A device and method for reducing laser hardened soft band

A technology of laser quenching and soft belt, applied in the field of laser quenching device and process, can solve the problems affecting the effect of laser quenching and strengthening, and achieve the effect of uniform laser strengthening surface, uniform hardness of workpiece, and reducing soft belt area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The invention discloses a device for reducing laser quenching soft bands and a method for using the device, which are suitable for the process of laser quenching a workpiece. The following are specific examples:

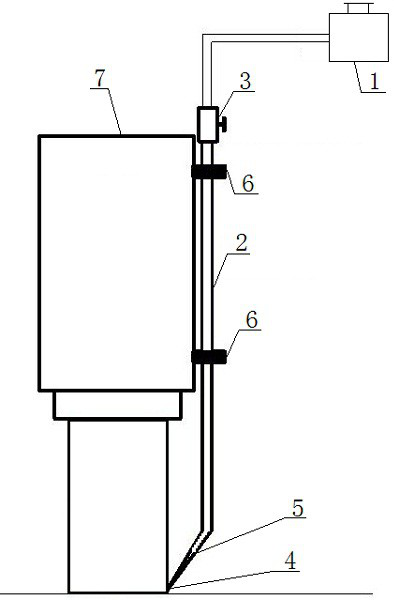

[0027] Devices for reducing laser hardened soft bands in the present invention, such as figure 1 As shown, it includes a spraying device 1 and a paint delivery pipe 2 connected with the spraying device 1 . The device is used to apply the light-absorbing paint to the corresponding preset overlapping area on the surface of the workpiece, so as to increase the light absorbing rate of the preset overlapping area. The outlet of the paint delivery pipe 2 is aligned with the edge of the laser irradiation area on the surface of the workpiece, which is the preset overlapping area during laser quenching. A flow valve 3 is provided on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com