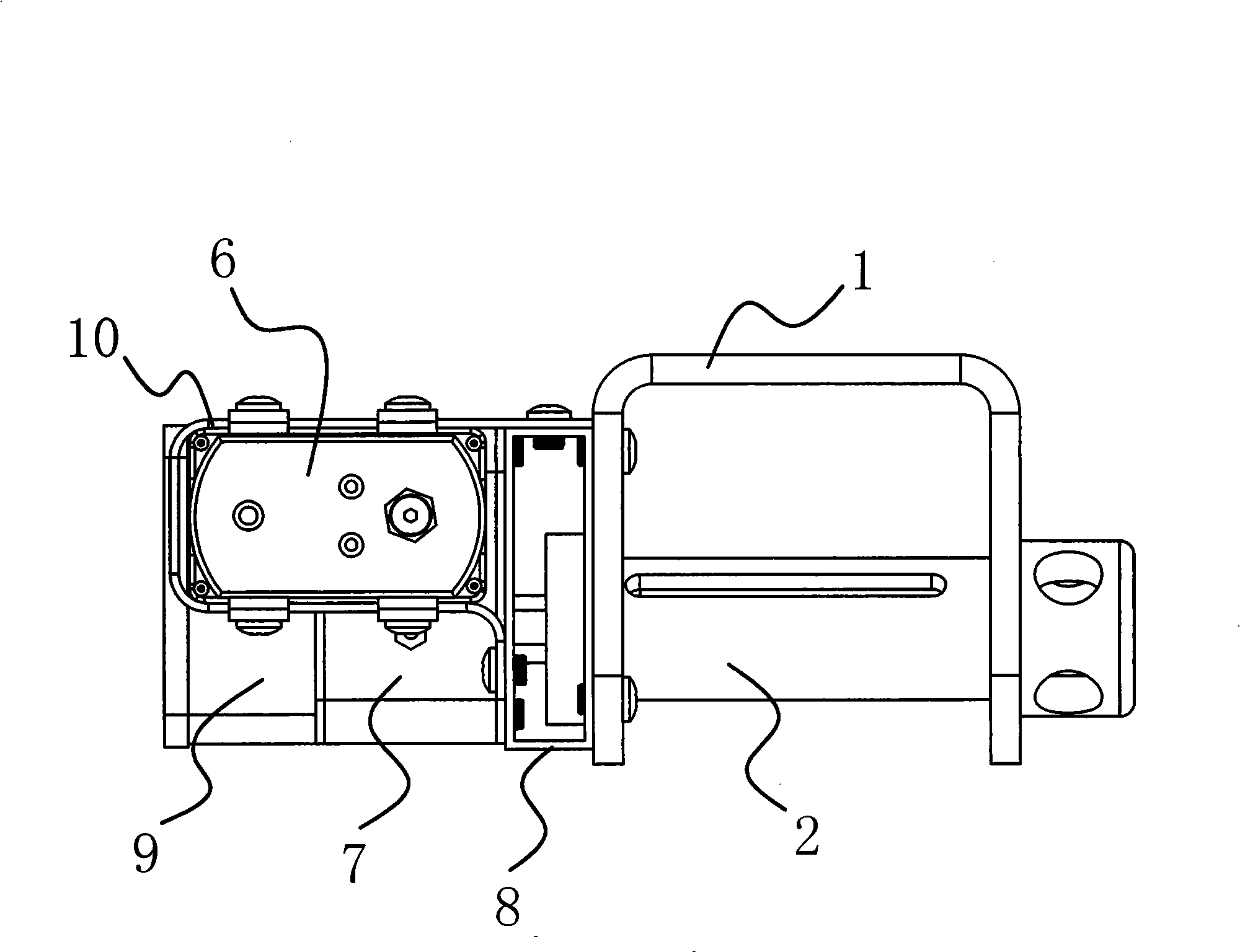

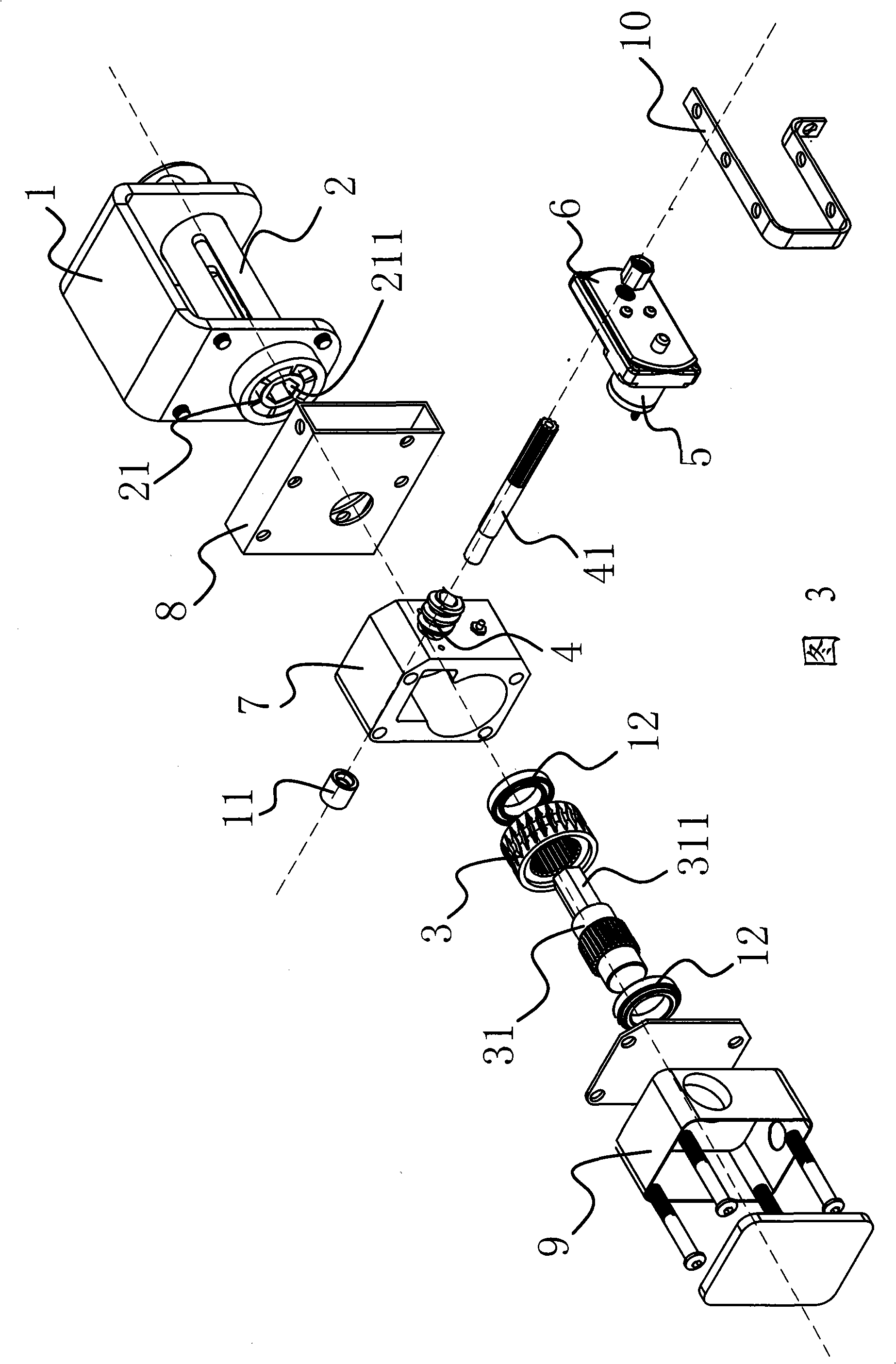

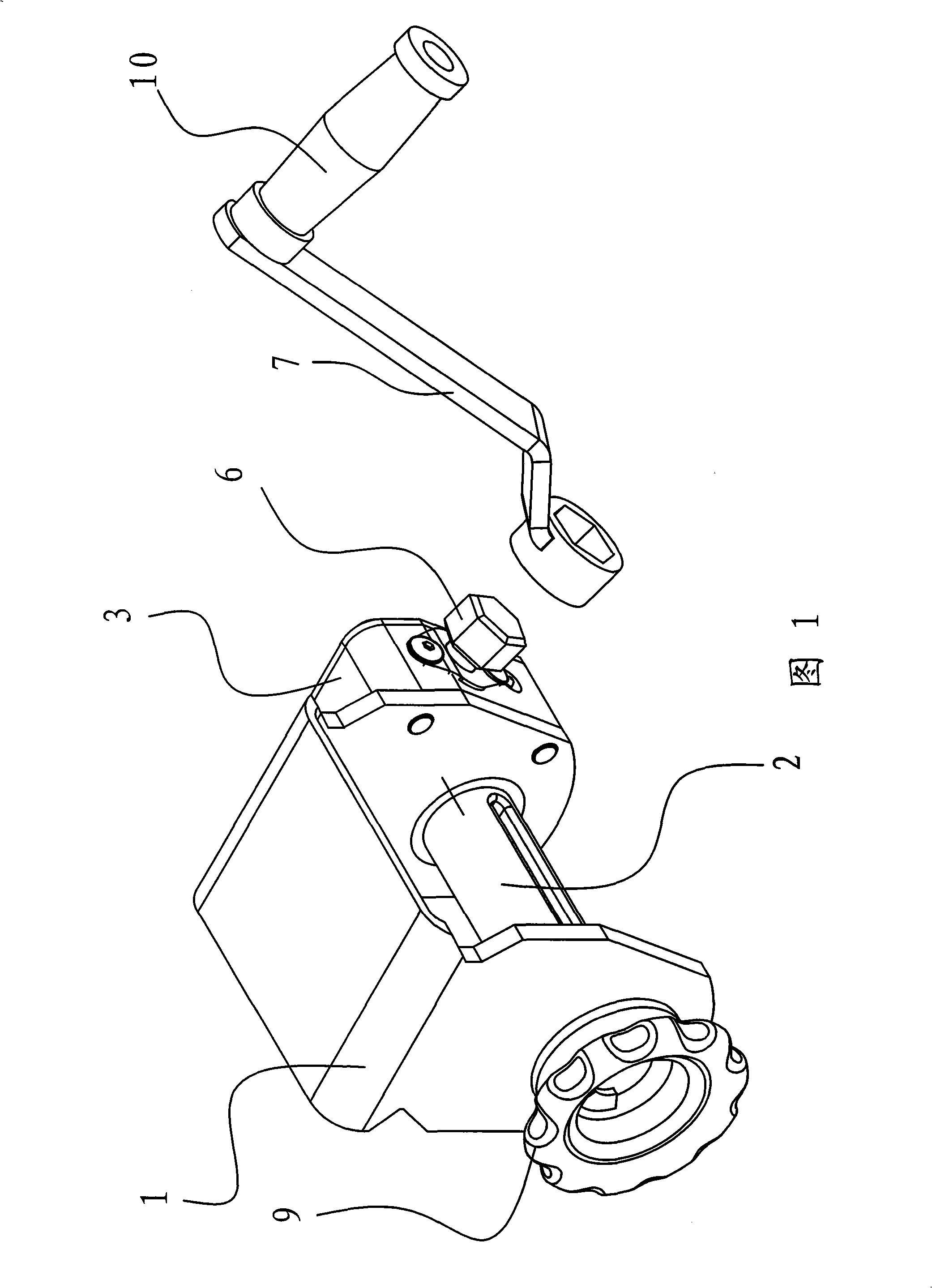

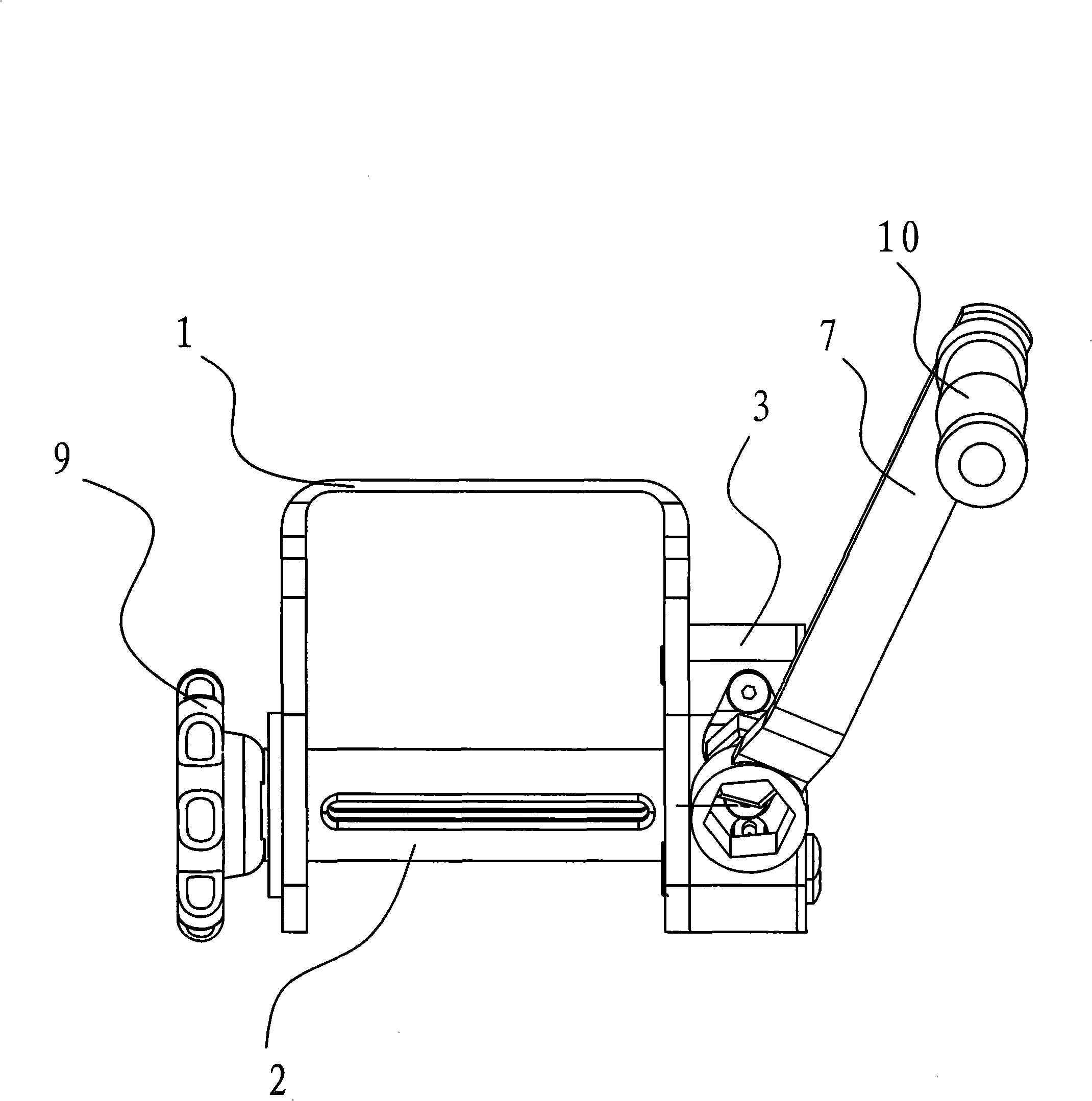

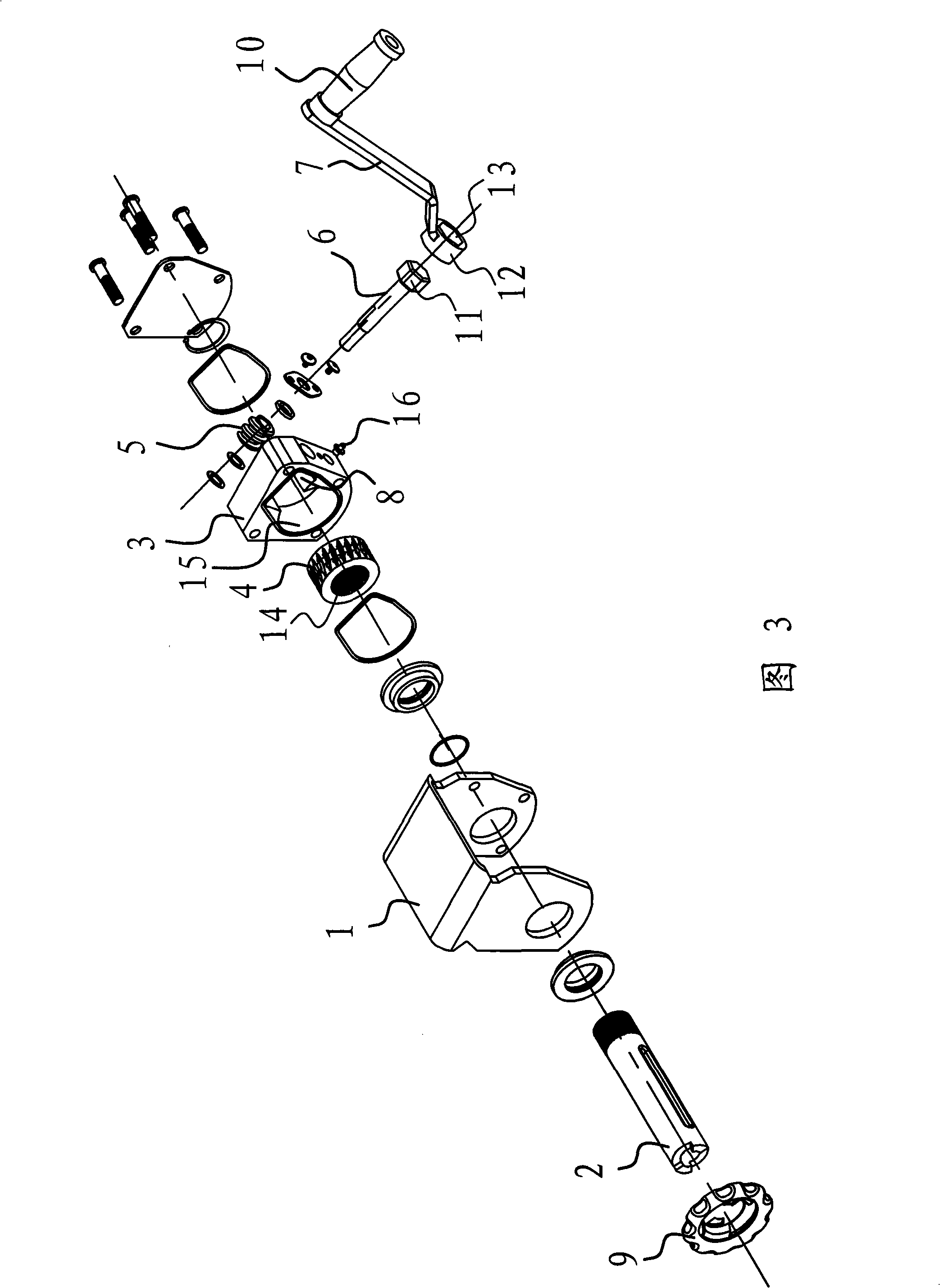

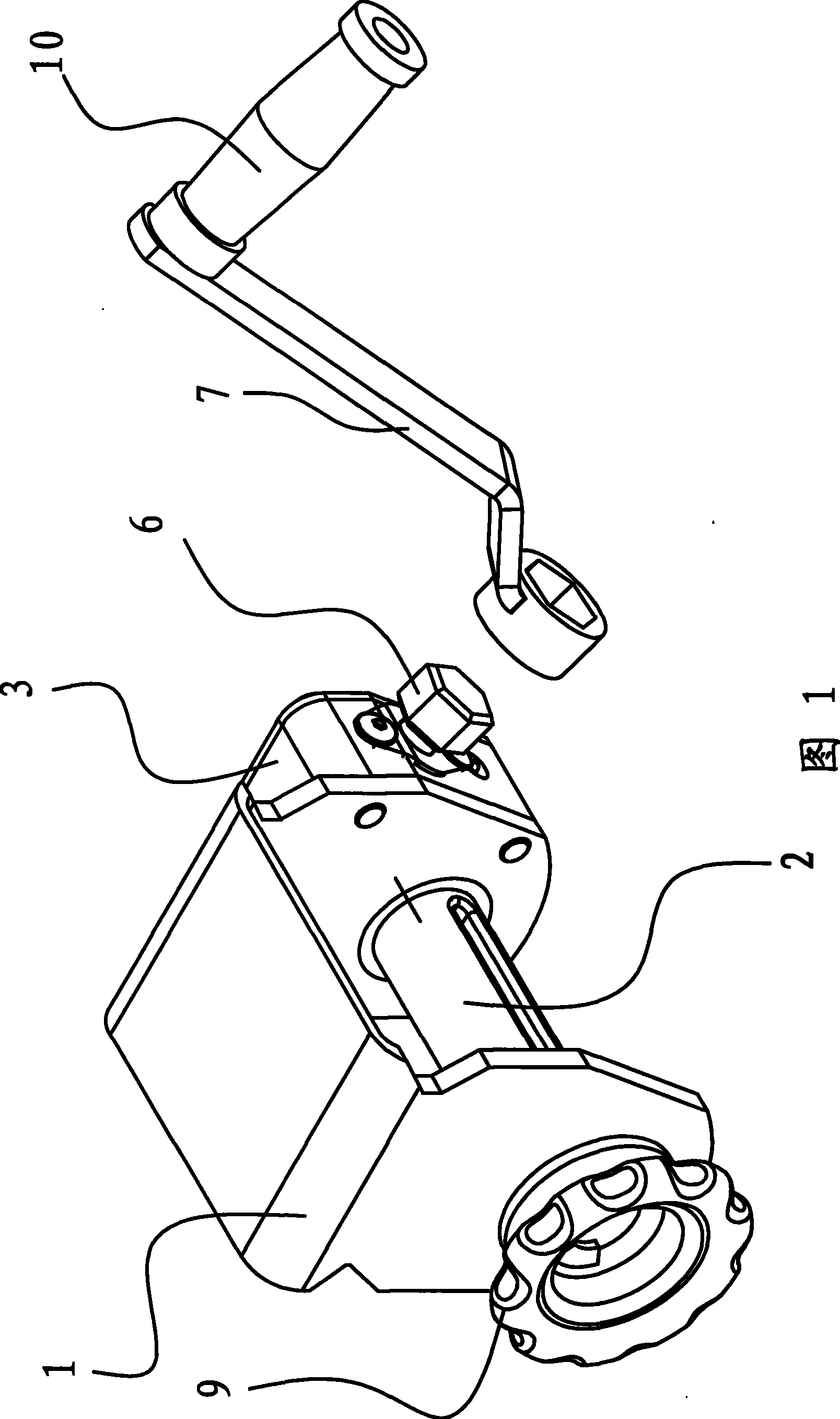

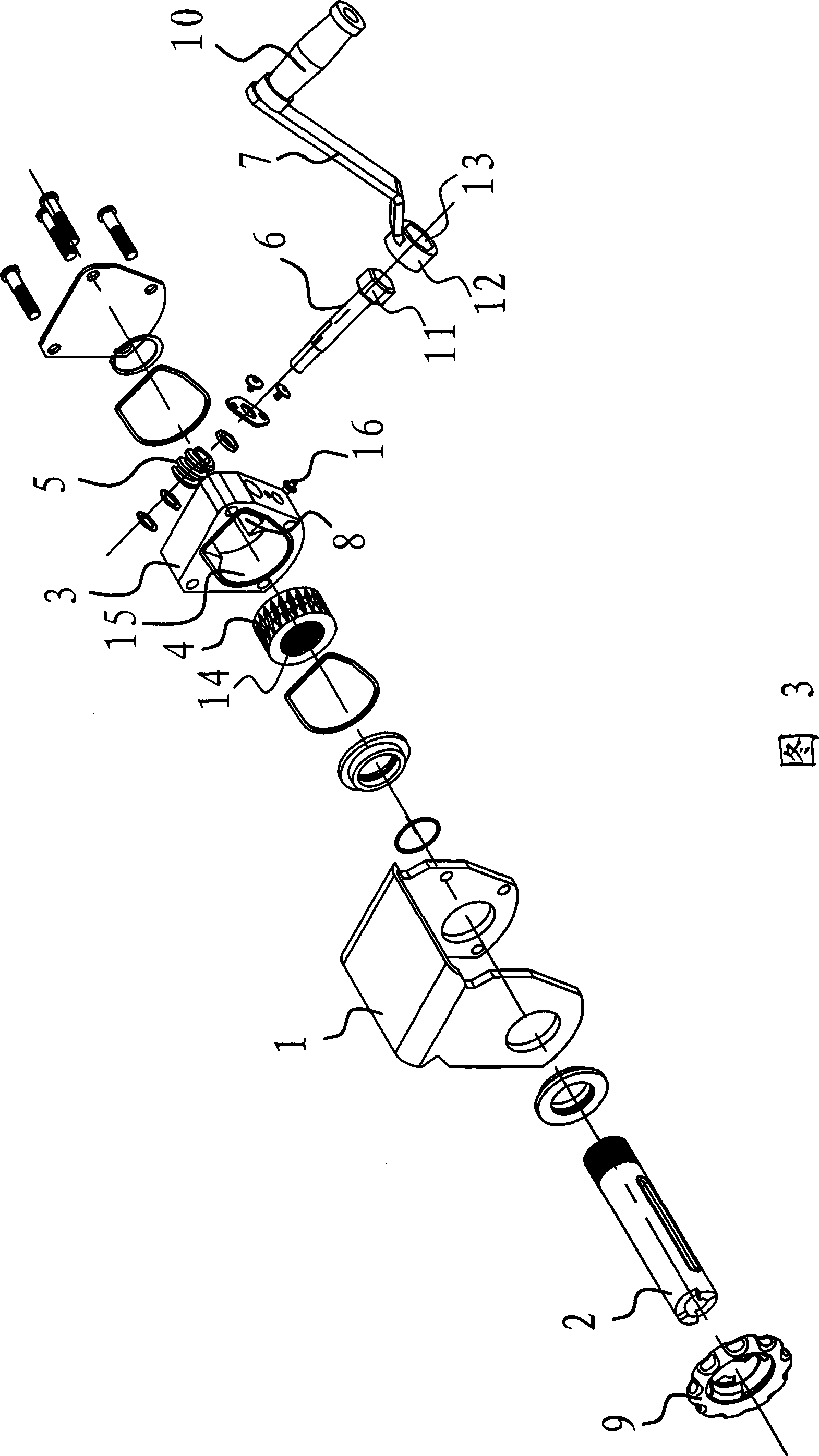

Tape spool control device of hauling winch

ActiveCN101348175AOperation controlConvenient one-way continuous rotationLoad securingBundling machine detailsEngineeringWinch

The invention provides a spool control device for a winch, belonging to the transport machinery product field. The device solves the problems of complicated structure, poor safety and stability during operation, inconvenient operation, and the like, in the existing twirling hand winch device. The spool control device for the winch is arranged on a winch support and is connected with a spool, and comprises a case body fixed on the side part of the winch support, wherein, a worm wheel and a worm which are engaged with each other are arranged in the case body; the worm wheel is connected with one end of the spool and can rotate along with the spool, while the other end of the spool extends outside the winch support; the worm is connected with a drive mechanism which can drive the worm to rotate; and when the drive mechanism does not work, the worm wheel is separated from the worm by rotating the worm wheel to drive the worm to axially move. The spool control device for the winch has the advantages of convenient operation, high work stability, higher use security, simple and compact structure, small space usage, etc.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

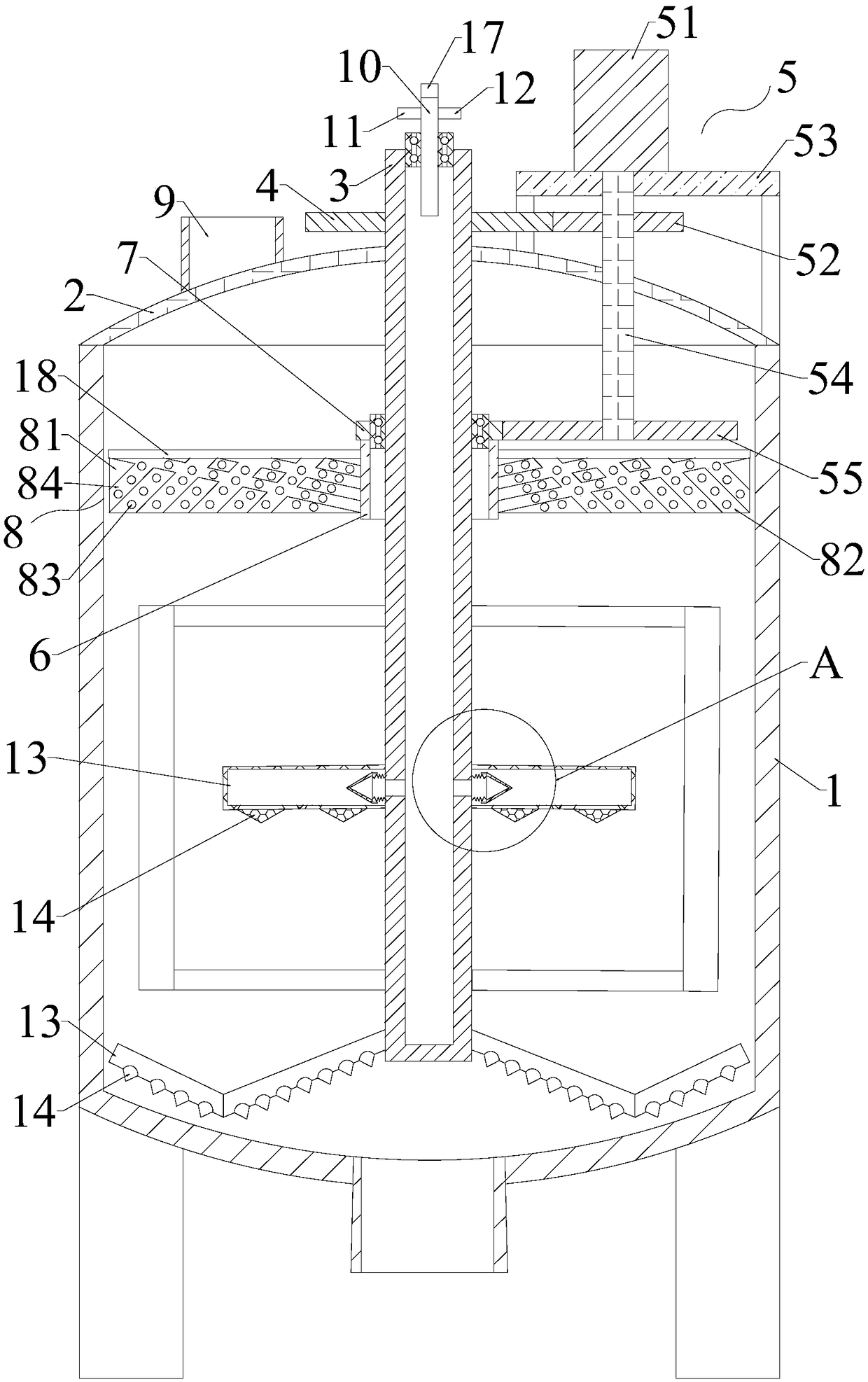

