Mechanical automatic feeding device of spring grinding machine

A technology of automatic feeding and spring grinding machine, which is applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of workers' mistakes in work, increase the labor intensity of workers, etc., and achieve improved stability, accuracy and stability Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present application will be further described in detail below with reference to the accompanying drawings.

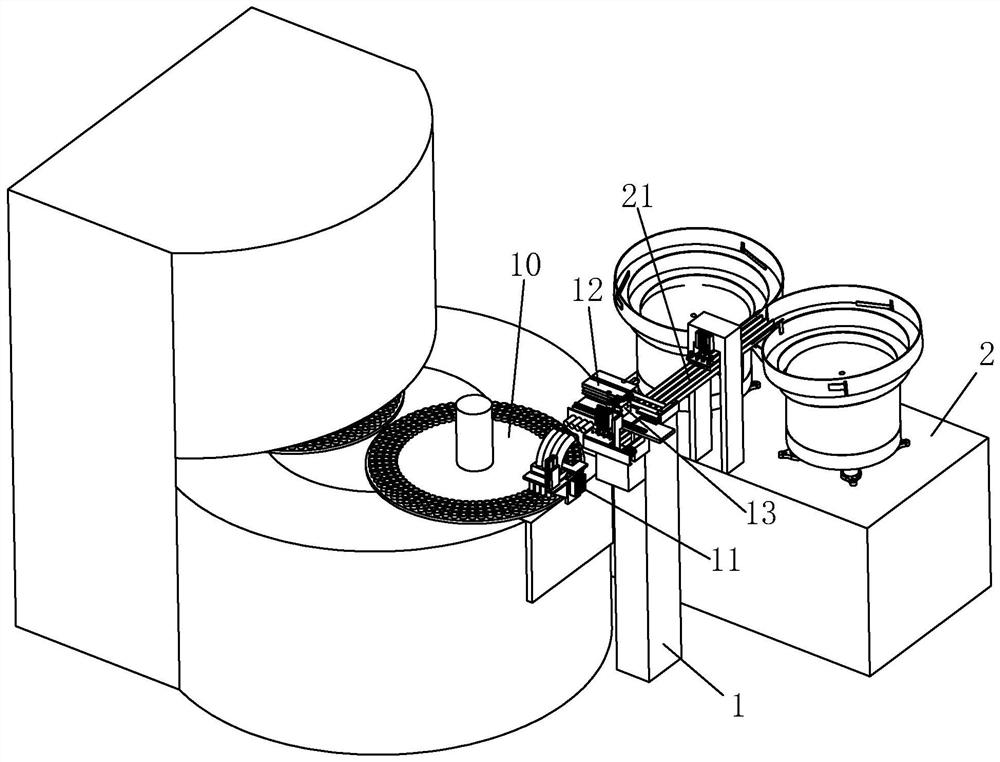

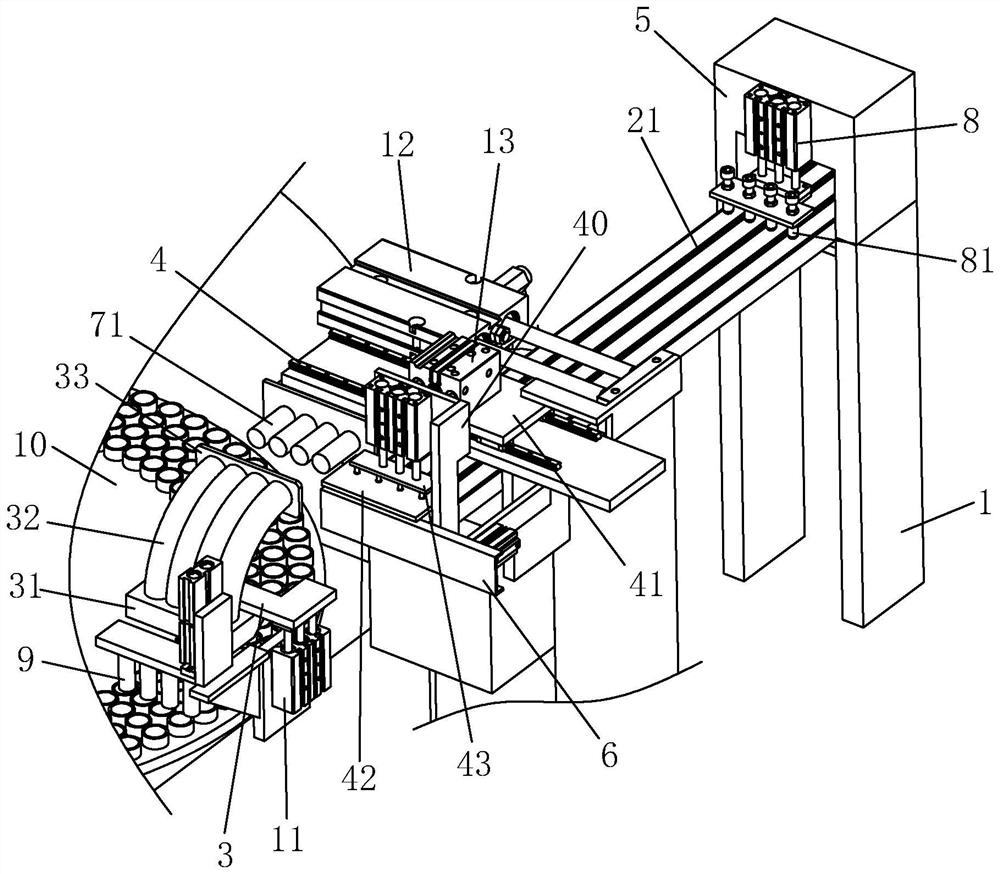

[0035] The embodiment of the present application discloses a mechanical automatic feeding device for a spring grinder, such as figure 1 and figure 2 As shown, it includes: a frame 1, a workbench 