Distillation device based on sedimentation impurity removal mechanism

A distillation device and impurity removal technology, applied in the direction of distillation separation, filtration separation, chemical instruments and methods, etc., can solve the problems of unqualified finished product content, unreasonable structure design of distillation device, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

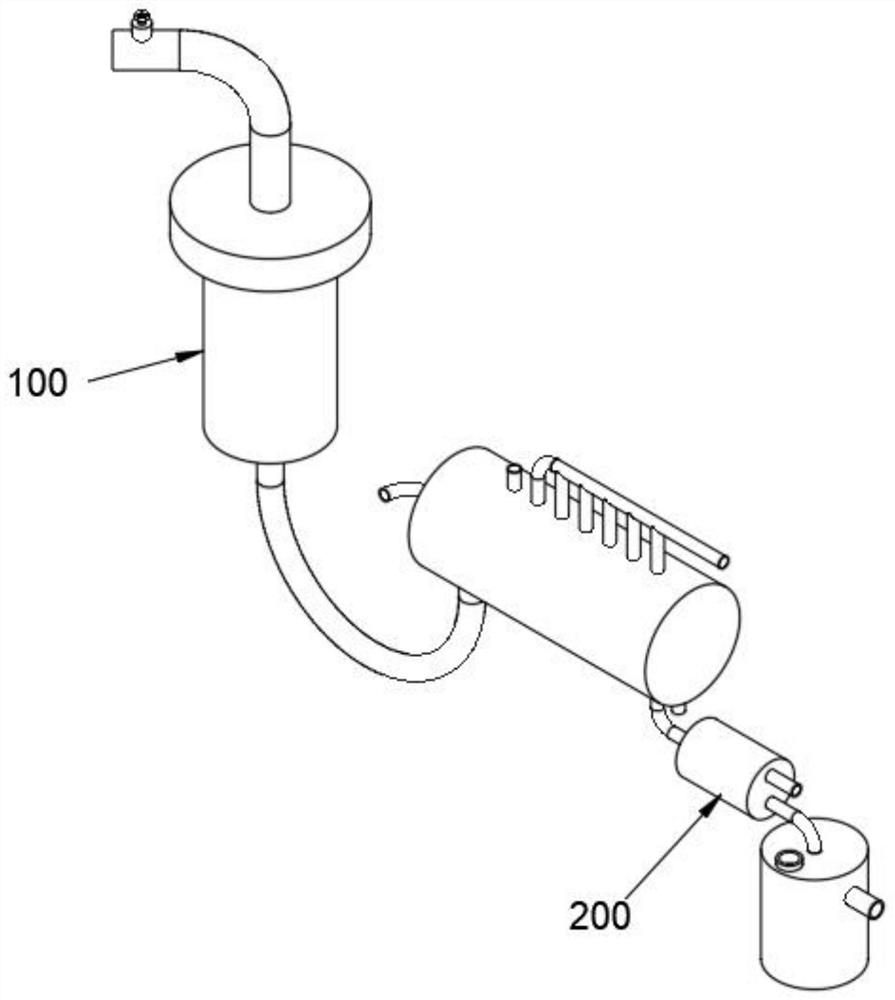

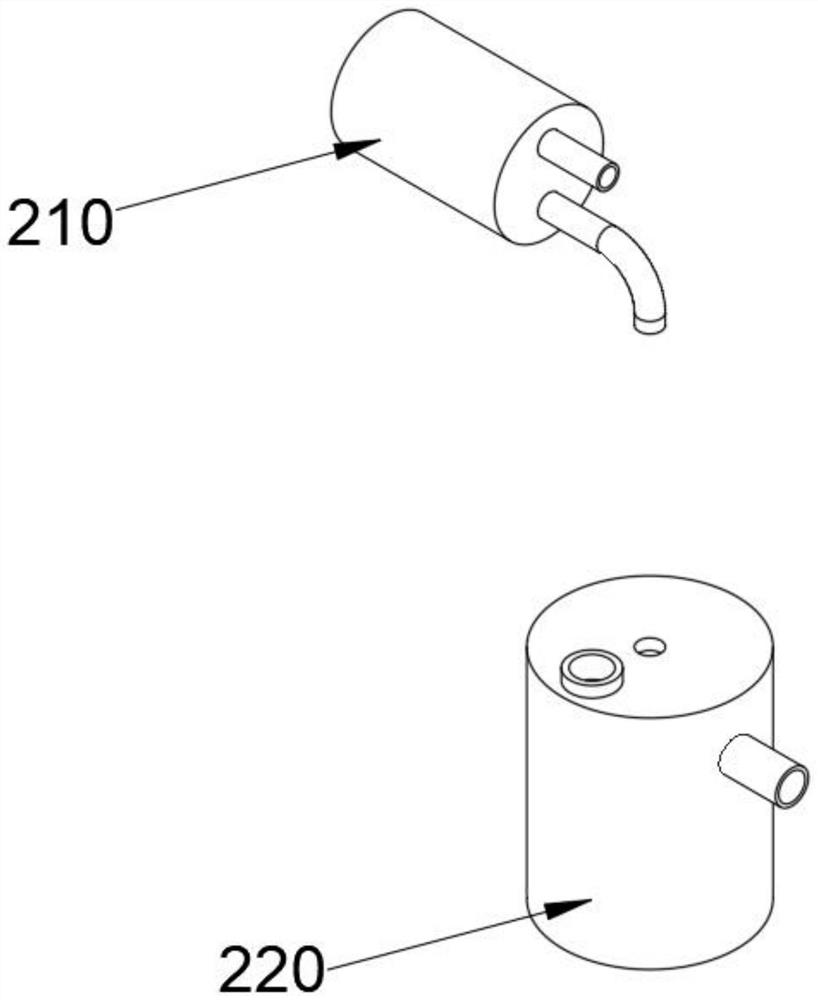

[0054] see Figure 1-Figure 12 As shown, the purpose of this embodiment is to provide a distillation device based on a sedimentation and impurity removal mechanism, including a distillation structure 100 for heating and condensing objects to remove impurities. structure 200;

