Patents

Literature

127results about How to "Control delivery speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

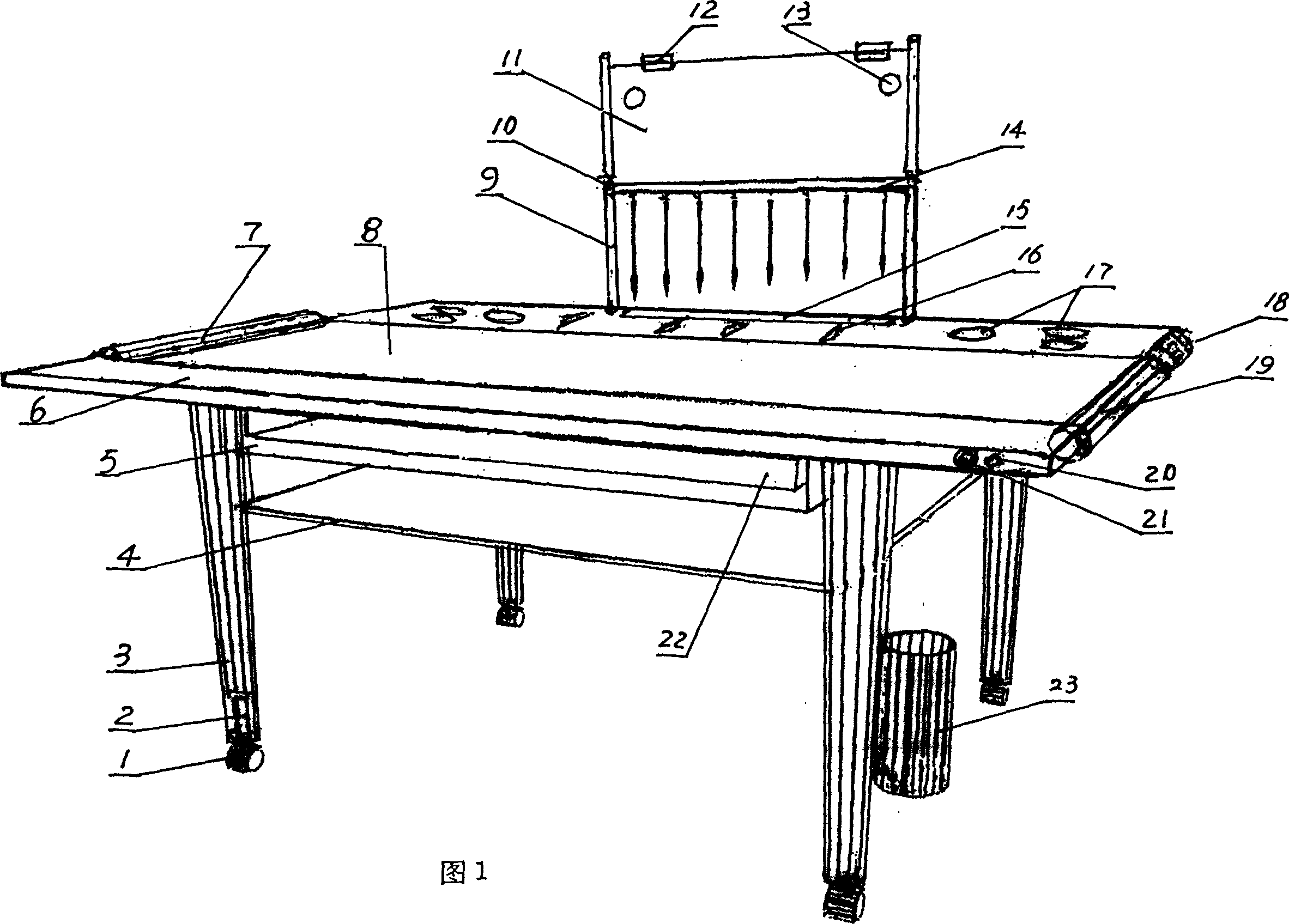

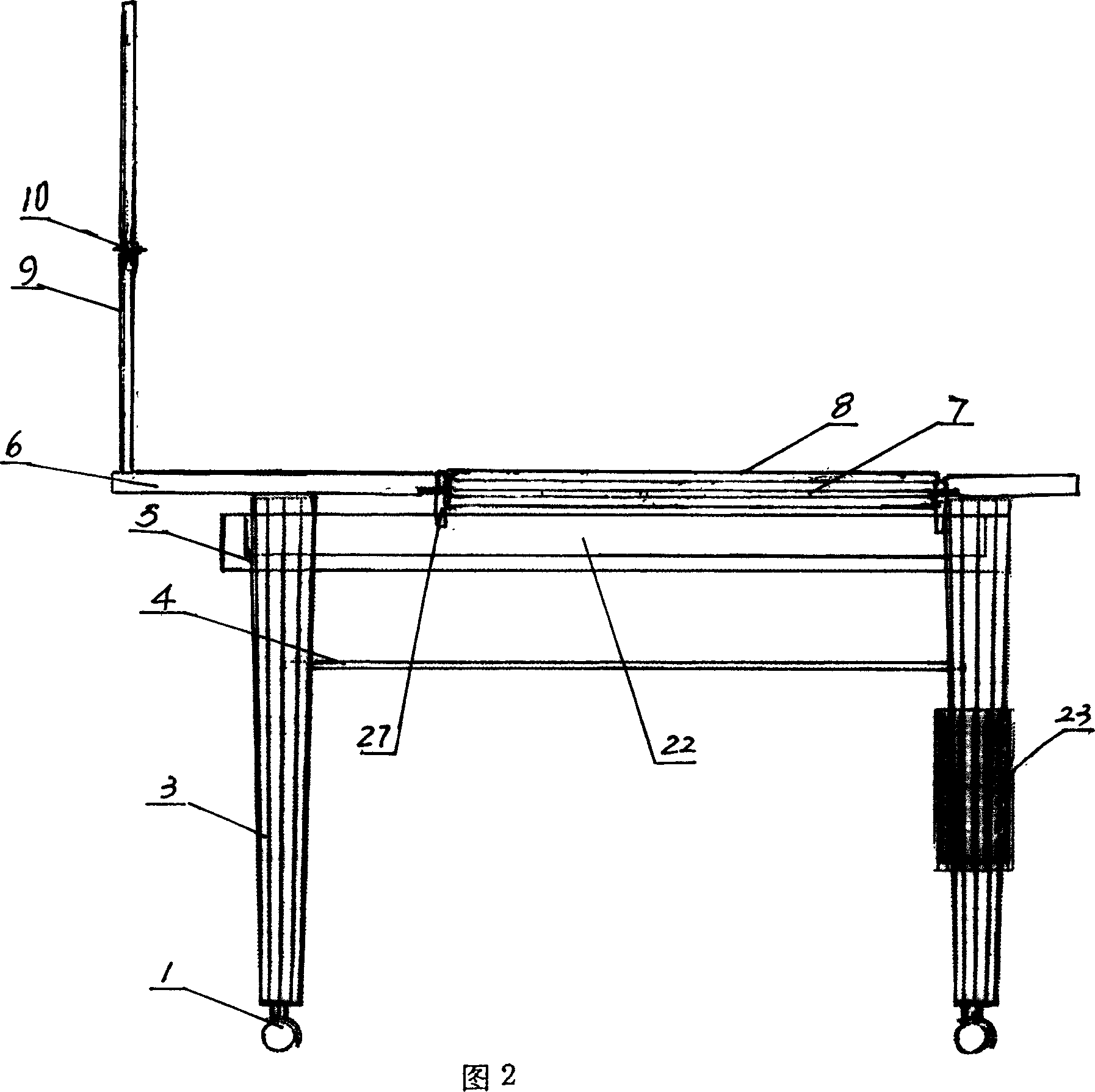

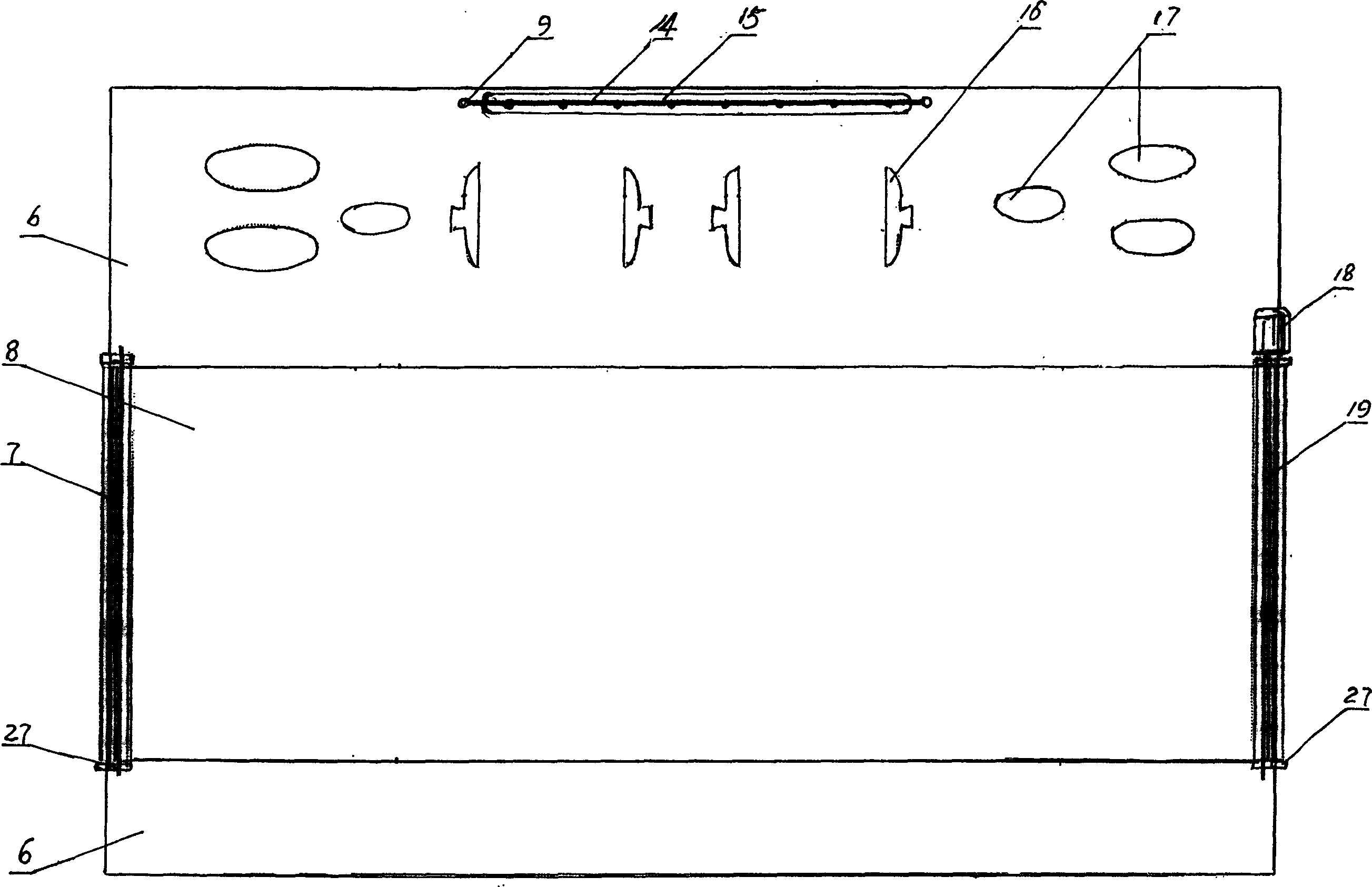

Multi-purpose table for calligraphy and painting

InactiveCN1647950AReasonable designCompact structureOther artistic work equipmentsDrive motorEngineering

The multipurpose calligraphy and painting table is especially suitable for calligraphing and painting and as office desk. The multipurpose calligraphy and painting table has the structure comprising movable top assembly, fixed top, table frame and hanging frame assembly. The movable top assembly includes movable top with felt layer and conveying belt, winding reel on the inner side of the top, and driving motor on one end of the reel. The driving motor drives the winding reel and the movable top directly or via a drive mechanism. The table frame below the fixed top has legs, paper holder and document drawer. The hanging frame assembly on the back side of the fixed top has hanging frame, reflector or writing board, and brush hanger.

Owner:郭传洲

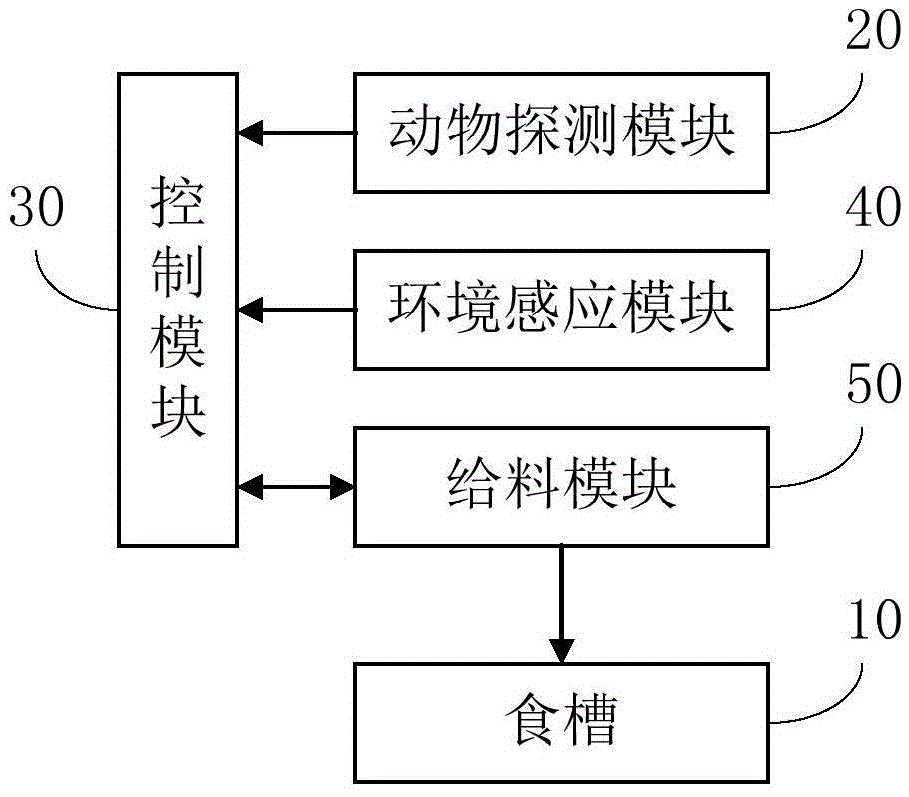

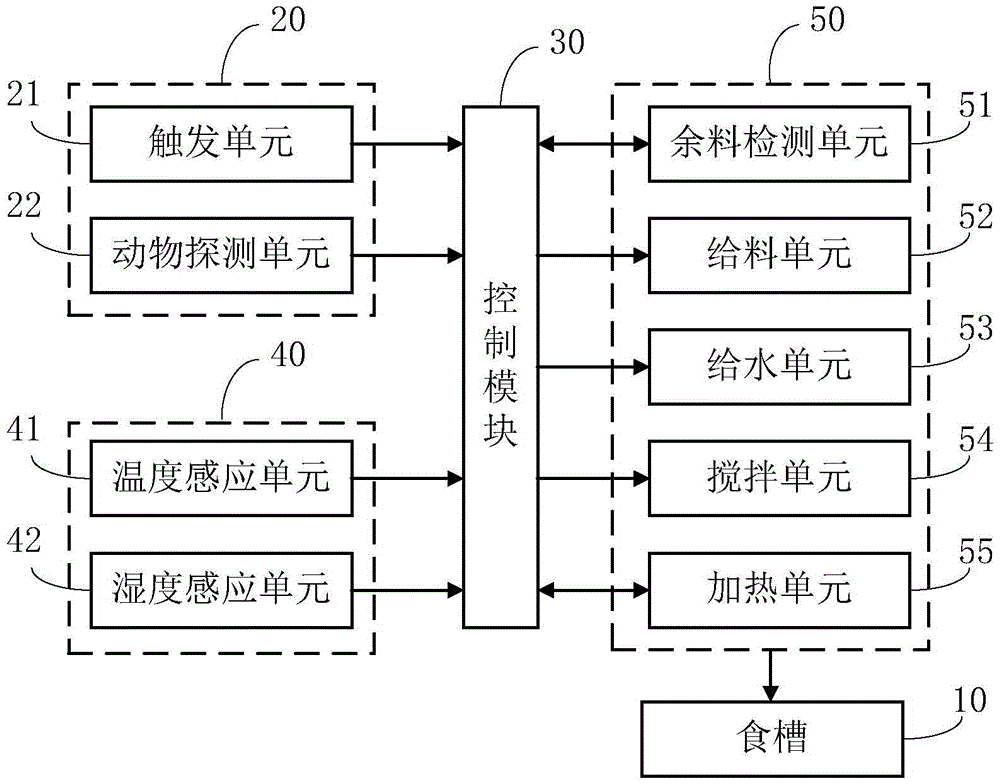

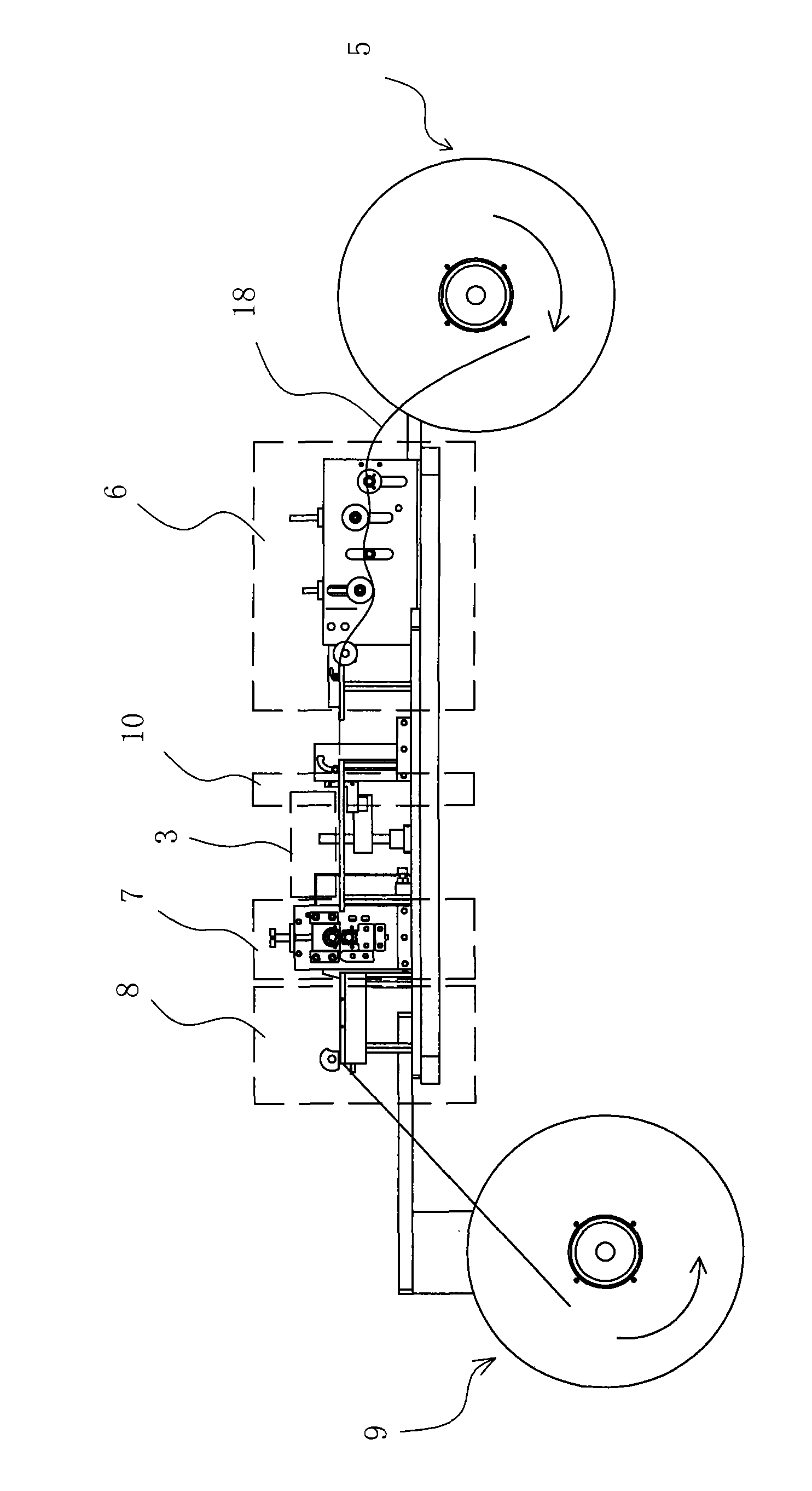

Intelligent feed put-in system and method

The invention is applicable to the field of animal breeding, and provides an intelligent feed put-in system and method. The system comprises a trough, and further comprises an animal detecting module for sensing animals entering an eating area and for detecting the number and weights of the animals, a control module for calculating the equivalent number and body sizes of the animals according to the number and weights of the animals, an environment sensing module for sensing the environment parameters around the intelligent feed put-in system, a feed module for detecting the residual amount of feed in the trough and processing a prefixed amount of feed and water into a feed and water mixture with preset humidity according to the equivalent number and body sizes of the animals, the environment parameters and the residual amount of feed, and putting the feed and water mixture into the trough. The animals entering the eating area can be sensed, and the put-in amount and humidity of feed can be controlled according to the residual amount of feed, the environment parameters and the equivalent number and body sizes of the animals, feed surplus and deficiency can be effectively avoided, and breeding benefits are improved.