2 is installed on the frame 1, two feeding devices are installed on the workbench 2, and a feeding channel 21 arranged side by side is installed at the discharge end of the feeding device, The feeding device can carry a spring and transport the spring to a predetermined position along the feeding channel 21. The feeding device in this embodiment adopts a relatively common vibrating plate, and the discharge end of each vibrating plate is connected with two feeding channels. 21, that is to say, four conveying channels 21 arranged side by side convey the springs of the vibrating discs to a predetermined position.

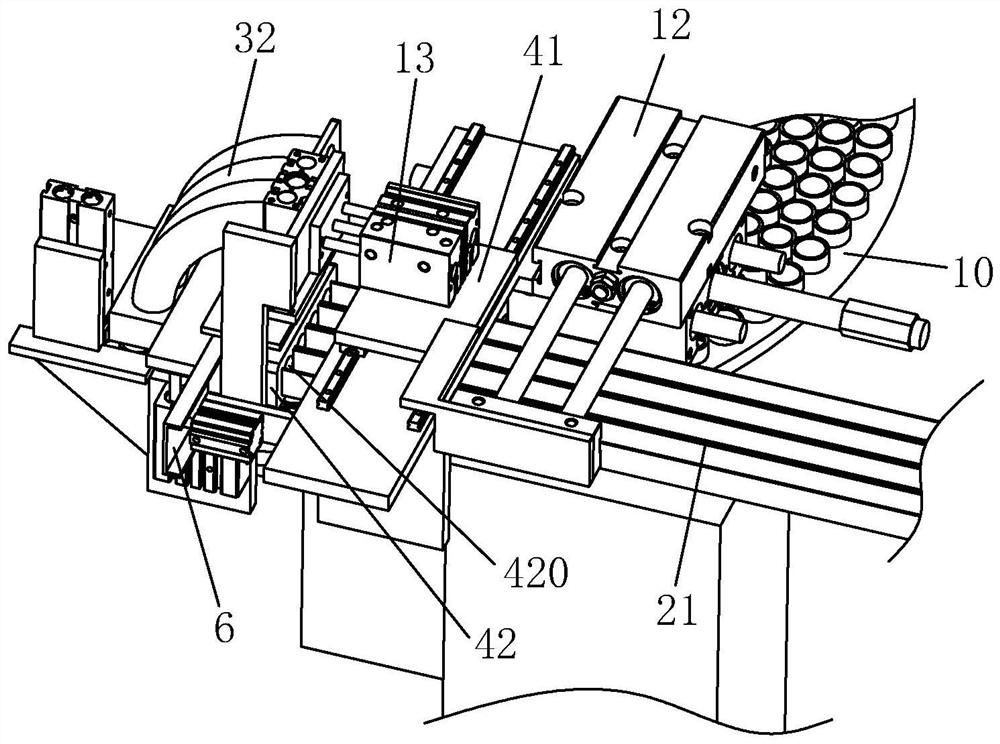

[0036] A transfer mechanism is installed at the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com