Full automatic production line for medical operating coat

A surgical gown, fully automatic technology, applied to sewing tools, protective clothing, clothing, etc., can solve the problems of cutting knife and cutting groove wear, long cutting knife, separation, etc., to speed up the feeding speed and improve The effect of rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

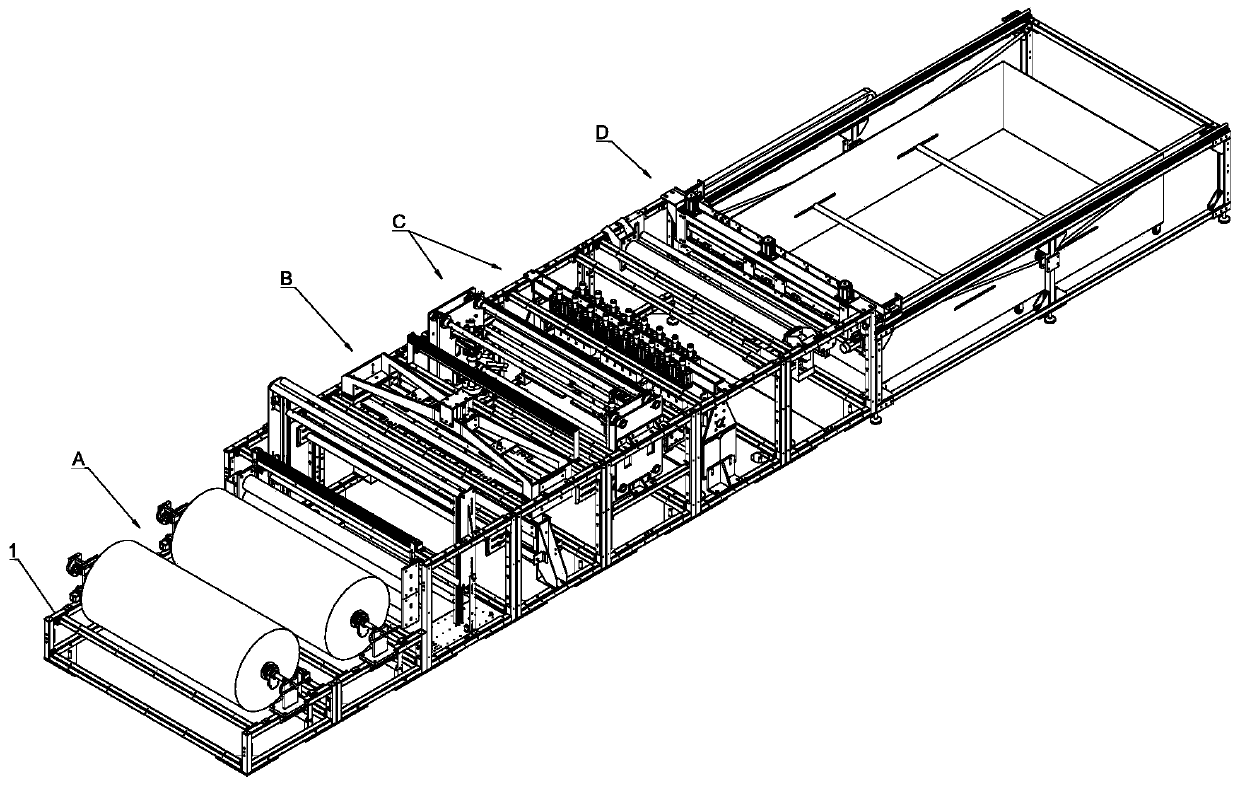

[0052] see Figure 1-Figure 12 , a fully automatic production line for medical surgical gowns, including a frame 1, a feeding device A, a punching device B, a composite device C, and a cutting device sequentially arranged on the frame along the direction in which the non-woven fabric advances D; where,