Owner:深圳市润农科技有限公司

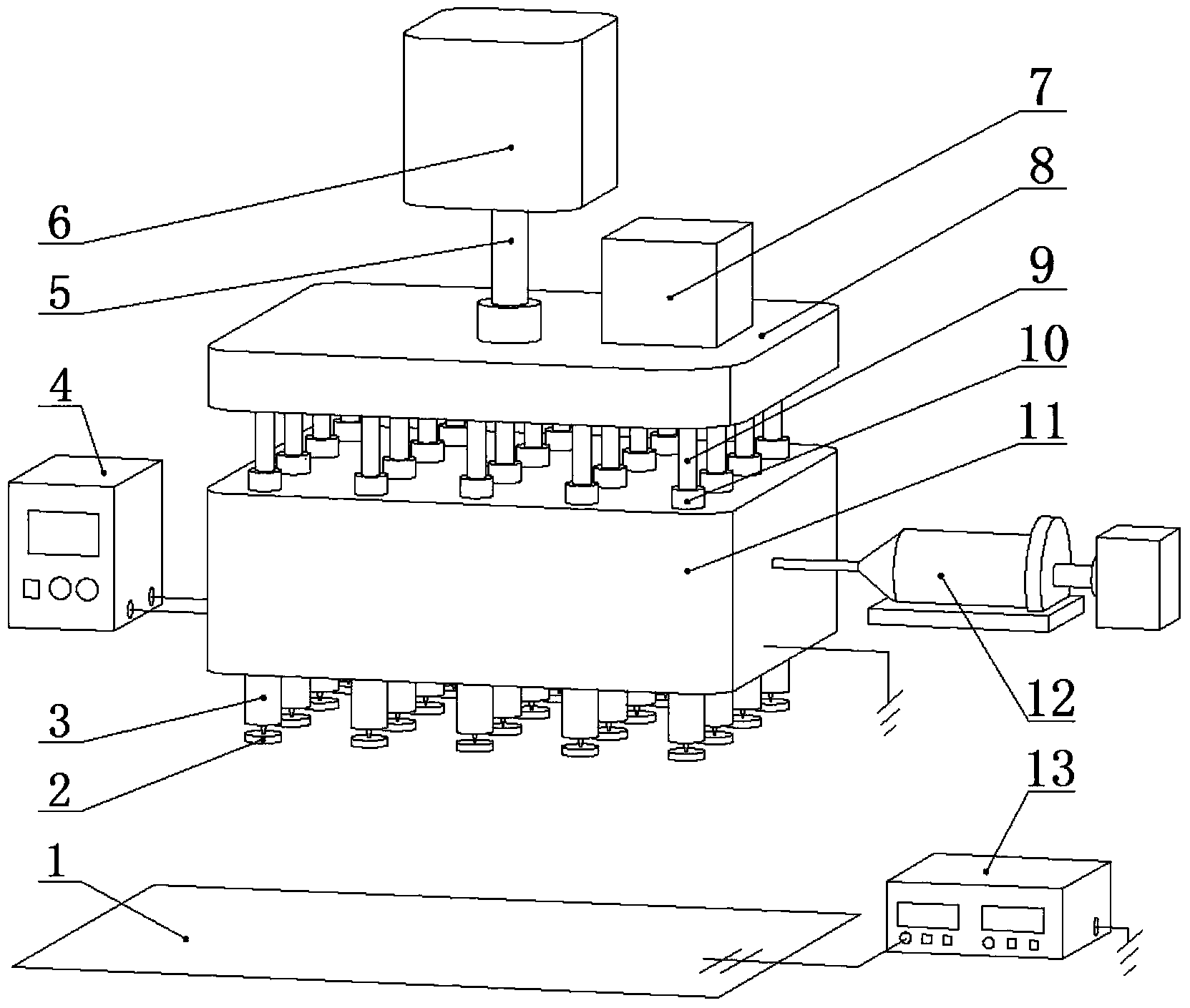

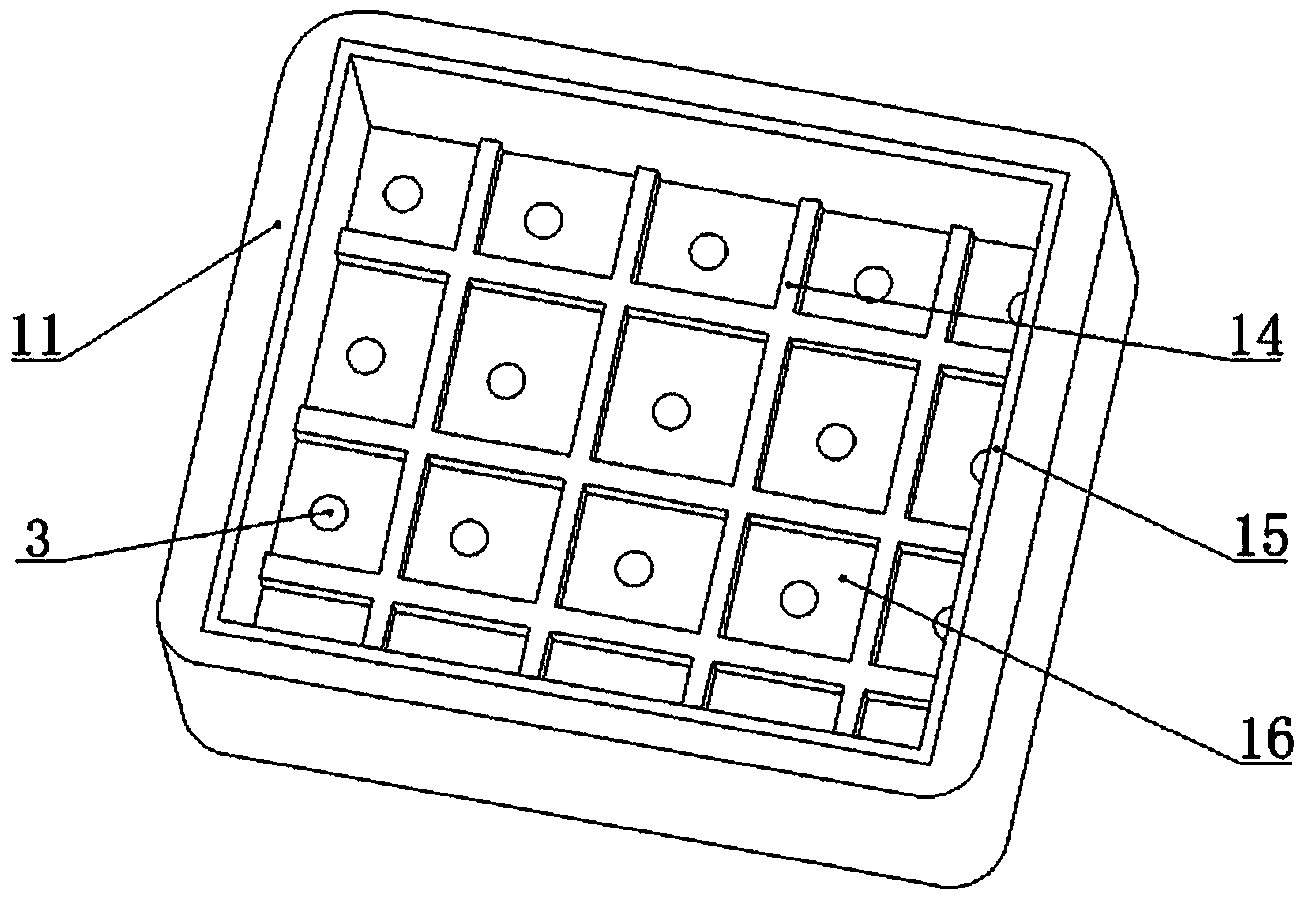

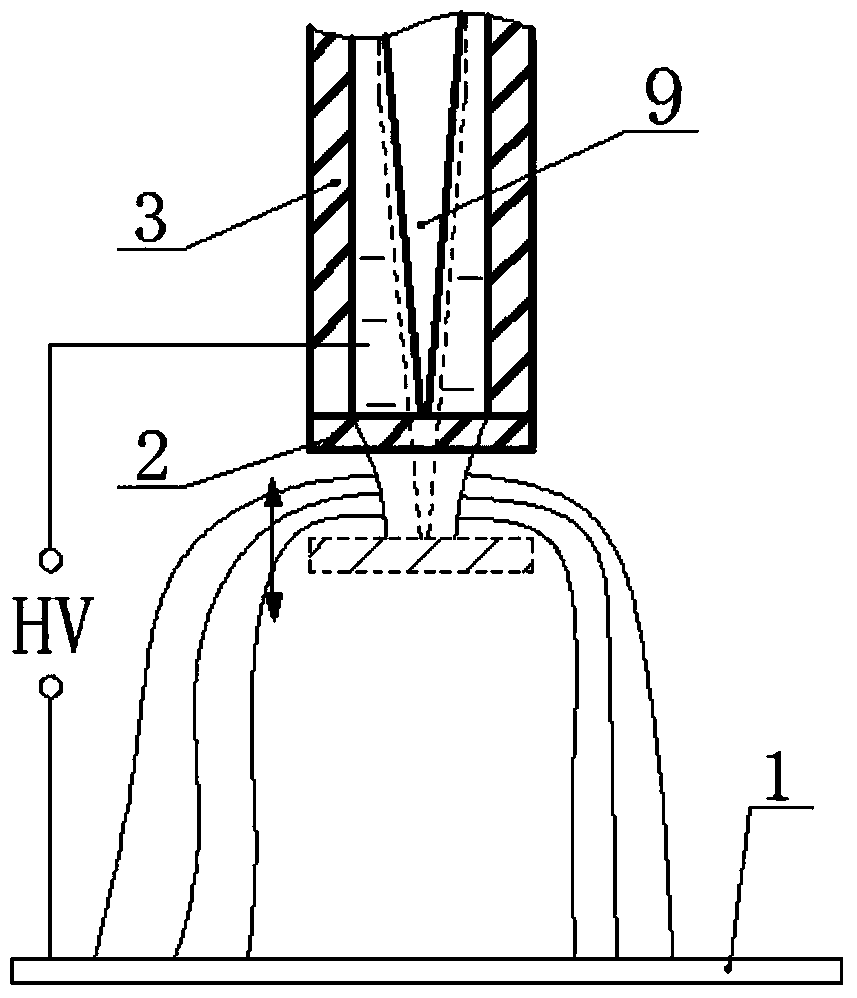

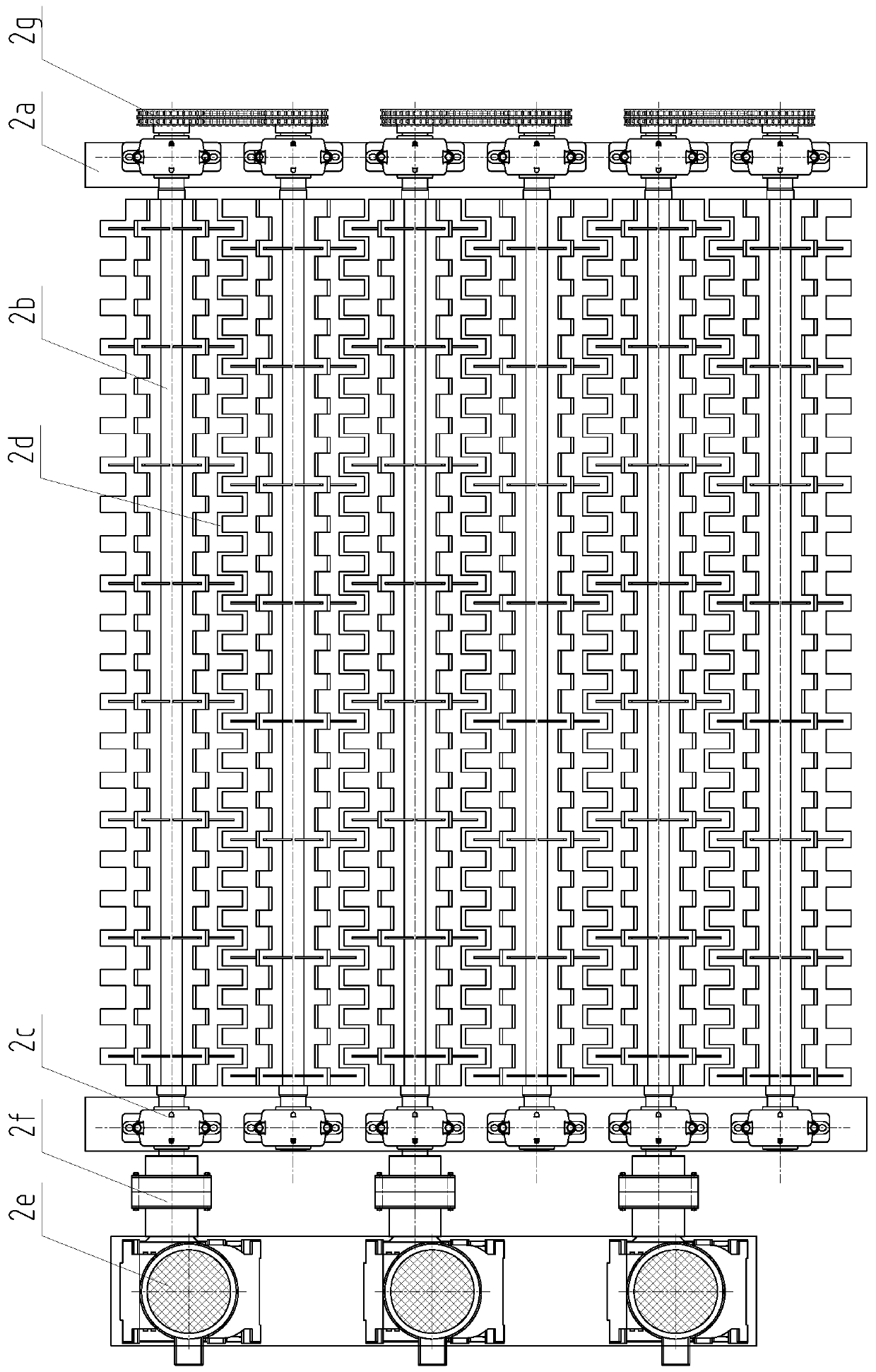

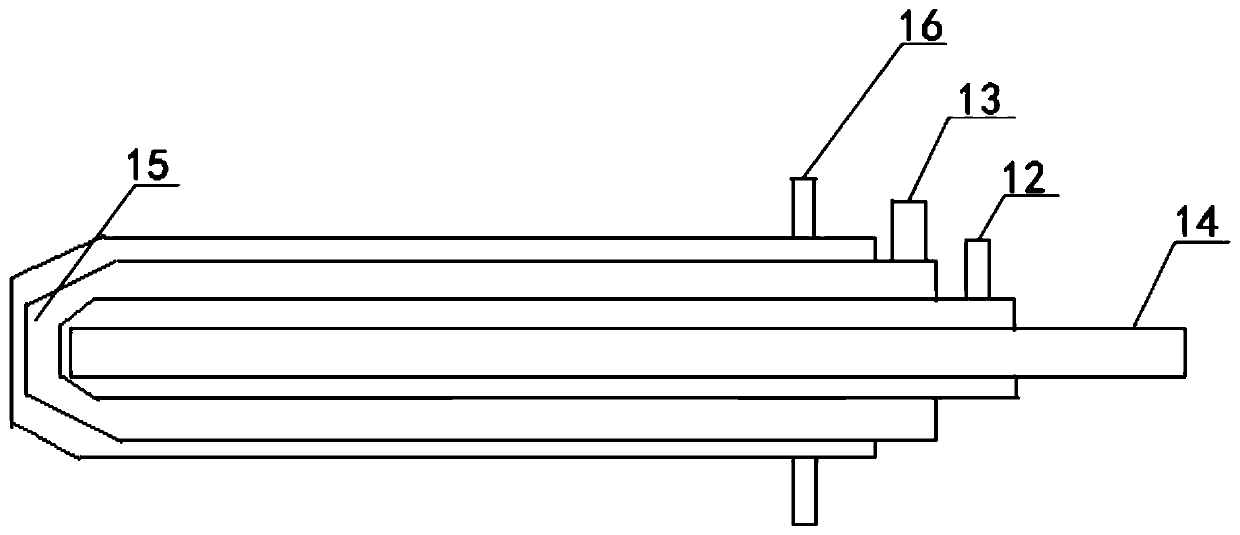

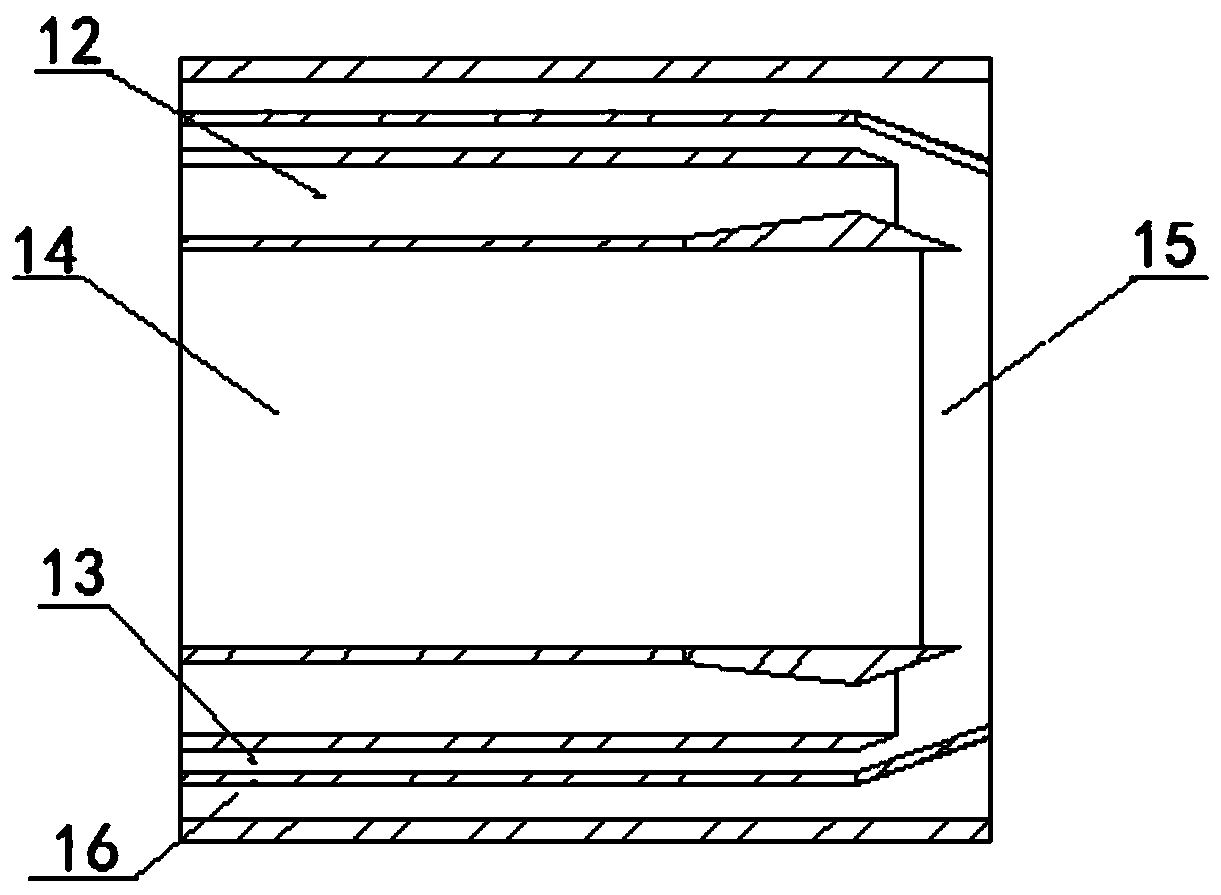

Opening-closing induction type batch electro-spinning device

ActiveCN103993371AImprove delivery efficiencyIncrease delivery speedFilament/thread formingElectricityTemperature control

The invention discloses an opening-closing induction type batch electro-spinning device and relates to an electrostatic spinning device. A material storage box is communicated with a liquid supply device. A heating piece and a temperature sensor are arranged on an inner cavity wall of the material storage box. The heating piece and the temperature sensor are electrically connected with a temperature control box. A nozzle array is arranged at the bottom of the material storage box. Center shafts are arranged in nozzles. The center shafts penetrate through the material storage box vertically. The lower ends of the center shafts are connected with nozzle covers which are placed outside nozzle outlets. The upper ends of the center shafts extend out of the upper end face of the material storage box. A driving motor and a multi-shaft output box are arranged above the material storage box. The driving motor is arranged on the multi-shaft output box. An output shaft of the driving motor is connected with the input end of the multi-shaft output box. The output ends of the multi-shaft output box are connected with the upper ends of the center shafts. A vibration output end of a vibration generator is in rigid connection with the multi-shaft output box. Conducting metal strips are arranged on the bottom face in the material storage box at intervals horizontally and longitudinally. The conducting metal strips are connected to the ground or are electrically connected with a high-voltage power supply. A collecting device is placed below the material storage box. The collecting device is electrically connected with the high-voltage power supply or is connected to the ground.

Owner:XIAMEN UNIV

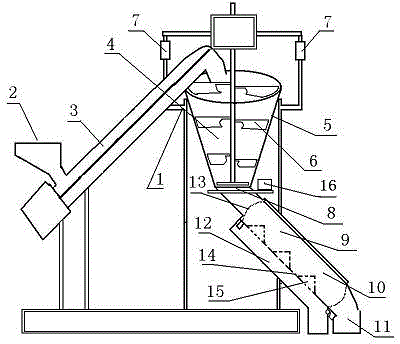

Sand mulling and sieving device

The invention provides a sand mulling and sieving device which comprises a bracket, a feeding hole, a spiral conveyer, a sand mulling machine and a vibrating sieve, wherein the sand mulling machine is composed of a barrel, a spiral stirring impeller, an impeller lifting structure and a discharge hole, wherein the barrel is of an inverted conical structure; the spiral stirring impeller is clung to the barrel from top to bottom; the discharge hole is formed in the bottom of the barrel; the vibrating sieve is composed of a sleeve, a semi-circular barrel structure sieve and a vibrating motor; the semi-circular barrel structure sieve stretches into the sleeve and is divided into a semi-arc sealed barrel plate and a straight plate sieve; one end of the vibrating sieve is connected to the discharge hole of the sand mulling machine on the bracket, and the other end of the vibrating sieve is provided with a discharge device; the angle between the vibrating sieve and a horizontal surface is kept within 30-45 degrees. The barrel of the sand mulling machine is of the inverted conical structure, the spiral stirring impeller is clung to the barrel from top to bottom and the impeller lifting structure is capable of fully and uniformly stirring; the vibrating sieve is independent in structural design is of a slope automatic-flow vibrating sieve form, and is capable of effectively obstructing unclean high-speed downflow sieving by use of a triangular bulge.

Owner:WUHU RONGCHUAN ELECTROMECHANICAL TECH

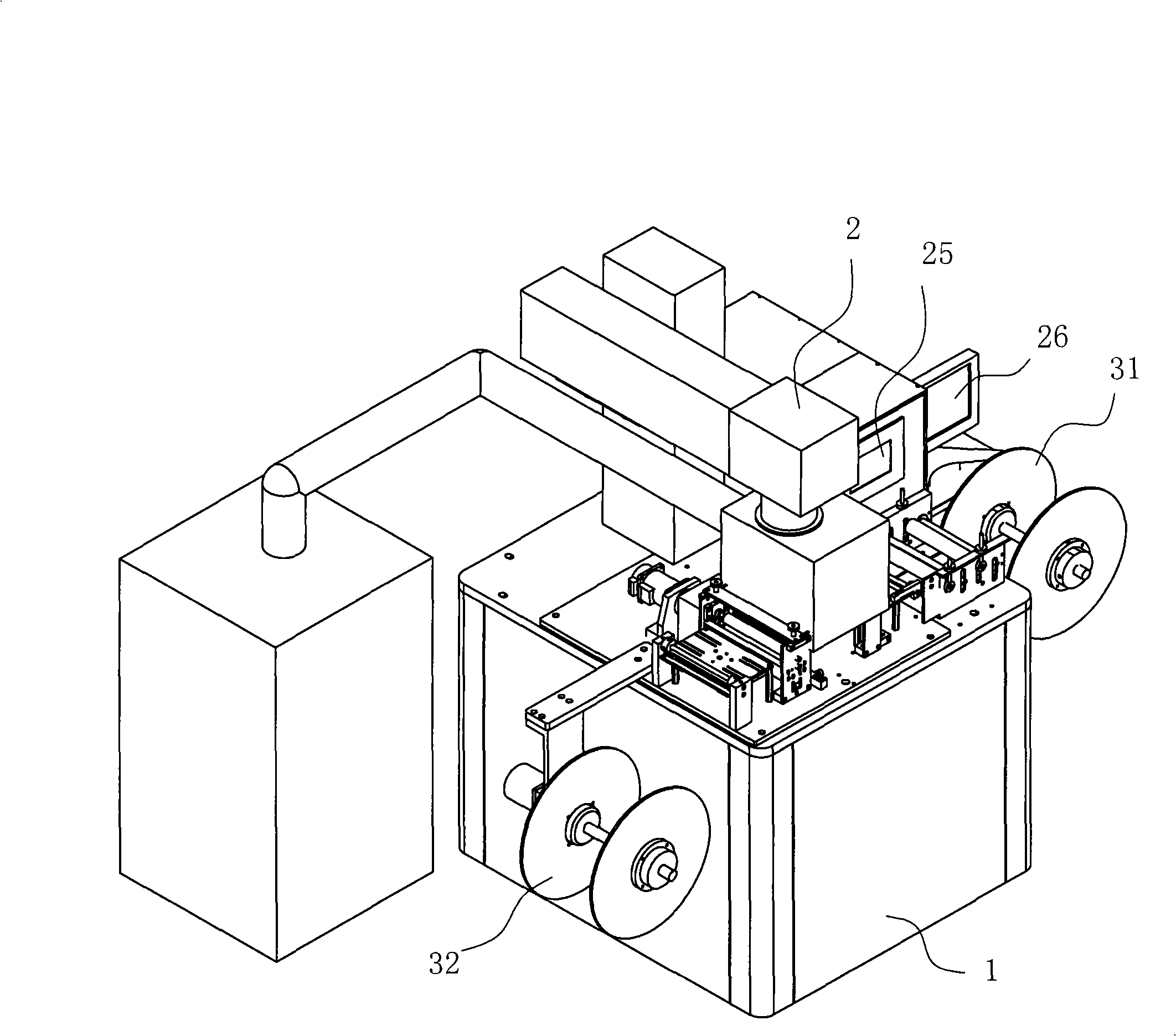

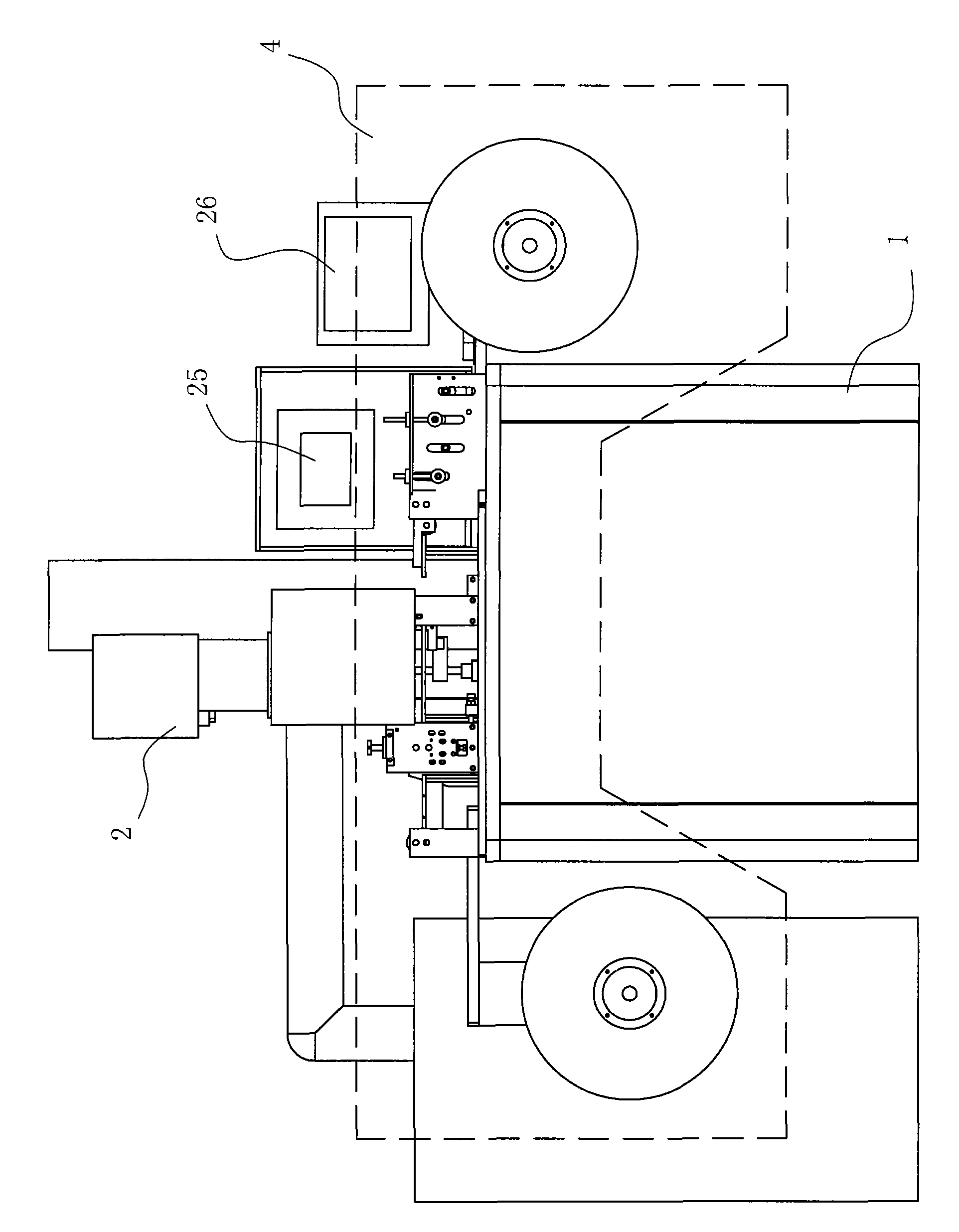

Winding type laser marking machine

InactiveCN101537738AAutomatic continuous printing operationImprove work efficiencyTypewritersOther printing apparatusControl systemEngineering

The invention discloses a winding type laser marking machine comprising a main body stand, a laser machine installed on the main body stand, and a control system. A laser working platform is arranged below the laser machine. The winding type laser marking machine is characterized by further comprising a material conveying device which is spliced into a material conveying runway at a same plane with the operation surface of the working platform; at least one gravitation rod is arranged between the working platform and a tension adjusting mechanism and is connected to the material conveying runway in a spanning mode; the bottom of the gravitation rod is abutted on the surface of a material positioned on the material conveying runway; and a sensor mechanism is arranged near the feeding position of the working platform, acquires signals of printing medium positioned on the material conveying runway and inputs the signals to the control system which is a control device with programmable software. The invention realizes the continuous automatic printing of high-precision laser labels through the arrangement of the material conveying device, the sensor mechanism and the gravitation rod and effectively improves the printing efficiency and the use range.

