Patents

Literature

36results about How to "Uniform conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

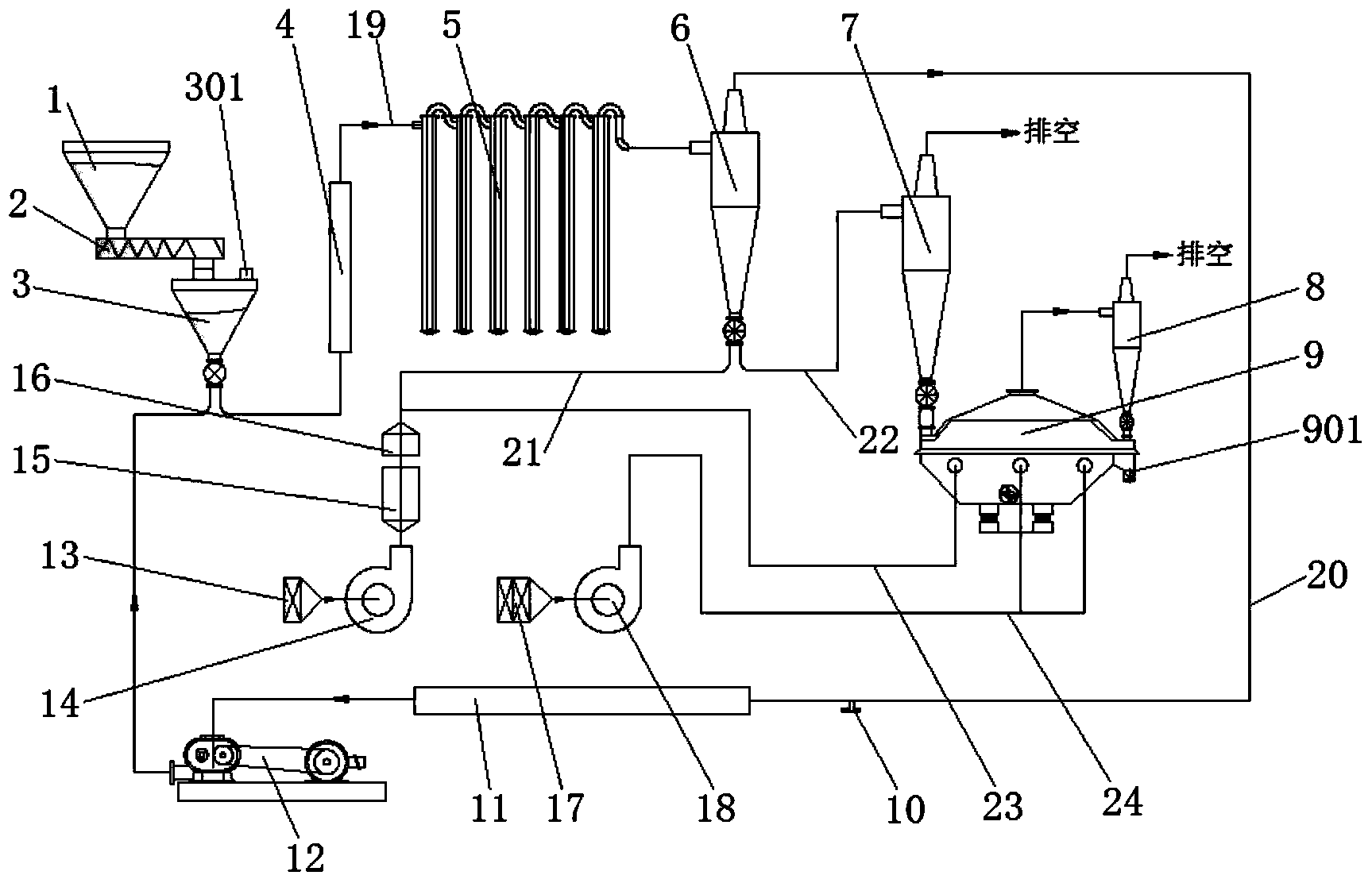

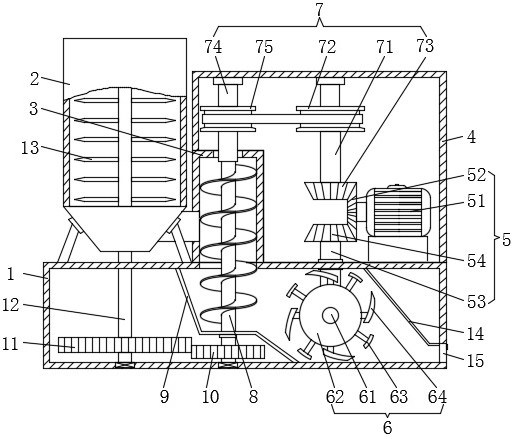

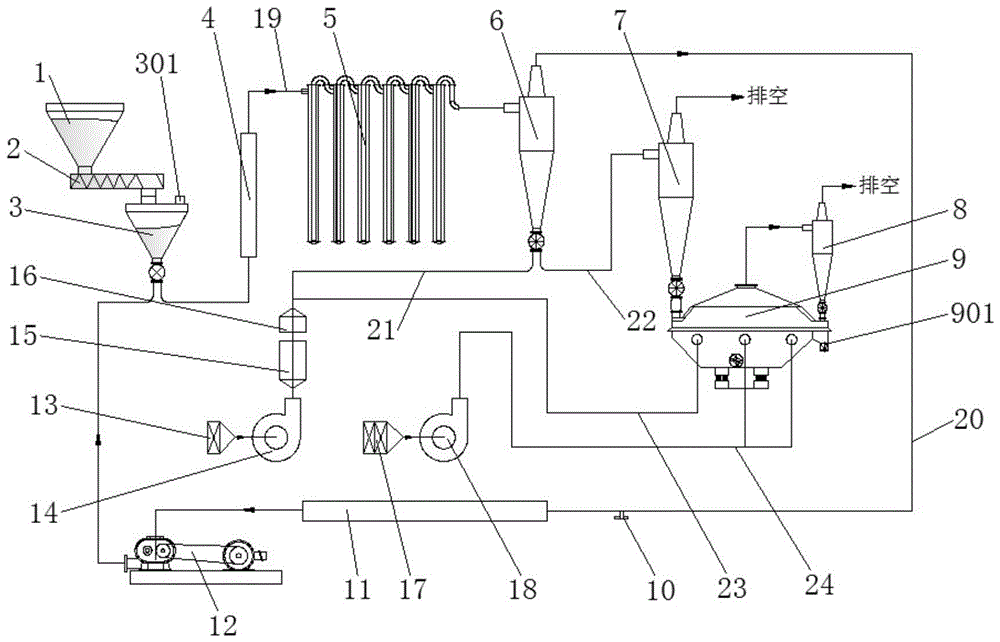

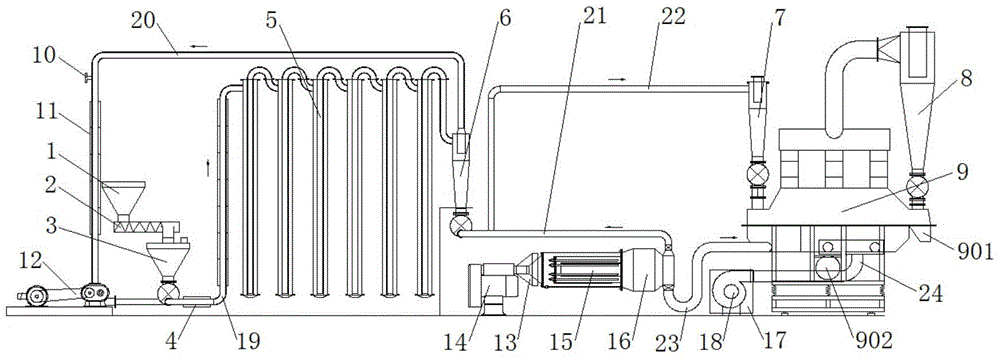

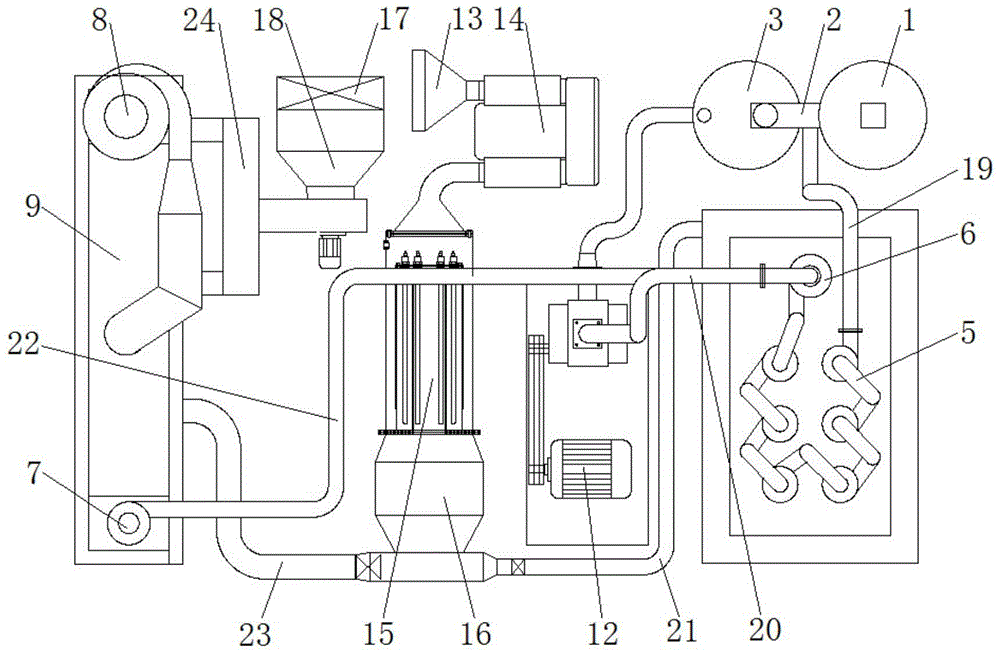

Technology and system of powder body superheated steam sterilization

The invention discloses a technology and a system of powder body superheated steam sterilization, and belongs to the field of material sterilization and drying. The technology comprises the following steps: (1) adding a powder body material steam into a superheated steam stream; (2) controlling the superheated steam stream to form a cyclone stream, so that the material is dispersed in the cyclone stream, and utilizing the steam heat for sterilization for 3-10 seconds, and controlling the sterilization temperature within the range of 120-250 DEG C; (3) causing the steam stream to form cyclone stream, and utilizing the centrifugal force to separate the material and the steam stream; (4) utilizing the dried hot wind to dry the material, and utilizing dried cold air to cool the dried material; (5) performing steam and temperature compensation on the steam stream in the step (3), and participating in the superheated steam stream feeding technology in the step (1). The invention further discloses a system of powder body superheated steam sterilization. According to the invention, the technology is convenient in operation and simple in device structure, realizes automatic and continuous sterilization production, is low in consumption for sterilization, and is greatly increased in production efficiency.

Owner:FANQUN DRYING EQUIP FACTORY WUJIN CITY

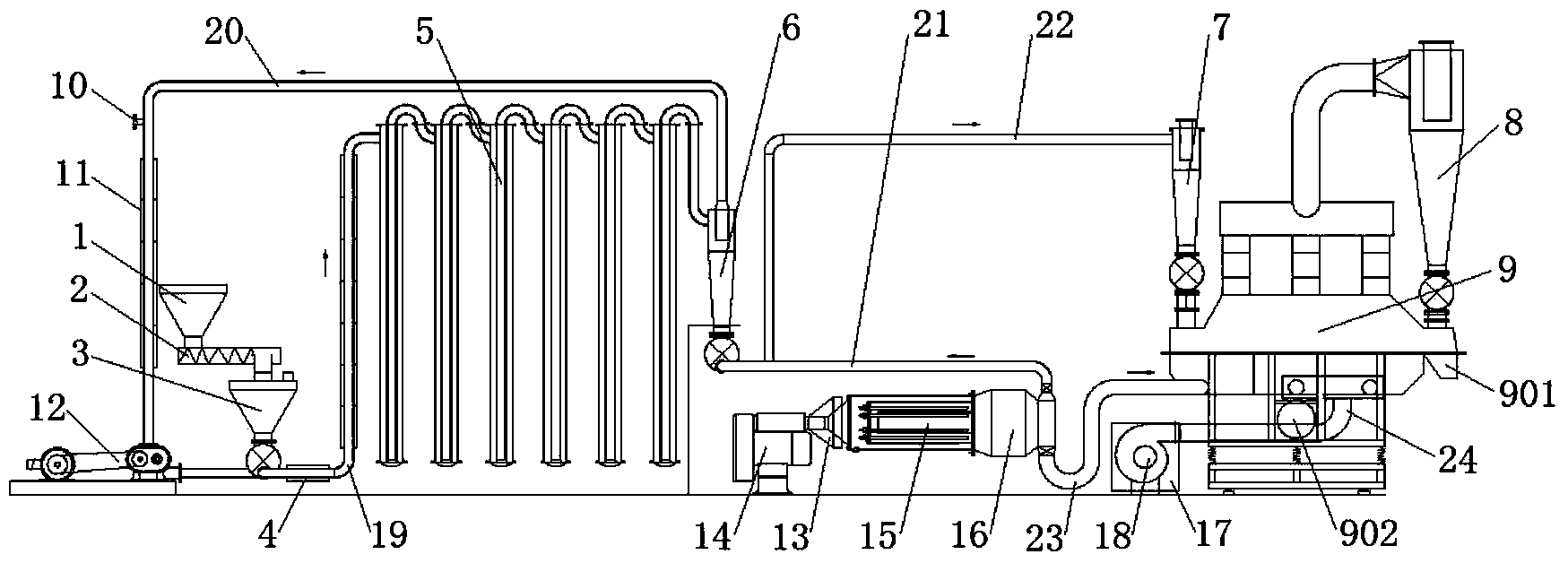

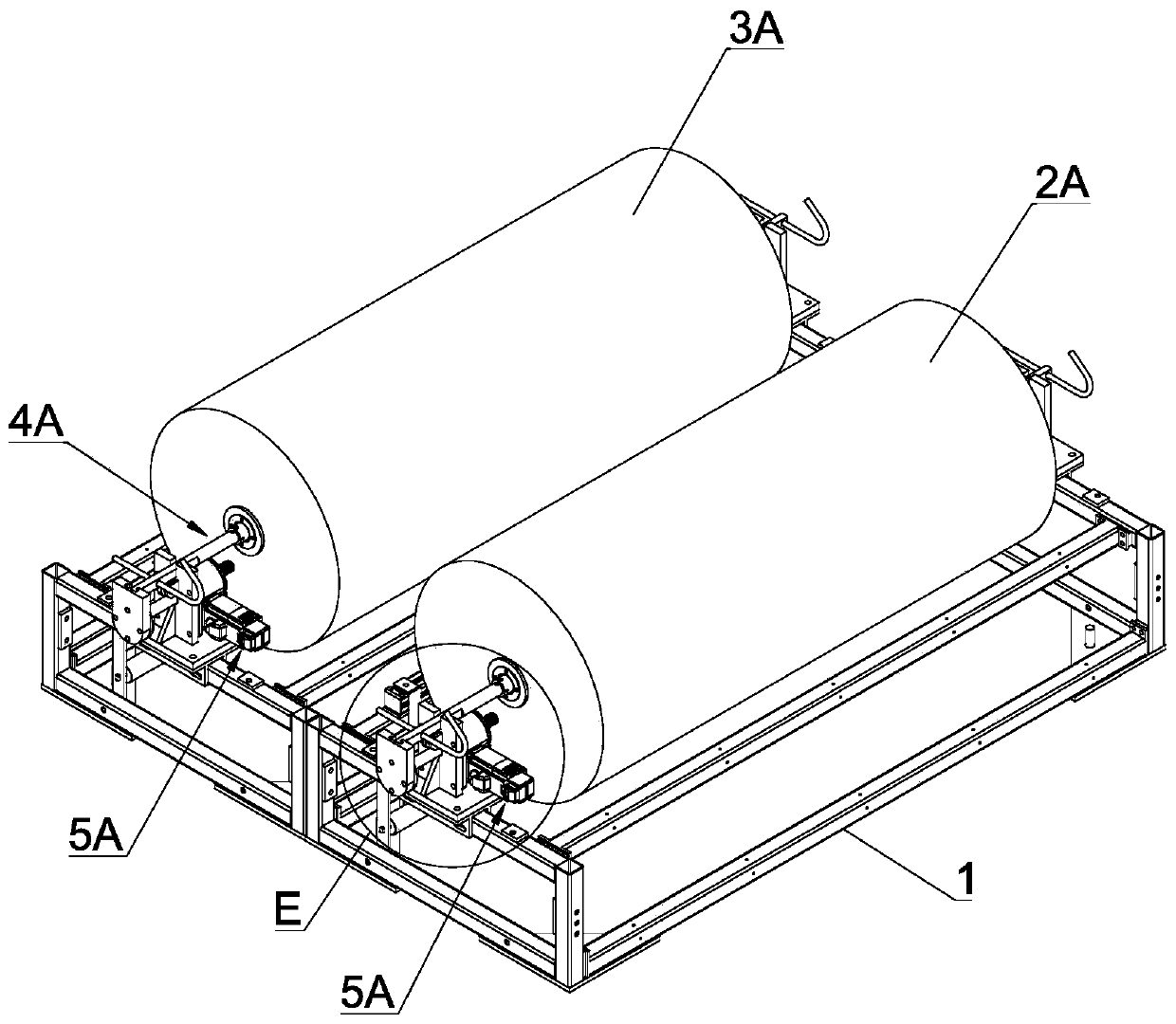

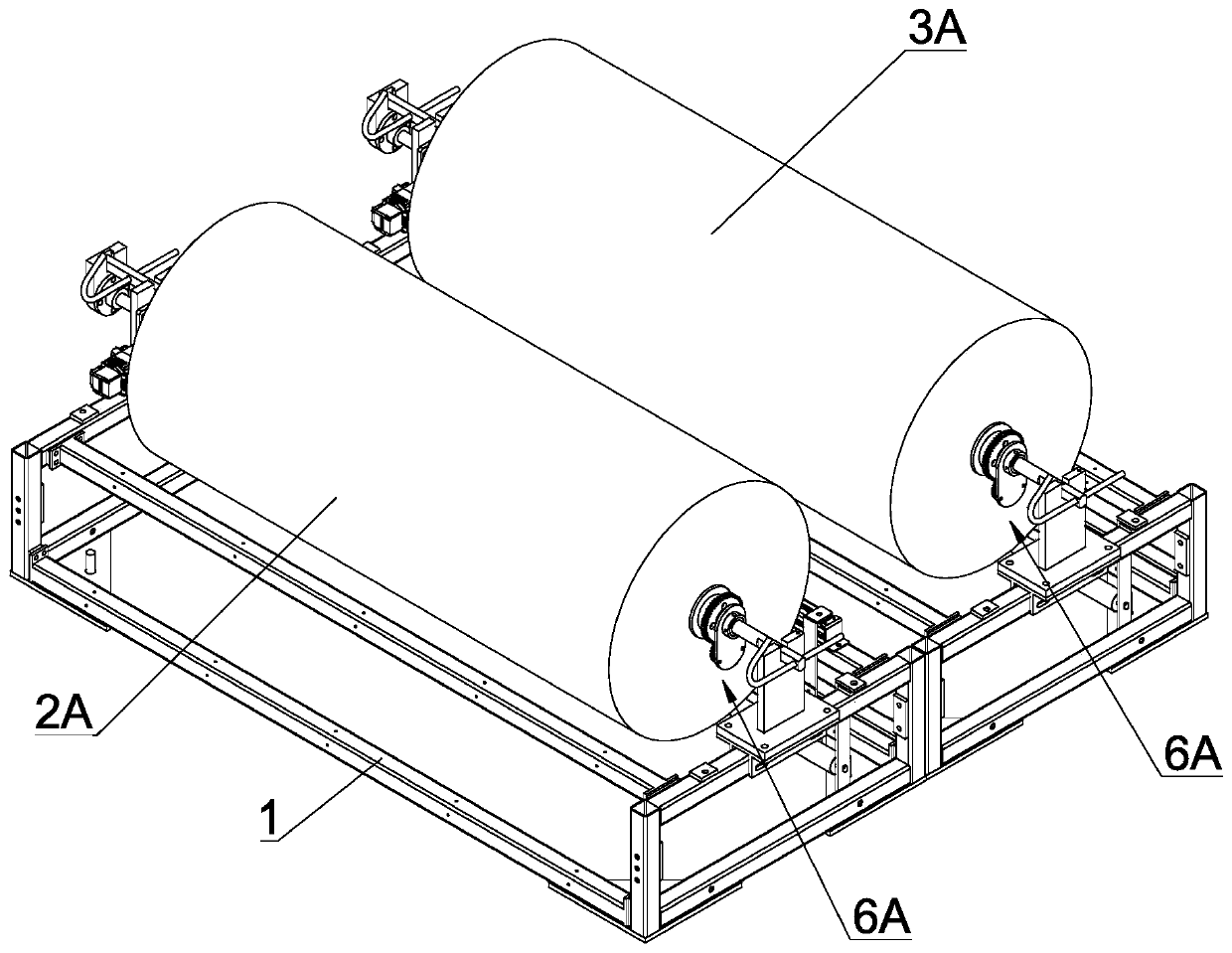

Full automatic production line for medical operating coat

ActiveCN110731563ARealize the normal trendIncrease the feeding speedProtective garmentClothes making applicancesRotational axisPunching

The invention discloses a full automatic production line for a medical operating coat. The production line comprises a rack, and a discharge device, a punching device, a composite device and a cuttingdevice arranged on the rack, wherein the discharge device comprises an upper-layer non-woven fabric roll, a lower-layer non-woven fabric roll, a deviation correction drive mechanism and a damping anti-rotating mechanism arranged on the rack; the composite device comprises a lateral side welding module and a middle part welding module; the lateral side welding module comprises a roll welding mechanism; the roll welding mechanism comprises a welding head and a rotation shaft adaptive separation mechanism used for separating a non-woven fabric body from lateral side margin wastes; the cutting device comprises a cutting mechanism, a fabric pressing mechanism and an adaptive material pulling mechanism arranged on the rack; the fabric pressing mechanism comprises a fixed mount, a movable mountand a compression drive mechanism; and the cutting mechanism comprises a cutter and a cutting drive mechanism. The production line can improve production efficiency and production quality of the operating coats.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