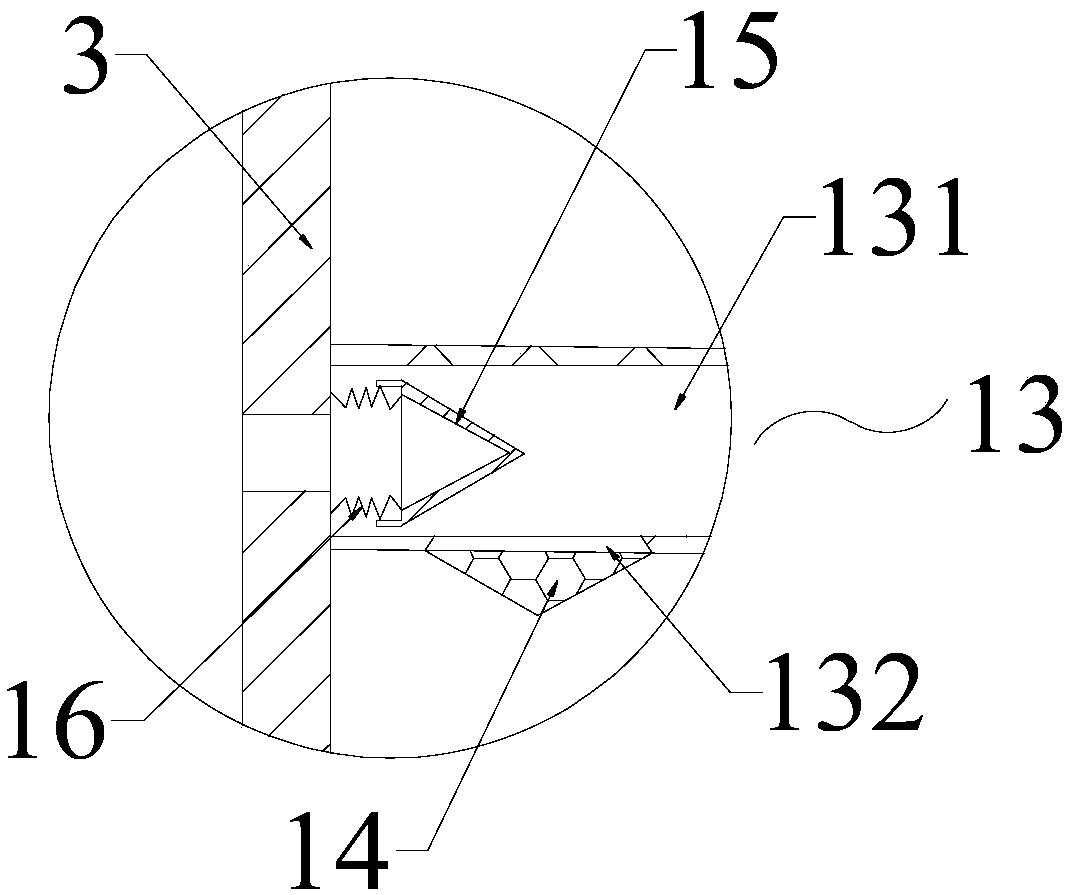

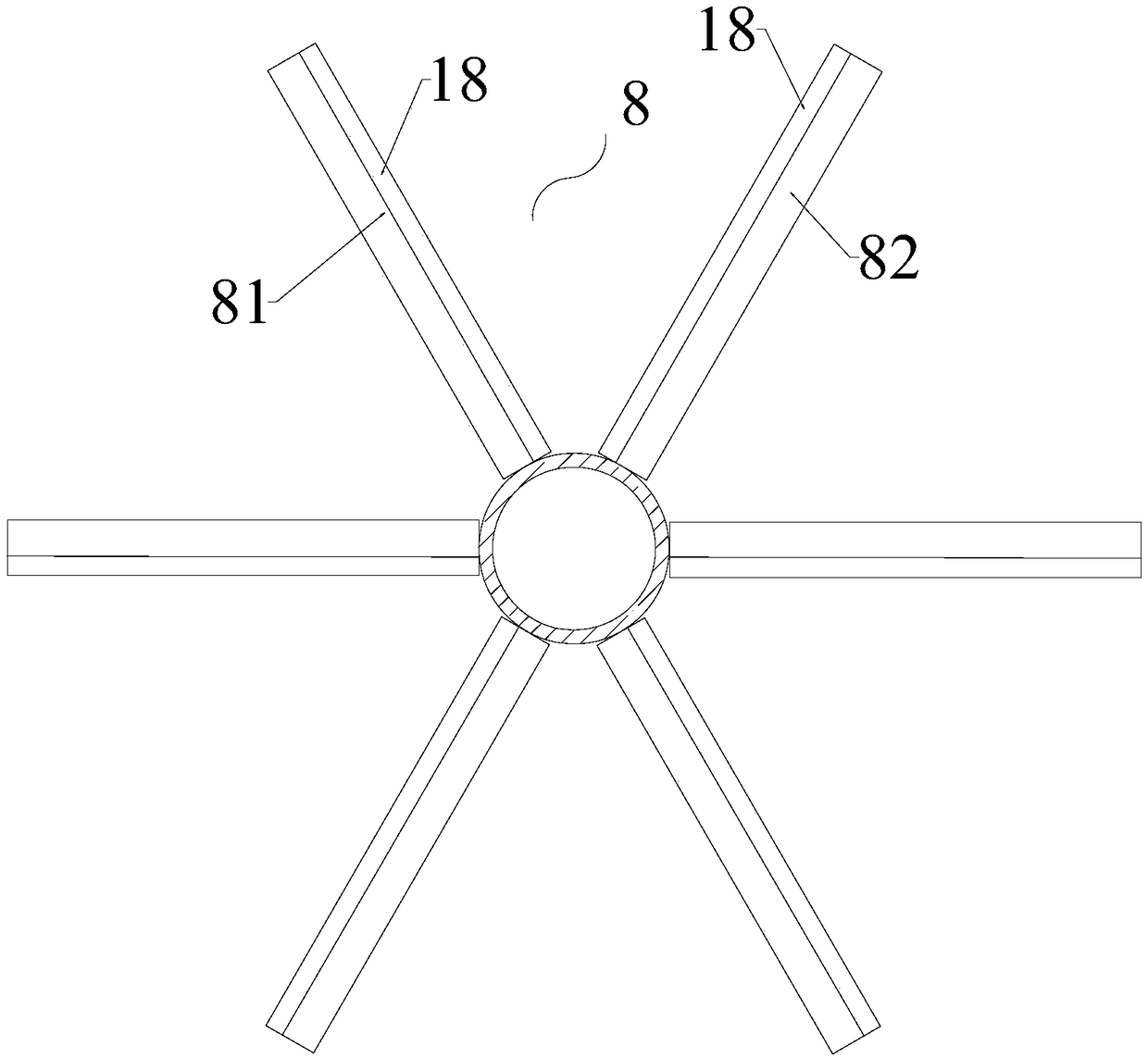

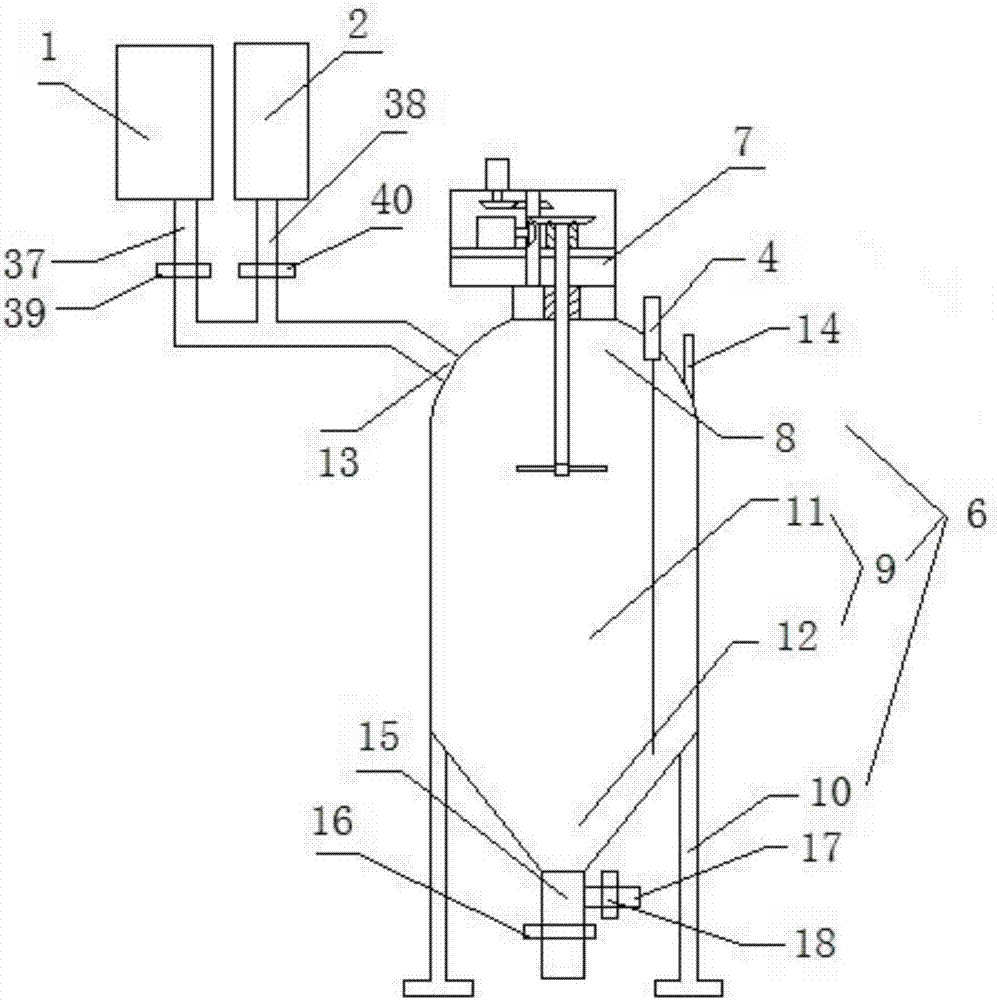

Vertical reaction kettle

ActiveCN109225070AImprove work efficiencySmooth rotationProcess control/regulationChemical/physical/physico-chemical stationary reactorsDrive shaftControl engineering

The invention provides a vertical reaction kettle, and belongs to the technical field of chemical equipment. The vertical reaction kettle comprises a kettle body, a kettle cover and a stirring shaft,wherein a first gear is sheathed on the stirring shaft; a power device is arranged on the kettle cover; the power device comprises a motor fixedly connected with the kettle cover through a fixing element and a second gear sheathed on an output shaft of the motor; the second gear is engaged with the first gear; the second gear is connected with a third gear arranged in a reaction kettle through a transmission shaft; a rotating sleeve is sheathed on the stirring shaft, and is in rotation connection with the stirring shaft through a first bearing; a fourth gear engaged with the third gear is sheathed on the upper part of the rotating sleeve; a uniform material distribution plate extending to the side wall of the kettle body is arranged at the middle lower part of the rotating sleeve. The vertical reaction kettle provided by the invention aims at solving the technical problems that in the prior art, after solid materials are added into the reaction kettle, the solid materials fall along the same direction; the fast fusion of materials and solution is not facilitated; the uniform material distribution effect of the existing material guide device is poor; the production cost is high.

