Coal gasification system and gasification process

A technology of coal gasification and coal gas, which is applied to the gasification of granular/powdered fuels, the petroleum industry, and the manufacture of combustible gases. It can solve the problems of low carbon conversion rate, difficulty in handling fly ash, and difficult reaction, and achieve an increase in carbon conversion rate. , prevent damage, fully respond to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

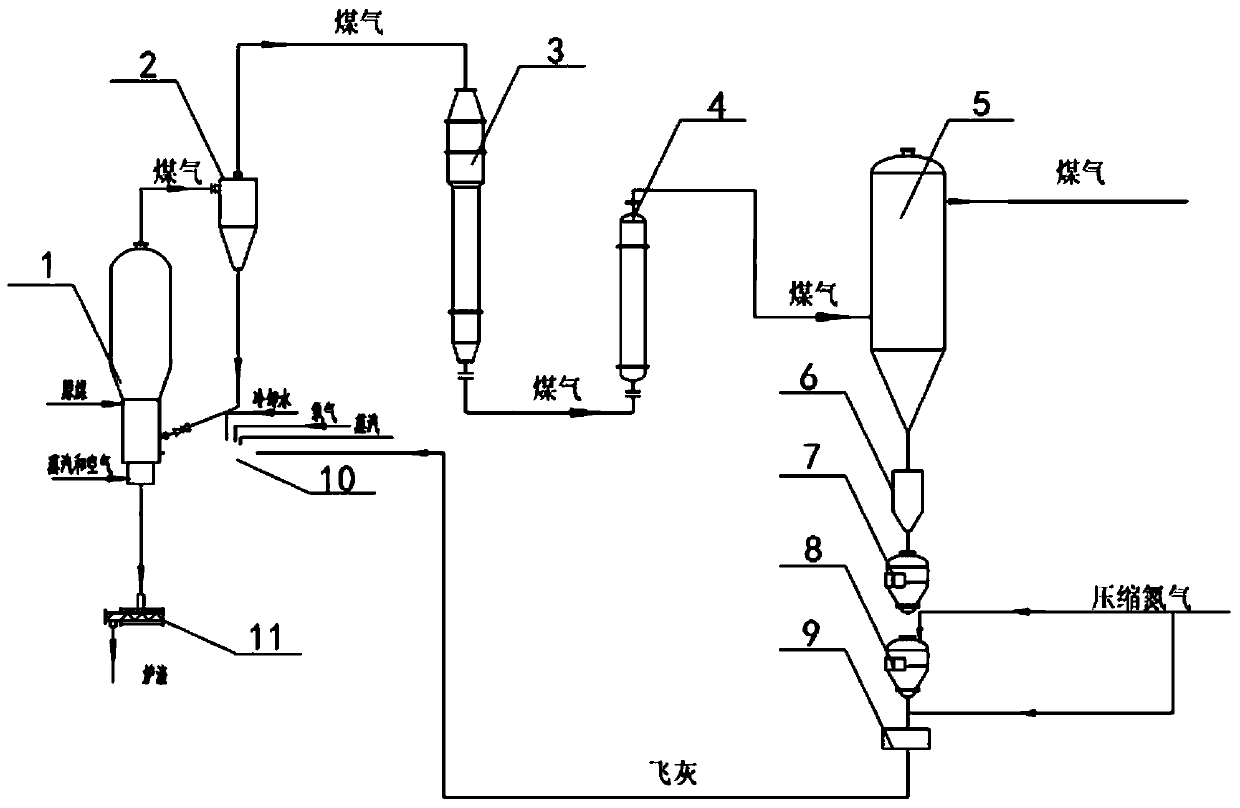

[0042] Such as figure 1 As shown, a coal gasification system includes a gasification device, a heat exchange device and a dust removal device 5 connected in sequence. Among them, the gasification device is a device for coal gasification reaction, the heat exchange device is used to cool down the high-temperature gas generated by the gasification device and recover heat, and the dust removal device 5 is used to remove fly ash particles in the gas to improve the cleanliness of the gas. degree, and the removed fly ash particles are collected and transported back to the gasification device for secondary reaction to increase the carbon conversion rate and gas production of the entire system. The work of the system will be elaborated below by making a detailed description of the specific structure and connection relationship of each device.

