Distilling production method for sandalwood essential oil and equipment

A technology of sandalwood essential oil and production method, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of waste, insufficient extraction of essential oil components, etc., and achieve high product extraction rate, which is conducive to distillation and collection, and uniform quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

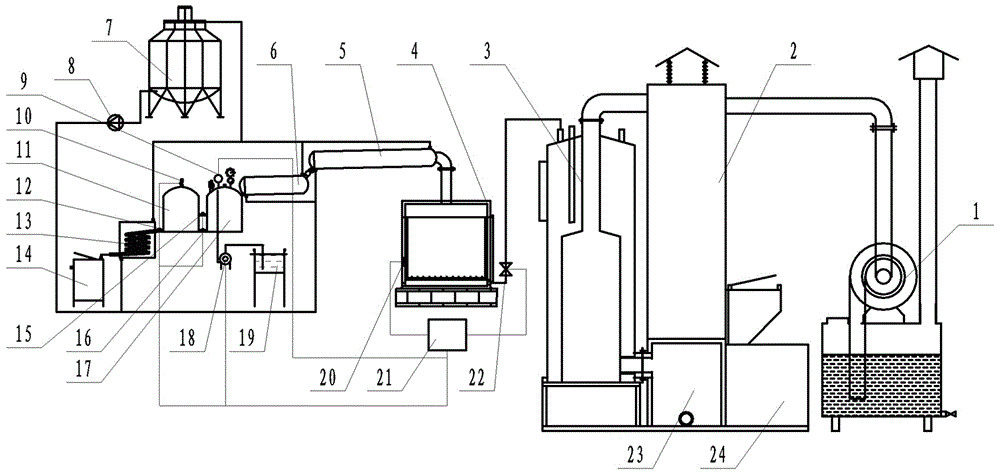

[0050] Sandalwood essential oil can be distilled using the following steps:

[0051] (1) Break the sandalwood root, sandalwood or sandalwood leaves into pieces of 1 to 6 mm and put them in the distillation cabinet;

[0052] (2) Pass the steam generated by the steam boiler into the distillation cabinet, distill the sandalwood fragments, and control the temperature in the distillation cabinet at 93°C-98°C;