Owner:湖北凌晟药业股份有限公司

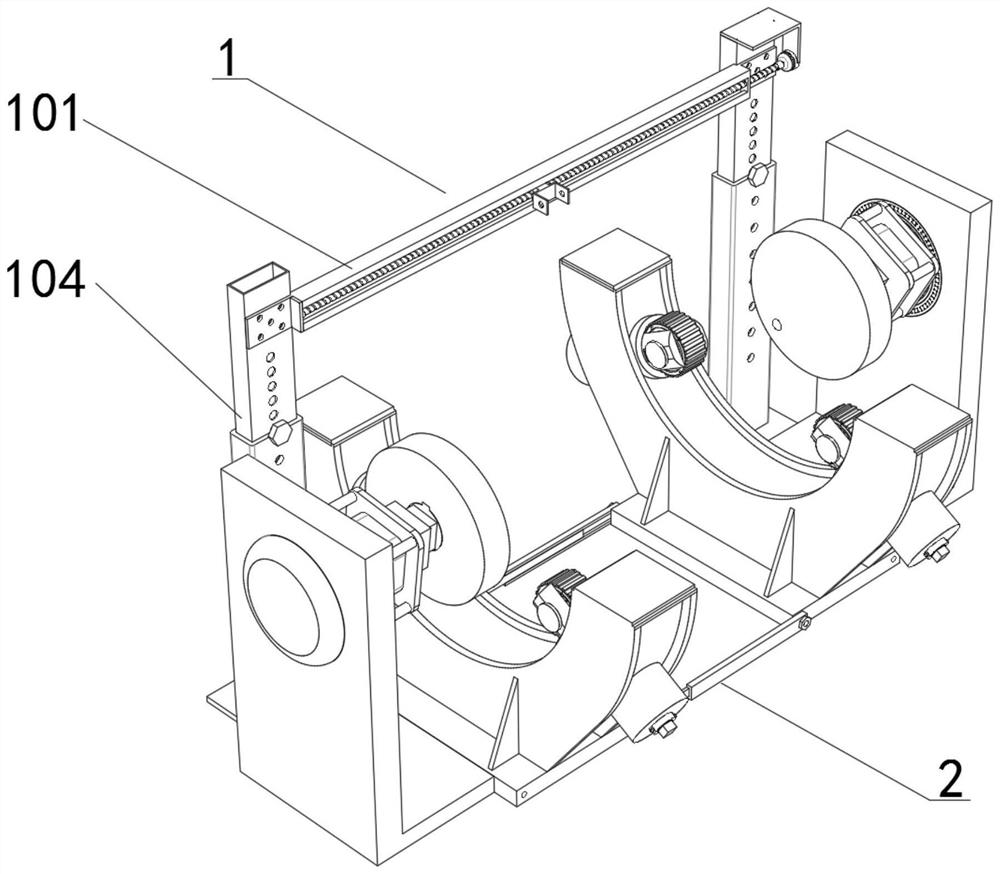

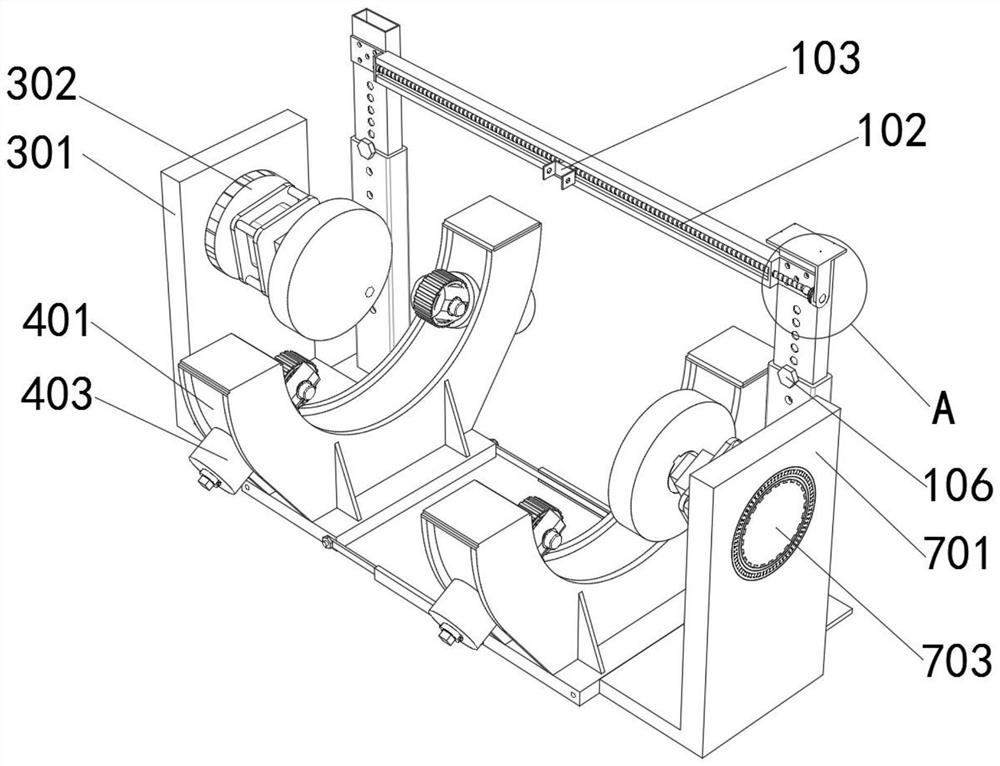

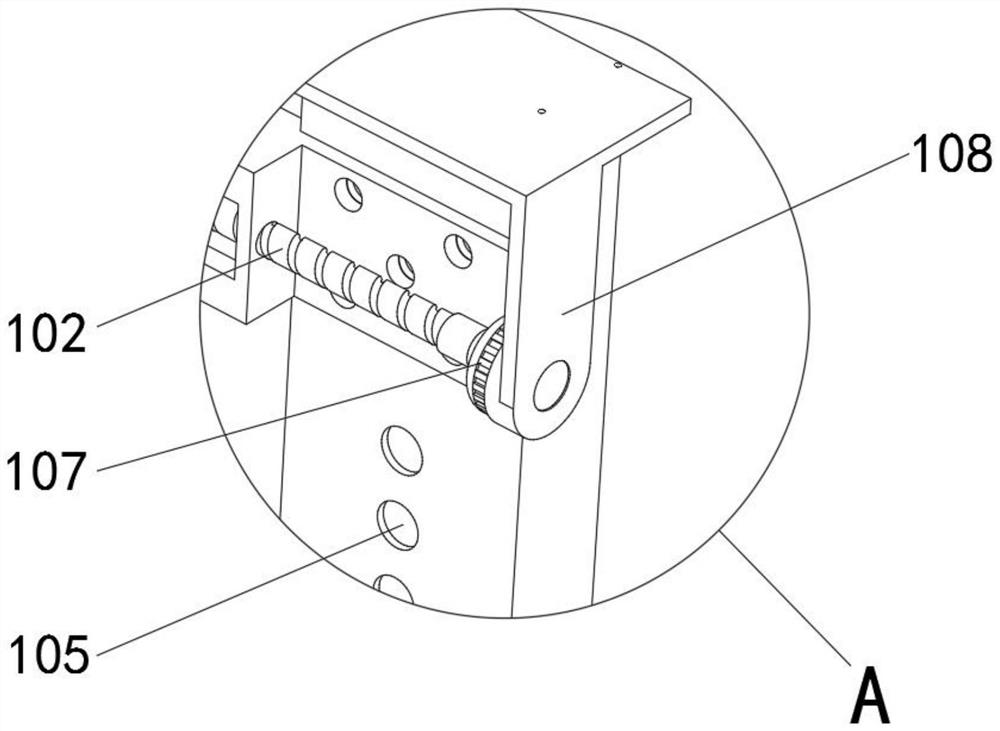

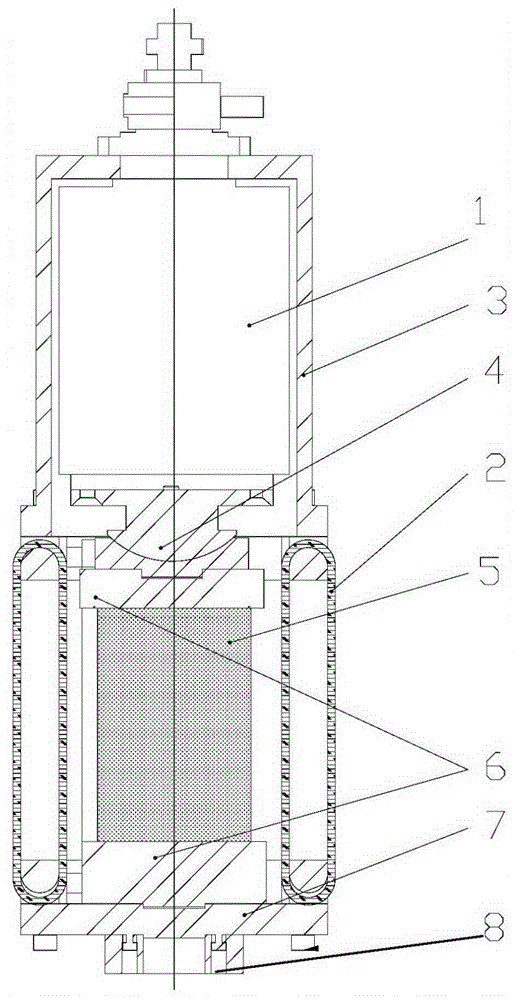

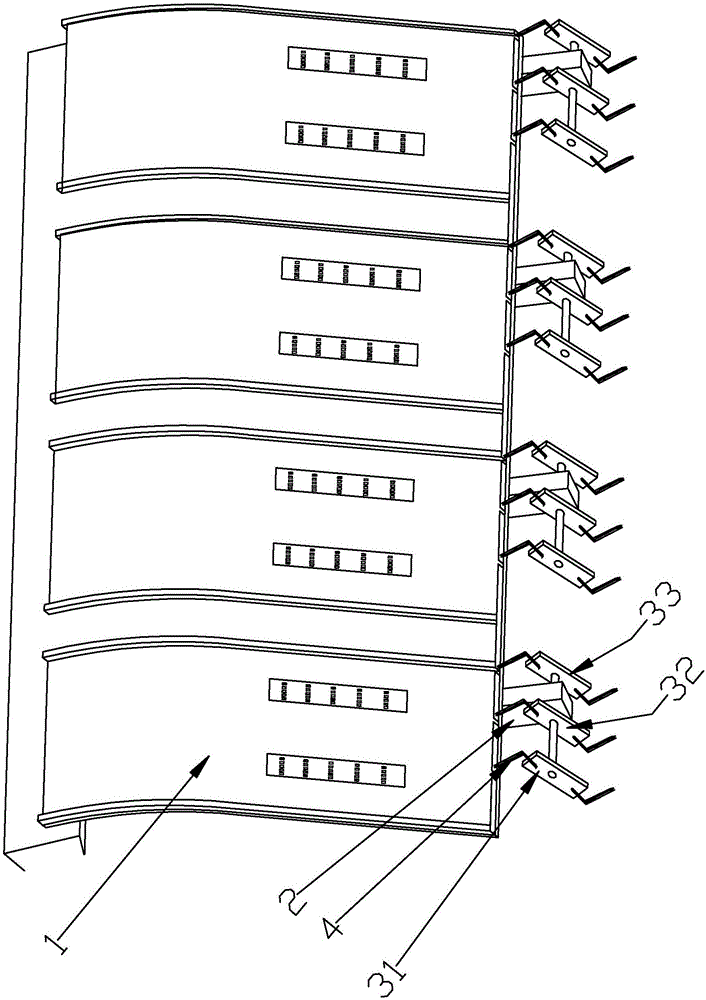

Surfacing control equipment for roller press surface repair

PendingCN112077473AAccurate surfacingReduce the hassle of manual screeningWelding/cutting auxillary devicesAuxillary welding devicesElectric machineControl engineering

The invention relates to the technical field of roller press surfacing repair, and discloses surfacing control equipment for roller press surface repair. The surfacing control equipment comprises a surfacing bracket, a roller press part clamping mechanism is arranged at one side of the surfacing bracket, the clamping mechanism comprises a driving mechanism, the driving mechanism comprises a firstfixing frame, a driving motor is fixedly arranged in the upper end of the first fixing frame, a first servo electric cylinder is fixedly arranged at the output end of the driving motor, a first auxiliary rotating device is arranged at one side of the driving mechanism, a sliding device is arranged at the other side of the first auxiliary rotating device, and the sliding device comprises a slidingrail; and a second auxiliary rotating device is arranged at the other end of the sliding device, the structure of the first auxiliary rotating device is completely consistent with that of the second auxiliary rotating device, and a driven mechanism is arranged at one side of the second auxiliary rotating device. According to the surfacing control equipment, the trouble of manual screening can be reduced, the working efficiency is improved, surfacing errors are reduced, and the surfacing efficiency is improved.

