Emulsion composition of modified polypropylene

An emulsified composition, polypropylene technology, applied in the field of modified polypropylene emulsified composition, can solve the problems of low solubility of organic solvents, adverse effects, polypropylene degradation performance, etc., and achieve the effect of high-efficiency emulsified composition and high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 1. Preparation of polypropylene

[0030] In the present invention, the method of producing polypropylene as the base material of the above-mentioned modified polypropylene is not particularly limited as long as the racemate fraction [r] of the polypropylene falls within the range of 0.12 to 0.88. limit. Usually, metal complex catalysts in a homogeneous system are used to polymerize propylene in solvents such as benzene, toluene, xylene, butane, pentane, hexane, cyclohexane, heptane, ethylcyclohexane, THF, etc. while preparing.

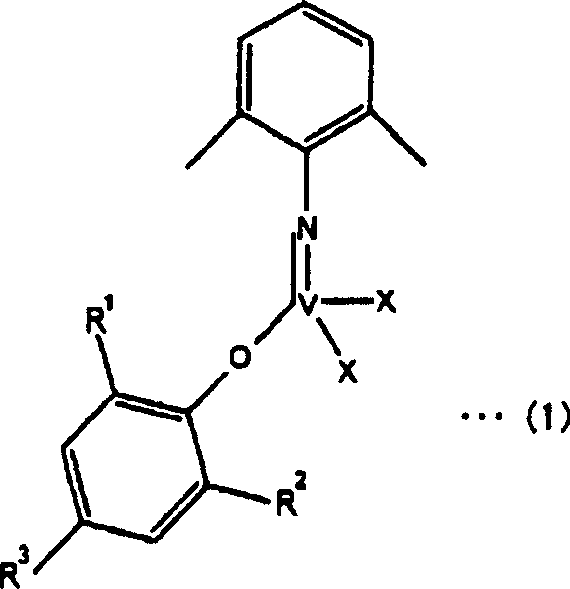

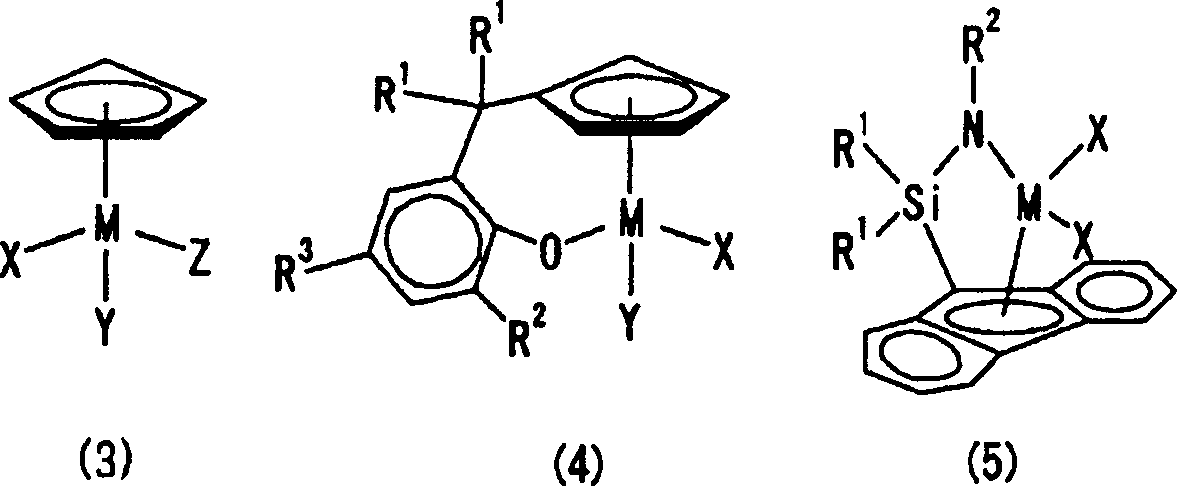

[0031] As a metal complex catalyst in a homogeneous system, it is a catalyst formed by an organometallic compound and an organoaluminum compound, or a metal complex formed by an organic compound containing heteroatoms such as oxygen and nitrogen and a transition metal. For example, it can be listed

[0032] (i) catalysts formed from vanadium complexes and organoaluminum compounds;

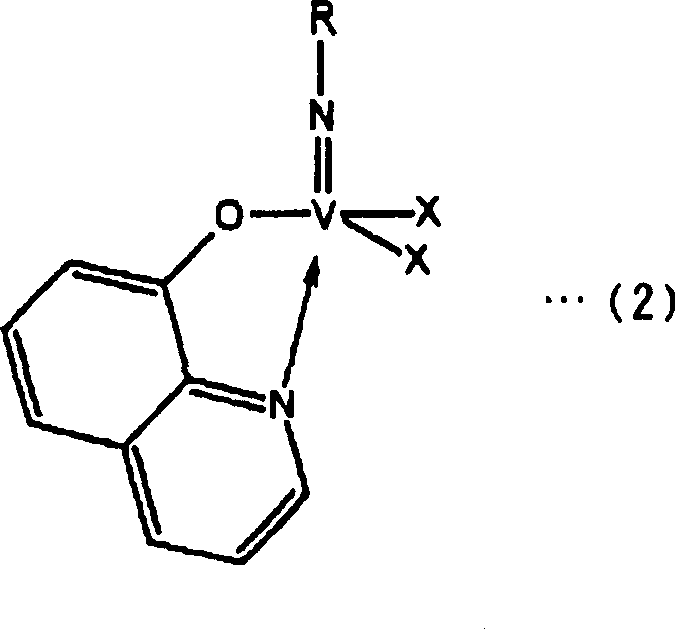

[0033] (ii) A compound having a cyclodienyl group or a deriv...

Embodiment 1

[0196] Polymerization of propylene

[0197] Add 150 ml of toluene and 100 ml of 2 mol / l diethylaluminum chloride toluene solution to a stainless steel reaction kettle equipped with a stirrer fully replaced with nitrogen, and after feeding 8.3 mol of propylene, cool to -78° C. under stirring. Under the condition of maintaining at -78°C, 50 ml of a toluene solution of 0.1 mol / l tris(2-methyl-1,3-butanedione)vanadium was added to carry out polymerization. After 1.5 hours of polymerization, the stirring was stopped, and the reaction solution was poured into 2L of ethanol-hydrochloric acid solution cooled to -78°C. The produced polymer was washed five times with 1 L of ethanol, and dried under reduced pressure at room temperature to obtain 5.5 g of a polymer.

[0198] The obtained polymer was analyzed by GPC, and the weight average molecular weight (Mw) was 6000, and the value of Mw / Mn was 1.5. further through 13 The stereoregularity of the obtained polymer was analyzed by C-NMR...

Embodiment 2~7

[0205] In the same manner as in Example 1, propylene was polymerized under the conditions shown in Table 1, and various modifiers were introduced into polypropylene under the conditions shown in Table 3.

[0206] After completion of the modification, IR measurement was performed to quantify the amount of modifier introduced, and it was confirmed that no absorption due to crystalline polypropylene was observed. Further, the obtained modified polypropylene was emulsified in the same manner as in Example 1. Immediately after emulsification, the state of the emulsified product was observed, and the stability of the emulsified state was evaluated. The results are listed in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com