Patents

Literature

82 results about "Formal control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formal control exists whenever a controlling variable evokes a response and there is point-to-point correspondence between the controlling variable and the response.

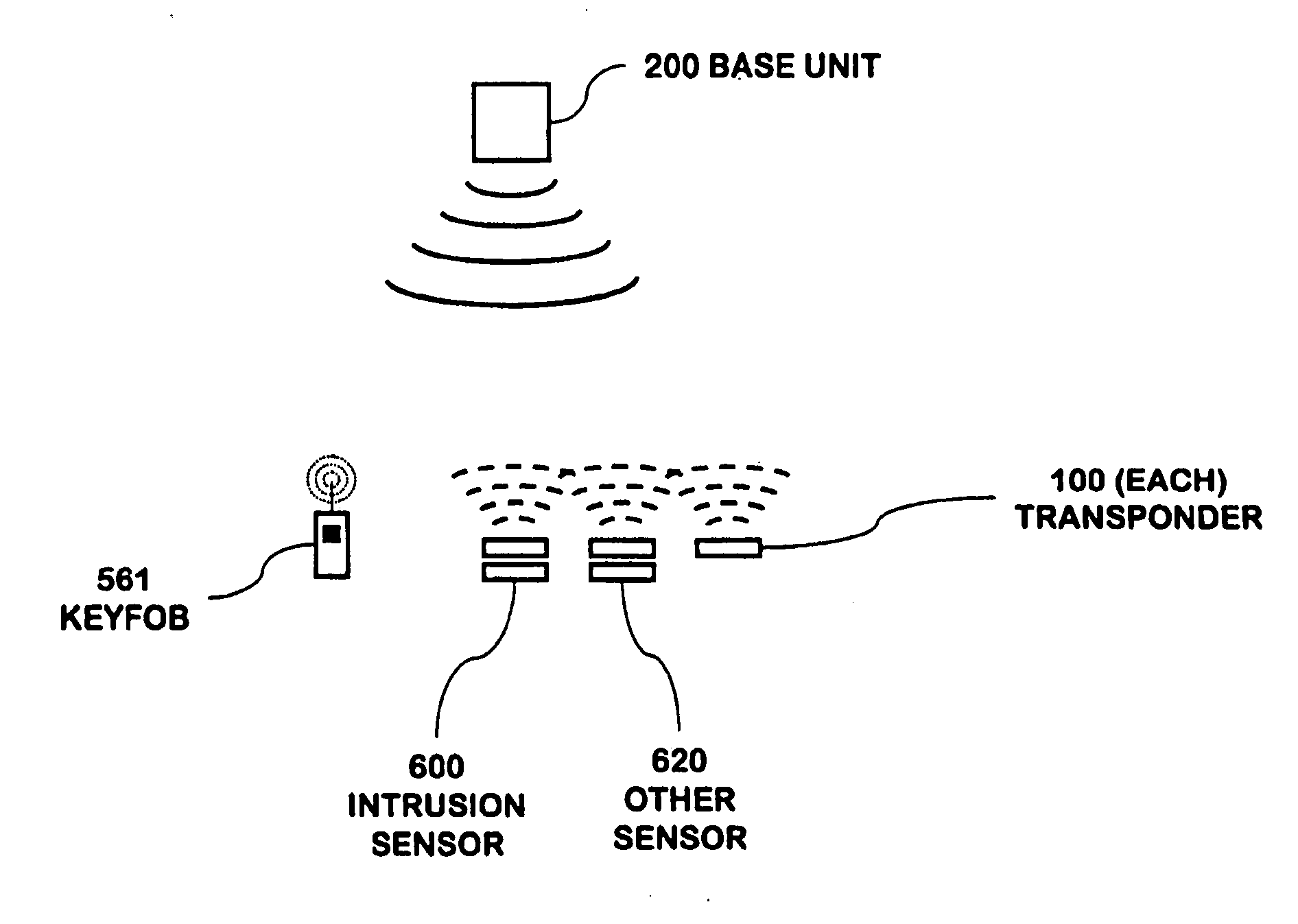

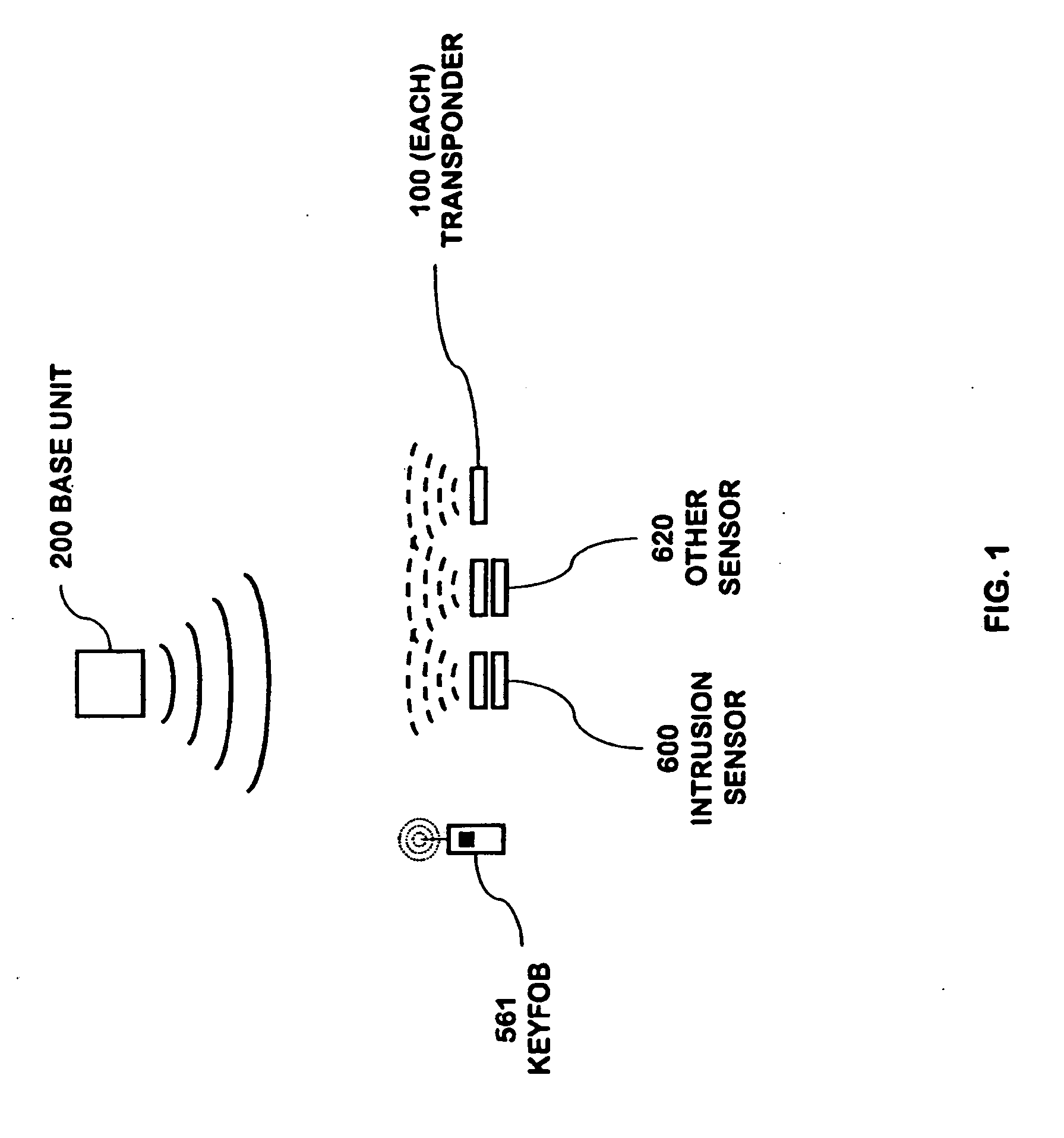

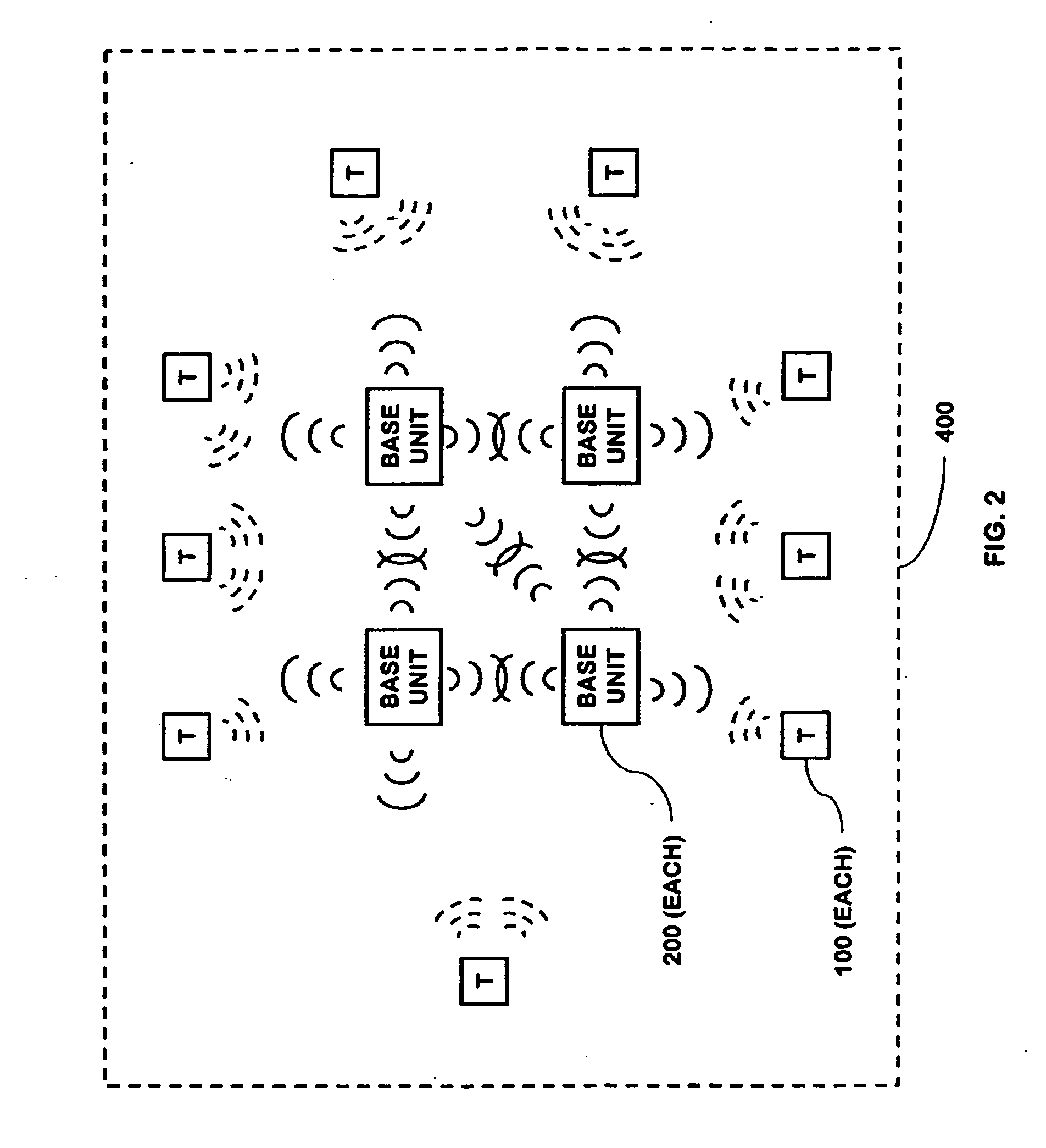