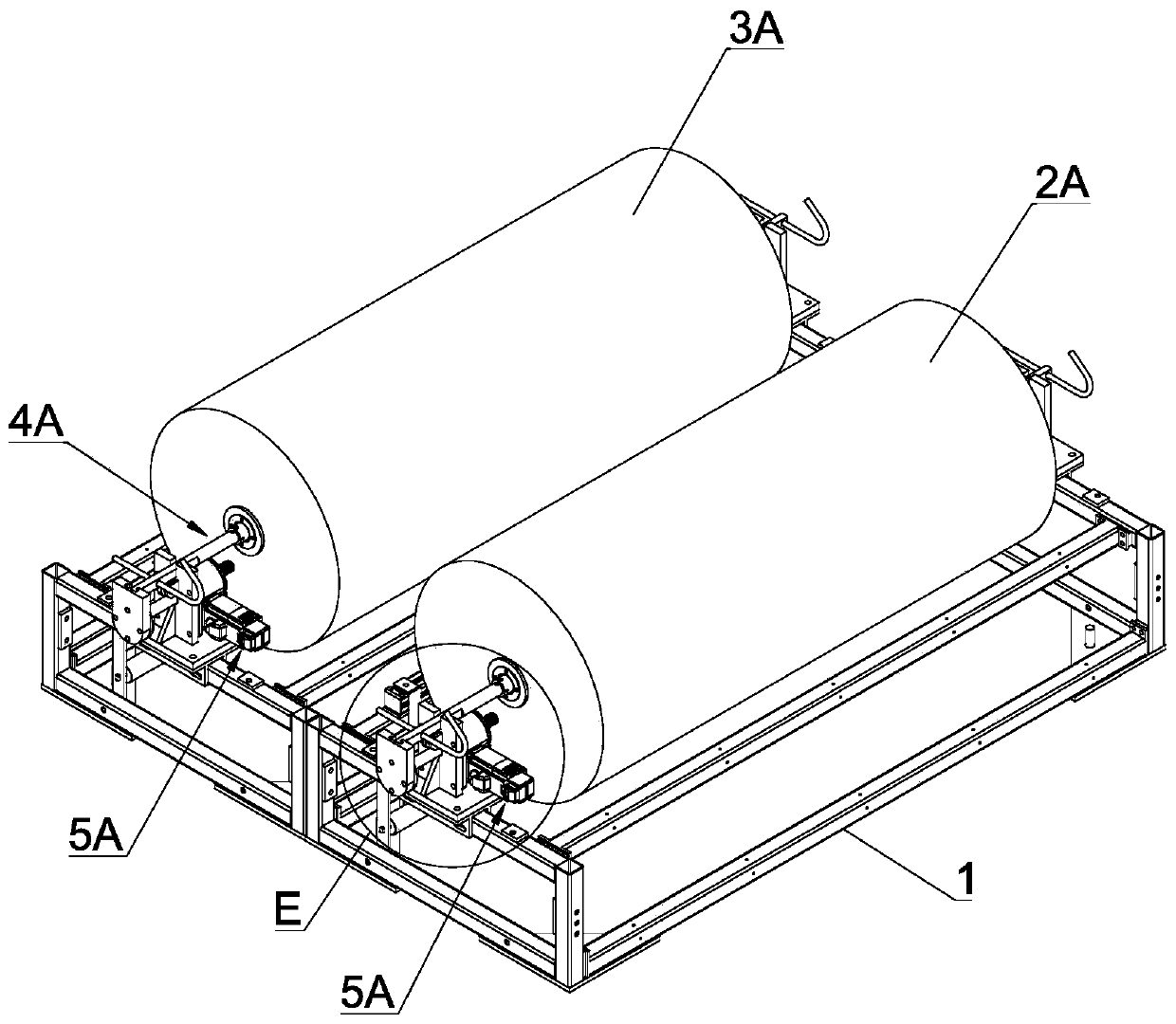

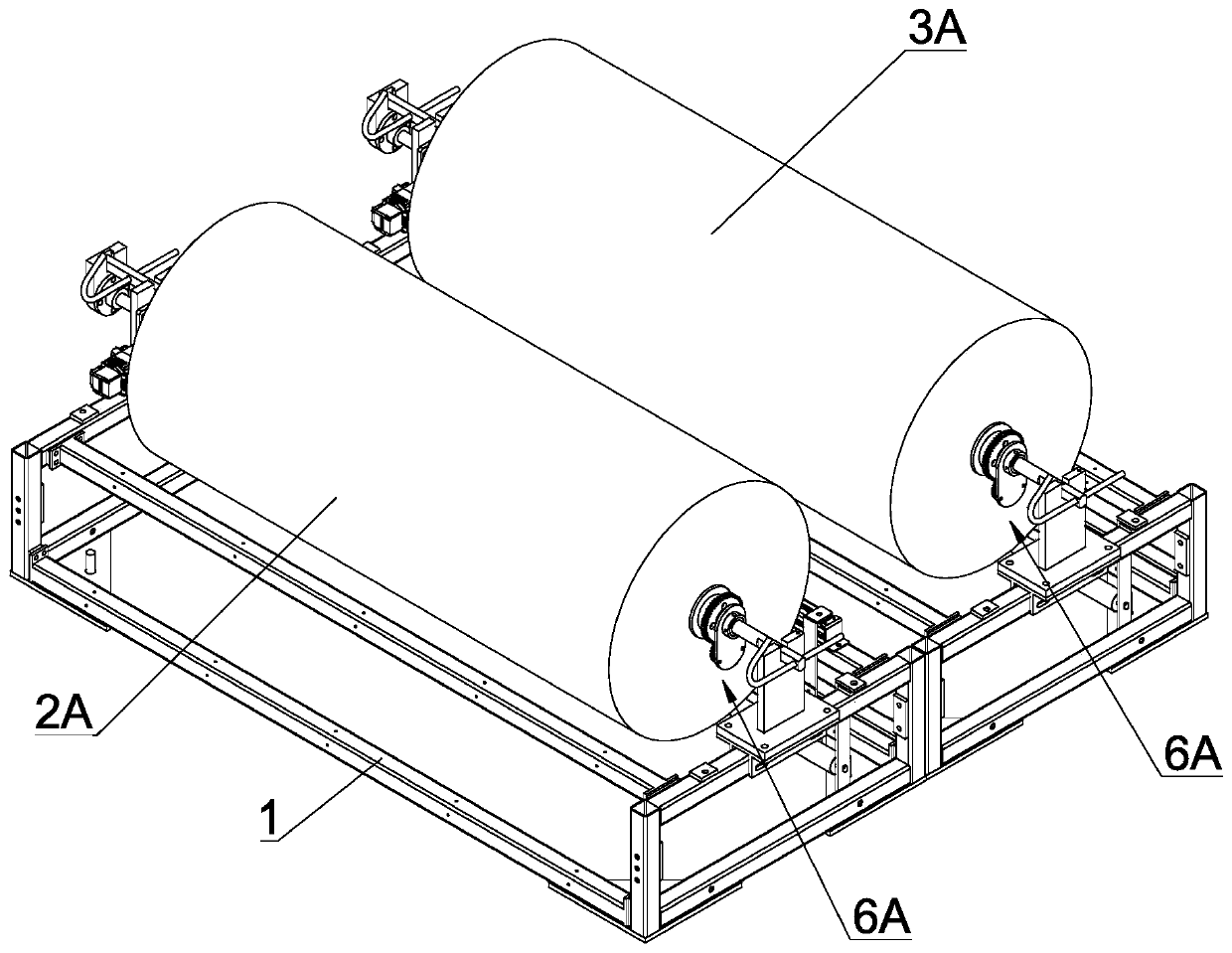

[0053] The discharge device A includes an upper non-woven roll 2A and a lower non-woven roll 3A which are rotated on the frame 1; The front of the woven fabric roll 2A; the upper layer of non-woven fabric roll 2A and the lower layer of non-woven fabric roll 3A are installed on the frame 1 through the discharge roller 4A;

[0054] see Figure 1-Figure 12 The deviation correction drive mechanism 5A in the discharge device A includes a drive motor 5-1A, a worm 5-5A transmission mechanism, and a synchronous drive plate arranged between the discharge roller 4A and the worm 5-5A transmission mechanism 5-2A; wherein, the worm 5-5A transmission mechanism includes a box 5-3A, a worm...

Embodiment 2

[0107] The other structures of this embodiment are the same as those of Embodiment 1, except that the inclination angle and the number of the traction protrusions 4-1C can be determined according to the actual situation.

Embodiment 3

[0109] see Figure 32 The other structures of this embodiment are the same as those of Embodiment 1, except that the anti-skid lines 3-1C are raised strips 3-12C arranged staggered along the outer surface of the pressing roller 3C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com