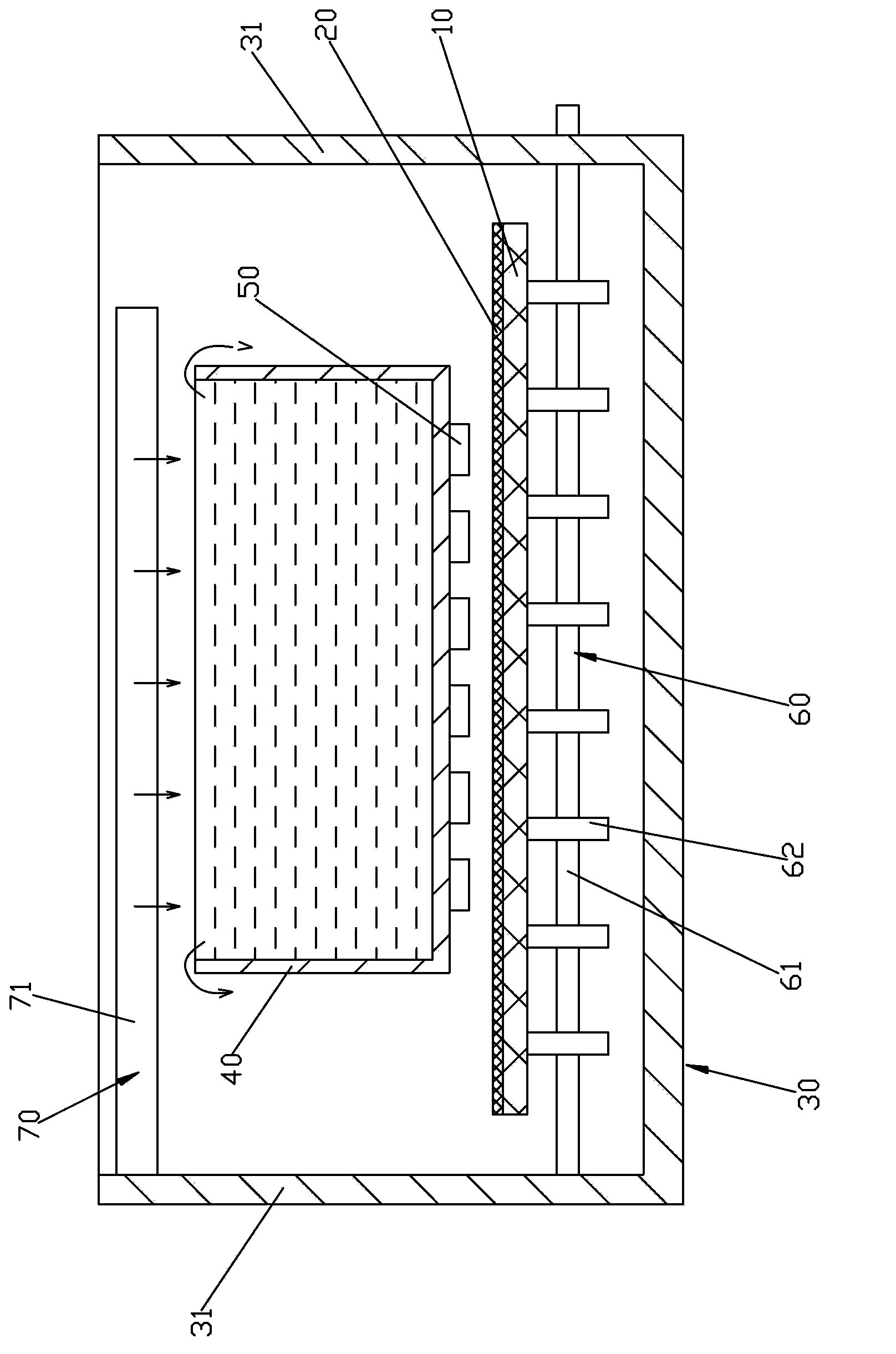

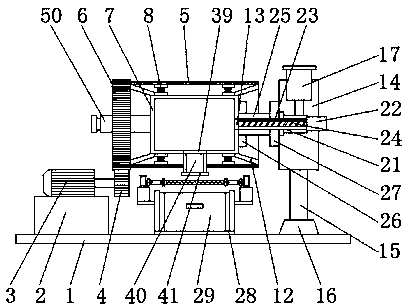

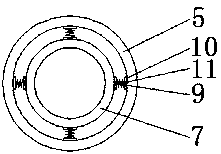

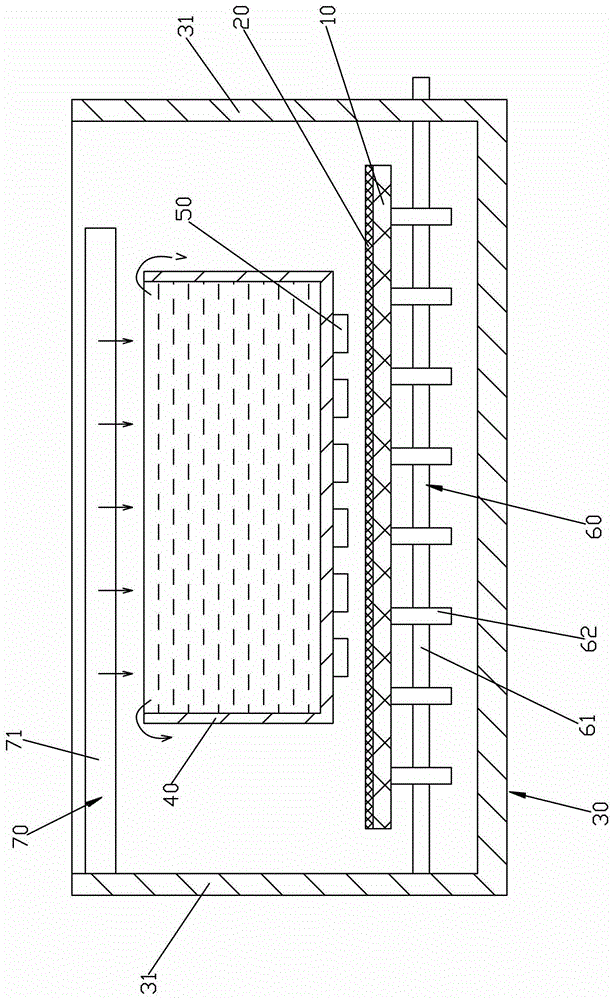

Cleaning device for liquid crystal glass substrate

ActiveCN104096693AEasy to cleanSimple structureCleaning using liquidsIndium tin oxideMechanical engineering

The invention discloses a cleaning device for a liquid crystal glass substrate. The first surface of the glass substrate is coated with an ITO (Indium Tin Oxide) membrane in a sticking manner; the cleaning device comprises a machine frame, a box body mounted on the machine frame in a connecting manner, an ultrasonic generator and a conveying unit mounted on the machine frame in a connecting manner, the ultrasonic generator is mounted below the box body in a connecting manner, the conveying unit is positioned below the ultrasonic generator and used for conveying the glass substrate, the second surface of the glass substrate faces downwards and is arranged on the conveying unit in a supporting manner, and the ITO membrane of the glass substrate faces upwards; a liquid supplying unit for supplying a cleaning solution is additionally arranged, the liquid supplying unit is used for adding the cleaning solution into the box body and enabling the cleaning solution to overflow from the box body, the overflowing cleaning solution flows onto the ITO membrane of the glass substrate, the ultrasonic generator sends out ultrasonic wave, and the cleaning to the ITO membrane is performed through the cleaning solution on the ITO membrane. The cleaning device has the advantages as follows: the ITO membrane can be protected, ultrasonic waves face the ITO membrane directly, the cleaning effect is good, the structure is simple, the cost is low, automatic production is achieved, and the labor cost is reduced.

Owner:莆田市嘉辉光电有限公司

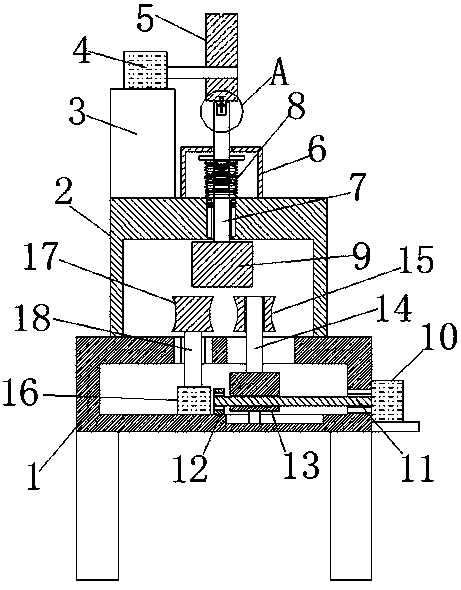

Shearing device for production of rubber and plastic products

InactiveCN108437000AReduce labor intensityRealize repeated cuttingMetal working apparatusEngineeringCam

The invention discloses a shearing device for production of rubber and plastic products. The shearing device comprises a shearing table. A portal frame is fixedly connected to the upper surface of theshearing table. A fixed plate is fixedly connected to the upper surface of the portal frame. A first motor is fixedly connected to the upper end of the fixed plate. An output shaft of the first motoris fixedly connected with a cam. A shell is fixedly connected to the upper surface of the portal frame. A movable rod is movably connected into the upper surface of the shell in a sleeved mode through a first through hole. The upper end of the movable rod penetrates through the first through hole to stretch out of the shell and is connected with the cam in a rolling mode. The lower end of the movable rod penetrates through the upper surface of the portal frame through a wall hole and is fixedly connected with a tool. The wall of the movable rod is fixedly sleeved with a stop block. The shearing device is simple in structure and convenient to operate; rubber and plastic tubes can be sheared automatically, so that the labor intensity of workers is relieved, and the risks of manual operationare avoided; and the rubber and plastic tubes can be automatically conveyed at a constant speed so that the rubber and plastic tubes can be accurately sheared at equal intervals, and the labor intensity of the workers is further relieved.

Owner:响水煦隆贸易有限公司

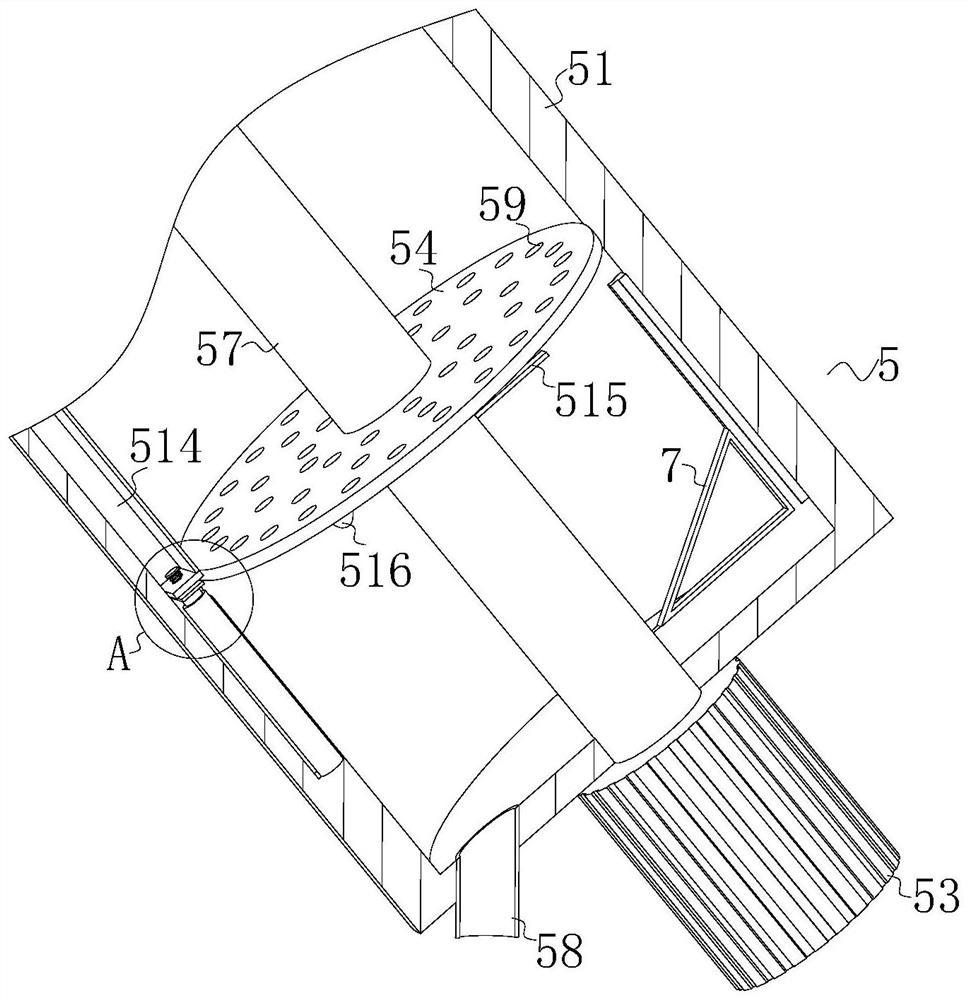

Mining electric locomotive sanding device

The invention relates to the technical field of mining machinery, in particular to a mining electric locomotive sanding device which comprises a first box body, a sand box and a second box body communicated to the right side of the sand box, the second box body is communicated with the first box body, a mounting shell is arranged on the upper right portion of the first box body, and a driving mechanism is arranged on the right side of the top of the first box body. The driving mechanism is used for providing a driving force, and a sand discharging mechanism is arranged on the right side of an inner cavity of the first box body. Through the arrangement of the first box body, the sand box, the second box body, the mounting shell, a driving mechanism, a sand outlet mechanism, a transmission mechanism, an auger rod and a slope surface, the problems that an existing sanding device cannot achieve constant-speed conveying of sand and stones, consequently, the sand and stones are discharged unevenly, part of the sand and stones are prone to being affected with damp and gathered into blocks, and a sand discharging opening is blocked are solved; the mining electric locomotive sanding device has the advantages of being capable of conveying sandstones at a constant speed and dispersing the damped sandstones.

Owner:湘潭长联机械制造有限公司

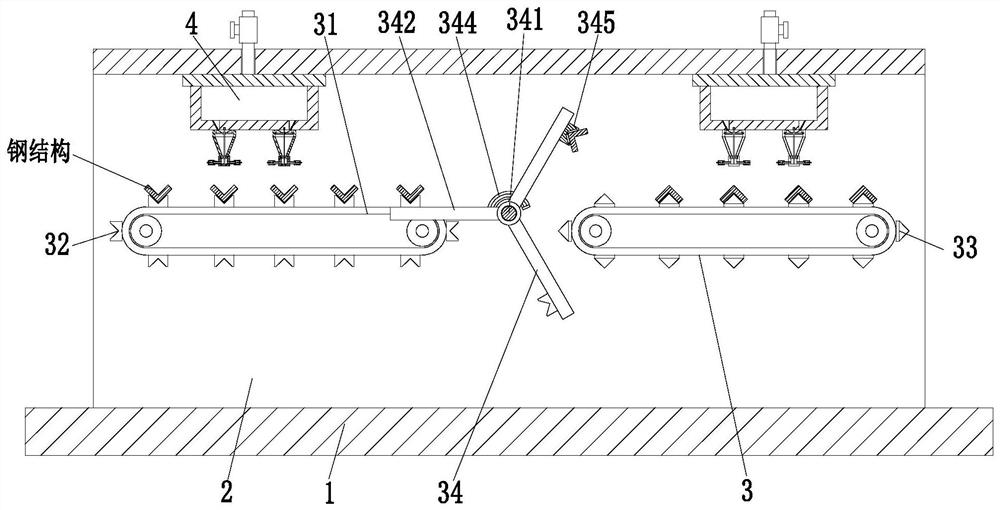

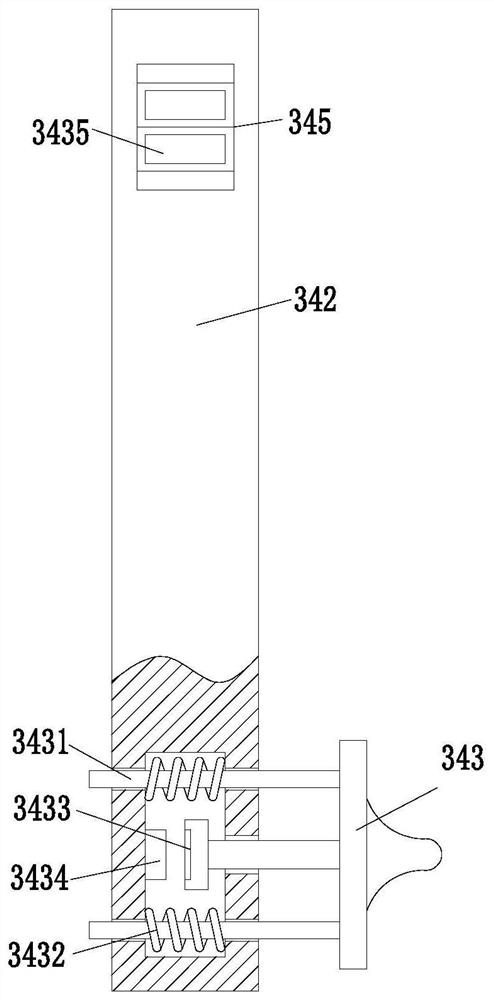

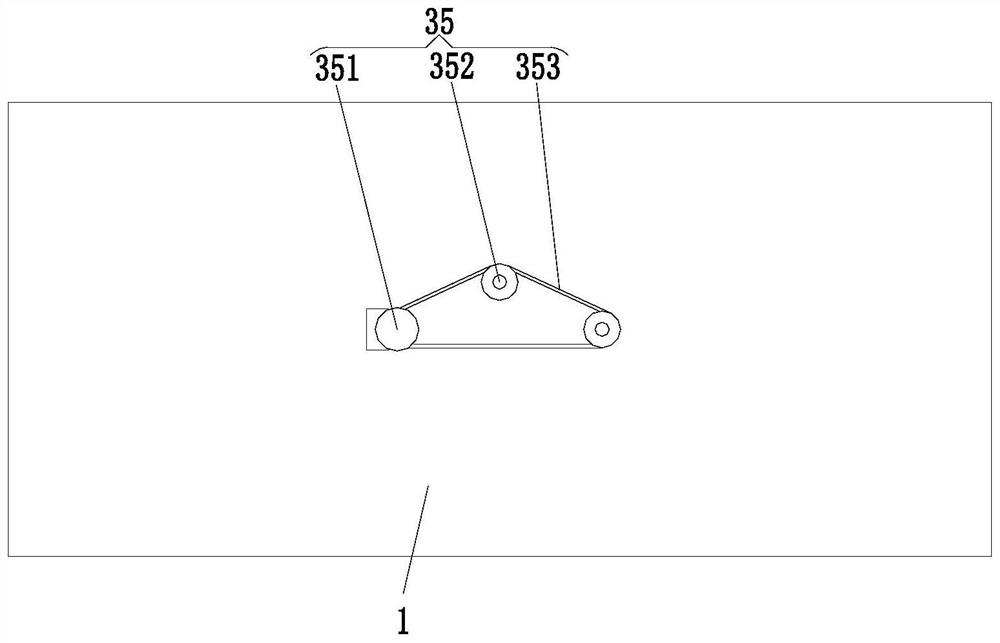

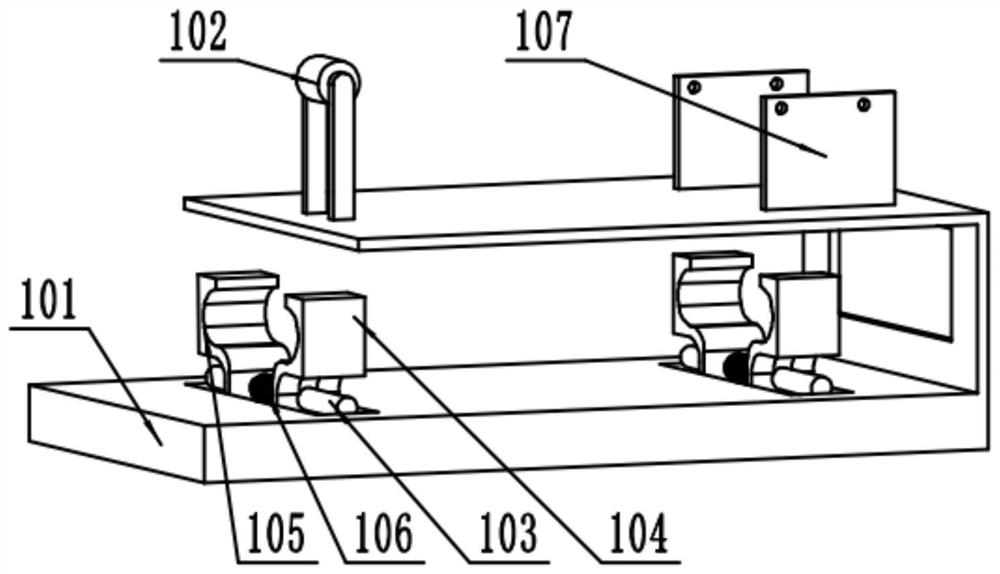

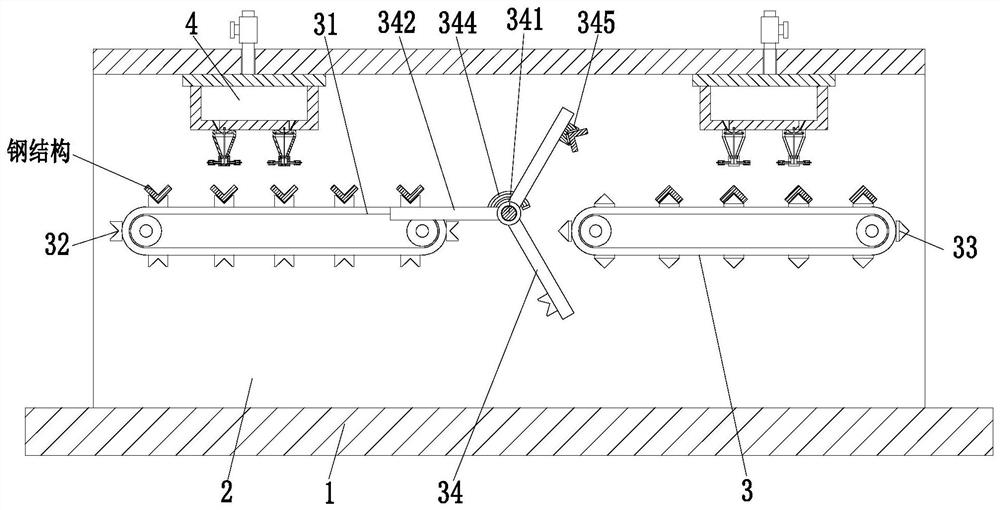

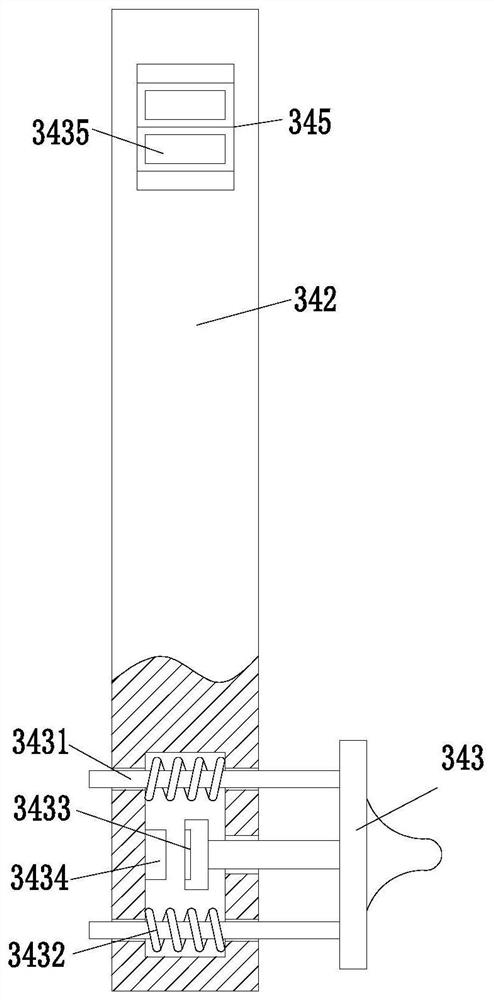

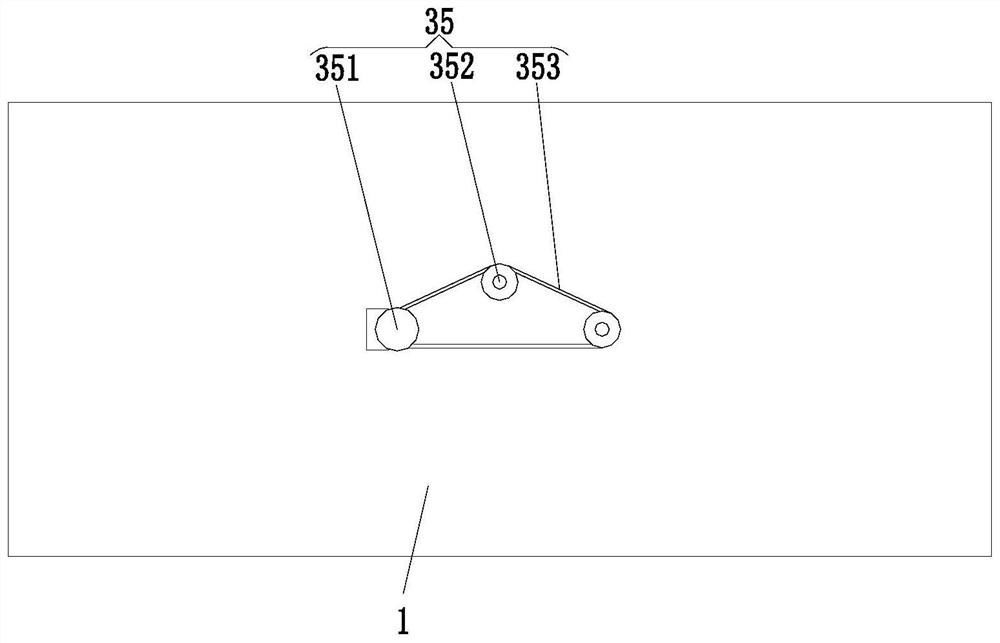

Steel structure spraying facility for power transmission iron tower

ActiveCN111841955AConvenient spray processingGuaranteed service lifeSpraying apparatusTowerIndustrial engineering

The invention relates to a steel structure spraying facility for a power transmission iron tower. The steel structure spraying facility for the power transmission iron tower comprises a base plate, asupporting frame, conveying devices and spraying devices. The supporting frame is installed at the upper end of the base plate, the conveying devices are installed in the middle of the interior of thesupporting frame, and the spraying devices are symmetrically arranged above the conveying devices and installed at the upper end of the interior of the supporting frame. The steel structure sprayingfacility for the power transmission iron tower can solve the problems that when an existing facility sprays rust-resisting materials to a steel structure, only one side of the steel structure can be sprayed in general, the omission phenomenon is prone to happen on the other side of the steel structure, and therefore the spraying effect of the steel structure is poor, spraying operation is not uniform, and the follow-up utilization of the steel structure is not facilitated; and when the existing facility conducts spraying processing operation on the steel structure, the spraying range of a spraying mechanism cannot be accurately adjusted in general, and therefore the phenomenon that a cross exists or a part is not sprayed is prone to exist on the sprayed steel structure, and the follow-up utilization effect of the steel structure is affected.