Owner:SHENZHEN YUTO PACKAGING TECH

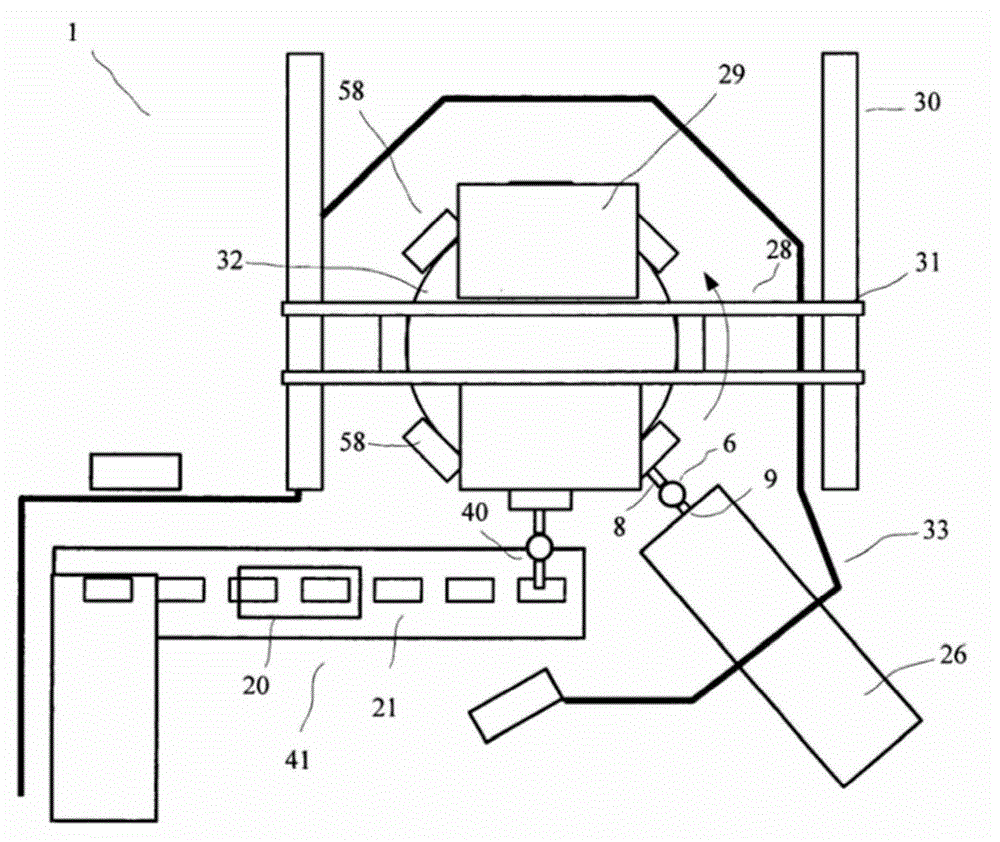

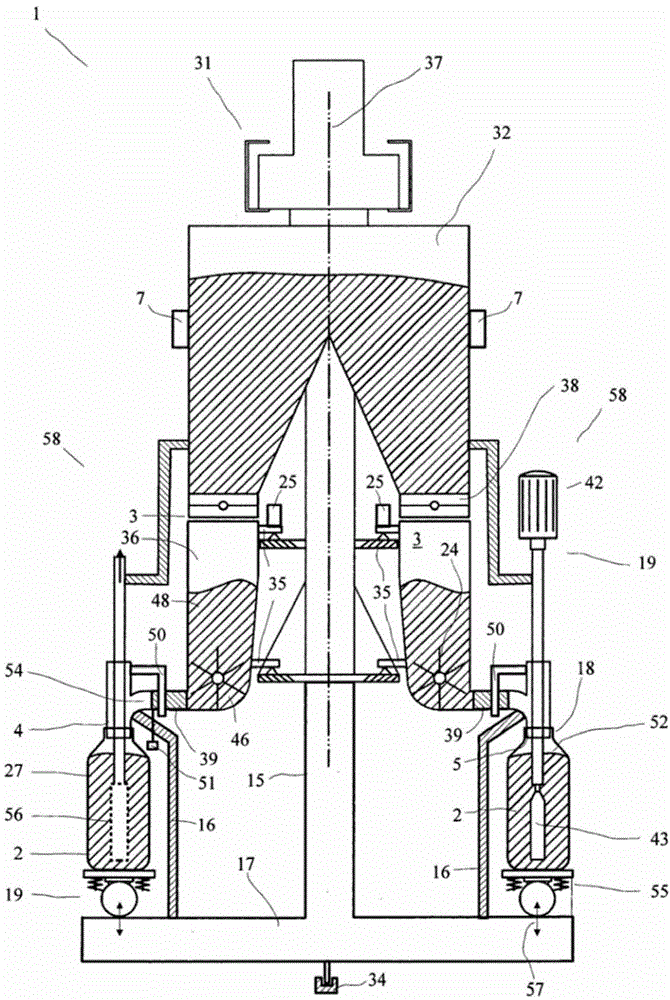

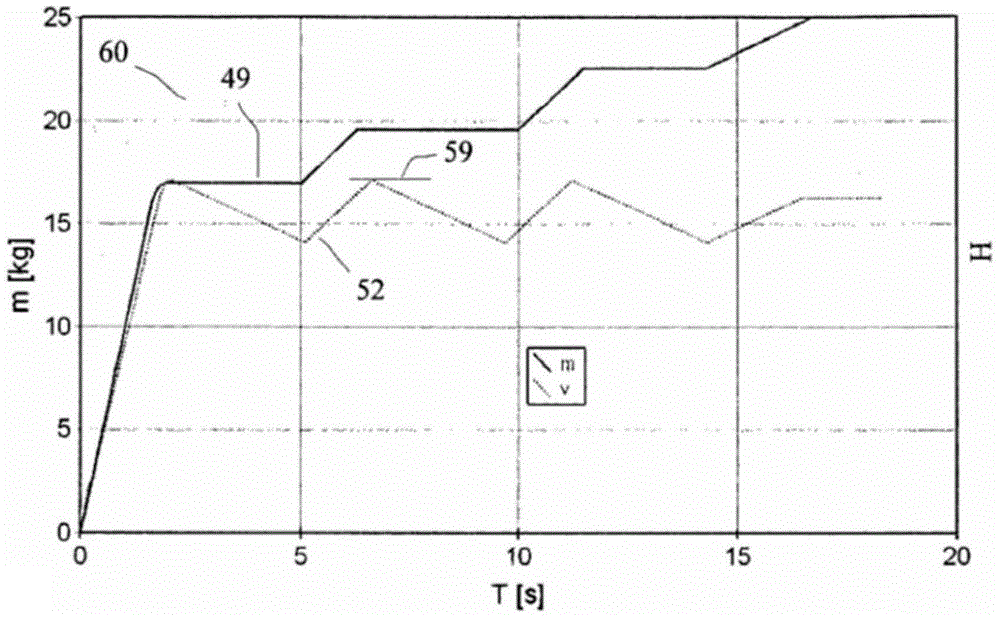

Packaging machine and method for filling pouches

ActiveCN104039653AVariable conveying speedConveying speed is variably controlledPackaging automatic controlSolid materialEngineeringPackaging machine

A packaging machine and method for filling bags with a supporting structure to which at least one filling box is fastened which includes a conveyor element and to which a weighing device and a filling spout are assigned. A control device is provided. The filling box is retained non-communicating with the supporting structure and the assigned filling box and is weighed separately by the assigned weighing device to discharge from the filling box a predefined quantity of intended fill product by way of differential weighing and to fill it into the bag through the tilling spout. The control device controls the strength of a volume flow into the bag over the time of the filling process so that the intended fill product is maintained at a high fill height while overflow is simultaneously prevented.

Owner:HAVER & BOECKER

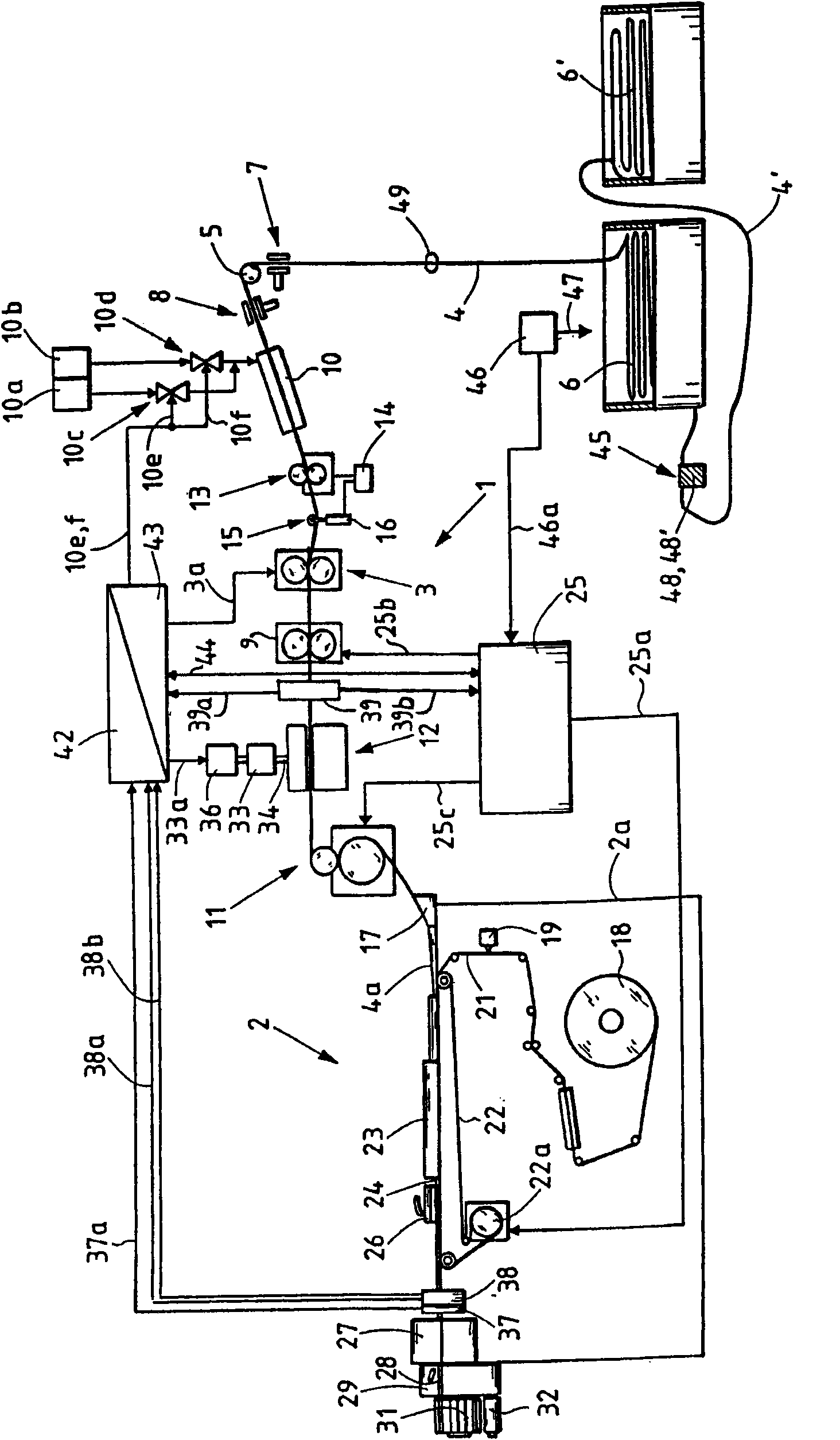

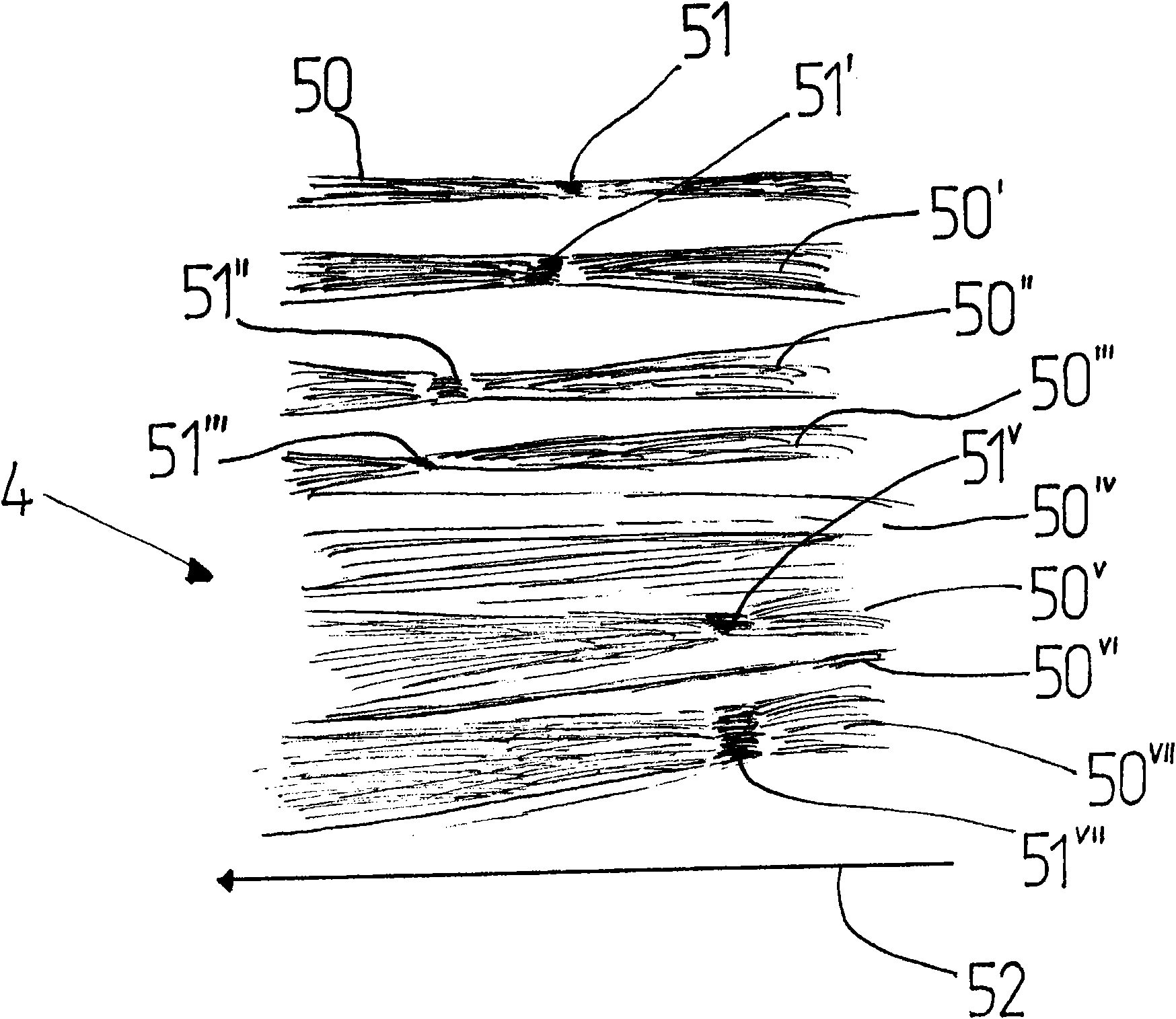

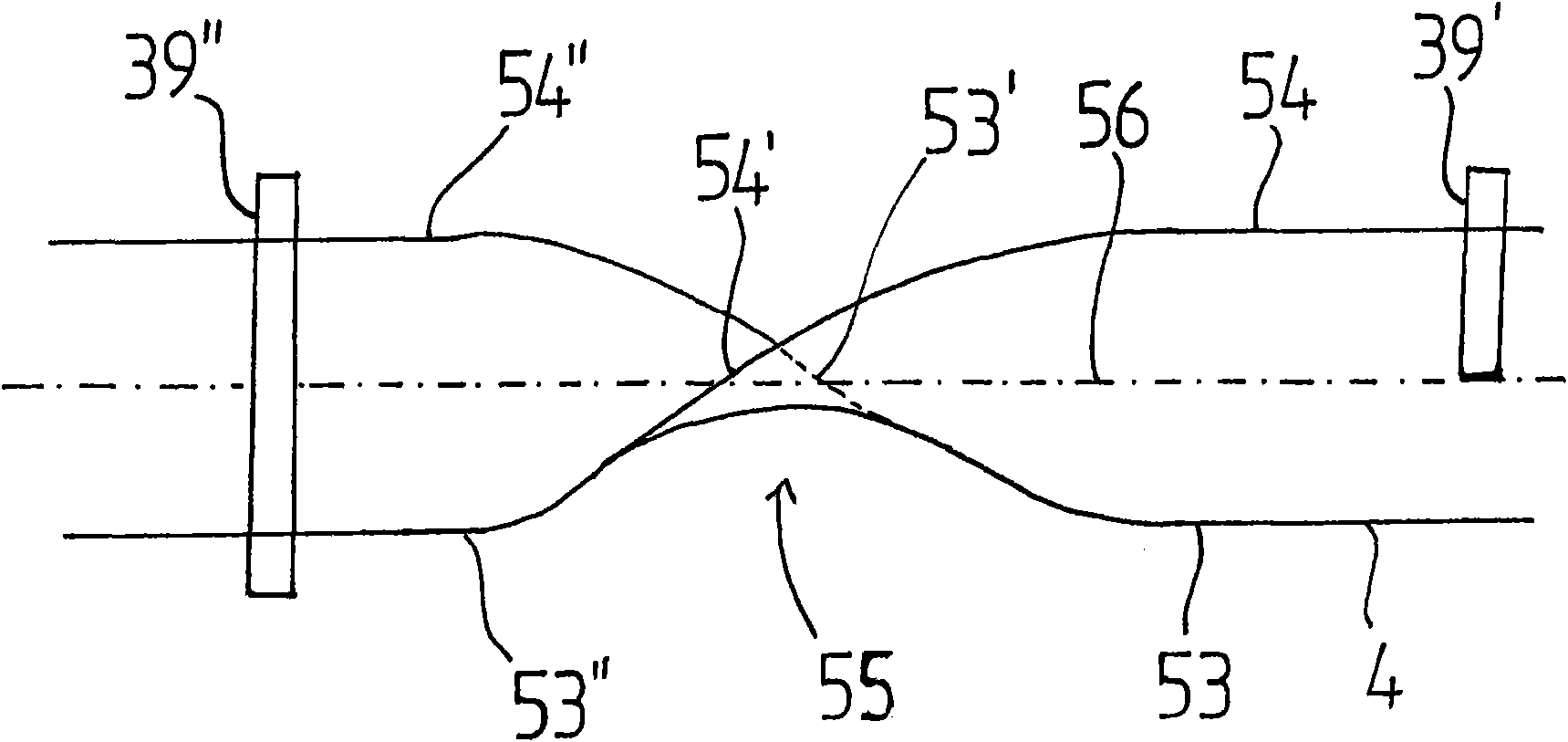

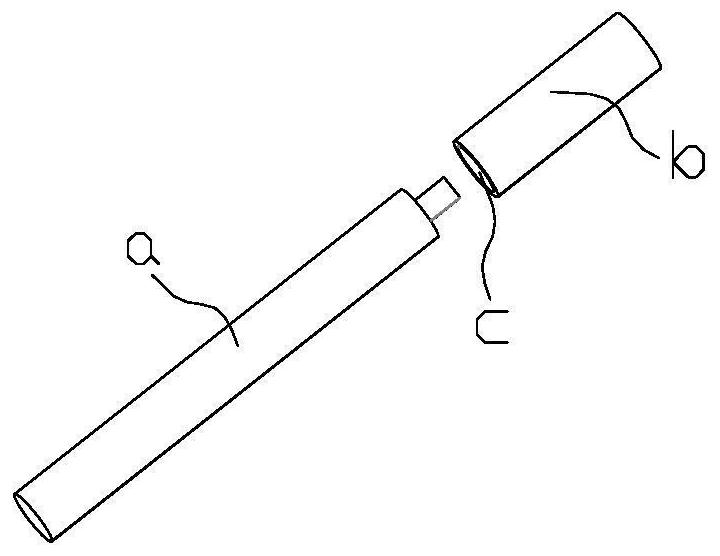

Method for operating a filter rod machine and filter rod machine

ActiveCN101856148AIncrease widthGood location resolutionCigarette manufactureTobacco smoke filtersEngineeringFilter material

This invention relates to a method for operating a filter-tip rod machine and a filter-tip rod machine, wherein the filtering material is extracted from a storage, spread, extended and transmitted through the coating device, then provided to the forming apparatus, furthermore, a filtering material strip is formed to be a filter-tip rod. It is characterized in that at least one sensor identifies the default part and produces at least one signal after the extension of the filtering material strip and before the coating device, therefore, at least the area of the filter-tip rod with default parts will be excluded by the next process; the filter-tip rod has a filtering material output station, a spreading apparatus, a extending apparatus a coating device and a rod forming apparatus which helps making the filter-tip rod, wherein the apparatus comprises at least one sensor for identifying the default part of the filtering material strip, being characterized in that the sensor is arranged at the position of the extending apparatus or arranged at the lower part of the extending apparatus and the upper part of the coating device.