Owner:合肥中都机械有限公司

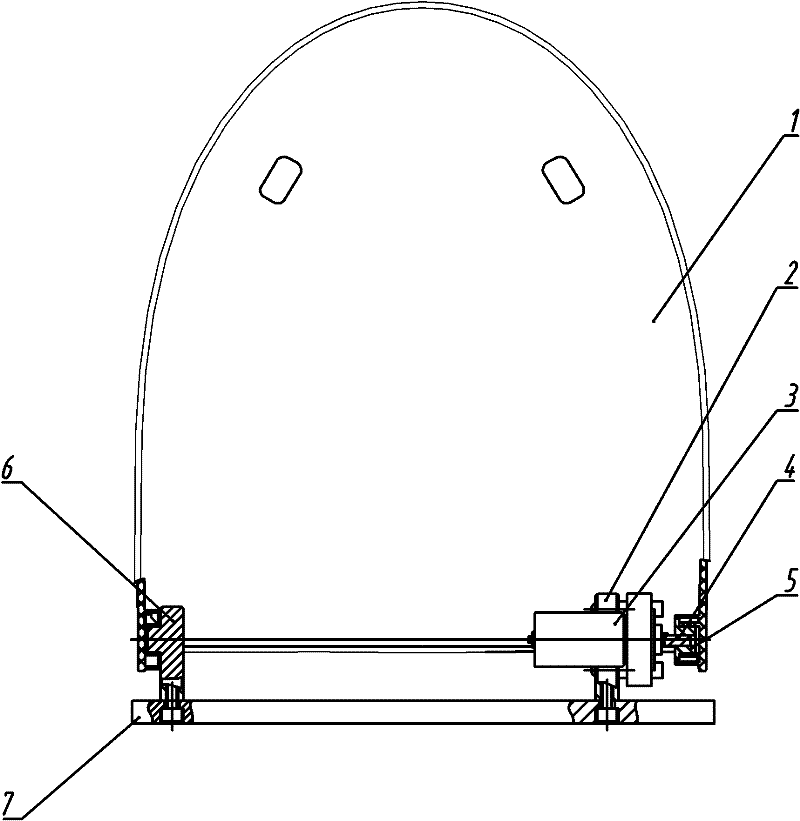

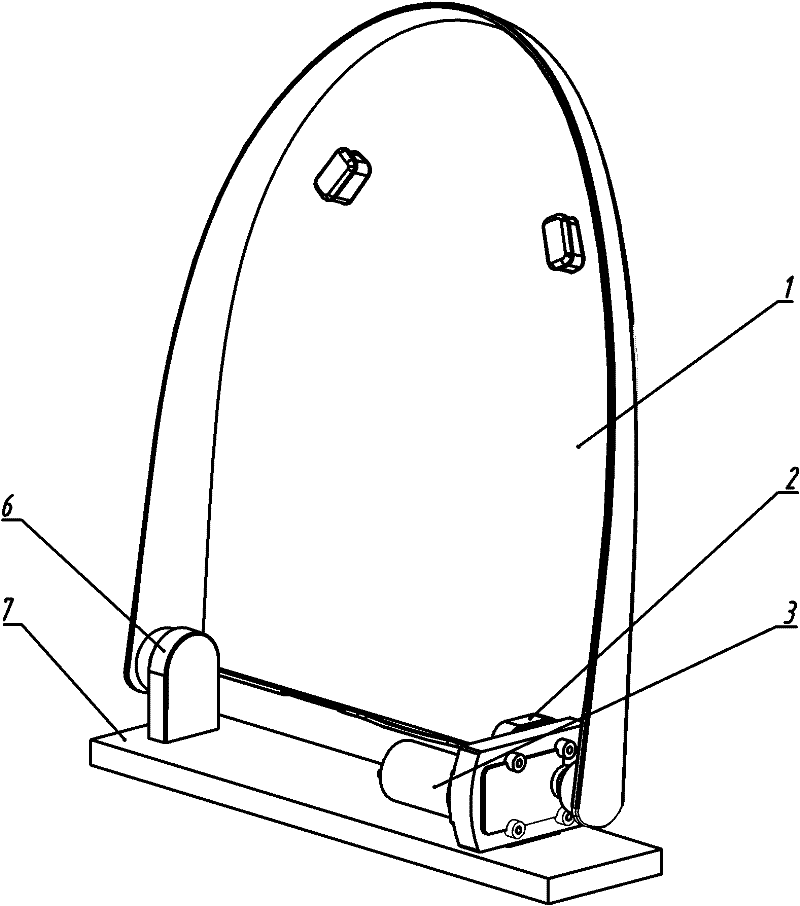

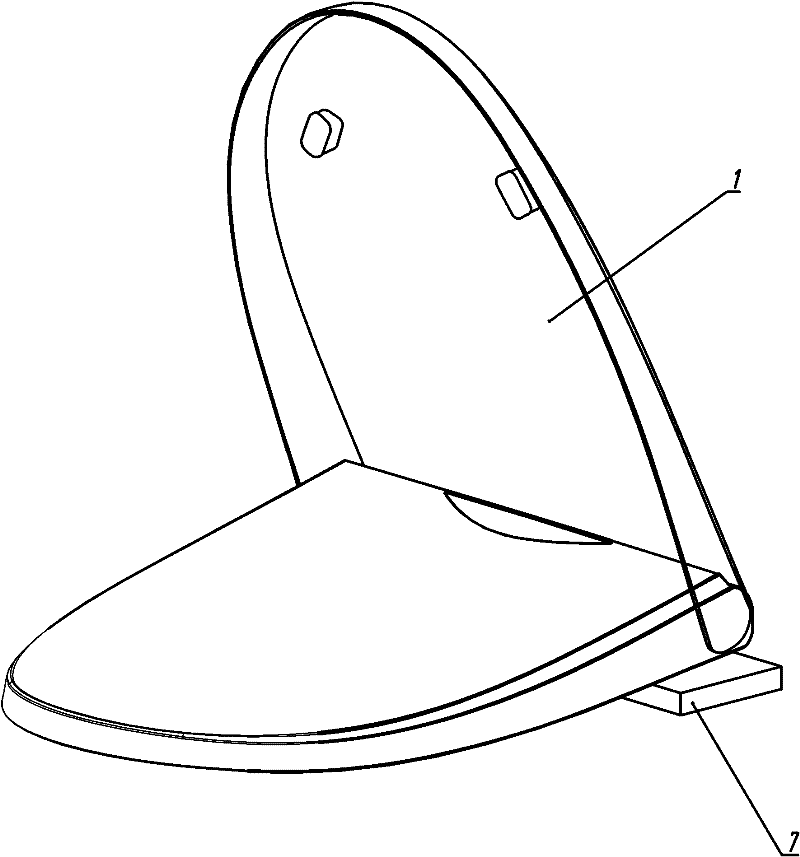

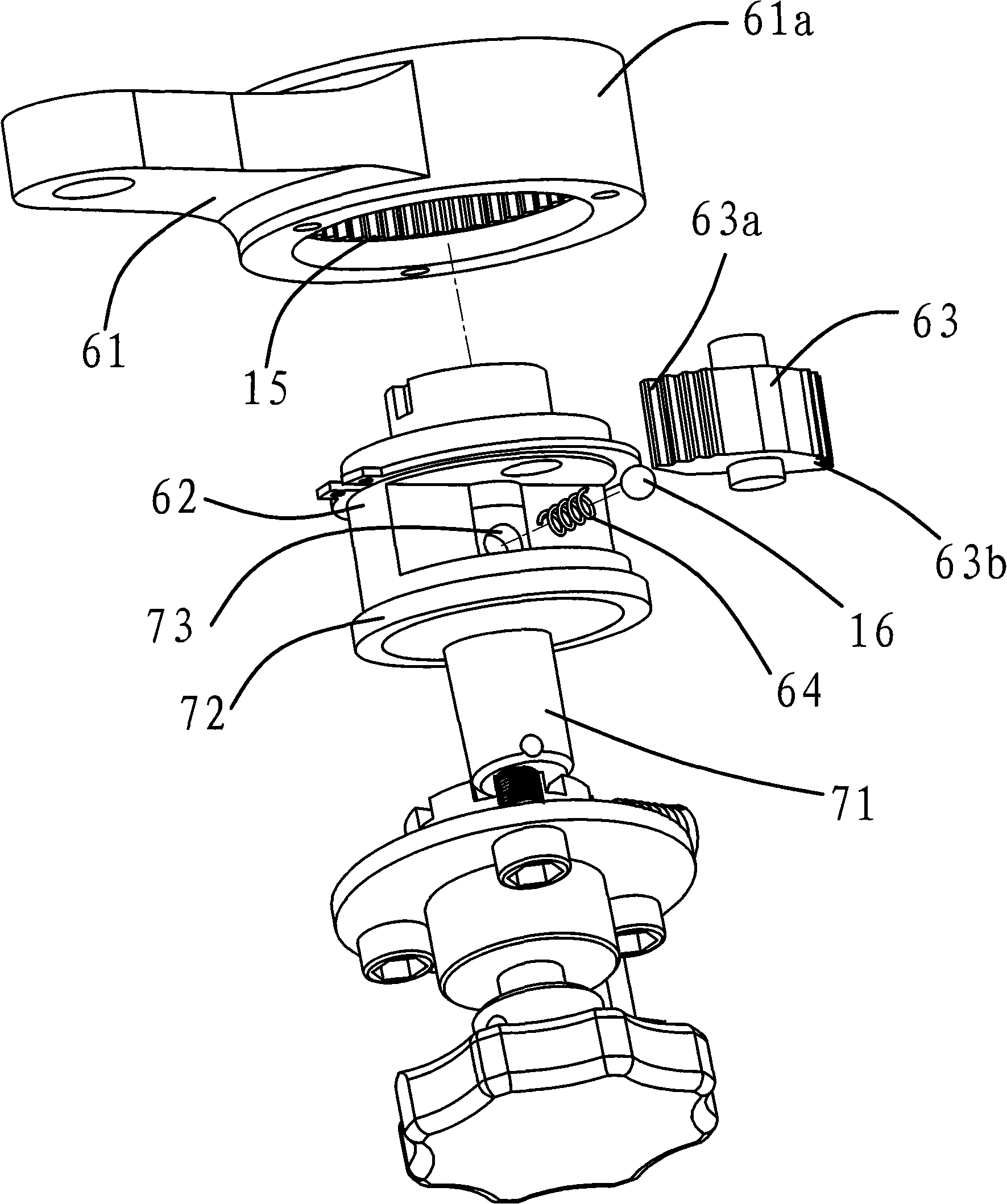

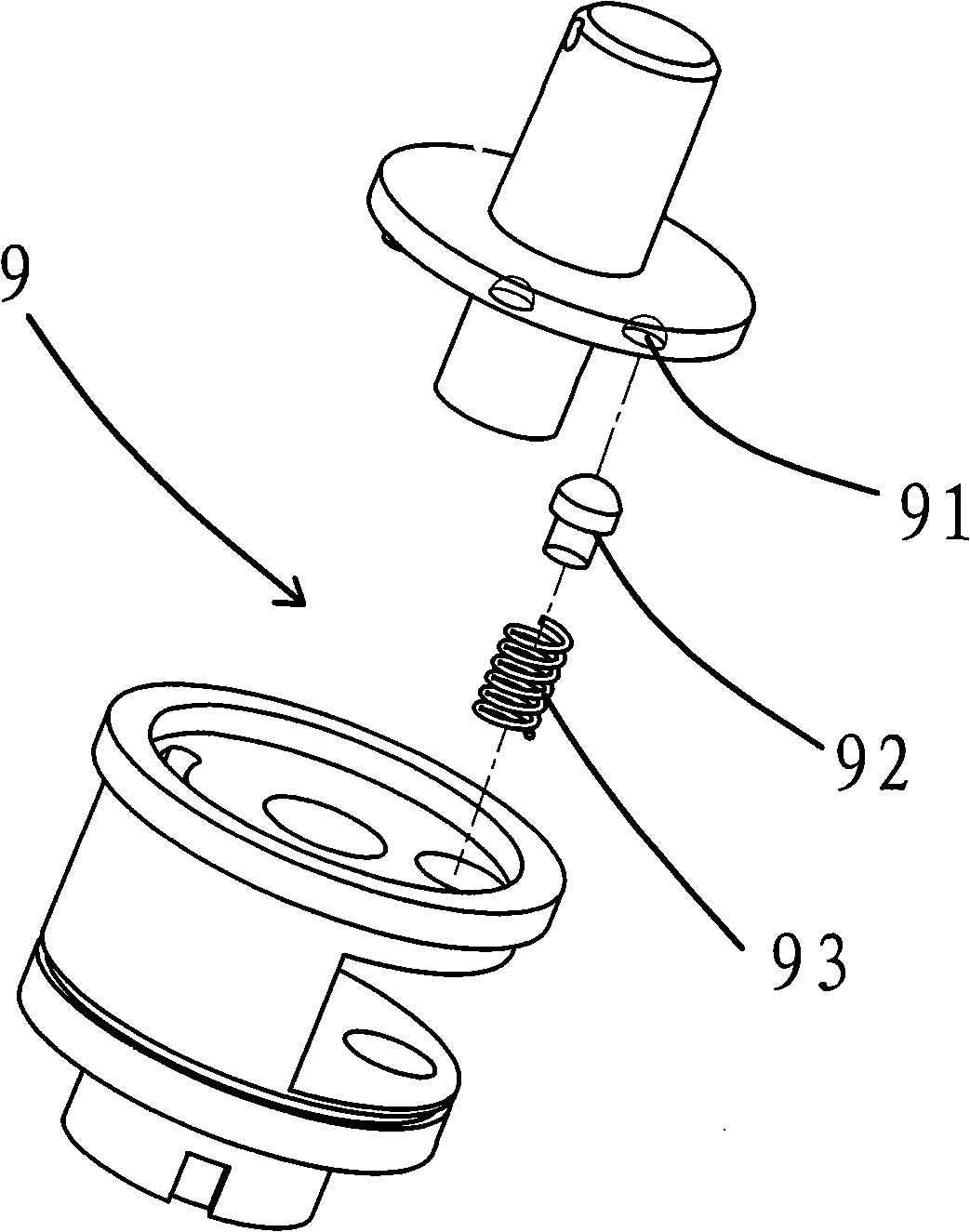

Automatic cover-overturning mechanism and control method thereof

ActiveCN102379654ASave the mechanical slow down structureSimple assembly structureBathroom coversEngineeringPower transmission

The invention discloses an automatic cover-overturning mechanism which comprises a DC machine, a cover body drive mechanism, and a speed regulating system for the DC machine, wherein the speed regulating system for the DC machine comprises a motor controller and a motor driver; the cover body drive mechanism comprises a rotation hinge arranged at the first side of the cover body, and a power transmission mechanism arranged at the second side of the cove body, opposite to the first side of the cover body; the power transmission mechanism comprises a member linked with the output shaft of the DC machine and fixedly connected with the cover body; and the rotation hinge and the member are both positioned on a rotation shaft on a same axial line. A cover body applying the cover-overturning mechanism can be opened or closed stably with uniform speed, thus meeting the use requirements of general customers.

Owner:HANYU GRP CO LTD

Automatic winding and unwinding device for winch

ActiveCN101274606AEasy to useImprove bundling efficiencyGearingLoad securingEngineeringConductor Coil

The invention provides a self-rendering device of a winch, which pertains to the technical field of machinery. The self-rendering device of the winch solves the problems of the inconvenient use of the rendering device and the low binding efficiency, etc. of the present winches. The self-rendering device of the winch is arranged at the bracket position of the winch and is interconnected with the rotating shaft of the winch; the device comprises a ratchet wheel, a pawl and a cylinder; the ratchet wheel is interconnected with the rotating shaft of the winch; the pawl is arranged on the bracket and imbedded on the ratchet wheel; a transmission mechanism which can drive the ratchet wheel to rotate uniaxially is arranged between the piston rod of the cylinder and the ratchet wheel. The self-rendering device of the winch has the advantages of convenient operation and comparatively high binding efficiency, etc.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

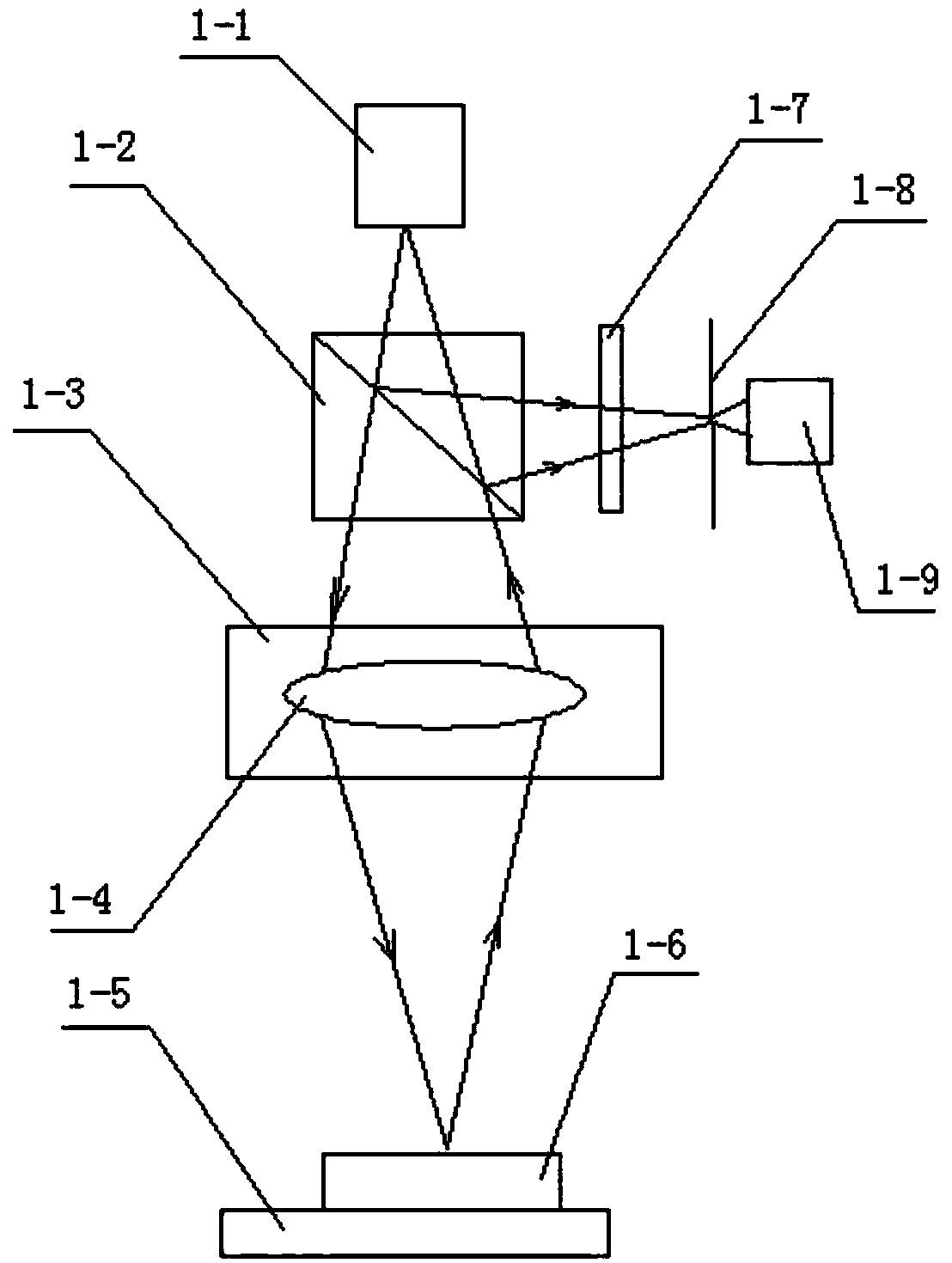

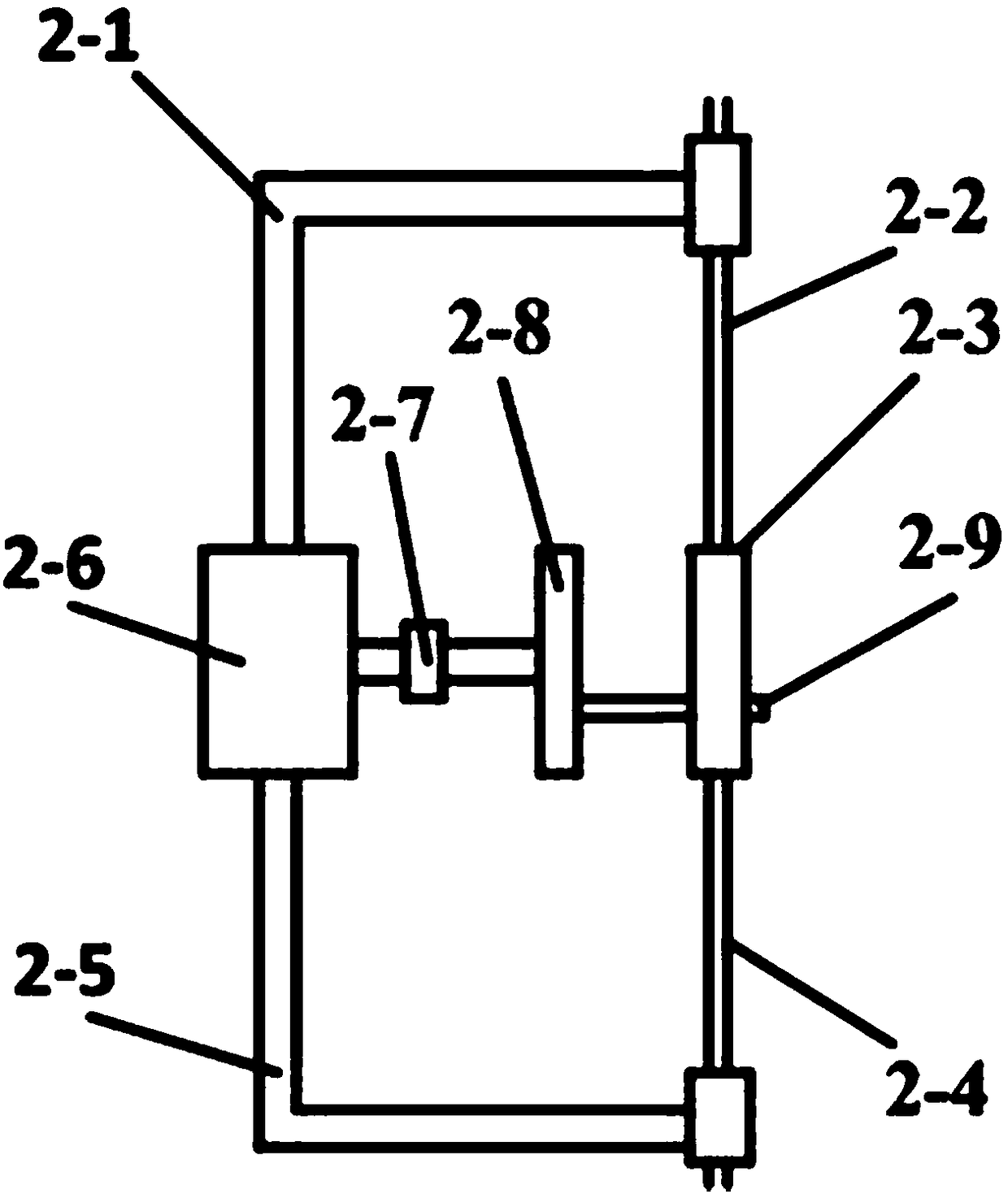

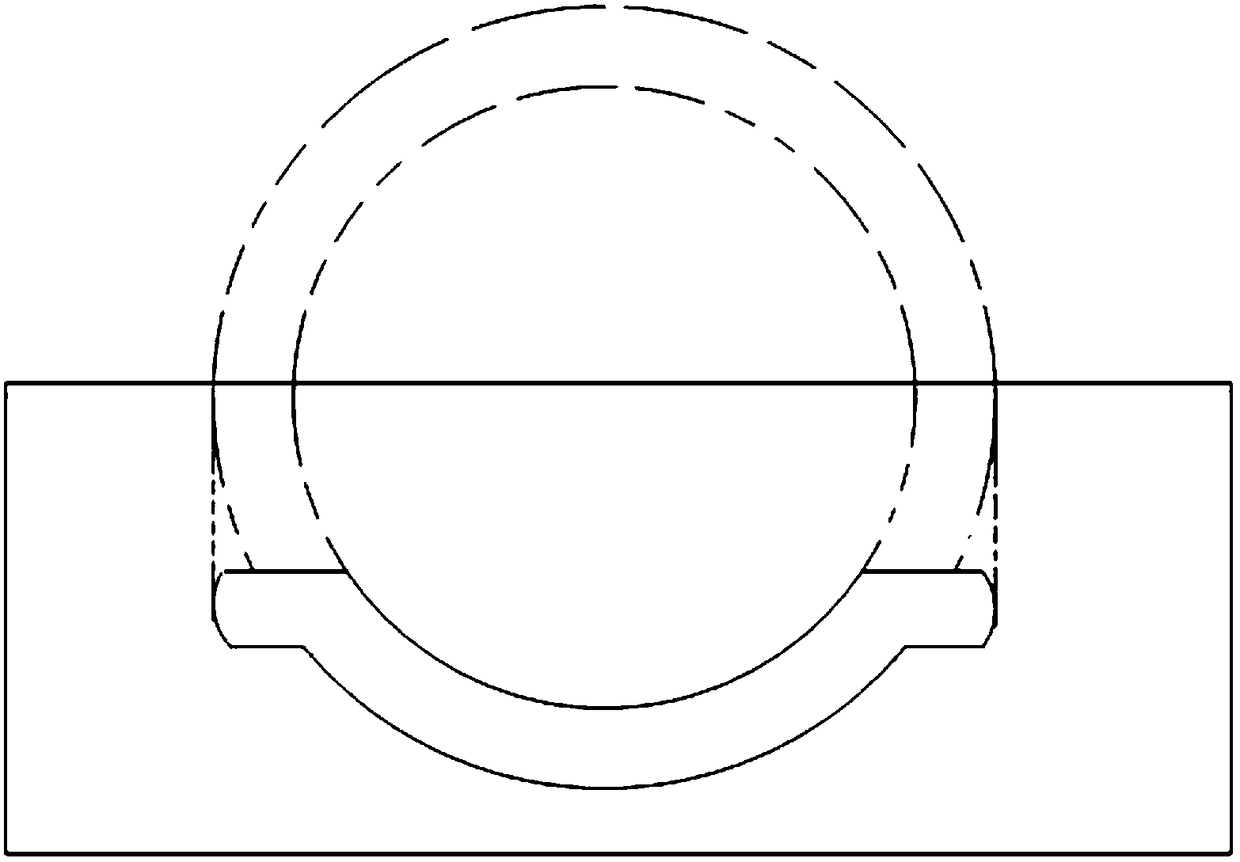

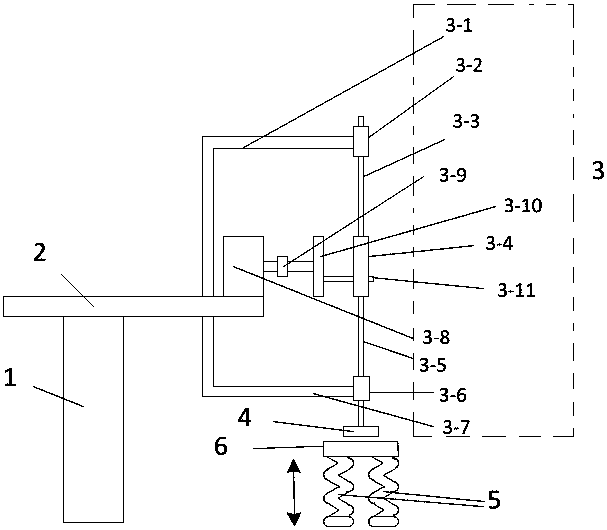

Device for rapidly measuring surface flatness of object

InactiveCN108387188AEasy to operateThe test result is accurateUsing optical meansMeasurement deviceLighting system

A device for rapidly measuring the surface flatness of an object of the invention belongs to the technical field of optical inspection and testing of industrial production machinery. The device is composed of an illumination imaging module and a motion mechanism; the illumination imaging module is composed of an illumination system and an imaging system; in the illumination system, a laser, a beamsplitter, an objective lens and a measured object are sequentially arranged along the light propagation direction; in the imaging system, an object to be tested, an objective lens, a beam splitter, an attenuator, a pinhole and an image sensor are sequentially arranged along the light propagation direction; the moving mechanism consists of an upper fixed end, an upper rod, a moving block, a lowerrod, a lower fixed end, a motor, a coupling, a T type turntable and a limit protrusion; when the motion block is in motion, a beam emitted by the laser is defocused to the surface of the object to betested, and a beam reflected by the object to be tested is defocused onto the pinhole. The device not only can qualitatively detect the surface flatness of the object, but also is simple in operationprocess and easy in operation method, and can filter or monitor the noise, and the detection result is accurate.