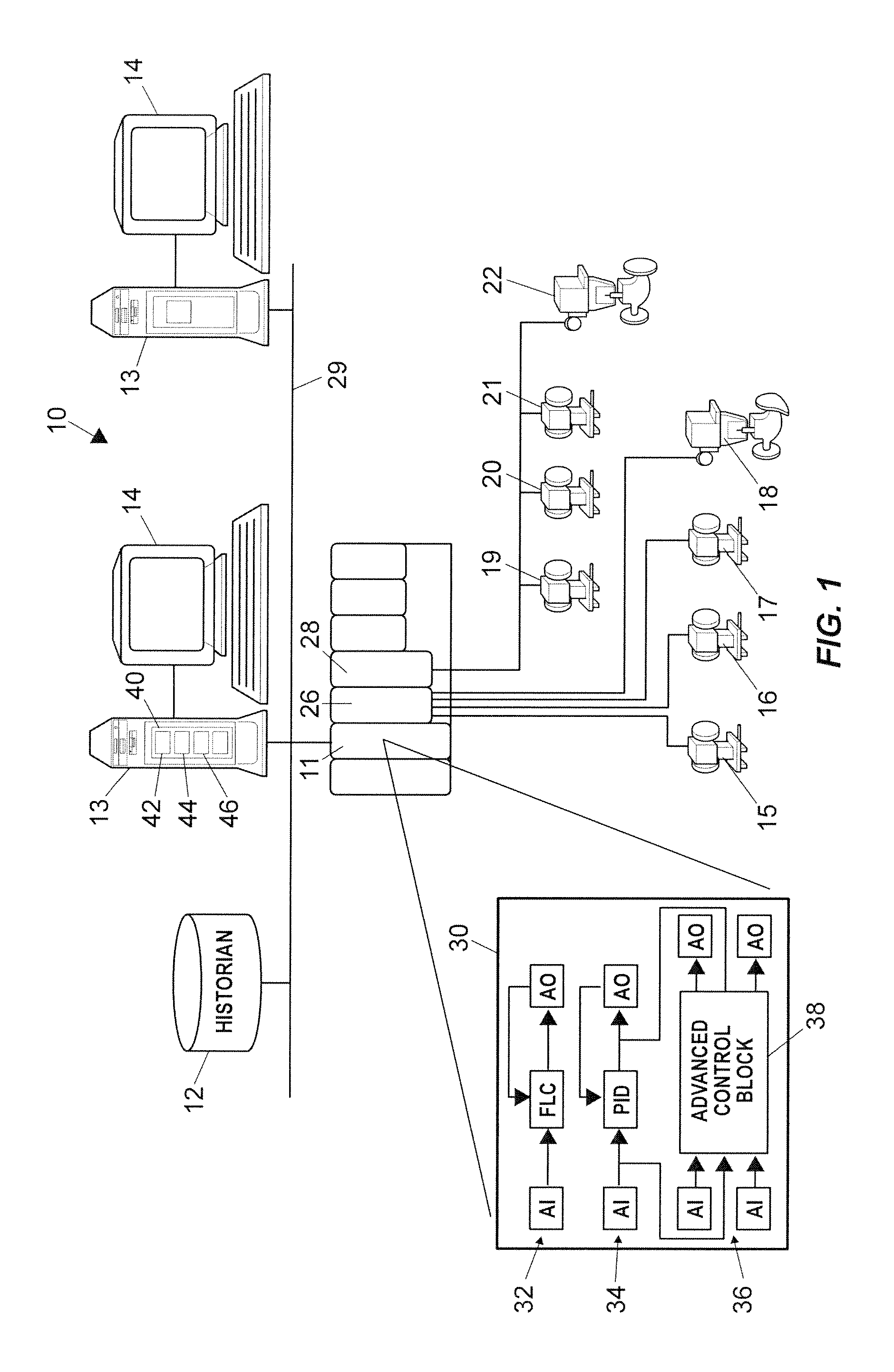

Portable telephone in a security network

InactiveUS20080001734A1Improve reliabilityLow costSafety arrangmentsComputer controlKey pressingNetwork communication

A security network for use in a building with an opening to be monitored for possible intrusion. The network includes an intrusion sensor monitoring the opening; an RFID transponder associated with the sensor; an RFID reader in wireless communication with the transponder; and a portable telephone handset having first keys activating conventional telephone capability and second keys activating interaction with the other security network components. The handset wirelessly communicates with the reader. The reader may take the form of a security cradle for the handset. Alternatively, the reader may take the form of a telephone console. The console has keys enabling a user to dial remote telephone numbers; circuitry adapted to receive wireless communications from the transponder; circuitry in wireless communication with the handset; circuitry in communication with an external network; and a processor executing program code enabling the handset to communicate with the external network via the telephone console.