Owner:KOERBER TECH GMBH

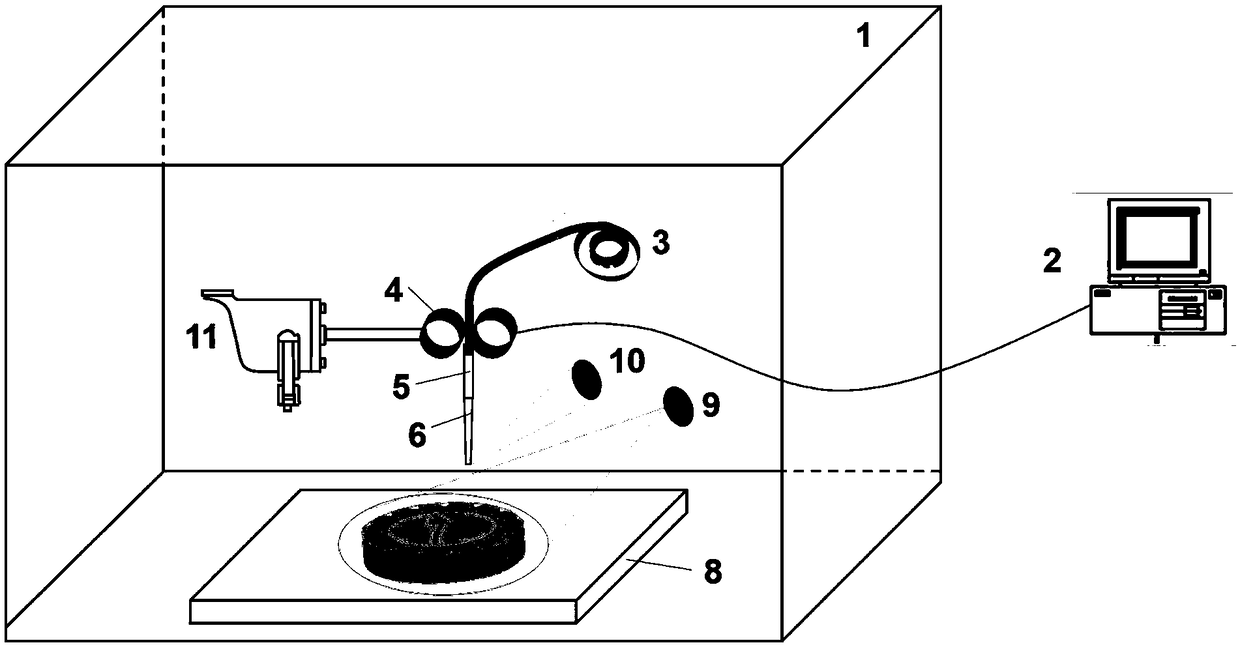

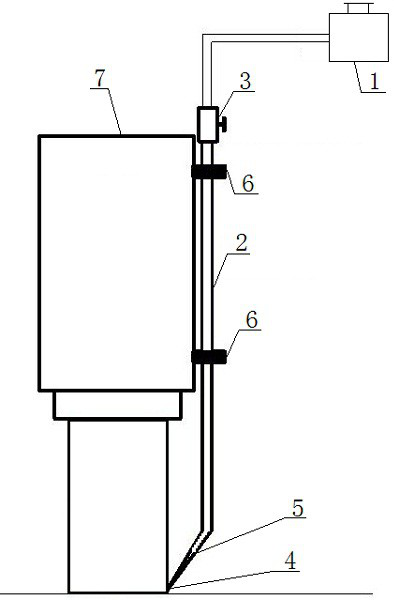

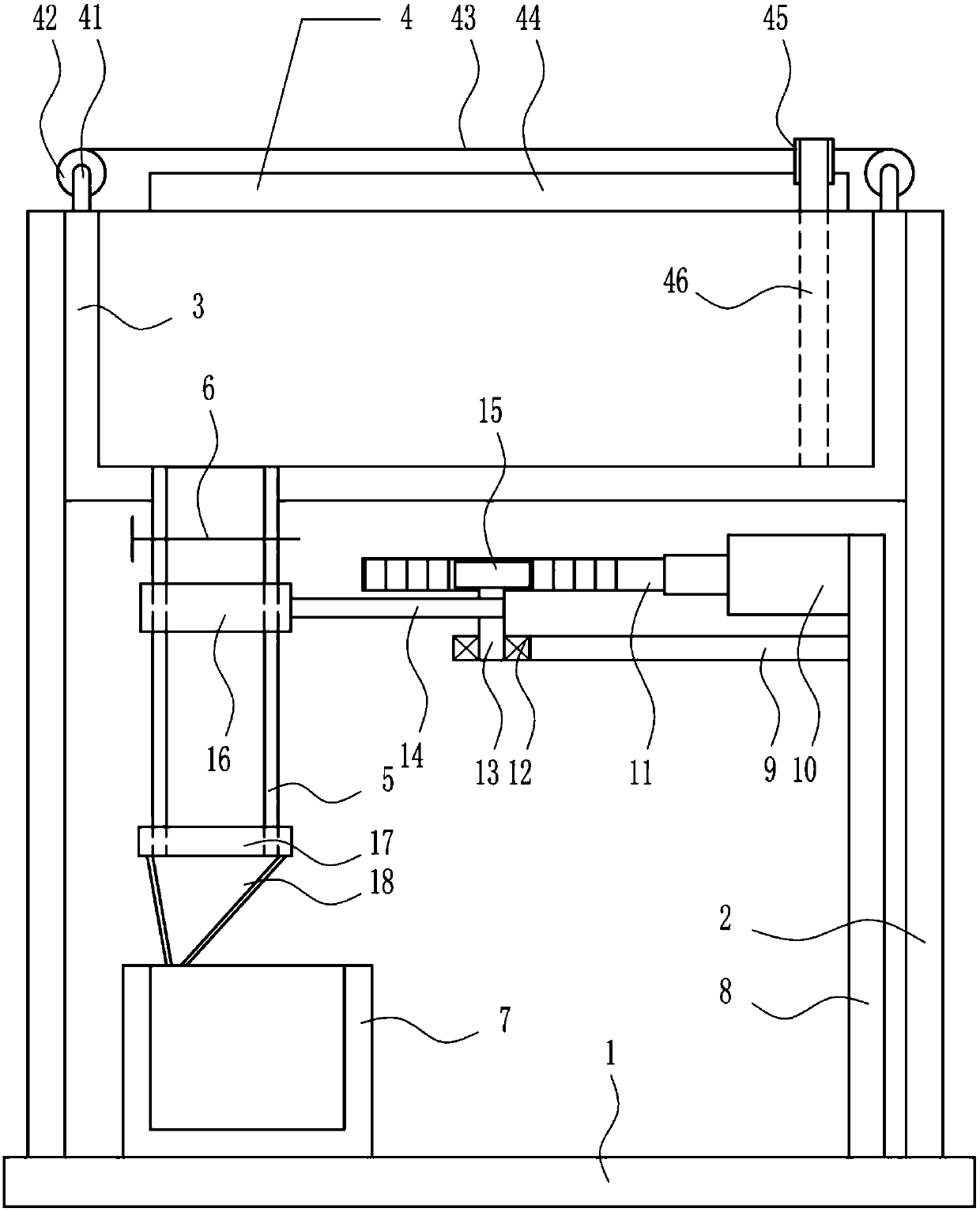

Space 3D printing system based on amorphous alloy superplastic welding

PendingCN109434112AAvoid the risk of high temperature crystallizationImprove job stabilityAdditive manufacturing apparatusSpace environmentOrbit

The invention discloses a space 3D printing system based on amorphous alloy superplastic welding. The space 3D printing system comprises a shell (1), a control unit (2), a workbench (8) arranged inside the shell (1), an amorphous alloy material (3), a heating device, a mechanical loading device (11) and a conveying device, wherein the mechanical loading device (11) controls the speed of the conveying device and the pressure load of a spray head (6) according to the material use requirements of 3D printing molding parts, and the heating device performs local heating and welding on the amorphousalloy material (3) to realize part molding. According to the space 3D printing system based on the amorphous alloy superplastic welding, the heating device only heats an area near the spray head, thecrystallization risk of amorphous alloy under a long-time high-temperature condition is avoided, and the amorphous alloy is heated to a superplastic state of a supercooled liquid phase area to realize molding, a laser or electron beam heating device is cancelled, the equipment working stability is increased, and the space 3D printing system based on the amorphous alloy superplastic welding is especially suitable for in-orbit fabrication in the space environment.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY +1

An ore sorting device

InactiveCN104084288ARealize sortingRealize secondary crushingSievingScreeningEngineeringConveyor belt

The invention relates to the field of ore separation production equipment, and particularly relates to an ore sorting device. The ore sorting device comprises a hopper, a first sorting mechanism, a smasher, a second sorting mechanism, a storing box, a rack and a conveyor belt. The hopper is fixedly installed on the rack. The bottom of the hopper is connected to the first sorting mechanism. The first sorting mechanism is connected to the storing box through a conveying pipeline. The first sorting mechanism is also connected to the smasher. The smasher is connected to the second sorting mechanism through a conveying pipeline. The second sorting mechanism is connected to the storing box through a conveying pipeline. The second sorting mechanism is also provided with a material outlet. The material outlet leads to the conveyor belt. The conveyor belt is communicated with the top of the hopper. The beneficial effects of the ore sorting device are that: the structure of the device is simple, operation is convenient, ore sorting is achieved by utilization of the simple device and secondary smashing processing of the ore is achieved at the same time.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

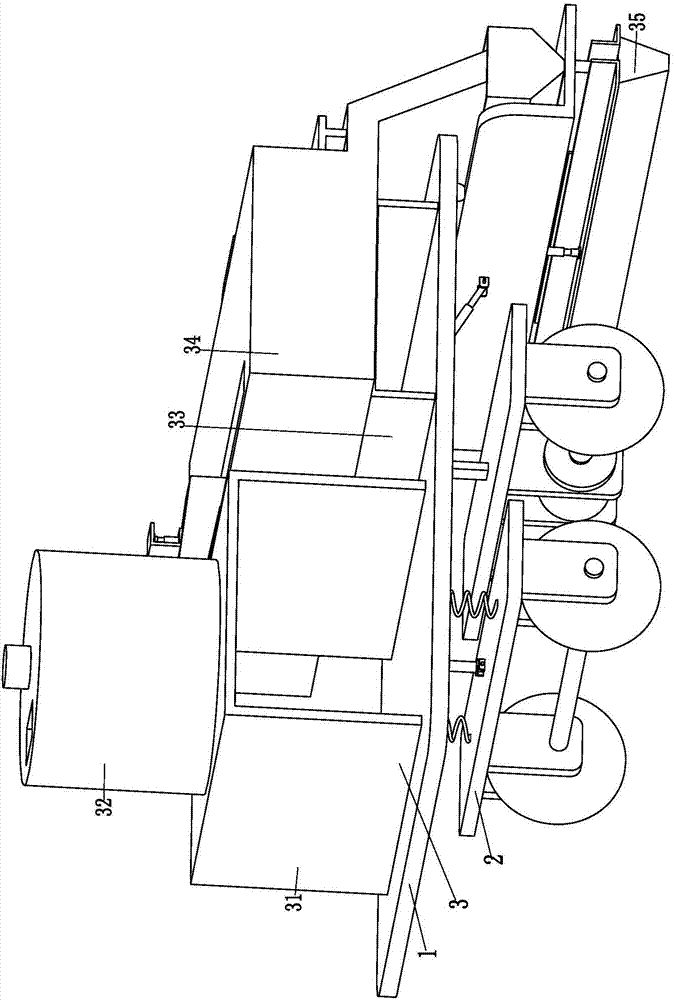

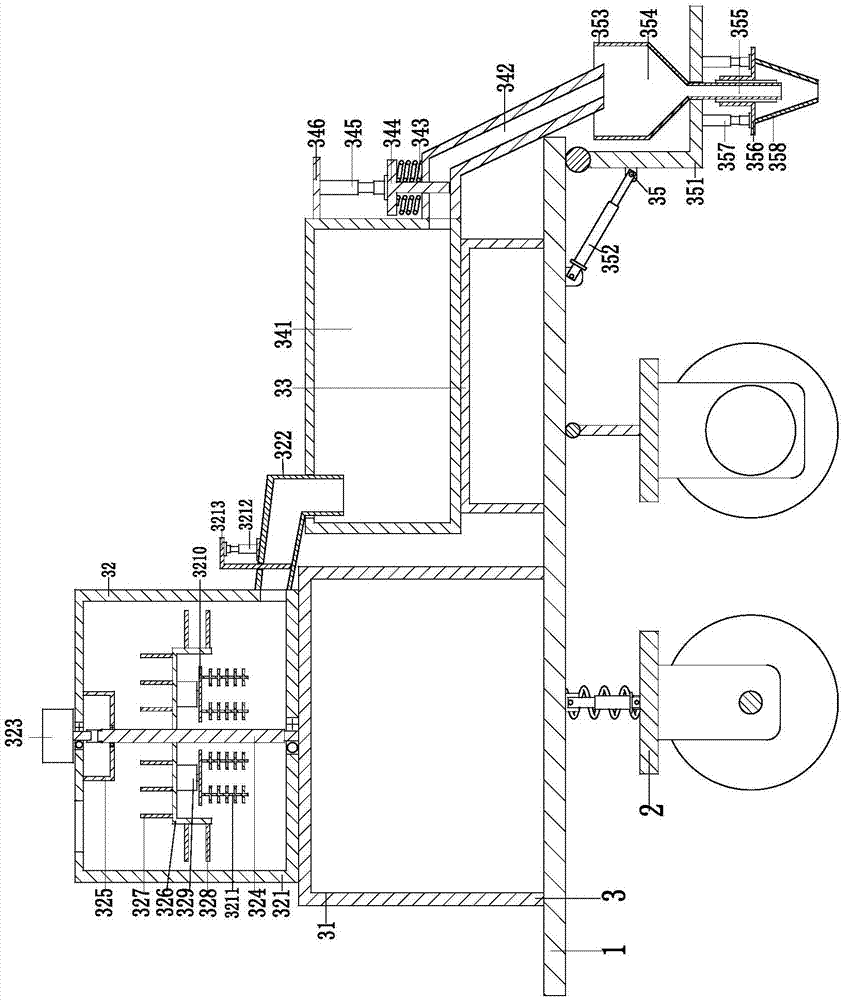

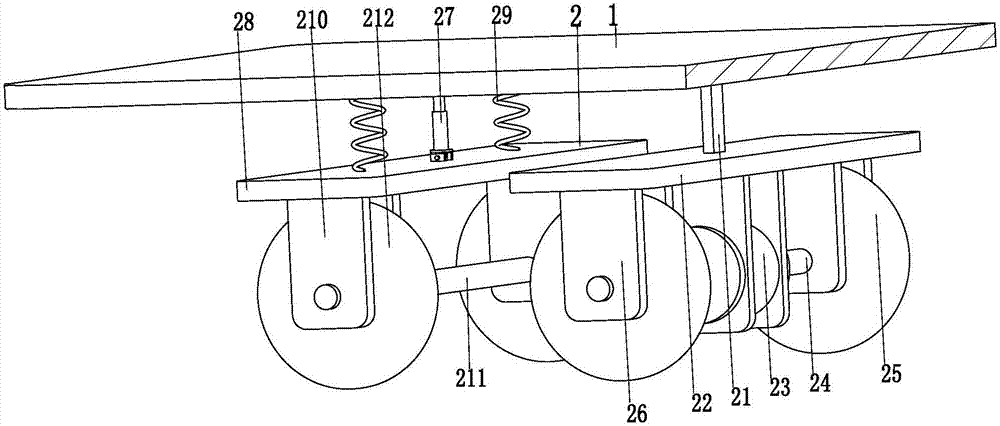

Polyurethane rubber plastic track surface glue automatic construction machine for playgrounds

The invention relates to a polyurethane rubber plastic track surface glue automatic construction machine for playgrounds. The automatic construction machine comprises a baseplate, a moving device is mounted at the lower end of the baseplate, a surface glue construction device is mounted at the front end of the baseplate, and the moving device and the surface glue construction device cooperate with each other to complete automatic glue scraping during surface glue construction of mixed plastic tracks. By the automatic construction machine, the problems that manual surface glue raw material stirring is nonuniform, manual control on speed of existing surface glue construction equipment is nonuniform, manual adjustment of surface glue consumption is inaccurate, manual control on surface glue coating thickness cannot be adjusted timely according to actual conditions, operation is complex, labor intensity is high, and working efficiency is low due to the fact that manpower is needed to stir surface glue raw materials, to control existing surface glue equipment to move for working, to adjust surface glue consumption during each time of working and to control surface glue coating thickness in existing mixed plastic track surface glue construction processes can be solved, and a function of automatic construction of surface glue of the mixed plastic tracks can be realized.

Owner:冒俊

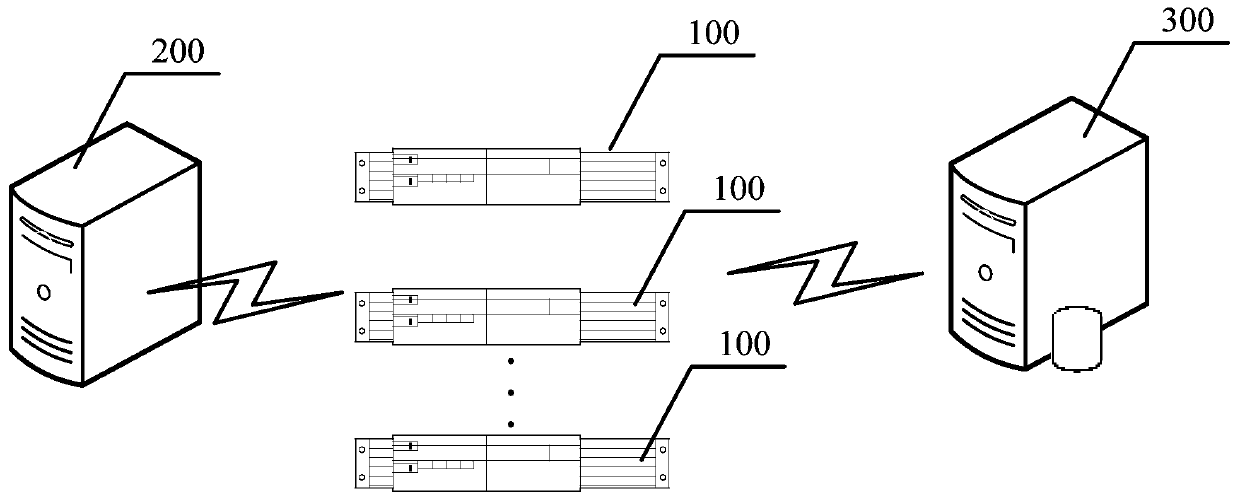

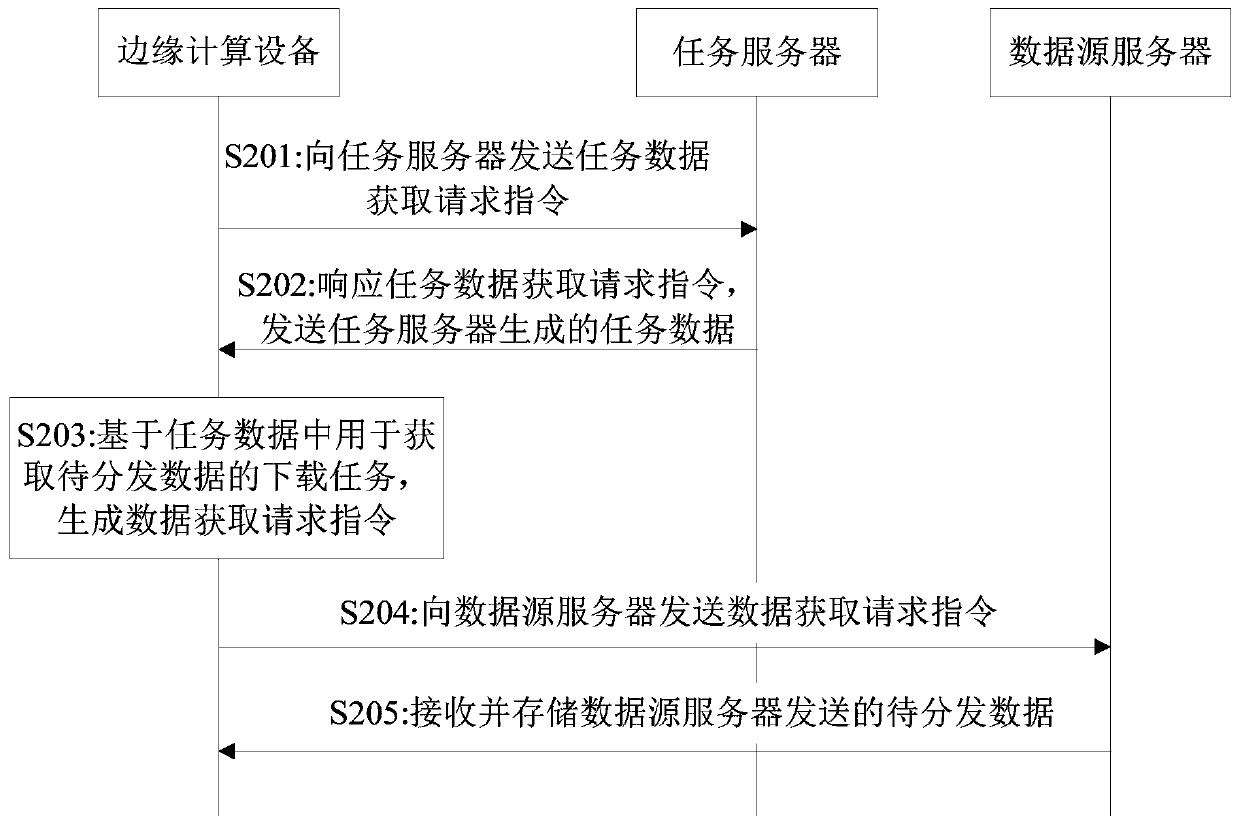

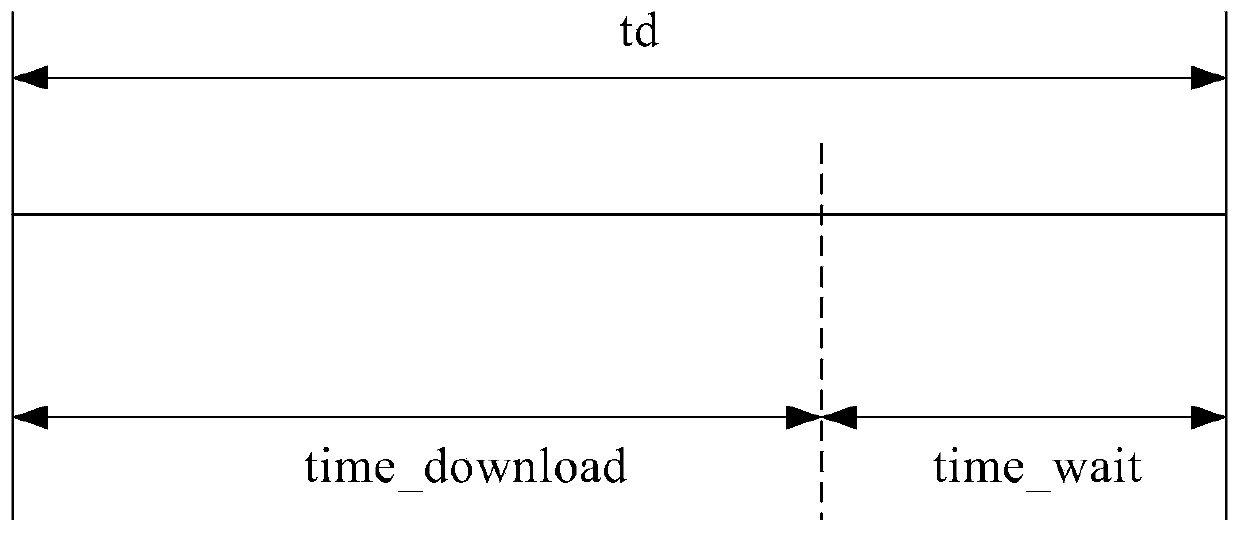

Data acquisition control system, data acquisition control method and related device

ActiveCN110691127AQuick responseAccess traffic peak reductionTransmissionEdge computingControl system

The invention provides a data acquisition control system, a data acquisition control method and related devices. The edge computing device sends a task data acquisition request instruction to the taskserver, the task server responds to the task data acquisition request instruction; task data generated by the task server is sent to the edge computing device; the edge computing device is based on adownloading task and is used for obtaining to-be-distributed data in task data, and generating data acquisition request instruction; the edge computing device sends a data acquisition request instruction to the data source server, wherein the data acquisition request instruction is used for triggering the data source server to acquire to-be-distributed data matched with the data acquisition request instruction from the storage area; and the edge computing device receives and stores the to-be-distributed data sent by the data source server so as to undertake part of service requests of the data source server through the edge computing device, so that the access flow peak value of the data source server is reduced, and when the access flow peak value is reduced, the bandwidth cost calculated according to the access flow peak value is also reduced.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