Owner:FUYANG SANHUAN POWER EQUIP CO LTD

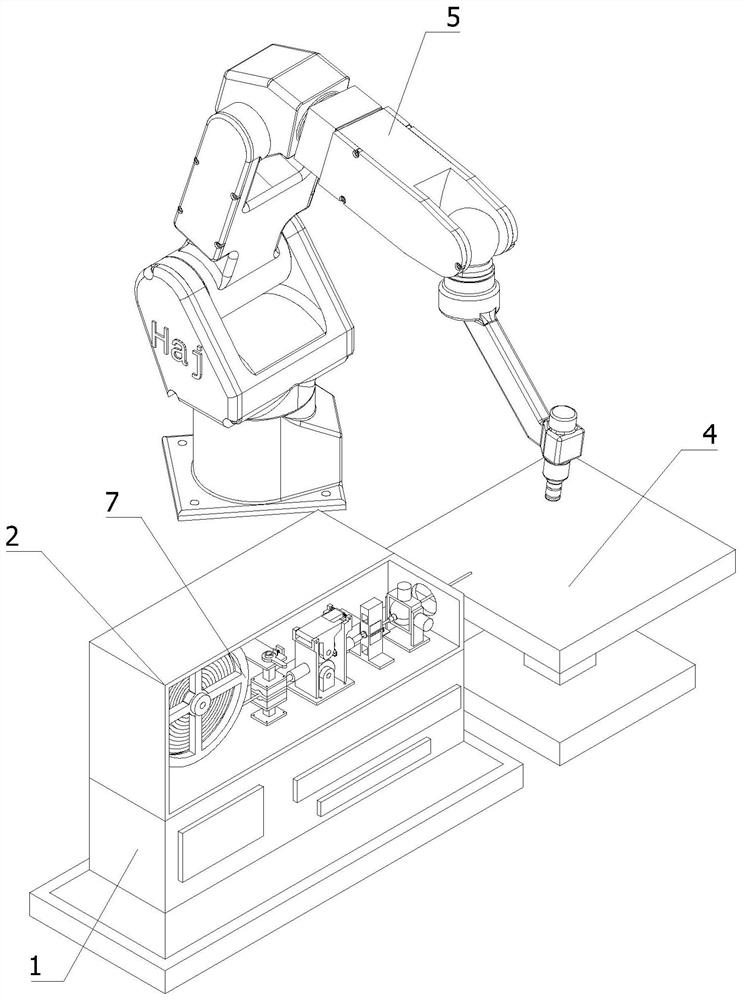

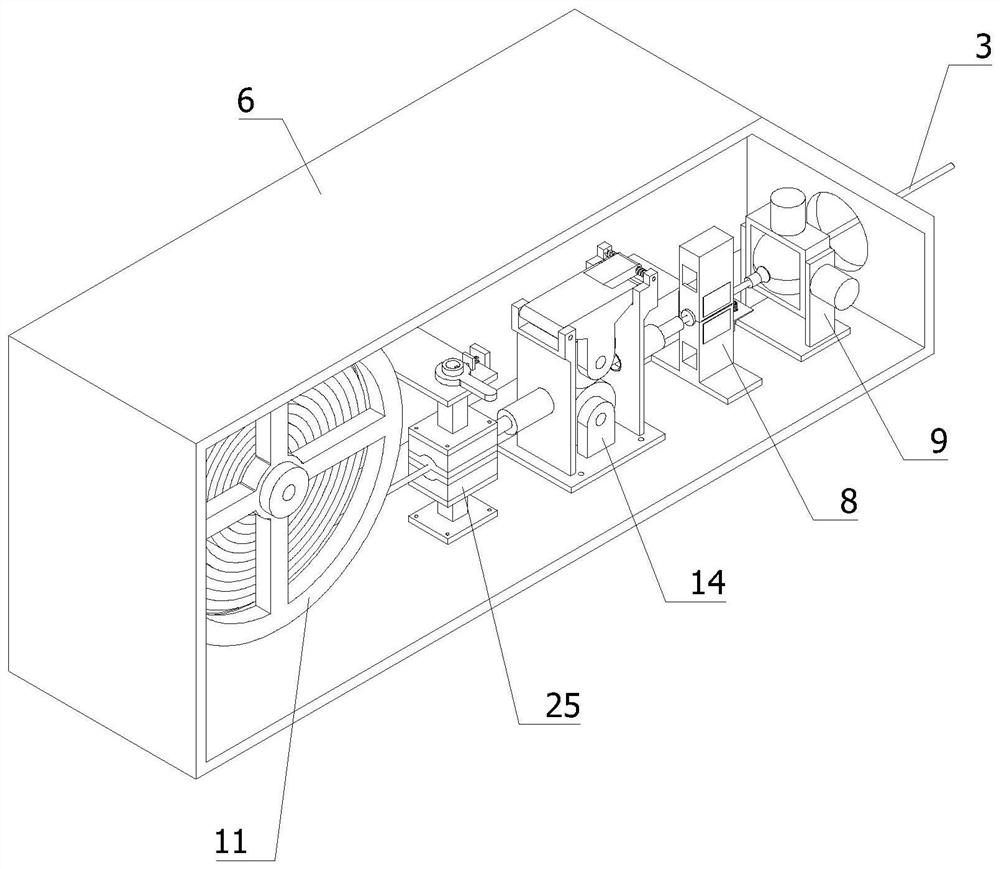

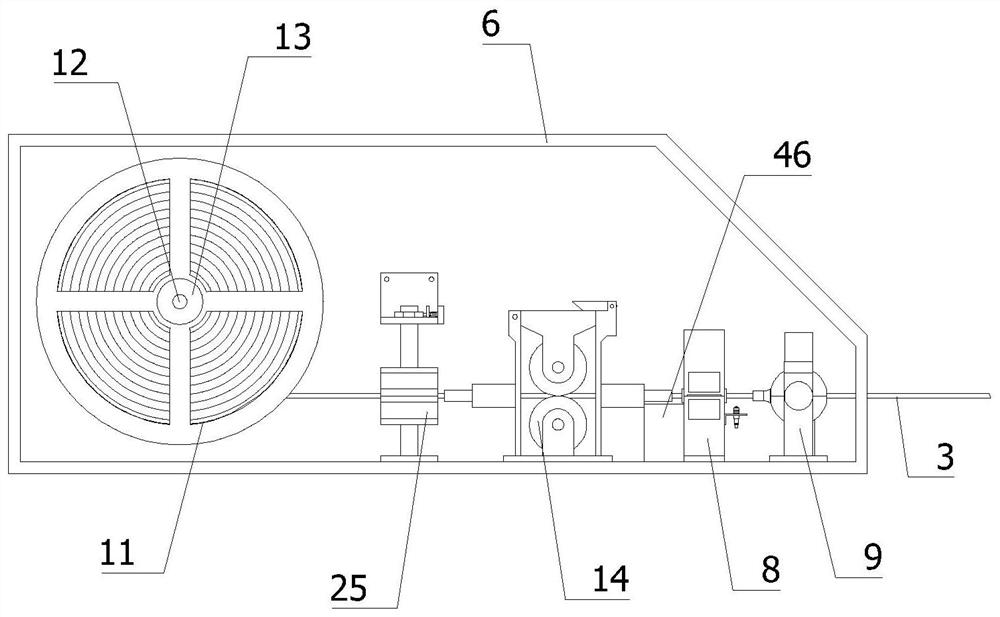

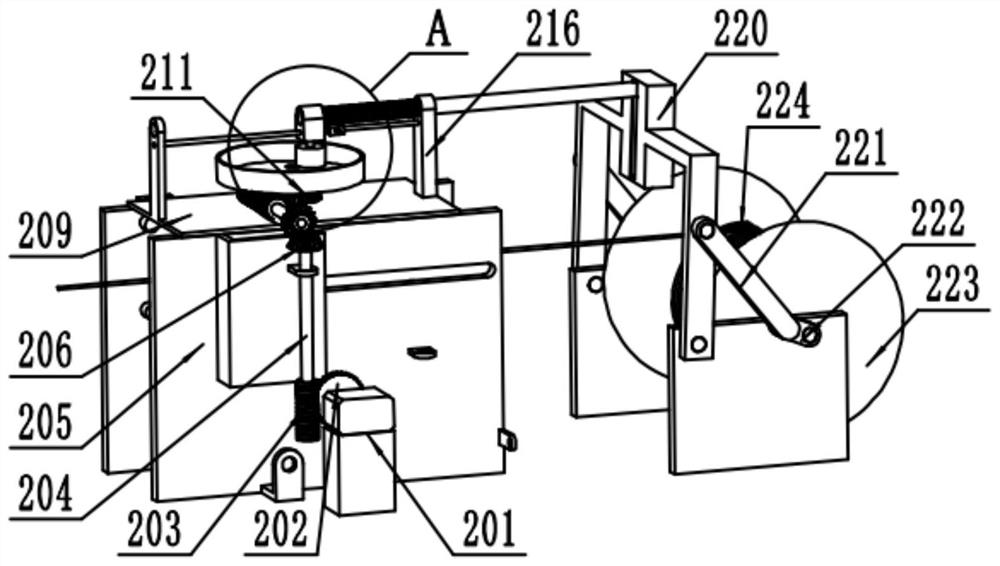

Intelligent welding machine using rod-shaped welding wires

ActiveCN113399786AImprove welding efficiencyWire delivery remains stableWelding accessoriesEngineeringWelding

The invention relates to the technical field of welding, in particular to an intelligent welding machine using rod-shaped welding wires. The machine comprises an industrial robot, a wire feeding device, a welding table and a welding robot; the welding table is used for placing workpieces and is arranged beside the wire feeding device; the wire feeding device comprises an adjustable wire feeding assembly and an angle adjusting assembly; the adjustable wire feeding assembly is used for adjusting the wire feeding speed of the welding wires according to the welding efficiency of the workpieces and comprises a shell, a wire rolling mechanism and a wire feeding speed sensing mechanism; a displacement sensor used for sensing the conveying amount of the welding wires is arranged on the wire feeding speed sensing mechanism; and the wire rolling mechanism, the wire feeding speed sensing mechanism and the angle adjusting assembly are all located on the unified horizontal line. through cooperation of the wire rolling mechanism and the wire feeding speed sensing mechanism, the welding wire conveying speed can be conveniently adjusted according to the welding condition, and the angles of the welding wires can be freely adjusted through the angle adjusting assembly during welding, so that the welding efficiency and the welding precision are improved.

Owner:广州市顺卓建设工程有限公司

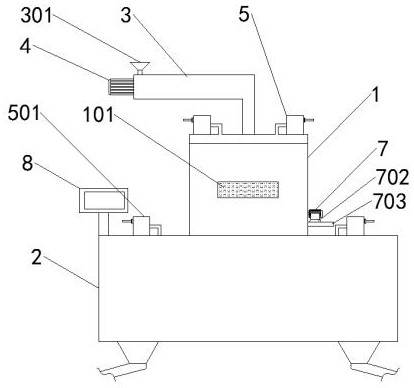

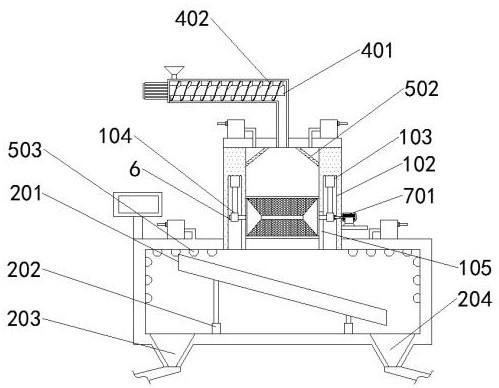

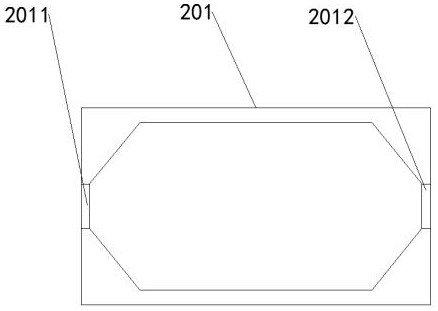

Heating spiral type material conveying device

The invention discloses a heating spiral type material conveying device. The heating spiral type material conveying device comprises a warehousing shell, a feeding mechanism, a stirring paddle and a horizontally-arranged conveying stirring cage. The warehousing shell is provided with a feeding port and a discharging port and used for material heating and stirring. The feeding mechanism is connected with the feeding port and used for conveying materials into the warehousing shell. The stirring paddle is arranged in the warehousing shell and comprises a hollow rotating shaft and a plurality of paddle blades spirally arranged on the rotating shaft. The top end of the rotating shaft stretches out of the warehousing shell and is connected with a two-joint rotation connector. The paddle blades are of a hollow structure and sequentially communicate through a connecting pipe. The paddle blades at the topmost part and the bottommost part of the rotating shaft communicate with an air outlet way and an air inlet way of the two-joint rotation connector through a rotating shaft cavity or an air pipe correspondingly. The conveying stirring cage is connected with the discharging port. The heating spiral type material conveying device can effectively crush, stir and heat greasy filth, and smooth heating and conveying of the greasy filth are achieved.

Owner:浙江博世华环保科技有限公司

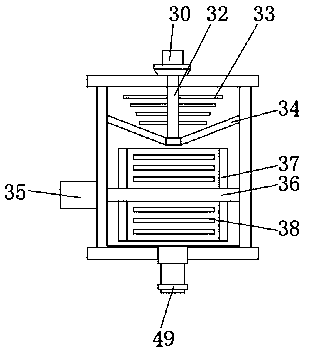

Ball milling equipment for lithium battery material processing

InactiveCN108940471AImprove grinding efficiencyImprove grinding effectTransportation and packagingMixersEngineeringMaterials processing

The invention discloses ball milling equipment for lithium battery material processing. The equipment comprises a bottom plate, a supporting base, a first motor, a driving gear, a damping shell, a driven gear ring, a ball milling barrel, a damping mechanism, a connection plate, a feed inlet, a support, a supporting column, a supporting foot, a stirring box and a screw rod conveyor. The screw rod conveyor comprises a second motor, a conveying barrel and a conveying screw rod arranged inside the conveying barrel, an output shaft of the second motor is fixedly connected with one end of the conveying screw rod, the output end of the screw rod conveyor penetrates through one side wall of the support to communicate with a feed inlet, the outer side of the conveying barrel is sleeved with a hollow rotating shaft, the end, close to the ball milling barrel, of the hollow rotating shaft is fixedly provided with a first bearing pedestal in a matched mode, a second bearing pedestal is fixedly installed at the other end of the hollow rotating shaft and located on the outer wall of one side of the support, a limiting groove is formed below the damping shell, and a collection box is arranged inside the limiting groove. Operation is convenient and fast, and the ball milling efficiency and the ball milling effect are improved.

Owner:张天才

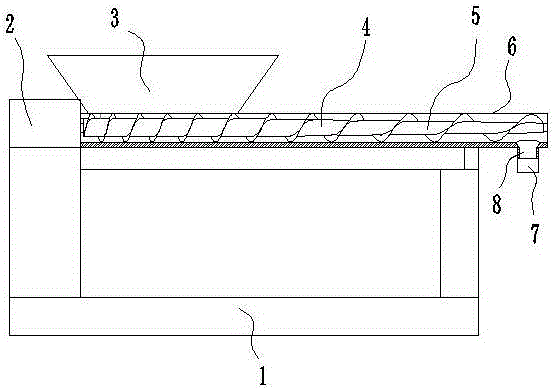

Anti-blocking material conveyer

The invention discloses an anti-blocking material conveyer. The anti-blocking material conveyer comprises a frame, the frame is provided with a driving mechanism and a screw connected to the driving mechanism, the screw is sleeved with a charging barrel, one end of the charging barrel is provided with a feed hopper, the other end of the charging barrel is provided with a discharge outlet, a spirally extended conveyer channel is disposed, between the feed hopper and the discharging outlet, in the periphery of the screw, the cross sectional area of the conveyer channel, close to the feed hopper is less than the cross sectional area of the other end. The volume of the conveyer channel spirally extended from and disposed to the periphery of the screw increases gradually from the feed hopper to the discharge outlet, the increased volume can prevent from short pause caused by split charging of material, powder or granule will not be extruded and caked even affected with damp, the conveyer process of the powder or granule is uniform in speed and smooth, accurately metering can be achieved in the subsequent split charging split charging operation, so the whole production line can continuously work at high efficiency.