Owner:ADT US HLDG INC

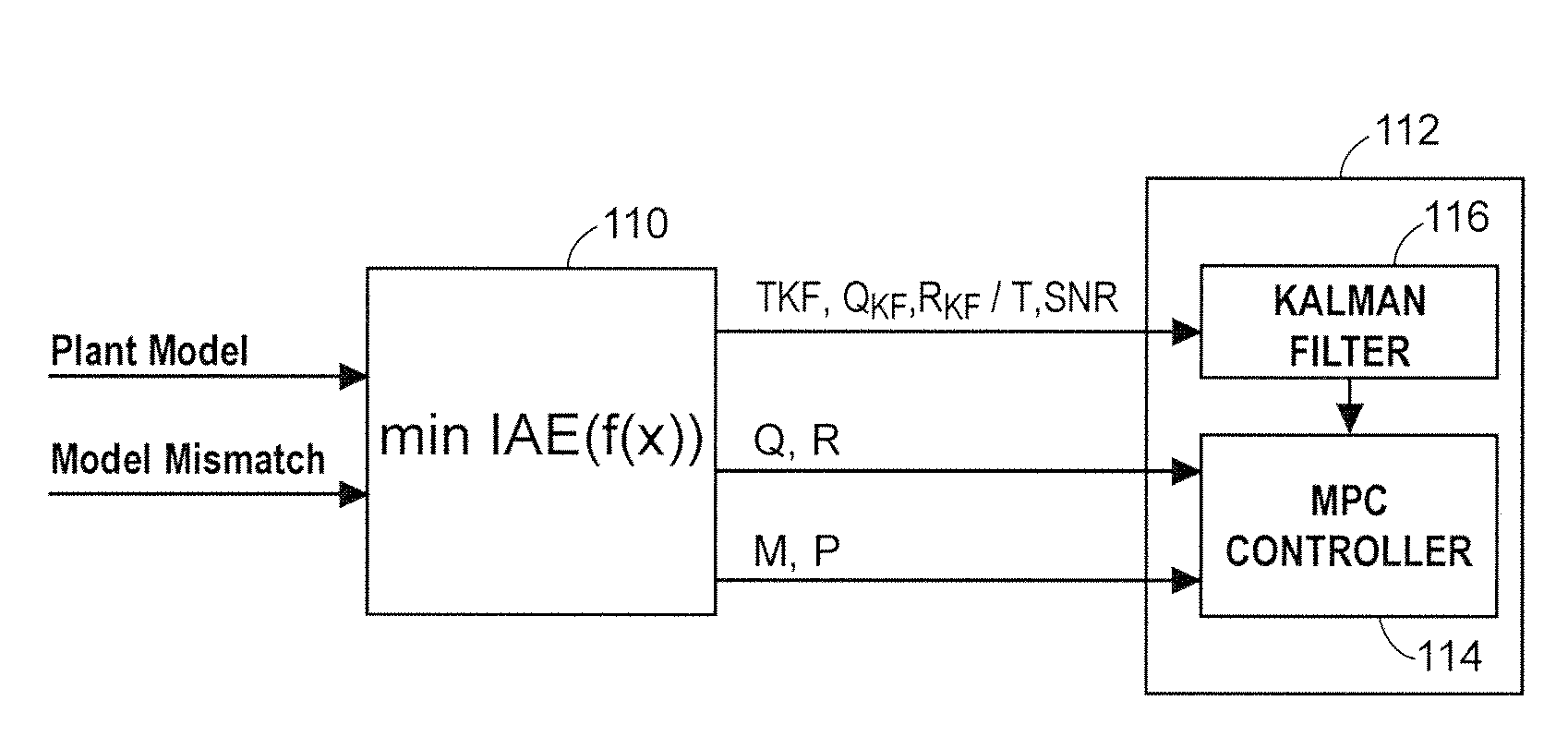

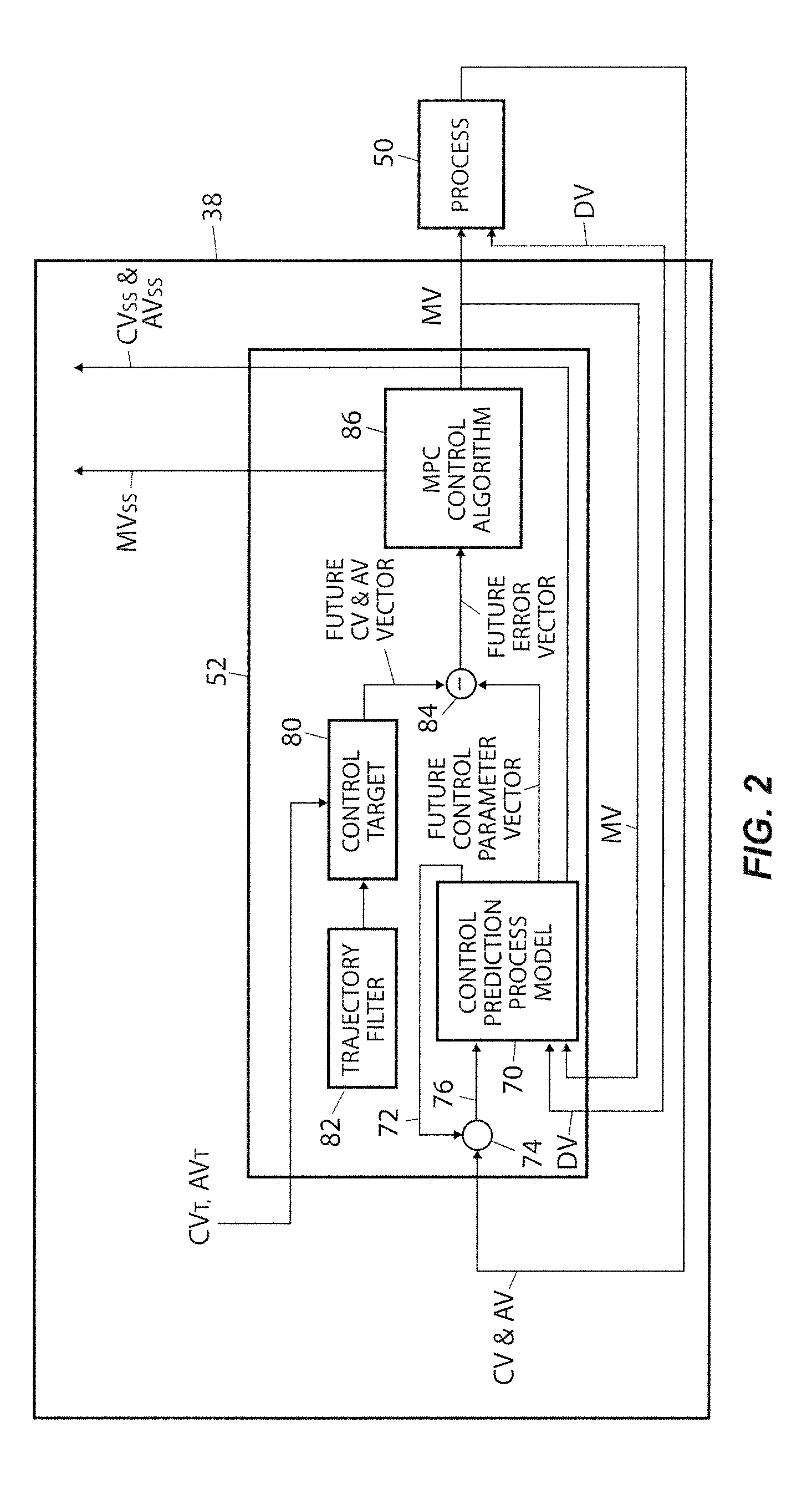

Robust adaptive model predictive controller with tuning to compensate for model mismatch

ActiveUS20090198350A1Improve immunityImprove performanceComputer controlSimulator controlClosed loopPredictive controller

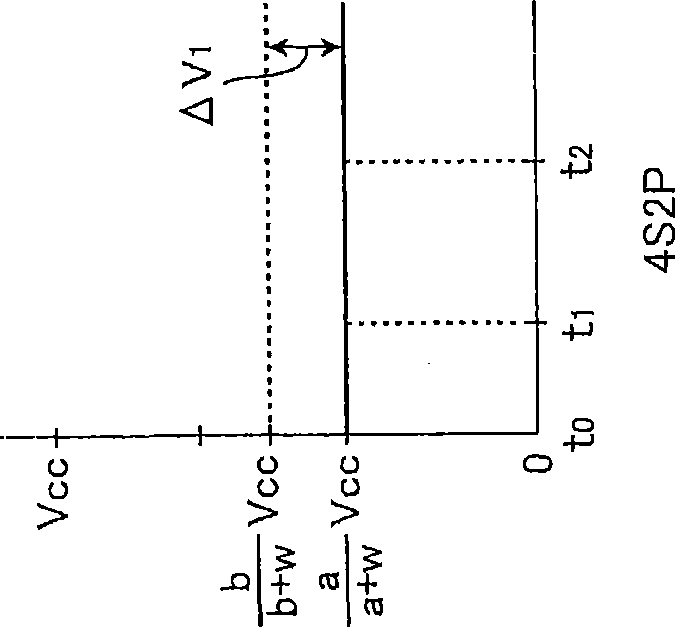

An MPC adaptation and tuning technique integrates feedback control performance better than methods commonly used today in MPC type controllers, resulting in an MPC adaptation / tuning technique that performs better than traditional MPC techniques in the presence of process model mismatch. The MPC controller performance is enhanced by adding a controller adaptation / tuning unit to an MPC controller, which adaptation / tuning unit implements an optimization routine to determine the best or most optimal set of controller design and / or tuning parameters to use within the MPC controller during on-line process control in the presence of a specific amount of model mismatch or a range of model mismatch. The adaptation / tuning unit determines one or more MPC controller tuning and design parameters, including for example, an MPC form, penalty factors for either or both of an MPC controller and an observer and a controller model for use in the MPC controller, based on a previously determined process model and either a known or an expected process model mismatch or process model mismatch range. A closed loop adaptation cycle may be implemented by performing an autocorrelation analysis on the prediction error or the control error to determine when significant process model mismatch exists or to determine an increase or a decrease in process model mismatch over time.