Owner:仲东明

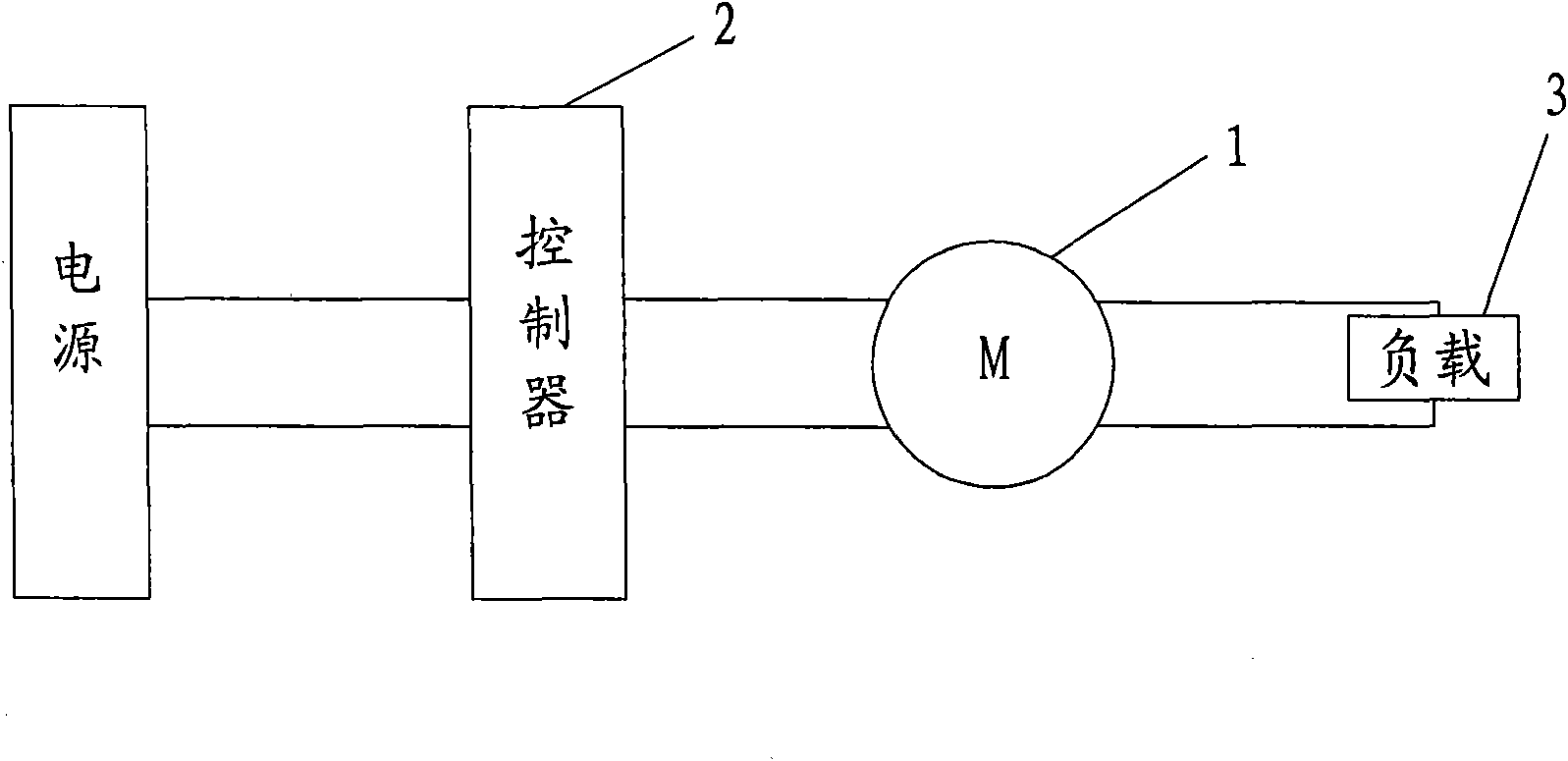

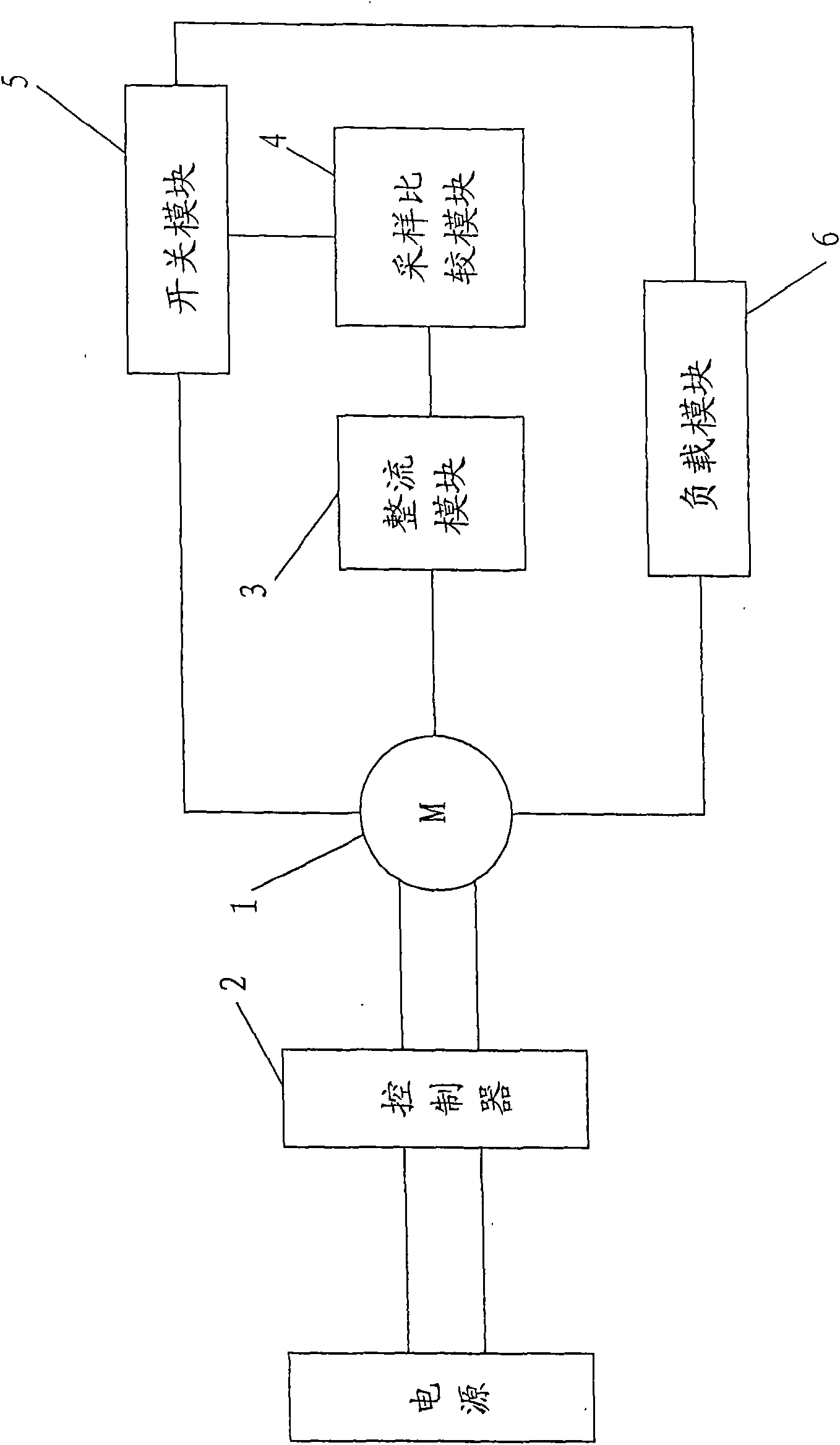

Device and method for controlling DC motor to lower roller shutter door at constant speed

InactiveCN101614106AReduce the impactShorten the timeDC motor speed/torque controlDoor/window protective devicesControl signalComputer module

The invention discloses a control device of a DC motor for lowering a roller shutter door at constant speed, which comprises a rectifying module, a sampling comparison module, a switch module and a load module, wherein the switch module is serially connected with the load module and then parallelly connected to both ends of the DC motor; the input end of the rectifying module is parallel connected to both ends of the DC motor to rectify voltage signals at both end of the DC motor; and the sampling comparison module is connected with the output end of the rectifying module and he switch module and samples the rectified voltage signals, and the sampling comparison module sends out a control signal to the switch control according to a comparison result after a sampling value is compared with a setting value. The control device can block voltage at both ends of the DC motor within a certain range so as to lower the roller shutter door at constant speed, prolong the service life, and eliminate potential safety hazard. The invention also discloses a method for controlling the DC motor to lower the roller shutter door by using the device.

Owner:FUJIAN ANLIN INTELLIGENT SCI & TECH

Tape spool control device of hauling winch

ActiveCN101348175BOperation controlConvenient one-way continuous rotationLoad securingBundling machine detailsEngineeringWinch

The invention provides a spool control device for a winch, belonging to the transport machinery product field. The device solves the problems of complicated structure, poor safety and stability during operation, inconvenient operation, and the like, in the existing twirling hand winch device. The spool control device for the winch is arranged on a winch support and is connected with a spool, and comprises a case body fixed on the side part of the winch support, wherein, a worm wheel and a worm which are engaged with each other are arranged in the case body; the worm wheel is connected with one end of the spool and can rotate along with the spool, while the other end of the spool extends outside the winch support; the worm is connected with a drive mechanism which can drive the worm to rotate; and when the drive mechanism does not work, the worm wheel is separated from the worm by rotating the worm wheel to drive the worm to axially move. The spool control device for the winch has the advantages of convenient operation, high work stability, higher use security, simple and compact structure, small space usage, etc.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Rock wear-resisting tester

ActiveCN104048889AStrong representativeEasy to analyzeInvestigating abrasion/wear resistanceNeedle penetrationFixed frame

The invention discloses a rock wear-resisting tester which comprises a rock grinding amount testing part and a rock needle penetration testing part, wherein the rock grinding amount testing part comprises a grinding disc, a first weight, a first three-jaw chuck, a rolling ball, a reading meter, an inductance waterproof flexible displacement meter, a first motor, a main bracket and a chassis; the rock needle penetration testing part comprises a secondary bracket, a fixed frame, a second three-jaw chuck, a needle valve, a transmission block, a second weight, a second motor, a transmission shaft, a telescopic probe and a wiping plate. The rock wear-resisting tester has the beneficial effects of testing the grinding amount of a rock end plane in real time while realizing that the needle penetration on a rock line is tested, so as to more completely analyze the relation between the hardness and the wear-resisting performance of rock. A range represented by the abrasion amount of the rock end face is more than the linear range of the needle penetration, thus the representation to the rock is stronger.

Owner:泰州市海通资产管理有限公司

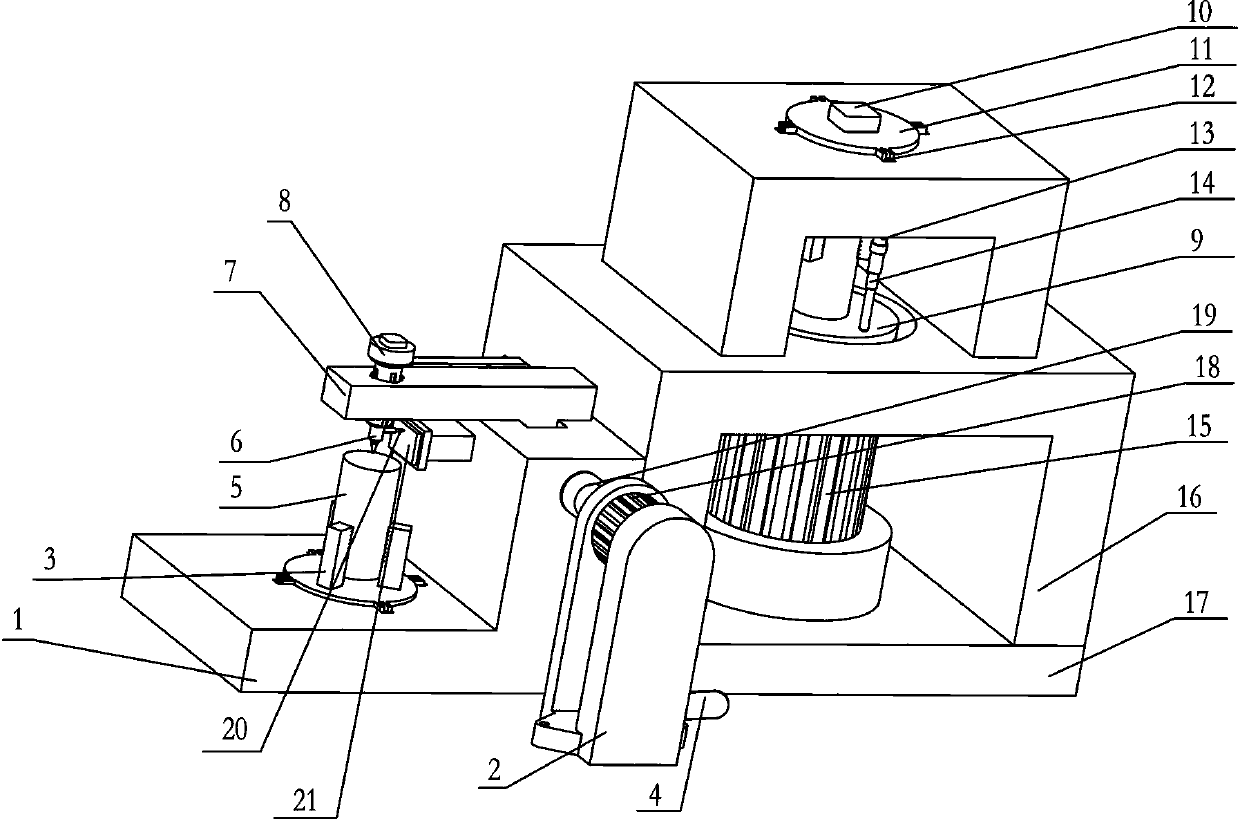

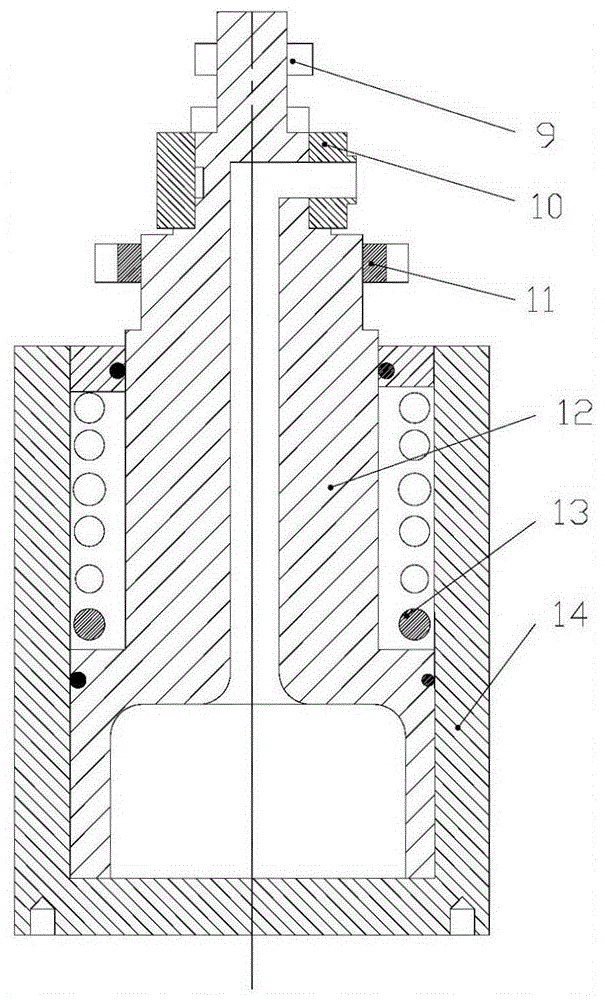

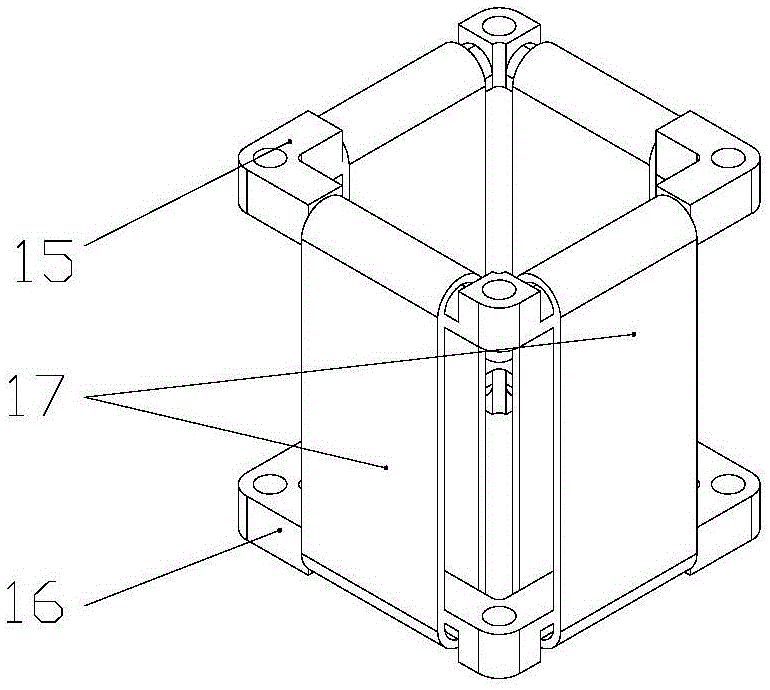

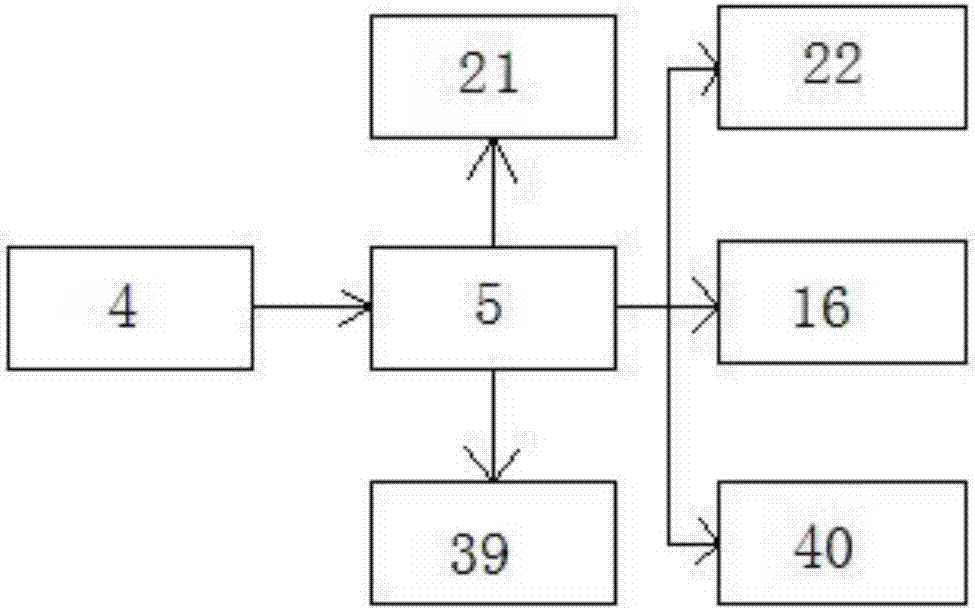

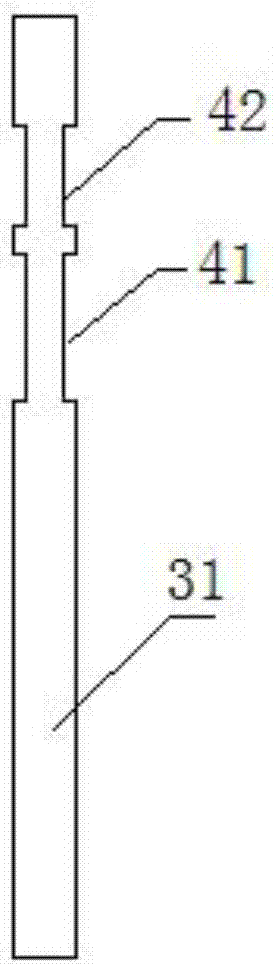

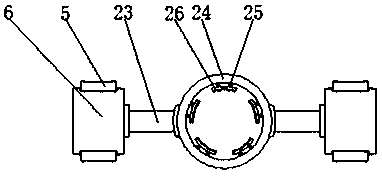

Industrial CT scanner synchronous loading test apparatus and industrial CT scanner

ActiveCN105115995AAchieve synchronous rotationLoad stability compensationMaterial analysis by transmitting radiationFiberCarbon fibers

The invention relates to an industrial CT scanner synchronous loading test apparatus and an industrial CT scanner, and belongs to the field of test detection equipment. The apparatus comprises a single-acting rotating loading oil cylinder, a see-through carbon fiber counterforce frame, a micro-torque rotating mechanism, an oil pressure loading system and a pressure display system; the single-acting rotating loading oil cylinder comprises an oil cylinder body and a rotary oil receiving hole which can conduct relative rotation with the oil cylinder body, the see-through carbon fiber counterforce frame comprises an upper connecting box and a lower connecting plate, as well as a carbon fiber support wound between the upper connecting box and the lower connecting plate, and a test piece is positioned between the upper connecting box and the lower connecting plate. A self-counterforce mechanism is formed by the single-acting rotating loading oil cylinder and the see-through carbon fiber counterforce frame jointly. The see-through carbon fiber counterforce frame almost has no absorption of X-rays, and the X-rays pass through carbon fiber to irradiate the test piece without generating energy loss. The industrial CT scanner synchronous loading test apparatus provided by the invention works together with the industrial CT scanner, and can achieve loading of the test piece, and real-time scanning of change conditions such as the damage to the test piece can be realized.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

Intelligent fermenting tank

PendingCN107227254AWell mixedImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsGear wheelControl engineering

The invention provides an intelligent fermenting tank which comprises a fermenting tank body. A stirring device is arranged on the fermenting tank body; the fermenting tank body comprises a cover body, a kettle body and a supporting column; the stirring device is arranged on the cover body; the stirring device comprises a first fixed shell, a second fixed shell, a first stepping motor, a second stepping motor, a first driving gear, a first driven gear, a second driving gear, a second driven gear, an adjusting fixed plate, a lead screw, a first fixed ring, a second fixed ring, a fixed rotating shaft and a propeller. Intelligent full-automatic operation is achieved, strong swirling flow is generated in reactant through rotation of the propeller in a reaction process, a fermenting reaction process can be fully accelerated, fermentation can be more complete, cost is reduced to a great extent, and the intelligent fermenting tank has convenience in maintenance.

