Patents

Literature

91results about How to "Easy to distill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

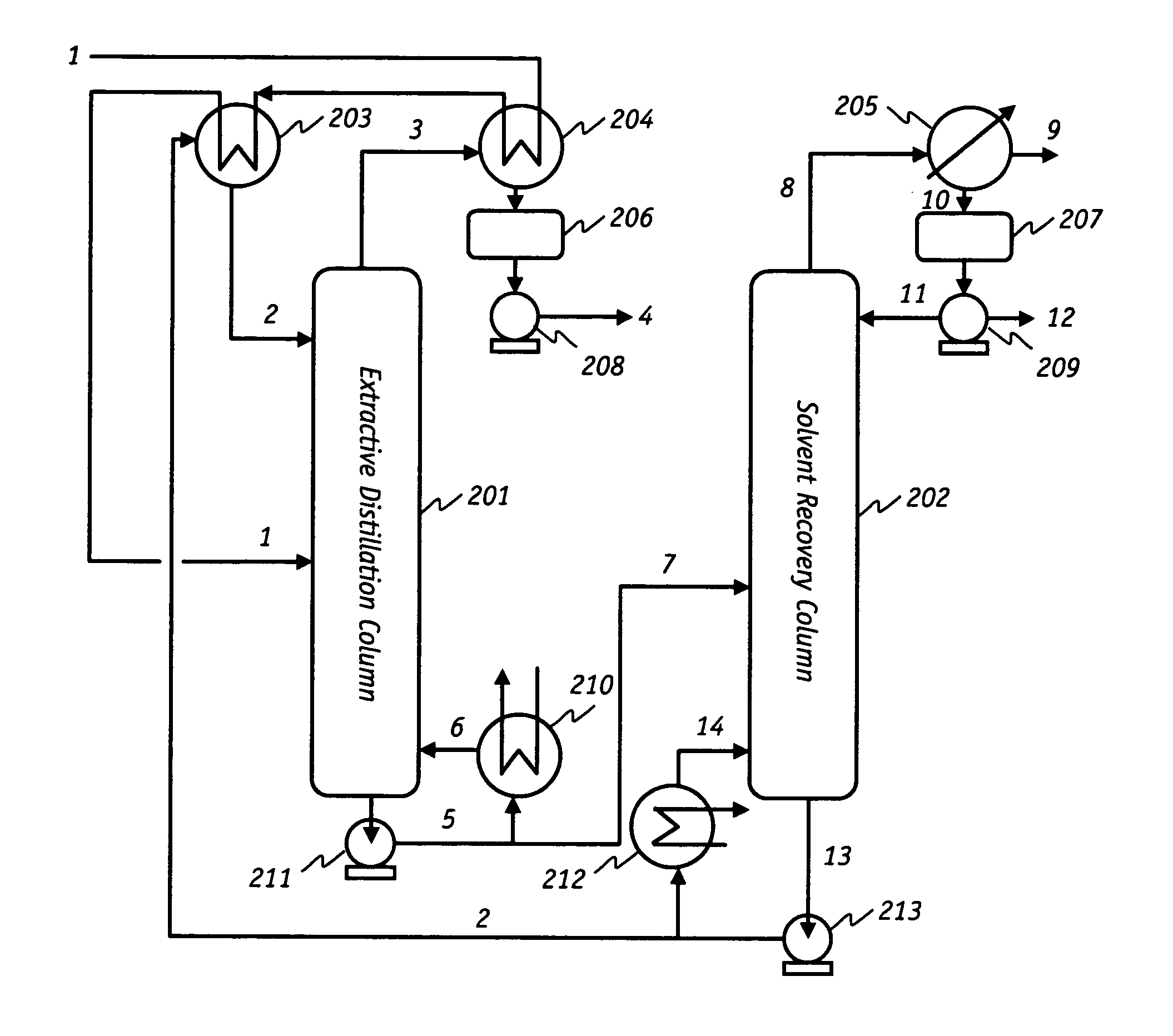

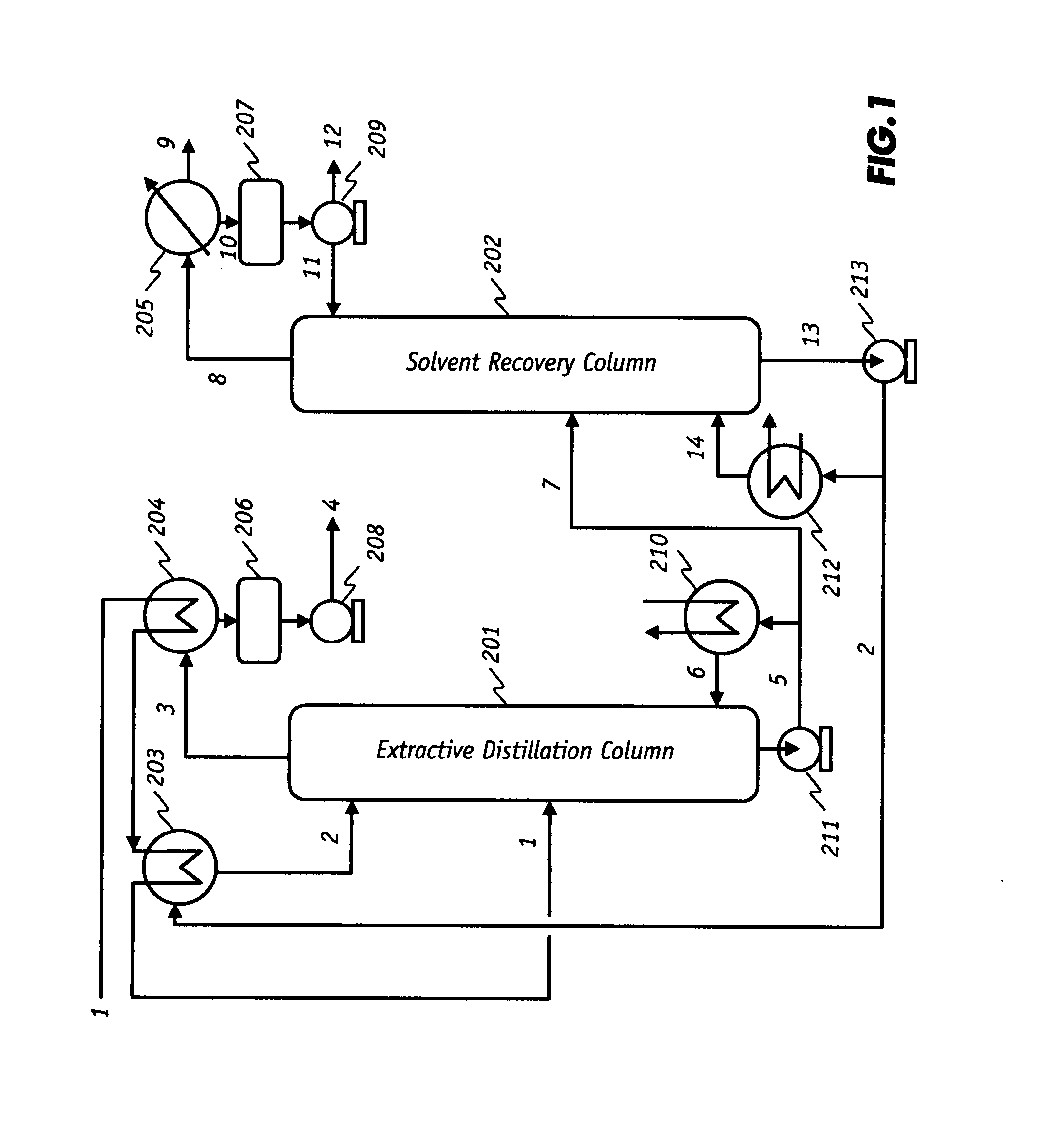

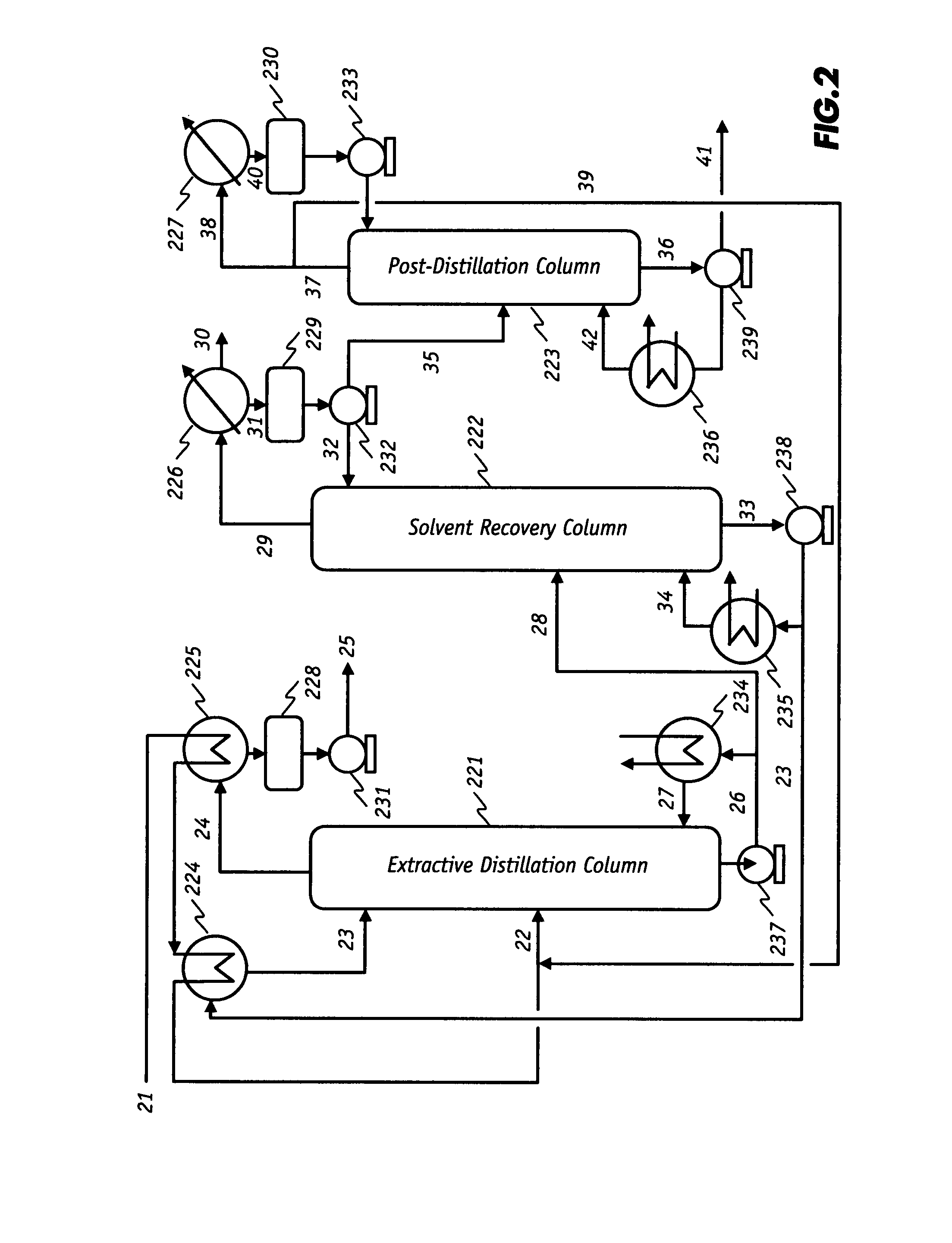

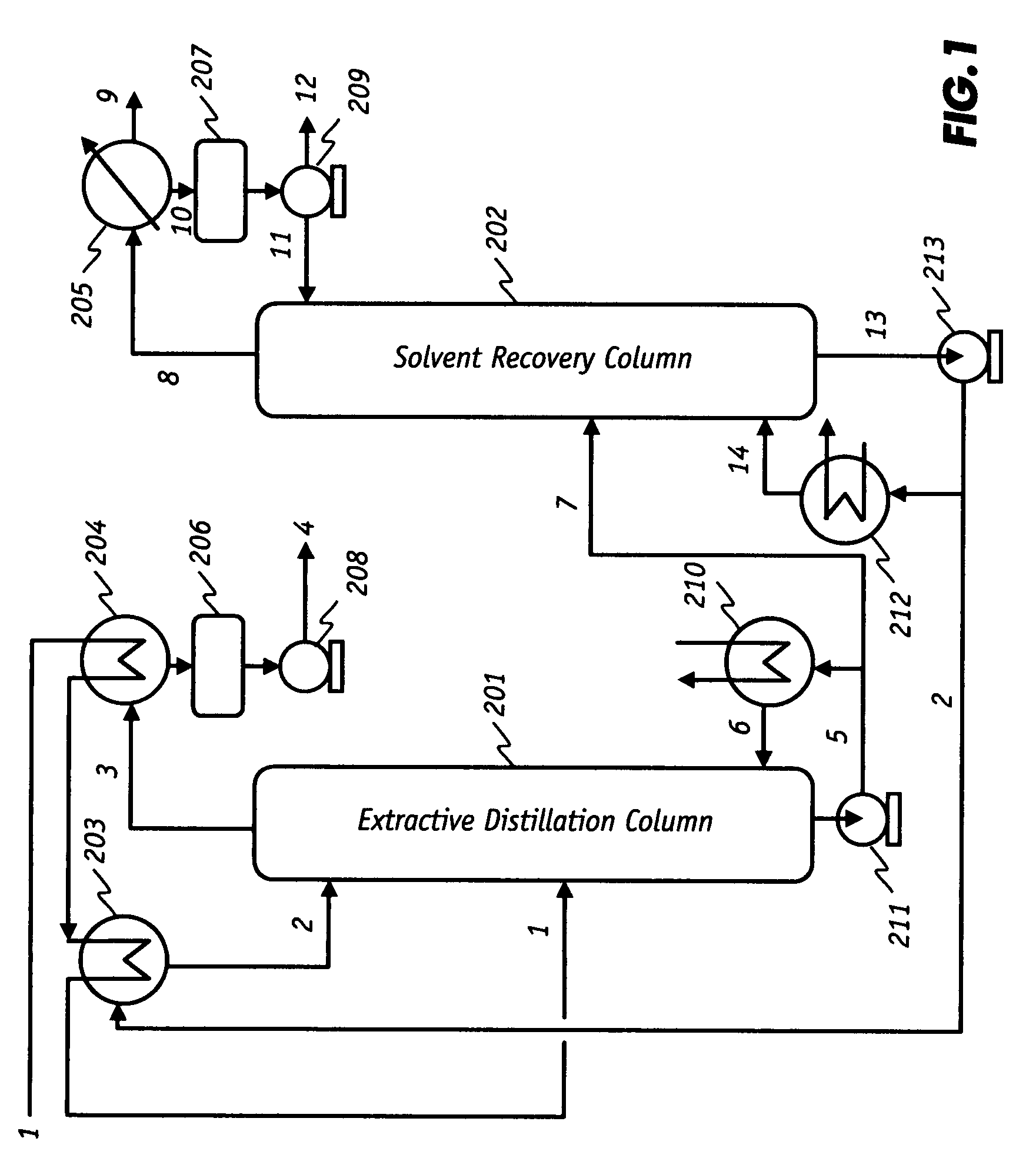

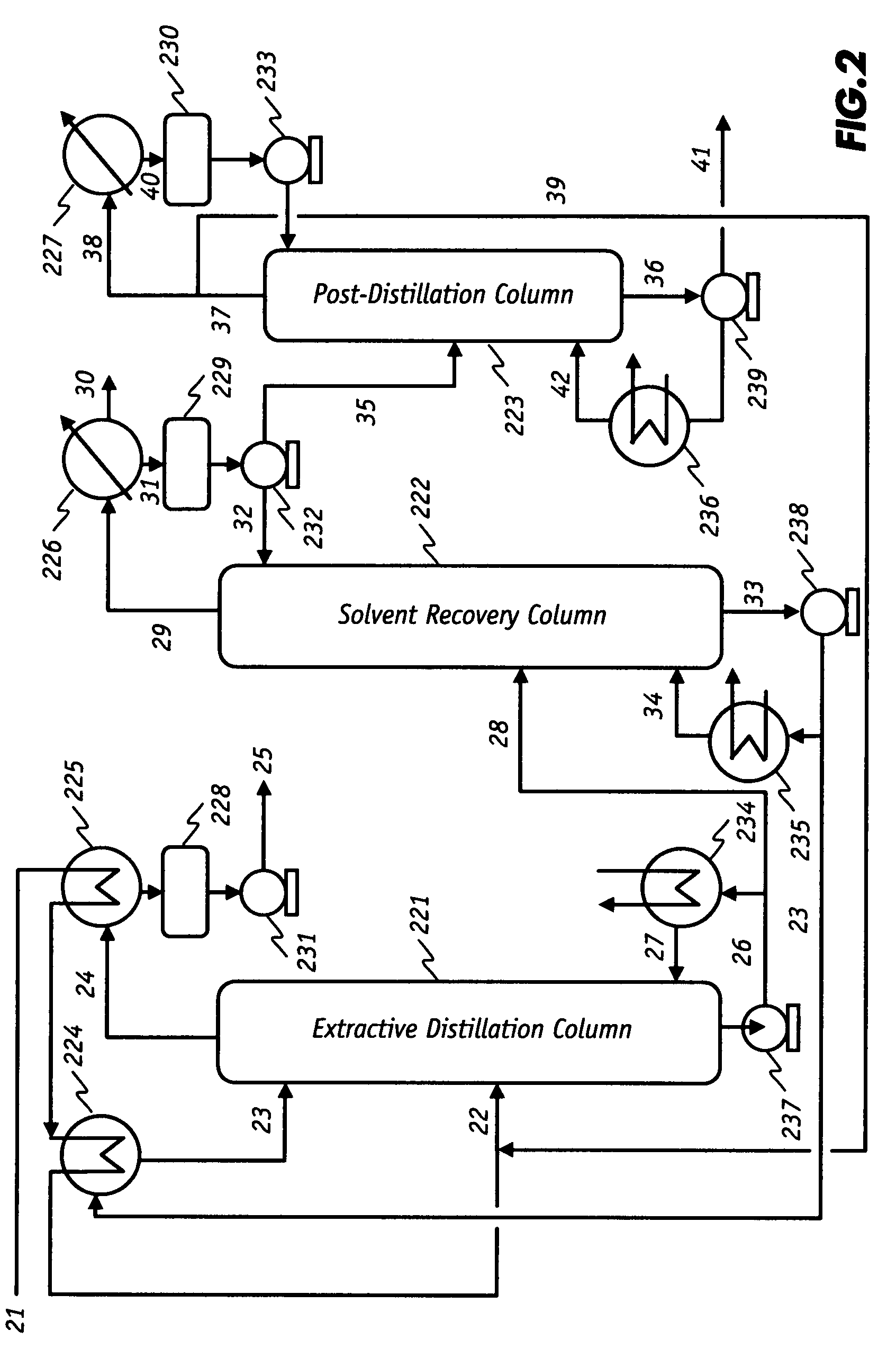

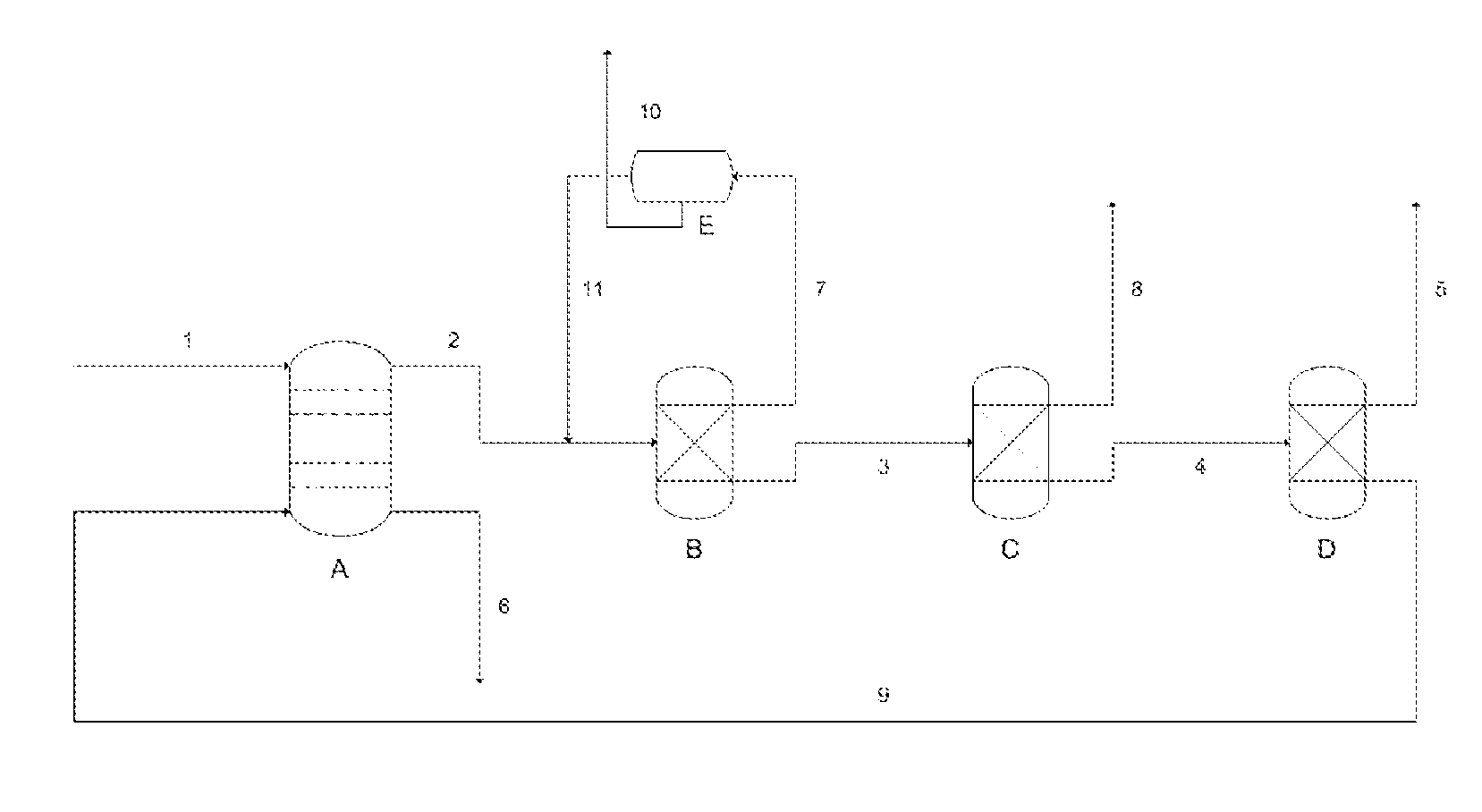

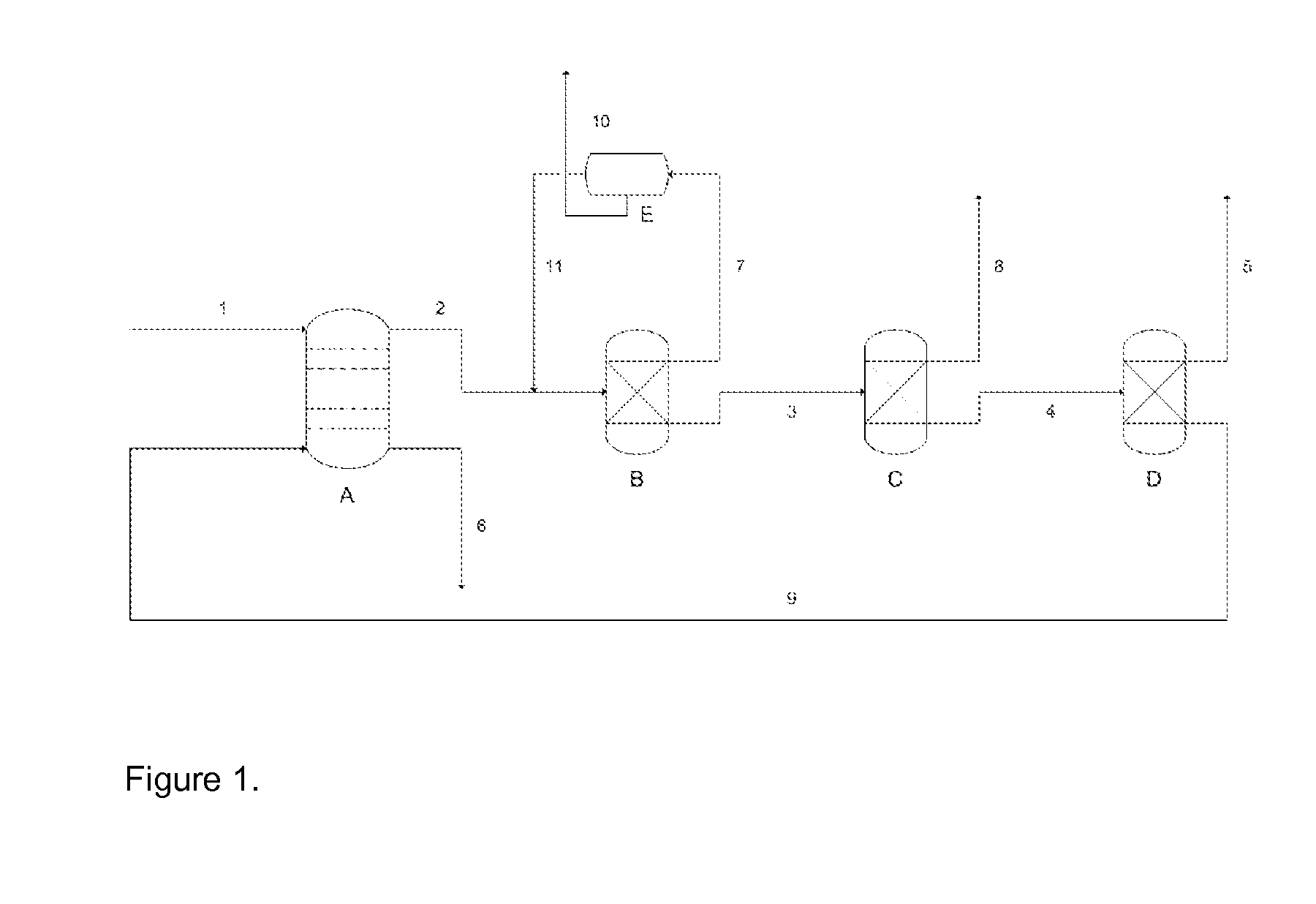

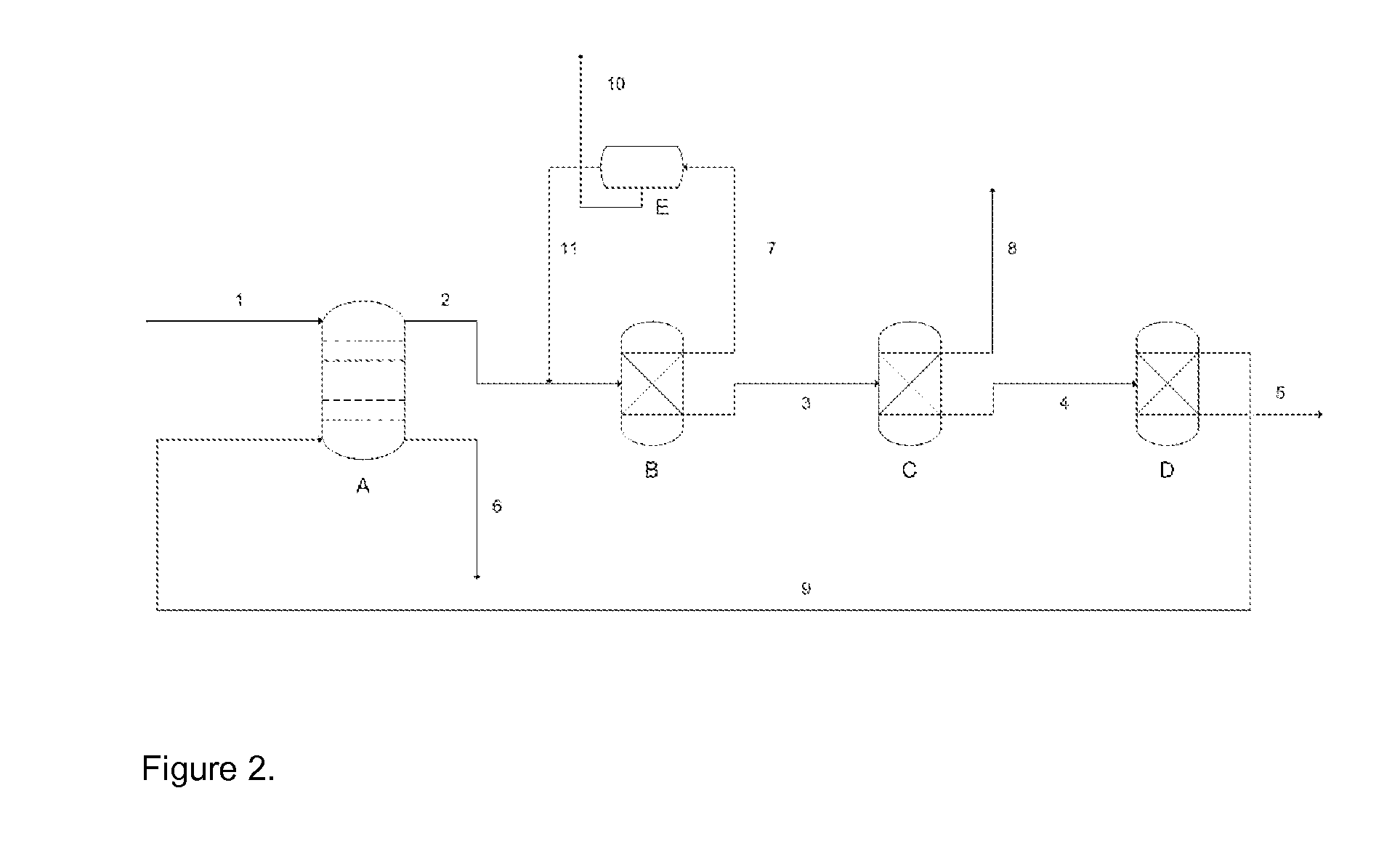

Low-energy extractive distillation process for dehydration of aqueous ethanol

ActiveUS20090014313A1Simple distillationEnergy efficientFermented solutions distillation/rectificationOrganic compound preparationChemistryBoiling point

An energy-efficient extractive distillation process for producing anhydrous ethanol from aqueous / ethanol feeds containing any range of ethanol employs an extractive distillation column (EDC) that operates under no or greatly reduced liquid reflux conditions. The EDC can be incorporated into an integrated process for producing anhydrous ethanol used for gasoline blending from fermentation broth. By using a high-boiling extractive distillation solvent, no solvent is entrained by the vapor phase to the EDC overhead stream, even under no liquid reflux conditions. The energy requirement and severity of the EDC can be further improved by limiting ethanol recovery in the EDC. In this partial ethanol recovery design, ethanol which remains in the aqueous stream from the EDC is recovered in a post-distillation column or the aqueous stream is recycled to a front-end pre-distillation column where the ethanol is readily recovered since the VLE curve for ethanol / water is extremely favorable for distillation.

