Thin-wall gear ring type part quenching method for keeping accuracy level

A thin-walled ring gear, high-precision technology, used in furnace types, furnaces, heat treatment equipment, etc., can solve problems such as scorching and overheating, quenching cracks, environmental pollution, etc., to improve production efficiency, reduce deformation, and achieve accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

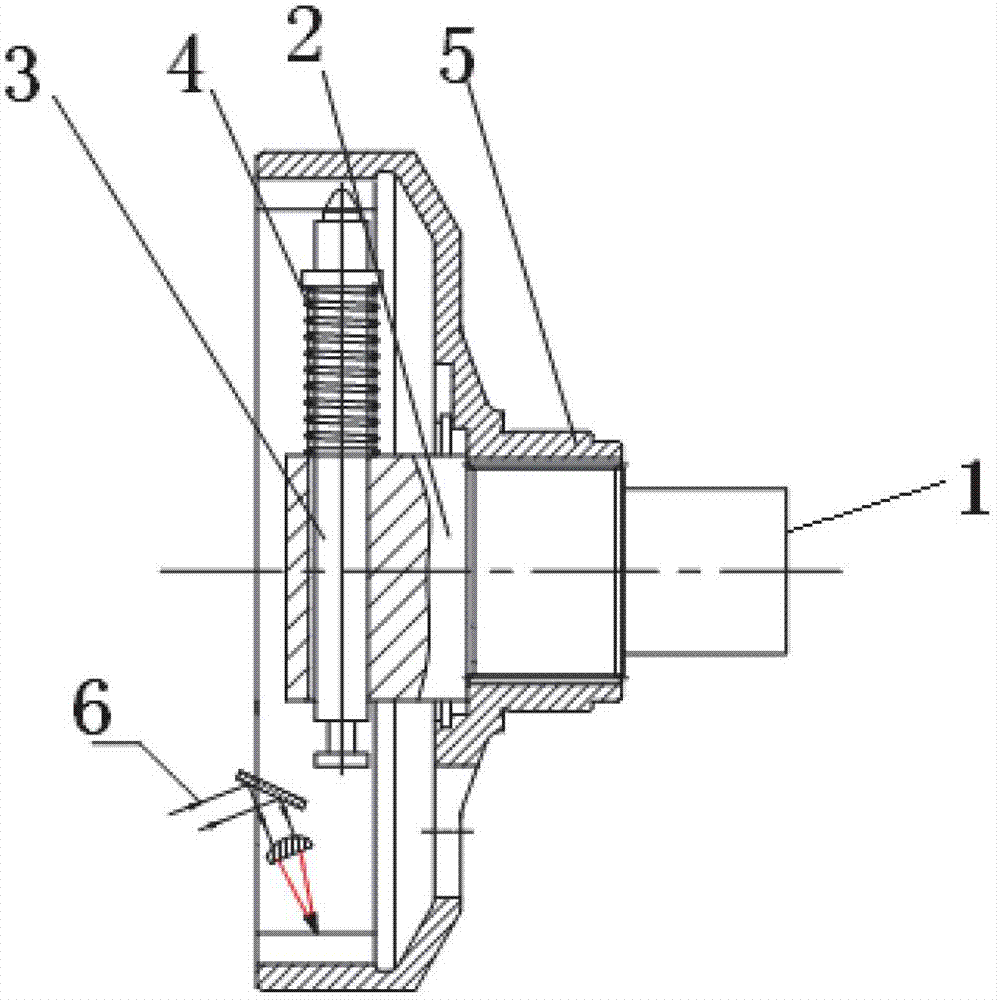

[0017] The steps of the present invention are as follows:

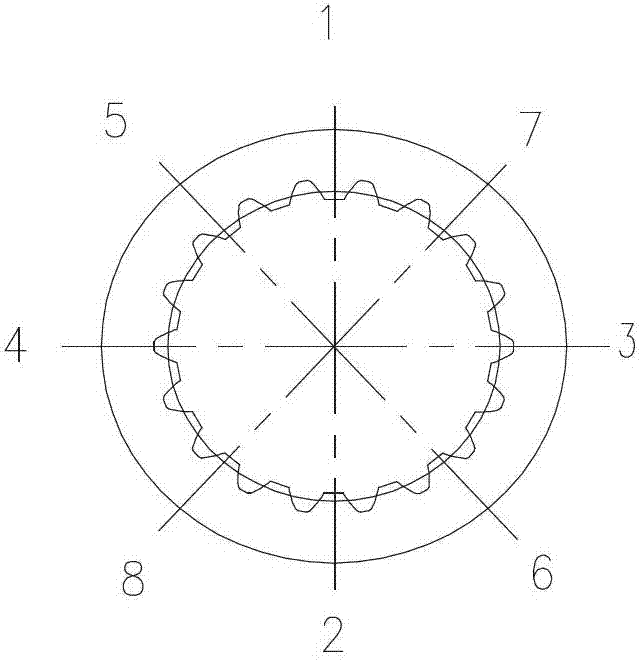

[0018] Step 1. The thin-walled ring gear parts of medium carbon nitriding steel are processed according to the cutting amount specified in the process, and the stress relief and tempering are carried out respectively. The main purpose is to eliminate the mechanical stress of the parts as much as possible. After the processing is completed, it is cleaned and dried, and its processing accuracy is 7 grades.

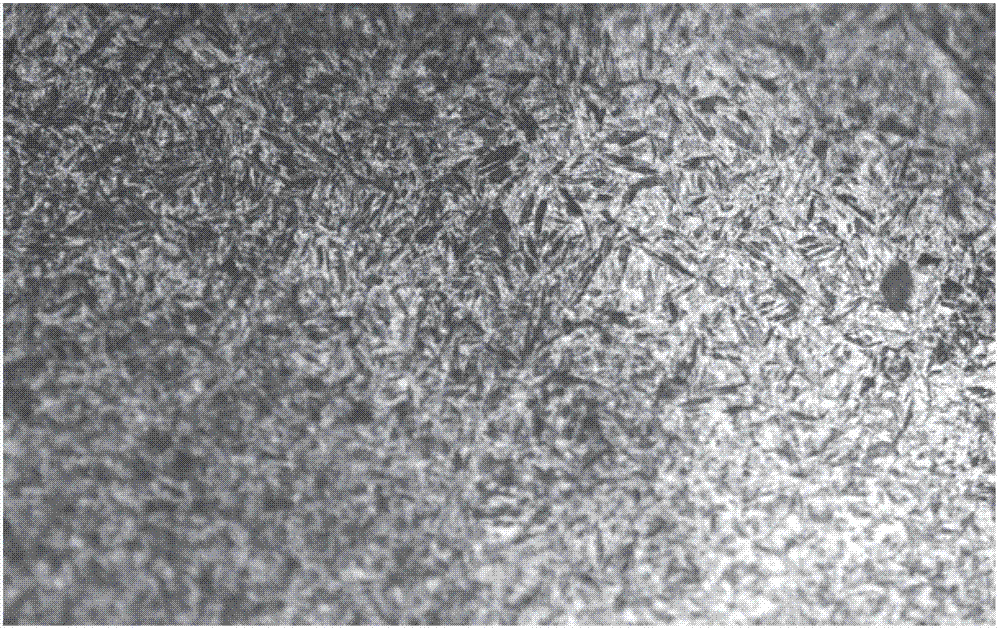

[0019] Step 2. Use a special coating material to evenly coat the surface to be strengthened, scan the surface of the workpiece with a high-energy laser beam, the surface material of the workpiece absorbs the laser radiation energy and converts it into heat energy, and the heat conduction makes the temperature around the material rise at an extremely fast speed To the process temperature above the austenite transformation, and then through the self-cooling effect of the material matrix, the heated surface material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com