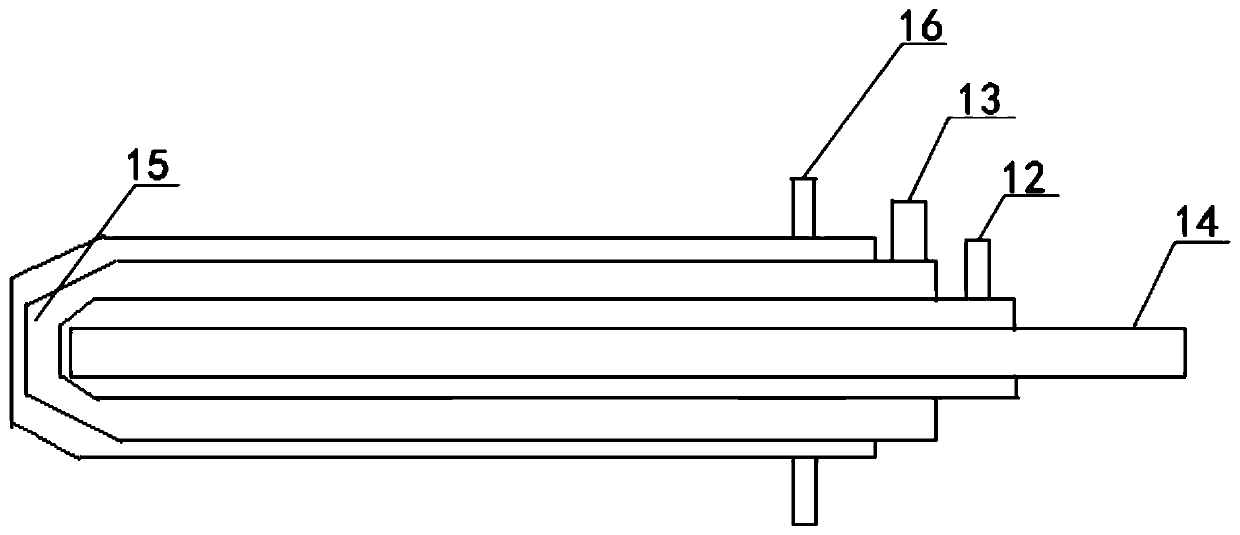

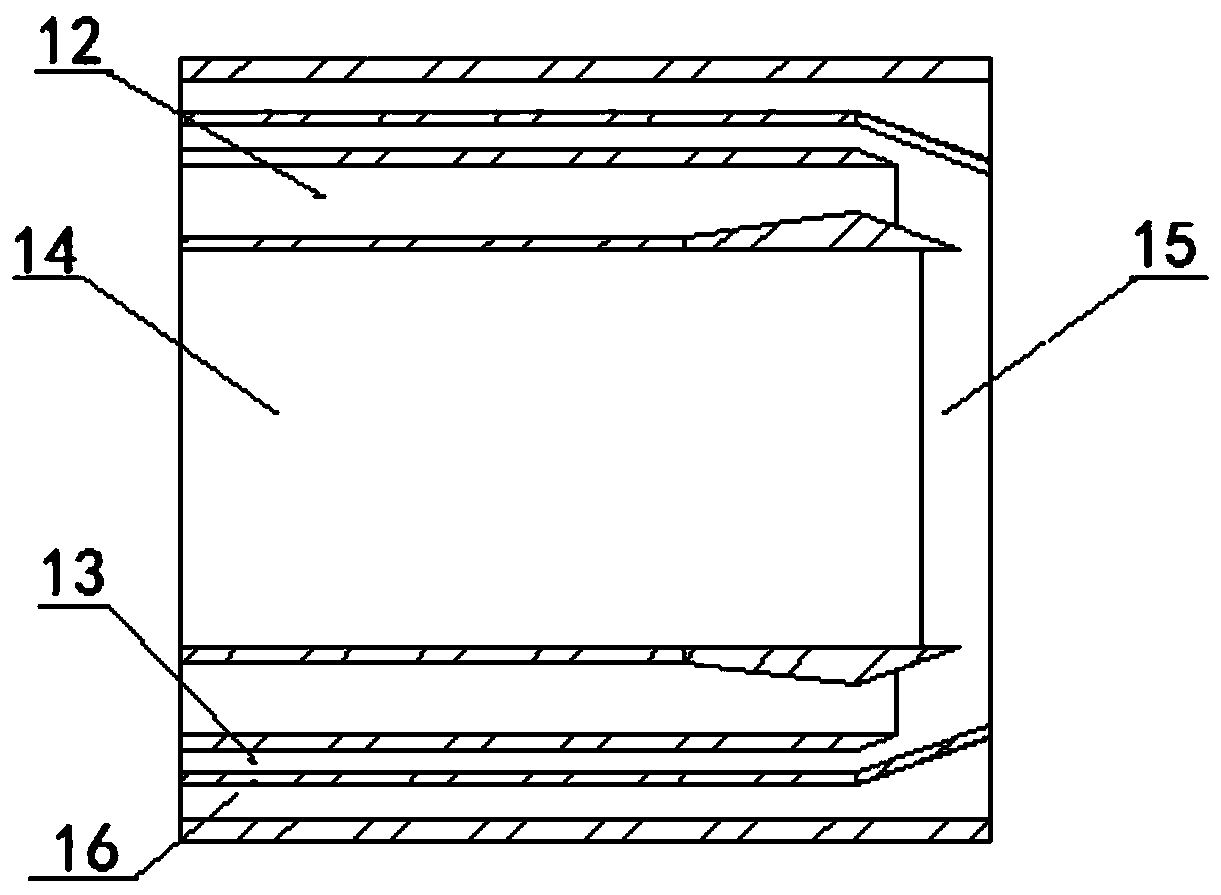

[0043] In this embodiment, a gasifier 1 is used as a gasification device, and the type of the gasifier 1 is a common fluidized bed gasifier o...

Embodiment 2

[0060] When the coal gasification system in Example 1 is working, the fly ash particles in the gas can be separated and collected by the dust removal device 5, and the collected fly ash particles are sent to the fly ash burner 10 through the pipeline to be mixed with steam and oxygen-enriched air , and then sent to the gasifier 1 for reaction. However, since the amount of fly ash particles collected per unit time is not fixed, the speed at which the fly ash particles are transported to the fly ash burner 10 through the pipeline cannot be kept consistent, thereby affecting the mixing of fly ash particles with steam and oxygen-enriched air The effect is to reduce the reaction efficiency of fly ash after returning to the furnace. In addition, fly ash particles have a certain degree of adhesion, and the pressure in the pipe is not stable enough when it is transported in the pipe. The fly ash is easily adsorbed on the inner wall of the pipe, causing blockage.

[0061] In view of t...

Embodiment 3

[0066] The coal gasification system of embodiment 2 can continuously and quantitatively send fly ash particles to the fly ash burner 10 through the pneumatic conveying device, and it adopts a bag filter as the dust removal device 5. The separation effect is very good, and the separation rate can reach 99% even for fly ash particles with a particle size below 1 micron. However, this approach also brings some problems:

[0067] (1) Due to the excellent dust removal effect of the bag filter, the amount of fly ash particles separated and collected per unit time is relatively large. On the one hand, a large number of fly ash particles are more likely to cause blockage of the transportation pipeline; It is not conducive to the full mixing with steam and oxygen-enriched air in the fly ash burner 10, and affects the reaction efficiency of the fly ash after returning to the furnace;

[0068] (2) Only a single bag filter with good dust removal effect is used to separate the fly ash parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com