Laser quenching equipment and use method

A technology of laser quenching and equipment, which is applied in the direction of quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of heat softening in the quenching area, achieve the effects of saving procedures and costs, improving automation, and rapid laser surface quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

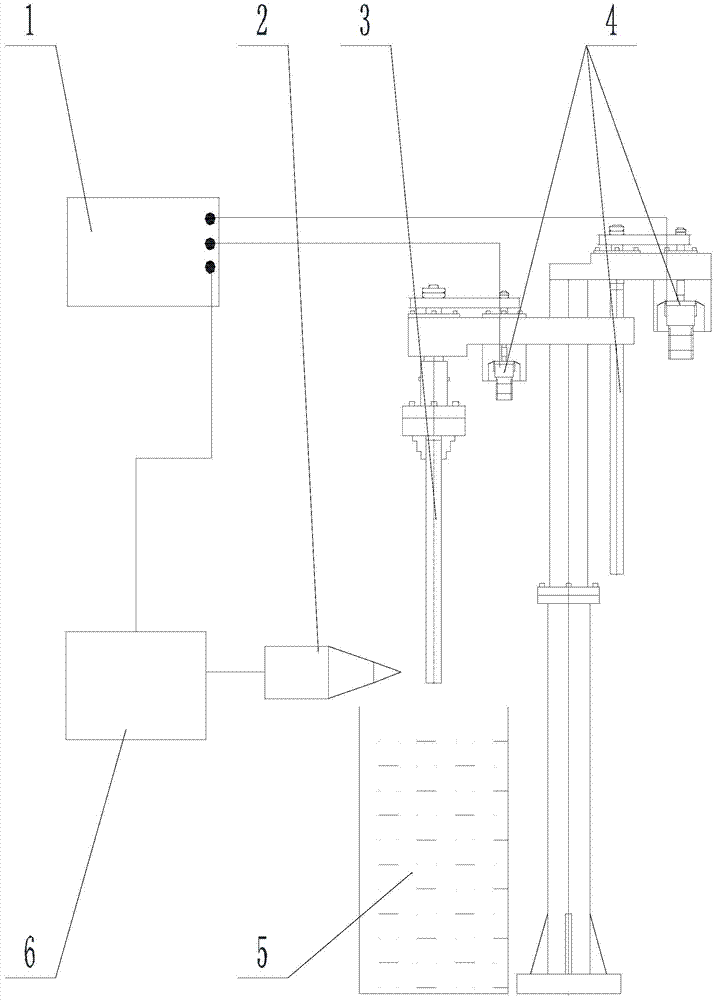

[0025] Such as figure 1 As shown, a laser hardening equipment includes a programmable controller 1, a laser 6, a laser head 2 connected to the laser 6 and used for laser hardening the workpiece 3, and used to clamp the workpiece 3 and drive the movement of the workpiece 3 The mechanism 4 is located at the cooling liquid tank below the workpiece 3, and the cooling liquid 5 is housed in the cooling liquid tank.

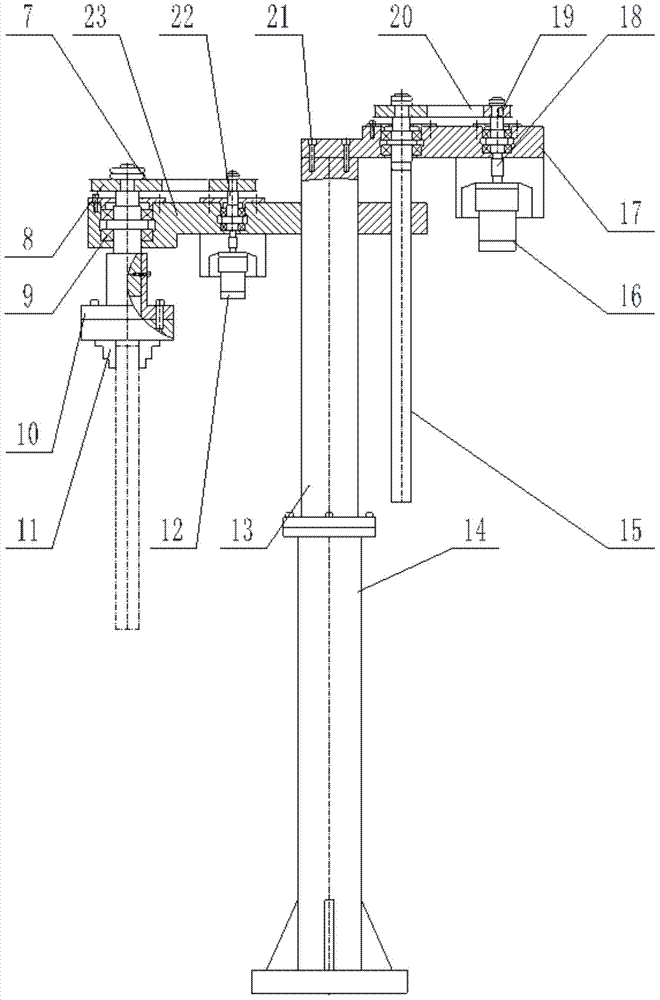

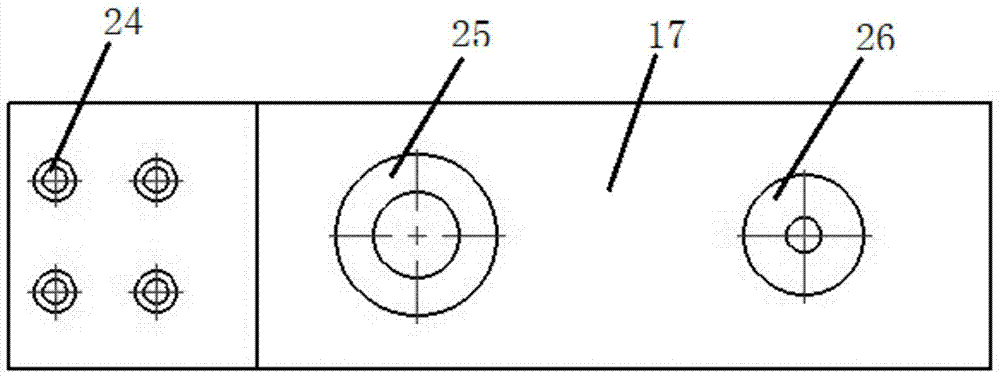

[0026] Such as figure 2 Shown motion mechanism 4 has base 14, and base 14 top is provided with guide rod 13, and the top of guide rod 13 is detachably installed fixed plate 17, and fixed plate 17 is provided with motor II 16 and leading screw 15, and fixed plate 17 is as image 3 with 4 As shown, there are installation holes I24, installation holes II25 and installation holes III26. The fixed plate 17 is fixed to the top of the guide rod 13 through the installation holes I24. There is a screw bearing in the installation hole II25, and the screw 15 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com