Owner:AMT INT INC +1

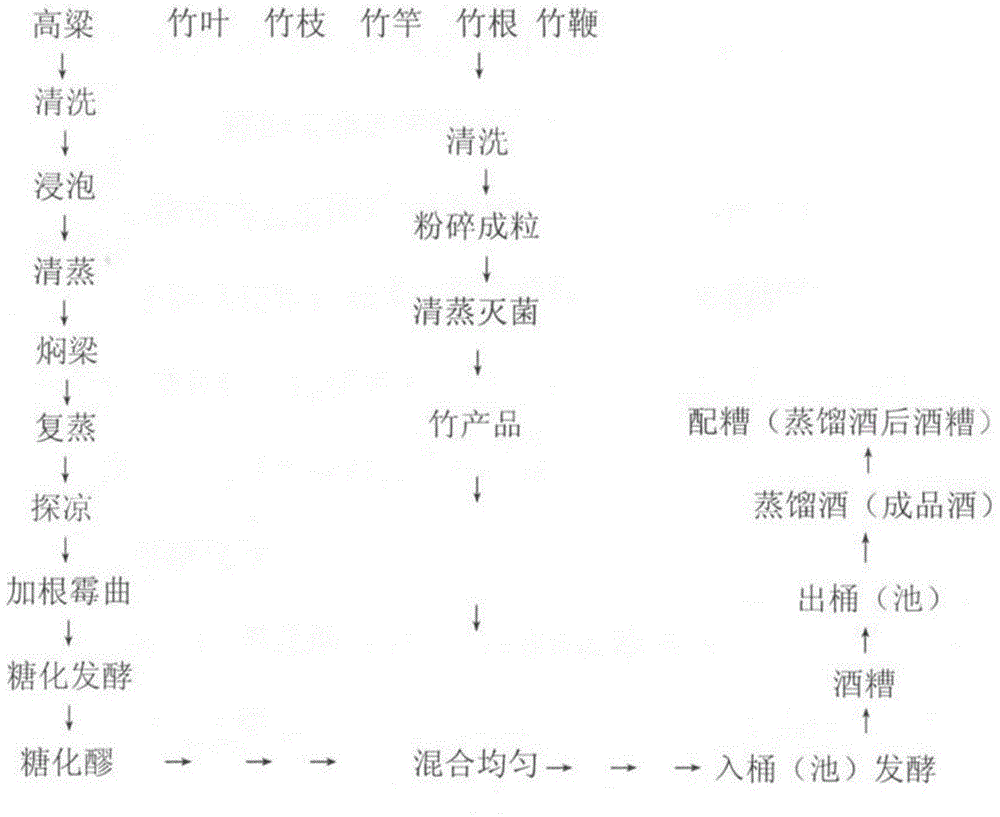

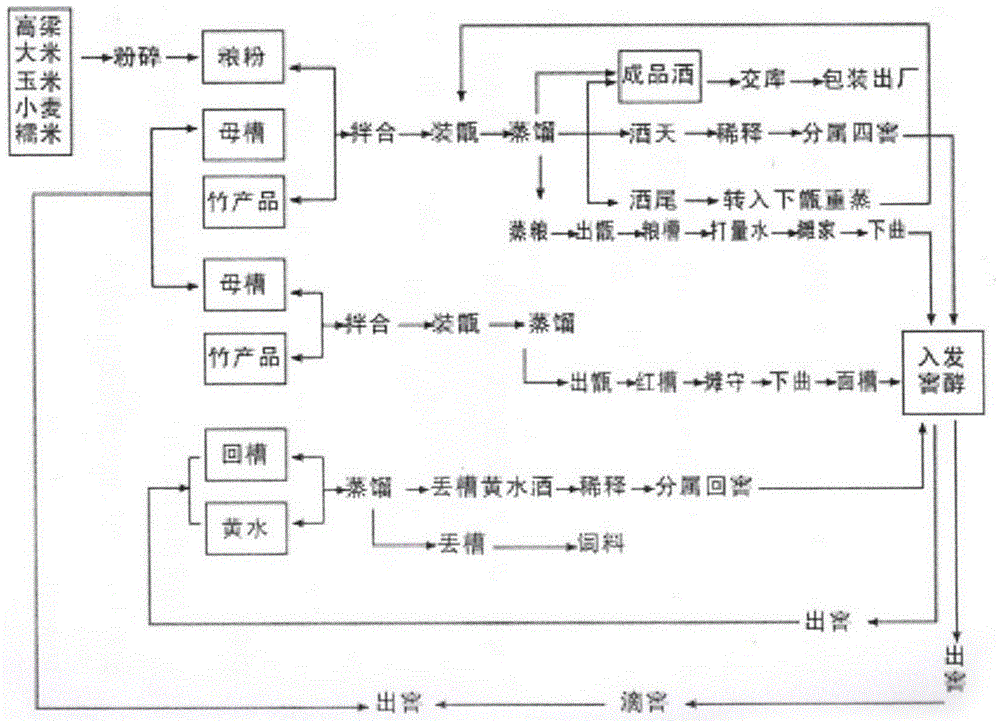

Method of making liquor by virtue of solid fermentation with bamboos as fluff

ActiveCN104651199APromote fermentationEasy to distillAlcoholic beverage preparationDistillationFood flavor

The invention discloses a method of making liquor by virtue of solid fermentation with bamboos as fluff. The method comprises the following steps: crushing clean bamboo products into particles with the particle size of 3-10mm, then steaming the particles of the bamboo products for 10-30 minutes, cooling, mixing the particles serving as the fluff, grains and vinasse, and carrying out solid fermentation to brew Fen-flavor bamboo wines, strong-flavor bamboo wines or soy sauce flavor bamboo wines, wherein the bamboo products are one or more of bamboo stems, bamboo leaves, bamboo branches and bamboo rhizome; and after crushing, the particle sizes of the bamboo rhizome and the bamboo stem are 8-10mm, the particle size of the bamboo branch is 5-8mm, and the particle size of the bamboo leaf is 3-5mm. According to the method disclosed by the invention, the bamboo products and the grains are used for brewing according to a certain ratio, so that the grains can be saved by 10-15 percent under the condition of the same yield of liquor; as different parts of the bamboos in different particle sizes are mixed as the fluff for brewing, the traditional hulls can be completely replaced; meanwhile, as the bamboos and the grains form a particle size gradient, fermentation and distillation of the grains are facilitated.