Owner:浙江百纳橡塑设备有限公司

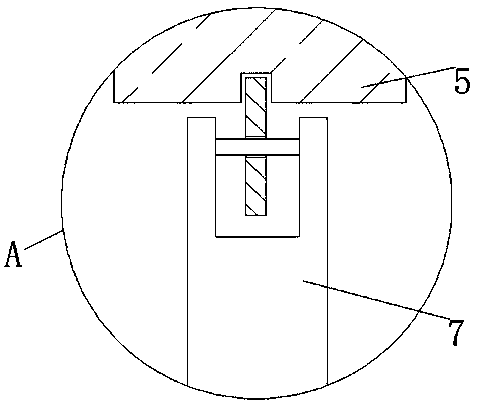

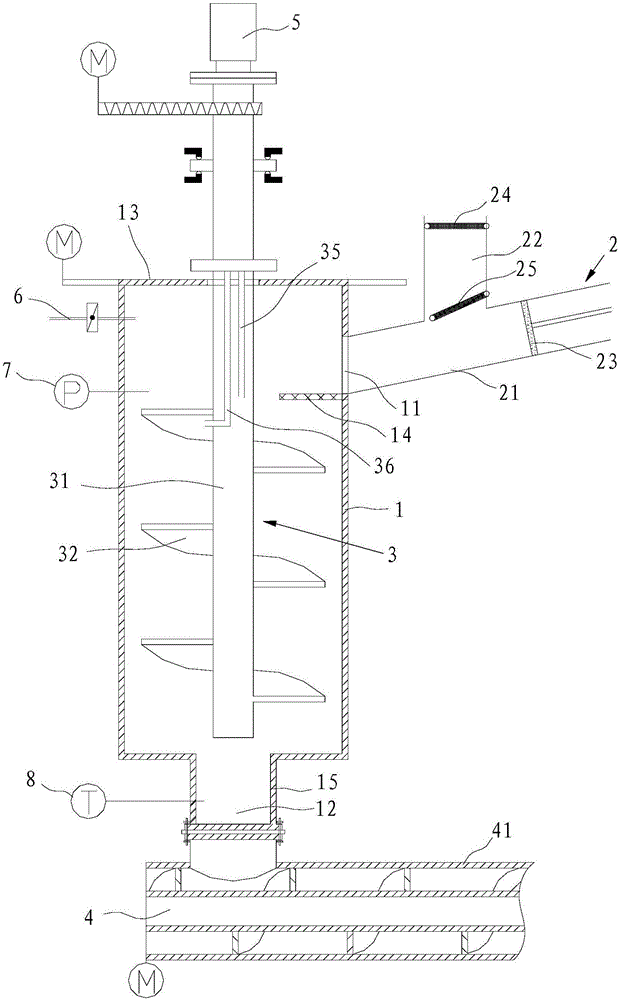

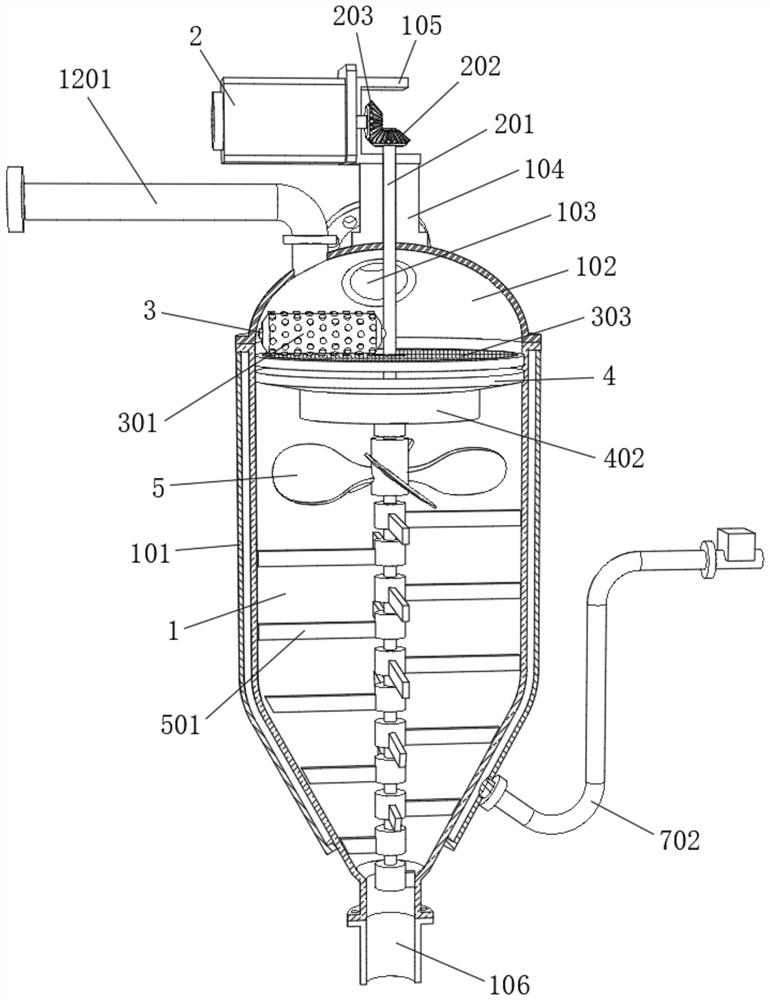

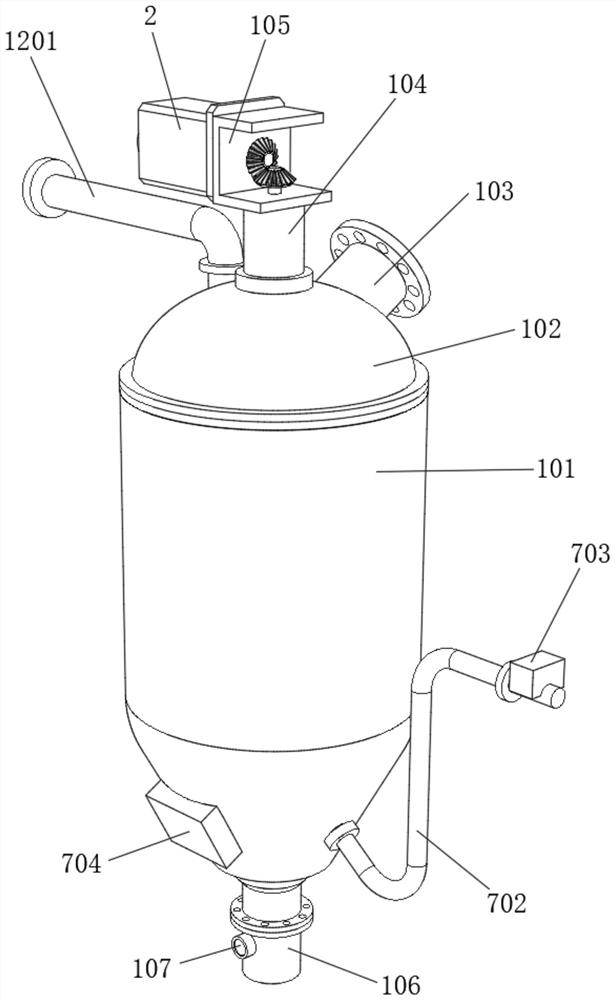

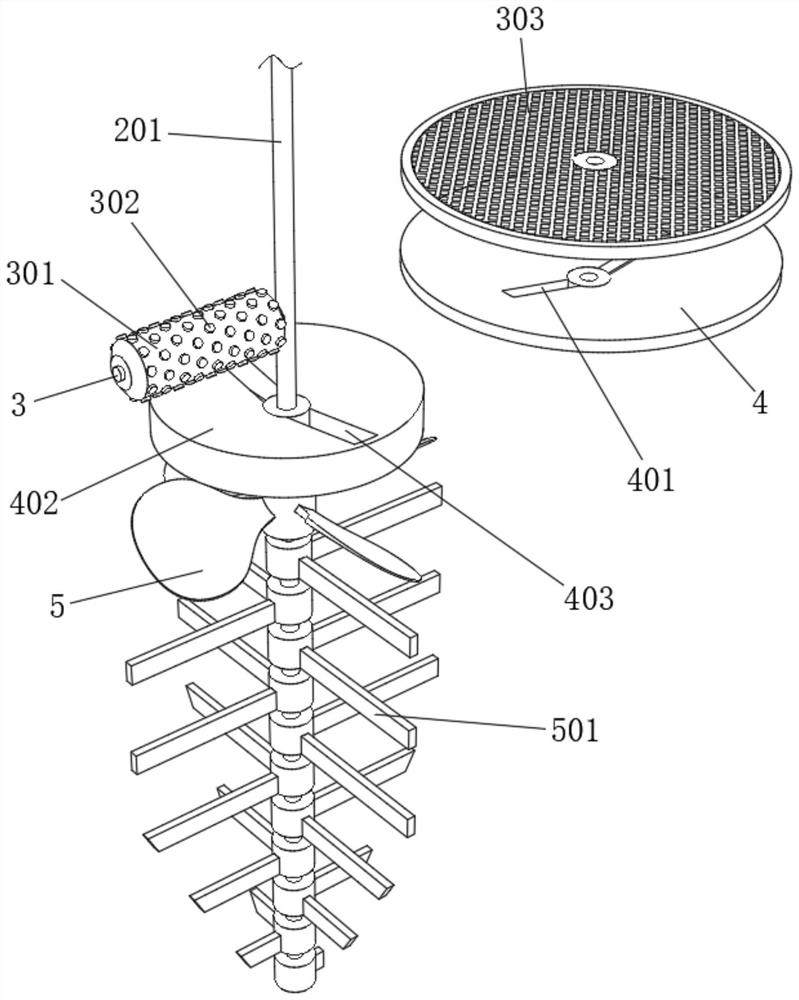

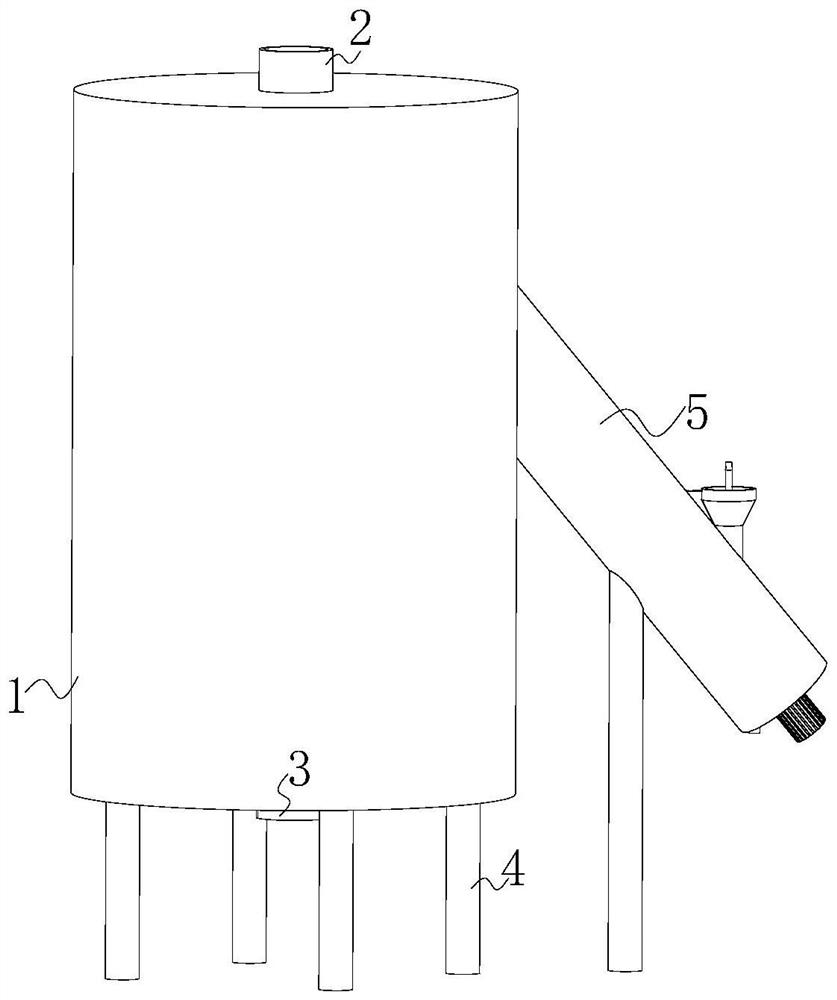

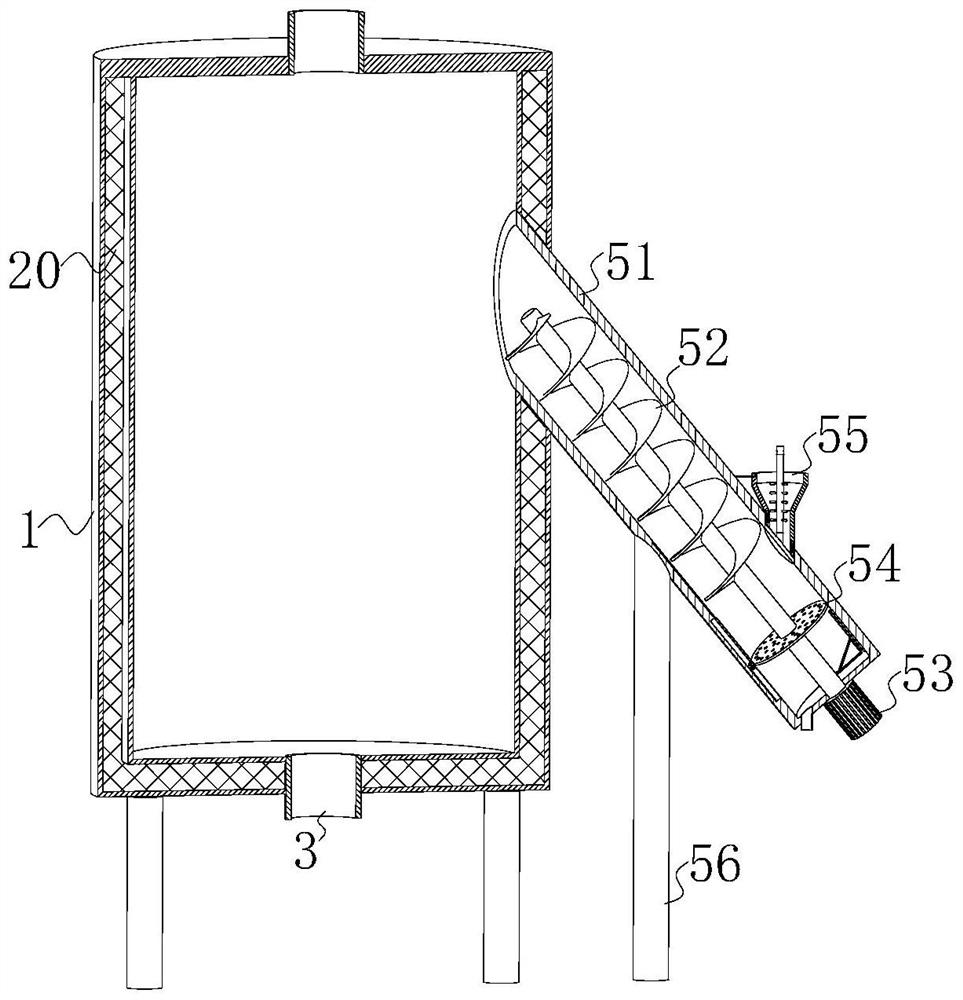

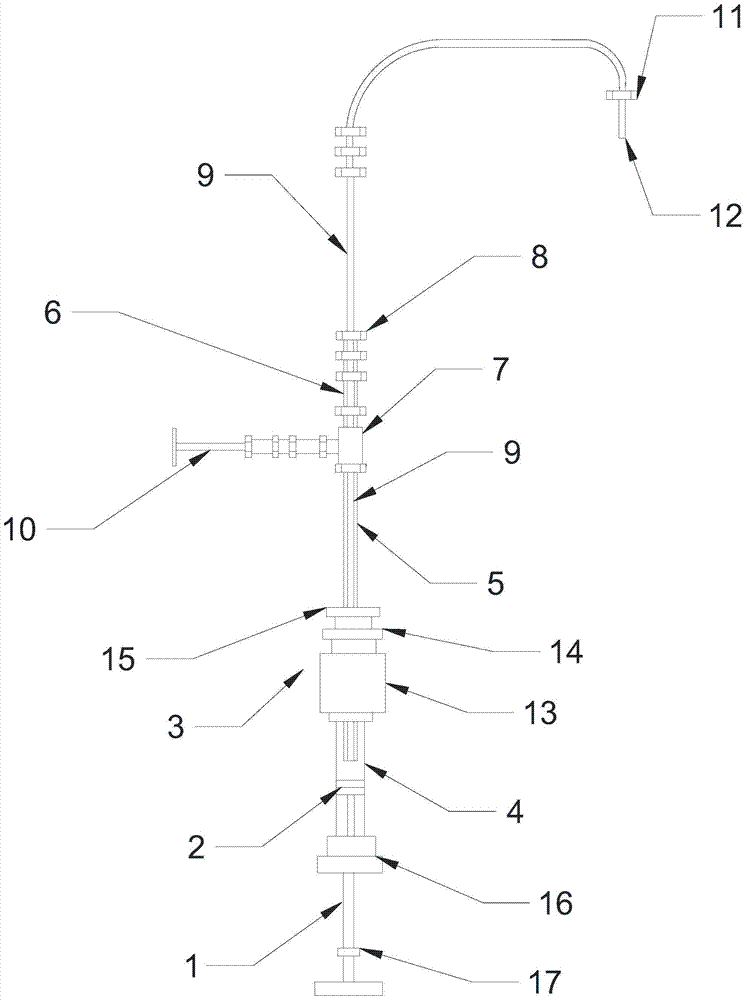

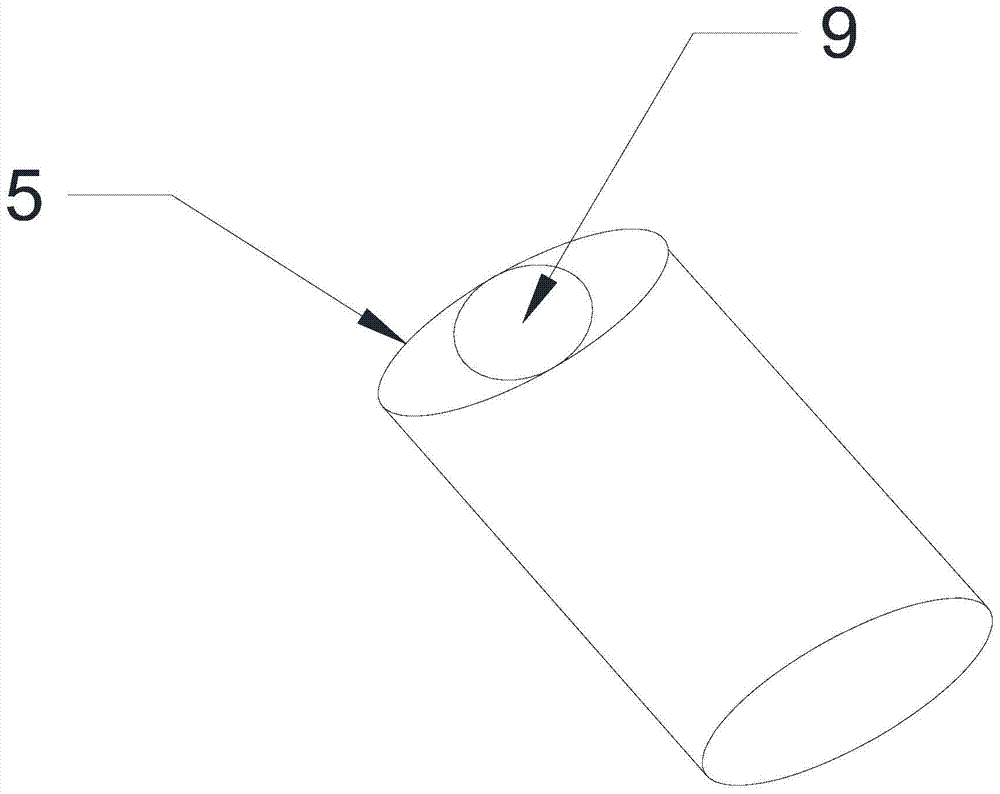

Vertical sludge drying machine

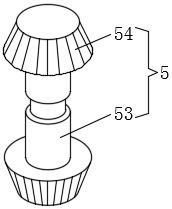

PendingCN113511795AUniform conveyingKeep drySludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to the technical field of sludge drying machines, and discloses a vertical sludge drying machine which comprises a bottom plate and a reaction kettle; the outer surface of the reaction kettle is sleeved with a shell, an oil guide layer is arranged between the shell and the reaction kettle, the top of the reaction kettle is fixedly connected with a cover body, and a feeding pipe is inserted into the top of the cover body; a filter plate and a first conical plate are fixedly connected to the top of the circumferential inner wall of the reaction kettle, the filter plate and the first conical plate are arranged up and down, and a discharging opening is formed in the upper surface of the first conical plate; a supporting column is fixedly connected to the upper surface of the cover body, a C-shaped base is fixedly connected to the top of the supporting column, and a motor is fixedly connected to one side of the C-shaped base; and one end of an output shaft of the motor is fixedly connected with a longitudinal bevel gear. According to the vertical sludge drying machine, the discharging opening can be indirectly opposite to a material passing opening, so that sludge can be conveyed at a constant speed, sludge drying in the later period is facilitated, and the dryness of the sludge is guaranteed.

Owner:QINGDAO ZHONGWANFANG ENERGY TECH CO LTD

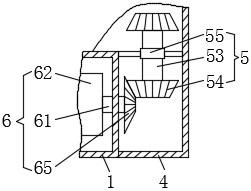

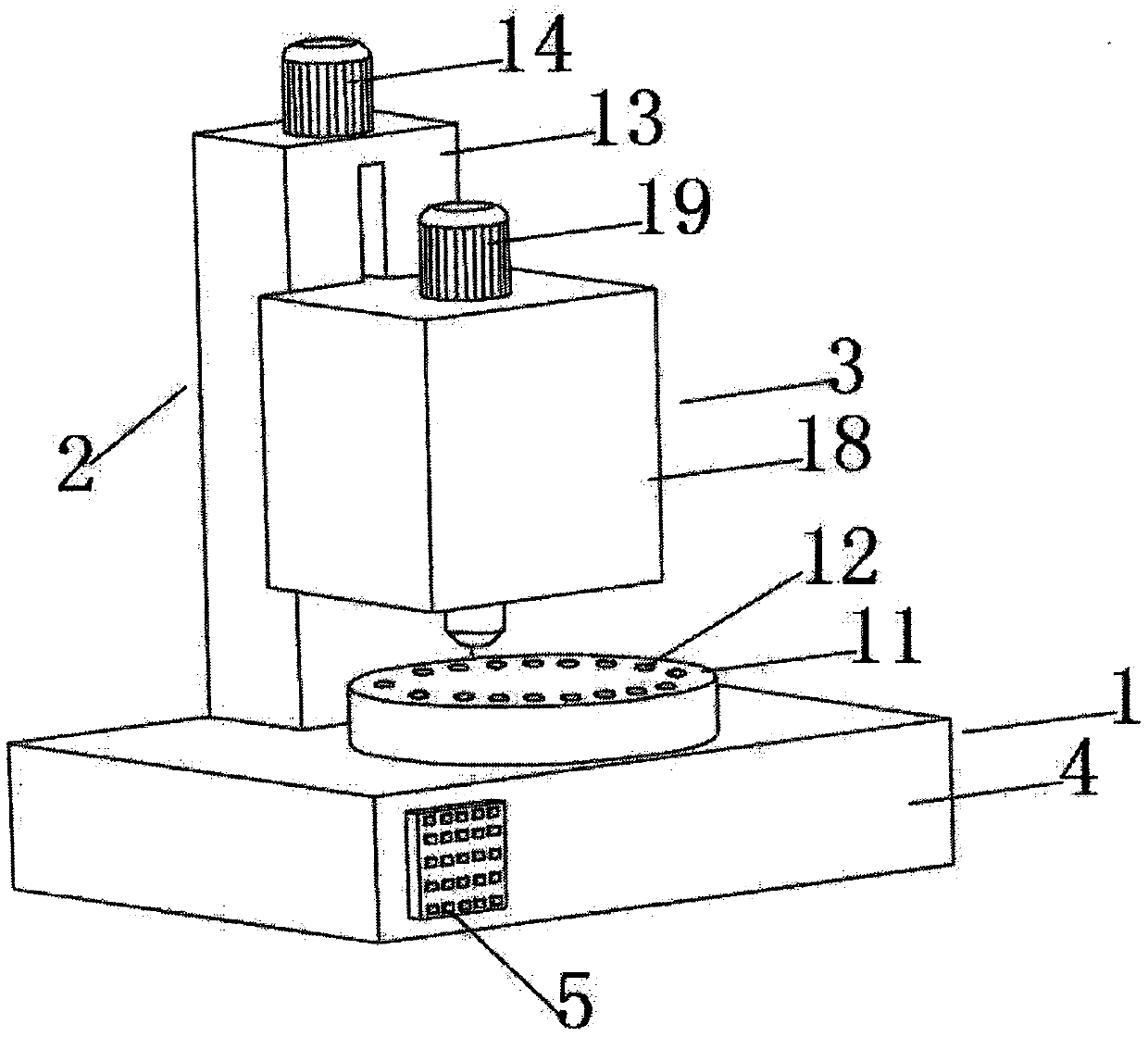

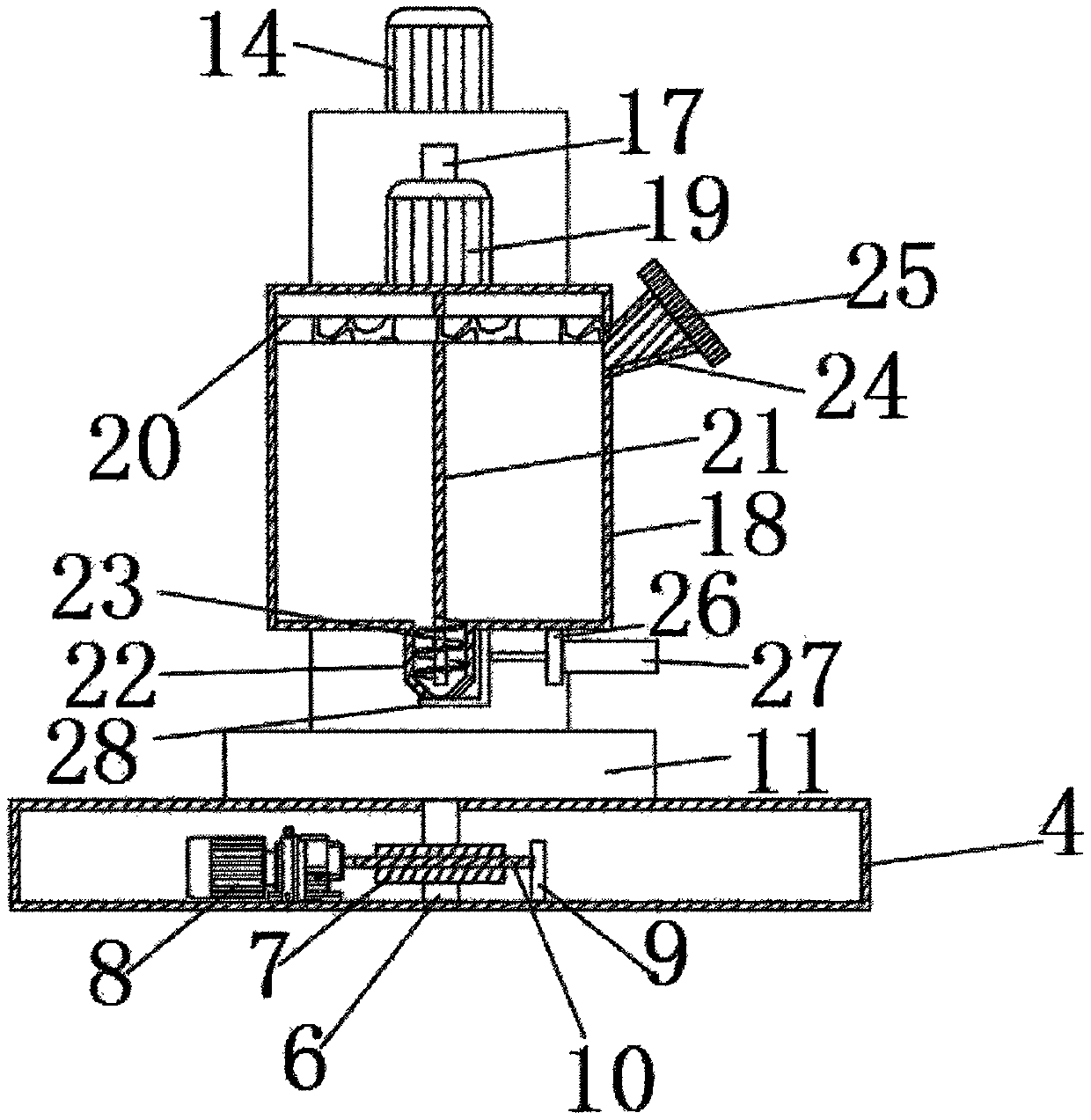

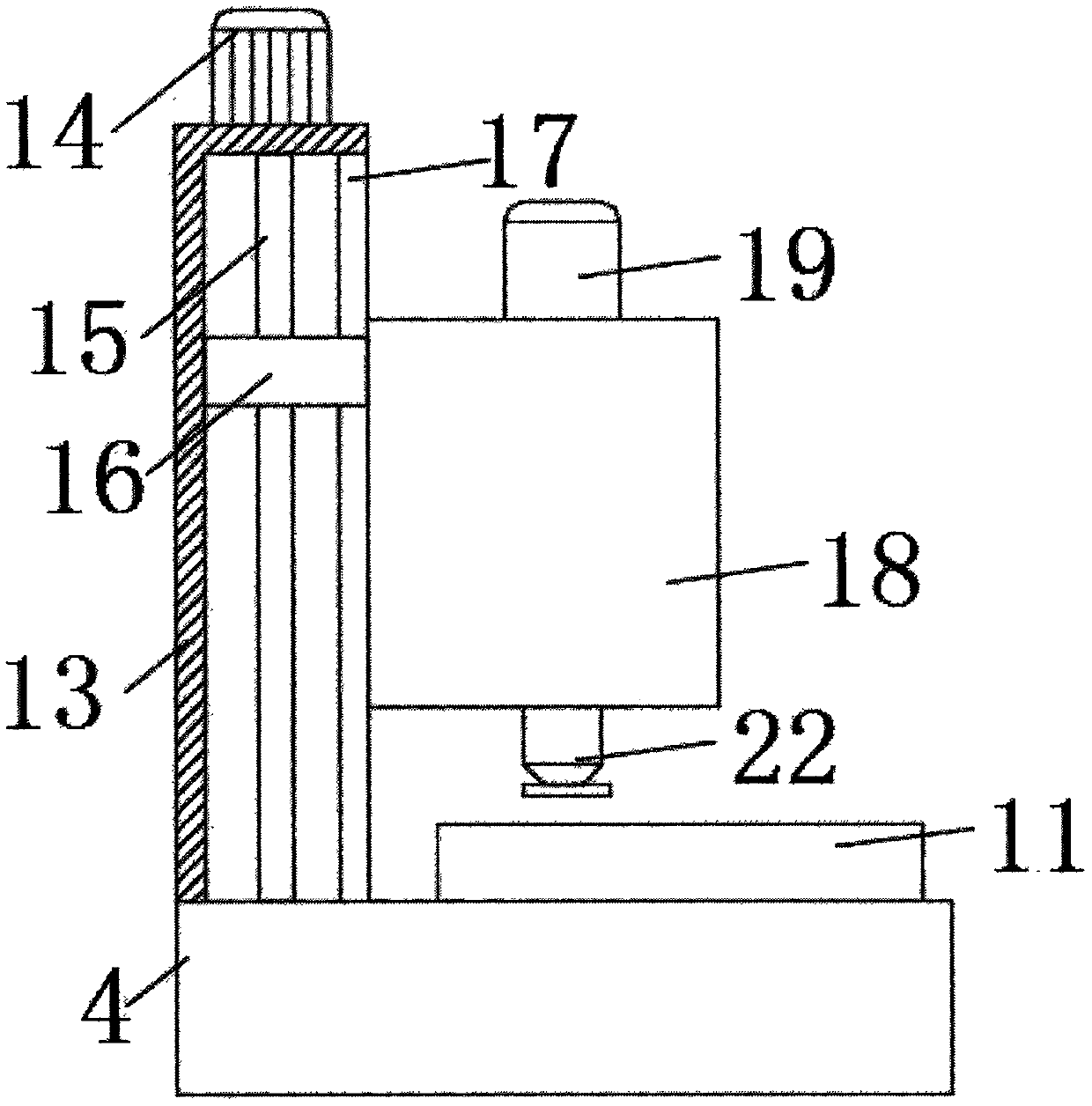

Paint detection sampling device

The invention discloses a paint detection sampling device. The device comprises a rotation mechanism, a lifting mechanism and a sampling mechanism. The lifting mechanism is arranged above the rotationmechanism, and a sampling mechanism is arranged on one side of the lifting mechanism. The rotation mechanism is composed of a working table, a control panel, a rotating main shaft, a transmission turbine, a servo motor, a support frame, a transmission vortex rod, a rotary table and a placement slot. An internal portion of the working table is rotatably connected with the rotating main shaft. Through setting the lifting mechanism, a height of a feeding nozzle can be flexibly adjusted, which is convenient for sampling bottles of different heights. By setting the servo motor and the rotary table, the sampling bottles can be conveniently placed, and the sampling bottles can be easily taken out after sampling is completed. By setting an injection piston and a material conveying screw, under aneffect of the material conveying screw, powdery or thick paint can be conveyed at a uniform speed, and an inner wall material can be cleaned under the effect of the injection piston so as to realizesimultaneous conveying and cleaning. Detection and sampling can be conveniently achieved.

