Bearing surface laser quenching device and method based on distributed three-dimensional light beam scanning

A technology of laser quenching and beam scanning, applied in quenching devices, heat treatment equipment, furnaces, etc., to achieve high-quality quenching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The preferred embodiments of the invention are given below in conjunction with the accompanying drawings to describe the technical solutions of the present invention in detail. Here, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not used to limit or limit the present invention.

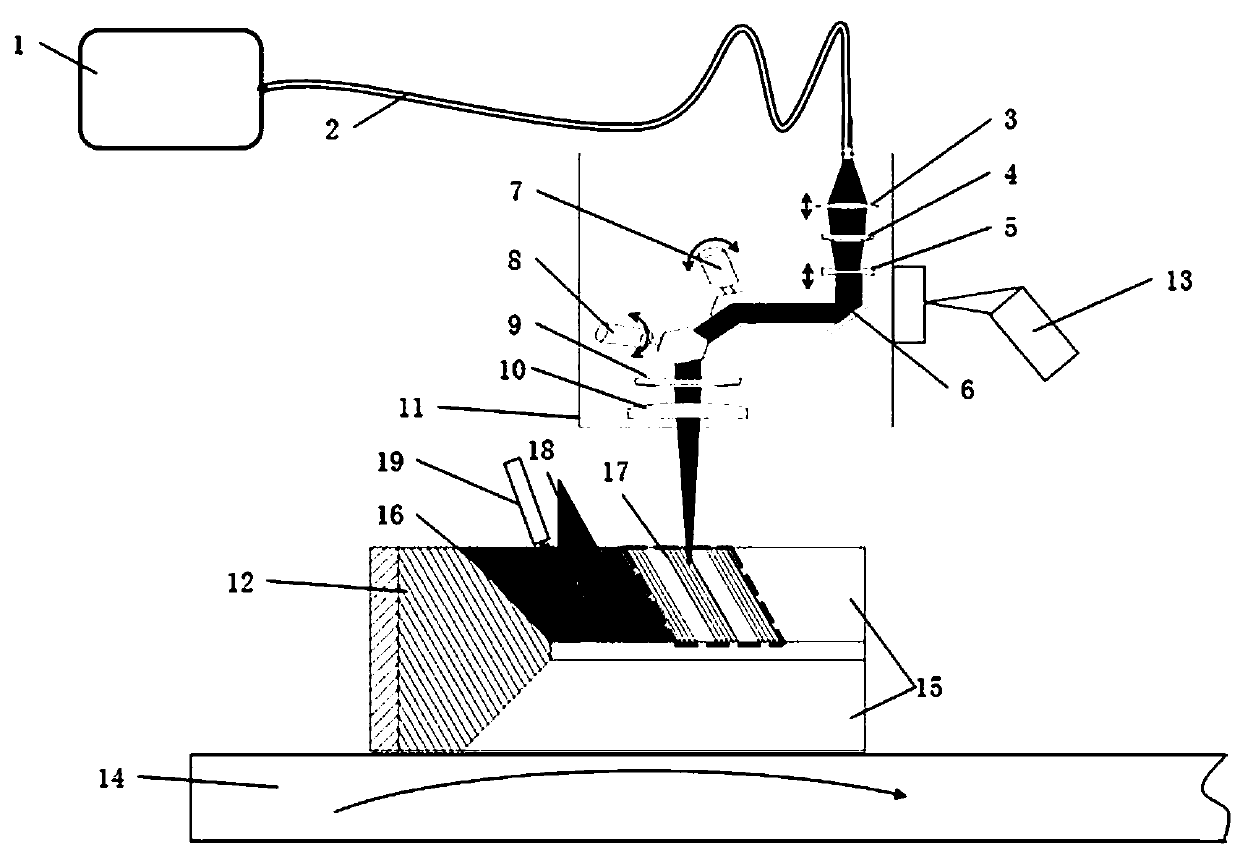