Owner:四川活之酿酿酒公社有限公司

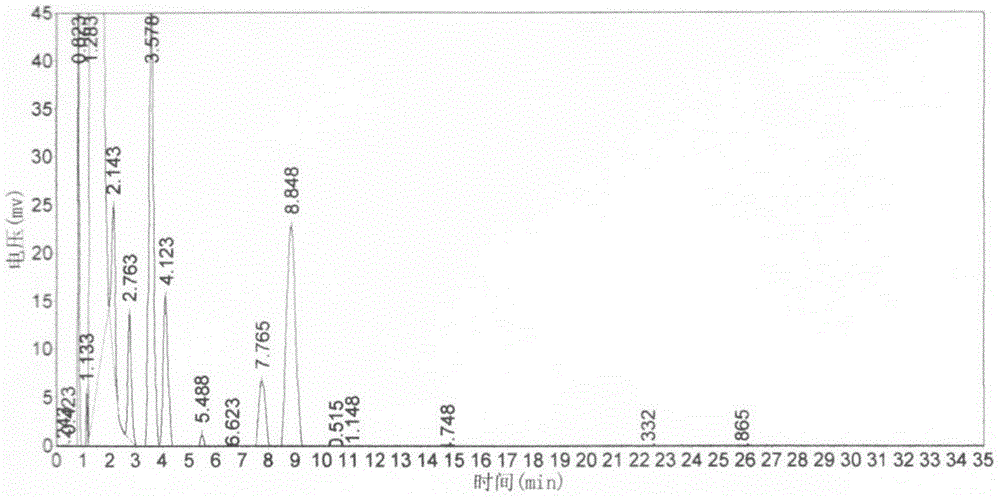

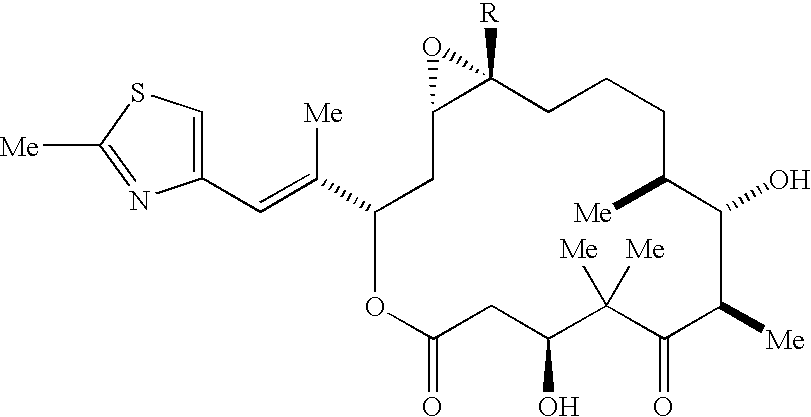

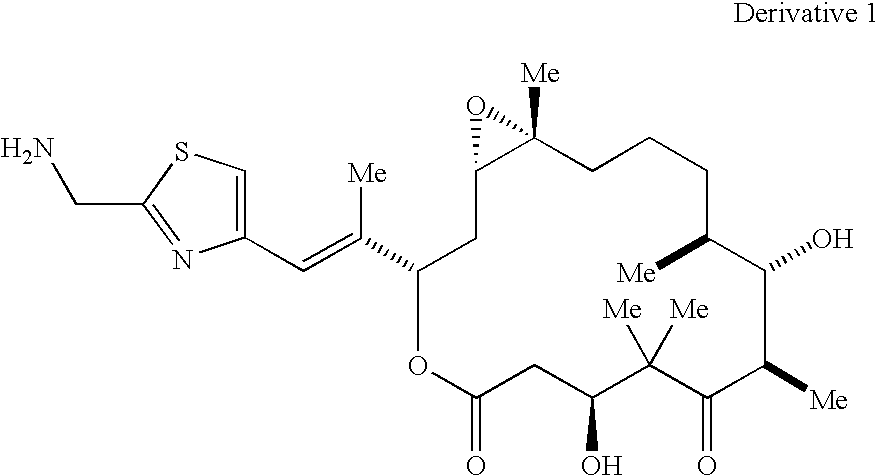

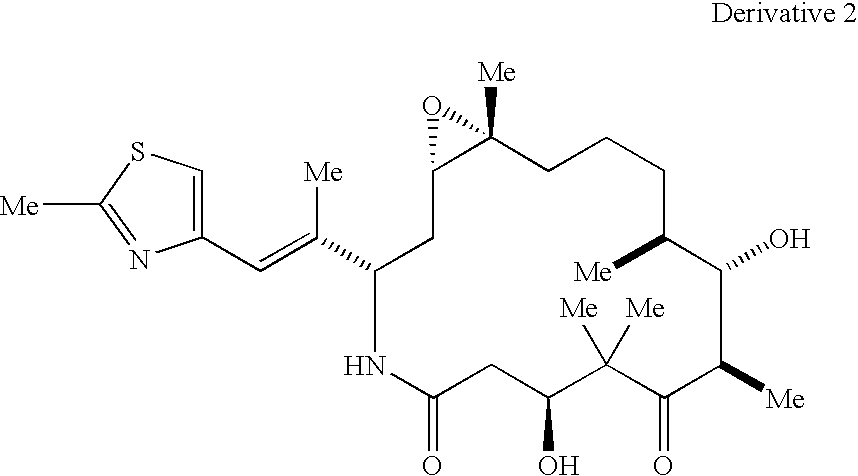

Methods for the preparation, isolation and purification of epothilone B, and x-ray crystal structures of epothilone B

ActiveUS20040132146A1Improve epothilone titerQuality improvementOrganic active ingredientsBiocidePurification methodsEpothilone B

The present invention relates to improved methods for the production, isolation and purification of epothilone B. These methods include, for example, a fermentation process for the production of epothilone B, isolation via adsorption onto a resin, and subsequent purification.

Owner:GESELLSCHAFT FUR BIOTECHNOLOGISCHE FORSCHUNG MBH GBF +1

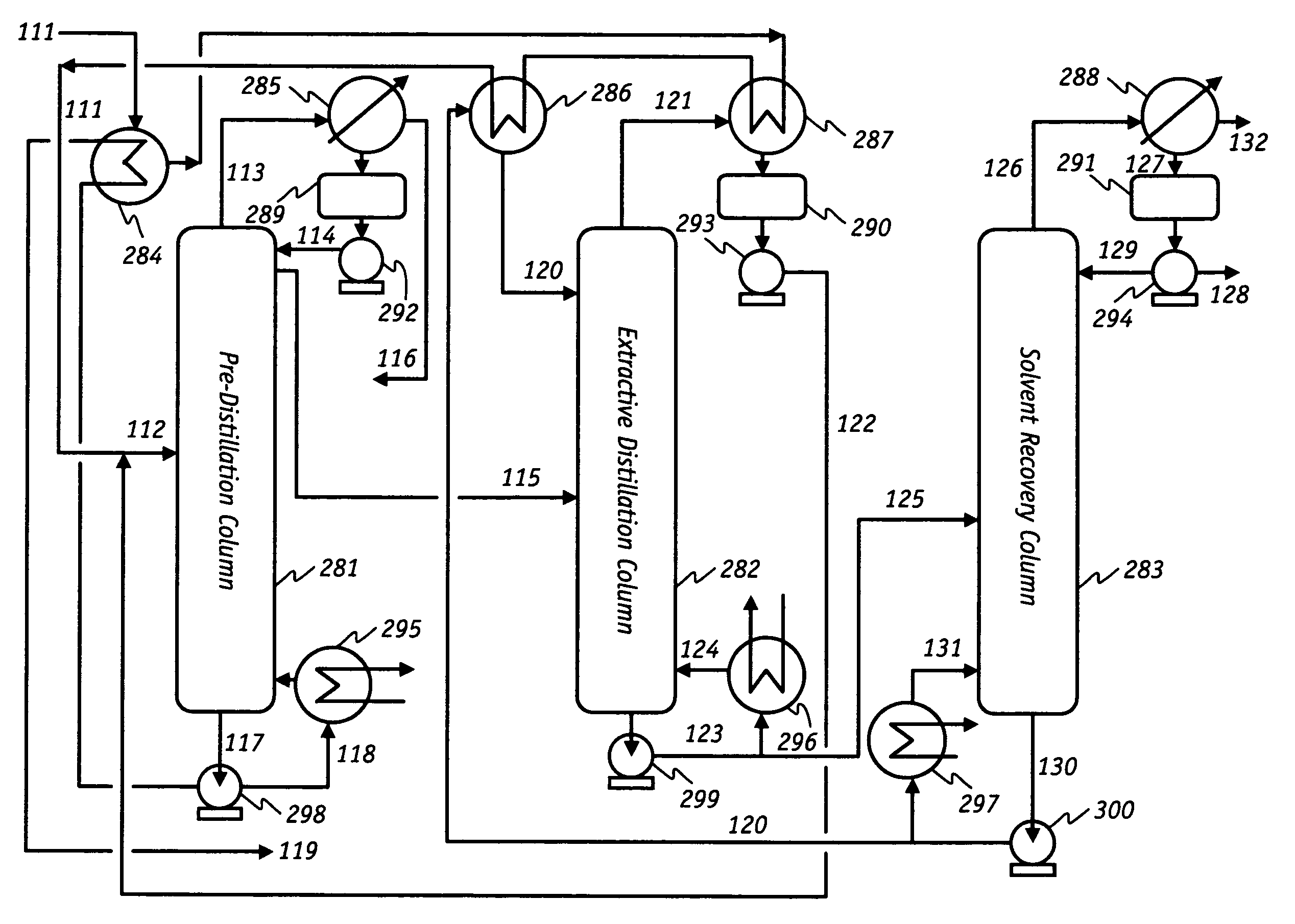

Low-energy extractive distillation process for dehydration of aqueous ethanol

ActiveUS8002953B2Energy efficiencyReduce energy inputFermented solutions distillation/rectificationOrganic compound preparationGas phaseExtractive distillation

Owner:AMT INT INC +1

Vacuum puffing process technique for Chinese traditional medicine

ActiveCN101129292AIncrease profitReduce consumption costPharmaceutical product form changeFood shapingAdditive ingredientTraditional medicine

The invention discloses a vacuum bulking manufacturing technique of traditional Chinese medicine, which is characterized by the following: adopting vacuum bulking technique to control and select the shape, size and moisture content of the traditional Chinese medicine to generate many pores at the cell wall of the traditional Chinese medicine; lixiviating and distilling the cell content to improve the extracting quantity of effective component or ingredient; fitting for extracting volatile oil component in the traditional Chinese medicine; opening a new path for drug value.

Owner:高尚先 +1

Method for extracting nervonic acid from oil of Mono Maple by using technique of molecular distillation

InactiveCN101092344ASimple stepsReasonable workmanshipCarboxylic compound separation/purificationChemistryEthyl ester

This invention relates to a method for extracting nervonic acid from Acer truncatum oil by molecular distillation. The method solves the problems of complex procedures, easy emulsification, high product acid value and low product purity faced by present technique. The method comprises: (1) preparing Acer truncatum oil; (2) performing deacidification treatment on Acer truncatum oil, removing oil foot, washing with water, and dehydrating; (3) mixing Acer truncatum oil, absolute ethanol and alkaline catalyst, esterifying, washing with water, and separating to obtain ethyl nervonate; (4) performing molecular distillation in different vacuum conditions and temperatures, and collecting the product.

Owner:陕西七彩生物科技有限公司

Method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores

InactiveCN102633233AFast sublimation volatilizationHigh puritySulfur compoundsEnergy inputVacuum pumpSulfur containing

The invention discloses a method for recovering sulfur from atmospheric-pressure oxygen-rich leached residues of lead-zinc ores, and particularly relates to the recovery of sulfur in lead-zinc ore leached residues through vacuum distillation, belonging to the field of reclamation and reuse of solid waste resources. The method comprises the following steps of: placing atmospheric-pressure oxygen-rich leached residues, subjected to drying, milling and screening pretreatment, of lead-zinc ores into a vacuum distillation furnace, heating the residues to 200-400 DEG C, and controlling the pressure of the inside of the furnace to 600-10000 Pa, so that sulfur in the leached residues is sublimated and volatilized; pumping sulfur-containing vapor out of the distillation furnace by a vacuum pump; and cooling the sulfur-containing vapor so as to obtain a sulfur product. After the distillation is completed and the sulfur is completely volatilized, high-boiling-point residues are discharged out of the distillation furnace in a solid powder form. In the whole process, the furnace is internally sealed, thereby avoiding the oxidation and environmental pollution of elemental sulfur. The method is simple in technological process and equipment, high in sulfur recovery rate and product quality, low in energy consumption, strong in adaptability to raw materials and pollution-free, so that the method disclosed by the invention is an economic and efficient sulfur extraction method and can realize the zero discharge of waste smelting residues in a lead-zinc wet process, thus the method has broad application prospects.

Owner:CENT SOUTH UNIV

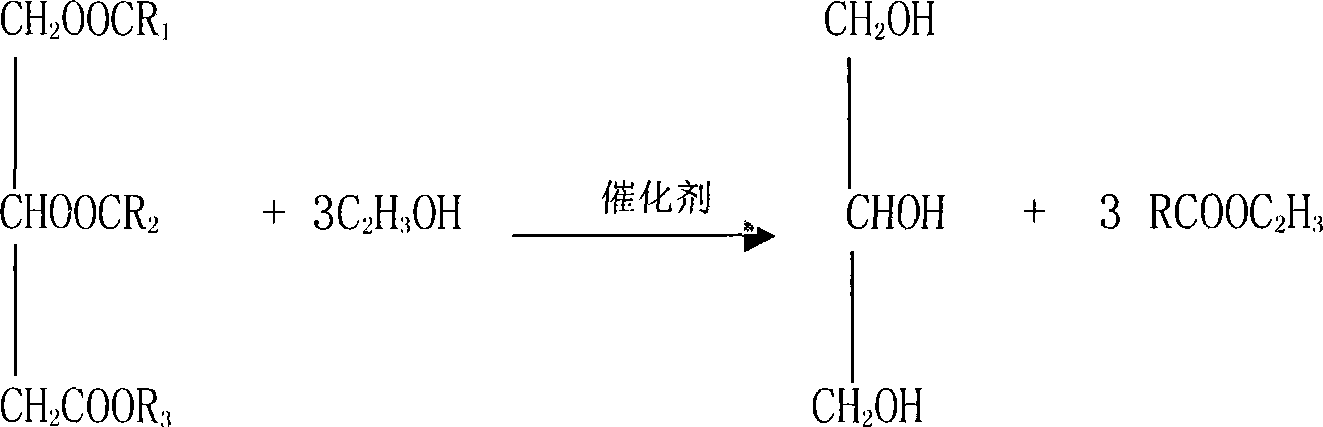

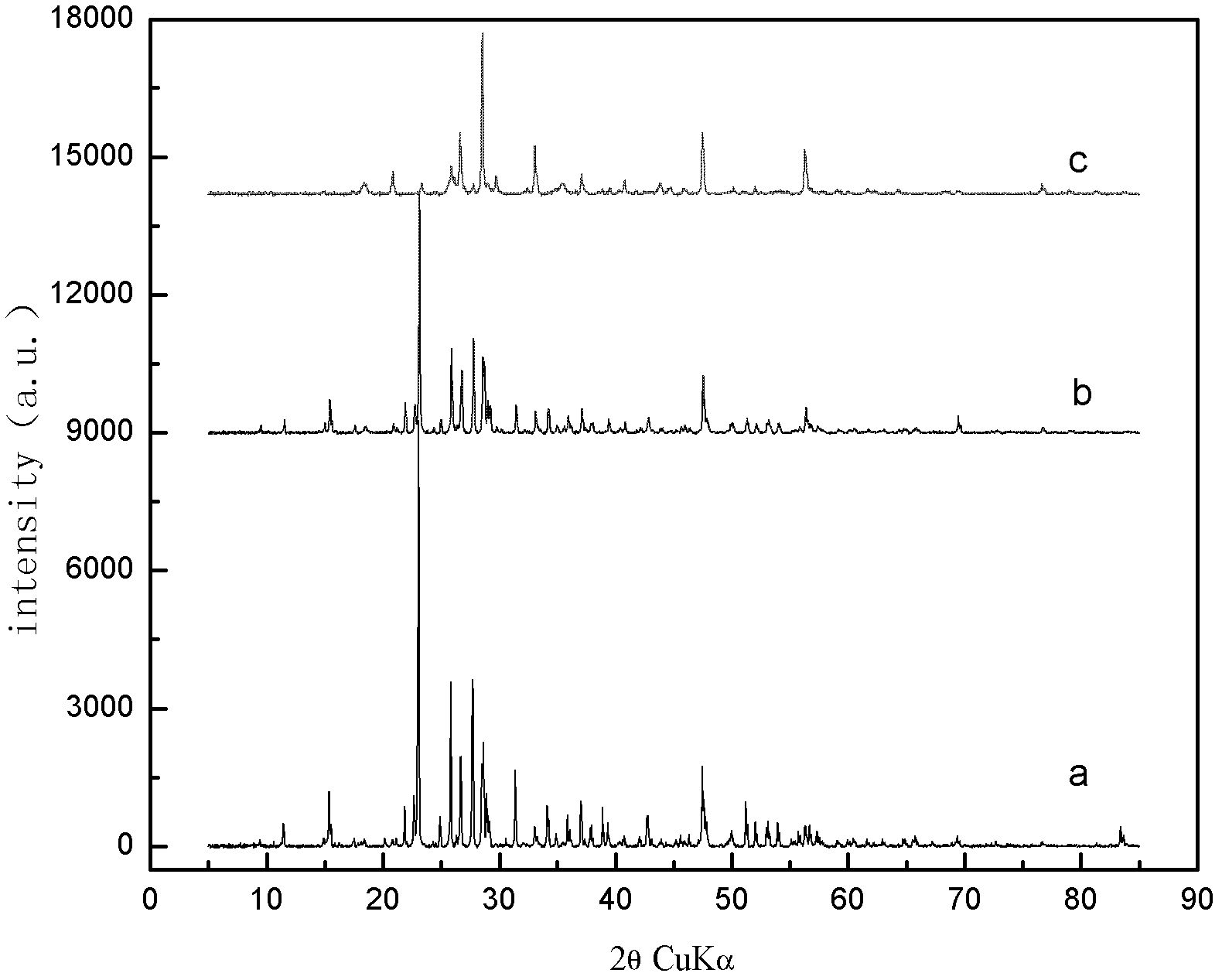

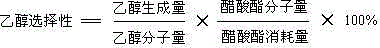

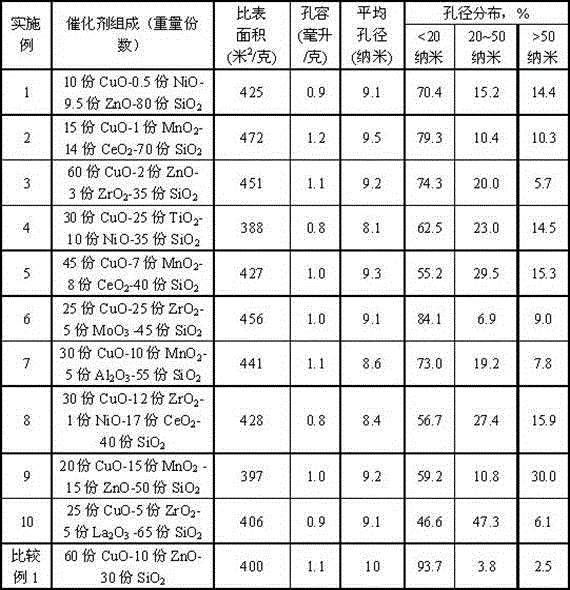

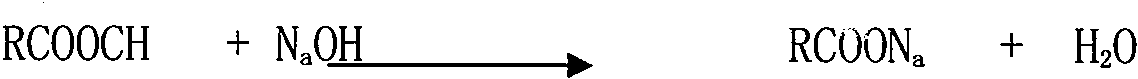

Catalyst and method for preparing ethanol by hydrogenating acetic ester

InactiveCN104148079ALarge specific surface areaIncrease chance of contactOrganic compound preparationHydroxy compound preparationHydrogenGram

