Method for extracting nervonic acid from oil of Mono Maple by using technique of molecular distillation

A technology of molecular distillation and ingot maple, applied in the field of fatty acid preparation technology, can solve the problems of easy emulsification, low product purity and high product acid value, and achieve the effects of easy operation, high purity and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

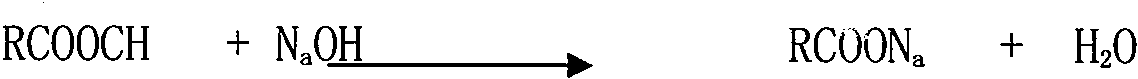

Problems solved by technology

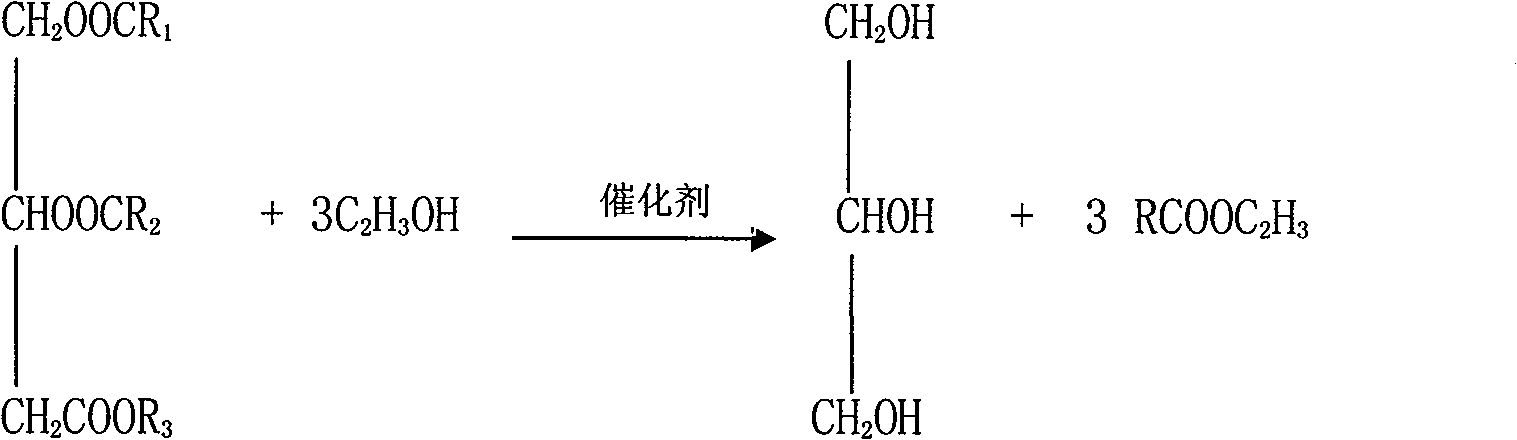

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of Yuanbao maple oil:

[0027] (1) Shelling: Control the moisture content of the maple seeds in the range of 8-12%, and put them into a special peeling machine for maple seeds for peeling treatment. After the treatment, the shell kernels are separated by winnowing to obtain maple seeds.

[0028] (2) Oil extraction: the shelled and separated Yuanbao maple kernels are subjected to moisture adjustment, so that the moisture content is controlled within the scope of 8-10%, and oil extraction is carried out with a 90-type oil press, and the oil yield is more than 85%.

[0029] (2) Preparation of ethyl nervate:

[0030] (1) Pretreatment: filter the Yuanbao maple oil to remove impurities, add a concentration of 5% sodium hydroxide solution according to the weight of 0.8% of the weight of Yuanbao maple oil and add alkali, the reaction temperature is 50°C, the stirring speed is 40r / min, and the time is 30min, after the reaction is completed, the temperature is ra...

Embodiment 2

[0035] (1) Preparation of Ingot Maple Oil: Same as Example 1.

[0036] (2) Preparation of ethyl nervate:

[0037] (1) Pretreatment: filter the Yuanbao maple oil to remove impurities, add a concentration of 4% sodium hydroxide solution according to the amount of alkali added to 1.0% of the weight of Yuanbao maple oil, the reaction temperature is 40°C, the stirring speed is 30r / min, and the time is 60min, after the reaction is completed, the temperature is rapidly raised to 80°C at a rate of 1°C / hour, and the temperature is kept for 6 hours, so that the soap particles are completely separated, the oil residue is removed and washed 3 times with water, and then the water is removed;

[0038] (2) transesterification: after mixing 100 parts by weight of ingot maple oil with 50 parts by weight of absolute ethanol and 1.2 parts by weight of basic catalyst potassium hydroxide, carry out transesterification reaction at a temperature of 75°C for 2 hours After the reaction, wash with wat...

Embodiment 3

[0042] (1) Preparation of Ingot Maple Oil: Same as Example 1.

[0043] (2) Preparation of ethyl nervate:

[0044] (1) Pretreatment: filter the Yuanbao maple oil to remove impurities, add a concentration of 6% sodium hydroxide solution according to the amount of alkali added to 0.5% of the weight of Yuanbao maple oil, the reaction temperature is 30°C, the stirring speed is 60r / min, and the time is After the reaction is completed, the temperature is rapidly raised to 80°C at a rate of 1°C / hour, and the temperature is kept for 8 hours to completely separate the soap particles, remove the oil residue and wash twice with water, and then remove the water.

[0045] (2) transesterification: carry out transesterification after mixing 100 parts by weight of ingot maple oil with 60 parts by weight of absolute ethanol and 1.5 parts by weight of alkaline catalyst potassium hydroxide, and react at a temperature of 80° C. for 3 hours After the reaction, wash with water twice to remove glyce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com