Catalyst and method for preparing ethanol by hydrogenating acetic ester

A technology of acetate hydrogenation and catalyst, applied in the field of catalytic chemistry, can solve the problems of low hydrogen-ester ratio, poor selectivity of ethanol, low conversion rate of raw materials, etc., achieve high ethanol selectivity, avoid loss, and high conversion of raw materials rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

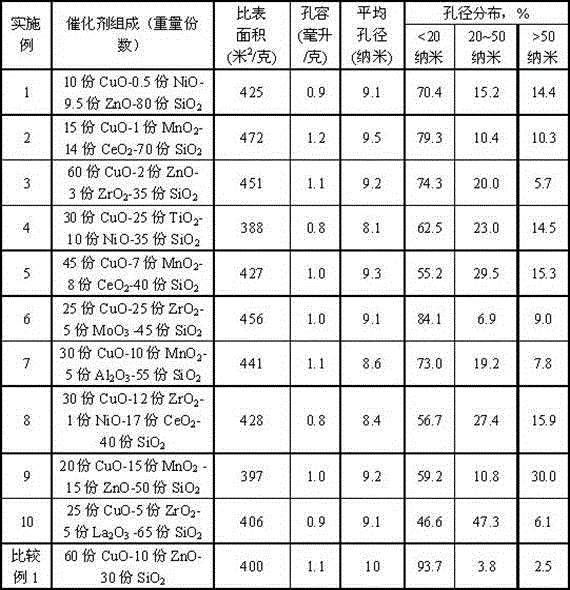

Embodiment 1

[0030]Pour 640g of silica sol (mass concentration: 25%) into a three-necked flask, weigh 60.4g of copper nitrate trihydrate, 3.89g of nickel nitrate hexahydrate, and 69.44g of zinc nitrate hexahydrate, add distilled water to dilute to 0.8L, and stir evenly. Add the mixed salt solution into the flask for thorough stirring, add ammonia water dropwise to control the pH of the solution to 10, heat to 75°C, stir for 5 hours until the pH of the solution is 6.0; then wash the precipitate with suction and filter, and dry at 90°C for 5 hours , calcined at 400°C for 5 hours, and pressed into pellets to obtain catalyst 1. The composition and physical property data of Catalyst 1 are shown in Table 1.

[0031]

Embodiment 2

[0033] Pour 466.7g of silica sol (mass concentration: 30%) into a three-necked flask, weigh 90.6g of copper nitrate trihydrate, 5.75g of manganese nitrate tetrahydrate, and 70.6g of cerium nitrate hexahydrate, add distilled water to dilute to 0.8L, and stir well , put the mixed salt solution into the flask for full stirring, add dropwise ammonia water to control the pH of the solution to 11, heat to 75°C, stir for 5 hours until the pH of the solution is 6.0; then wash the precipitate with suction and filter, and dry at 90°C for 5 hours, calcined at 400° C. for 10 hours, and pressed into tablets to obtain catalyst 2. The composition and physical property data of catalyst 2 are shown in Table 1.

[0034]

Embodiment 3

[0036] Pour 175g of silica sol (mass concentration 40%) into a three-necked flask, weigh 362.4g of copper nitrate trihydrate, 14.62g of zinc nitrate hexahydrate, and 11.26g of zirconium oxynitrate, add distilled water to dilute to 1.5L, stir evenly, and Add the mixed salt solution into the flask for thorough stirring, add ammonia water dropwise to control the pH value of the solution to 10, heat to 75°C, stir for 5 hours until the pH value of the solution is 6.0; then wash and filter the precipitate, and dry it at 90°C for 5 hours, Calcined at 400° C. for 10 hours, and pressed into pellets to obtain catalyst 3 . The composition and physical property data of catalyst 3 are shown in Table 1.

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com