The invention relates to a catalyst and a method for preparing ethanol by hydrogenating acetic ester and mainly solves the problems that in the prior art, the ratio of hydrogen to ester is too high, the conversion rate of raw materials is low and the selectivity of ethanol is poor. The catalyst is composed of the following components in parts by weight: (a) 5-80 part of metallic copper or copper oxide, (b) 0.05-60 parts of catalyst promoter and (c) 5-90 parts of silicon dioxide carrier, wherein the catalyst promoter is selected from at least one of transitional metal or oxide of the transitional metal; the specific area of the catalyst is 150-500 m<2> per gram; the total pore volume is 0.1-3.0 ml / gram; the pore volume of the diameter less than 20nm is 40-90% of the total pore volume; the pore volume of the diameter less than 50nm and larger than 20nm is 5-75% of the total pore volume; and the pore volume of the diameter larger than 50nm is 5-75% of the total pore volume. By adopting the technical scheme, the problems are well solved; and the catalyst can be used for industrial production of ethanol by hydrogenating acetic ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

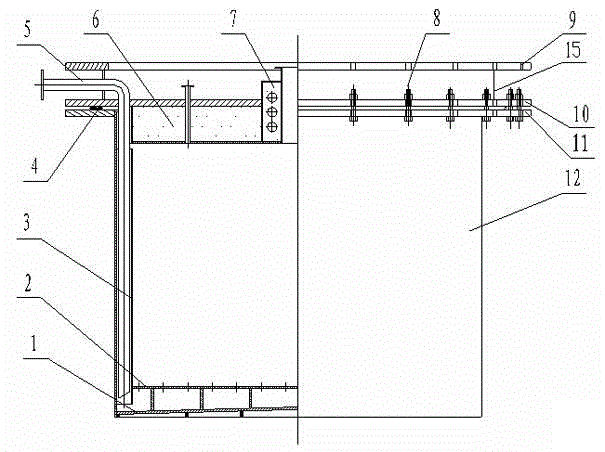

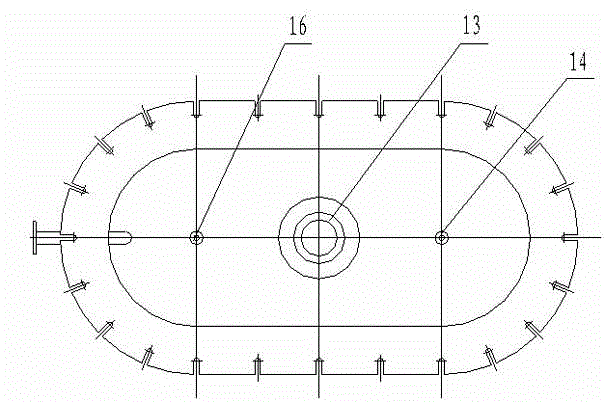

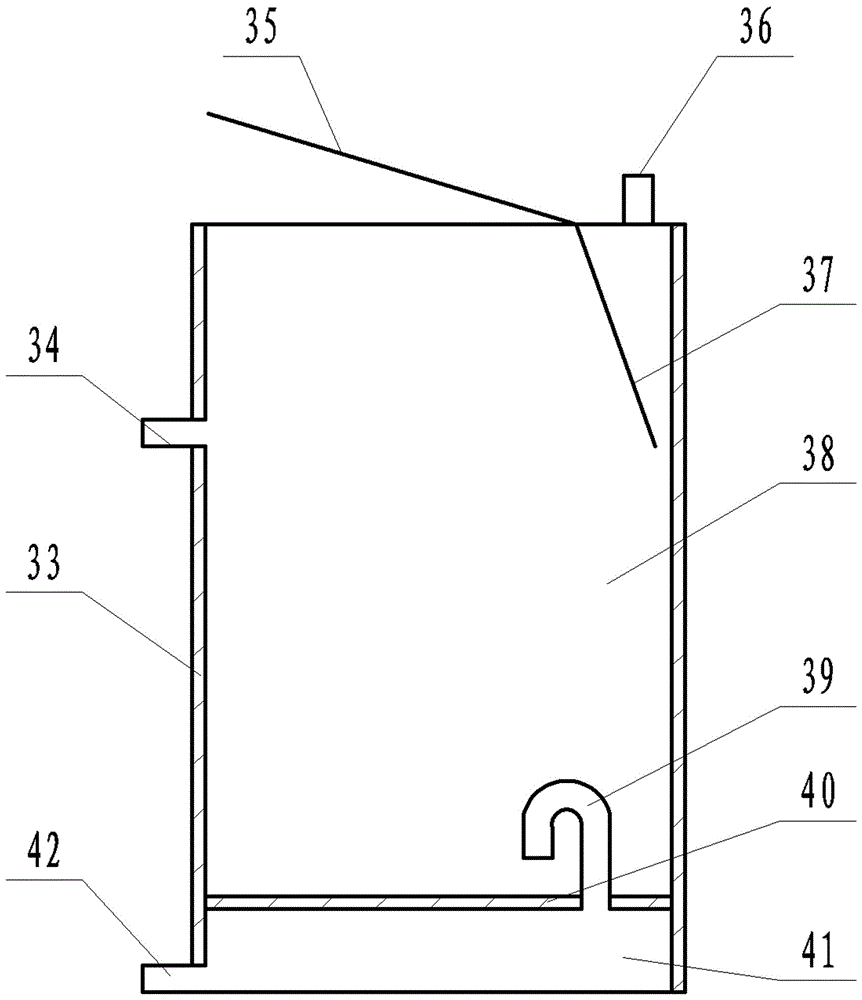

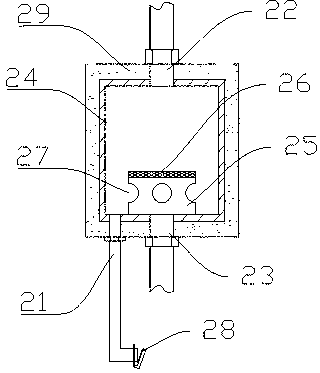

Sponge titanium reduction distillation reactor and production technique thereof

The invention relates to a sponge titanium reduction distillation reactor which is formed by connecting a tank body and a large cover through a flange rubber cushion and a bolt set, wherein the tank body comprises a bottom plate, a sieve plate, a magnesium chloride discharge casing, a tank body flange and a waist-type cylinder; the large cover comprises a magnesium chloride discharge pipe, a thermal insulation layer, an internal heating device, a large cover upper flange, a large cover lower flange, a central pipe, a charging casing 1, a short cylinder and a charging casing 2; the integral reactor is in a stereoscopic waist circular structure; and the bottom plate is a sloping plate positioned on the lowest part of the whole reactor, and is matched with the waist-type cylinder to form an open stereoscopic waist-type tank body. The integral effective width of the reactor is 1.2-1.5 meters, the height is 1.5-2.5 times of the width, and the length is 2-3 times of the width. The reactor for producing sponge titanium can change the sponge titanium structure, solve the problem of compactness, greatly enhance the overall charging rate, simplify the distillation process and greatly shorten the period.

Owner:罗时雨

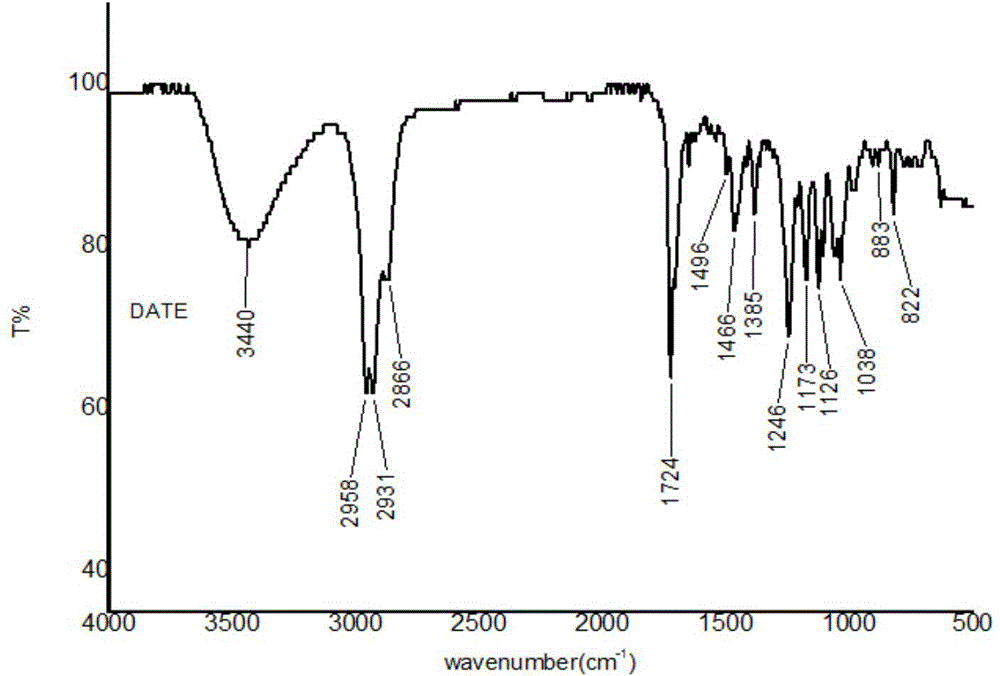

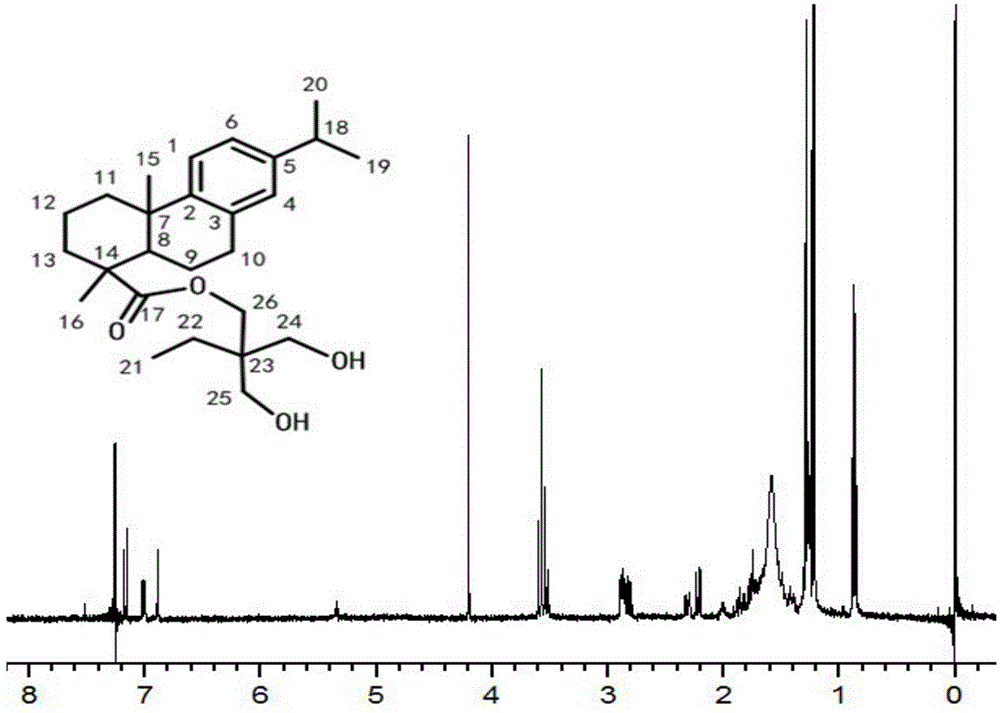

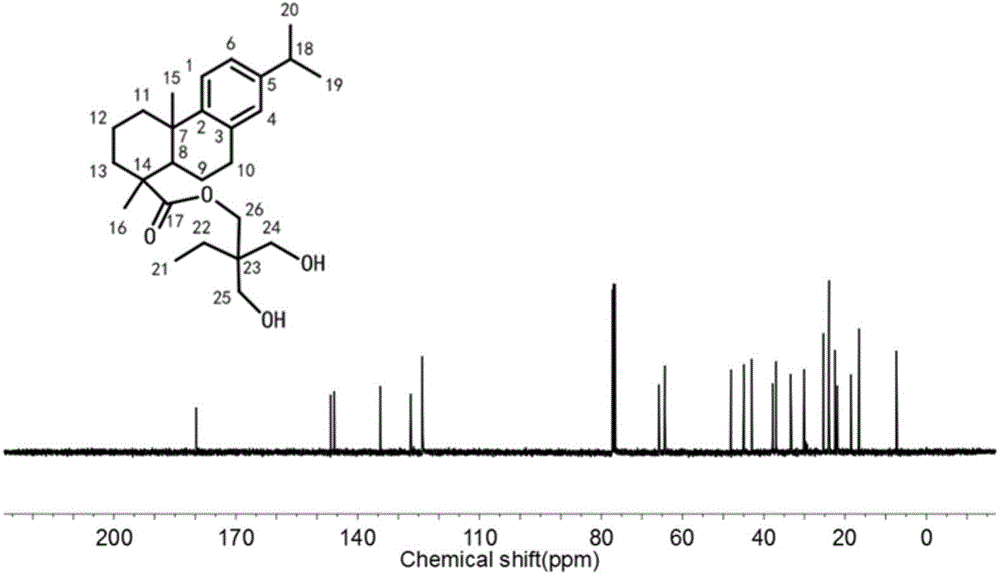

Rosin triol ester as well as preparation method and application thereof

InactiveCN104693024ABiodegradableLow costOrganic compound preparationTransportation and packagingTrimethylolpropaneTriol

The invention discloses a rosin triol ester and a preparation method therefore. The chemical name of the rosin triol ester is trimethylolpropane dehydroabietyate. The preparation method of the rosin triol ester comprises the following steps: by taking dehydroabietic acid and trimethylolpropane as the raw materials, EDC / DMAP as the catalysts, and any one of methylene chloride, tetrahydrofuran and N,N-dimethyl formamide as the solvent, performing an esterification reaction at normal temperature to synthesize the trimethylolpropane dehydroabietyate. The esterification method is completed in one step; the steric hindrance can be effectively overcome; the yield is high; the reaction is performed at room temperature so that the energy consumption can be reduced; the byproducts are soluble in water and easy to purify; the smell is light and few three wastes are generated; and the solvent selection range is wide. The ester prepared by use of the method is wide in use, and can be used as plasticizers and modifiers of various resins, excellent adhesives for pressure-sensitive and thermosensitive adhesive tapes, hot melt coatings, surface activators and pharmaceutical vectors.