Owner:山东腾翔产品质量检测有限公司

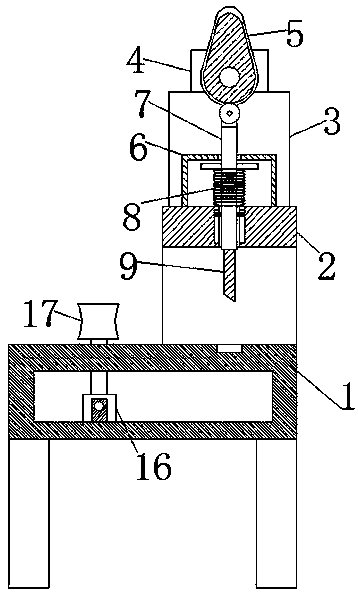

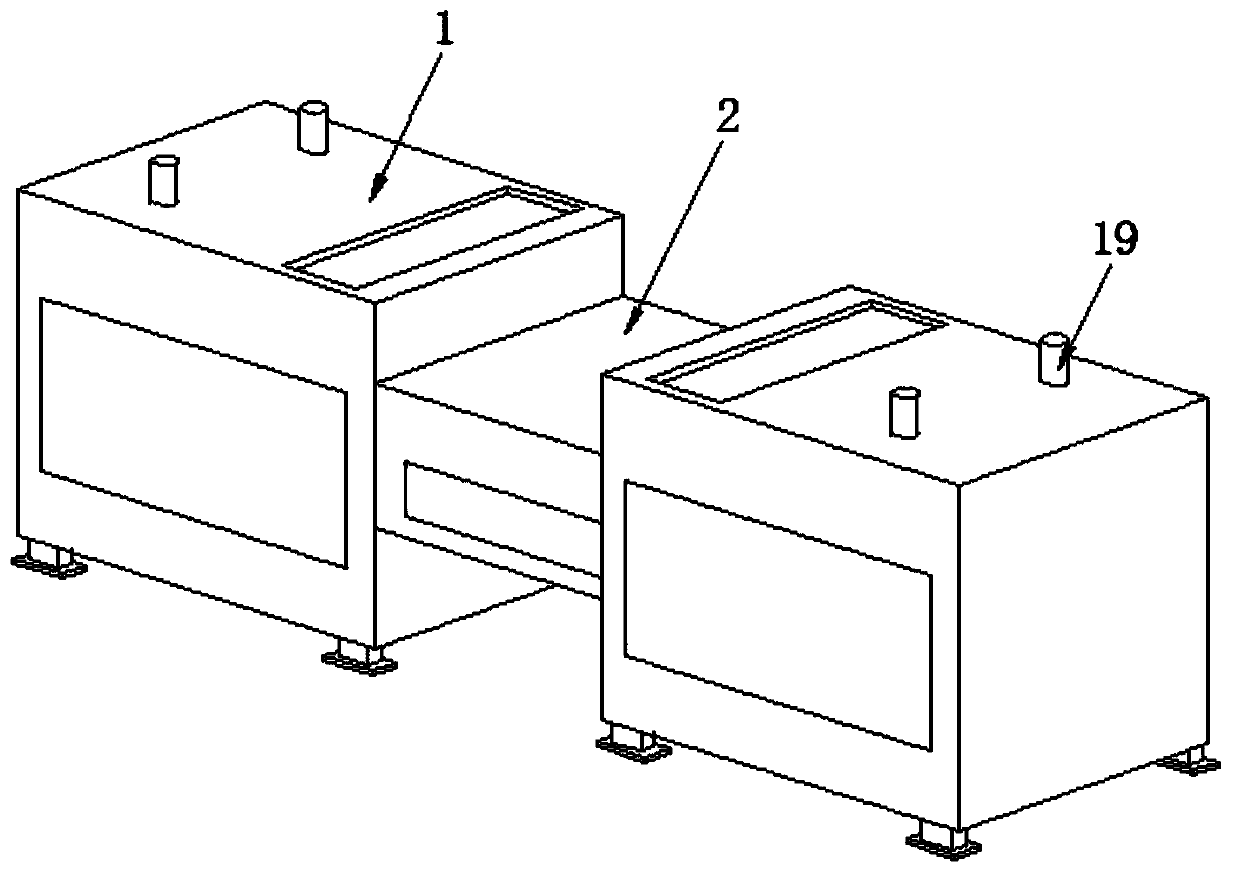

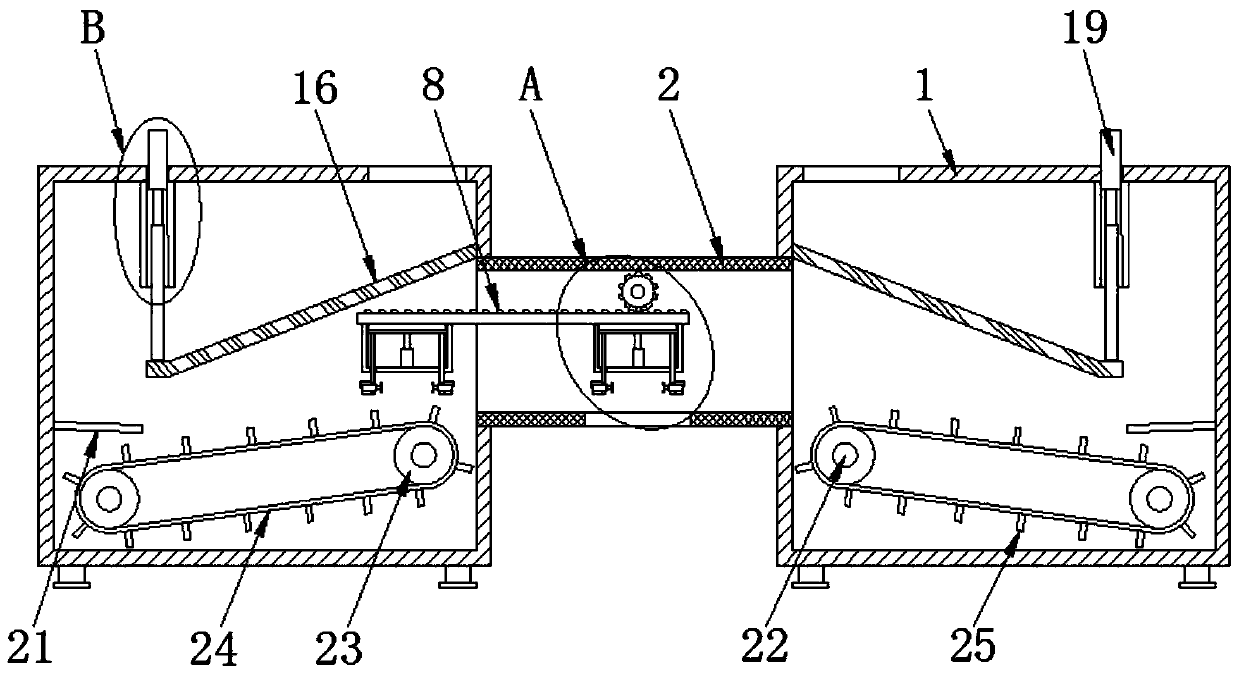

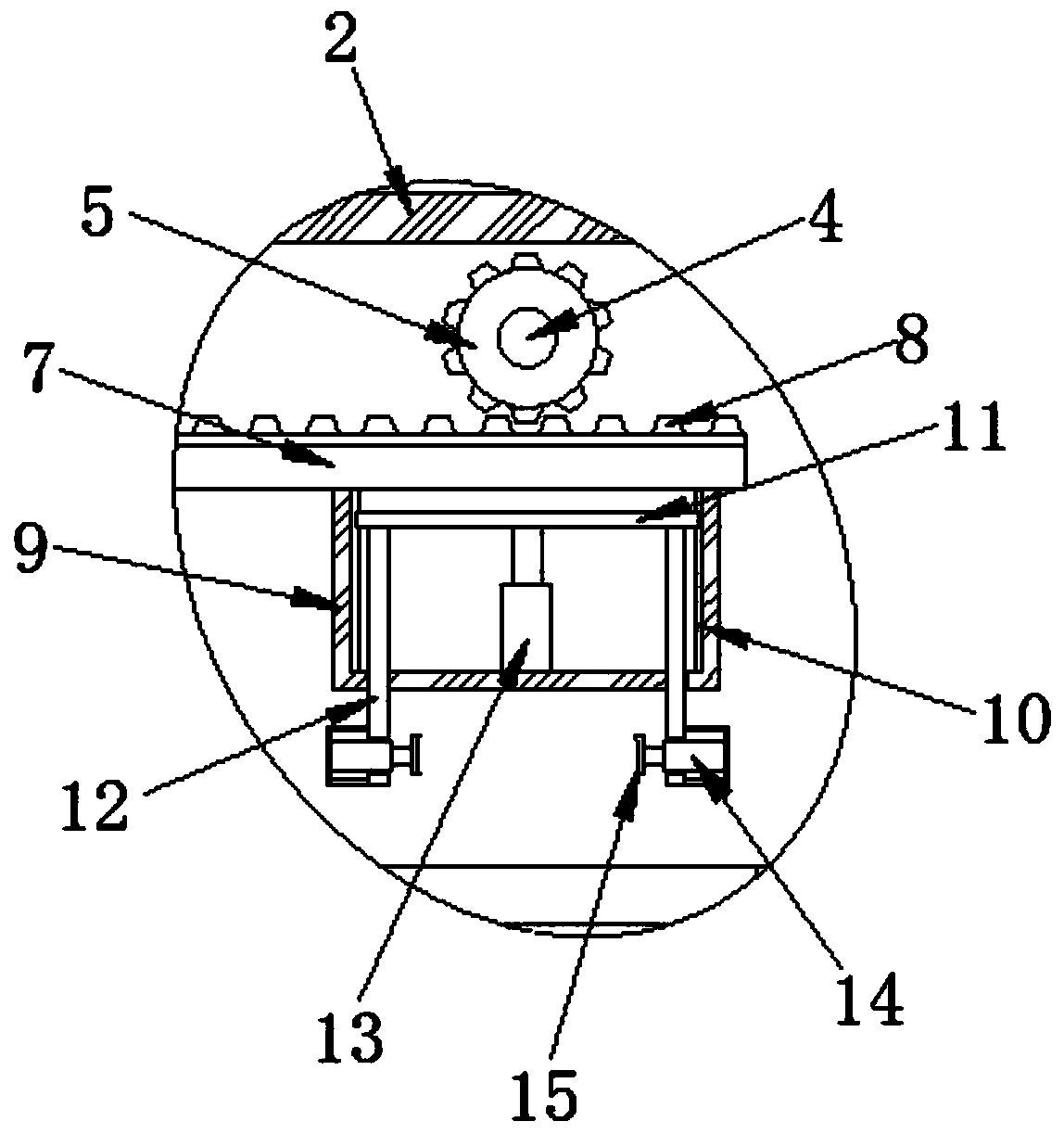

Feeding equipment for hot forging process

The invention discloses feeding equipment for a hot forging process, and relates to the technical field of forging equipment. The feeding equipment comprises two boxes, a fixed frame is fixedly connected between the opposite sides of the two boxes, a motor is fixedly mounted at the back of the fixed frame, a rotating rod is fixedly connected with one end of the output shaft of the motor, the end,away from the motor, of the rotating rod penetrates through the fixed frame and extends to the interior of the fixed frame, and the end, located in the fixed frame, of the rotating rod is rotatably connected with the front of the inner wall of the fixed frame through a bearing. According to the feeding equipment for the hot forging process, the operation of the motor can drive a moving plate to move left and right, when a left splint moves to the interior of the left box, a workpiece can be clamped, meanwhile, a right splint moves to the center of the fixed frame, discharging can be carried out, the two processes can be conducted simultaneously and have no influence on each other, the speed is increased by twice than the speed of common single-side feeding equipment, the work efficiency isimproved, and the practicability is higher.

Owner:武汉武兴盛锻造有限公司

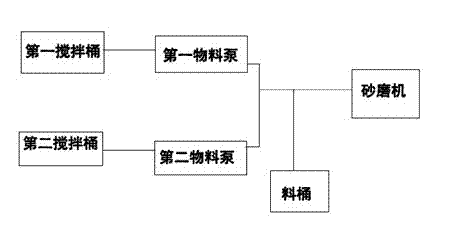

Adjustable sanding system for gravure solvent ink

The invention provides an adjustable sanding system for gravure solvent ink. The system comprises a sanding machine, wherein the feed end of the sanding machine is connected with a first material pump and a second material pump which are arranged in parallel; and feed ends of the first material pump and second material pump are respectively connected with discharge ends of a first agitating vessel and a second agitating vessel. The adjustable sanding system has the beneficial effects that high and low viscosity materials can be ground, conveyed at a constant speed, and switched conveniently as long as the valves corresponding to materials are opened or closed, so that the production efficiency of ink can be improved.

Owner:SUZHOU ZHONGYA INK

A powder and granular body superheated steam sterilization process and system

The invention discloses a technology and a system of powder body superheated steam sterilization, and belongs to the field of material sterilization and drying. The technology comprises the following steps: (1) adding a powder body material steam into a superheated steam stream; (2) controlling the superheated steam stream to form a cyclone stream, so that the material is dispersed in the cyclone stream, and utilizing the steam heat for sterilization for 3-10 seconds, and controlling the sterilization temperature within the range of 120-250 DEG C; (3) causing the steam stream to form cyclone stream, and utilizing the centrifugal force to separate the material and the steam stream; (4) utilizing the dried hot wind to dry the material, and utilizing dried cold air to cool the dried material; (5) performing steam and temperature compensation on the steam stream in the step (3), and participating in the superheated steam stream feeding technology in the step (1). The invention further discloses a system of powder body superheated steam sterilization. According to the invention, the technology is convenient in operation and simple in device structure, realizes automatic and continuous sterilization production, is low in consumption for sterilization, and is greatly increased in production efficiency.

Owner:FANQUN DRYING EQUIP FACTORY WUJIN CITY

Cardiovascular interventional therapy auxiliary equipment

PendingCN114870207AImprove stabilityImprove efficiencyGuide wiresOperating tablesCardiologyHeart position

The invention discloses cardiovascular interventional therapy auxiliary equipment, and relates to the technical field of medical instruments, the cardiovascular interventional therapy auxiliary equipment comprises a clamping device, an intermittent supply device and an auxiliary steering device are fixedly arranged on the clamping device, a constant-speed insertion device is rotatably arranged on the intermittent supply device, and the clamping device is used for fixing an arm of a patient. The intermittent supply device intermittently supplies a cardiac catheter and is matched with the constant-speed insertion device, the cardiac catheter is clamped through the clamping plate I and the clamping plate II to extend into the cardiovascular system at a constant speed, and the auxiliary steering device is started when the cardiac catheter encounters vascular bifurcation to drive the cardiac catheter to slightly rotate, so that the cardiac catheter can reach the heart position more accurately.

