Sponge titanium reduction distillation reactor and production technique thereof

A technology of reaction device and sponge titanium, which is applied in the field of sponge titanium reduction distillation reaction device, can solve the problems of long time for single furnace products, poor heat dissipation conditions of products, and poor processability, so as to reduce the temperature and solve the problem of compactness Problems, effects of feed rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

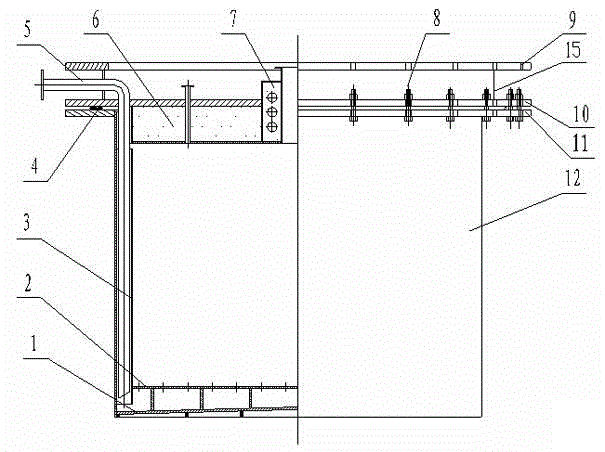

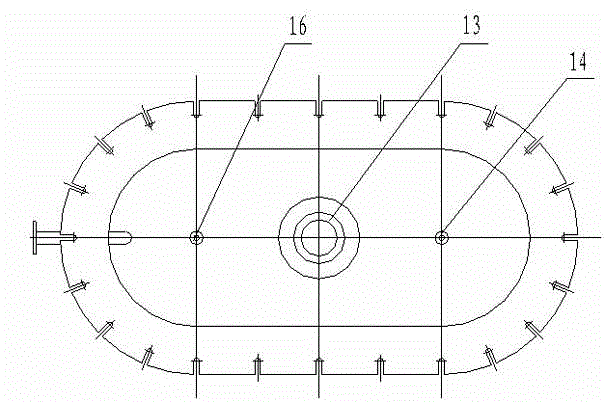

[0026] The present invention is described in detail below in conjunction with accompanying drawing 。

[0027] The present invention achieves large-scale equipment by increasing the size horizontally, adopts parallel multi-point feeding, not only reduces the reaction heat at the vertical position of the feeding point, but also improves the heat dissipation at the center of the reaction device, thereby solving the problem of dense titanium sponge.

[0028] Such as figure 1 , figure 2 As shown, a sponge titanium reduction distillation reaction device is composed of a tank body and a large cover connected by a flange rubber pad 4 and a bolt group 8. The tank body includes: a bottom plate 1, a sieve plate 2, a magnesium chloride row casing 3, Tank flange 11, waist-shaped cylinder 12; big cover includes: row magnesium chloride tube 5, insulation layer 6, inner heating device 7, big cover upper flange 9, big cover lower flange 10, center pipe 13, feeding sleeve Pipe one 14, short...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com