Owner:GUANGXI UNIV FOR NATITIES

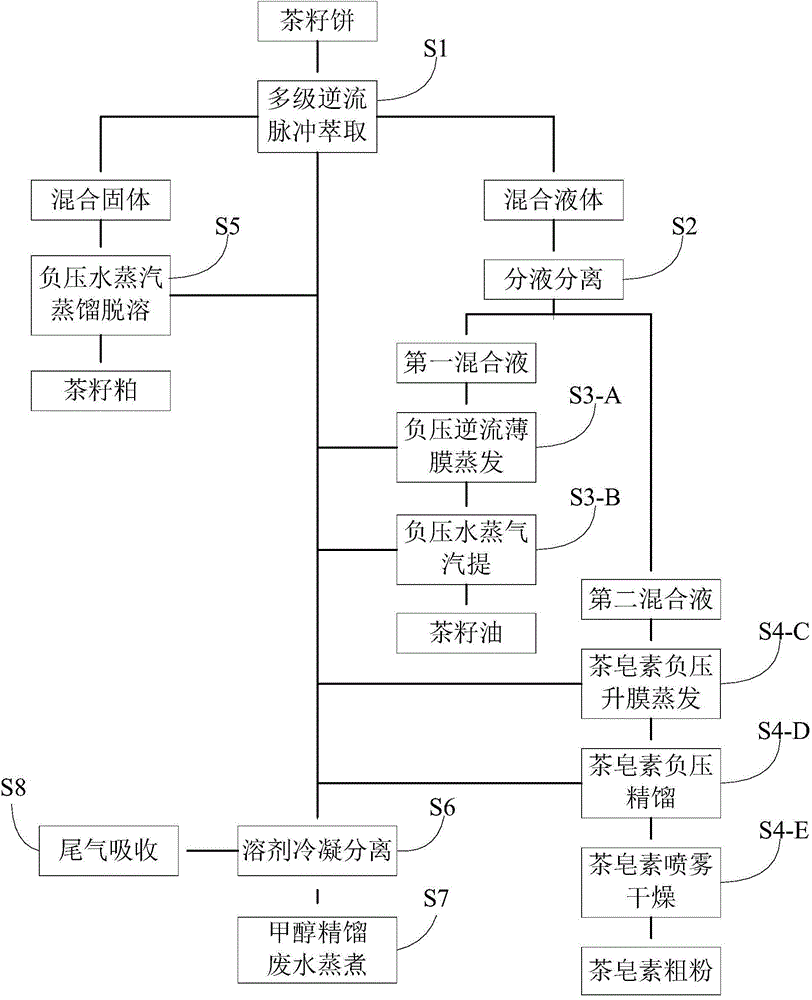

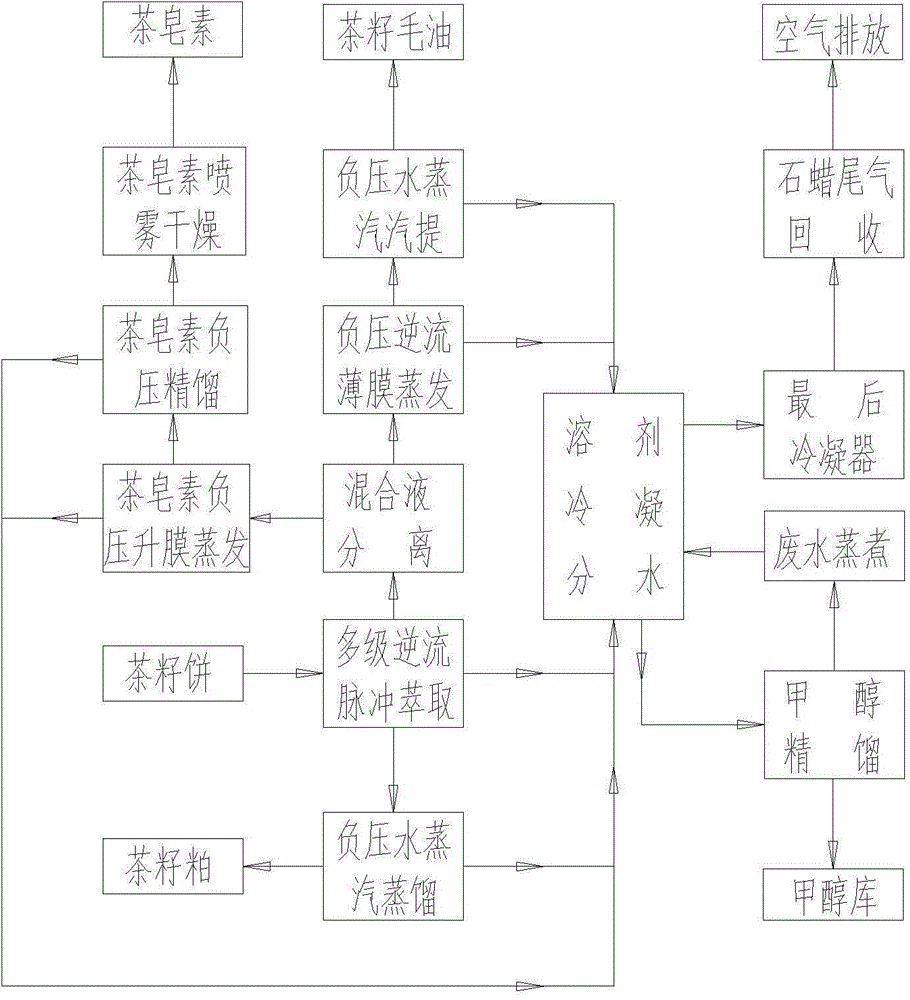

Production method of synchronously extracting tea-seed oil and tea saponin from tea seed cakes

The invention discloses a production method of synchronously extracting tea-seed oil and tea saponin from tea seed cakes. The production method comprises the following steps: multi-stage impulse countercurrent extraction: feeding the tea seed cakes to an extractor and carrying out N-stage spraying and soaking extraction by using an extracting agent containing tea-seed oil and tea saponin to obtain a mixed solution and a mixed solid, wherein the mass fraction of the tea-seed oil in the extracting agent used in the Mth-stage spraying and soaking extraction is higher than that of tea-seed oil in the extracting agent used in the (M-1)th-stage spraying and soaking extraction, and M is greater than or equal to 2 but less than or equal to N; skimming and separating: filtering and skimming the mixed solution to obtain the first mixed solution containing tea-seed oil and a second mixed solution containing saponin; extracting the tea-seed oil: evaporating and steam-stripping the first mixed solution to obtain the tea-seed oil; extracting the saponin: evaporating, distilling and drying the second mixed solution to obtain tea saponin crude powder. The production method disclosed by the invention is suitable for industrial production on a large scale, solves the problem that the yield of tea saponin is low and the input of the extracting agent is great, and is energy-saving and consumption-reducing, and particularly free of environmental pollution.

Owner:安徽嘉旗粮油工程技术有限公司

Process for recovery of formic acid

InactiveUS20110137051A1Easy to distillSlow collection rateOrganic compound preparationChemical recyclingLevulinic acidPropanoic acid

The invention relates to a process for the recovery of concentrated high purity formic acid having a concentration of at least 50%, most preferably at least 95%, from biomass wherein an aqueous liquid mixture containing levulinic acid and possibly furfural is subjected to a liquid-liquid extraction step, followed by the recovery of furfural, formic acid and levulinic acid.

Owner:TAMINCO FINLAND

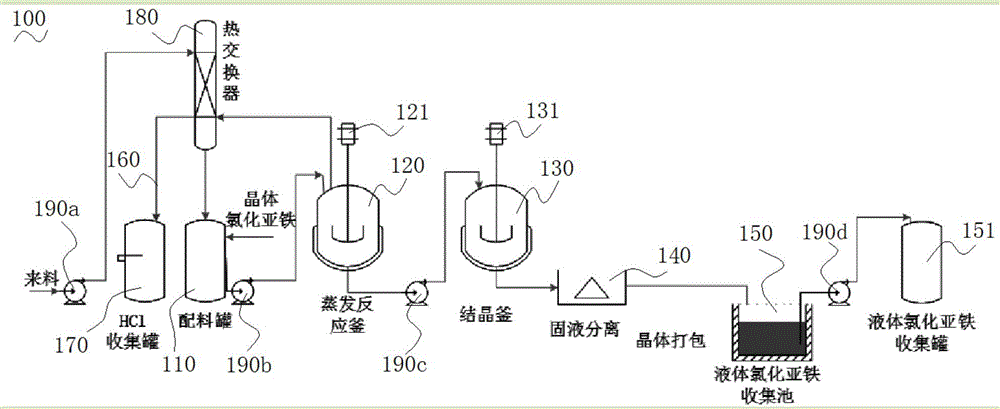

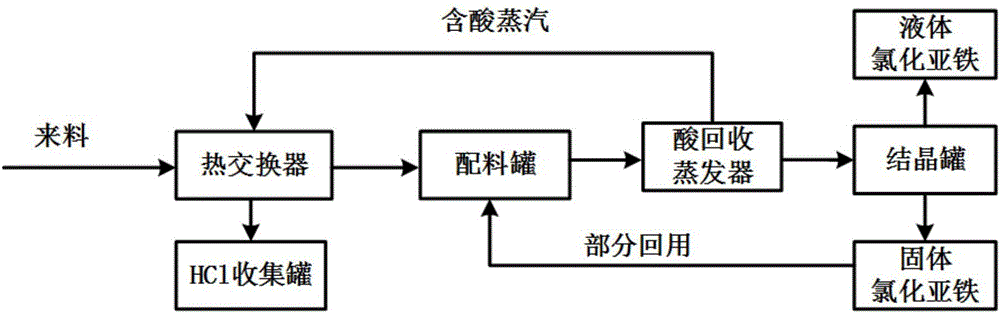

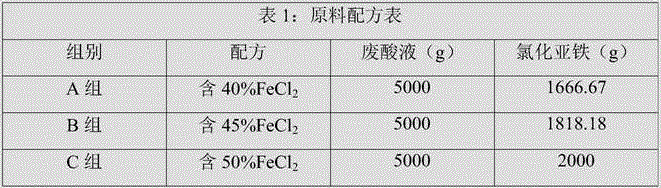

Continuous-production reduced pressure distillation device and process for recovering iron-containing waste acid liquid

ActiveCN106430100AAchieve separationEnable recyclingChlorine/hydrogen-chloride purificationDistillationResource utilization

The invention relates to the field of the recovery of waste acids, and particularly relates to a continuous-production reduced pressure distillation device and a continuous-production reduced pressure distillation process for recovering iron-containing waste acid liquid. The continuous-production reduced pressure distillation device comprises a blending tank, an evaporation reaction kettle, a crystallization kettle, a solid-liquid separation tank, a ferrous chloride solution collection pool and a ferrous chloride solution collection tank, and also comprises an exhaust pipe and a HCl collection tank, wherein the blending tank is used for blending a ferrous chloride solution; the evaporation reaction kettle is connected with an output end of the blending tank and is used for evaporating the ferrous chloride solution to be concentrated liquid; the crystallization kettle is connected with an output end of the evaporation reaction kettle and is used for separating out a ferrous chloride crystal from the concentrated liquid; the solid-liquid separation tank is connected with an output end of the crystallization kettle and is used for separating the crystallized ferrous chloride crystal from the ferrous chloride solution; the ferrous chloride collection pool and the ferrous chloride collection tank are connected with an output end of the separation tank and are used for collecting the separated ferrous chloride solution; the exhaust pipe is connected with the top of the evaporation reaction kettle and is used for outputting evaporated acid-containing steam; the HCl collection tank is connected with the exhaust pipe and is used for collecting the acid-containing steam. The continuous-production reduced pressure distillation device and the continuous-production reduced pressure distillation process for recovering the iron-containing waste acid liquid are low in treatment cost, high in treatment efficiency, low in safety production requirement and free from secondary pollution; the resource utilization rate can be improved.

Owner:江门市崖门新财富环保工业有限公司

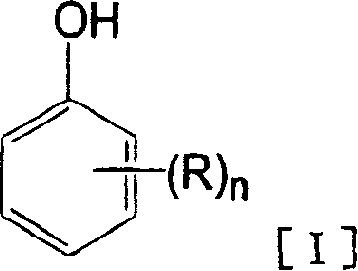

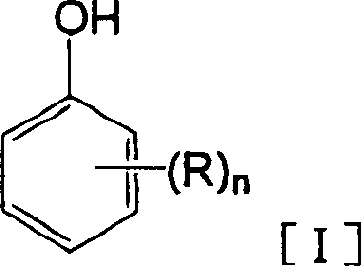

Process for production of hydroxybenzoic acids

InactiveCN1784373AHigh yieldInhibition of the Körber-Schmidt reactionOrganic compound preparationCarboxylic compound preparationAlcoholOrganic solvent

The present invention provides a method for producing a hydroxybenzoic acid compound, comprising: preparing an alkali metal salt of a phenolic compound from a phenolic compound, and reacting the resulting alkali metal salt of a phenolic compound with carbon dioxide, wherein, preparing from a phenolic compound The step of the alkali metal salt of the phenolic compound comprises the steps of: a) reacting an alkali metal alkoxide with an excess of the phenolic compound, the phenolic compound being in excess of the alkali metal alkoxide, to form an alkali metal salt of the phenolic compound; and b) While carrying out step a), the alcohol formed is distilled off from the reaction. The method of the present invention can produce hydroxybenzoic acid compound with high yield without using aprotic polar organic solvent.

Owner:UENO PHARMA CO LTD

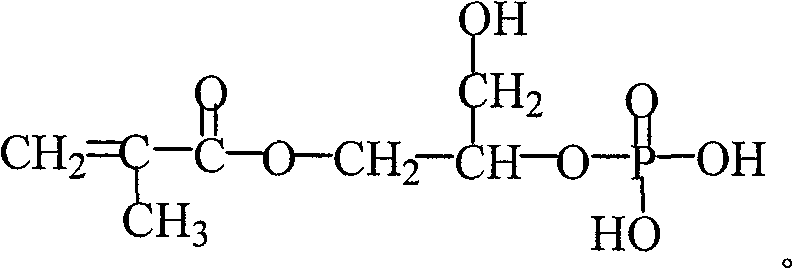

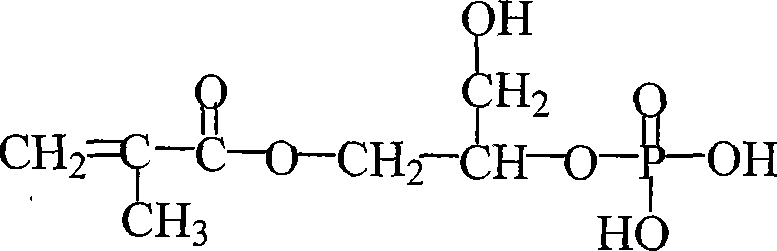

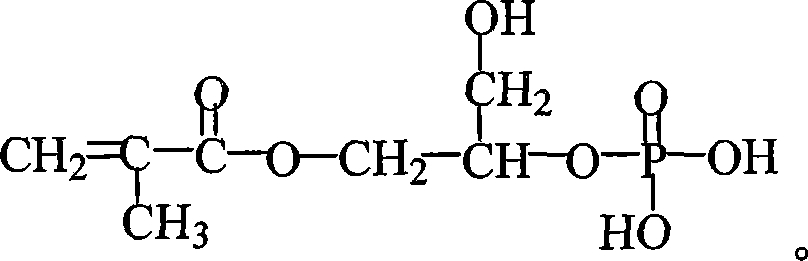

Reactive phosphoric acid esters emulsifying agents and method for preparing same

InactiveCN101284846BImprove antistatic performanceGood emulsifying effectTransportation and packagingMixingMethacrylatePhosphoric Acid Esters

The invention relates to a reaction-type phosphate ester-class functional emulsifying agent and a method for making the same. The chemical structure of the reaction-type phosphate ester-class functional emulsifying agent is as above. The functional emulsifying agent, adopting epoxypropyl methacrylate and phosphoric acid as raw material, acetone as reaction medium and hydrochinone as polymerization inhibitor, is obtained after solvent is removed through vacuum distillation when reaction is finished at a lower temperature. The functional emulsifying agent not only has the advantages of ordinaryfunctional emulsifying agent, but also has an anti-rust function. Therefore, the method provides an emulsifying agent with outstanding performances for the development of aqueous anti-rust paint, andhas tremendous application value.