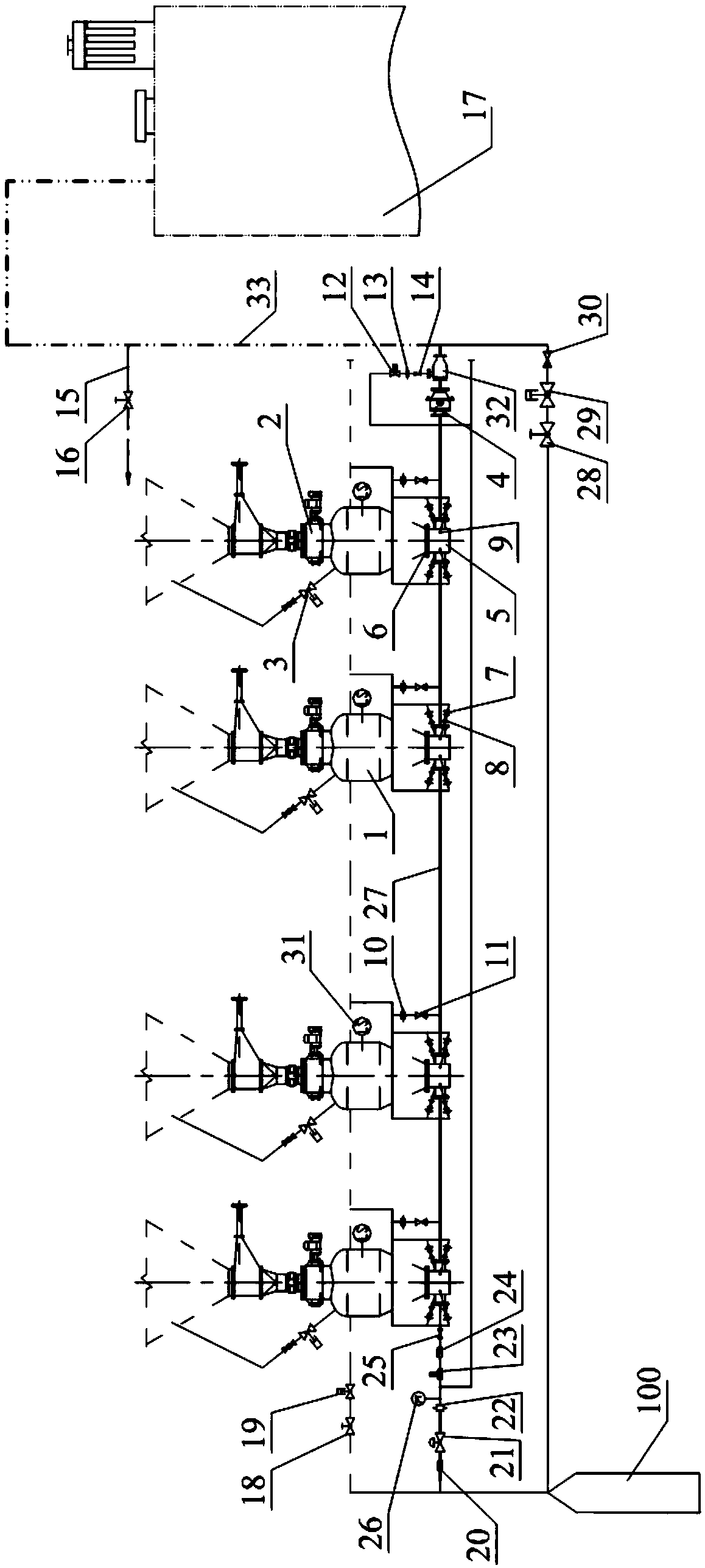

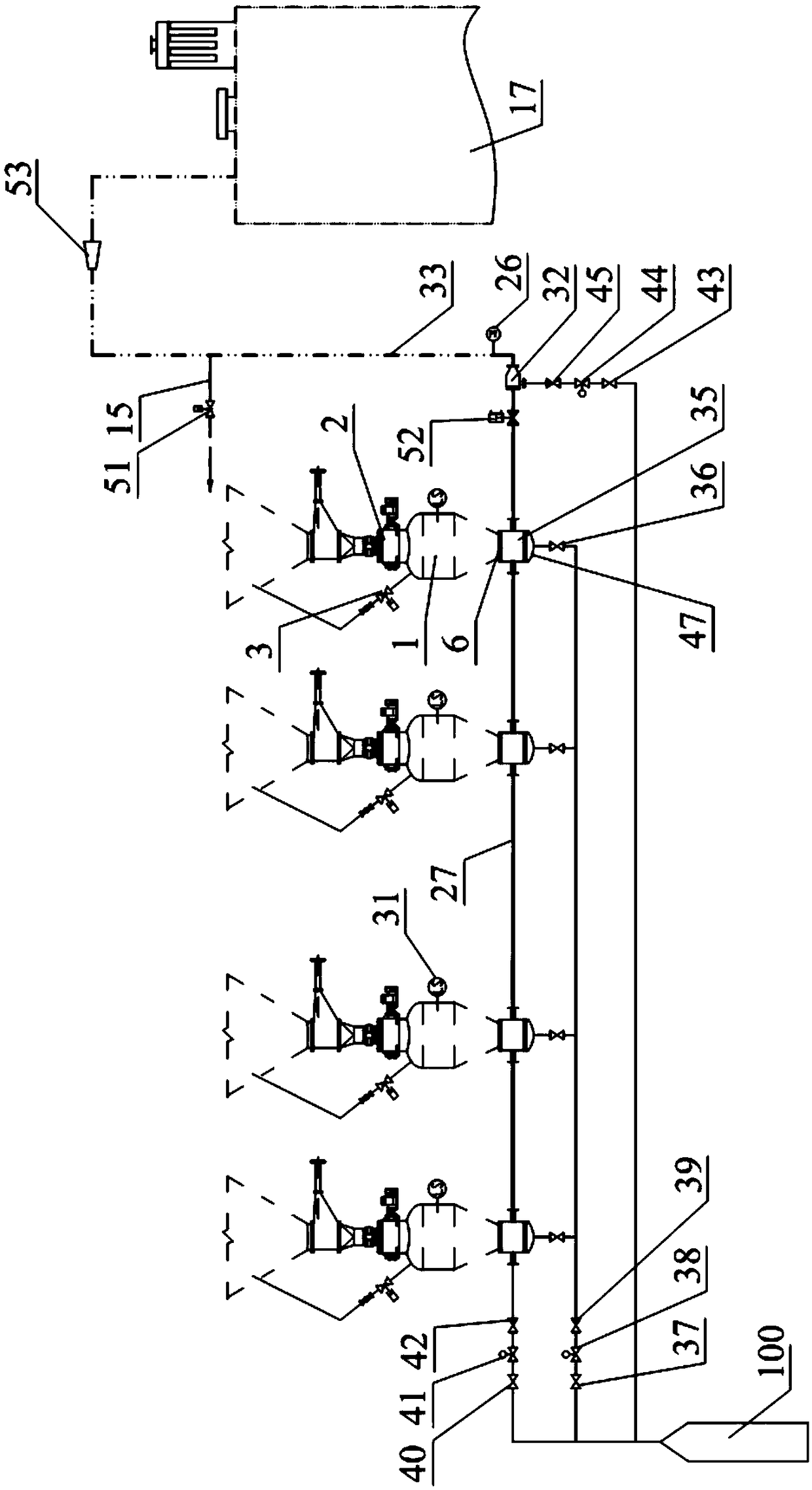

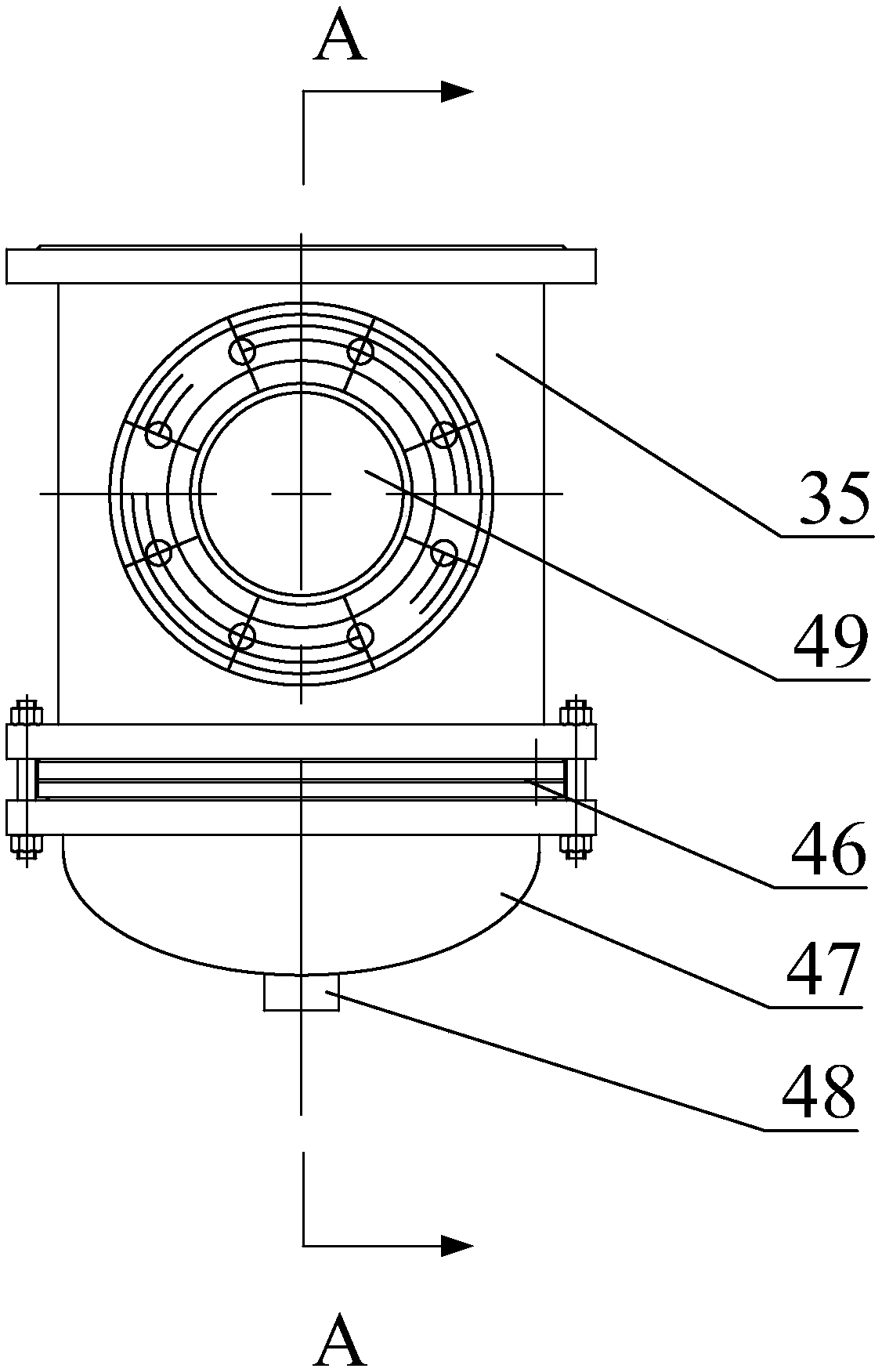

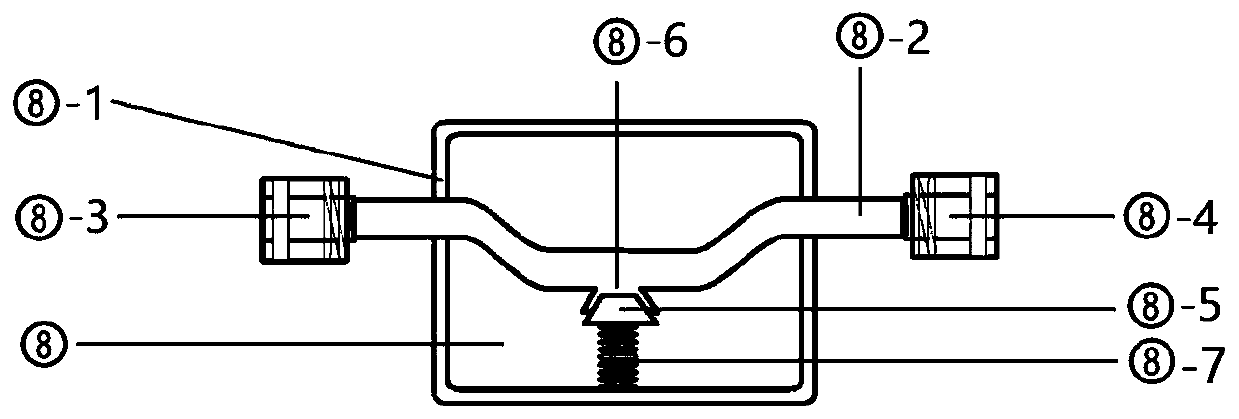

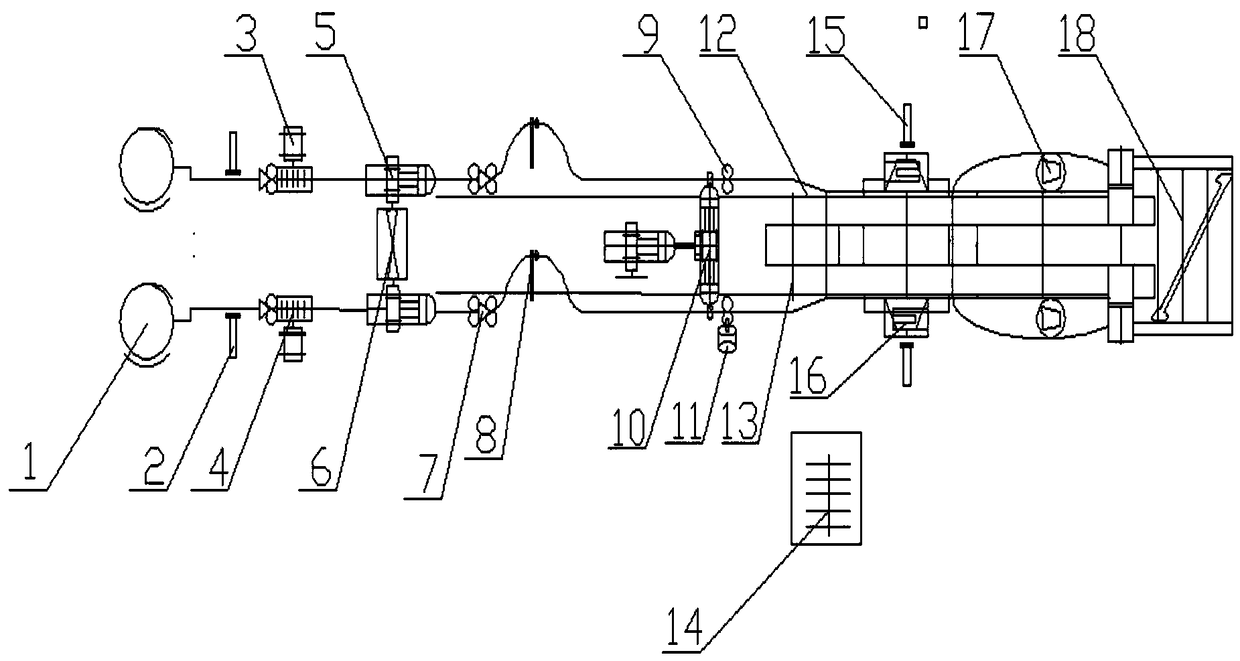

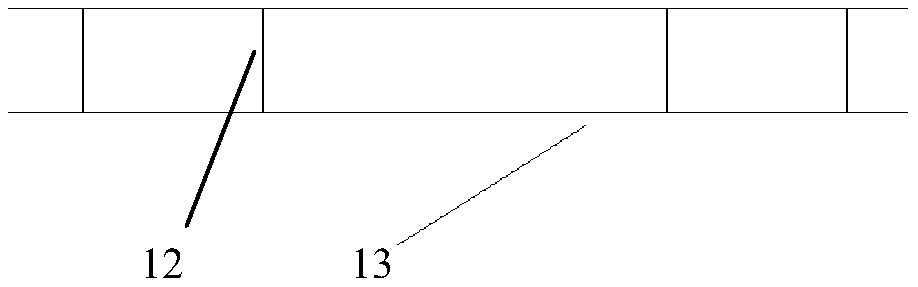

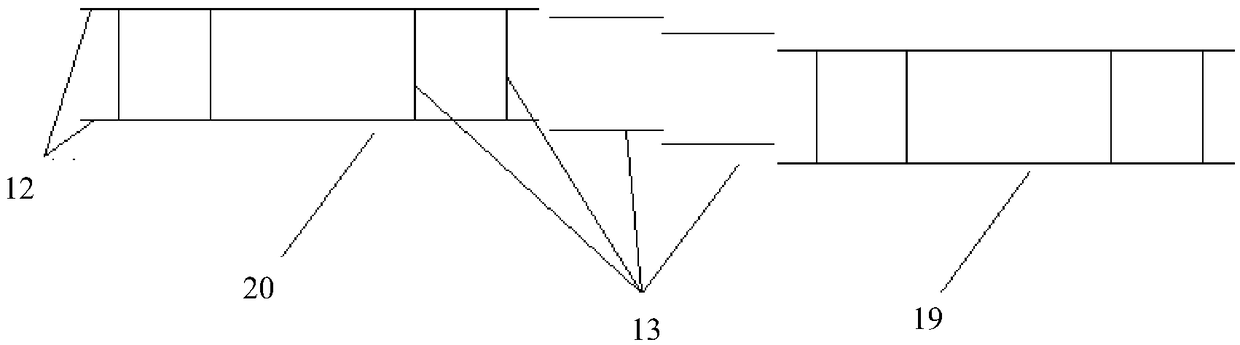

Pneumatic conveying system

The invention discloses a pneumatic conveying system. The pneumatic conveying system comprises a compressed air conveying mother tube, one or more bin pumps which are arranged in series, a discharge valve, a discharge hole gas supplementing machine, a conveying pipeline and a terminal bin, wherein the lower end of each bin pump is connected with a fluidizing device, the fluidizing device comprisesa fluidizing room, a fluidizing disc and a fluidizing room sealing head which are sequentially connected from top to bottom, and further comprises a fluidizing room discharge tube which transverselypenetrates through the fluidizing room, a fluidizing room discharge lifting tube which longitudinally communicates with the lower portion of the fluidizing room discharge tube and is positioned abovethe fluidizing disc is arranged inside the fluidizing room. According to the scheme adopted by the invention, the compressed air conveying mother tube is re-arranged, and is divided into three gas inlet branches, namely a fluidized gas inlet branch which communicates with the fluidizing room sealing head, a conveyed gas inlet branch which is connected to the first fluidizing room discharge tube which is in series connection in a gas flow conveying direction, and an auxiliary gas-blowing gas inlet branch which communicates with the discharge hole gas supplementing machine. According to the scheme adopted by the invention, the pneumatic conveying system is greatly simplified in structure, and also can realize great reduction of comprehensive gas consumption of the system.

Owner:FUJIAN LONGKING

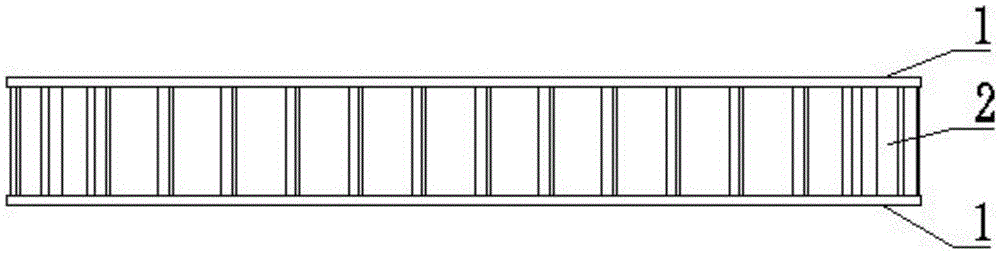

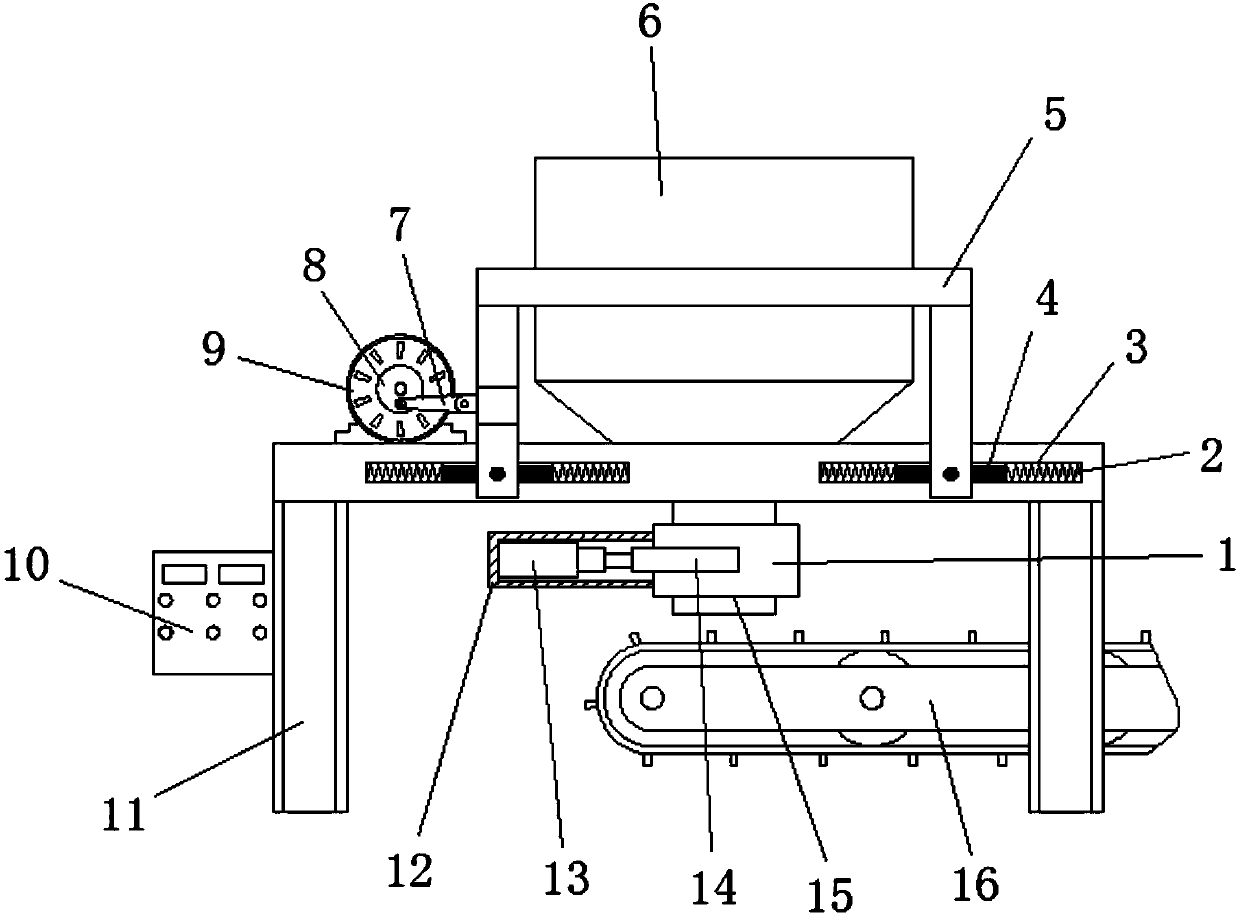

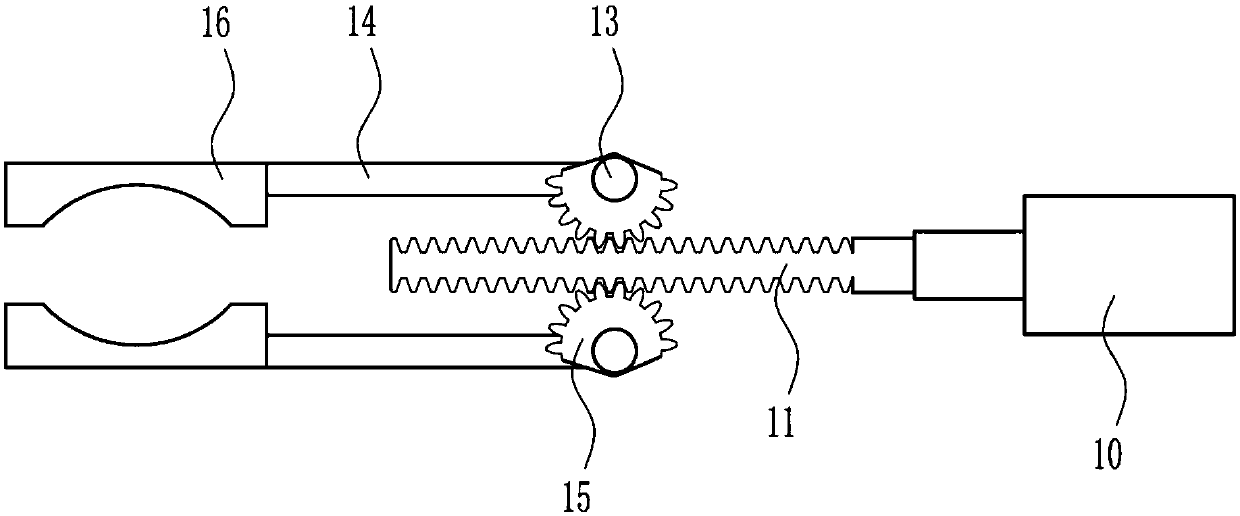

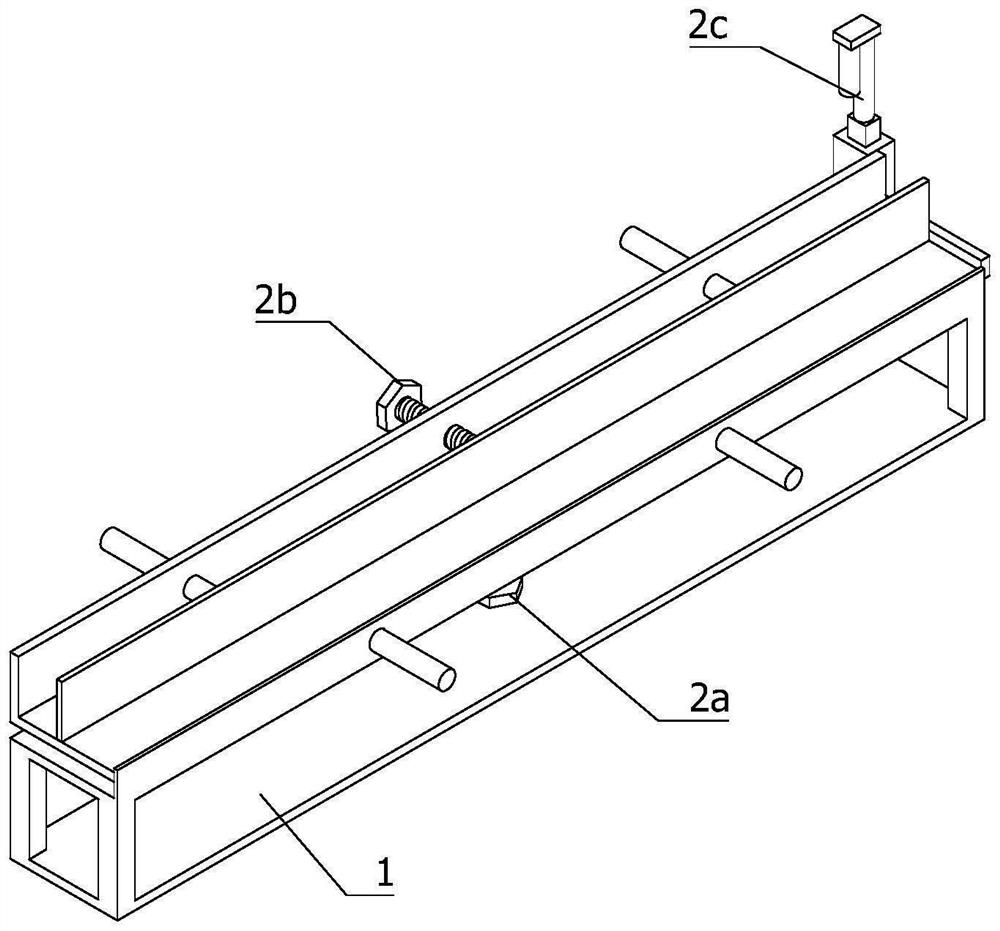

Counting type conveying control equipment

InactiveCN105540157AControl delivery speedControllable conveying speedControl devices for conveyorsPackaging automatic controlDrive wheelEngineering

The invention discloses counting type conveying control equipment which comprises baffles, a conveyor belt, a first driven wheel, a second driven wheel, an FXN-MR, a servo motor, a driving chain wheel, a chain and a driven chain wheel, wherein the baffles are installed on a working platform; a first driven wheel shaft, a second driven wheel shaft, the FXN-MR and the servo motor are fixedly installed on the baffles; the conveyor belt is composed of a base band and a transverse partition plate; the baffles are installed on the two side surfaces of the conveyor belt respectively; an interval is formed between the conveyor belt and each baffle; the first driven wheel is installed on the first driven wheel shaft and is provided with a rotary pair; and the second driven wheel is installed on the second driven wheel shaft and is provided with a rotary pair. According to the counting type conveying control equipment disclosed by the invention, with the adoption of the nylon conveyor belt with the transverse partition plate, uniform large-inclination conveying of goods can be realized; meanwhile, as the conveyor belt moves controlled by a PLC counting manner, the conveying speed of the goods can be controlled; and as being controlled by a PLC module, the whole process is smooth and reliable and is rapid in operation speed.

