Winding type laser marking machine

A laser marking machine, laser machine technology, applied in typewriters, printing devices, printing, etc., can solve the problems of label printing that cannot be completed, cannot be completed, and the accuracy cannot meet the label requirements, so as to broaden the scope of printing application and improve accuracy. Degree, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

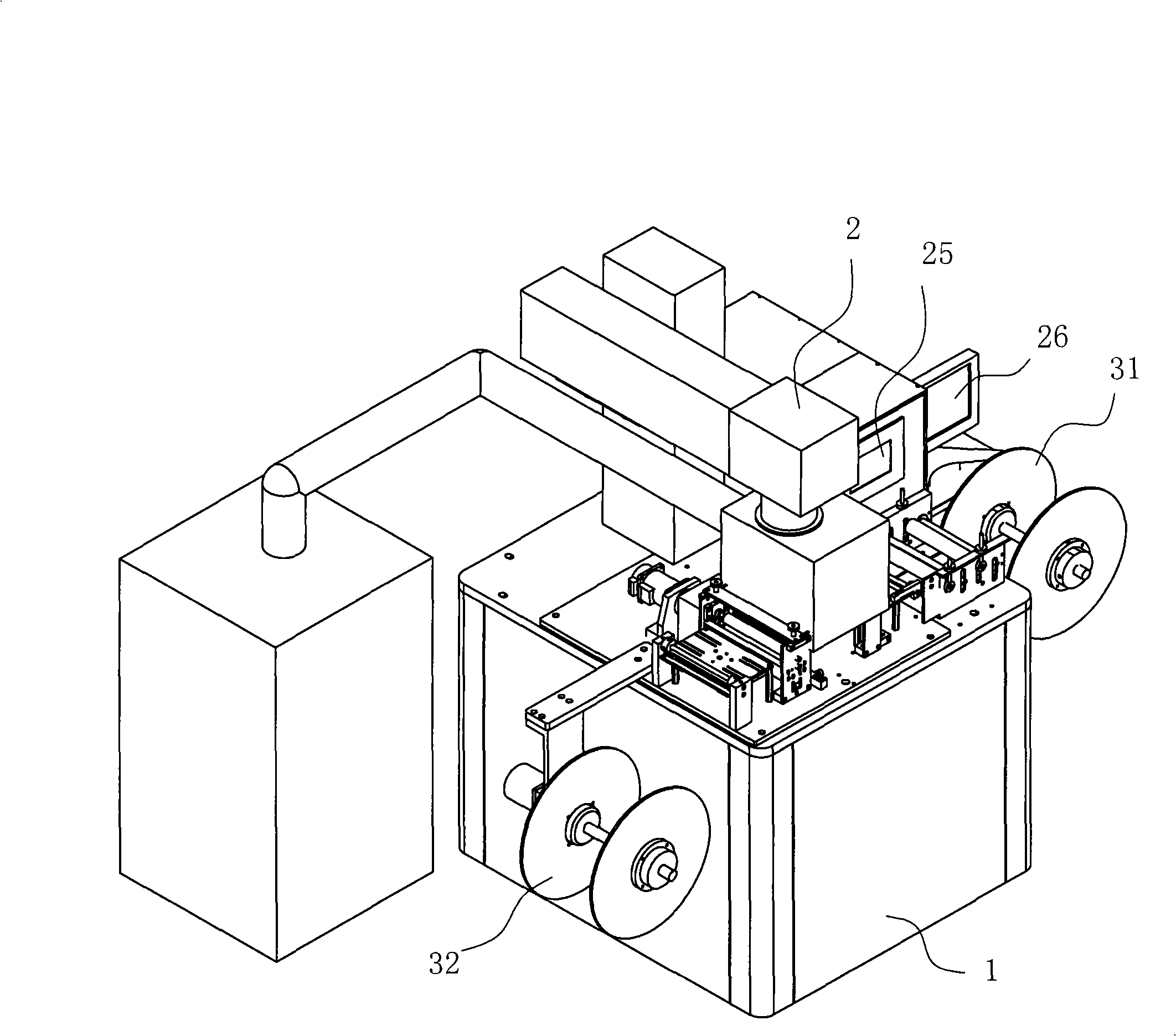

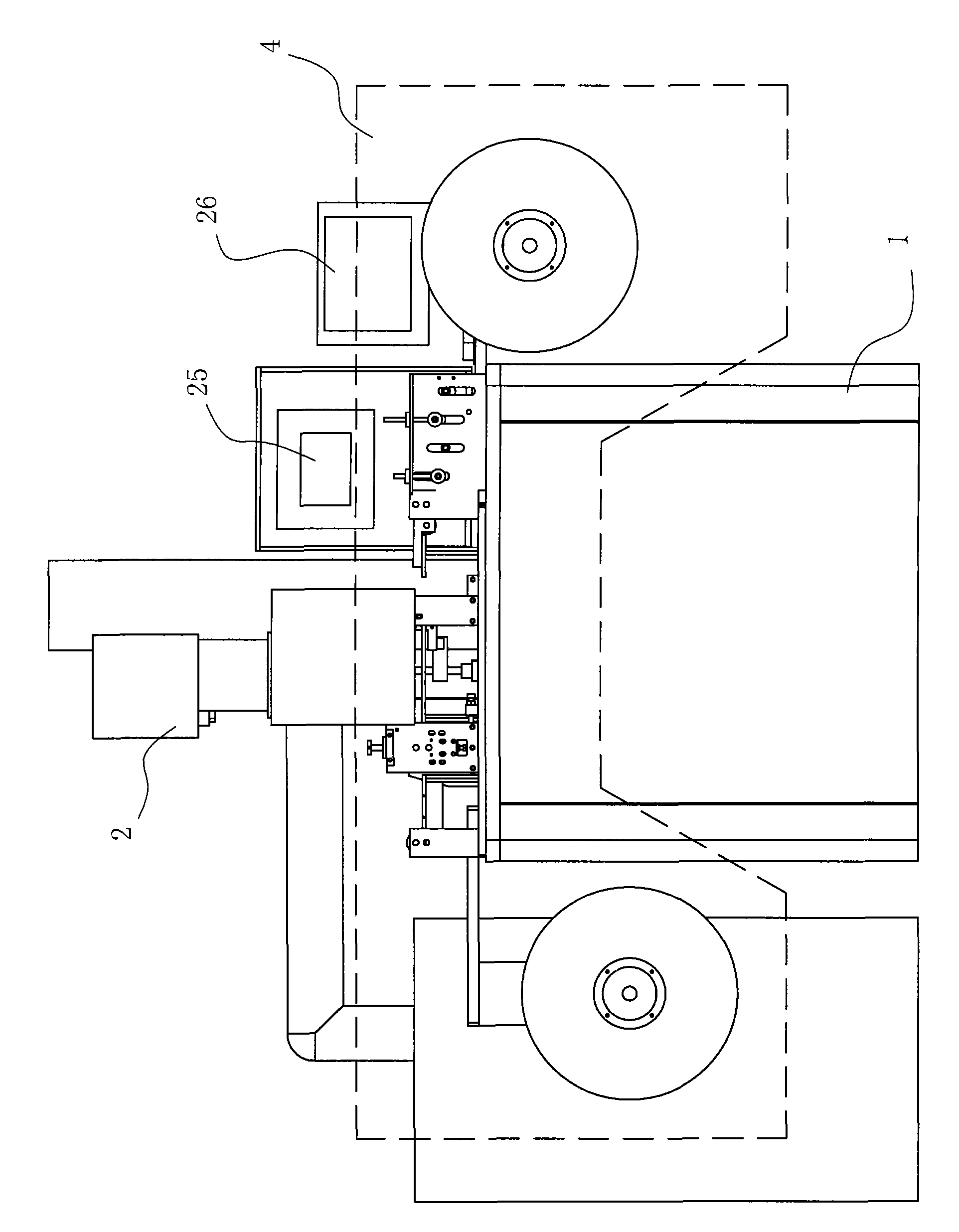

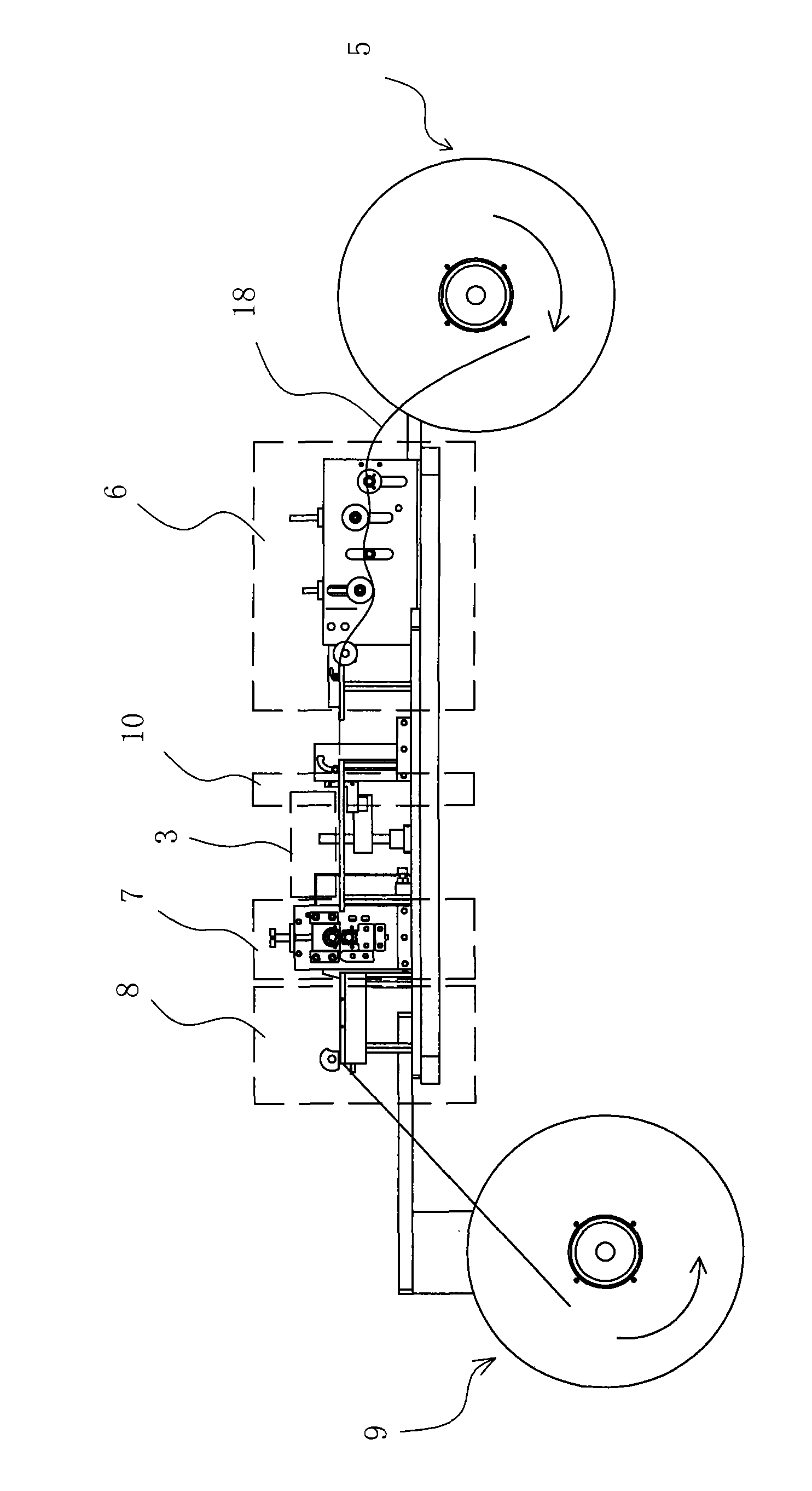

[0030] Embodiment one: see Figure 1 to Figure 8 As shown, a roll-to-roll laser marking machine includes a main body frame 1, a laser machine 2 installed on the main body frame 1 and a control system, a laser working platform 3 is provided below the laser machine 2, and the main body machine The frame 1 is provided with a feeding device 4 at the working platform 3, and a feeding aisle is formed on the same plane as the working surface of the working platform 4. The feeding device 4 is successively composed of a feeding mechanism 5, a tension An adjustment mechanism 6, a transmission mechanism 7, a cutter mechanism 8, and a material receiving mechanism 9 are formed, and the working platform 3 is located between the tension adjustment mechanism 6 and the transmission mechanism 7, as image 3 shown;

[0031] Such as Figure 5 , 6 , 7, a sensor mechanism 10 is provided near the feed port of the working platform 3, and the sensor mechanism 10 includes a mounting bracket structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com