Owner:NORTHWEST NORMAL UNIVERSITY

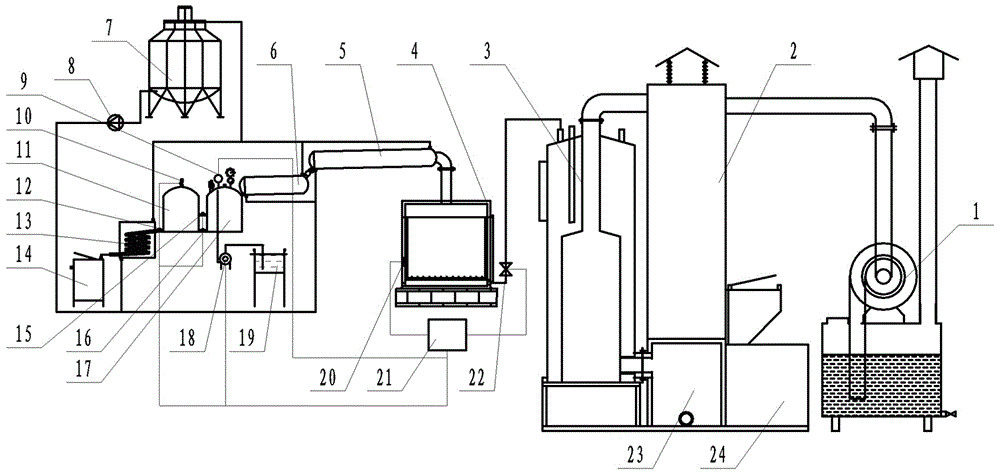

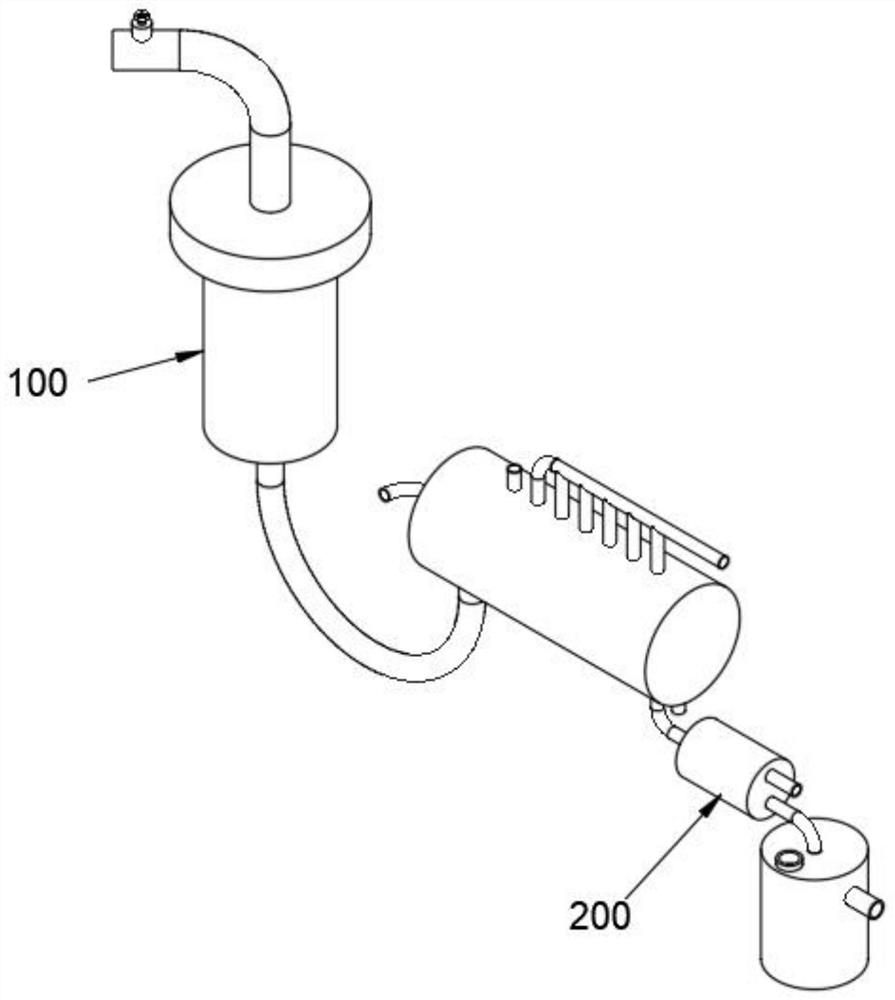

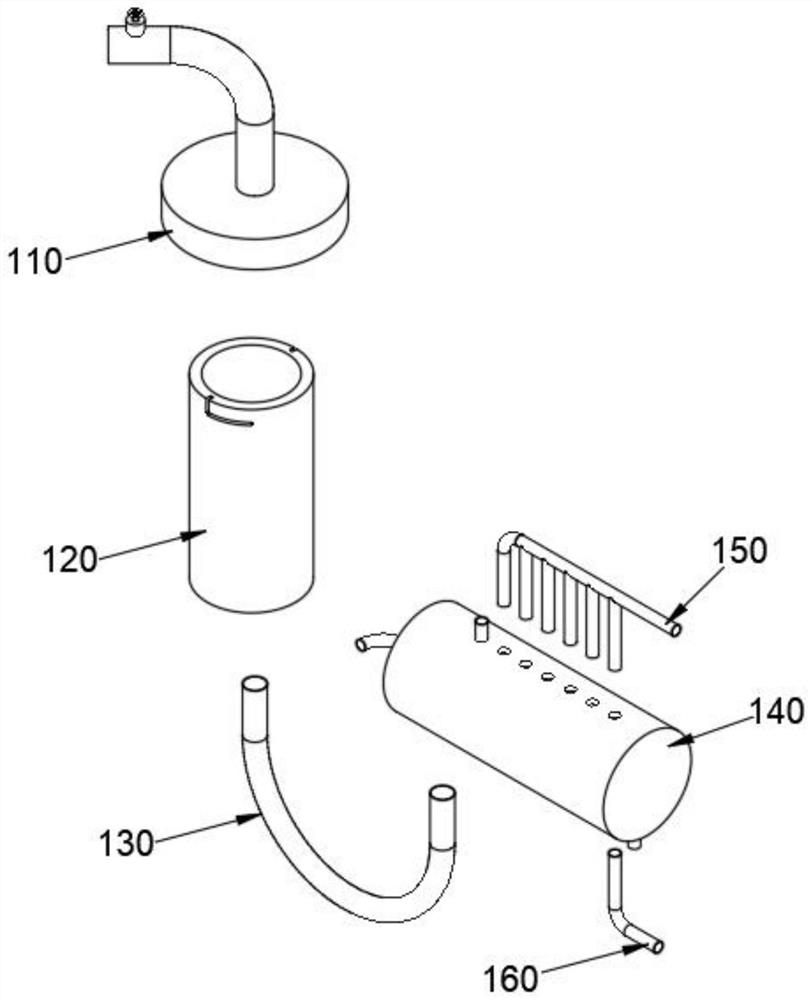

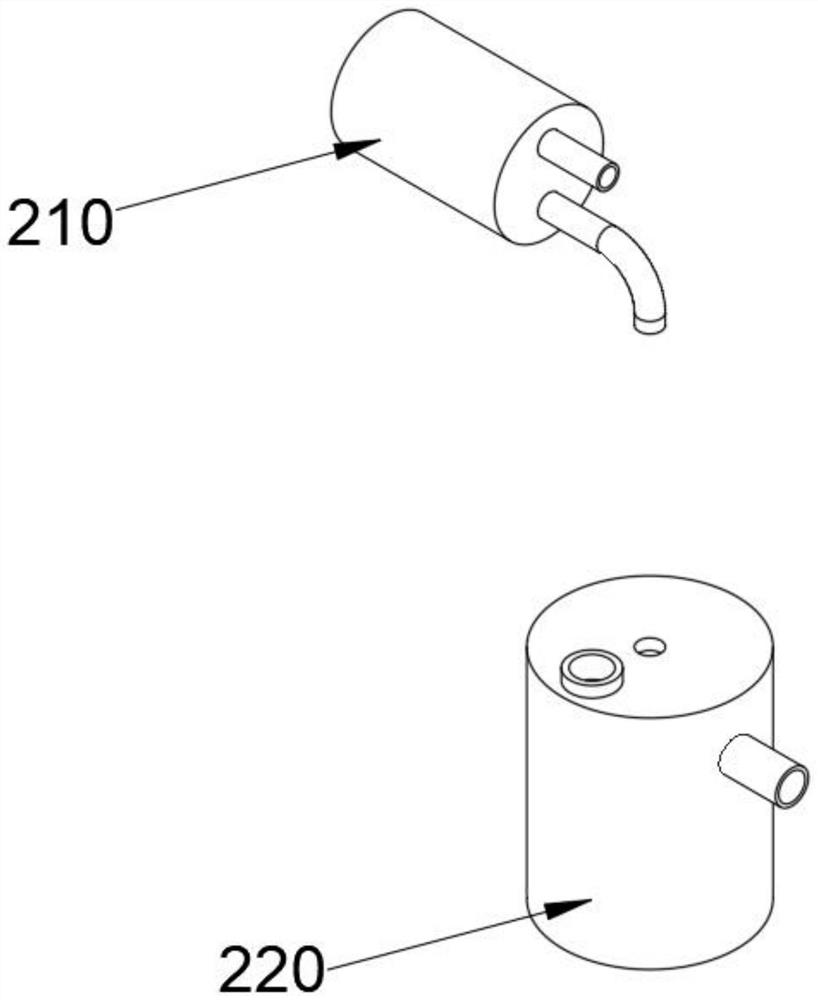

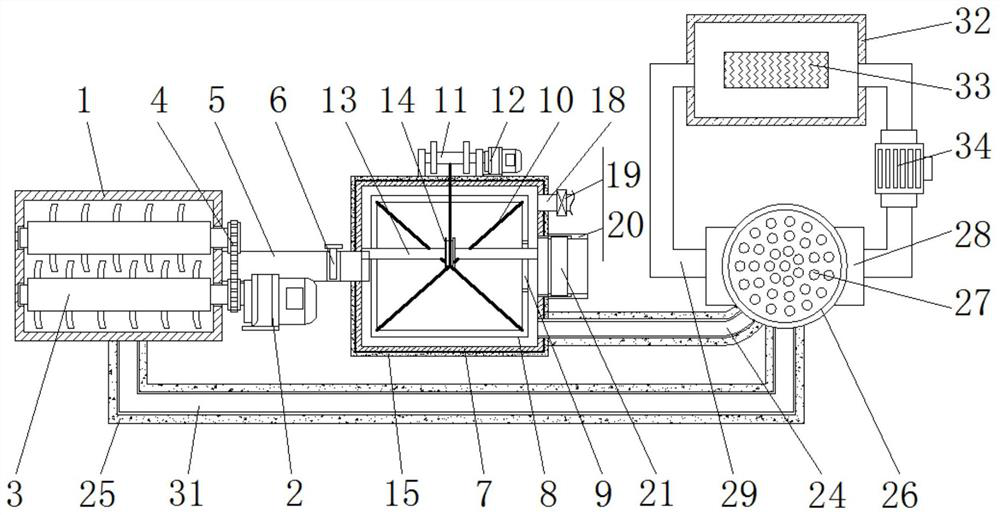

Distilling production method for sandalwood essential oil and equipment

InactiveCN105733814AAvoid enteringPrevent flashbackEssential-oils/perfumesEngineeringProcess engineering

The invention discloses a distilling production method for sandalwood essential oil.The method comprises the specific steps that 1, a sandalwood plant raw material is smashed into fragments with the thickness of 1 millimeter to 6 millimeters, and the fragments are placed in a distilling cabinet; 2, steam generated by a steam boiler is led into the distilling cabinet, and the sandalwood fragments are distilled; 3, tail gas of the steam boiler is processed through a first-level dust remover and a second-level dust remover before being discharged out of a chimney; 4, the steam discharged from the distilling cabinet passes through a first-level condenser and a second-level condenser before entering a receiving tank and an excessive receiving tank, and distillate is obtained; 5, the pressure in the receiving tank is kept between 0.01 Mpa and 0.3 Mpa; 6, the distillate in the excessive receiving tank passes through a third-level condenser before being discharged into a fractionation barrel; 7, the distillate is discharged out of an essential oil outlet of the fractionation barrel, and then the sandalwood essential oil is obtained.The method is simple, the oil is discharged quickly, time is short, the obtained sandalwood essential oil is high in quality, and adopted equipment is easy to operate.

Owner:GUANGXI GUIGANG HONGLI BIOENERGY TECH CO LTD

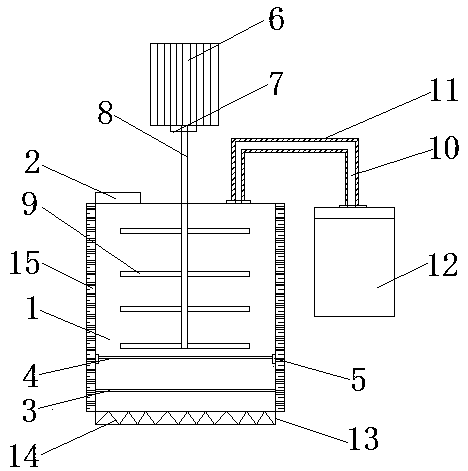

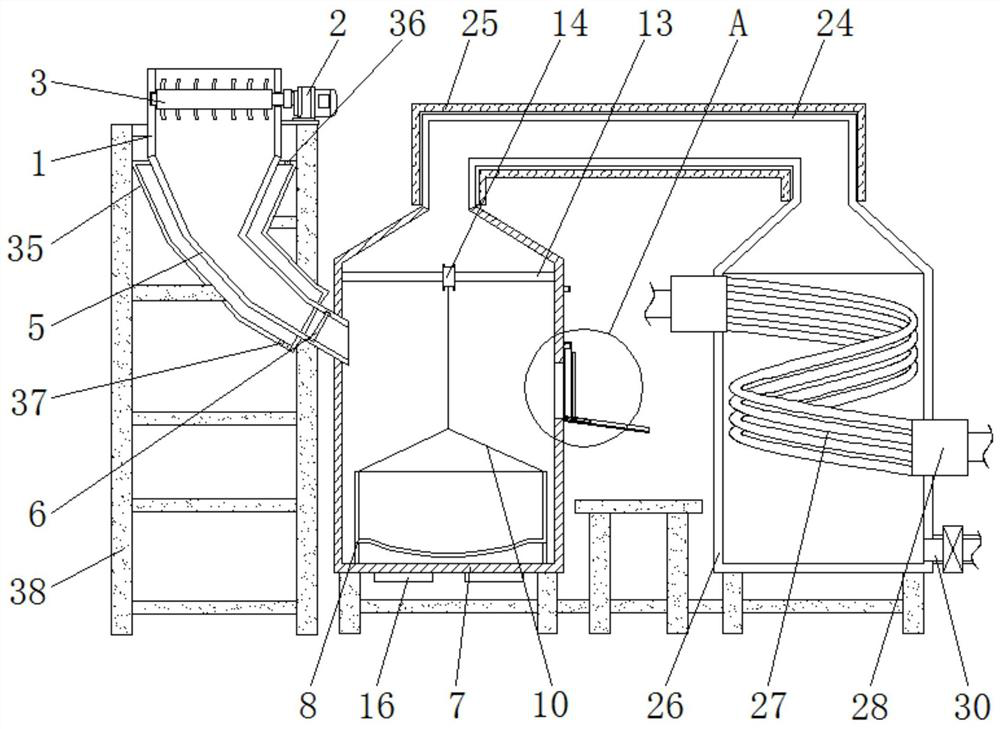

Traditional Chinese medicine extraction apparatus

InactiveCN108201707ASimple structureEasy to useRotary stirring mixersTransportation and packagingRefluxThermal insulation

The invention discloses a traditional Chinese medicine extraction apparatus, which comprises an extraction tank, a motor and a liquid storage tank, wherein the bottom portion of the extraction tank isfixedly connected to a heating chamber, heating wires are uniformly spread in the heating chamber, the outer wall of the extraction tank is wrapped with a thermal insulation jacket, the top portion of the extraction tank is fixedly connected to the liquid storage tank through a steam pipe, the outer surface of the steam pipe is wrapped with a thermal insulation layer, the other side of the top portion of the extraction tank is further provided with a material inlet, and a speed reducer and a stirring shaft are fixedly arranged on the bottom portion of the motor. According to the present invention, the traditional Chinese medicine extraction apparatus has advantages of simple structure and convenient use; the extraction tank can be subjected to effective thermal insulation by fully considering the situation encountered in the extraction of the traditional Chinese medicine, such that the distilling can be easily performed, and the reflux caused by the liquidification of the medicine liquid steam entering the liquid storage tank can be avoided; and the solution in the extraction tank can be stirred, such that the medicine liquid is uniform, the uniform heating on the extraction tankcan be achieved, and the components of the medicine liquid steam can be uniform.

Owner:刘红

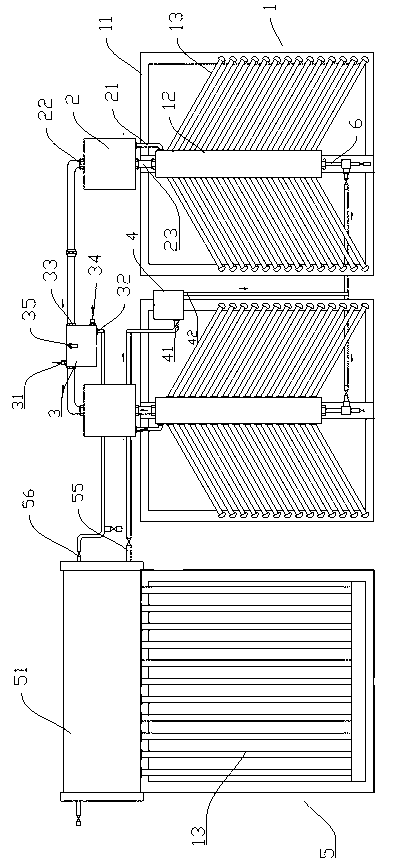

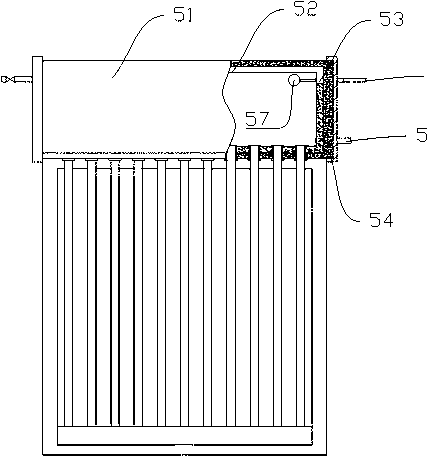

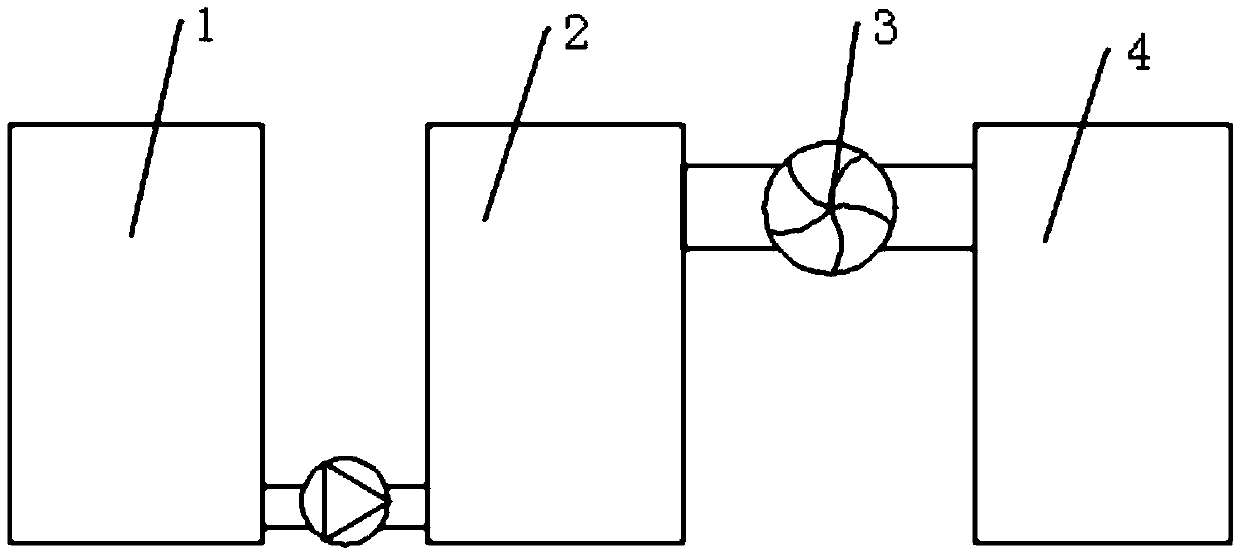

Solar seawater desalination system

ActiveCN103342400AFast deliveryQuick Pass PoolingGeneral water supply conservationSeawater treatmentWater circulationEngineering

The invention discloses a solar seawater desalination system, comprising a solar heating device, a steam-water separator, a condensation device, a water supplementing device and a warming and heat-storing device, wherein a header is vertically arranged, a water supplementing outlet of the water supplementing device is communicated with a water inlet of the header, the steam-water separator is arranged between and connected with an upper end opening of the header and the condensation device, a steam separating opening of the steam-water separator is communicated with a steam inlet of the condensation device, and a water supplementing inlet of the water supplementing device is connected with the warming and heat-storing device. The solar seawater desalination system provided by the invention is used for solar seawater desalination and has the characteristics of a fast water circulation speed, rapid heat transfer, long duration of continuous distillation, little influence by weather, good adaptability, etc. Moreover, in the operation process of the system, integral power consumption and energy dissipation are small, operation cost is low, latent heat of cooling of steam is effectively used, and a high utilization rate of solar energy is realized.