Owner:王嫣俐

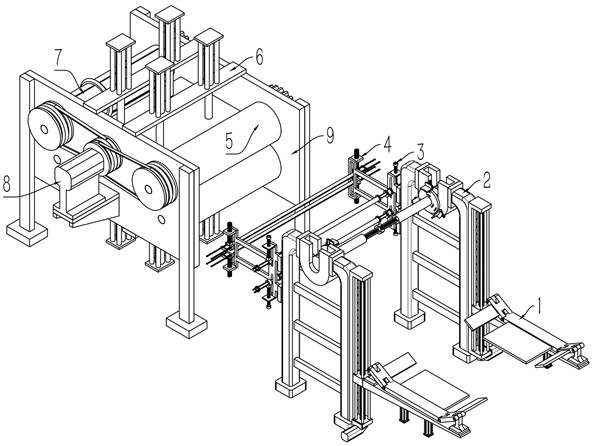

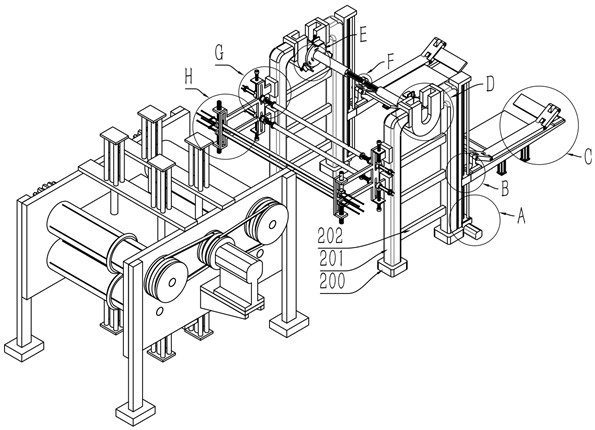

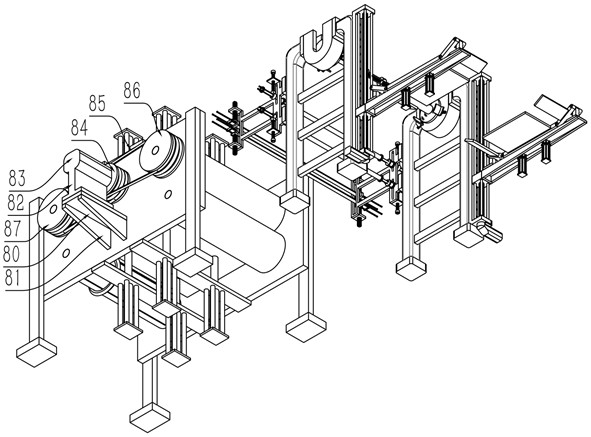

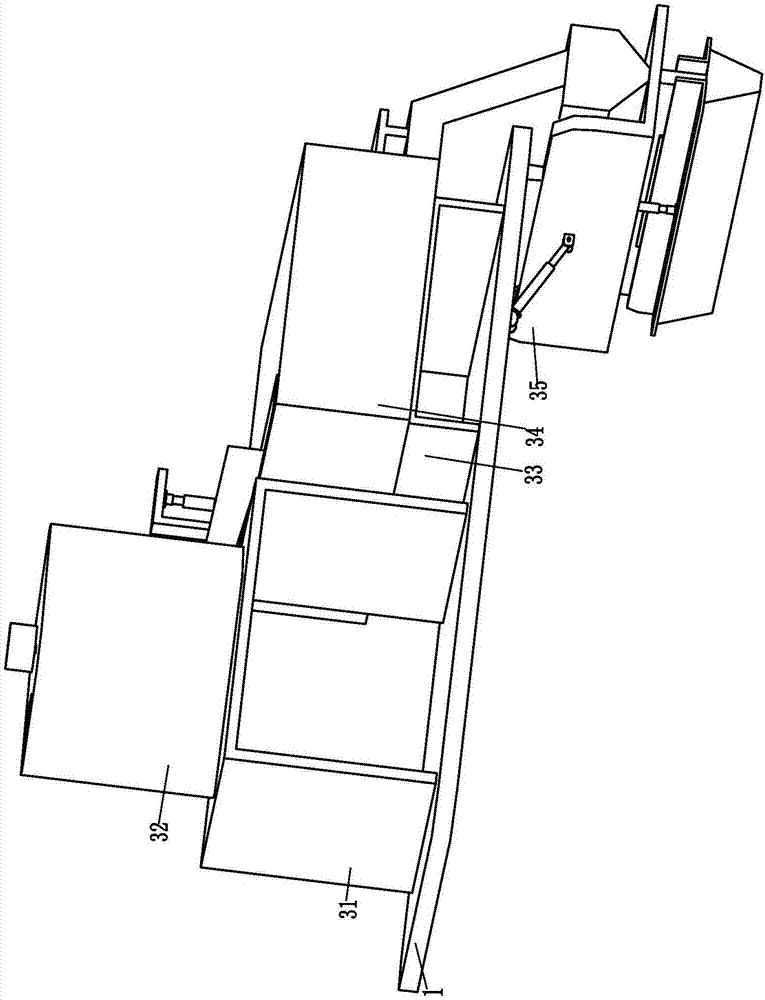

Plate flattening and cutting device for lamp post production line

ActiveCN111872702AEasy to transportImprove the flattening effectGrinding drivesShearing machinesSteel beltStructural engineering

The invention discloses a plate flattening and cutting device for a lamp post production line. The device comprises a transferring unit, a coil placing unit, a limiting unit, a surface treatment unit,a flattening unit, pressing units, a cutting unit and a driving unit; the surface treatment unit comprises a pair of fixing assemblies, two pairs of adjusting assemblies are arranged at each of the upper end and the lower end of each fixing assembly, and a treatment assembly is arranged between each pair of adjusting assemblies; the flattening unit is used for preliminarily flattening a coiled material; the pressing units are used for flattening the coiled material again; the cutting unit is used for cutting a plate; and the driving unit is used for driving the flattening unit and the cuttingunit. According to the device, steel strip coils can be conveniently transferred and conveyed, the steel strip coils can be effectively limited in the conveying process, the surfaces of the steel strip coils can be treated, and steel strips can be flattened twice, so that the flattening effect of the steel strips is improved, preset-length cutting of the steel strip coils is conveniently conducted, and the practicability is high.

Owner:SICHUAN HUATI LIGHTING TECH

Physical training runway polyurethane material plastic runway surface rubber high-efficiency construction machine

The invention relates to a high-efficiency construction machine for polyurethane material plastic runway surface glue for sports training tracks, which includes a bottom plate, a fixed frame is installed on the upper end of the bottom plate, a stirring mechanism is installed on the fixed frame, and an inverted U-shaped structure is installed on the rear end of the bottom plate. The supporting frame is equipped with a limiting mechanism, and the regulating scraping mechanism is installed on the limiting mechanism. The mixing mechanism, the limiting mechanism and the regulating scraping mechanism are used in conjunction with each other to complete the high-efficiency construction process of the surface rubber of the hybrid plastic runway. The present invention can solve the problems in the construction process of the existing hybrid plastic runway surface glue that the raw materials of the surface glue need to be manually stirred, and the coating thickness of the surface glue needs to be manually controlled. The raw material of the artificially stirred surface glue is not uniform, which is easy to cause waste. Manually control the surface glue coating The cover thickness cannot be adjusted in time according to the actual situation, the construction of the surface rubber is uneven, the operation is complicated, the labor intensity is high and the work efficiency is low, etc., and the function of high-efficiency construction of the mixed plastic runway surface rubber can be realized.

Owner:冒俊

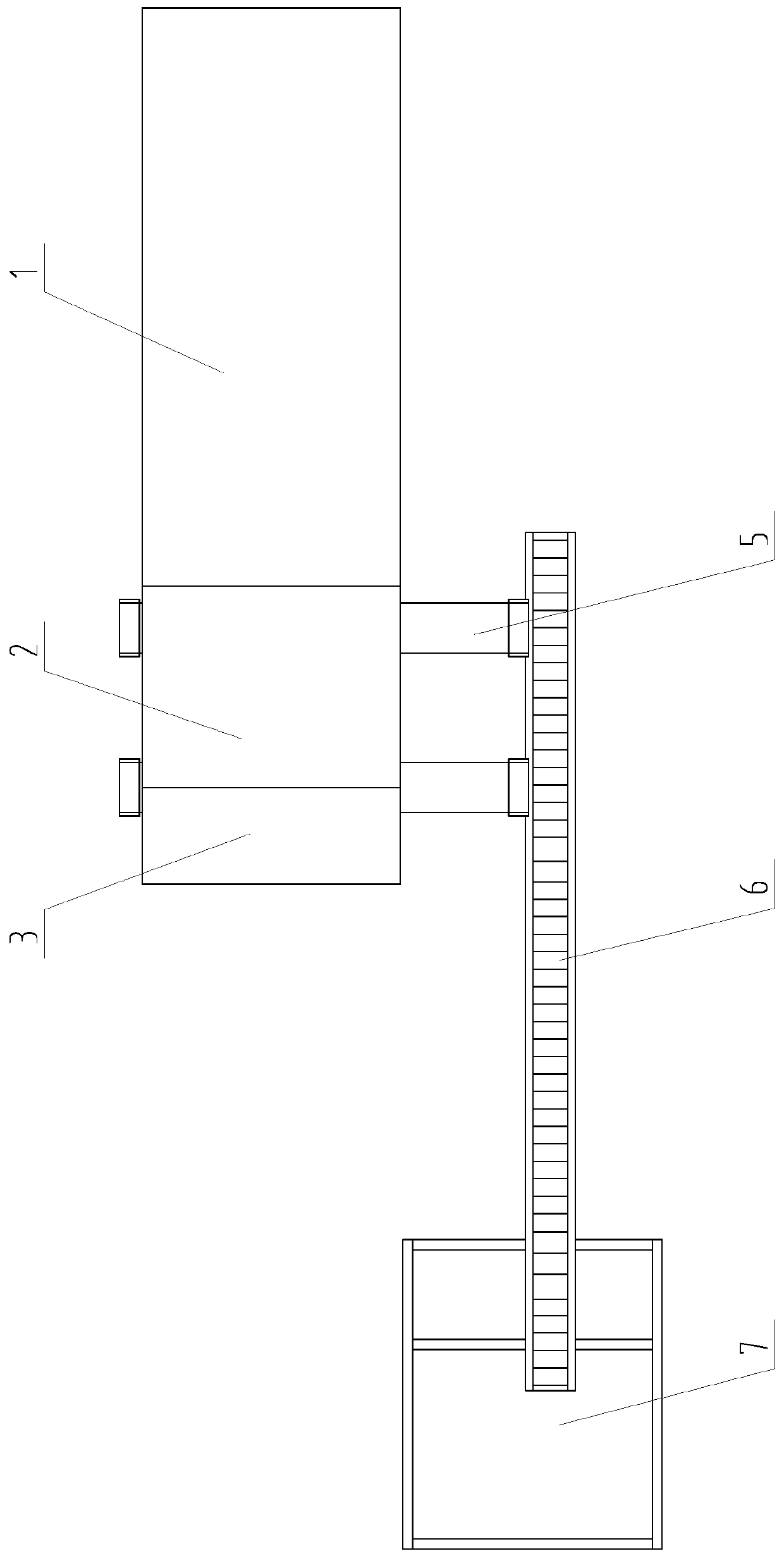

Chemicals feeding device

InactiveCN102849837AControl delivery speedSmooth feedingRotary stirring mixersMixer accessoriesDiaphragm pumpControl system

The invention discloses a chemicals feeding device which comprises a storage box and a plurality of stirring machines, wherein the storage box is internally provided with a vibration motor; one ends of the stirring machines are connected with a pneumatic diaphragm pump, the storage box is connected with the stirring machines through a control valve, and the control valve comprises a star-type cinder valve, a manually-operated flap valve and a splitting valve; and the manually-operated flap valve is connected with the storage box, the splitting valve is connected with the stirring machines, and the star-type cinder valve is arranged between the manually-operated flap valve and the splitting valve. The chemicals feeding device provided by the invention can be used for automatically or manually controlling the cast of materials through a control system, the operation is convenient, the automaticity is high, and the efficiency of sewage treatment is greatly improved; and meanwhile, the control valve is arranged between the storage box and the control valve, the baiting of the material is smooth, the releasing speed of the material is effectively controlled, the pipeline and the valve have less possibility of being blocked, and the device is convenient to use.

Owner:徐臻毅

Novel feeding device

Owner:天津金泰盛世石化设备有限公司

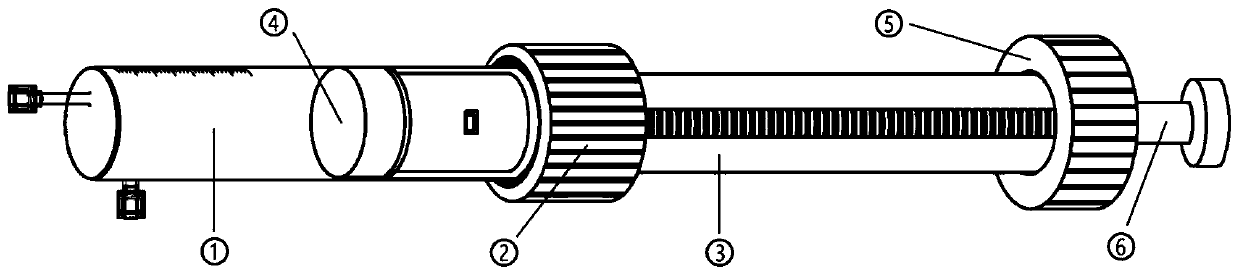

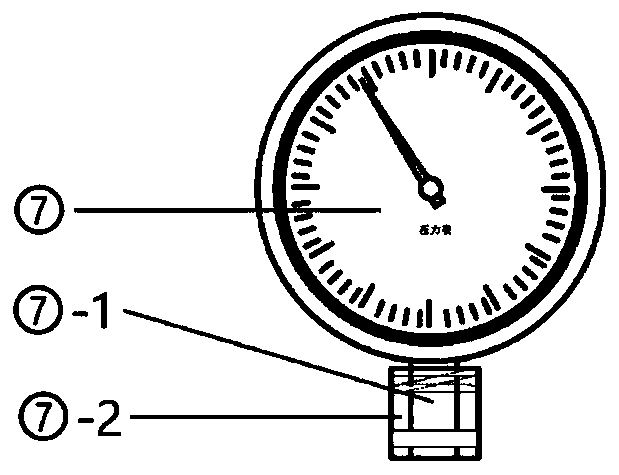

Trigeminal nerve micro-balloon accurate contrast medium propeller

ActiveCN109793979AReal-time dynamic monitoring of pressureAccurate calculationSurgeryDilatorsDiseasePropeller

The invention provides a trigeminal nerve micro-balloon accurate contrast medium propeller. Scales are arranged on the outer wall of an outer cylinder, and a nozzle and a pressure gauge interface arearranged at the front end of a cylinder body; the inner core of the propeller is a hollow cylinder body, the side wall is axially provided with a hole, after one end of the inner core of the propelleris provided with a rubber plug, the inner core of the propeller is placed in the outer cylinder, and the inner core and the outer cylinder together form a piston; a propulsion speed control rod is arranged in the inner core of the propeller, one side of the propulsion speed control rod is provided with inclined teeth facing the rubber plug, and the other side of the propulsion speed control rod is provided with threads; the inner side wall of the inner core of the propeller is provided with a groove inclined towards the rubber plug and forms an inclined sliding surface together with the inclined teeth; and when the inclined teeth slide in the grooves, the threads extend out of or retract into the hole in the side wall of the inner core of the propeller, and when the threads extend out ofthe holes, the threads are in threaded fit with the inner wall of the outer cylinder. The trigeminal nerve micro-balloon accurate contrast medium propeller can accurately and dynamically monitor the volume and pressure of a contrast medium in a balloon in a disease treatment process.

Owner:任鹏宇

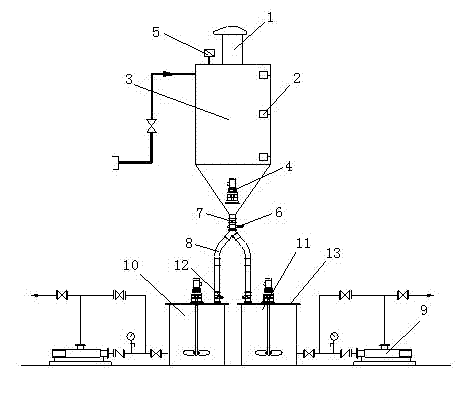

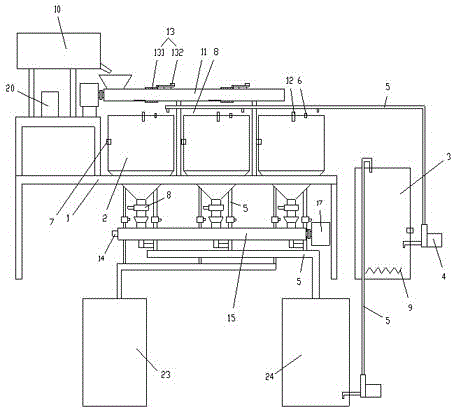

Soybean soaking system with automatic loading device and water-soybean separation conveying system

InactiveCN105594879ALow impurity contentQuality improvementCheese manufacturePackagingWater dischargeLevel sensor

The invention discloses a soybean soaking system with an automatic loading device and a water-soybean separation conveying system. The soybean soaking system includes a washing and loading device, a soybean soaking device and a discharging and conveying device; the soybean soaking device includes a rack, a soybean soaking bin and a circulating water device; the washing and loading device includes a drum type washing machine, a loading spiral feeder and a material level sensor; a discharging spiral feeder includes a filter tube, a supporting tube, a spiral feeding shaft and a motor. Soybeans are washed by the drum type washing machine, then the soybeans after washing are sent into the soybean soaking bin through the loading spiral feeder, washing and loading of the soybeans are automatically completed, and the working efficiency of washing and loading is high; moreover, water addition and water discharge for the soybean soaking bin are achieved by the circulating water device, water addition and water discharge are automatically completed, the work efficiency of soybean soaking is high, and the labor intensity is low; and at the same time, the discharging spiral feeder integrates the functions of soybean transportation and water and soybean separation, and the soybean conveying device is simplified.

Owner:CHONGQING YUPAI AGRI PROD DEV

A device and method for reducing laser hardened soft band

ActiveCN108048626BImprove light absorption propertiesReduce the width of the soft beltLaser quenchingEngineering

