Production method of 4-hydroxy-2-butanone

A production method, technology of methyl ethyl ketone, applied in chemical instruments and methods, separation/purification of carbonyl compounds, preparation of carbonyl compounds, etc., can solve problems such as low yield, achieve reduced production costs, strong resistance to autooxidation, Post-processing for easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

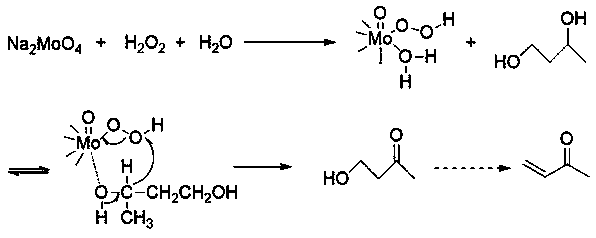

Method used

Image

Examples

Embodiment 1

[0030] Step 1. Add 1,3-butanediol 10,000mol, catalyst sodium molybdate 200mol, additive tetrabutylammonium chloride 200mol, water 50,000mol and water-carrying agent diisopropyl ether 4,000mol into a 3,000-liter reactor, and stir evenly. Form a mixed solution and heat up to 60°C;

[0031] Step 2. While stirring, drop 10,000 mol of hydrogen peroxide with a mass fraction of 30% into the mixed solution, and at the same time divide water by vacuum distillation. ;

[0032] Step 3. When the gas chromatography detects that the content of 1,3-butanediol in the reactor is not higher than 25% of the initial content, stop adding hydrogen peroxide dropwise, continue stirring for 1.5 hours, and control the temperature in the reactor not higher than 60°C , steam the water-carrying agent;

[0033] Step 4: Control the temperature of the system to not be higher than 60°C, and rectify under reduced pressure to obtain 428kg of the final product 4-hydroxy-2-butanone. The gas phase detection puri...

Embodiment 2

[0035] Step 1. Add 1,3-butanediol 10,000mol, catalyst sodium molybdate 240mol, additive tetrabutylammonium chloride 240mol, water 50,000mol and water-carrying agent diisopropyl ether 4,000mol into a 3,000-liter reactor, and stir evenly. Form a mixed solution and heat up to 60°C;

[0036] Step 2. While stirring, drop 10,000 mol of hydrogen peroxide with a mass fraction of 30% into the mixed solution, and at the same time divide water by vacuum distillation. ;

[0037] Step 3. When the gas chromatography detects that the content of 1,3-butanediol in the reactor is not higher than 25% of the initial content, stop adding hydrogen peroxide dropwise, continue stirring for 1.2 hours, and control the temperature in the reactor not higher than 60°C , steam the water-carrying agent;

[0038] Step 4: Control the temperature of the system to not be higher than 60° C., rectify under reduced pressure to obtain 416 kg of the final product 4-hydroxy-2-butanone, and the gas phase detection p...

Embodiment 3

[0040] Step 1. Add 1,3-butanediol 10,000mol, catalyst sodium molybdate 200mol, additive tetrabutylammonium chloride 200mol, water 50,000mol and water-carrying agent diisopropyl ether 5,000mol into a 3,000-liter reactor, and stir evenly. Form a mixed solution and heat up to 60°C;

[0041] Step 2. While stirring, drop 10,000 mol of hydrogen peroxide with a mass fraction of 30% into the mixed solution, and at the same time divide water by vacuum distillation. ;

[0042] Step 3. When the gas chromatography detects that the content of 1,3-butanediol in the reactor is not higher than 25% of the initial content, stop adding hydrogen peroxide dropwise, continue stirring for 1.5 hours, and control the temperature in the reactor not higher than 60°C , steam the water-carrying agent;

[0043] Step 4: Control the temperature of the system to not be higher than 60° C., rectify under reduced pressure to obtain 410 kg of the final product 4-hydroxy-2-butanone, and the purity of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com