Owner:SHANDONG KAIYUAN ELECTRONICS

Preparation method of solid vanadyl sulfate

ActiveCN110395766AAlleviate technical obstacles that are easy to extract but difficult to reverseLow densityVanadium compoundsSteelmakingDistillation

The invention relates to a preparation method of solid vanadyl sulfate. The preparation method comprises the following steps: roasting and leaching steelmaking converter vanadium slag to obtain a vanadium-containing solution; carrying out targeted iron removal and vanadium valence conversion, carrying out impurity removal and purification by using a solvent extraction method, and carrying out mixed acid back extraction to obtain a high-purity vanadyl sulfate solution; and finally, carrying out direct negative pressure distillation crystallization to obtain the solid vanadyl sulfate. The methodis simple in technological process and low in cost, and large-scale industrial preparation can be achieved. A tetravalent vanadium solution is purified by adopting a solvent extraction method for impurity removal and purification, and impurity elements such as iron, manganese, chromium, zinc, calcium and magnesium can be effectively removed by controlling proper technical parameter conditions.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

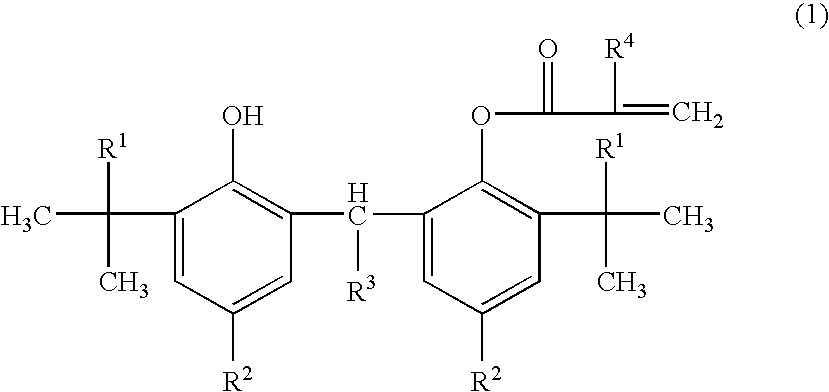

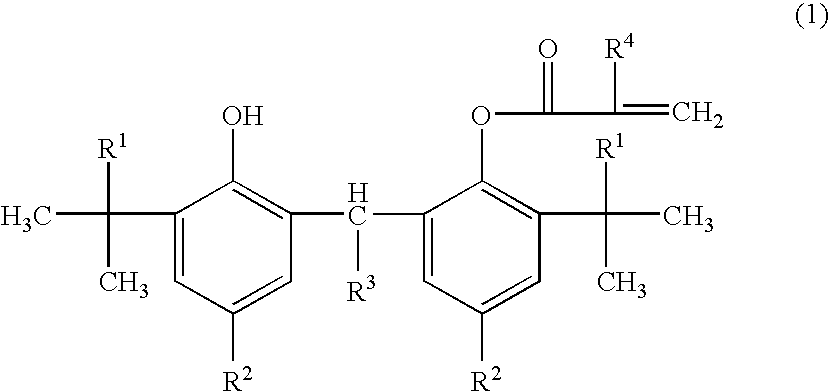

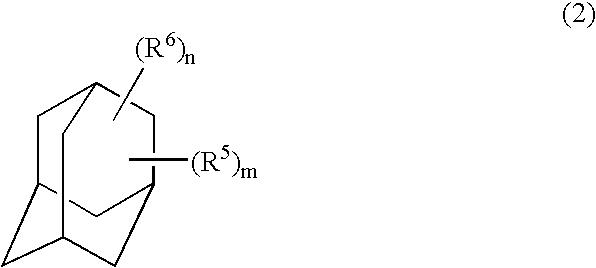

Adamantyl ester monomer composition

InactiveUS6861552B2High purityPrevent gelPreparation from carboxylic acid halidesOrganic compound preparationMonomer compositionHydrogen atom

The present invention discloses an adamantyl ester monomer composition characterized by containing at least an adamantyl ester monomer having at least one polymerizable unsaturated bond in the molecule, and a compound represented by the following general formula (1): (in the formula, R1 is an alkyl group of 1 to 5 carbon atoms, R2 is an alkyl group of 1 to 5 carbon atoms, R3 is a hydrogen atom or an alkyl group of 1 to 5 carbon atoms, and R4 is a hydrogen atom or a methyl group). The composition has high storage stability and, by subjecting it to distillation, an adamantyl ester monomer of high purity can be obtained easily.

Owner:TOKUYAMA CORP

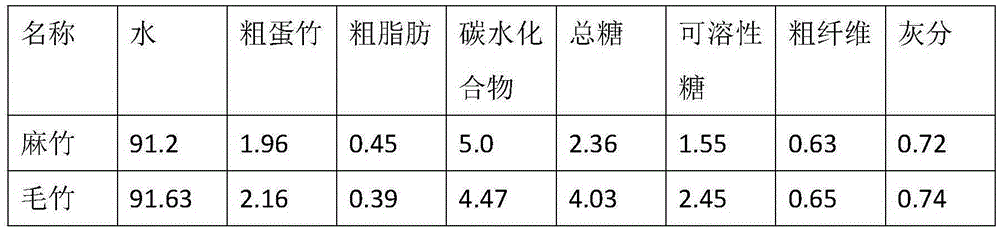

Technological method for preparing strong-flavor bamboo wine by mixing two kinds of bamboos in proportion

InactiveCN105273924APromote fermentationEasy to distillAlcoholic beverage preparationFlavorDistillation

The invention relates to a technological method for preparing strong-flavor bamboo wine by mixing two kinds of bamboos in proportion. The technological method has the technological characteristics that fresh bamboos are ground into granules according to different proportions, the granules are mixed and the granule mixture and grains are used as raw materials to undergo solid state fermentation and distillation, thus preparing the strong-flavor bamboo wine. The technological method has the beneficial effects that the bamboos are adopted as one of the raw materials to participate in brewing the bamboo wine through fermentation, thus taking full advantage of the nutrients of the bamboos; the prepared bamboo wine has the advantages that the bamboo wine has strong flavor, is mellow and sweet, has bright color and has the obvious functions of clearing away heat and toxic materials, strengthening bones and muscles, relieving cough and preventing insomnia and hypertension for human bodies; and the wine has pure bamboo flavor and grain flavor, tastes soft, sweet and refreshing and is rich in the trace elements, such as amino acid and flavone.

Owner:四川活之酿酿酒公社有限公司

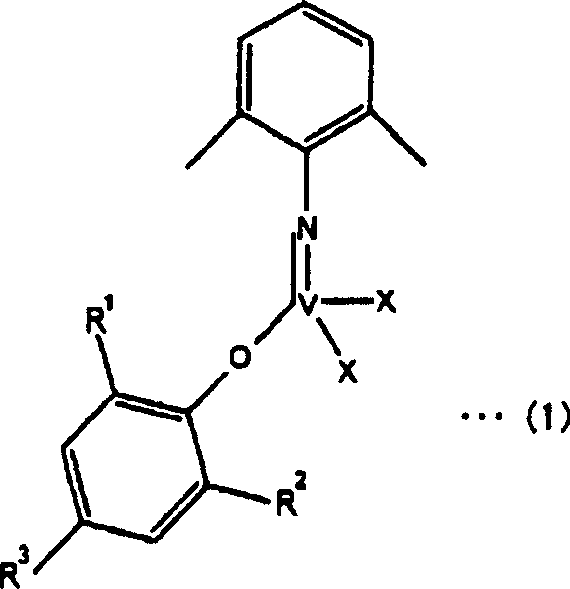

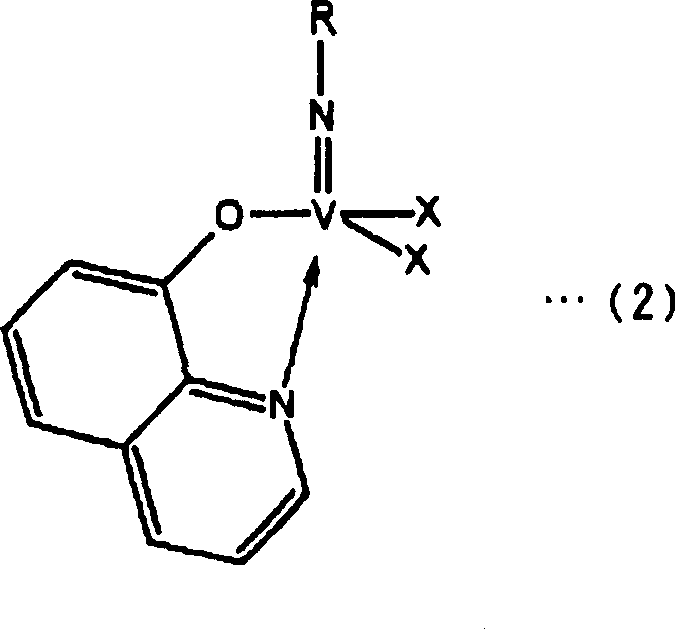

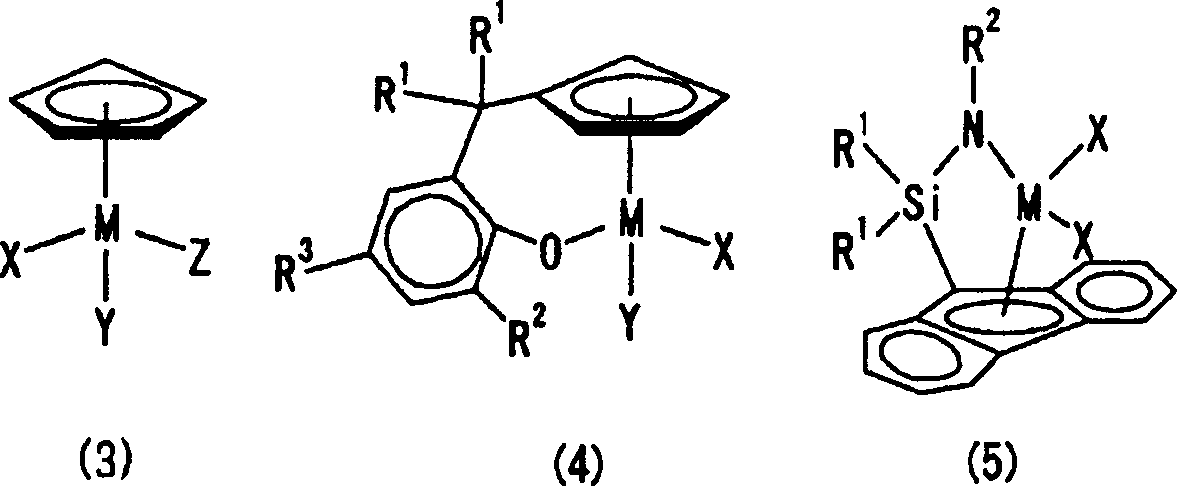

Emulsion composition of modified polypropylene

An emulsion composition of a modified polypropylene. It can have exceedingly improved emulsion stability because the modified polypropylene used has extremely high solubility in solvents and is easily emulsifiable. The modified-polypropylene emulsion composition comprises water and a modified polypropylene dispersed and emulsified therein, and is characterized in that the modified polypropylene has a racemic diad content [r] of 0.12 to 0.88 and has hydrophilic functional groups in a number of 0.5 or larger on the average per molecular chain of the polypropylene.

Owner:TONEN CHEM CORP

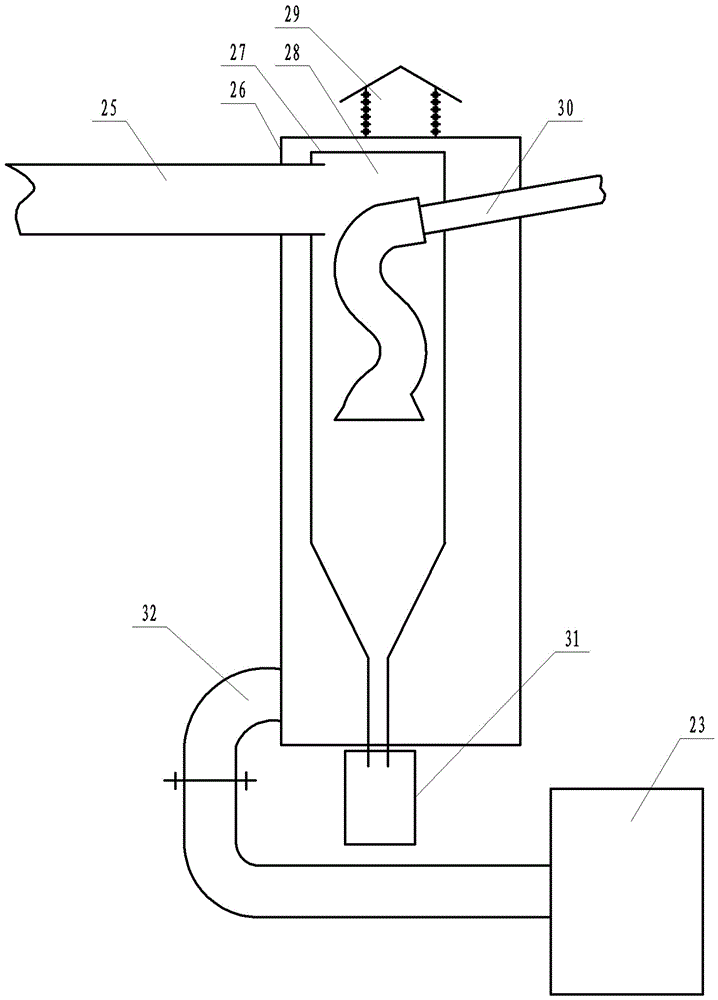

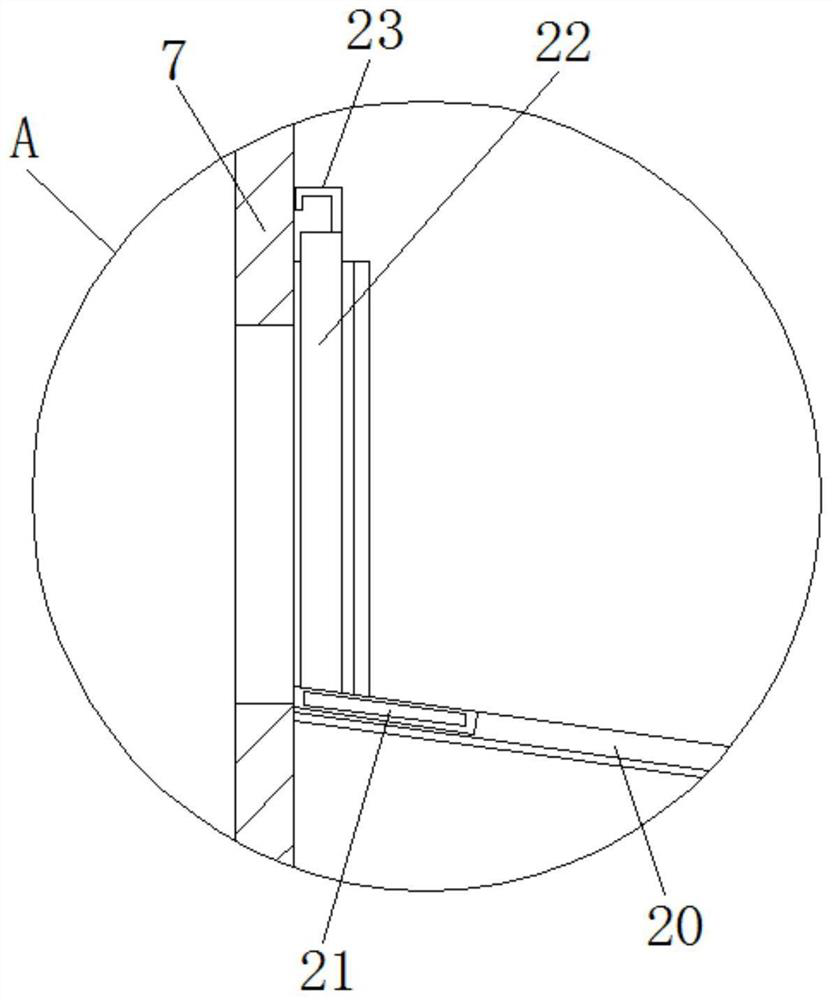

Distillation device based on sedimentation impurity removal mechanism

InactiveCN112807724ASimple processEfficient processDistillation separationFiltration circuitsThermodynamicsDistillation

The invention relates to the technical field of purification and distillation equipment, in particular to a distillation device based on a sedimentation impurity removal mechanism. The device comprises a distillation structure used for heating and condensing an object to remove impurities of the object, and the distillation structure is connected with a settling structure used for settling the impurities of the object; the distillation structure comprises a feeding body for controlling an object to enter and exit, the bottom of the feeding body is connected with a storage body for temporarily storing the object, the storage body is internally connected with a connecting pipe, the connecting pipe is connected with a distillation body for distillation, and the distillation body is connected with a condensation body for condensing a gas object and a sedimentation pipe; the settling structure comprises a pretreatment body for pretreating the solid-liquid mixture, and the pretreatment body is connected with a sedimentation treatment body for carrying out sedimentation treatment on the solid-liquid mixture. The invention mainly provides the distillation device for removing impurities in a sedimentation mode.

Owner:湖南两山环境科技有限公司

Method for preparing Fen-flavor bamboo liquor through proportioning and mixing seven bamboos

InactiveCN105296282APromote fermentationEasy to distillAlcoholic beverage preparationBiotechnologyMicrobiology

The invention relates to a method for preparing a Fen-flavor bamboo liquor through proportioning and mixing seven bamboos. The method comprises the following steps: crushing different proportions of fresh bamboos to form particles, mixing, and carrying out solid fermentation distillation on the obtained mixture and grains also used as a raw material to prepare the Fen-flavor bamboo liquor. The bamboos is adopted as one of raw materials to participate in fermentation brewing of the bamboo liquor, so nutrients of the bamboos are fully used, and the prepared bamboo liquor has faint scent, is mellow and sweet, has clear and bright color, and has the substantial human body heat clearing and detoxifying, muscle and bone strengthening, cough relieving, insomnia preventing and hypertension preventing effects; and the liquor also has the advantages of bamboo scent, pure grain scent, and soft-sweet-refreshing mouthfeel, and is rich in amino acids, flavones and trace elements.