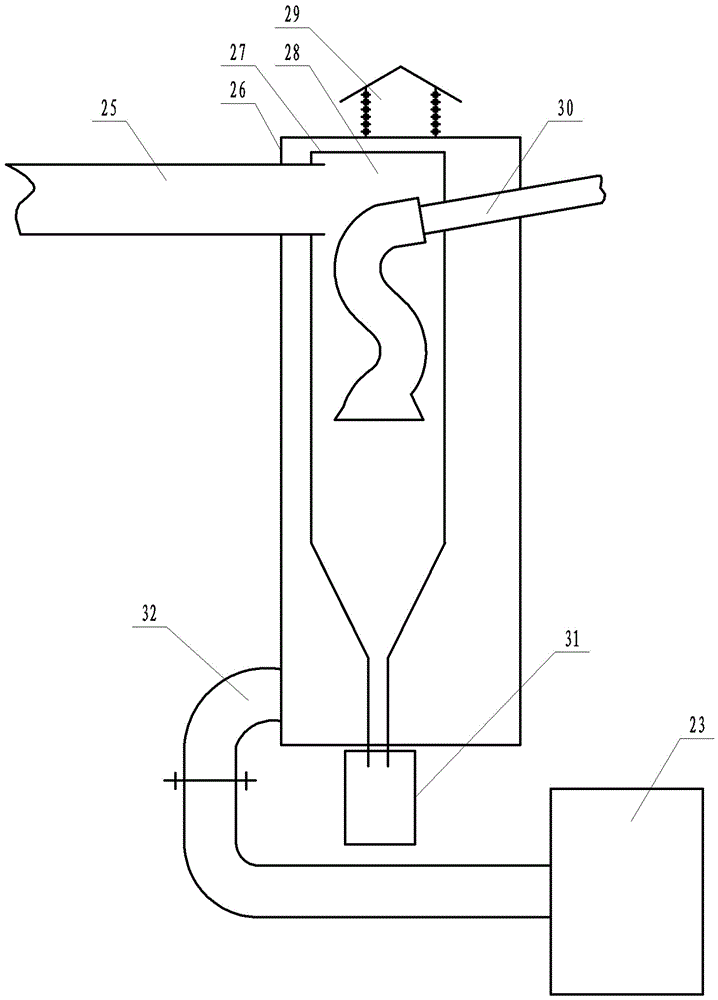

[0053] (3) The tail gas of the steam boiler is discharged from the chimney after being treated by the primary dust collector and the secondary dust collector;

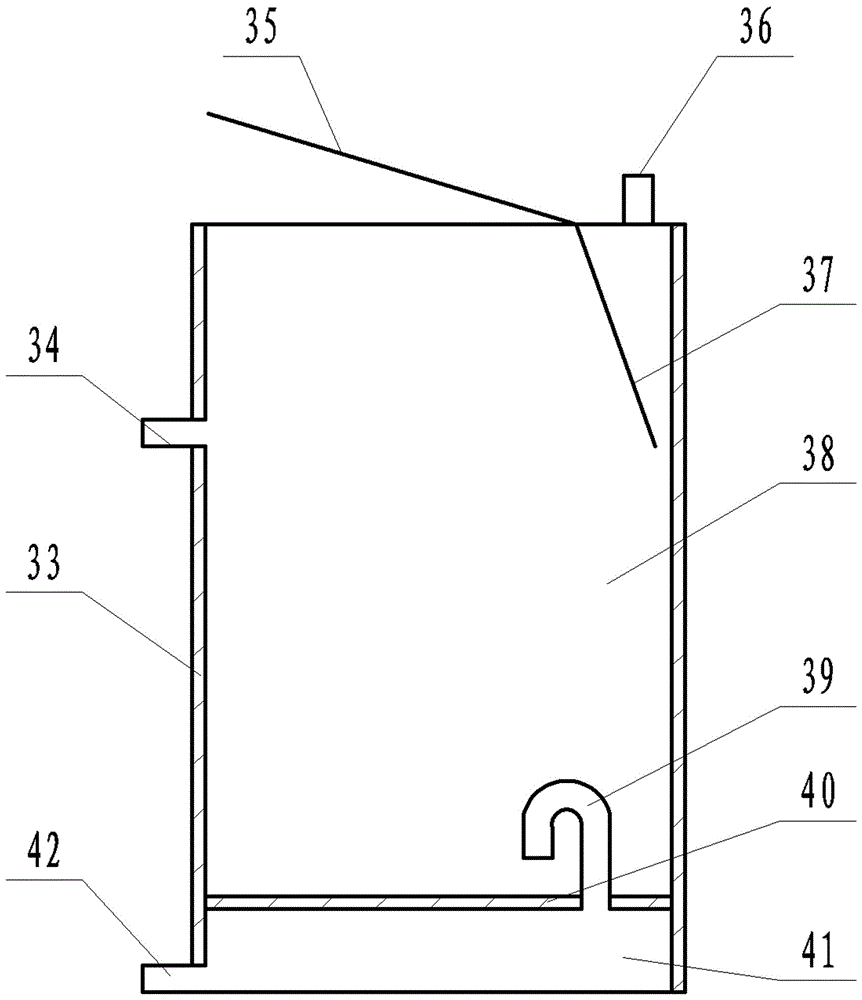

[0054] (4) The steam discharged from the distillation cabinet passes through the primary condenser and the secondary condenser, and then enters the receiving tank and the excessive receiving tank to obtain distillate;

[0055] (5) Keep the pressure in the receiving tank at 0.01-0.3Mpa;

[0056] (6) When the distillate in the over-receiving tank reaches the set liquid level, close the connection valve between the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com