Owner:韩景奇

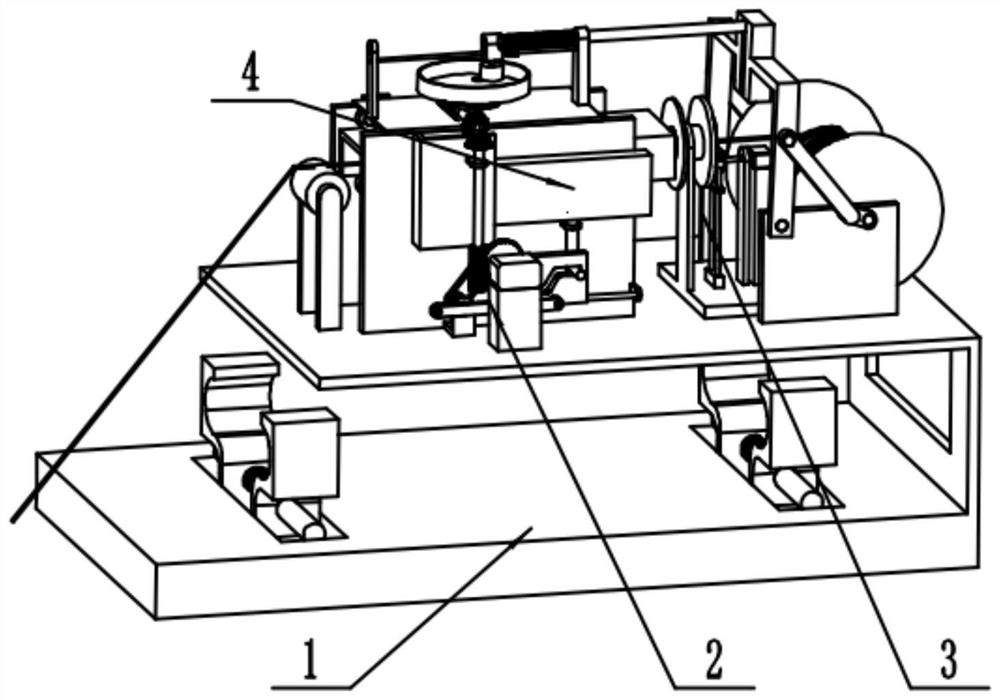

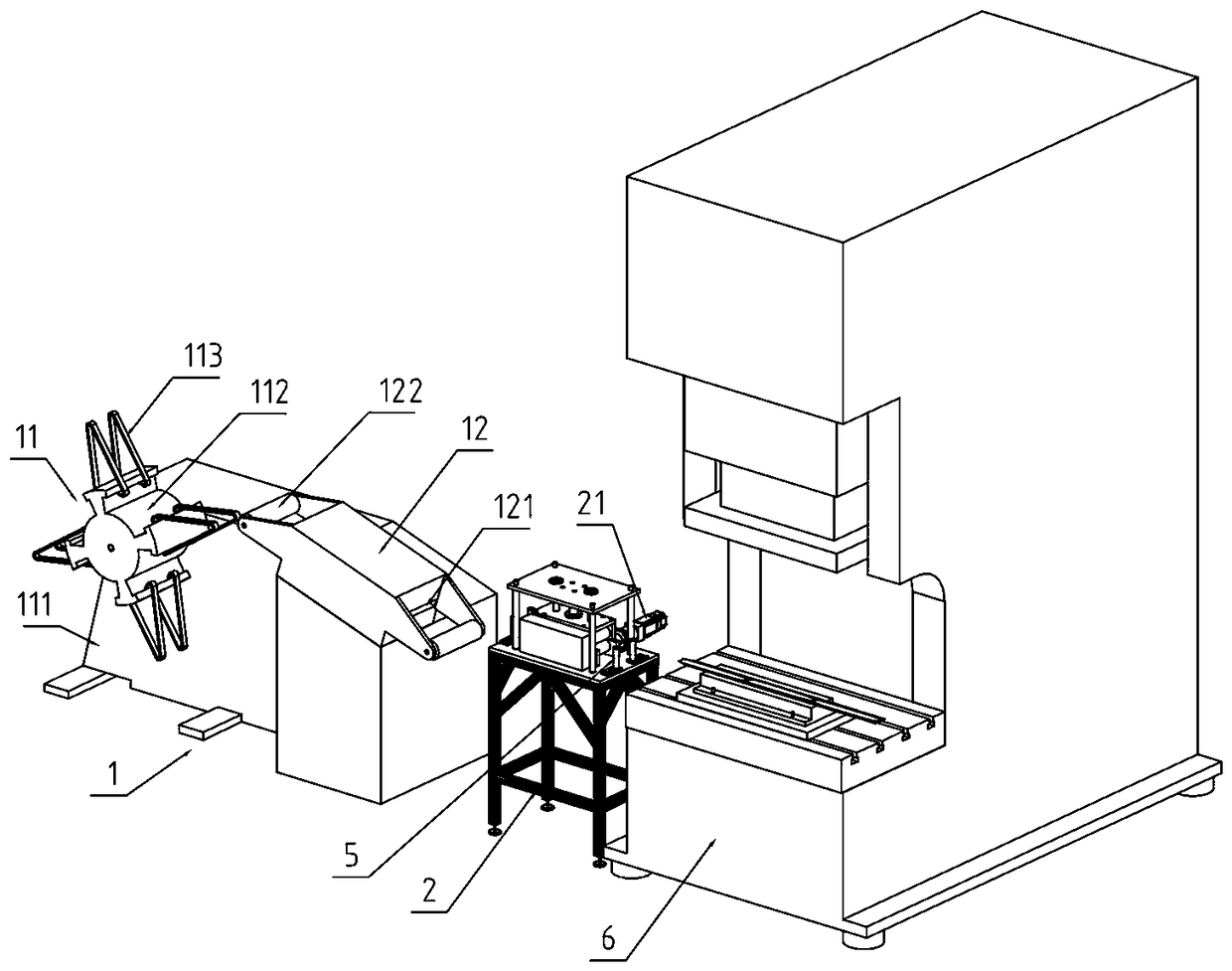

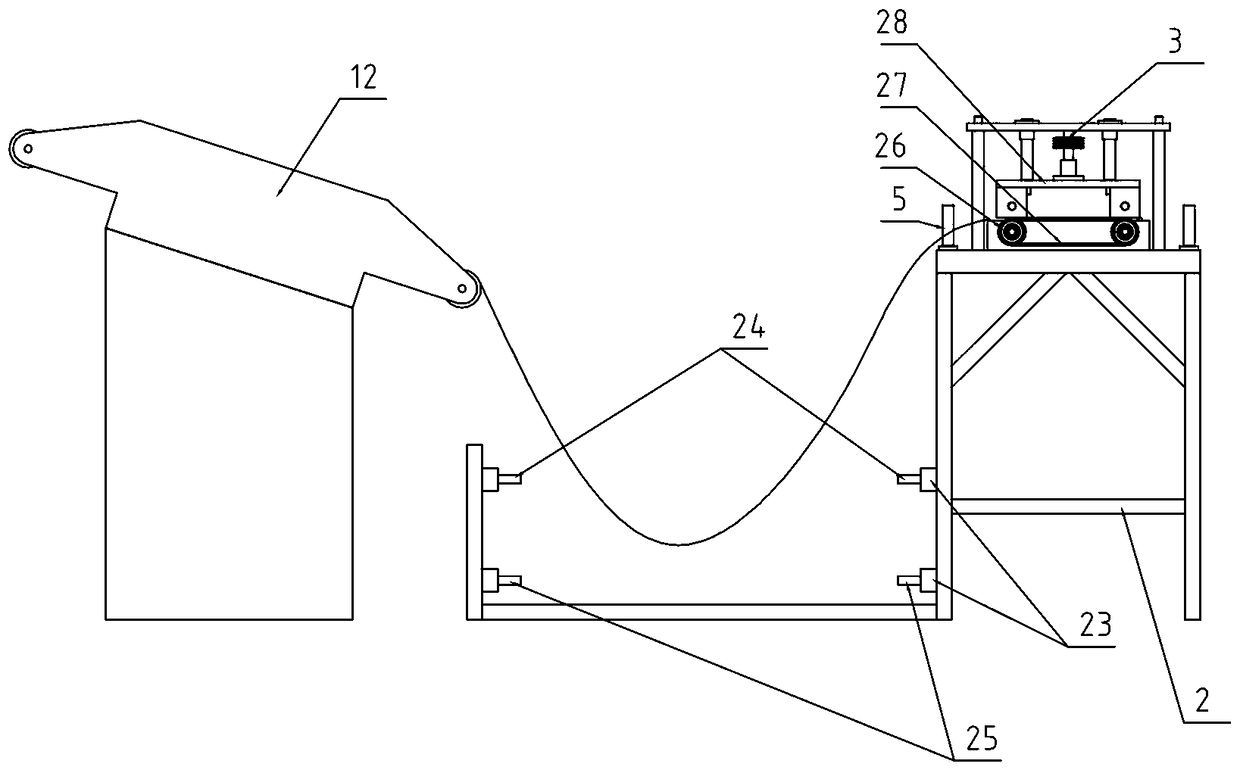

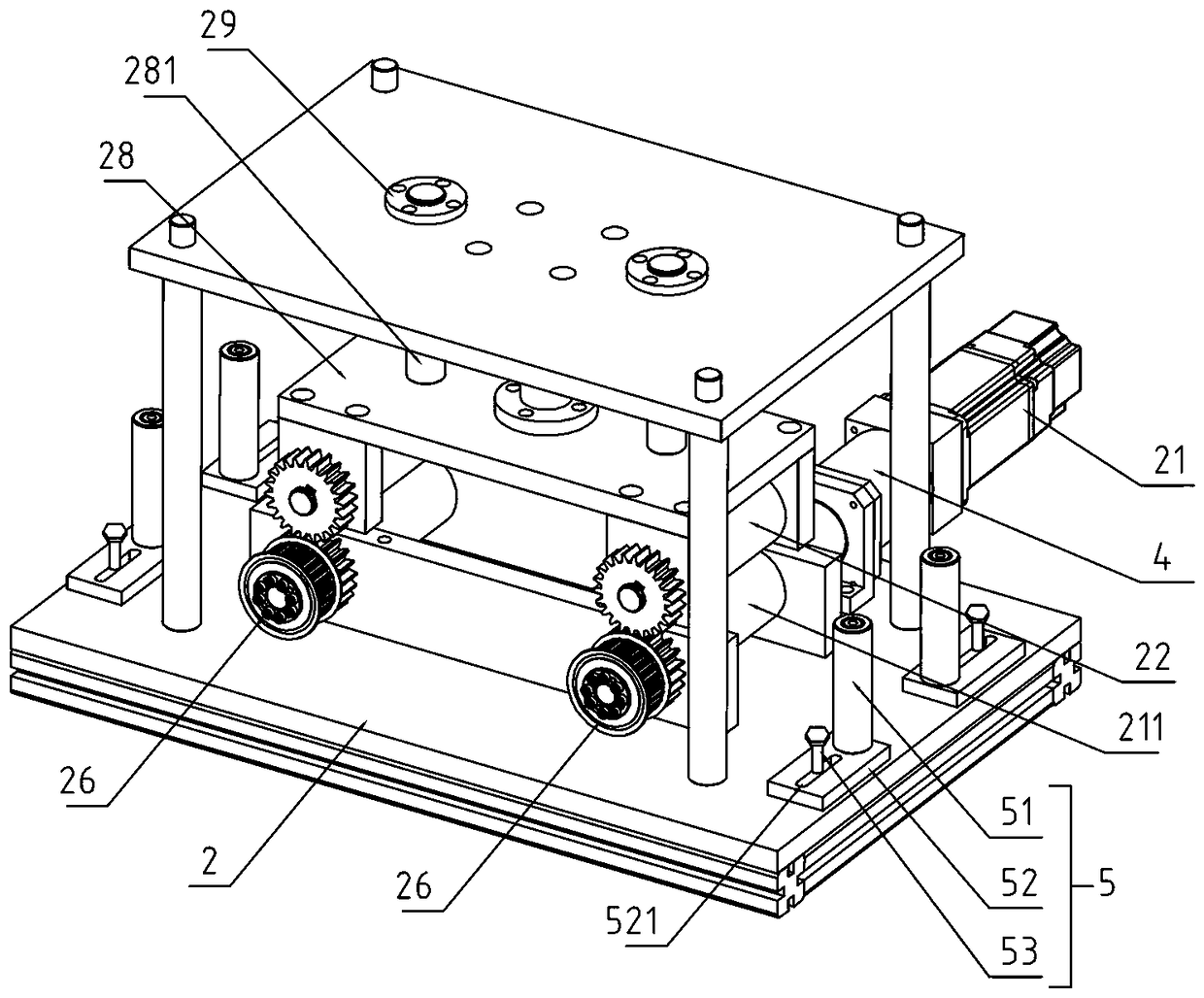

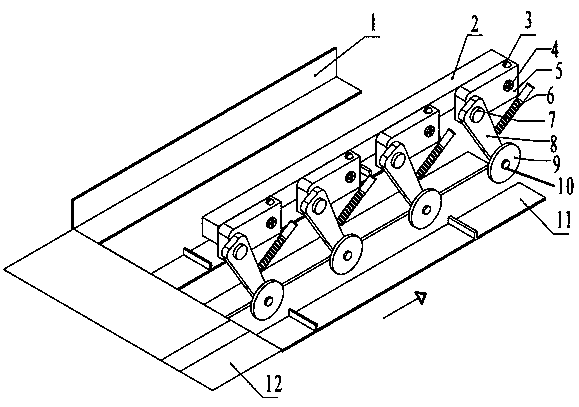

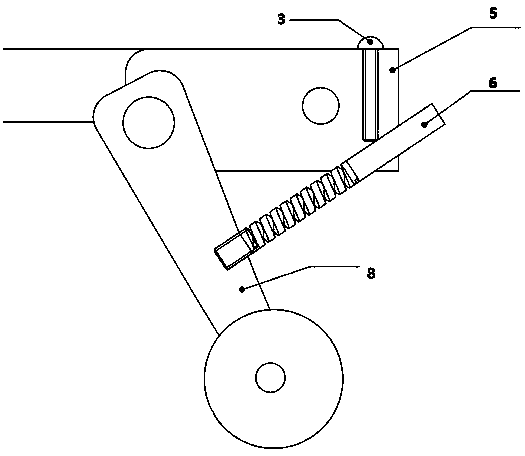

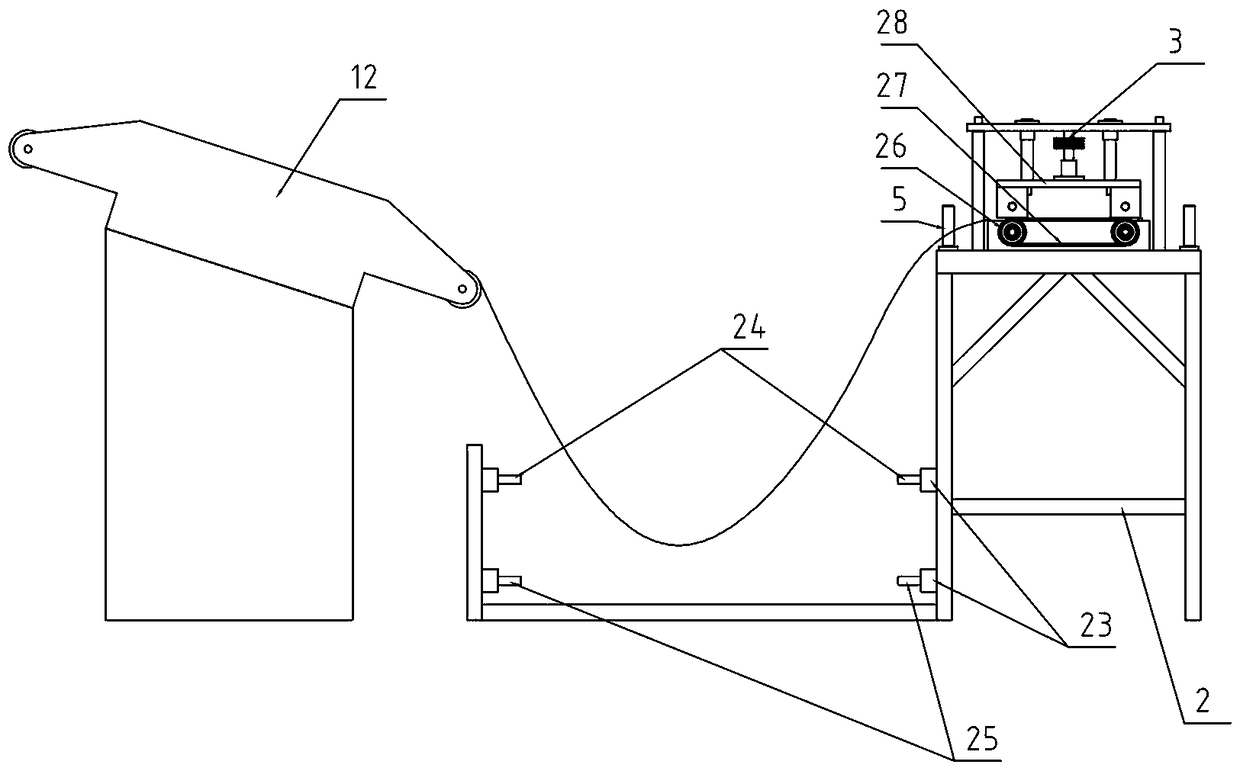

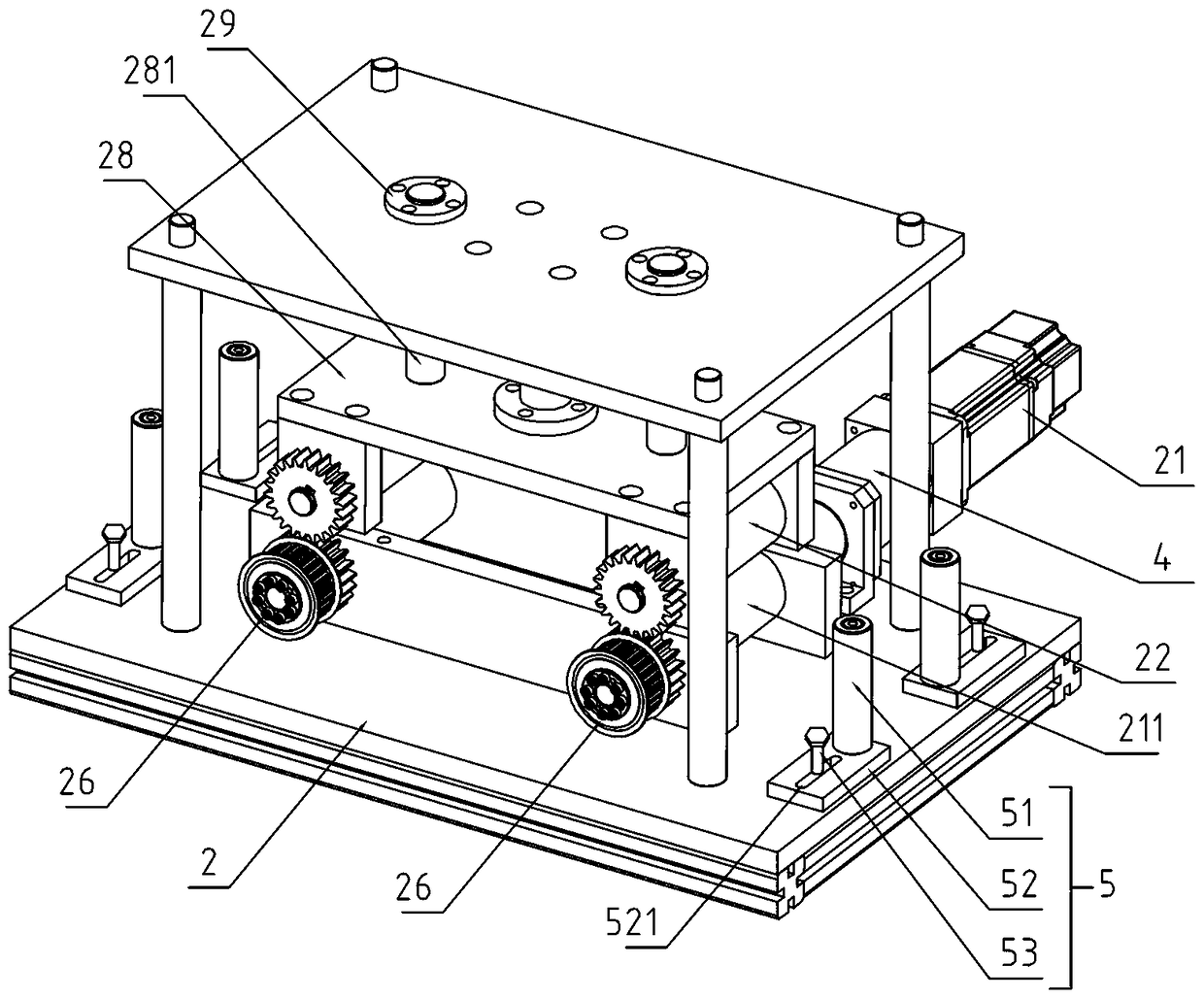

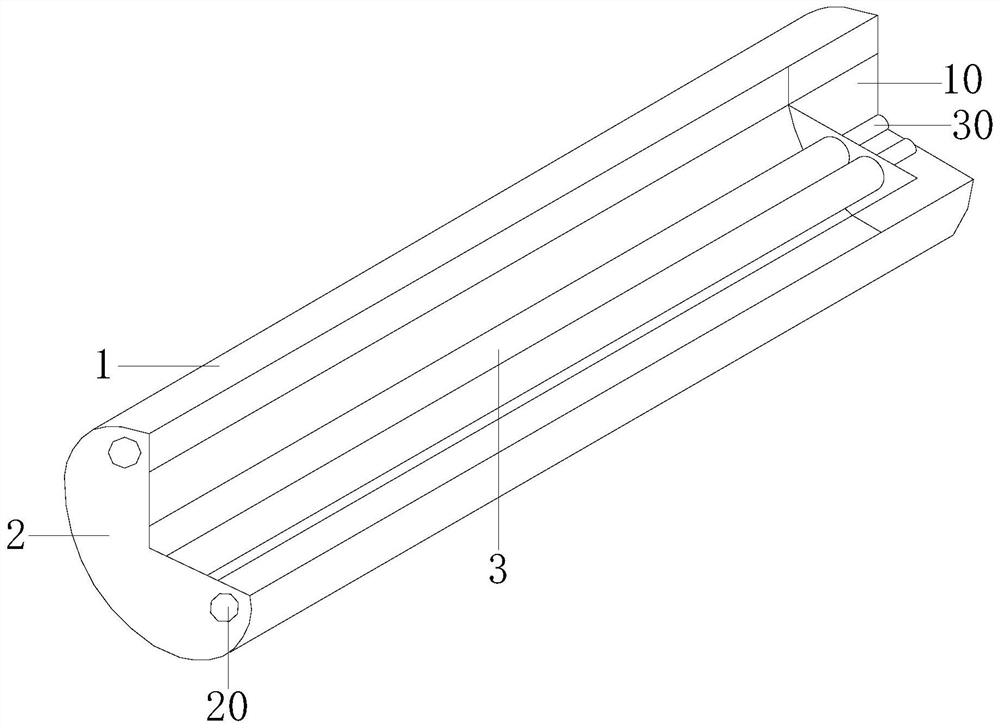

A guide plate coil material fixed-length feeding device

The invention discloses a fixed length feeding device for a coiled guide plate. The key point of the technical scheme is as follows: the device comprises an unloading mechanism, a feeding bracket, a punch press and a controller. A driving wheel, a driven wheel and a driving motor are arranged on the feeding bracket, and the driving motor drives the driving wheel to clamp a panel between the driving wheel and a driven wheel to be pushed toward a processing side; a first photoelectric sensor and a second photoelectric sensor are arranged on the feeding bracket, and are in communication connection to the controller; when the panel is detected by the first photoelectric sensor, a corrector continuously works; when the unloaded panel is detected by the second photoelectric sensor, the corrector stops working; when the unloaded panel cannot be detected by the first photoelectric sensor, the first photoelectric sensor sends a signal of enabling the corrector to work continuously to the controller and meanwhile sends a signal of stopping work of the driving motor and the punch press to the controller. The device can feed panels synchronously to the punch press, so that the processing efficiency of the punch press is increased.