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

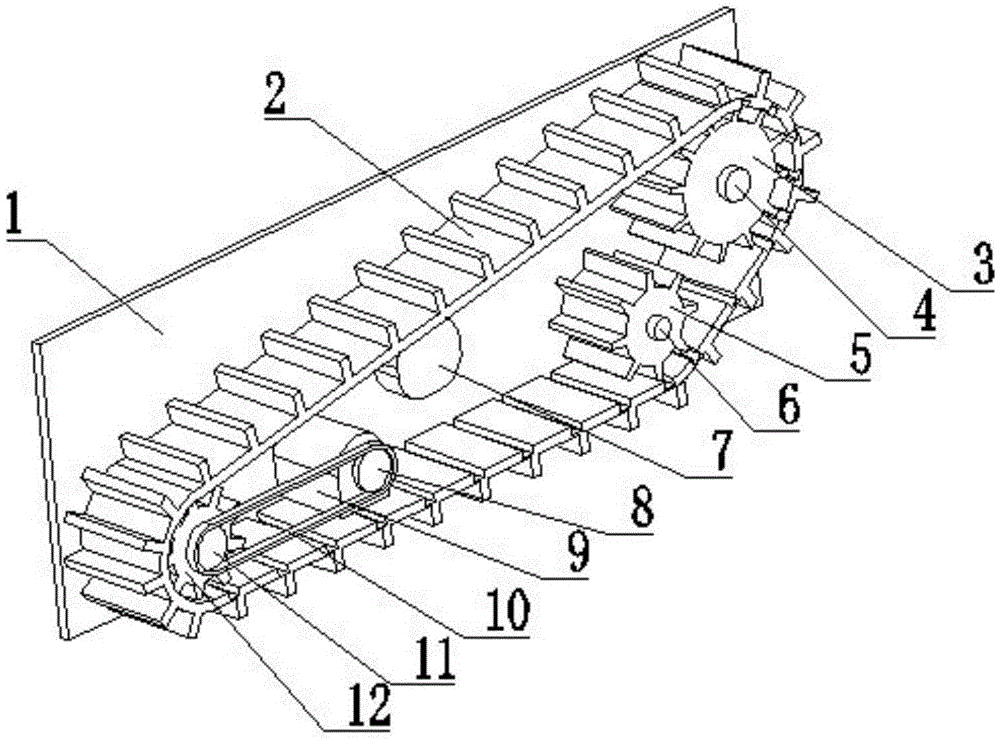

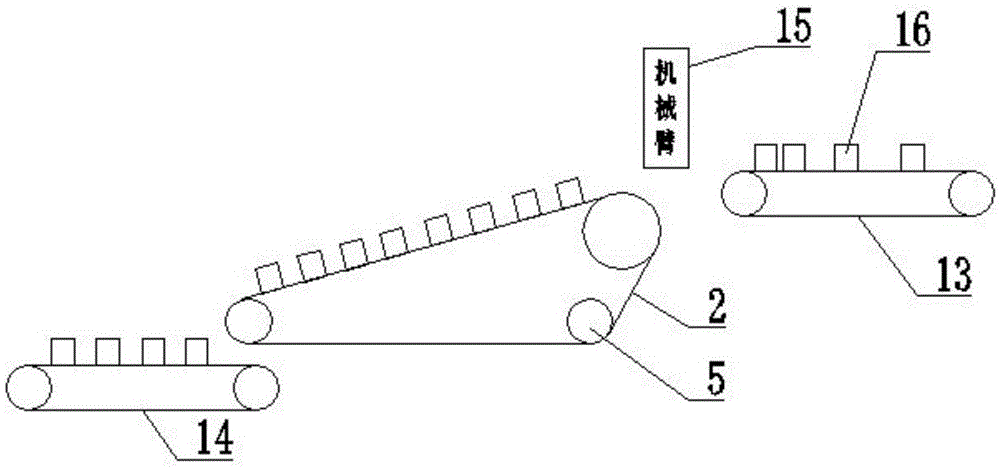

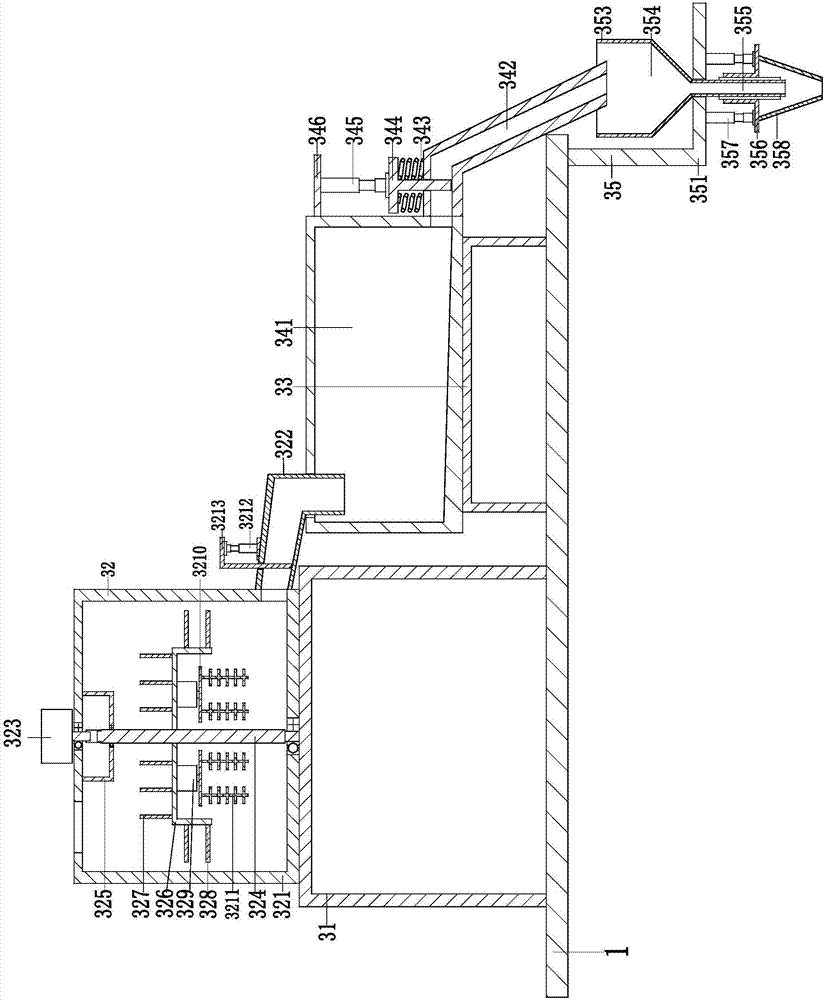

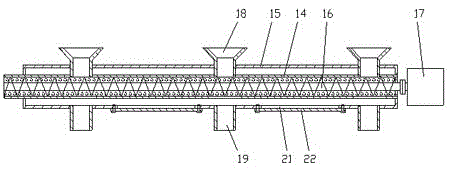

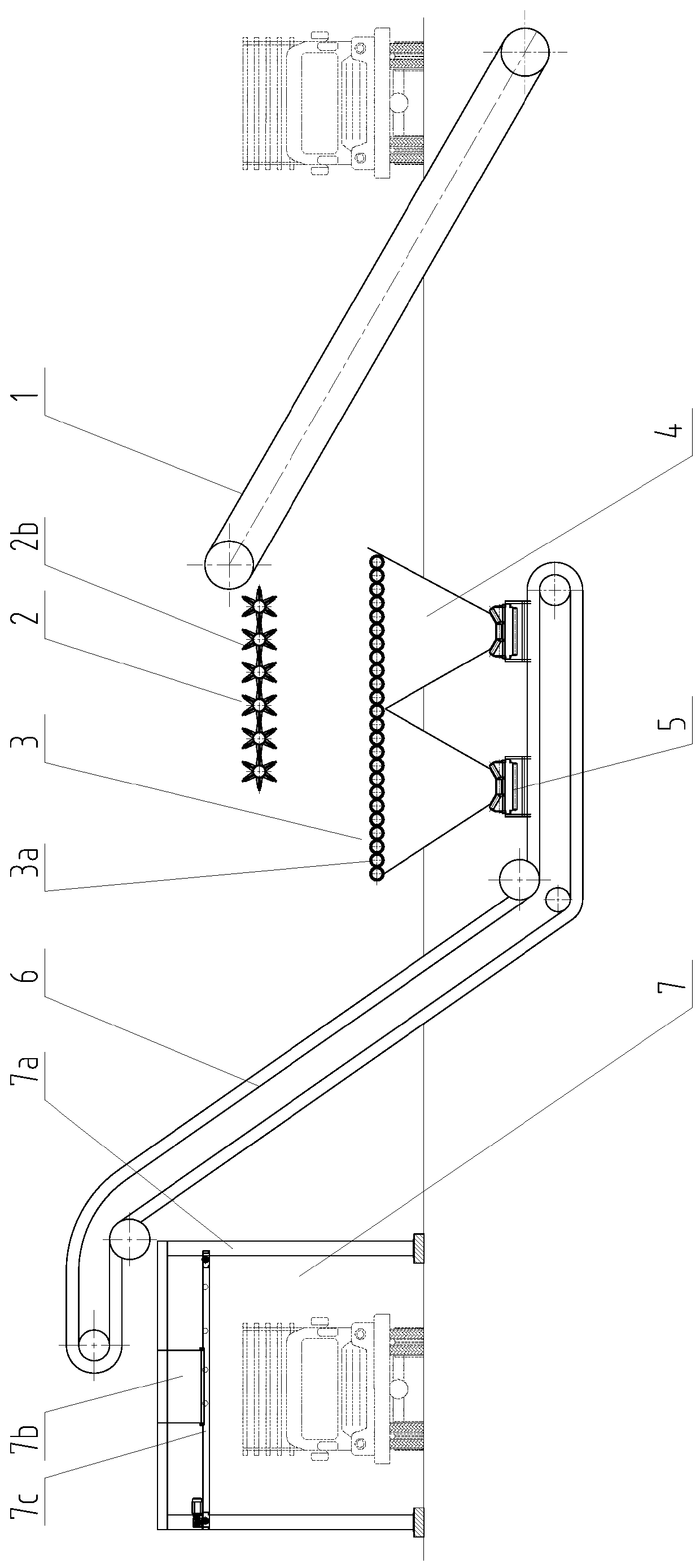

Impurity removing system for raw material sugarcane pretreatment

PendingCN110694886AEasy to install and maintainControl delivery speedSievingScreeningProcess engineeringManufacturing engineering

The invention provides an impurity removing system for raw material sugarcane pretreatment. An unloading chain plate conveyor, a multi-stage throwing conveyor, a tooth-roller-type impurity removing conveyor, an impurity collecting bucket, a groove-shaped belt conveyor, a large-angle of inclination corrugated belt-type conveyor, and an impurity loading platform are used for building the impurity removing system for raw material sugarcane pretreatment. The impurity removing system is reasonable in process design, the equipment is properly selected, and structures of key equipment of two systemsof the multi-stage throwing conveyor and the tooth-roller-type impurity removing conveyor are optimized, so compared with an existing raw material sugarcane impurity removing system, the equipment ofthe impurity removing system is simpler to install and maintain, the overall impurity removing effect is better, the material conveying speed in the process of removing impurities is controlled, and realizing of feeding to a subsequent stage uniformly is facilitated.

Owner:南宁科泰机械设备有限公司

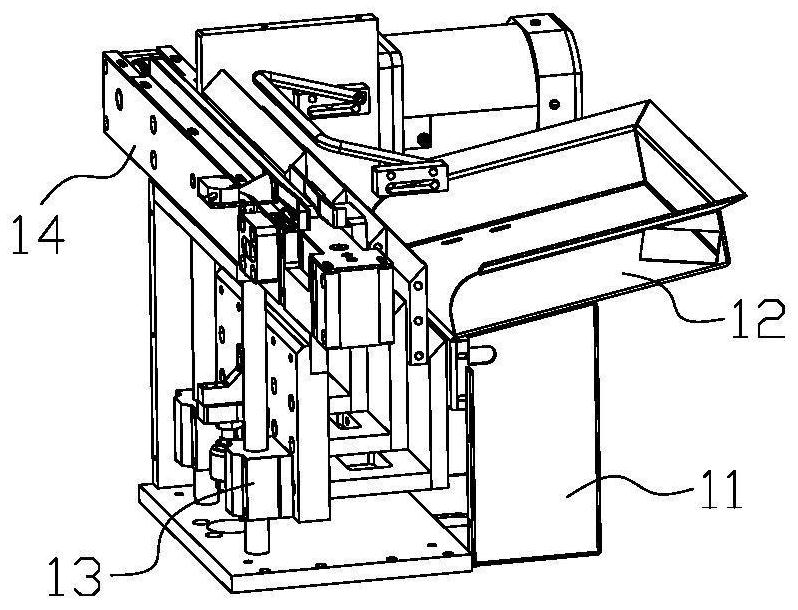

Loading device and loading method for lipstick box covers

InactiveCN111762542AGuaranteed tidy loadingAccurate understanding of the quantityConveyorsControl devices for conveyorsStructural engineeringWorkbench

The invention relates to the field of lipstick production. A loading device for lipstick box covers comprises a box cover loading rack as well as a box cover loading box, a stepped box cover loading mechanism and a box cover conveying mechanism which are fixed to the box cover loading rack, wherein the box cover loading rack is fixed to a workbench; the box cover loading box is placed slantwise, and the low side of the box cover loading box is connected with a charge port of the stepped box cover loading mechanism; a discharge port of the stepped box cover loading mechanism is connected with one end of the box cover conveying mechanism; and the other end of the box cover conveying mechanism is connected with a charge port of a box cover falling device. According to the device, the lipstickbox covers are orderly loaded by arranging the stepped box cover loading mechanism and a stepped loading shifting assembly.

Owner:王加两

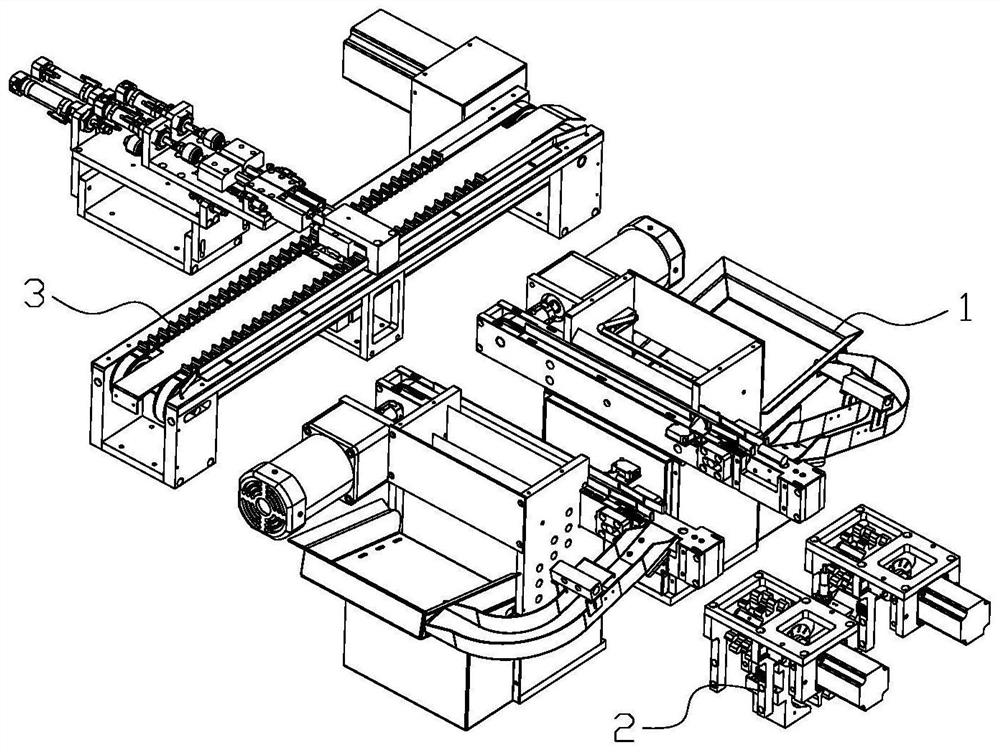

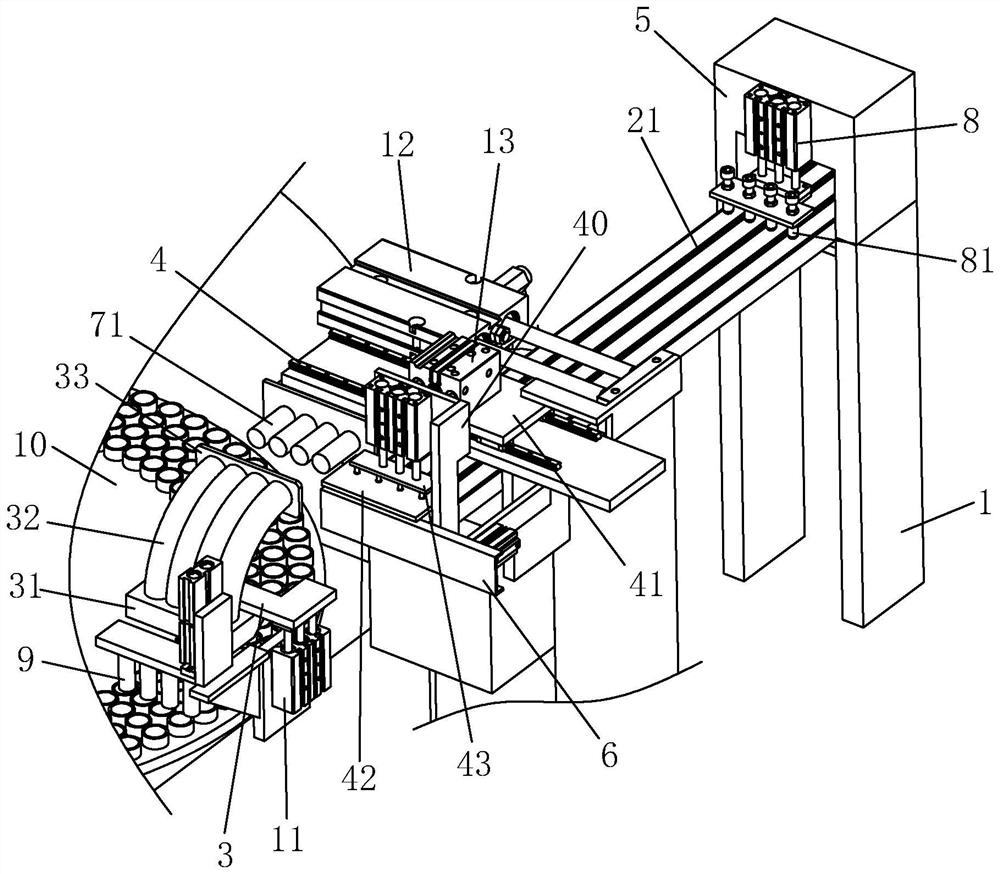

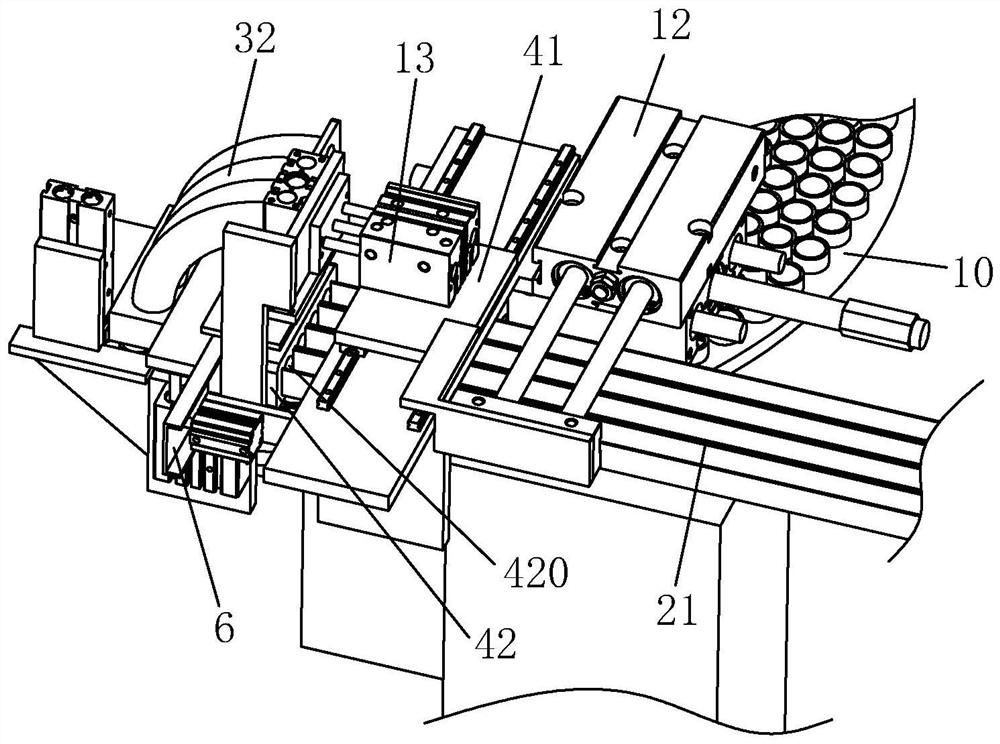

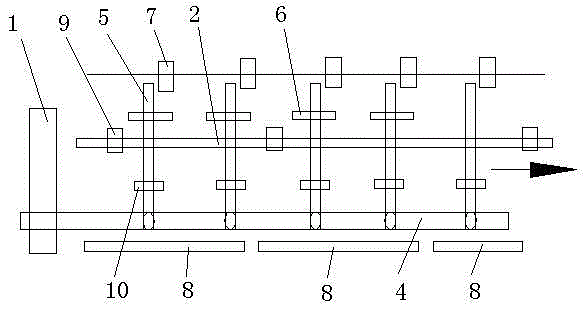

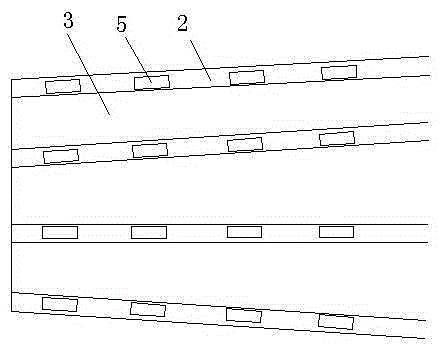

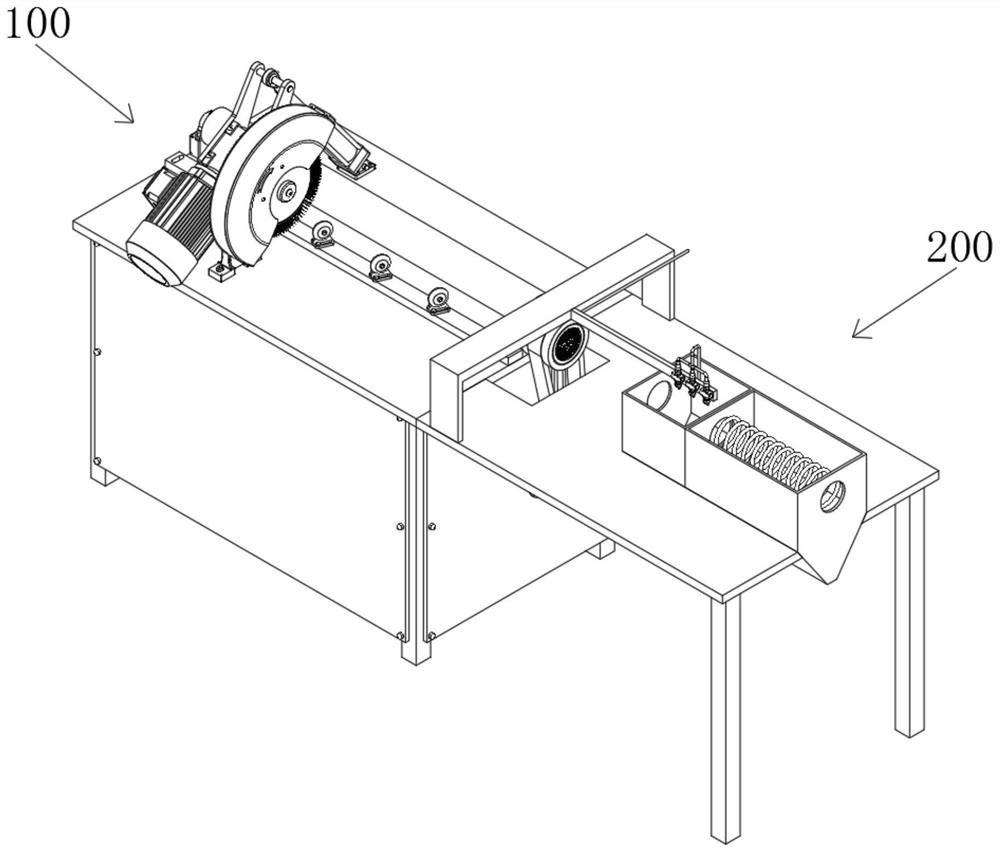

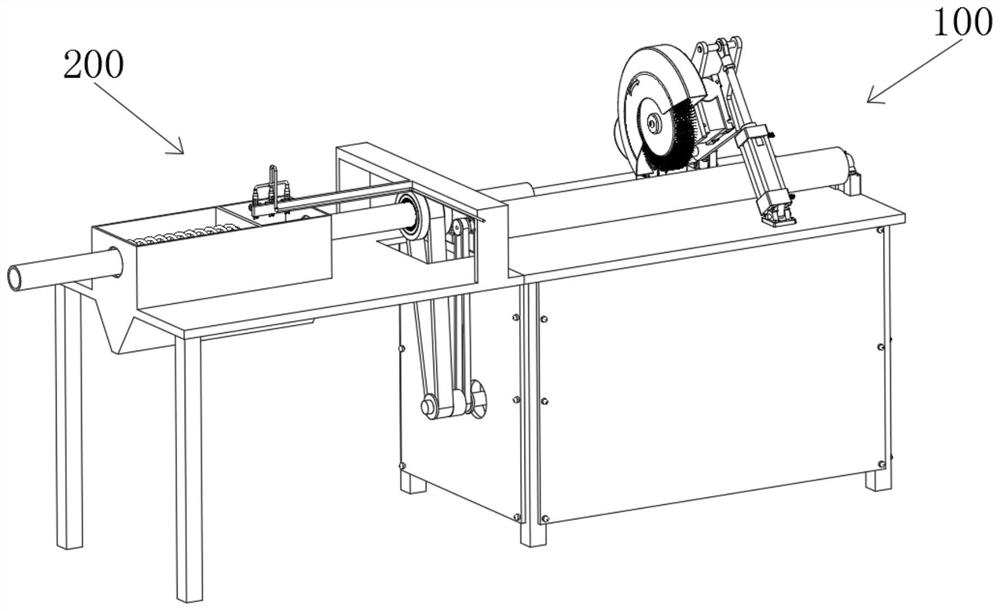

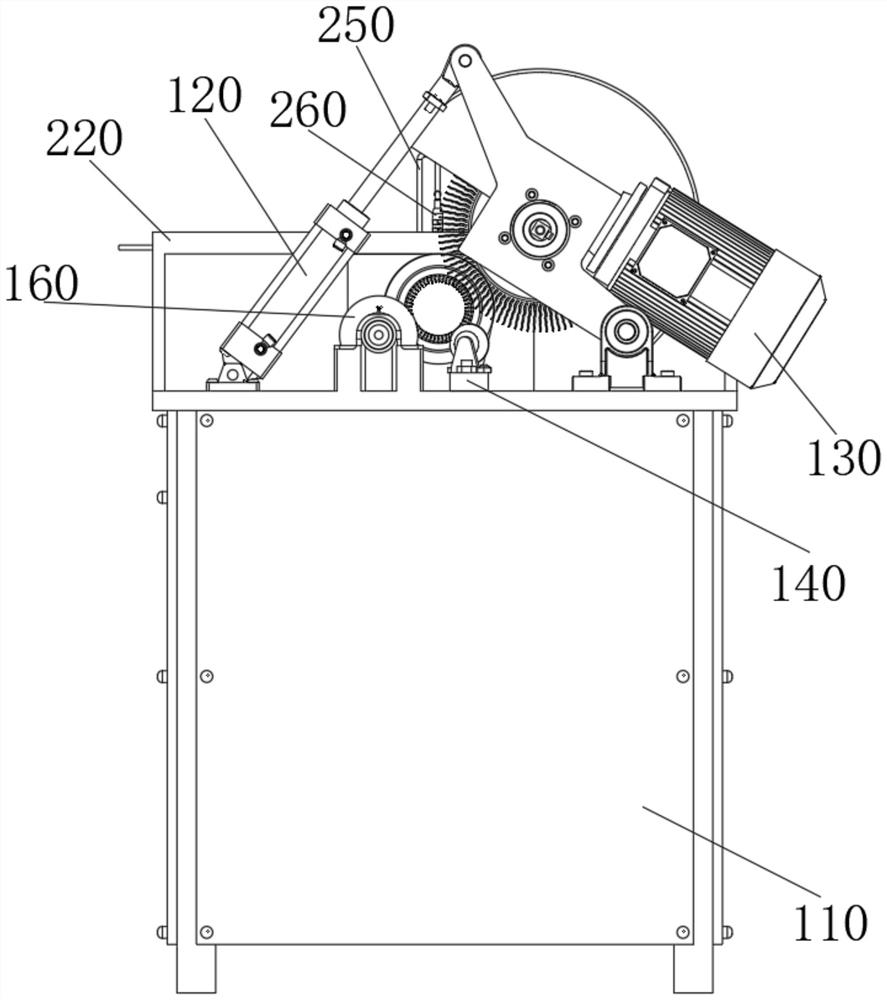

Mechanical automatic feeding device of spring grinding machine

PendingCN114700822AImprove work efficiencyImprove stabilityGrinding carriagesGrinding drivesGrindingTransfer mechanism

The invention discloses a mechanical automatic feeding device of a spring grinding machine. The mechanical automatic feeding device comprises a workbench installed on a rack; the feeding device is installed on the workbench, and the discharging end of the feeding device conveys springs to a preset position through a plurality of conveying channels arranged side by side. The transferring mechanism is mounted on the rack and is used for transferring the springs conveyed by the conveying channel to a preset position; and the material guiding mechanism is mounted on the rack and is used for receiving the springs conveyed by the transferring mechanism so as to convey the springs into the material placing holes of the material disc. When the spring feeding device is used, manual work can be replaced to achieve automatic spring feeding, so that the labor intensity of workers can be effectively reduced, and the working efficiency is improved.

Owner:湖北之江智能科技有限公司

Mine radial automatic flow dividing device and control method thereof

The invention relates to a mine radial automatic flow dividing device and a control method thereof, and relates to the field of mine equipment. The mine radial automatic flow dividing device comprises a power control device and multiple sets of conveying strips. A conveying gap is formed between the conveying strips in each group. The two conveying strips are arranged in each group. A structure similar to a guide rail is formed between every two conveying strips so that a corresponding push rack can advance to push minerals to run along the conveying strips. Each push rack is provided with branch strips, a stop block is arranged above each push rack, and the overturning and vibrating effects are formed for the minerals in the running process. Conveying belts are arranged below the push racks, and after the minerals different in size are sorted through the conveying gaps, the minerals are conveyed to the subsequent workshop section through the conveying belts. By the adoption of the device and the method, the minerals can be rapidly transported, the minerals are subjected to timely sorting treatment in the transporting process, the transporting process is in linkage with the subsequent workshop section, the transporting links are reduced, and the energy of the whole workshop section is saved.