Owner:FISHER-ROSEMOUNT SYST INC

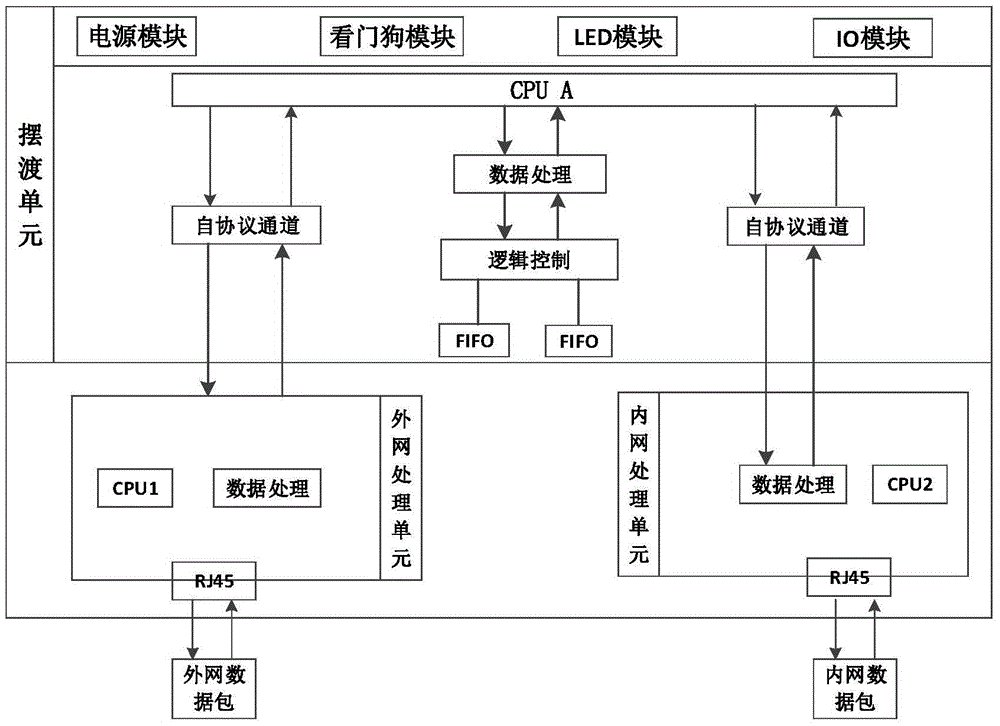

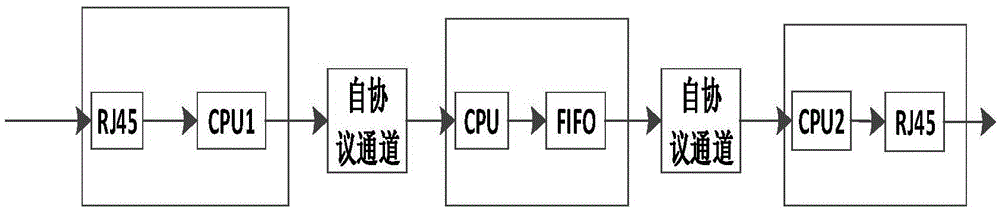

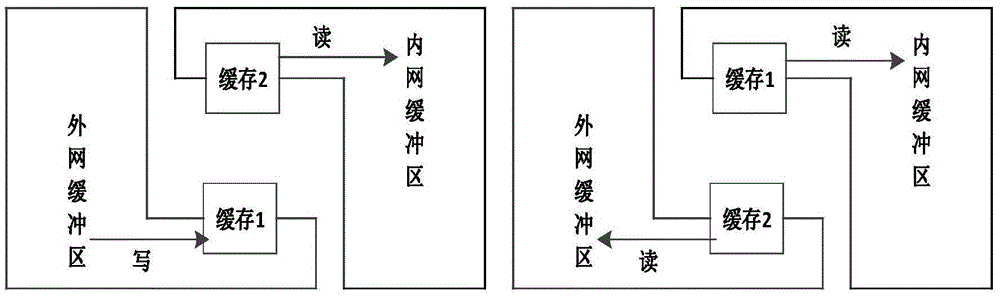

Unidirectional transmission internal and external network secure isolating gateway applicable to industrial control network

InactiveCN105656883AEnsure safetyEliminate vulnerabilityTransmissionNetwork processing unitPublic network