Owner:汇森生物设备镇江有限公司

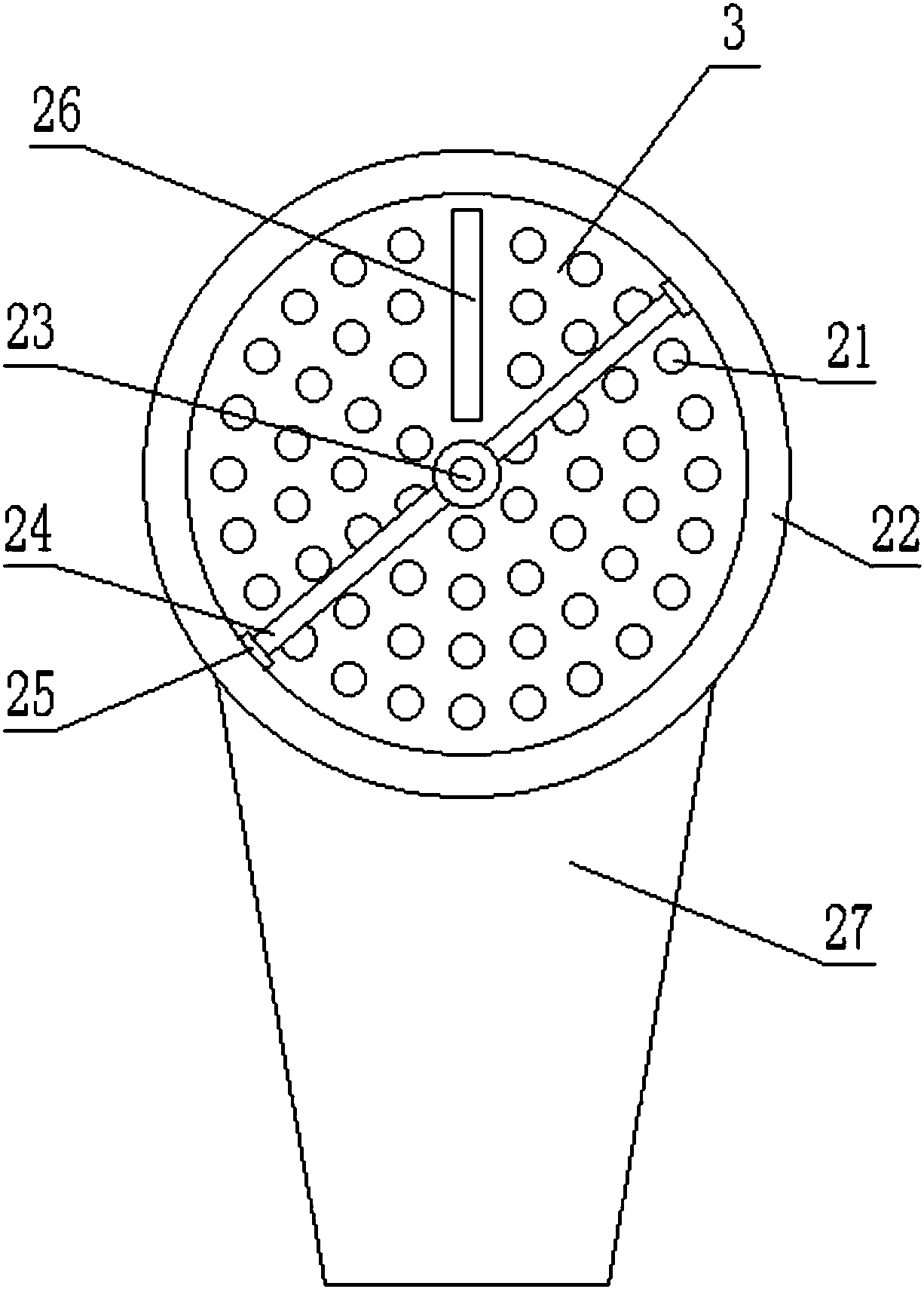

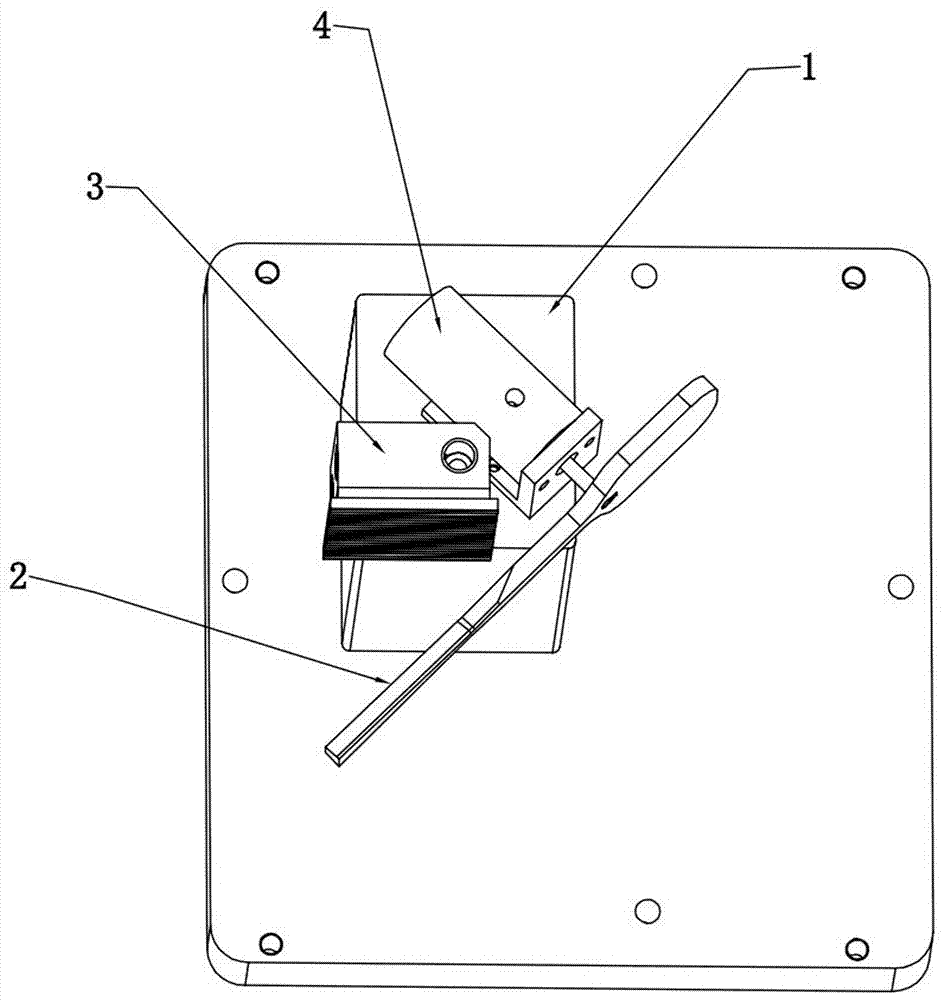

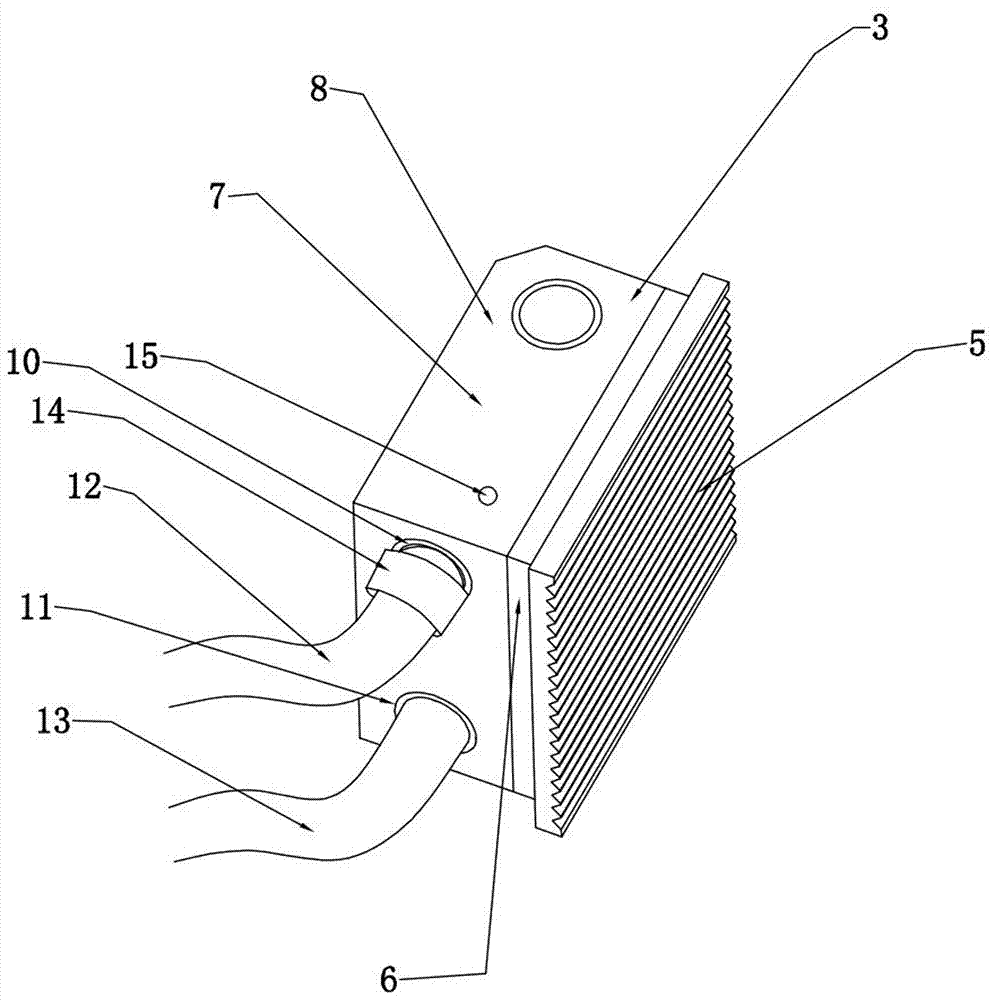

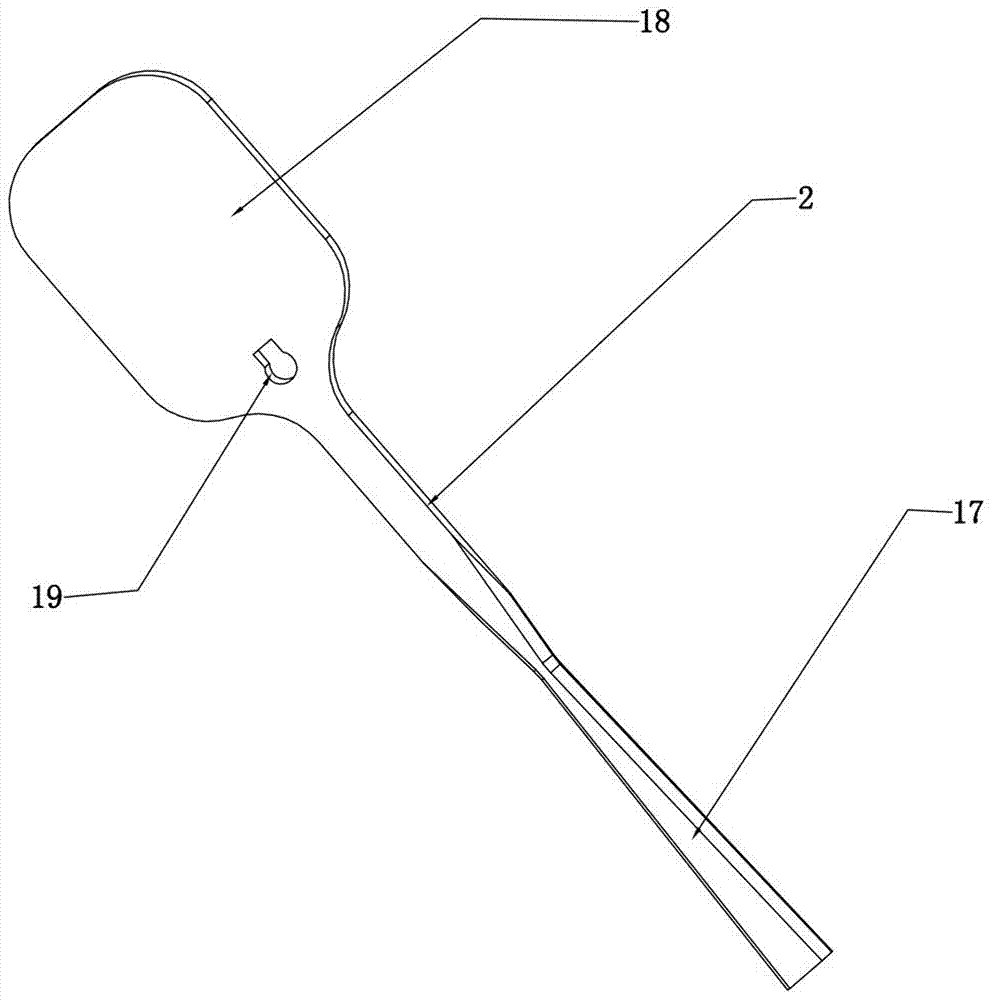

Surface runoff measuring instrument for urban hardened pavement

InactiveCN105043480APractical application valueAvoid momentumVolume measurement and fluid deliveryHydrometryMeasuring instrument

The invention discloses a surface runoff measuring instrument for an urban hardened pavement. The surface runoff measuring instrument is characterized by comprising a surface runoff gathering device (1), a surface runoff measuring device (2), a runoff recording device (3) and a housing (4); the water outlet of the surface runoff gathering device (1) is connected with the water inlet of the surface runoff measuring device (2); the surface runoff measuring device (2) is connected with the runoff recording device (3); the water inlet of the surface runoff gathering device (1) is arranged outside the housing (4); the water outlet of the surface runoff gathering device (1), the surface runoff measuring device (2) and the runoff recording device (3) are all arranged in the housing (4). The surface runoff measuring instrument for the urban hardened pavement can supply accurate and reliable data for researching problems of urban rainwater utilization, rainwater discharging pipe network design, urban hydrologic cycle, etc.