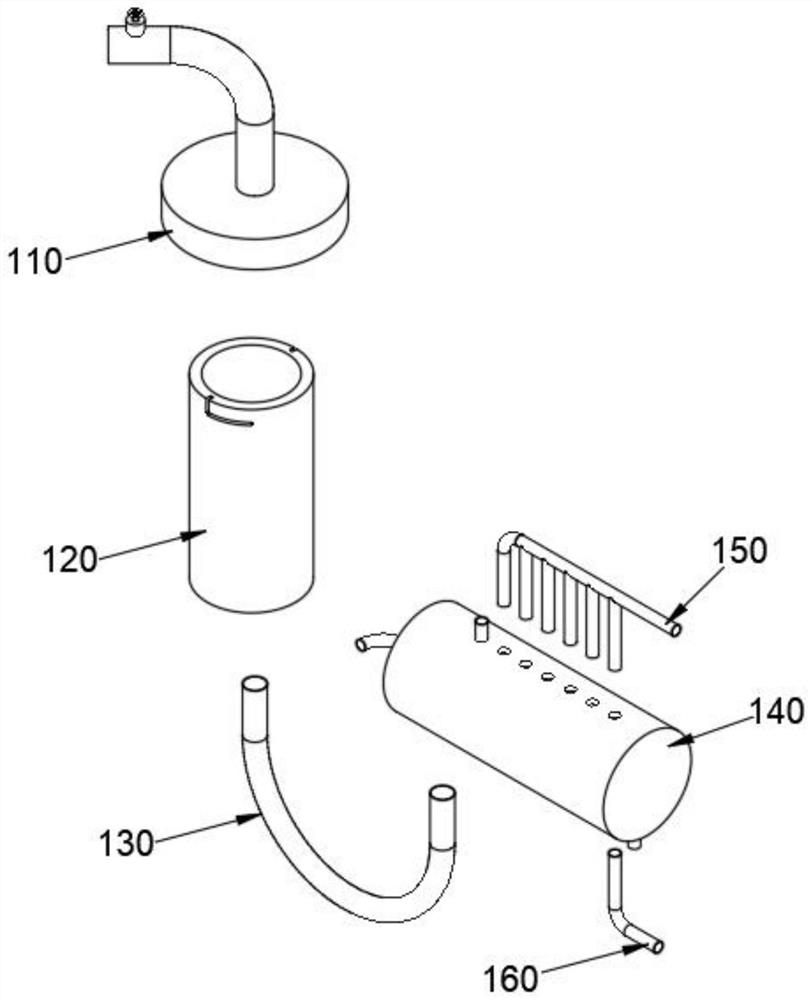

[0055] The distillation structure 100 includes a feed body 110 that controls the entry and exit of objects. The feed body 110 includes a feed cover 111. The feed cover 111 is a cylinder with a cylindrical structure groove at the bottom. The top of the feed cover 111 is connected to a feed pipe. 112. The object to be removed of impurities enters the interior of the device through the feed pipe 112. The bottom of the feed cover 111 is connected with a storage body 120 for temporarily storing the object. The storage body 120 includes a storage tank 121 with the feed cover 111. The storage tank 121 is A cylinder, the surface of the storage tank 121 is provided with a storage bin 122 that runs through its su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com