Counting type conveying control equipment

A conveying control and counting technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems that ordinary conveyor belts cannot achieve reliable and uniform transportation, fixed-quantity transportation and large-inclination transportation, and achieve operational The effect of high speed and low manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

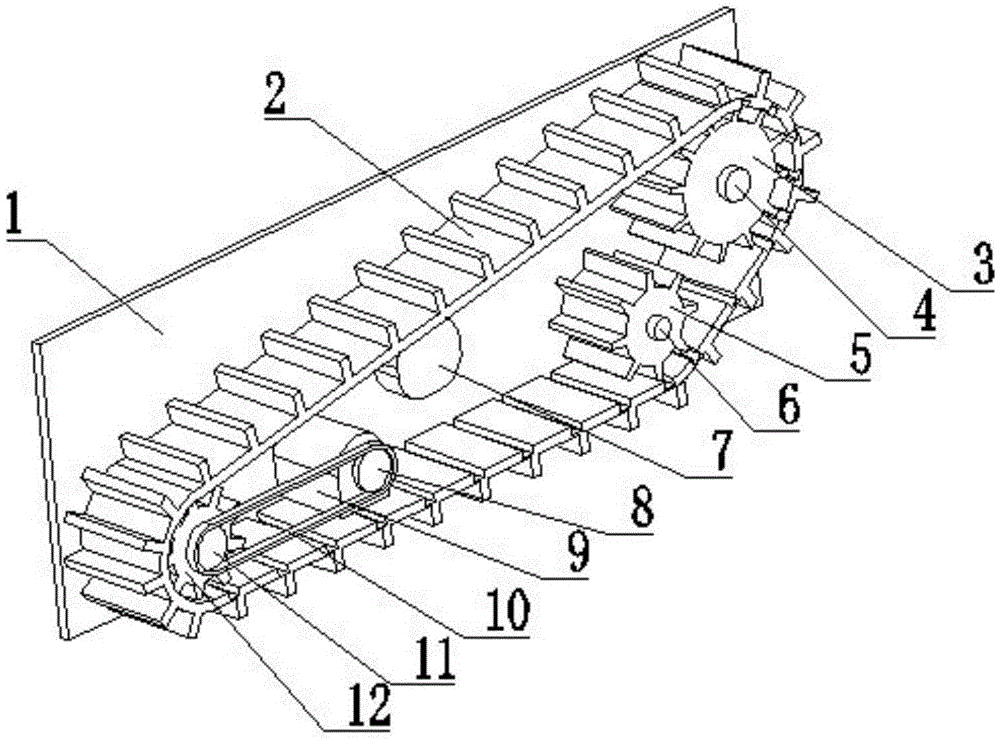

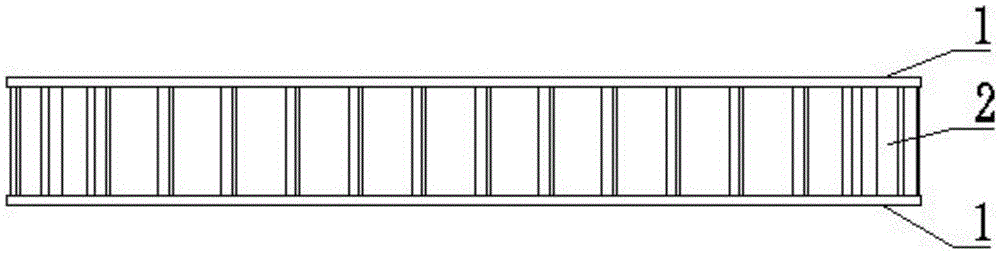

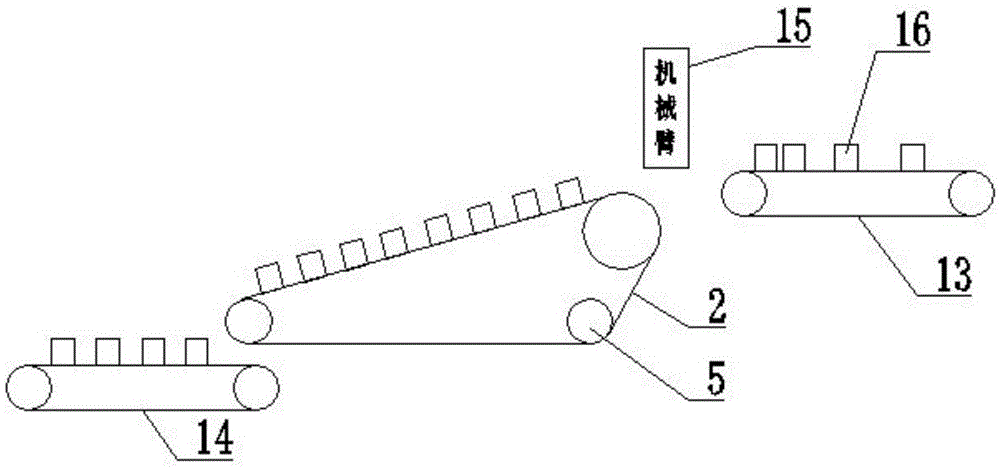

[0019] refer to figure 1 , figure 2 with image 3 , a counting conveying control device of the present invention, including a baffle plate 1, a conveyor belt 2, a first driven wheel 3, a second driven wheel 5, FX2N-32MR7, a servo motor 9, a driving sprocket 8, a chain 10 and a driven Sprocket 11, the baffle plate 1 is installed on the working platform, the first driven wheel shaft 4, the second driven wheel shaft 6, FX2N-32MR7, servo motor 9 are fixedly installed on the baffle plate 1; the conveyor belt 2 is composed of Composed of a base belt and a transverse partition, baffles 1 are installed on both sides of the conveyor belt 2, and there is a gap between the conveyor belt 2 and the baffles 1 on the left and right sides; the first driven wheel 3 is installed on the first driven wheel shaft 4 On, the first driven wheel 3 has a rotation pair; the second driven wheel 5 is installed on the second driven wheel shaft 6, and the second driven wheel 5 has a rotation pair; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com