Owner:HOHAI UNIV

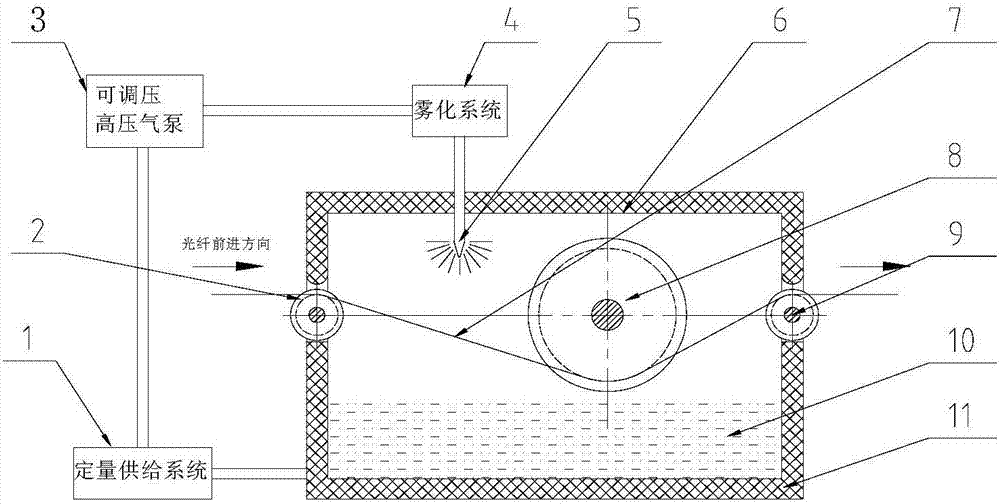

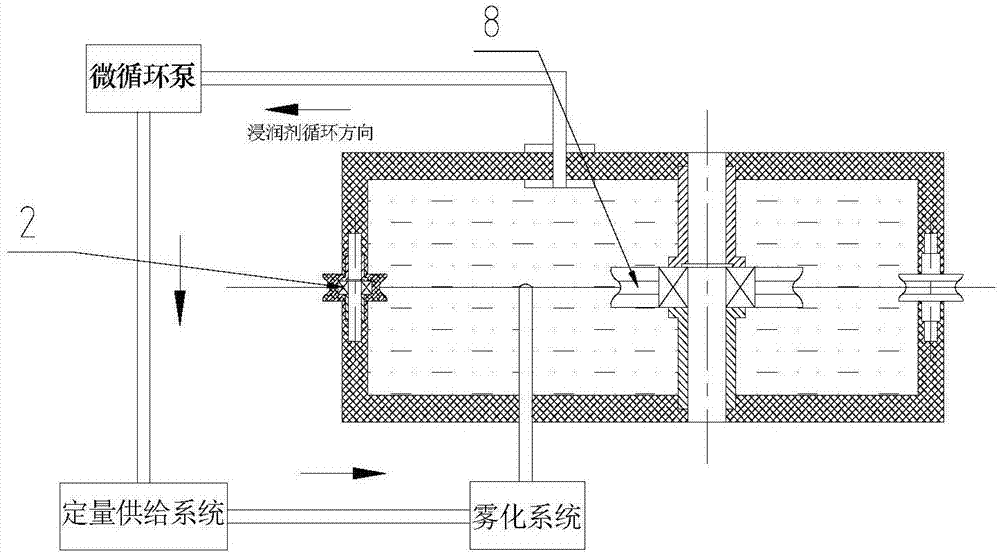

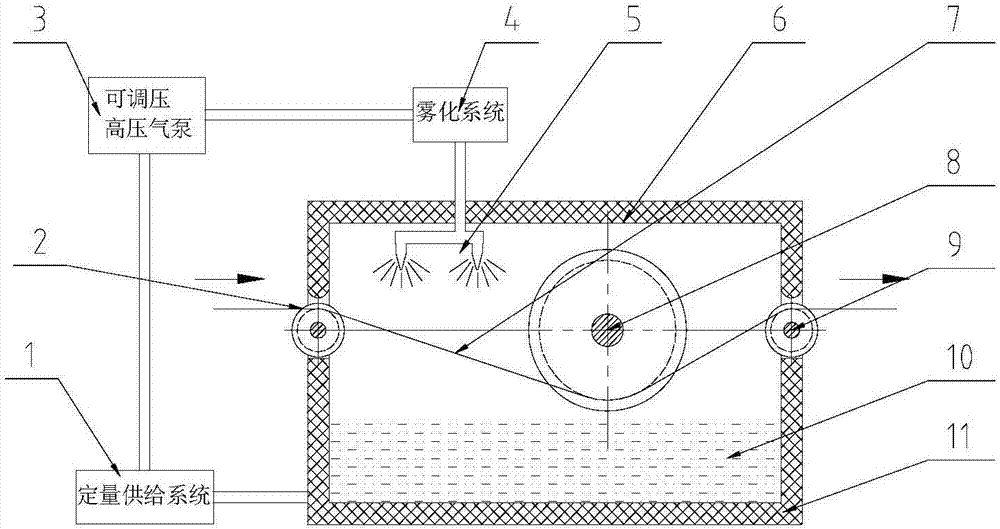

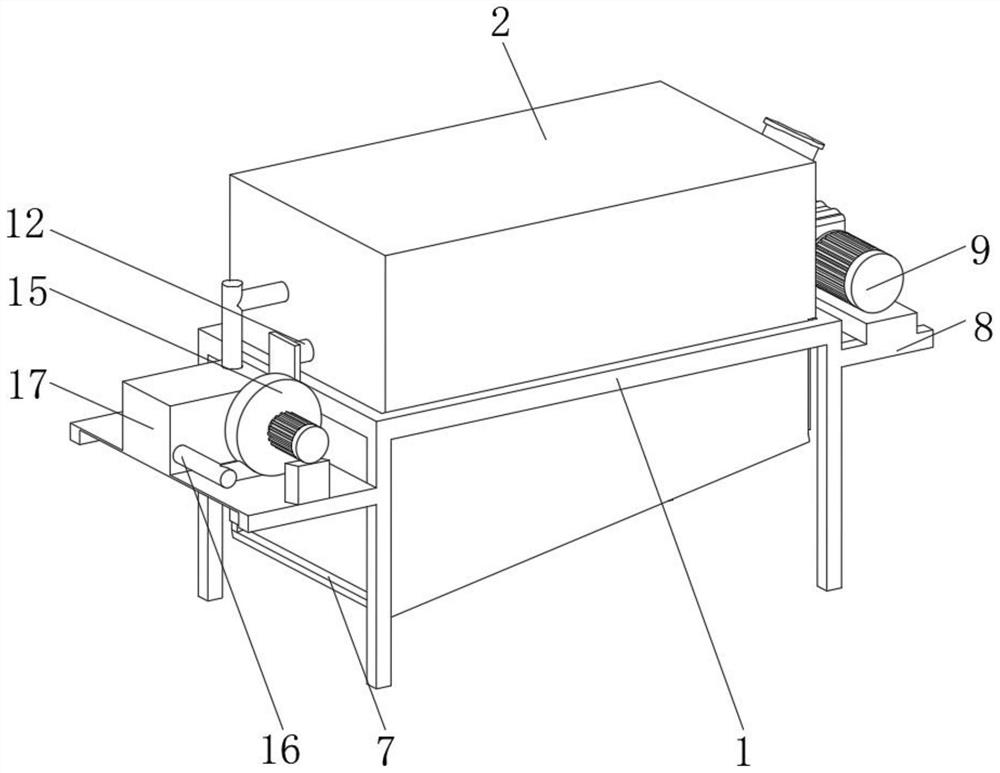

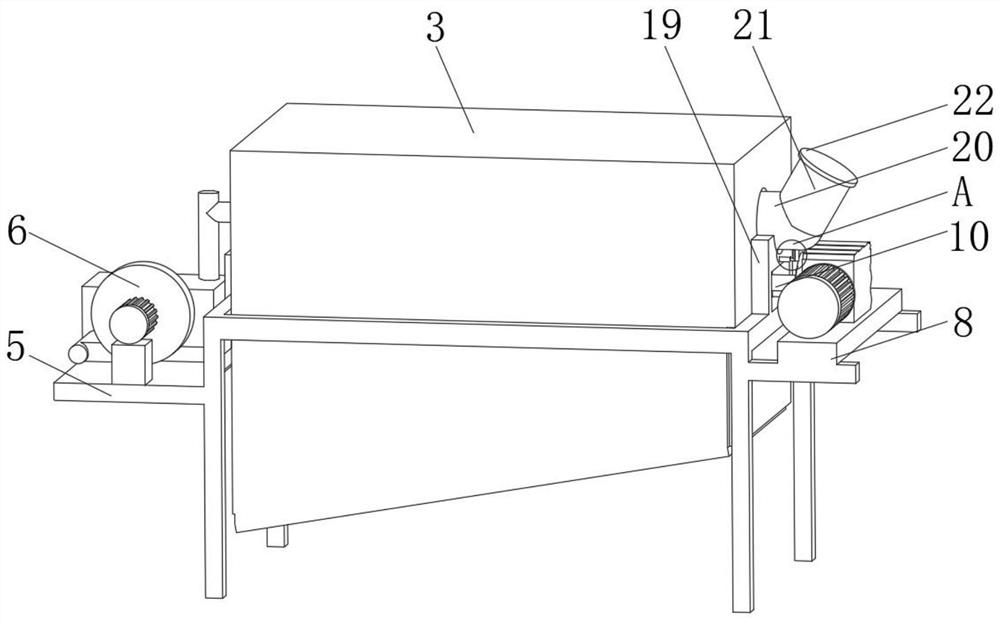

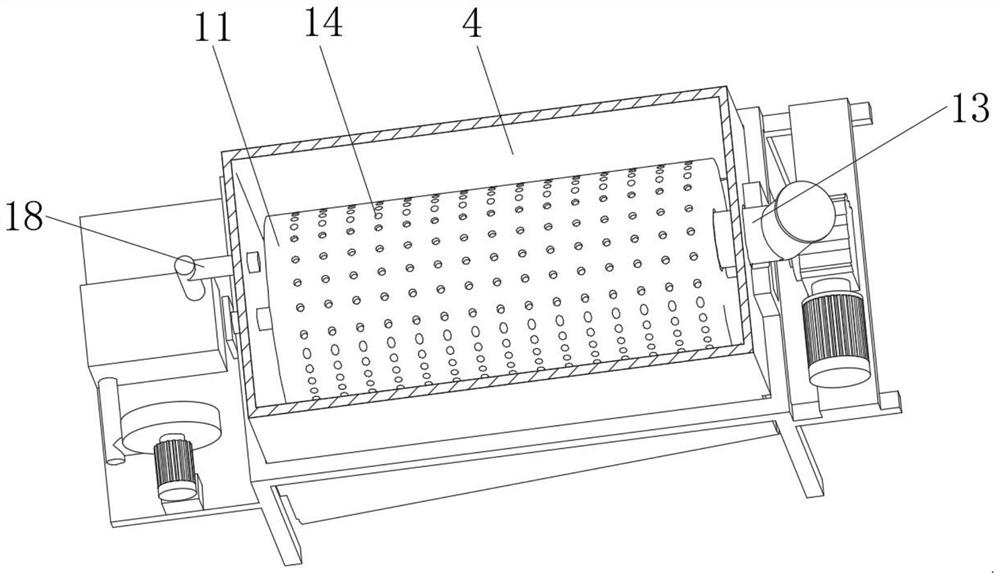

Precision coating device and coating method for special optical fiber impregnating compounds

PendingCN107963817ARotate at a constant speedUniform thicknessLiquid circulationAnalytical chemistry

The invention discloses a precision coating device and coating method for special optical fiber impregnating compounds. The coating device comprises a liquid circulation system and a coating homogenization mechanism, the liquid circulation system comprises a trace given supply system, a pressure-adjustable high-pressure gas pump and an atomizing system, and the coating homogenization mechanism comprises an inlet guide wheel, a homogenization wheel, an outlet guide wheel, a storage bottom box and a sealing cover. Quantitative impregnating compounds are added into the storage bottom box, the quantitative supply system and the pressure-adjustable high-pressure gas pump jointly function to quantitatively convey the impregnating compounds into the atomizing system under constant pressure, the atomized impregnating compounds are sprayed out of an atomizing nozzle by the aid of pressure difference, an atomizing state is formed in a cavity, the atomized impregnating compounds are naturally anduniformly adsorbed on special optical fiber tows, the homogenization wheel can rotate at a uniform speed by the aid of friction force between a drawn special optical fiber tow 7 and the homogenization wheel, so that the impregnating compounds naturally adsorbed on the special optical fiber tows are homogenized, and a coating is uniform in thickness, good in compactness and not easy to fall off.

Owner:NANJING CHUNHUI SCI & TECH IND

Mechanical drying device for biomass particle production

InactiveCN112378199ADry evenlyKeep shapeDrying gas arrangementsDrying chambers/containersProcess engineeringComposite material

The invention discloses a mechanical drying device for biomass particle production. The mechanical drying device comprises a supporting frame, wherein a drying and screening device capable of uniformly drying straw particles gathered into a cluster is arranged at the top of the supporting frame; the drying and screening device comprises an outer drying cylinder located at the top of the supportingframe; a feeding and screening device is arranged inside the outer drying cylinder; a supporting plate is arranged on the outer side of one end of the supporting frame; a drying device is arranged atthe top of the supporting plate; the bottom of the outer drying cylinder is an inclined surface; and a discharging port is formed in the inclined angle position of one end of the outer drying cylinder. According to the drying device for biomass straw particle production, the drying and screening device is additionally arranged on an original drying device so that the biomass straw particles can be uniformly dried, the dried straw particles can be screened, the shape after processing can be kept, and the outgoing quality of the straw particles is guaranteed; and the straw particles can be screened while being uniformly dried, and the shape integrity of the straw particles is guaranteed.

Owner:湖南中泉环保能源科技有限公司

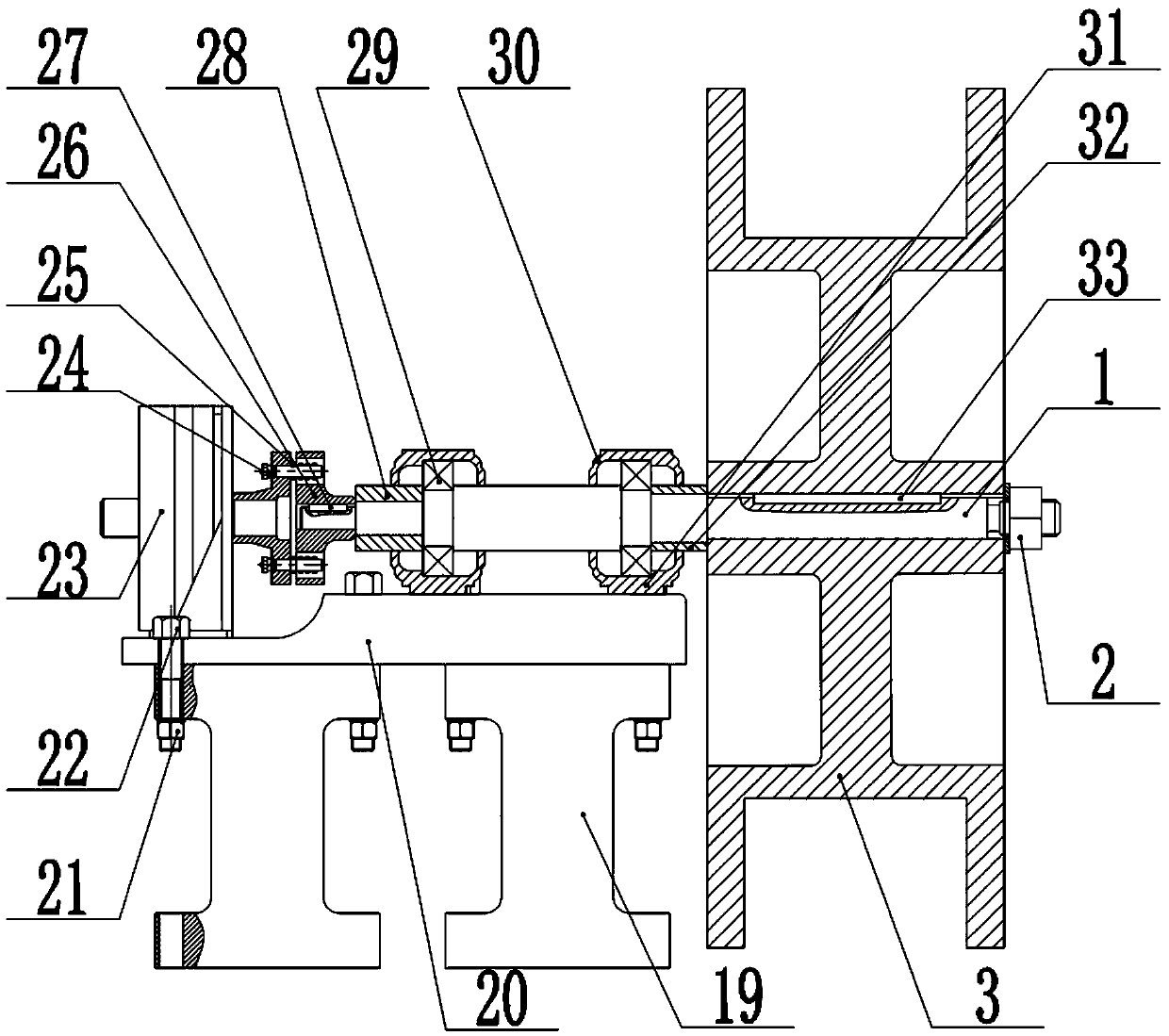

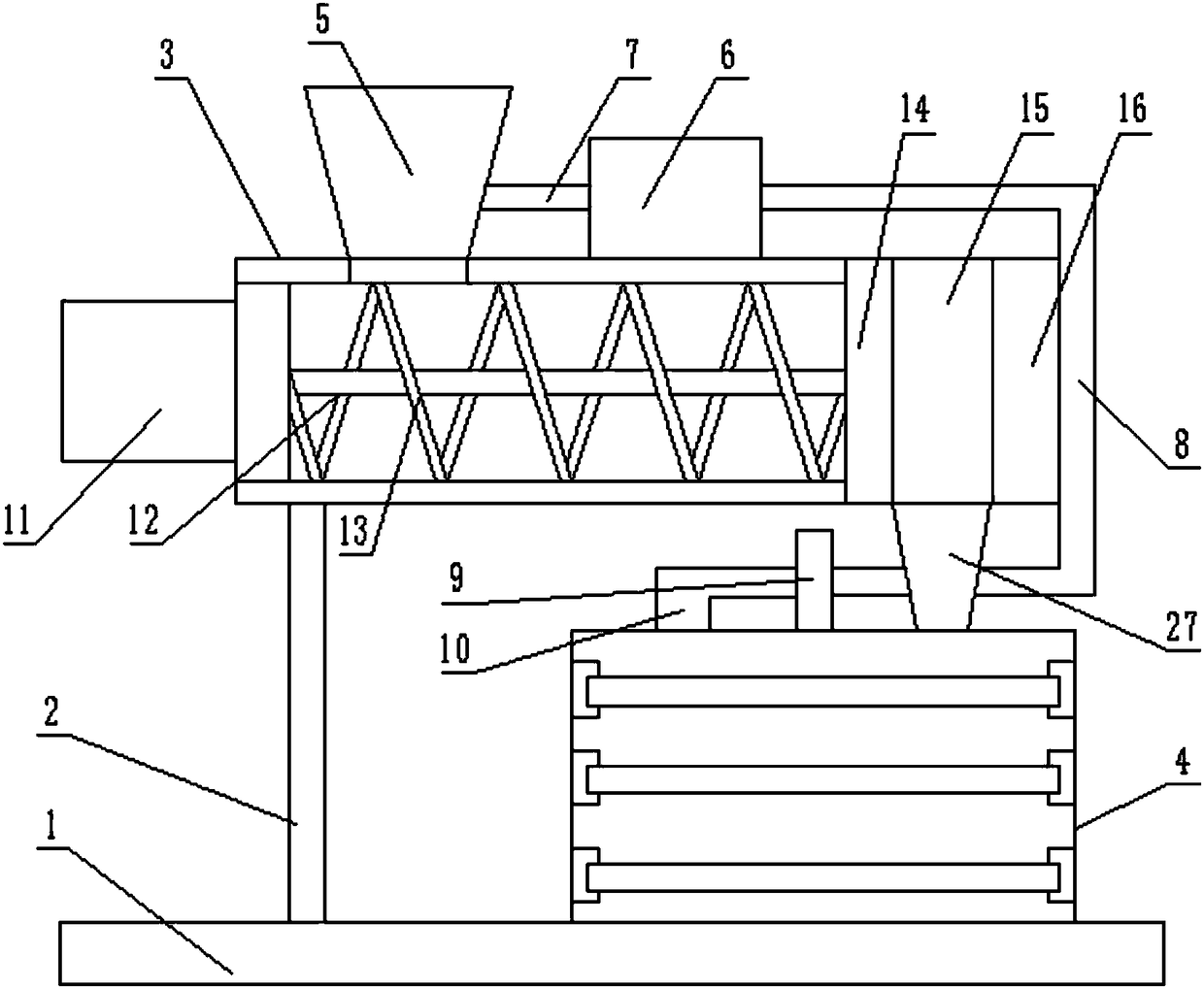

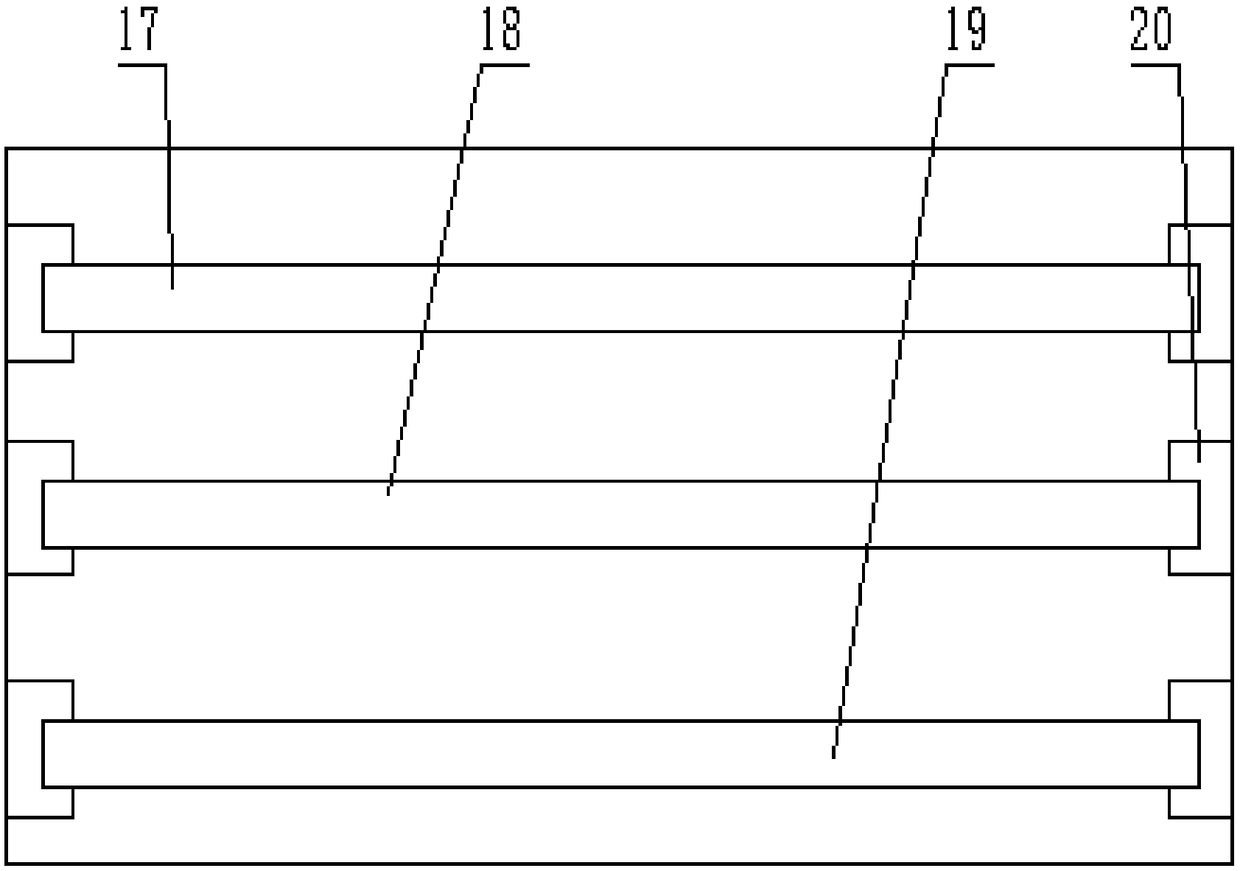

Device for forming basalt fiber-wound composite pipe

The invention provides a device for forming a basalt fiber-wound composite pipe. The device comprises a fiber unwinding part, a tension control part, a glue dipping part and a fiber winding part. Thefiber unwinding part comprises an unwinding roller, an unwinding shaft and a torque motor. The tension control part comprises a main speed roller, a magnetic powder brake and a tension detection mechanism. The glue dipping part comprises a glue dipping pool, a glue dipping roller and a glue extrusion roller. The fiber winding part comprises a rack, incomplete gears, a bevel gear reversing mechanism, a supporting table, a guide rail, a guide wheel, the composite pipe, a mandrel, a three-jaw chuck and a yarn nozzle, wherein the two sides of the rack are each provided with one incomplete gear, the yarn nozzle is fixed to the rack, and the bevel gear reversing mechanism drives the incomplete gears to rotate synchronously. According to the device, a horizontal structure is adopted to prevent manual interference of all the parts, so that the stability is high; the tension can be kept constant all the time in the fiber winding process, it is guaranteed that basalt fibers are uniformly wound on the surface of the composite pipe, and the physical properties of the composite pipe are improved.

