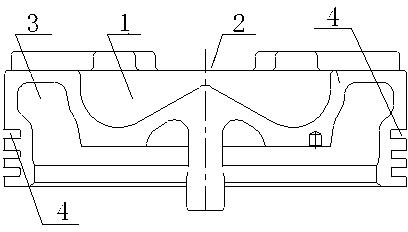

Piston crown structure

A piston top and piston technology, applied to pistons, engine components, machines/engines, etc., can solve problems that are prone to damage and affect the service life of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 As shown, the piston top structure includes a combustion chamber 1, a valve avoidance cavity 2, an inner chamber 3 and a piston ring groove 4, the combustion chamber 1 is set on the upper part of the piston top, and the valve avoidance cavity 2 is arranged in four places evenly distributed around the top of the piston. The inner cavity 3 is set on the inner side of the piston top, and the piston ring groove 4 is set on the outer cylindrical surface of the piston top. There are 3 piston ring grooves 4, and the width of the piston ring groove 4 is 3.5 mm. The piston ring groove 4 is quenched by laser. In the piston top structure of the present invention, the piston ring groove adopts laser quenching, which can improve the surface hardness of the ring groove, improve the service life of the piston, and can be applied to occasions where the working environment is relatively harsh; the matrix structure is changed, and the focused laser beam is used for rapid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com