Owner:ZHEJIANG SEOKHO ROBOT TECH CO LTD

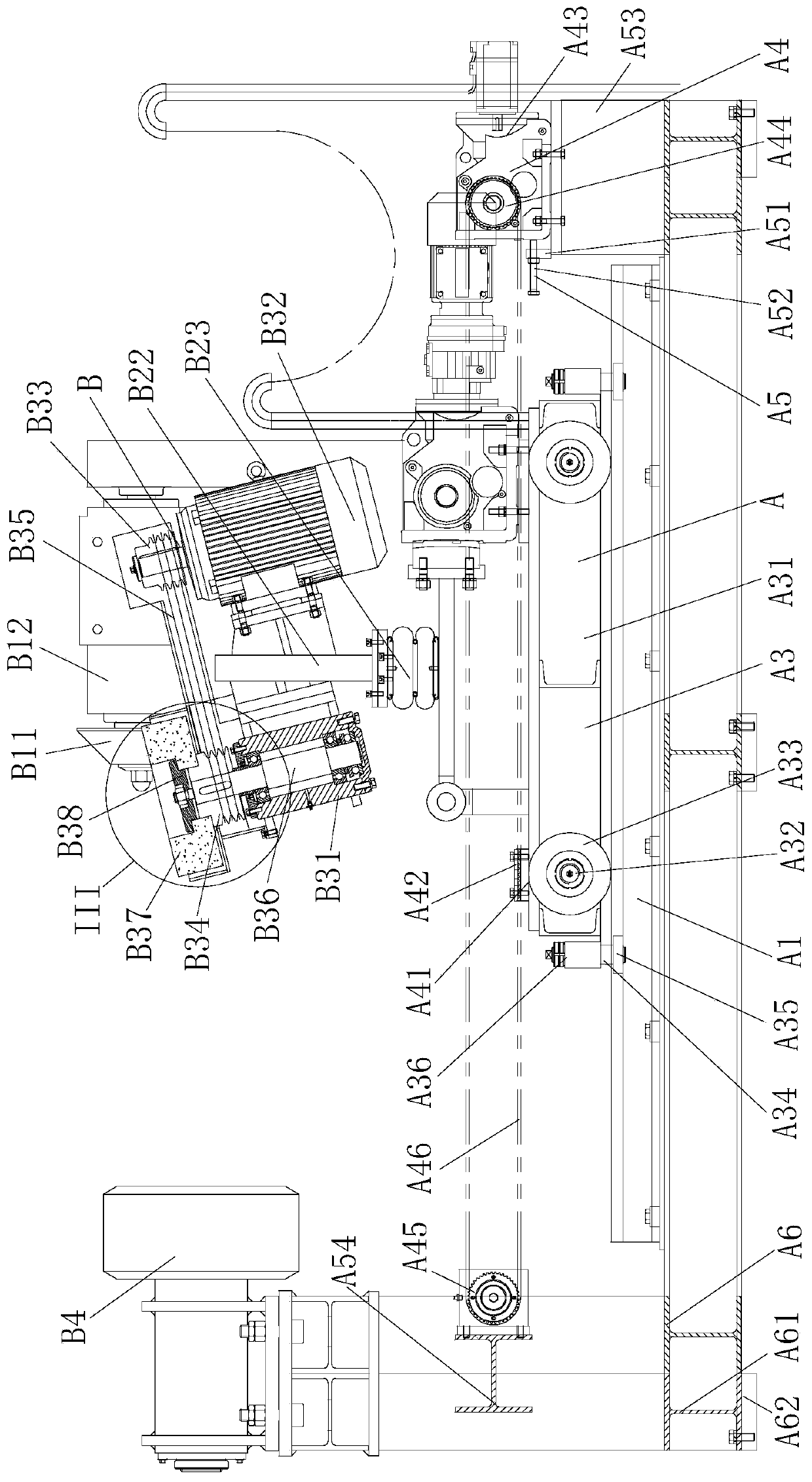

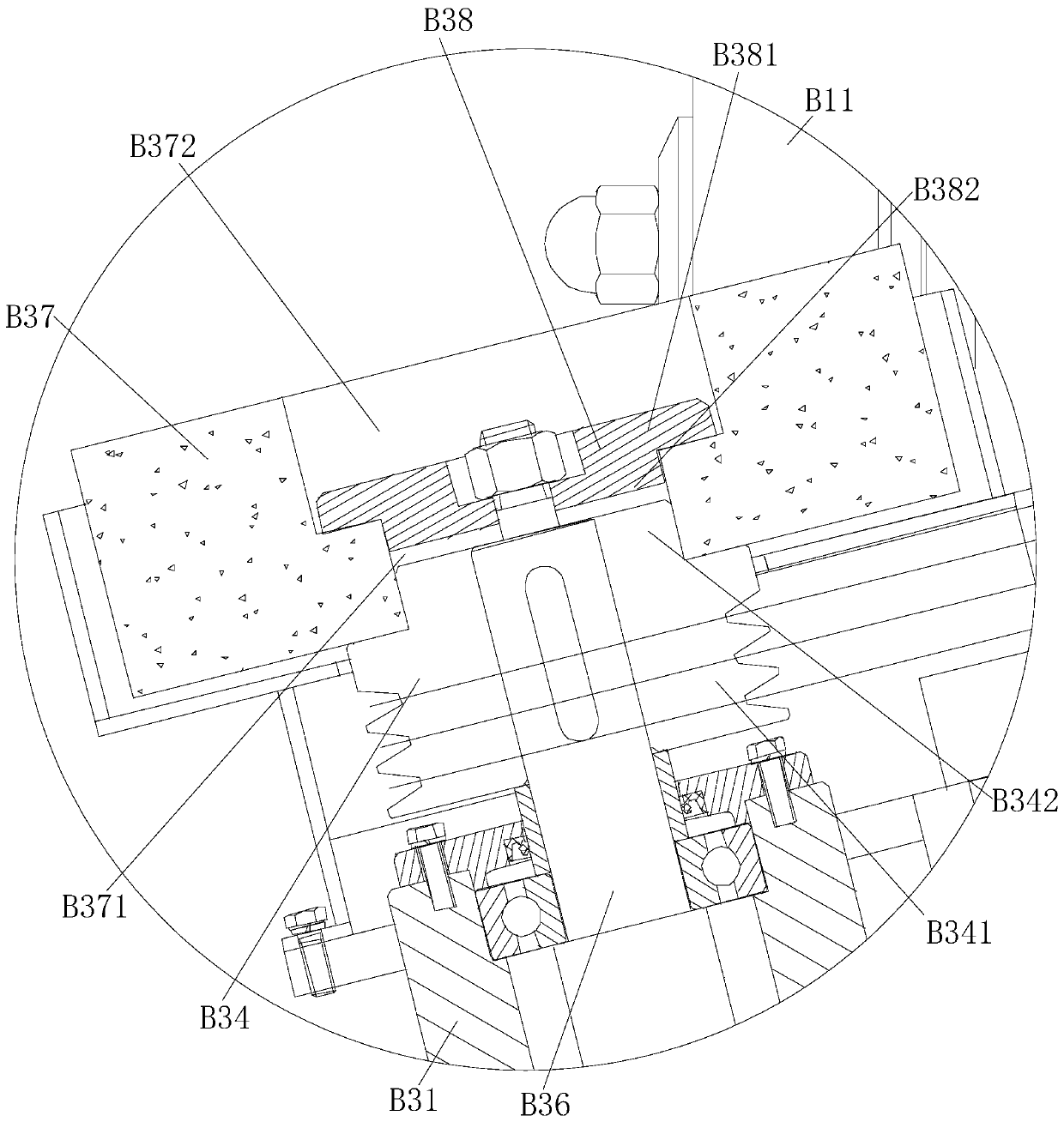

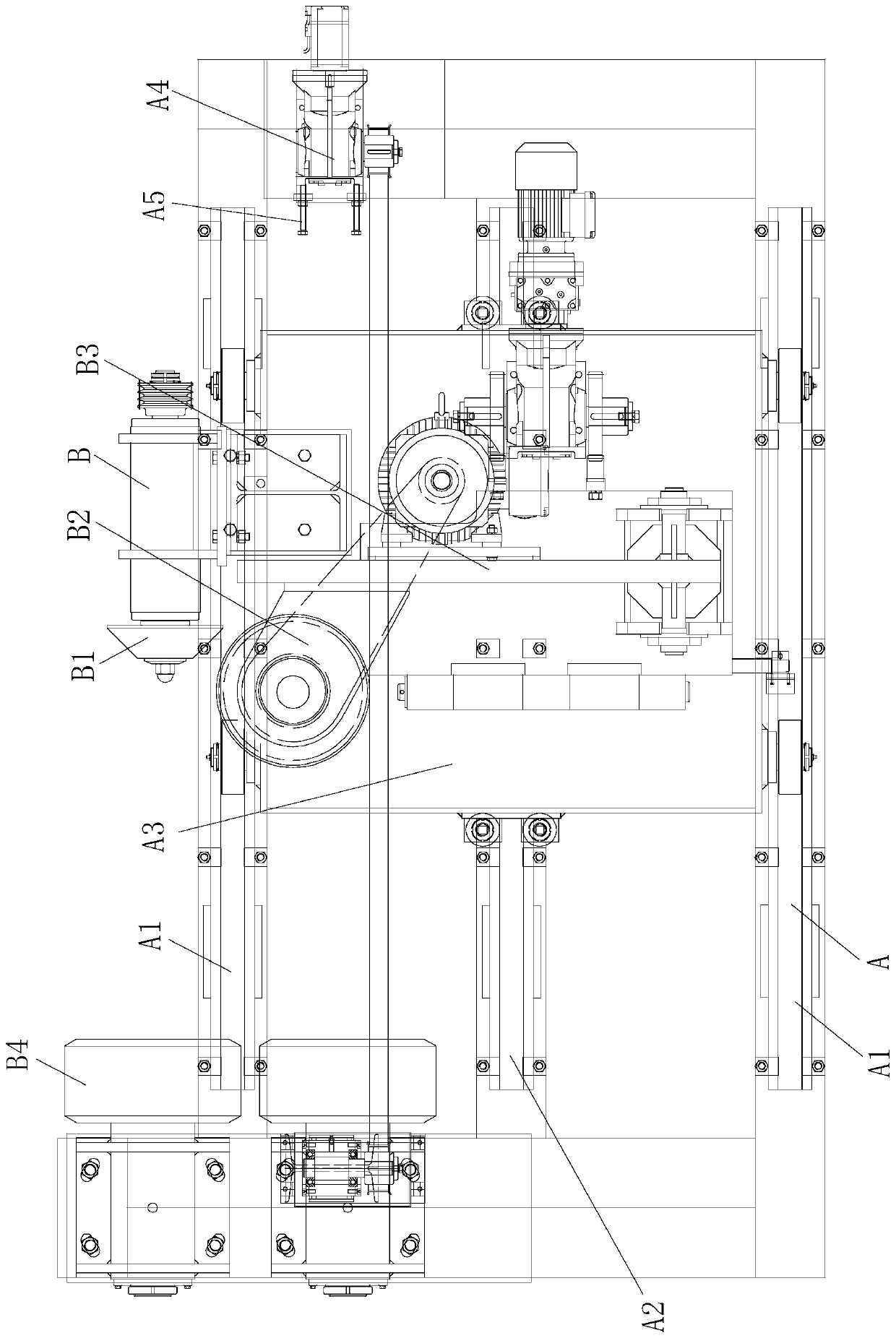

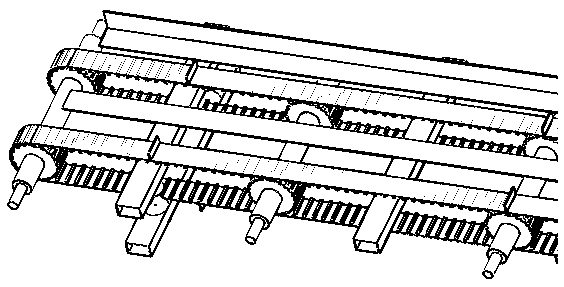

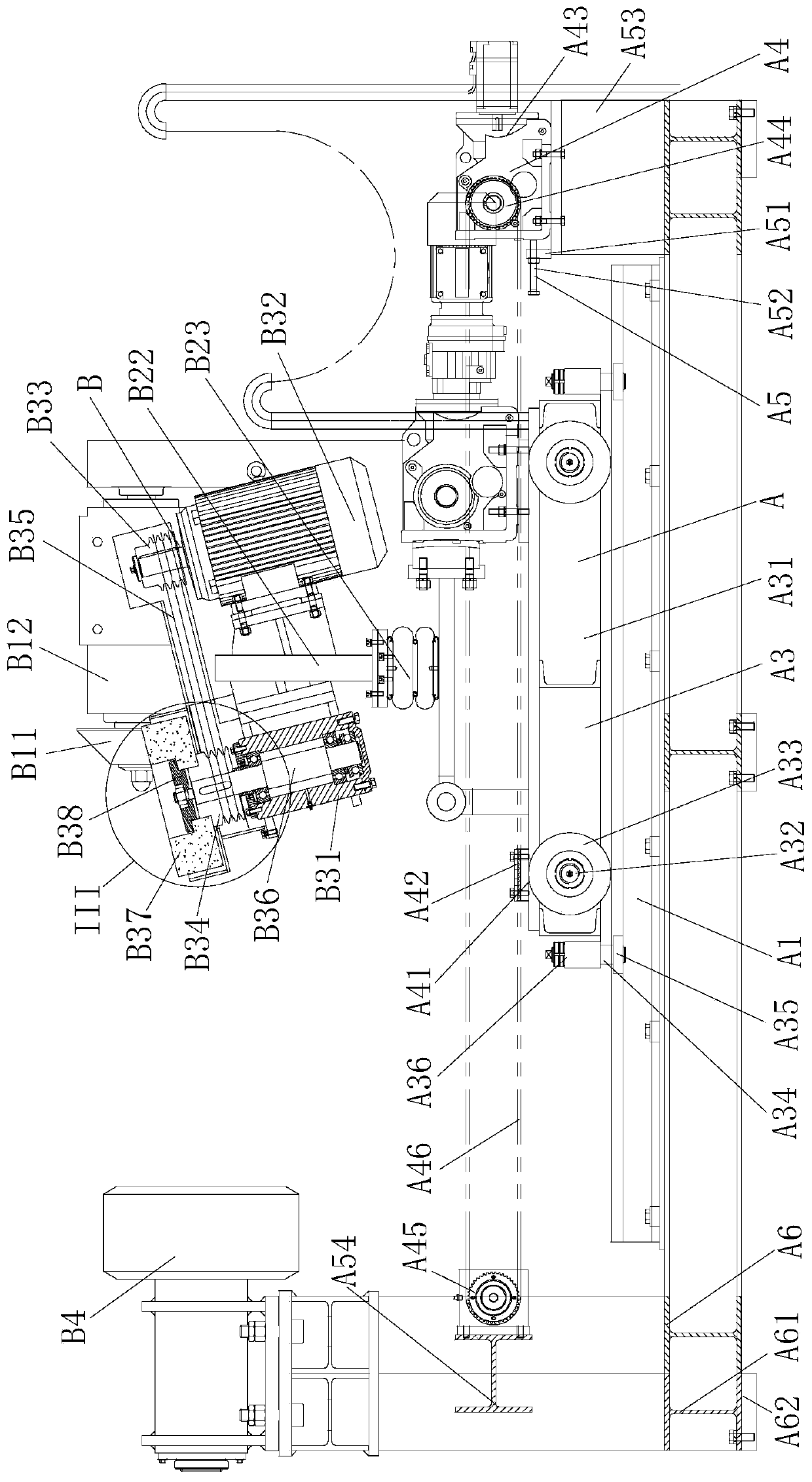

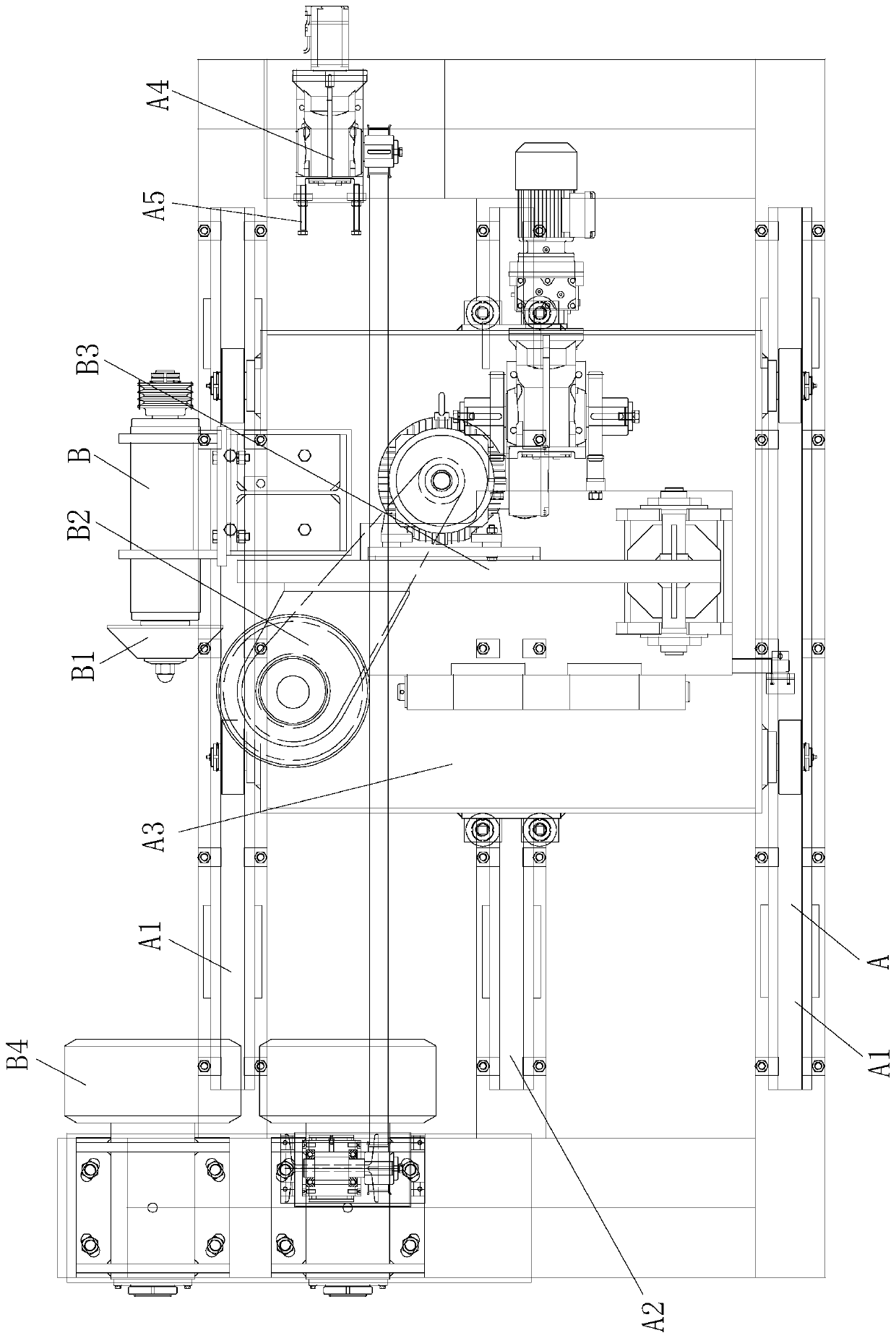

Machining production method special for nodular cast iron pipe finishing unit

InactiveCN109702563AAchieving tension adjustmentGuaranteed uptimeLiquid surface applicatorsRevolution surface grinding machinesGrinding wheelCast iron pipe

The invention relates to a machining production method special for a nodular cast iron pipe finishing unit, and belongs to the field of pipe production equipment. In the prior art, independent operation needs to be carried out, and a working period is long. The machining production method special for the nodular cast iron pipe finishing unit comprises the following steps that a to-be-chamfered pipe is placed on a chamfering station for being chamfered through a travelling crane, and the to-be-chamfered pipe is erected on a chamfering riding wheel assembly, so that one end of the to-be-chamfered pipe is in contact with a chamfering grinding wheel; the chamfered pipe is placed on an internal grinding station for inner grinding through the travelling crane, the to-be-ground pipe is erected onan inner grinding driving riding wheel and an inner grinding driven riding wheel, and one end of the to-be-ground pipe is in contact with a blocking wheel body; and the internally-ground pipe is placed on a roller coating station for roller coating through the travelling crane, the to-be-roller-coated pipe is erected on a roller coating riding wheel assembly, one end of the to-be-roller-coated pipe is erected on a roller coating positioning boss, and roller coating is conducted on the to-be-roller-coated pipe. According to the method, the working efficiency is improved, and assembly among allpipes is facilitated.

Owner:杭州春风机械工程股份有限公司

Test paper bag sealing label pressing device

PendingCN110239807AUniform conveyingEasy accessLabelling deformable materialsLabelling machinesEngineeringConveyor belt

The invention discloses a test paper bag sealing label pressing device. The device comprises an L-shaped baffle, a supporting pipe, an adjusting screw, an anti-compression spring mounting plate, an anti-compression spring, a mounting shaft, a bearing mounting plate, a deep groove ball rolling bearing, a bearing axial fixing shaft and a conveyor belt. The device can adapt to test paper bags with different specifications and sizes by utilizing the L-shaped baffle, and it is guaranteed that the positions needing to be pressed of the test paper bags are located below the deep groove ball rolling bearing; a protruding baffle is arranged on the conveyor belt, so that the conveying of the test paper bags is kept at a constant speed, and the resistance is counteracted; and the movement of the deep groove ball rolling bearing is kept within a certain range by utilizing the anti-compression spring, and the device is suitable for sealing label pressing of the test paper bags with different thicknesses. According to the device, the design is simple, required components are easy to obtain, machining and manufacture are easy; and the device is simple in structure, high in practicability, convenient to operate and adjust, high in working efficiency and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

A guide plate servo fixed-length feeding device

The invention discloses a guide plate servo fixed-length feeding device. According to the technical scheme, the guide plate servo fixed-length feeding device is characterized by comprising a releasing mechanism, a feeding support and a controller, wherein the feeding support is provided with a driving wheel, a driven wheel and a drive motor, and the drive motor drives the driving wheel to push a plate clamped between the driving wheel and the driven wheel to a machining side; the feeding support is provided with a first set of photoelectric sensors and a second set of photoelectric sensors, and both the first set of photoelectric sensors and the second set of photoelectric sensors are in communication connection with the controller; and when the plate is detected by the second set of photoelectric sensors, the releasing mechanism stops releasing, or when the released plate cannot be detected by the first set of photoelectric sensors, the first set of photoelectric sensors sends the signal of increasing the releasing speed of the releasing mechanism to the controller until the first set of photoelectric sensors detects the released plate, and the first set of photoelectric sensors sends the signal of recovering the preset releasing speed of the releasing mechanism to the controller. The device can achieve synchronous feeding for a punching machine, and improve the machining efficiency of the punching machine.

Owner:ZHEJIANG SEOKHO ROBOT TECH CO LTD

Pre-foaming equipment for EPS (Expandable Polystyrene) foam product

The invention relates to the technical field of foam product production, in particular to pre-foaming equipment for an EPS foam product. The ventilation opening is fixedly formed in the middle position of the upper surface of the foaming barrel in a penetrating mode, and the discharging opening is fixedly formed in the middle position of the lower surface of the foaming barrel in a penetrating mode; the number of the first supporting legs is four, and the four first supporting legs are uniformly and fixedly mounted on the lower surface of the foaming barrel; a feeding mechanism; a feeding mechanism capable of screening out fine powder in foaming raw materials and uniformly conveying the foaming raw materials is fixedly mounted on the right side of the outer surface of the foaming barrel, and the feeding mechanism comprises a feeding barrel. By arranging the feeding mechanism, the raw materials can be uniformly conveyed, so that the foaming ratio of the raw materials is stable; fine powder in the raw materials can be removed while the raw materials are conveyed, so that the granularity of the raw materials is uniform, foam particles are prevented from caking, and the production quality of foam products is improved.

Owner:刘念

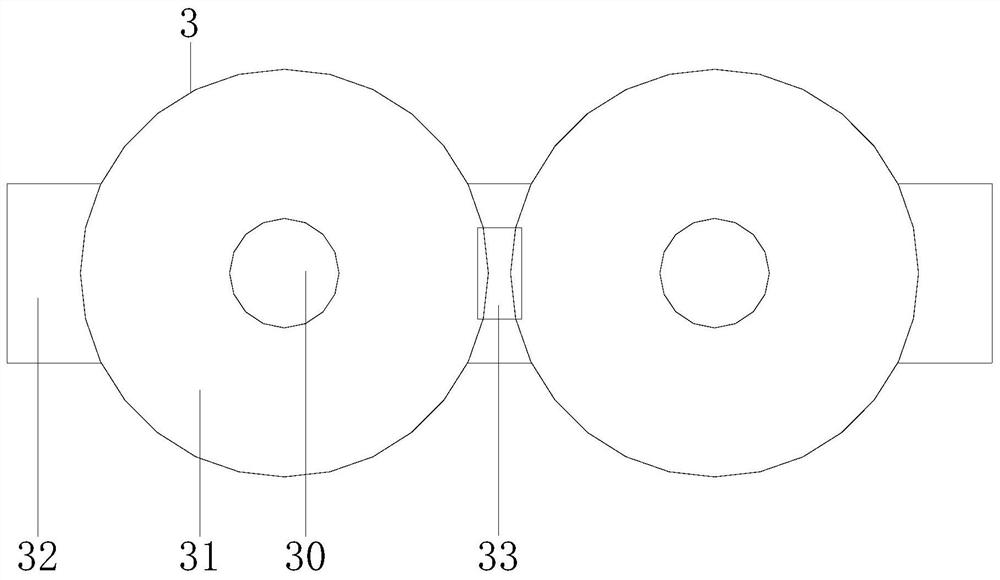

A drawing frame cleaning device

ActiveCN112064155BControl delivery speedGood centering effectDrafting machinesEngineeringStructural engineering

The invention discloses a drawing frame cleaning device, the structure of which comprises a dust collecting frame, a side mounting plate, and conveying double rollers, the dust collecting frame and the side mounting plate are installed and connected, and the conveying double rollers are installed on the dust collecting frame and the side mounting plate , the dust collection rack is equipped with thickened side plates, and the side plate is equipped with a lock shaft, the thickened side plate and the lock shaft are located at the left and right ends of the double conveying rollers, and the conveying double rollers include rod shafts, transmission line double rollers, mounting The plate and the middle device, the rod shaft is connected with the double roller shaft of the transmission line, the double rollers of the transmission line are attached to the middle device, the rod shaft and the middle device are installed on the mounting plate, and the middle device includes an embedded roller frame, a wire groove device, and an embedded roller frame Installed and connected with the wire groove device, the cotton sliver of the present invention is fed from the middle device, that is, fed from the wire groove device, and is located in the middle of the wire feeding structure. The uniform speed of the sliver conveying ensures that the sliver is moderately elastic, reasonably centered and not scattered, and prevents the sliver from being scattered and knotted due to the adhesion of flying flowers and dust.

Owner:李秀铅

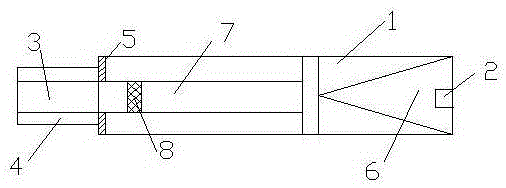

Novel high-pressure descaling nozzle

A novel high-pressure descaling nozzle comprises a sprayer, wherein a nozzle is arranged at the front end of the sprayer, particularly in a groove of the sprayer; a connecting pipeline is arranged behind the nozzle; a conveyor pipe is arranged behind the connecting pipeline; a connecting part is arranged outside the conveyor pipe; and an elastic part is arranged between the connecting part and the sprayer. As the connecting pipeline is arranged behind the nozzle and divided into a front pipe and a rear pipe, water can be conveyed at a more constant speed, and the spraying effect is guaranteed when the nozzle is in use. As a filter screen is further arranged in the sprayer, impurities can be filtered and prevented from being sprayed out and then adsorbed on the surface of a part.

Owner:扬州博泰冶金设备制造有限公司

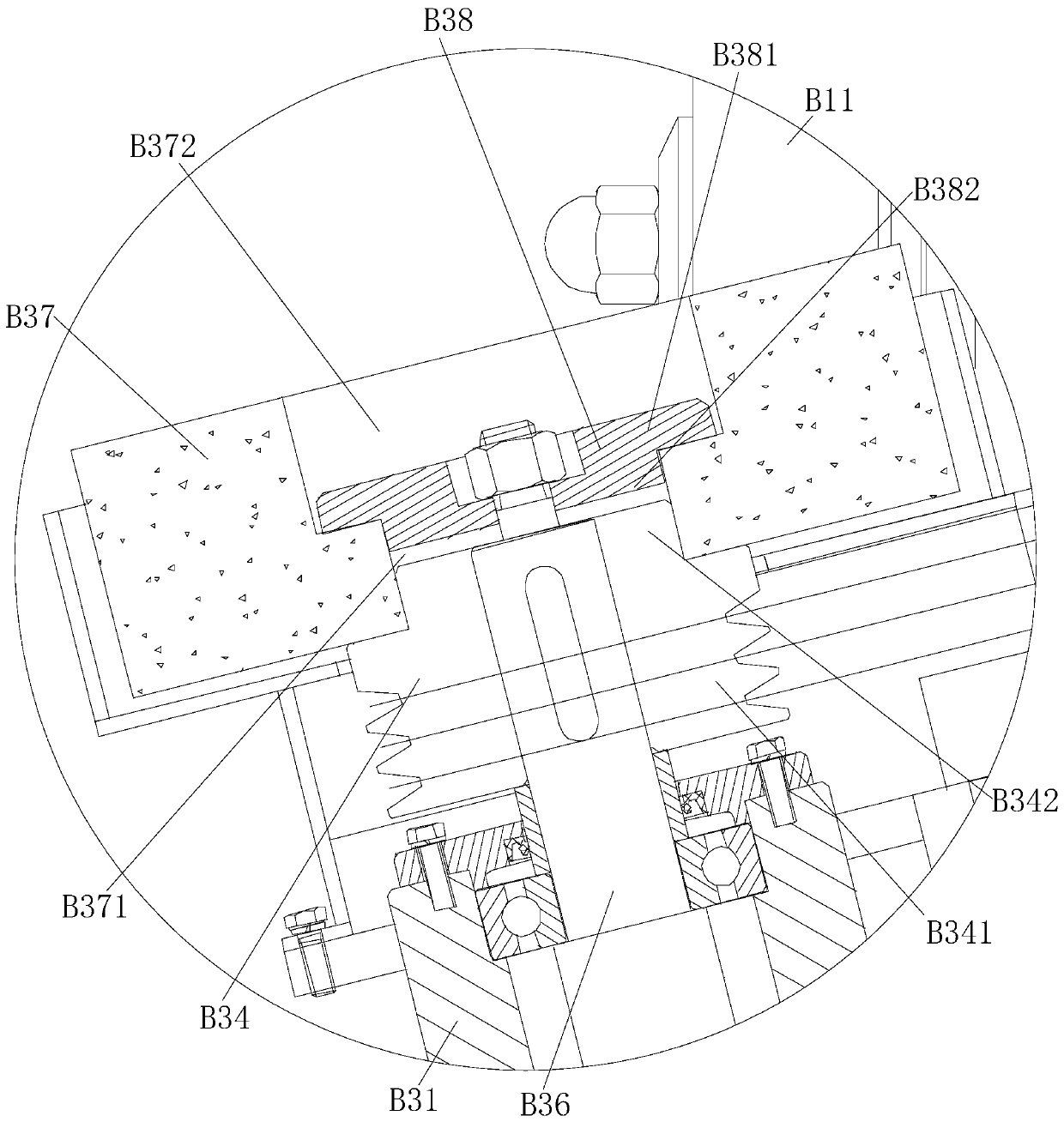

Processing production line special for finishing unit of nodular cast iron pipes

PendingCN109732452AImprove sealingExtended service lifeGrinding carriagesGrinding machinesCast ironConstant torque

The invention relates to a processing production line special for a finishing unit of nodular cast iron pipes, and belongs to the field of pipe fitting production equipment. In the prior art, chamfering, inner grinding and coating rolling need to be independently operated, so that the working period is long and the efficiency is low. The processing production line comprises a chamfering device, aninner grinding device, a coating rolling device and three constant-torque bearing devices, wherein the three constant-torque bearing devices are a No.1 constant-torque bearing device, a No.2 constant-torque bearing device and a No.3 constant-torque bearing device; the chamfering device, the inner grinding device and the coating rolling device are separately mounted on the three constant-torque bearing devices; the chamfering device is in driving cooperation with the inner grinding device; and the inner grinding device is in driving cooperation with the coating rolling device. According to theprocessing production line disclosed by the invention, the working efficiency is improved, and investment of labor cost is reduced, so that after pipe fittings are assembled, the sealing performanceof the pipe fittings is high, the rolled coating on the outer wall of the pipe fittings is more uniform, the service life of the pipe fittings is prolonged, and the inner walls of the pipe fittings are ground to be more smooth and flat.

Owner:杭州春风机械工程股份有限公司

A gas conveying biomass feeder

The invention discloses a gas conveying biomass feeder, which includes an air supply pipe, an air inlet pipe, a feeding pipe, a feeding pipe and a storage pipe for containing biomass materials; The inlet pipe is set on the feed pipe, the feed port of the feed pipe is set in the tube hole at the second end of the storage tube, and the first end tube hole of the storage tube is provided with a sealing plug that can move along the axial direction of the storage tube , the first end of the sealing plug is fixedly connected with the propulsion rod; the second end of the storage pipe is sealed and connected with the outer wall of the intake pipe through the first reducing joint. The biomass is transported in the feeder by using gas. By controlling the intake rate, the material can be conveyed at a uniform speed, and the continuous non-blocking feeding can be realized, the adhesion between the material and the inner wall of the feeder can be reduced, and the material blockage can be avoided; At the same time, the equipment is easy to use, and the basic investment cost and maintenance cost are low; the present invention can not only transport biomass, but also transport coal particles and similar powders.

