Impurity removing system for raw material sugarcane pretreatment

A pretreatment and sugarcane technology, applied in the field of impurity removal system, can solve the problems of unreasonable equipment structure, unreasonable equipment selection, unfavorable uniform feeding of the latter stage, etc., and achieves reasonable system process design, simple installation and maintenance, and impurity removal effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

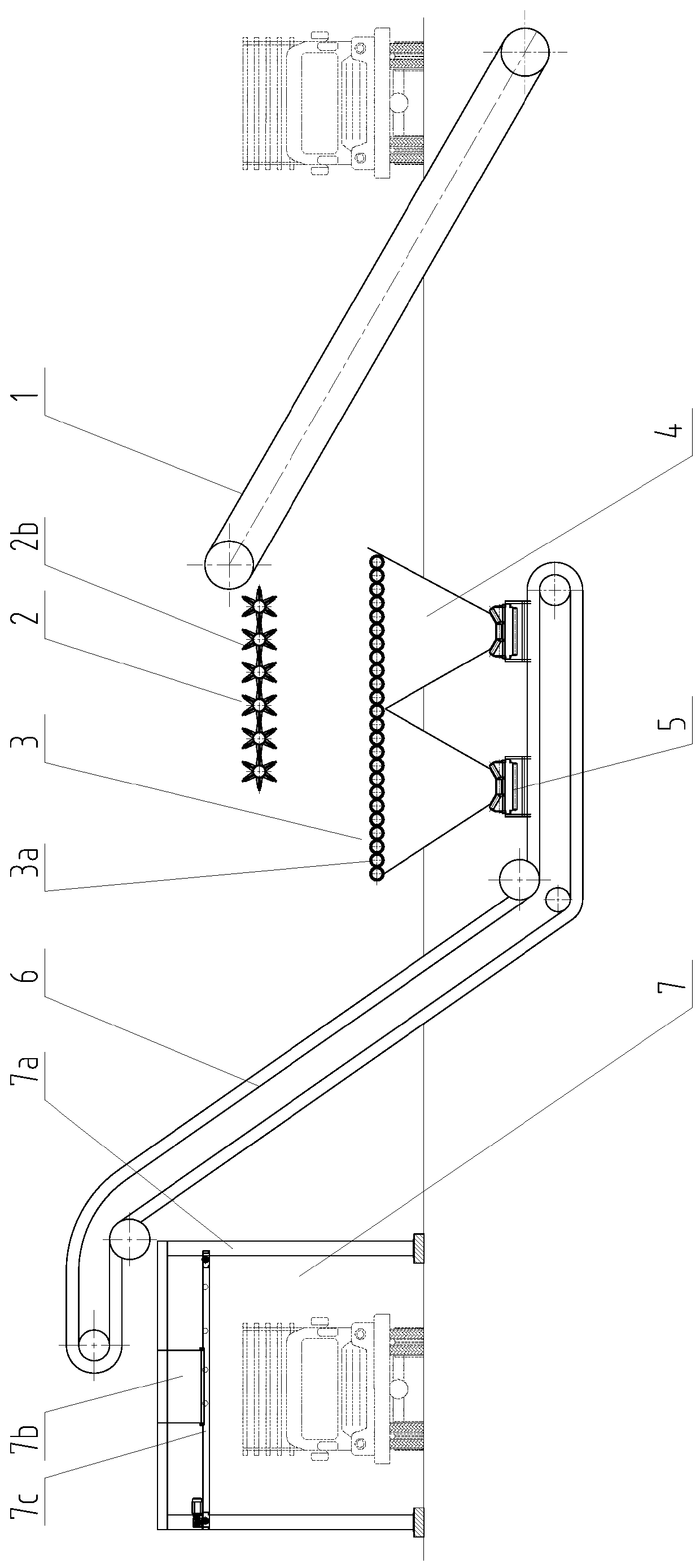