Owner:郑小蓉

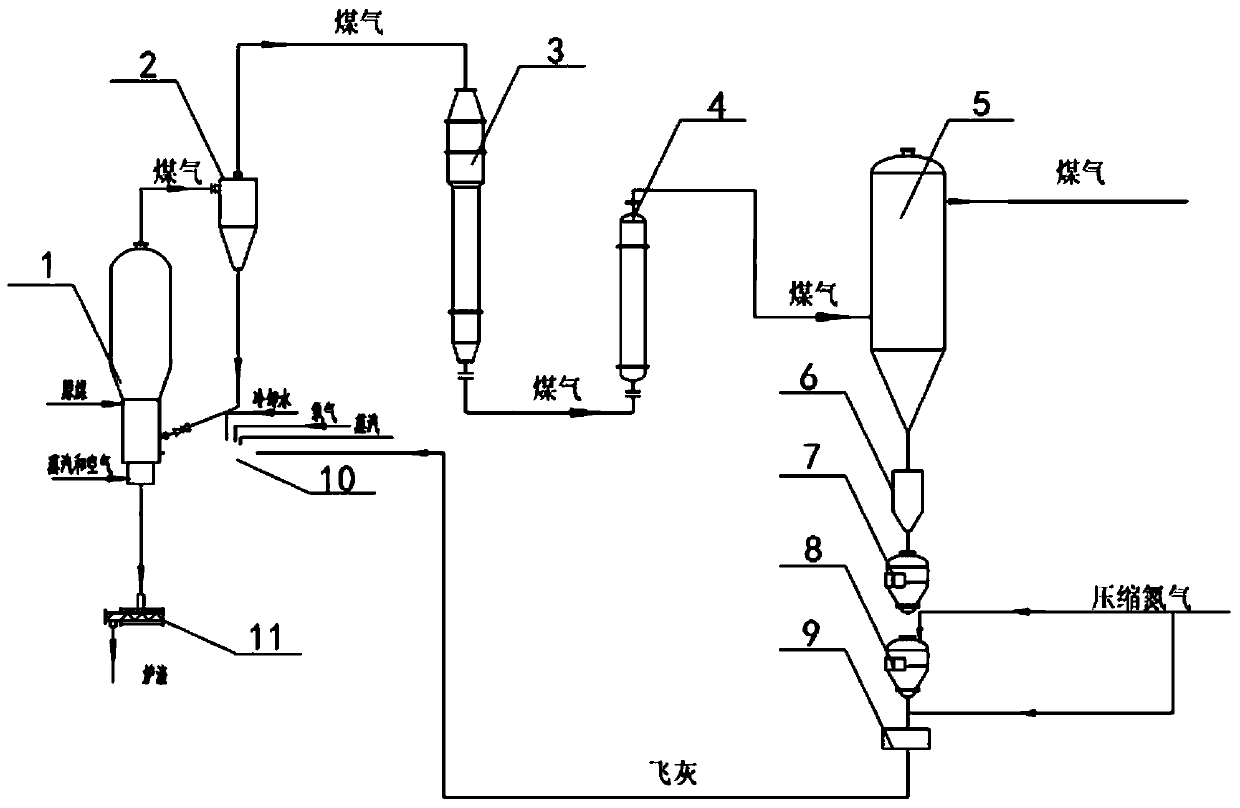

Coal gasification system and gasification process

PendingCN109777521AImprove cleanlinessImprove carbon conversionGranular/pulverulent flues gasificationProcess engineeringFly ash

The invention discloses a coal gasification system and a gasification process, and belongs to the field of gas manufacturing. The system comprises a gasifier, a dust removal device and a fly ash burner. The air inlet end of the dust removal device is connected with an air outlet of the gasifier. The fly ash burner includes a gasifier channel, a steam channel and a pulverized coal channel. The inlet end of the gasifier channel is connected with a gas source, and the inlet end of the steam channel is connected with a steam device. The inlet end of the pulverized coal channel is connected with adischarge outlet of the dust removal device; the outlet ends of the gasifier channel, the steam channel and the pulverized coal channel are connected with a premixing zone of the fly ash burner, and the premixing zone is connected with a return inlet of the gasifier. The coal gasification system is used for gas production, fly ash in a coal gasification reaction can be collected and fully mixed with a reaction medium before returning to the gasifier, the reaction efficiency of the fly ash after returning to the gasifier is greatly improved and coking is avoided.

Owner:KEDA MAS CLEAN ENERGY

Fodder particle dispensing equipment for livestock raising

InactiveCN107667895AAvoid wastingPrecise deliveryAnimal feeding devicesAvicultureBaseboardLivestock breeding

The invention relates to fodder dispensing equipment, in particular to the fodder particle dispensing equipment for livestock raising. The technical purpose to be achieved is to provide the fodder particle dispensing equipment for livestock raising, by means of the equipment, in a dispensing process, fodder is not wasted and is precisely dispensed, and the fodder dispensing speed can be adjusted.In order to achieve the technical purpose, the invention provides the fodder particle dispensing equipment for livestock raising which comprises a baseboard and first supporting frames; the first supporting frames are symmetrically arranged on the left and right sides of the baseboard, a fodder storage box is arranged between the upper portions of the first supporting frames on the left and rightsides, an auxiliary discharging mechanism is arranged on the top of the rear wall of the fodder storage box, a discharging pipe is arranged on the left side of the bottom of the fodder storage box, and a valve is arranged on the upper portion of the discharging pipe. By means of the fodder particle dispensing equipment for livestock raising, the effects are achieved that in the dispensing process,the fodder is not wasted and is precisely dispensed, and the fodder dispensing speed can be adjusted; by controlling movement of a rack in the leftward direction and the rightward direction, the dispensing speed of fodder particles is controlled, so that it is convenient for a feeder to dispense the fodder particles more precisely.

Owner:刘飞

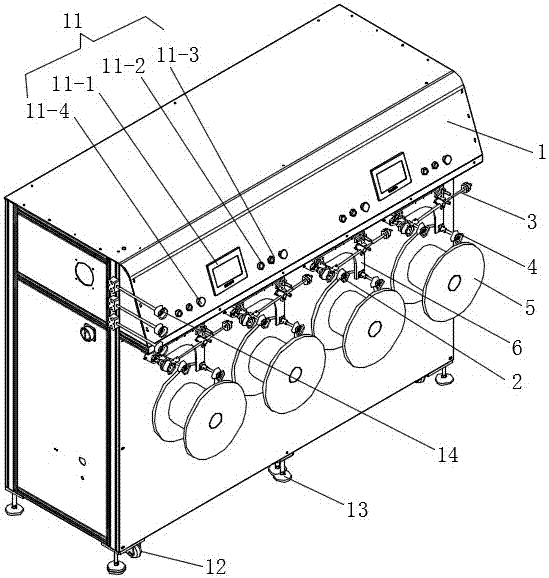

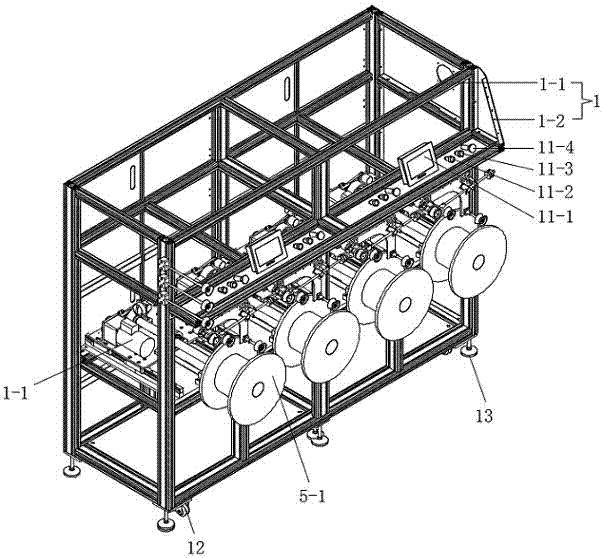

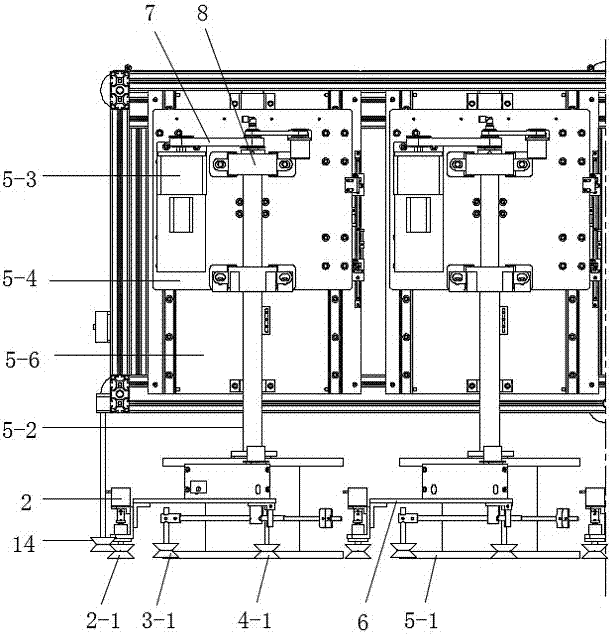

Automatic film yarn winding machine

PendingCN107298347AControl delivery speedControl thicknessFilament handlingAutomatic controlWinding machine

The invention discloses an automatic film yarn winding machine which comprises a body. At least two rolling stations are arranged on the body, each rolling station is provided with a speed measuring mechanism, a tension control mechanism, a positioning mechanism, a rolling and arranging mechanism and an automatic control system, each speed measuring mechanism, each tension control mechanism and each positioning mechanism are arranged on the front surface of the body, each automatic control system is arranged in the body, a part of each rolling and arranging mechanism is arranged outside the body, and another part of each rolling and arranging mechanism is arranged inside the body. The automatic film yarn winding machine has the advantages that actual film yarn winding speeds can be measured by speed measuring wheels, and accordingly the film yarn transmission speeds and the thicknesses of film yarns can be controlled; the magnitude of tension can be measured by the tension control mechanisms when the film yarns are rolled, accordingly, the actual rolling speeds can be controlled, and the film yarns have uniform thicknesses; shafts of the rolling and arranging mechanisms can rotate and can carry out reciprocating movement in the front-back directions, and accordingly the film yarns can be assuredly rolled and wound layer upon layer; the automatic film yarn winding machine is high in automation degree, good in quality and low in labor cost, and the like.

Owner:ZHEJIANG AET INTELLIGENT TECH

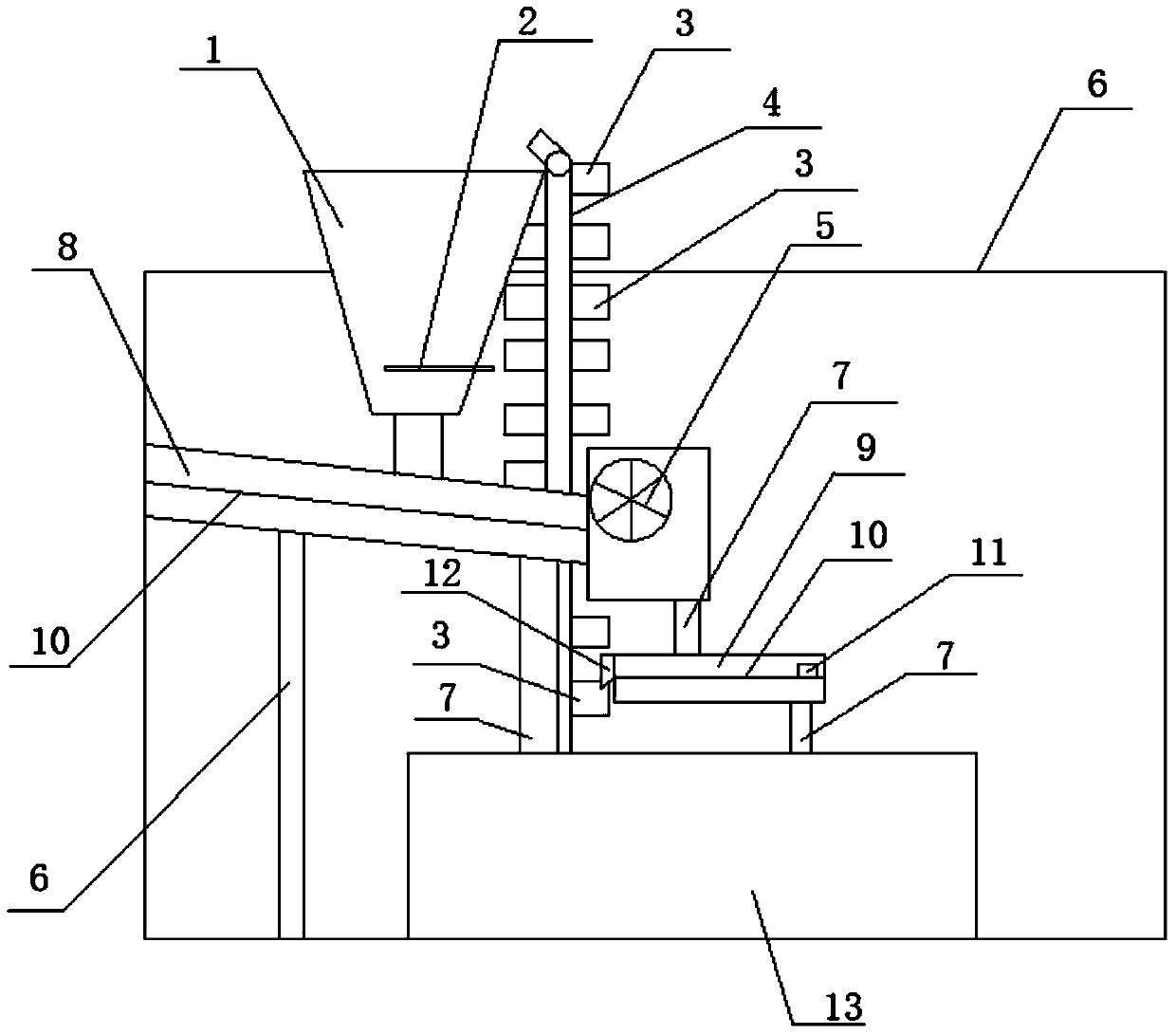

Welding system for generating steel bars and steel belts

ActiveCN109014634ASolve technical problems that pose a greater hazard to healthControl delivery speedWelding/cutting auxillary devicesAuxillary welding devicesRebarElectricity

The invention provides a welding system for generating steel bars and steel belts. The welding system comprises a roll material straightening system, a roll material butt welding device, a wheel conveying device, a stored material temporary storage and feedback system, a stay wire type sensor, a synchronous long material feeding device, a short joint feeding device, a resistance pressure-welding welding system and a control system. The roll material straightening system and the roll material butt welding device are connected. The roll material butt welding device and the stored material temporary storage and feedback system are connected through the wheel conveying device. The stay wire type sensor is arranged in the stored material temporary storage and feedback system. The stored material temporary storage and feedback system, the synchronous long material feeding device and the resistance pressure-welding welding system are sequentially arranged, and the short joint feeding device is located below the front of the resistance pressure-welding welding system. The welding system solves the technical problems that in the prior art, completion is achieved through a manual feeding andmanual mechanical shearing control manner, consequently, time and power are consumed, efficiency is low, the labor intensity of workers is large, and the welding quality is not stable and the technical problem that large harm is caused to the health of the workers.

Owner:CHINA SHENHUA ENERGY CO LTD +1

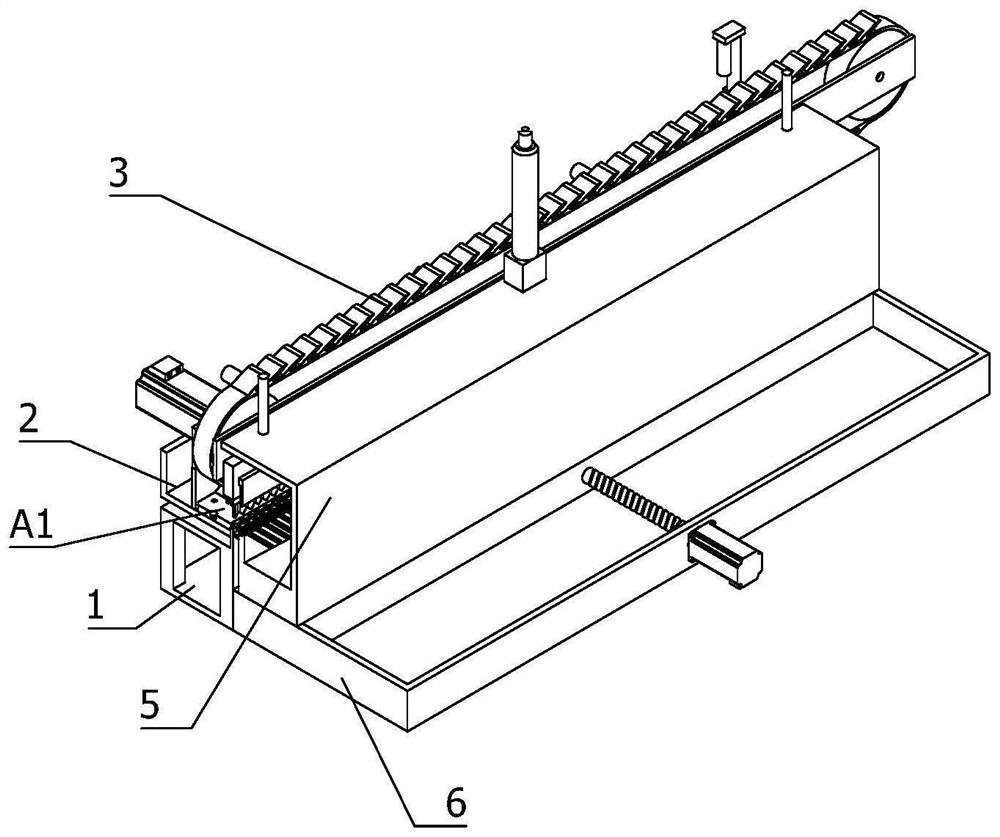

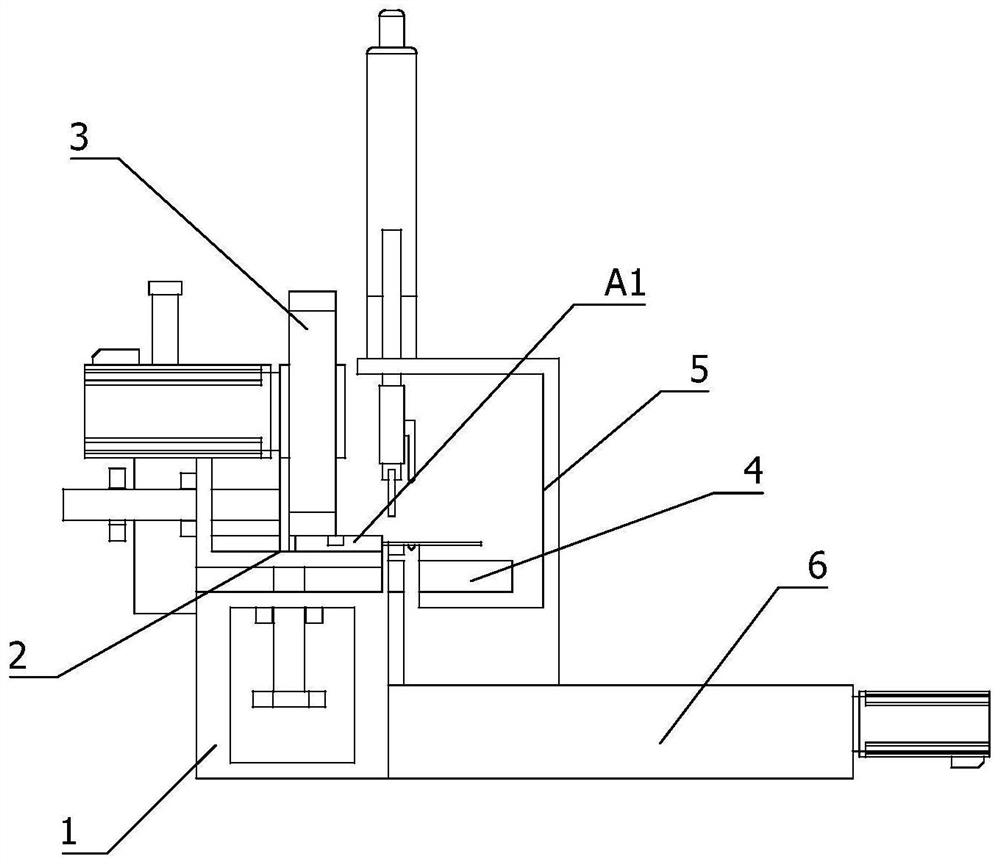

Building steel pipe rust removal protection device

InactiveCN112191425AControl delivery speedControl sanding operationsGrinding carriagesGrinding drivesArchitectural engineeringPipe

The invention relates to the technical field of building equipment, in particular to a building steel pipe rust removal protection device. The device comprises a rust removal mechanism, wherein the rust removal mechanism comprises an operation box body, a grinding machine is rotationally connected to the position, close to one long edge, of the top surface of the operation box body, and rust on the surface of a building steel pipe is removed through the grinding machine. According to the building steel pipe rust removal protection device, the rust on the surface of the building steel pipe is removed through the grinding machine, the building steel pipe is straightened and conveyed through a guide body and a control steering body, further impurity removal is conducted through a steel wire brush of an inner sleeve of a protection mechanism, paint spraying protection on the building steel pipe is achieved through paint spraying and drying, the whole protection work is conducted synchronously, therefore, the steel pipe protection efficiency is improved, the guide body composed of a bottom block capable of moving and a wheel frame capable of adjusting a position and rotating is arranged, so that a conveying speed of the building steel pipe is controlled, steel pipes of different specifications are ground, the structure is simple, and practicability is high.

Owner:黎友初

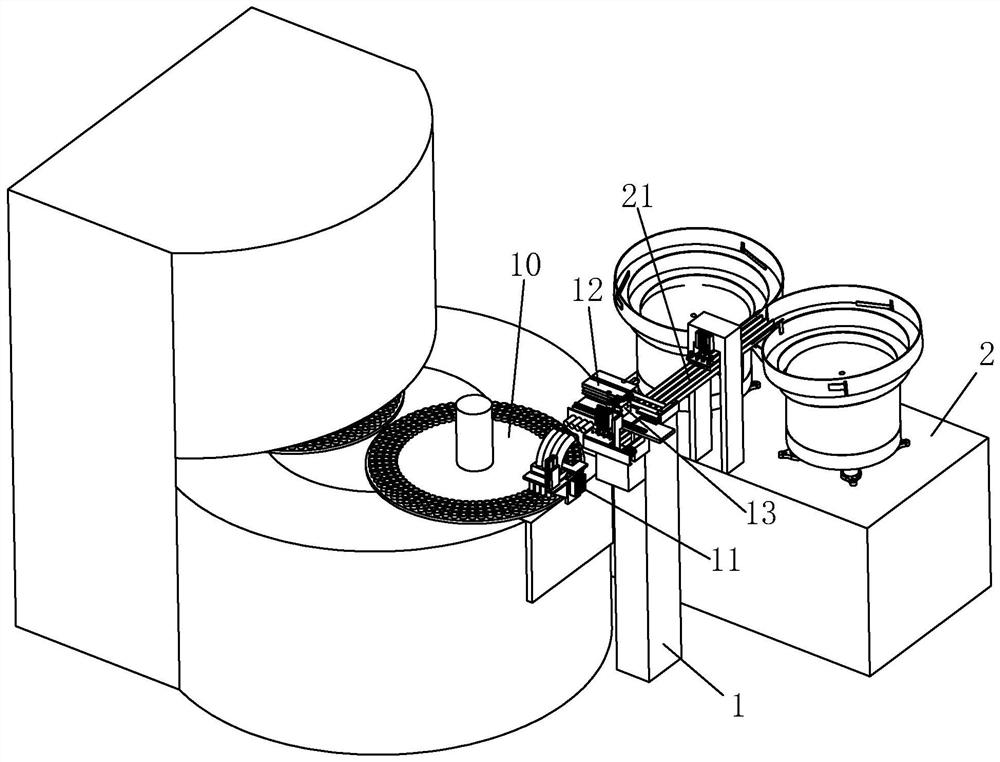

A pin-cutting device for high-power field effect transistors

ActiveCN114029424BSave human effortIncrease productivitySemiconductor/solid-state device manufacturingBall screwEngineering

The invention relates to the technical field of field effect transistor production, in particular to a pin cutting device for high-power field effect transistors, comprising a bracket, a transistor limiting arrangement device, a conveying device, a guide column, a pin carding and cutting device and a ball screw The sliding table; the transistor limit arrangement device is fixedly installed on the bracket; the conveying device is fixedly installed on the transistor limit arrangement device; the ball screw sliding table is arranged beside the bracket; The cutting device is fixedly connected with the working end of the ball screw slide table; the guide column is provided with several symmetrically arranged on the side of the bracket, one end of the guide column is fixedly connected with the bracket, and the end of the guide column away from the bracket slides and extends through the pin combing and cutting device. The present application can effectively save manpower and at the same time improve production efficiency.

Owner:先之科半导体科技(东莞)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com