Owner:SHANXI YITONG ENVIRONMENTAL ENERGY TECH GROUP

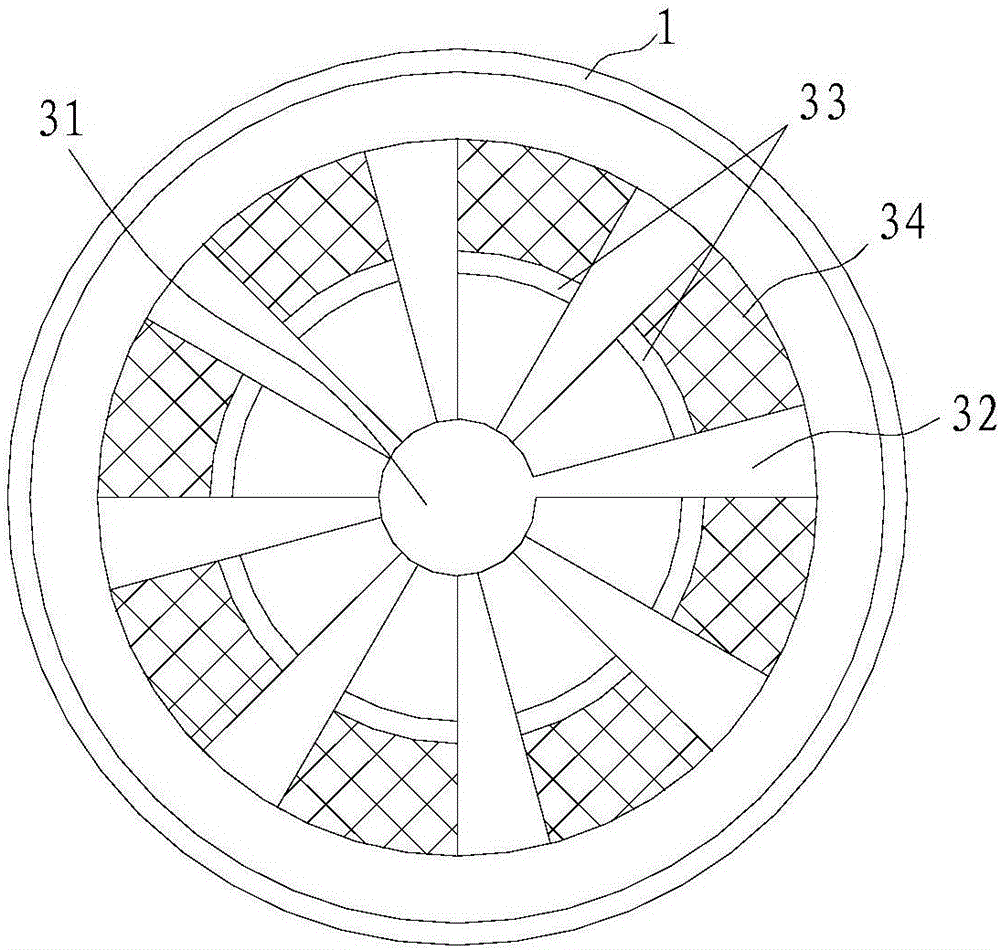

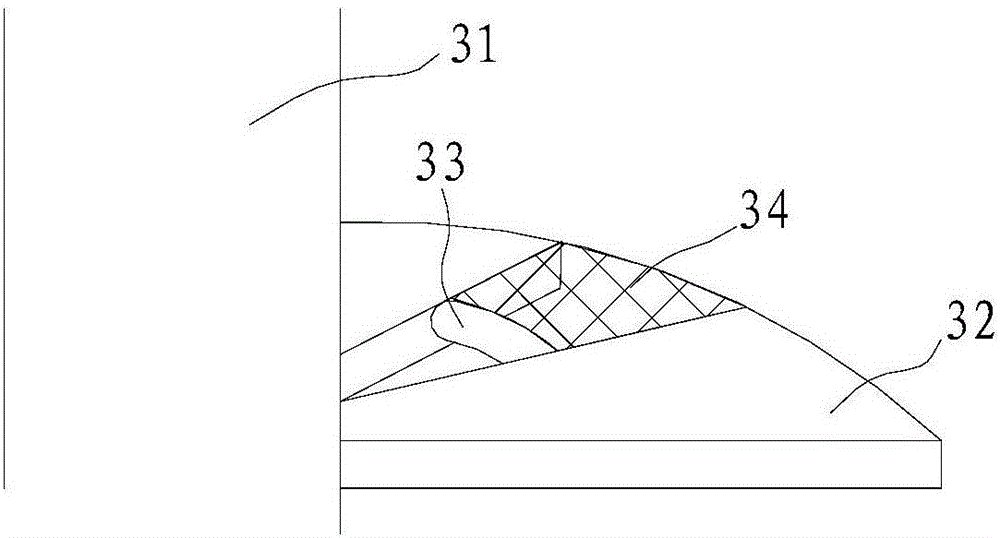

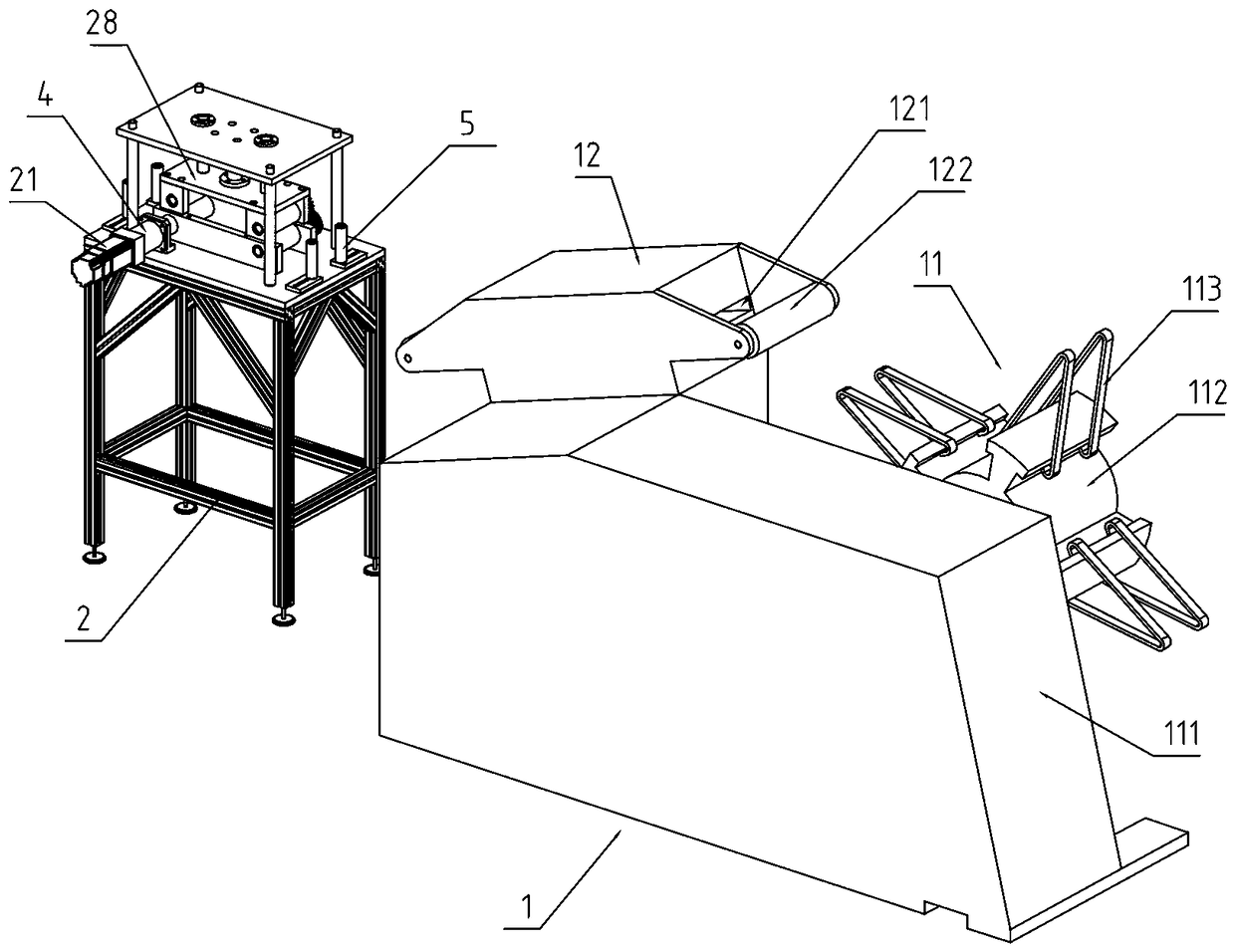

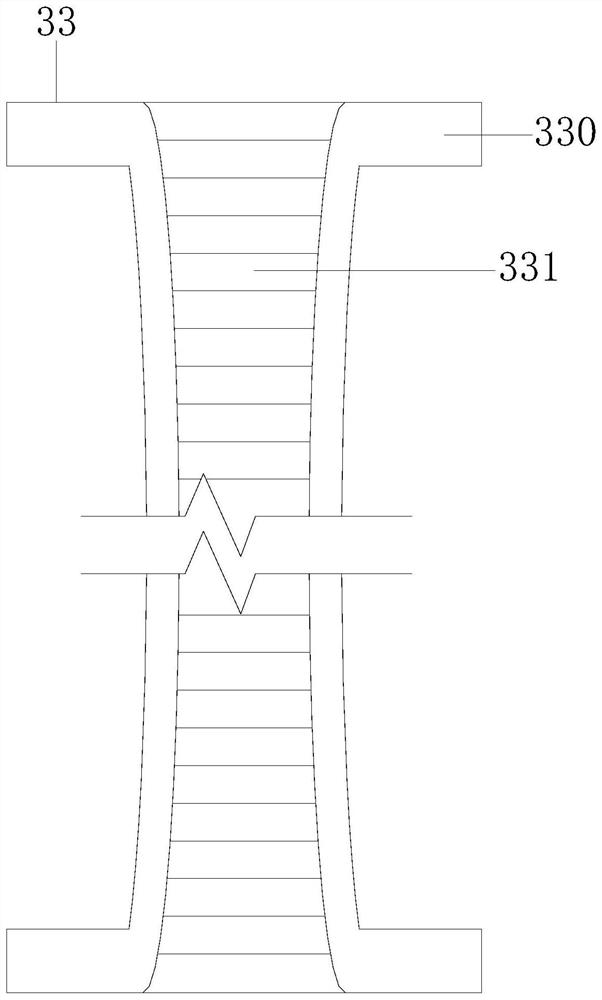

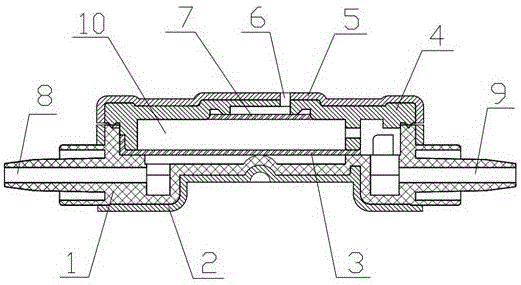

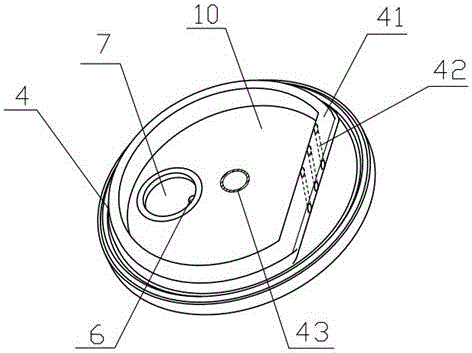

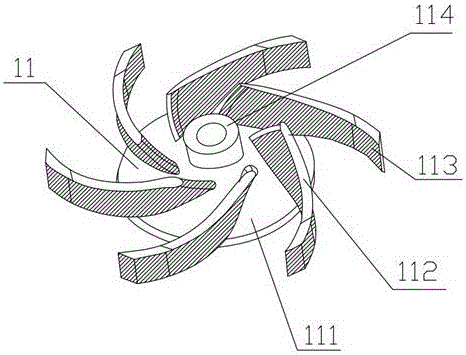

Novel filter for light-proof medicinal liquid with double injection molding and preparing method thereof

ActiveCN106344997ANovel structureEasy to useFiltering accessoriesMedical devicesEngineeringAir filter

The invention discloses a novelfilter for light-proof medicinal liquid with double injection molding, comprising atransparent upper shell (4), a transparent lower shell (1), a precision medicinal liquidfiltering membrane (3) and a air filtering membrane(7), wherein a swivel wheel (11) is arranged in a infusion chamber (10) formed between the transparent upper shell (4) and the transparent lower shell (1),the swivel wheel (11) is consisted of a base (111) and several blades (112) fixed on the base (111) and extending outwardly;the transparent upper shell (4) is hermetically connected bythe upper shell protrusion (41) and the transparent lower shell (1) , a transfusion passage (42) is arranged in the tangential direction of the transparent upper shell (4) on the upper shell protrusion (41). The novel filter for light-proof medicinal liquid with double injection molding of the novel filter for light-proof medicinal liquid with double injection molding can ensure the need of clinical large flow transfusion, the effect of prolonged use is more obvious, and the structure is novel, simple and reasonable, the effect of light-proof is good, safe and reliable.

Owner:上海振浦医疗设备有限公司

A steel structure spraying equipment for transmission iron tower

ActiveCN111841955BConvenient spray processingGuaranteed service lifeSpraying apparatusTransmission towerClassical mechanics

The invention relates to a steel structure spraying equipment for a power transmission tower, which includes a base plate, a support frame, a conveying device and a spraying device. A support frame is installed on the top of the base plate, a conveying device is installed in the middle of the support frame, and symmetrically arranged above the conveying device. The spraying device is installed on the inner upper end of the support frame. The invention can solve the problem that when the existing equipment sprays the antirust material on the steel structure, usually only one side of the steel structure can be sprayed, and the other side of the steel structure is prone to omission, resulting in poor spraying effect of the steel structure and poor spraying effect. Unevenness is not conducive to the subsequent use of the steel structure, and the existing equipment is usually unable to accurately adjust the spraying range of the spraying mechanism when spraying the steel structure, resulting in the possibility of crossing or crossing on the steel structure after spraying. Unsprayed phenomenon affects the subsequent use of steel structures and other problems.

Owner:FUYANG SANHUAN POWER EQUIP CO LTD

Cooling apparatus for rice processing

InactiveCN111992279AImprove filtering effectAffect processing qualitySievingDomestic cooling apparatusCold airRotational axis

The invention discloses cooling apparatus for rice processing, and belongs to the technical field of rice processing. Key points of the technical scheme are as follows: the cooling apparatus comprisesa first cooling cavity, a second cooling cavity and a feeding cylinder, wherein a rotating shaft is arranged inside the feeding cylinder, the outer side wall of the rotating shaft is fixedly connected with a plurality of uniformly distributed rotating hinges, a driving shaft is arranged inside the first cooling cavity, two uniformly distributed supporting wheels are fixedly connected with the outer side wall of the driving shaft, and the outer side walls of the two supporting wheels are fixedly connected with a filter screen body. Impurities in wind are prevented from influencing the processing quality of rice, the filtered cold air cools the rice, and meanwhile, the filter screen body arranged inside the first cooling cavity hinders a descending speed of the rice, so that the rice is rotated above the cylindrical filter screen body, and the rice sequentially passes through the outer part and inner part of the cylindrical filter screen body, so that the rice stays for several seconds,and thereby the rice cooling quality is improved.

Owner:湖南省伟利米业有限公司

Cleaning equipment for liquid crystal glass substrates

ActiveCN104096693BEasy to cleanSimple structureCleaning using liquidsIndium tin oxideMechanical engineering

The invention discloses a cleaning device for a liquid crystal glass substrate. The first surface of the glass substrate is coated with an ITO (Indium Tin Oxide) membrane in a sticking manner; the cleaning device comprises a machine frame, a box body mounted on the machine frame in a connecting manner, an ultrasonic generator and a conveying unit mounted on the machine frame in a connecting manner, the ultrasonic generator is mounted below the box body in a connecting manner, the conveying unit is positioned below the ultrasonic generator and used for conveying the glass substrate, the second surface of the glass substrate faces downwards and is arranged on the conveying unit in a supporting manner, and the ITO membrane of the glass substrate faces upwards; a liquid supplying unit for supplying a cleaning solution is additionally arranged, the liquid supplying unit is used for adding the cleaning solution into the box body and enabling the cleaning solution to overflow from the box body, the overflowing cleaning solution flows onto the ITO membrane of the glass substrate, the ultrasonic generator sends out ultrasonic wave, and the cleaning to the ITO membrane is performed through the cleaning solution on the ITO membrane. The cleaning device has the advantages as follows: the ITO membrane can be protected, ultrasonic waves face the ITO membrane directly, the cleaning effect is good, the structure is simple, the cost is low, automatic production is achieved, and the labor cost is reduced.

Owner:莆田市嘉辉光电有限公司

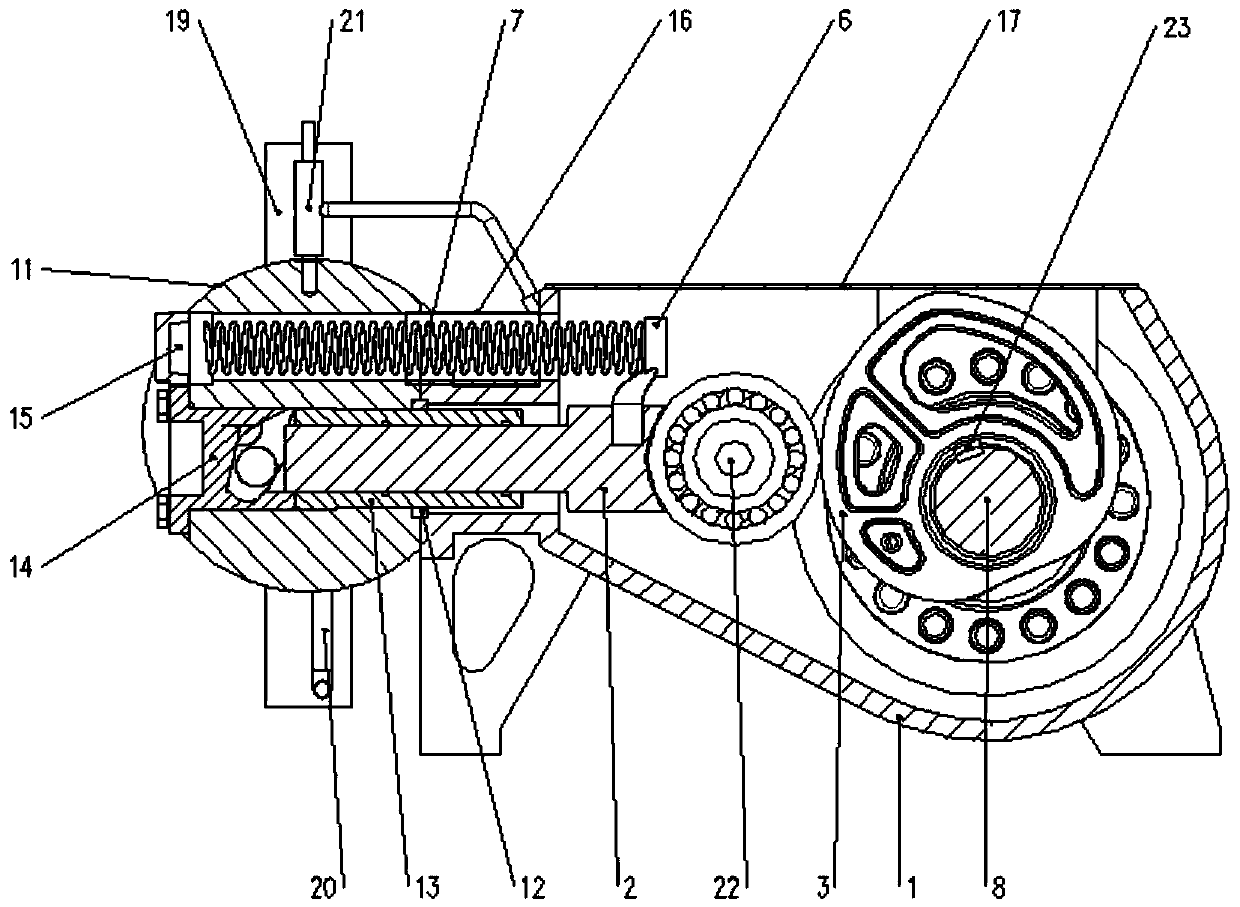

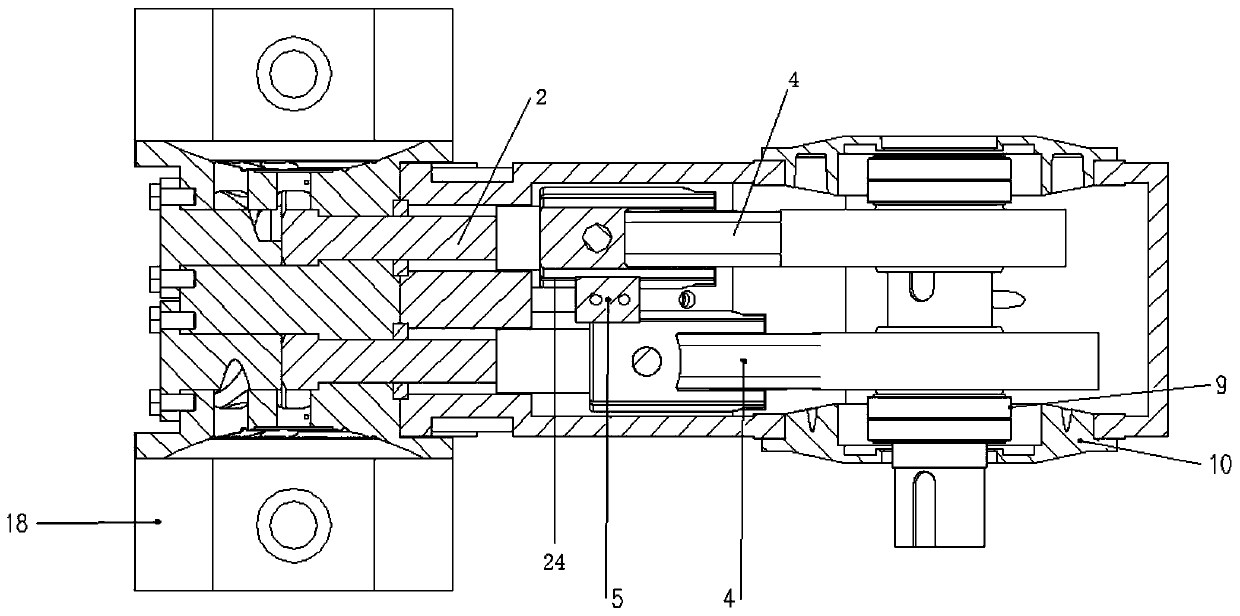

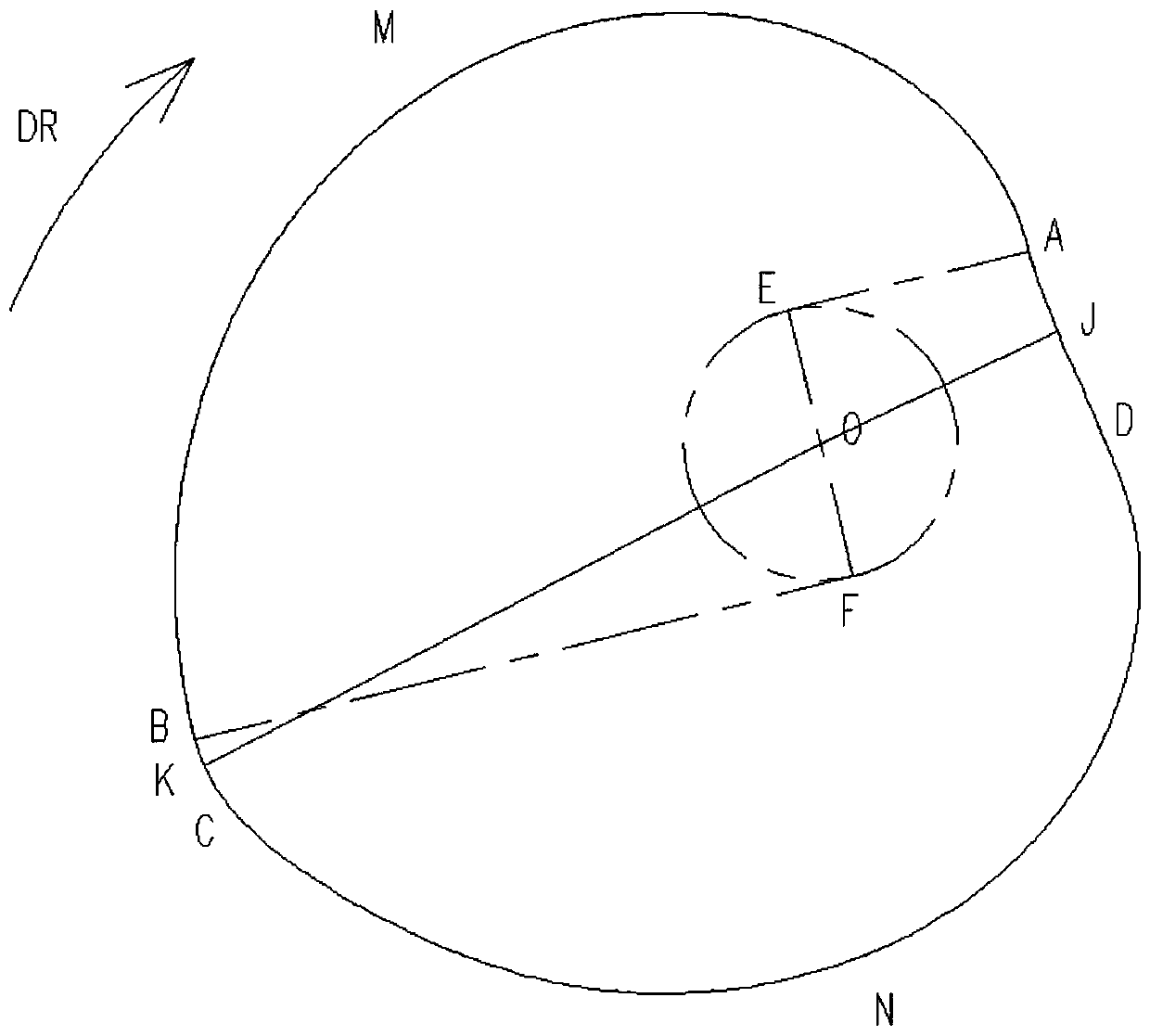

Reciprocating hydraulic diaphragm pump

PendingCN111502965AIncrease the itineraryLarge displacementGearingFlexible member pumpsDiaphragm pumpEngineering

The invention discloses a reciprocating hydraulic diaphragm pump. The reciprocating hydraulic diaphragm pump comprises a transmission box body, a plunger piston, a hydraulic cavity assembly, a diaphragm head assembly, an oil refill pipeline, and an oil return pipeline; a cylinder sleeve is installed in the hydraulic cavity assembly; the plunger piston is installed in the cylinder sleeve; a plungerpiston bearing is installed at the tail end of the plunger piston via a bearing pin; the plunger piston bearing is in contact with involute cams; the involute cams are connected with a mandrel; a bumping post is arranged on the plunger piston; the bumping post is connected with one end of a return spring; and the other end of the return spring is connected with a spring pressing cover. In the process of operation of the provided diaphragm pump, the distance between the plunger piston and an axes is equal to the base circle radius of the involute cams, so during working, the plunger piston bears no other lateral force other than gravity and therefore the phenomenon of eccentric wear does not occur. When the involute cams push the plunger piston to move forward, the plunger piston makes uniform linear motion, and the two cams are arranged to form a 180 degree angle, so medium can be continuously transported at uniform velocity, and stable pressure can be generated without the addition of an energy accumulator to a pipeline.

Owner:SHENYANG DOUBLE RING PUMP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com