Owner:四川活之酿酿酒公社有限公司

Method for extracting nervonic acid from oil of Mono Maple by using technique of molecular distillation

InactiveCN101092344BSimple stepsLow purityCarboxylic compound separation/purificationPtru catalystNervonic acid

This invention relates to a method for extracting nervonic acid from Acer truncatum oil by molecular distillation. The method solves the problems of complex procedures, easy emulsification, high product acid value and low product purity faced by present technique. The method comprises: (1) preparing Acer truncatum oil; (2) performing deacidification treatment on Acer truncatum oil, removing oil foot, washing with water, and dehydrating; (3) mixing Acer truncatum oil, absolute ethanol and alkaline catalyst, esterifying, washing with water, and separating to obtain ethyl nervonate; (4) performing molecular distillation in different vacuum conditions and temperatures, and collecting the product.

Owner:陕西七彩生物科技有限公司

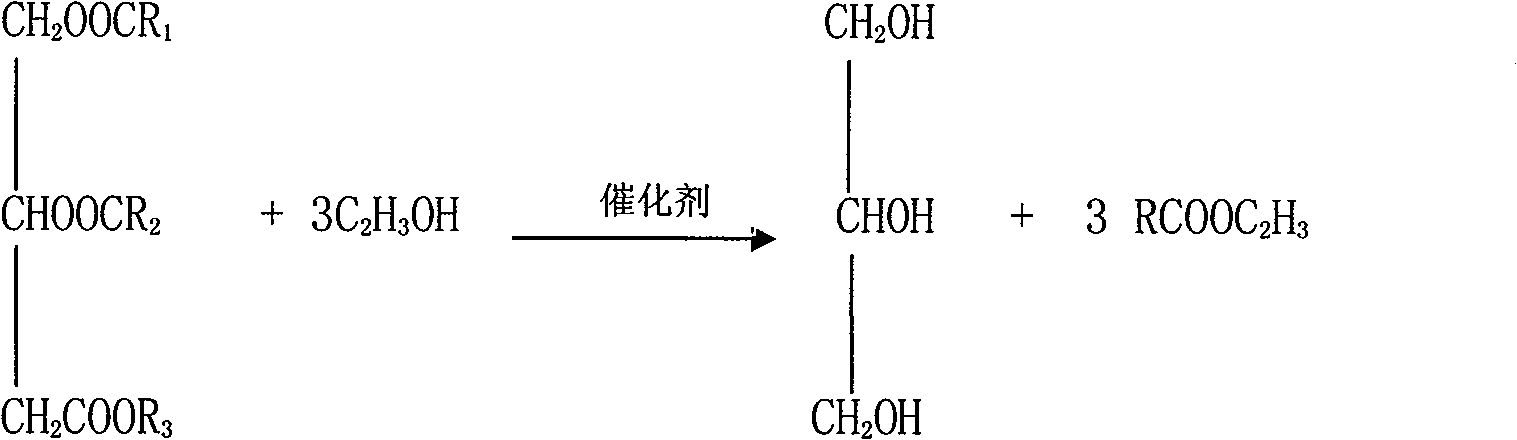

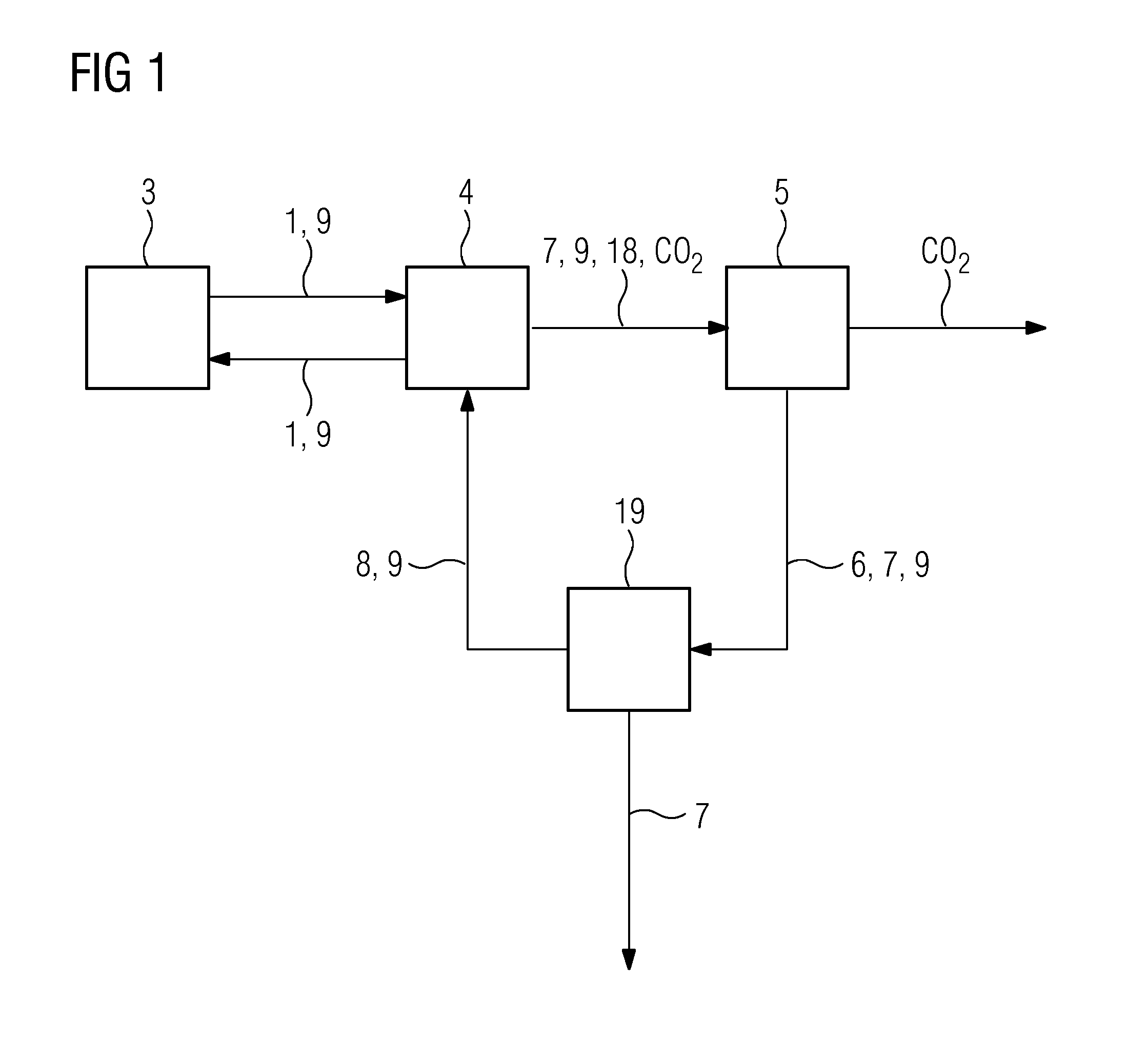

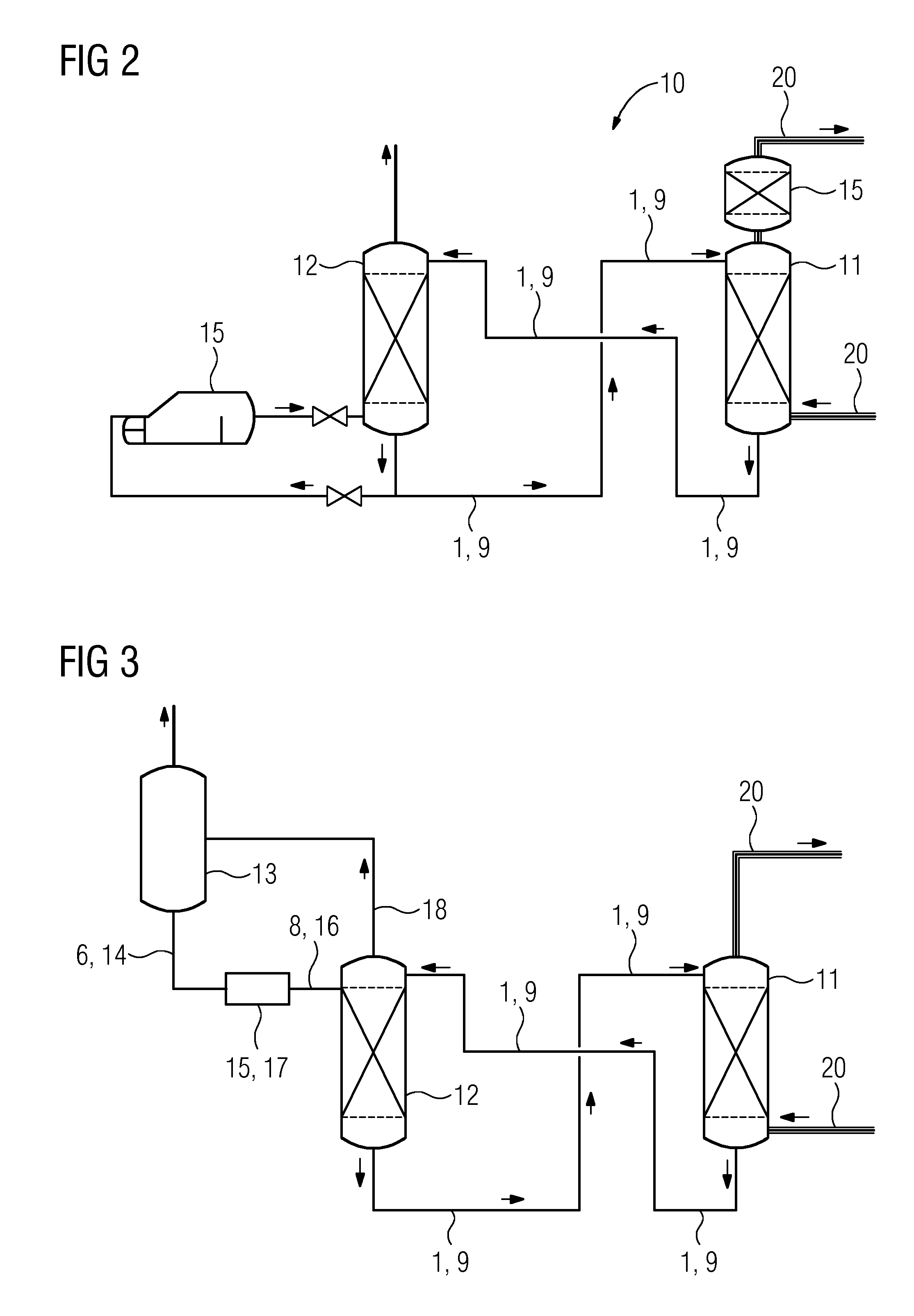

Method and device for extracting highly volatile degradation products from the absorbent loop of a co2 separation process

InactiveUS20150083964A1Minimum expenditure of energyConvenient treatmentGas treatmentDispersed particle separationChemistryCarbon dioxide

Apparatus and process for removal of volatile degradation products from the absorbent circuit of a CO2 separation process are provided. The CO2 separation process may use the absorbent circuit in an absorption process and a desorption process. Condensate is withdrawn from a condensation process connected downstream of the desorption process, and purified to substantially free such condensate of degradation products. The purified condensate is recycled back to the absorbent circuit.

Owner:SIEMENS AG

Method for preparing Fen-flavor bamboo liquor through proportioning and mixing three bamboos

InactiveCN105296284APromote fermentationEasy to distillAlcoholic beverage preparationBiotechnologyMicrobiology

The invention relates to a method for preparing a Fen-flavor bamboo liquor through proportioning and mixing three bamboos. The method comprises the following steps: crushing different proportions of fresh bamboos to form particles, mixing, and carrying out solid fermentation distillation on the obtained mixture and a raw material grains to prepare the Fen-flavor bamboo liquor. The bamboos is adopted as one of raw materials to participate in fermentation brewing of the bamboo liquor, so nutrients of the bamboos are fully used, and the prepared bamboo liquor has faint scent, is mellow and sweet, has clear and bright color, and has the substantial human body heat clearing and detoxifying, muscle and bone strengthening, cough relieving, insomnia preventing and hypertension preventing effects; and the liquor also has the advantages of bamboo scent, pure grain scent, and soft-sweet-refreshing mouthfeel, and is rich in amino acids, flavones and trace elements.

Owner:四川活之酿酿酒公社有限公司

Extraction device for medicinal material distillation, facilitating full utilization

InactiveCN111804001AEasy to crushEasy to collectDistillation in boilers/stillsSolid solvent extractionHerb medicineMedicinal herbs

The invention discloses an extraction device for medicinal material distillation, which is beneficial to ensuring full utilization. The device comprises a crushing barrel, a first motor, a second motor, a heating plate, a refrigerator and a water pump, wherein the first motor is arranged at the top of the right side of the crushing barrel; a material accumulation hopper is connected to the lower part of the crushing barrel; a movable door is arranged on the right side of a herbal medicine frame, a supporting rod is arranged at the top of a distillation barrel, a ceramic heat preservation layeris arranged on the outer side of the distillation barrel, a condensation pipe is arranged in the condensation barrel, a protective shell is connected to the outer side of the bottom of the material accumulation hopper, and supports are connected to the lower portions of the crushing barrel, the distillation barrel and the condensation barrel. According to the extraction device for medicinal material distillation beneficial to ensuring full utilization, medicinal materials are conveniently crushed and collected, heating distillation treatment of the medicinal materials is facilitated, used medicinal material residues are conveniently discharged, new medicinal materials are conveniently added, distillation is facilitated, distilled heat can be recycled, and energy is conveniently saved.

Owner:李姗姗

Waste organic solvent recycling device

PendingCN109628179ALow running costTo achieve the effect of energy saving and emission reductionGaseous fuelsIncinerator apparatusOrganic solventCombustion chamber

The invention discloses a waste organic solvent recycling device which comprises a solvent recycling device, a pressurizing atomization device, a power system and an RTO, wherein a solvent liquid outlet end of the solvent recycling device is communicated with the pressurizing atomization device, and the pressurizing atomization device is communicated with a combustion chamber of the RTO through the power system. By the adoption of the waste organic solvent recycling device, a regenerated solvent is used as fuel to replace natural gas after a series of treatments are carried out on the regenerated solvent, so that the operation cost is greatly reduced, the regenerated solvent is recycled, the utilization rate of the regenerated solvent is improved, and the effects of energy conservation andemission reduction are achieved.

Owner:SICHUAN JINSHI TECH

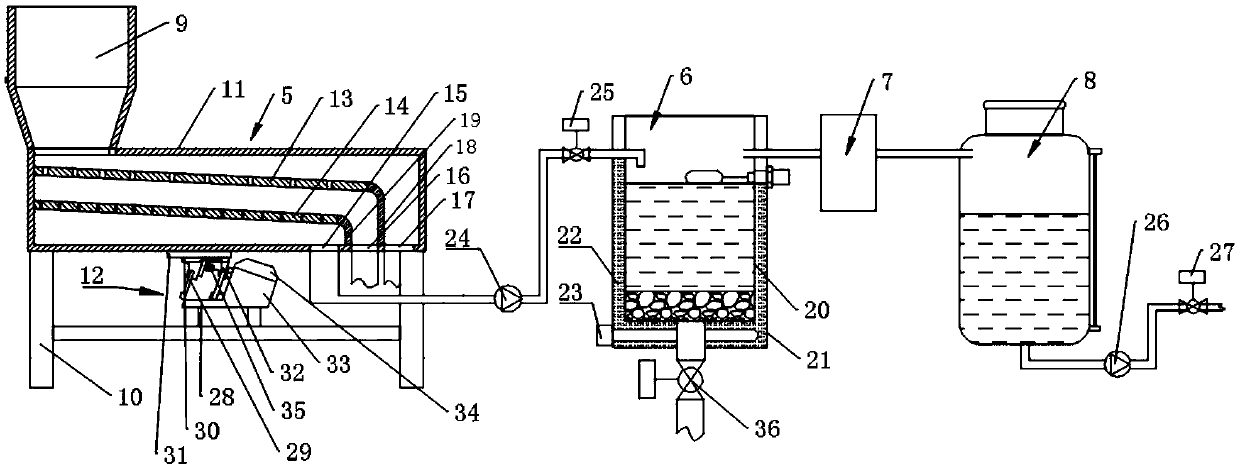

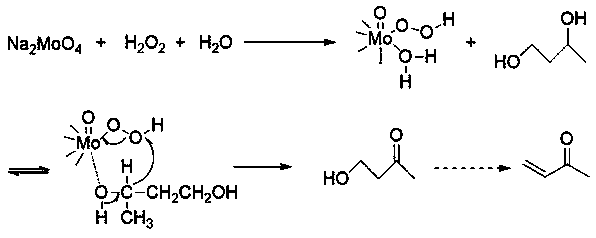

Production method of 4-hydroxy-2-butanone

InactiveCN110105187AImprove responseImprove conversion rateOrganic compound preparationPreparation by dehydrogenationChemical reactionDistillation

Belonging to the field of fine chemicals, the invention discloses a production method of 4-hydroxy-2-butanone, and solves the problem of low yield of existing synthetic methods. The method provided bythe invention includes the steps of: adding 1, 3-butanediol, a catalyst, an assistant, water and a water-carrying agent into a reaction kettle, and performing heating to 55-60DEGC; adding hydrogen peroxide dropwise into the mixed solution, and conducting reduced pressure distillation of water; stopping adding hydrogen peroxide, and further performing stirring for 1-1.5h to distill the water-carrying agent out; controlling the temperature of the system not higher than 60DEGC, and conducting reduced pressure rectification to obtain the final product 4-hydroxy-2-butanone. By adding the assistant, 1, 3-butanediol can better participate in the reaction, and the conversion rate can be improved. The chemical reaction carried out in the invention is carried out under a negative pressure condition, and the temperature is controlled not higher than 60DEG C, thus avoiding the generation of methyl vinyl ketone; and in a negative pressure system, the reaction can be fully carried out under a low temperature condition, the product is easier to distill, and impurities are not easily produced.

Owner:GANSU RES INSTION OF CHEM IND GRICI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com