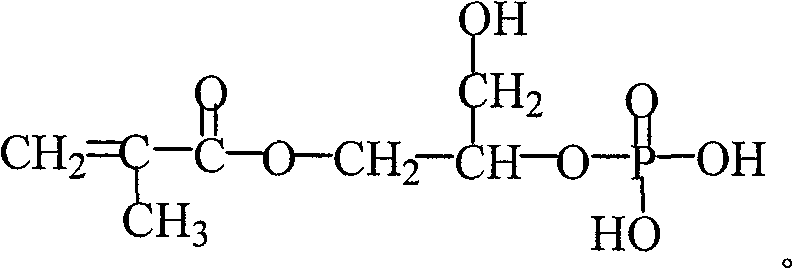

Reactive phosphoric acid esters emulsifying agents and method for preparing same

A reactive phosphoric acid and functional emulsifier technology, applied in chemical instruments and methods, applications, edible phospholipid compositions, etc., can solve problems such as poor product stability, whitening, environmental pollution, etc., and achieve superior performance, high conversion rate, Process stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 8 grams of 98% phosphoric acid and 20 grams of acetone to the reaction flask, add 0.06 grams of hydroquinone after stirring at 30 ° C for one hour, then add 12 grams of glycidyl methacrylate dropwise to the reaction system, drop for 1 hour After the addition was complete, the reaction was stirred at 40°C for 2 hours. After the reaction was completed, the acetone was distilled off under reduced pressure at 40°C to obtain the product, which was packaged and sealed at room temperature for storage.

Embodiment 2

[0024] Add 10 grams of 98% phosphoric acid and 30 grams of acetone to the reaction flask, add 0.07 grams of hydroquinone after stirring at 30 ° C for one hour, then add 14 grams of glycidyl methacrylate dropwise to the reaction system, drop for 2 hours After the addition was complete, the reaction was stirred at 40°C for 3 hours. After the reaction was completed, the acetone was distilled off under reduced pressure at 40°C to obtain the product, which was packaged and sealed at room temperature for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com