Owner:SOUTHWEST PETROLEUM UNIV

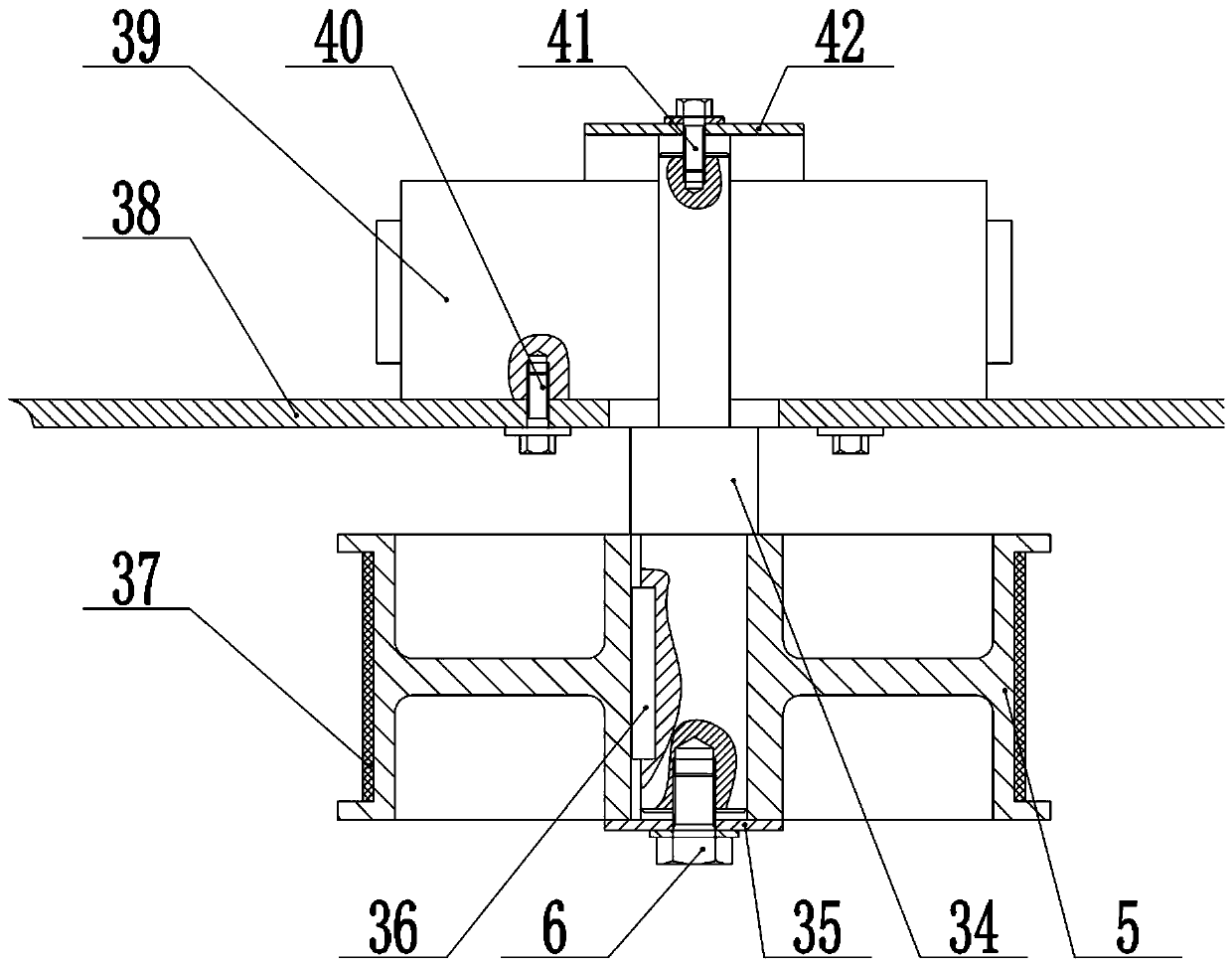

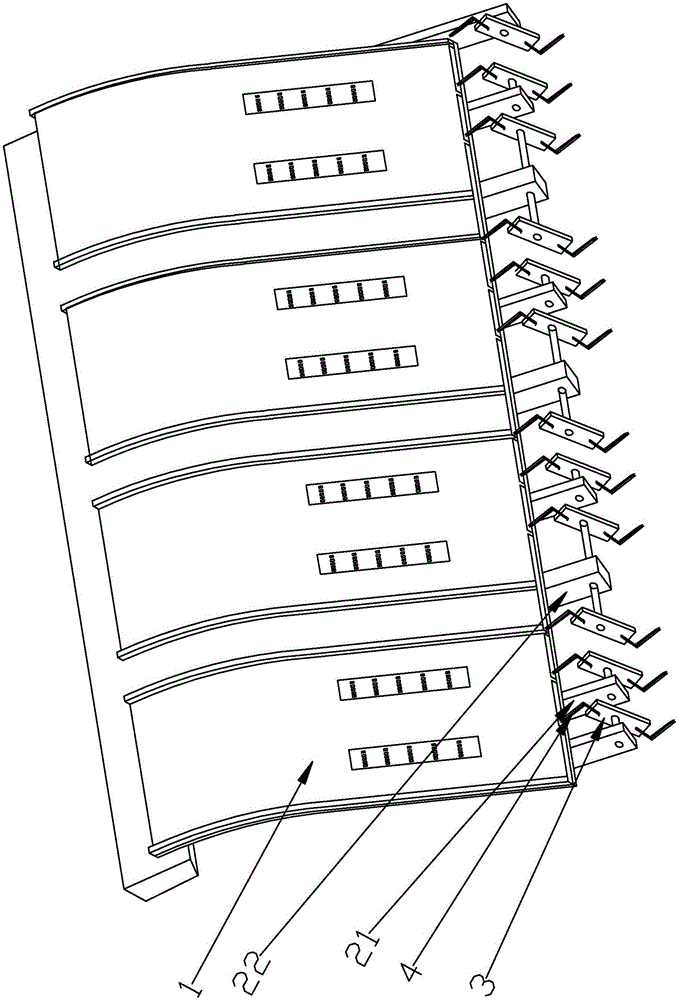

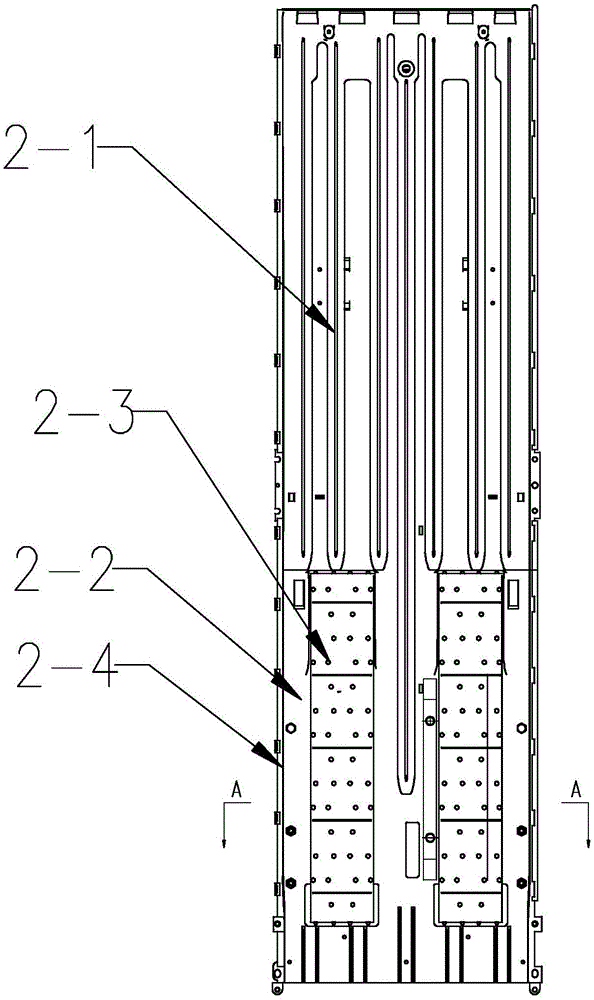

Uniform-rotating-speed two-dimensional wide and narrow transplanter

The invention relates to a uniform-rotating-speed two-dimensional wide and narrow row spacing transplanter. The transplanter comprises a vehicle frame, a seedling table and a transplanting mechanism. The transplanting mechanism is equipped with revolving boxes. Transplanting arms are arranged at two ends of each revolving box respectively. A transplanting claw is arranged on each transplanting arm. The seedling table is connected with a seedling table driving mechanism. The seedling table driving mechanism is equipped with a spiral shaft. Change of a movement speed of the seedling table is achieved through the spiral lead length change of the spiral shaft, and further alternative change of true transplanting for two times and empty transplanting for one time of the transplanting claw is achieved. Three revolving boxes are employed as a group. The revolving boxes in one group are equally spaced, and the spacing of adjacent revolving boxes of two adjacent groups is 1.5-2 times of the spacing of the revolving boxes in one group. Each group of revolving boxes corresponds to a seedling loading plate, therefore wide and narrow row spacing is achieved, and finally the purpose of two-dimensional wide and narrow transplanting is achieved.

Owner:浙江锦禾农业科技有限公司

Plastic pelletizing device

The invention discloses a plastic pelletizing device. The plastic pelletizing device comprises a base, an extrusion cylinder and a screening chamber. The extrusion cylinder is fixed to the base through a supporting rod, and the screening chamber is fixed to the base and located below the extrusion cylinder. The extrusion cylinder comprises a cylindrical barrel body, a heating and feeding hopper and a hot air chamber are arranged on the top of the extrusion cylinder, the lower end of the heating and feeding hopper communicates with the interior of the extrusion cylinder, a combustion cavity isformed in the hot air chamber, and the hot air chamber communicates with the heating and feeding hopper through an air supply pipe. The plastic pelletizing device is exquisite in structure, can conduct step-by-step screening on pelletized particles, and conveniently conducts collection and reprocessing in the later period. Due to the arrangement of a plurality of pipelines in the material fallingprocess, the operation of quick cooling, energy recycling and the like can be conducted, the energy utilization rate is greatly improved, and the pollution is reduced. The situation that tool edges ofmaterial cutting tools are sharp, and the material cutting tools rotate at a uniform speed can be guaranteed by means of the arrangement of sliding pieces and a material scraping block, and thereforethe specification of pelletizing is guaranteed, and then the percent of pass of products is guaranteed.

Owner:王会恩

Power detection device of laser device

ActiveCN107271035AImprove stabilityImprove detection accuracyPhotometry using electric radiation detectorsPower detectorOptoelectronics

The invention discloses a power detection device of a laser device. The power detection device comprises a power detection component which is composed of a light reflecting plate and a laser power detector. The light reflecting plate reflects the laser emitted by the laser device to the laser power detector to perform power detection. The light reflecting plate periodically reflects the laser beams of the laser device so that the laser power detector is enabled to periodically receive the laser reflected by the light reflecting plate. The power detection device of the laser device has low production cost, high detection value stability and high accuracy.

Owner:WENZHOU FIBER LASER

Vertical guiding device for piling machine

InactiveCN108589730AImprove stabilityAvoid being unstableDrilling rodsDerricks/mastsChinese charactersEngineering

The invention relates to a vertical guiding device for a piling machine. The vertical guiding device comprises a base, sliding blocks and a top post. Rolling wheels are connected to the lower end of the base. Sliding rails are arranged at the upper ends of the rolling wheels. The sliding blocks are distributed in the middles of the outer sides of the corresponding sliding rails. Hydraulic rods arecorrespondingly embedded into the tops of the sliding blocks. The top post is fixedly arranged on the tops of the sliding rails. An auxiliary rod is connected to the middle of the inner side of eachsliding rail. According to the vertical guiding device for the piling machine, through the arrangement of the base, the sliding rails and the top post, the base, the sliding rails and the top post form a structure in the shape like a Chinese character 'ji', and the base, the sliding rails and the top post are welded, so that the base, the sliding rails and the top post have good stability, the situation that the base, the sliding rails and the top post are unstably fixed, consequently collapse occurs among the base, the sliding rails and the top post, and the vertical guiding device cannot beeffectively used is prevented, and meanwhile a cylinder body is ensured to be vertically placed during use.

Owner:YUNHEMAN WALKER TOYS CO LTD

Semi-automatic stamp making machine

The invention discloses a semi-automatic stamp making machine, and belongs to the technical field of stamp making machines. The semi-automatic stamp making machine comprises a support, a carrying table, a continuous control reciprocating intermittent movement platform, a stamp, springs and a two-dimensional paper clamping structure. The semi-automatic stamp making machine has the advantages that the stamp of the semi-automatic stamp making machine with the structure can be automatically lifted up and dropped down, accordingly, stamp affixing actions can be automated, workload on stamp users can be relieved, and the stamp use time can be saved; components can carry out reciprocating intermittent movement under the condition that a motor rotates at a constant speed, a movement state and a halt state can be seamlessly connected with each other, the motor does not need to be accurately controlled to be matched with movement parameters of the components, and the difficulty of high-precisioncontrol can be lowered; clamping structures and paper accommodating plates of the paper clamping structure can be adjusted when the semi-automatic stamp making machine works, accordingly, stamp papercan be relatively fixedly positioned, clear stamp making effects can be realized, and abrasion of the semi-automatic stamp making machine can be reduced to the greatest extent.

Owner:陈晓辉

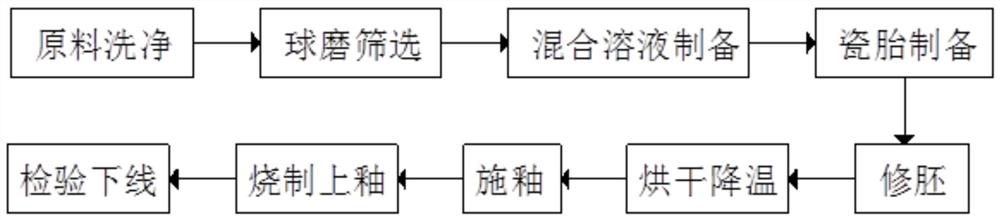

Preparation method of multi-layer glaze daily-use porcelain

The invention provides a preparation method of multi-glaze daily-use porcelain. The multi-glaze daily-use porcelain is prepared from the following raw materials of: aluminum oxide, silicon dioxide, ferric oxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, titanium dioxide, chromium carbonate, diboron trioxide, barium oxide, pigment and deionized water. Through reasonable matching of the raw materials, the selection of the ceramic materials is changed, the chemical reaction sufficiency of the ceramic materials is improved, the reaction among the chemical components of the ceramic materials is more stable. The preparation method comprises the following steps of: raw material washing, ball-milling and screening, mixed solution preparation, porcelain body preparation, blanktrimming, drying and cooling, glazing, firing and glazing, and inspecting and discharging. Clean and standard raw materials are used, meanwhile, the manufacturing precision of each link is guaranteed;the thermal stability of a ceramic product is improved; the ceramic product is not prone to cracking in a high-temperature or low-temperature environment; the ceramic is sintered at the medium temperature, the sintering cost of the ceramic is greatly reduced, and the energy-saving and consumption-reducing functions are achieved.

Owner:GUANGDONG SITONG GROUP

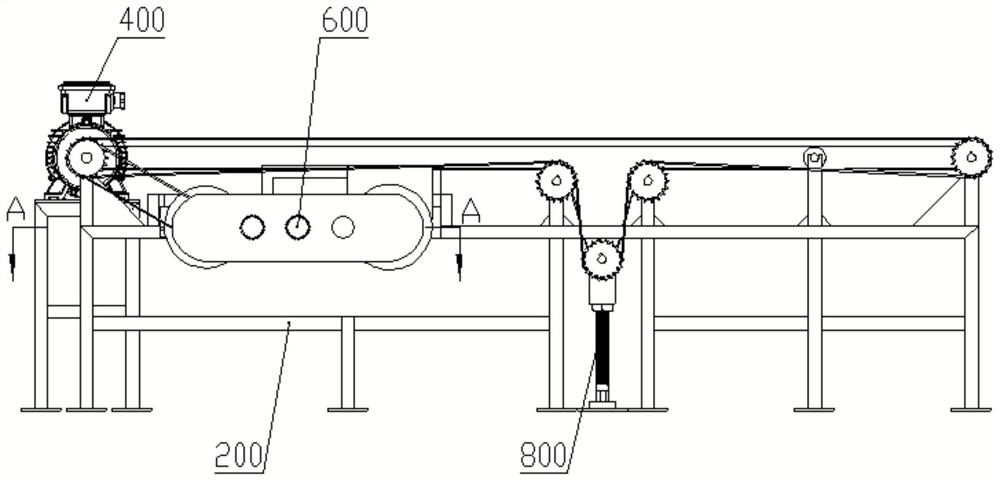

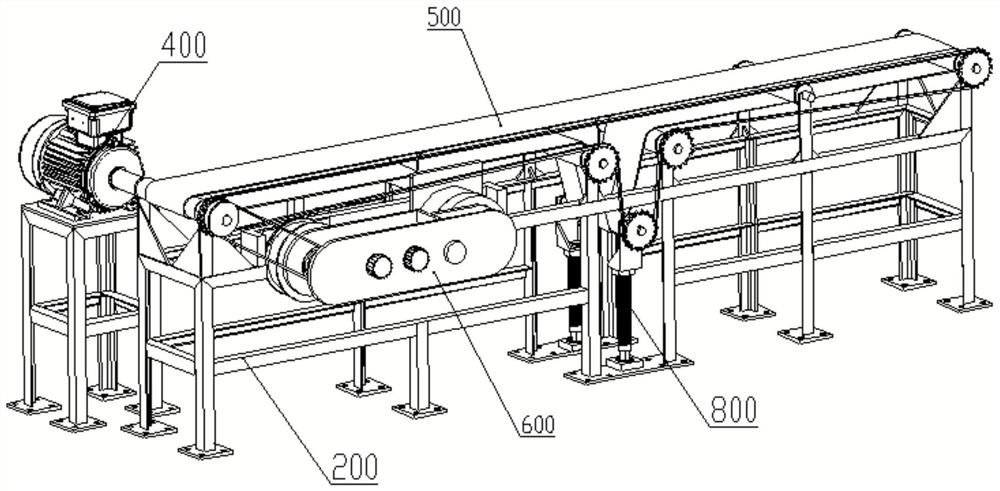

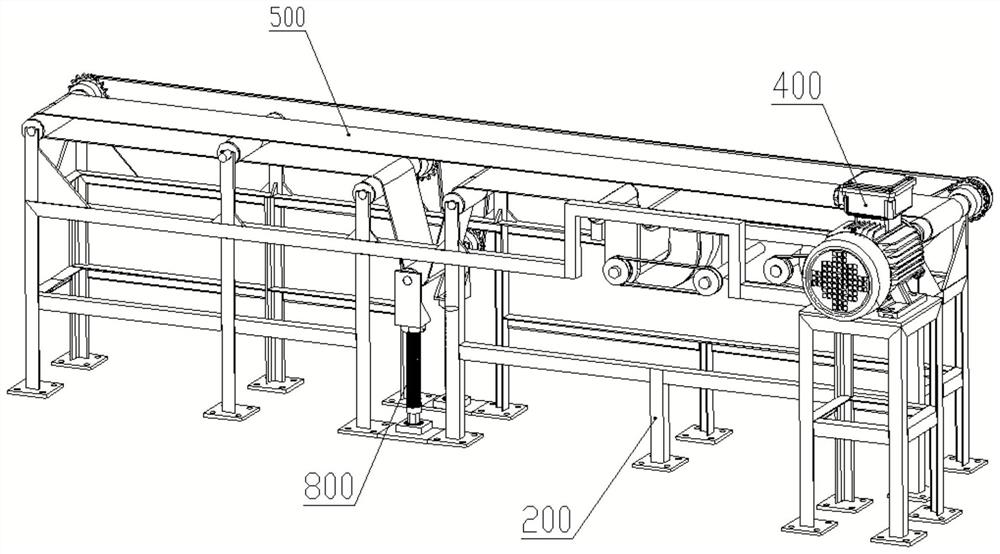

Anti-overspeed belt conveyor

InactiveCN111792287ARotate at a constant speedNo lossConveyorsControl devices for conveyorsControl theoryBelt conveyor

The invention discloses an anti-overspeed belt conveyor. The anti-overspeed belt conveyor comprises a frame body, belt rollers, a conveying belt, a driving mechanism, a belt adjusting mechanism, a roller speed limiting mechanism and a speed adjusting operation mechanism, wherein the belt roller is rotatably connected with the frame body, and the conveying belt is wound on the belt roller. The driving mechanism is connected with the conveying belt and used for driving the conveying belt to rotate. The roller speed limiting mechanism is connected with the belt roller and used for preventing thebelt roller from overspeed running. The speed adjusting operation mechanism is connected with the roller speed limiting mechanism and is used for regulating the running resistance of the roller speedlimiting mechanism. The belt adjusting mechanism is connected with the conveying belt and used for adjusting the tension degree of the conveying belt. By means of the anti-overspeed belt conveyor, itcan be guaranteed that the conveying device does not rotate in an overspeed mode, unnecessary losses caused by overspeed are avoided, and the anti-overspeed belt conveyor can safely and stably operateeven in a high-temperature and high-pressure severe environment and can be widely applied to various occasions needing speed limiting.

Owner:湖南零陵恒远发电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com