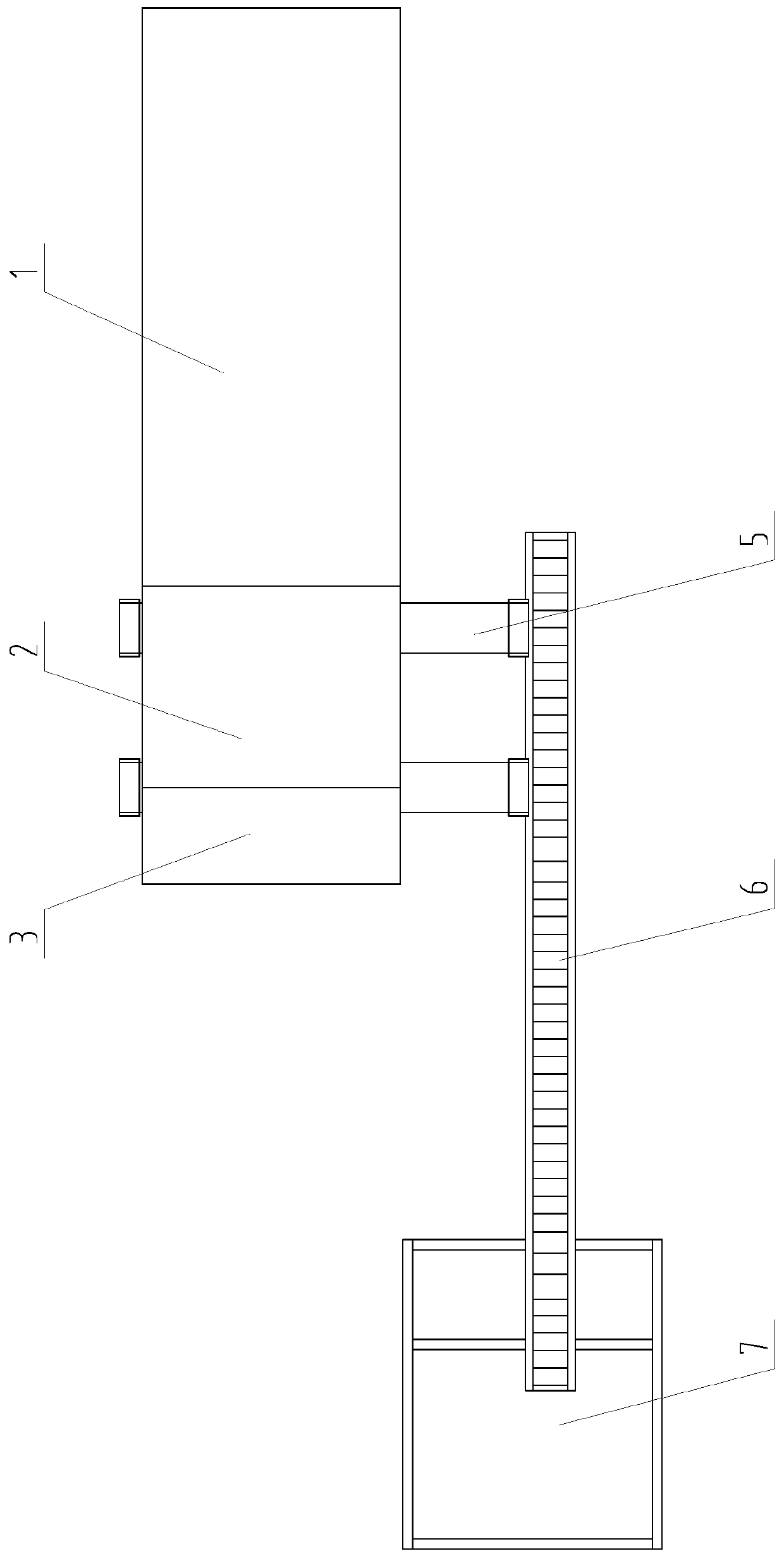

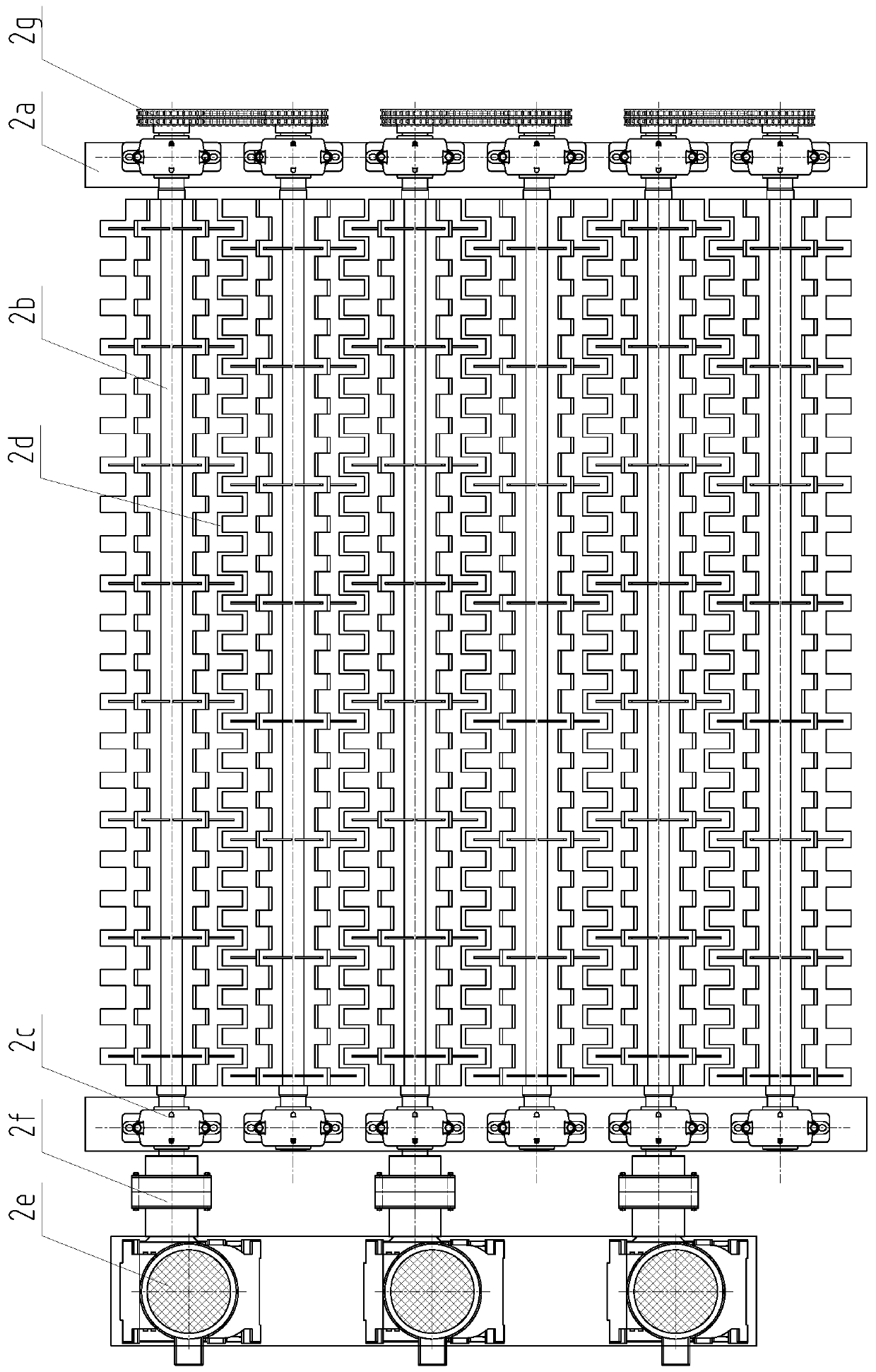

[0030] Such as Figure 1-2As shown, the impurity removal system includes unloading chain plate conveyor 1, multi-stage throwing conveyor 2, toothed roller type impurity removal conveyor 3, debris collection bucket 4, trough belt conveyor 5, large-inclination corrugated belt conveyor Conveyor 6, debris loading platform 7, wherein: the low-side feeding end of unloading chain-plate conveyor 1 is set at the unloading platform of raw sugar cane; At the lower position in front of the side discharge end, the multi-stage dispersing conveyor 2 is composed of a plurality of dispersing drums 2b that are parallel to each other and closely arranged together; the toothed roller type impurity removal conveyor 3 is set on the Directly below 2, the toothed roller type impurity removal conveyor 3 is composed of a plurality of conveying toothed rollers 3a that are parallel to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com