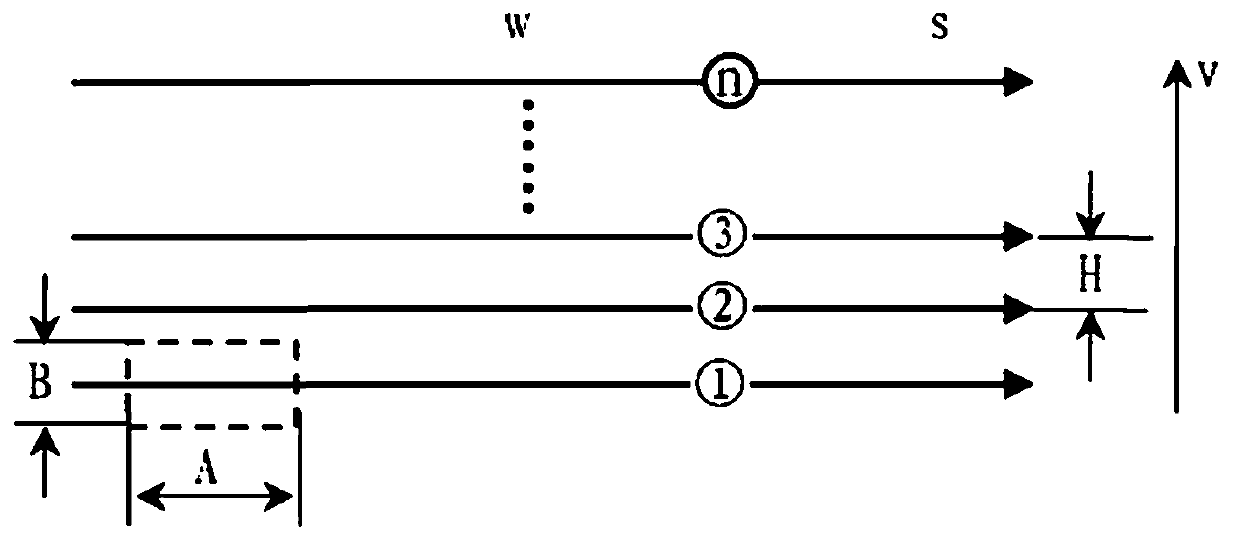

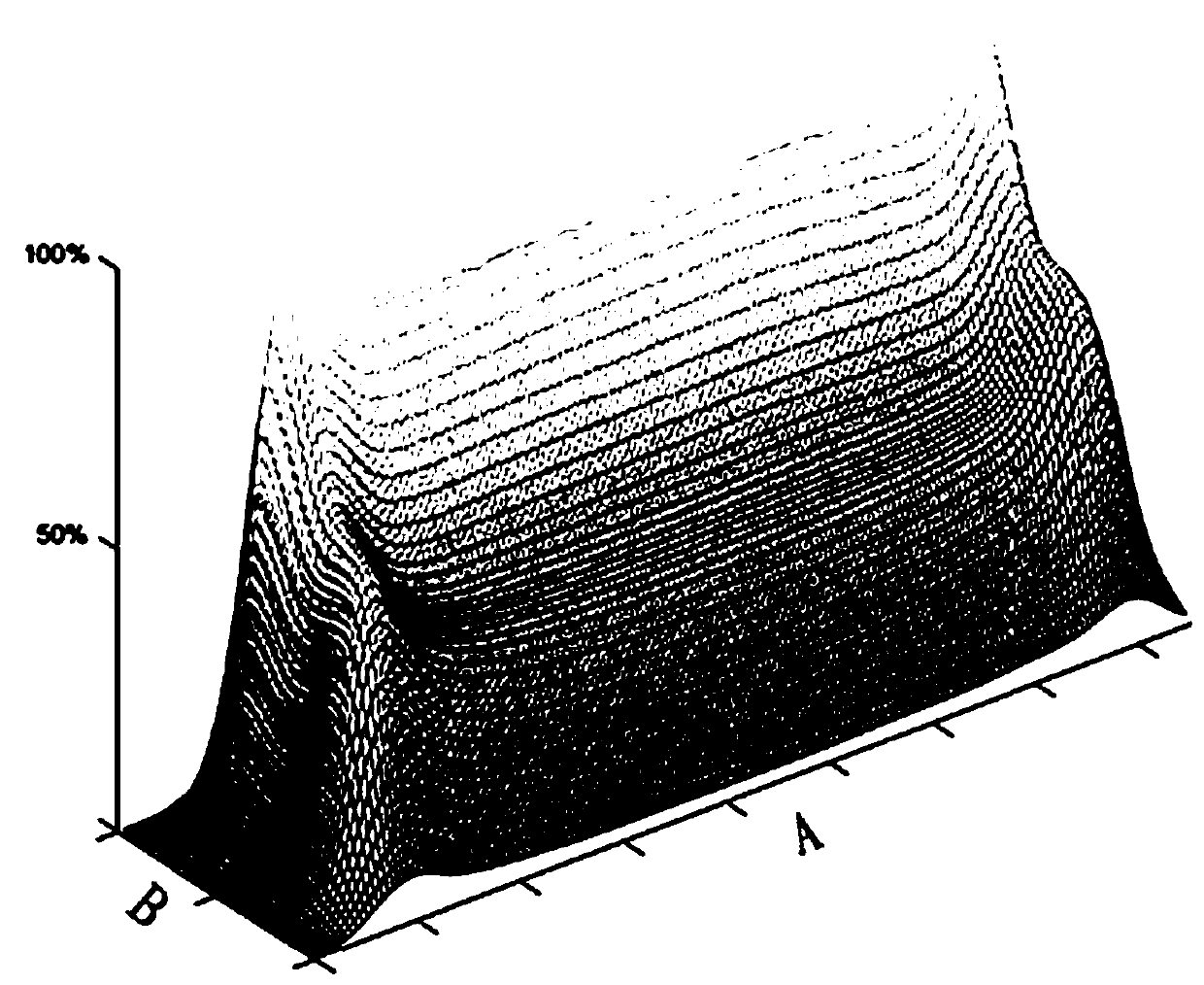

[0029] like figure 1 As shown, the bearing surface laser quenching device based on distributed three-dimensional beam scanning includes a laser 1, a laser transmission fiber 2, a laser processing head 11, a robot arm 13, a positioner 14, a partition 18, and a cooling medium nozzle 19; The laser beam emitted by the laser 1 sequentially passes through the laser transmission fiber 2 and the laser processing head 11 to reach the surface of the bearing raceway 15, the robot arm 13 is equipped with the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com