The invention discloses a unidirectional transmission internal and external network secure isolating gateway applicable to an industrial control network, belongs to the technical field of the industrial control network. The isolating gateway comprises an external network processing unit, a data ferry unit and an internal network processing unit; the external network processing unit is connected with the internal network processing unit through the data ferry unit; and the software and the hardware of the internal and external networks are isolated at the same time; the external network processing unit, the data ferry unit and the internal network processing unit are completely independent and communicate through a self-defined protocol. The isolating gateway is advantaged by that the isolating gateway is used for realizing unidirectional data transmission by the industrial control network and an upper computer public network under a physical isolating condition; identity authentication and content filter are controlled through a plug-in mode; and the reliability and the security of the industrial control network are ensured to the maximum extent.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

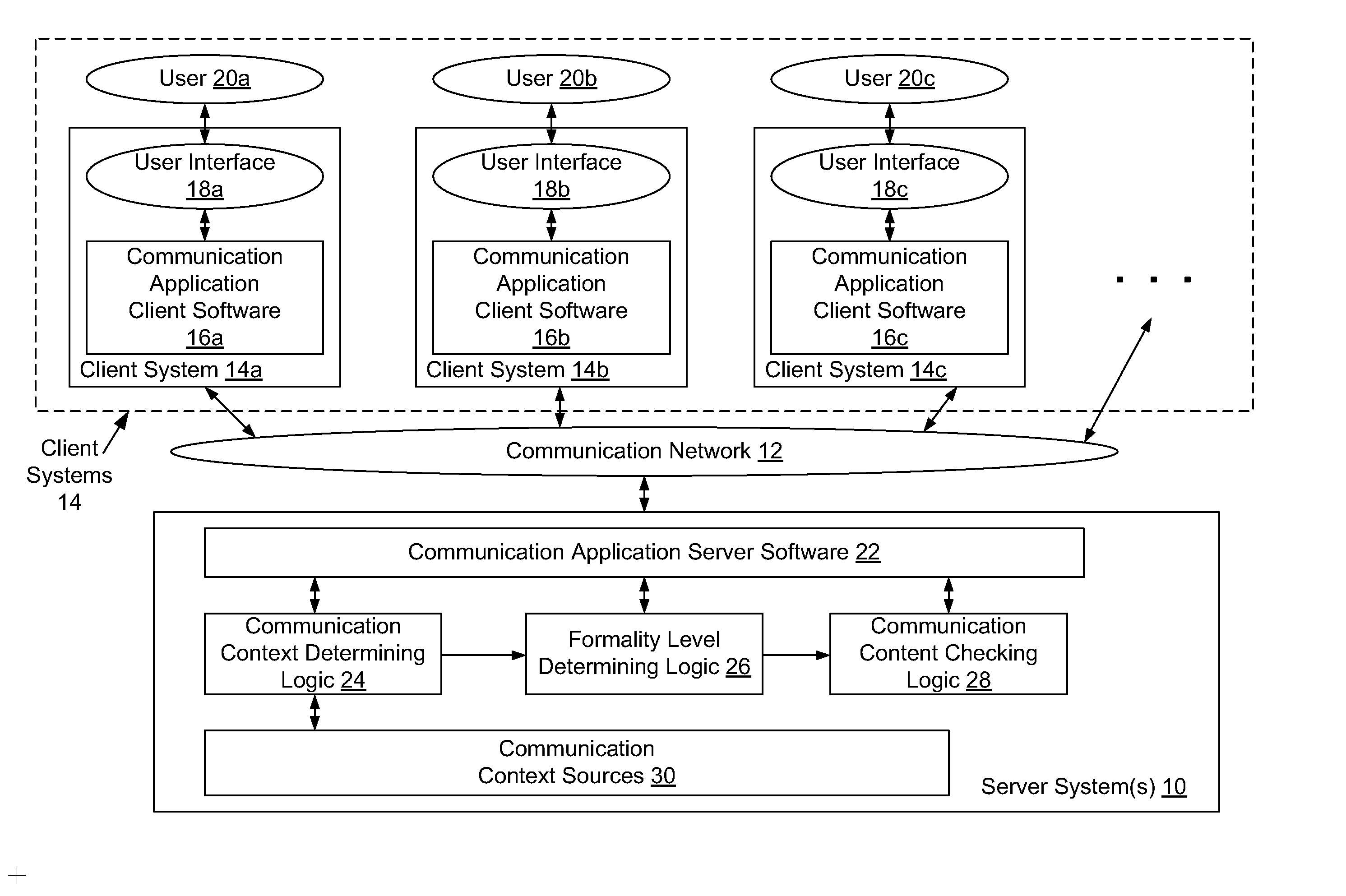

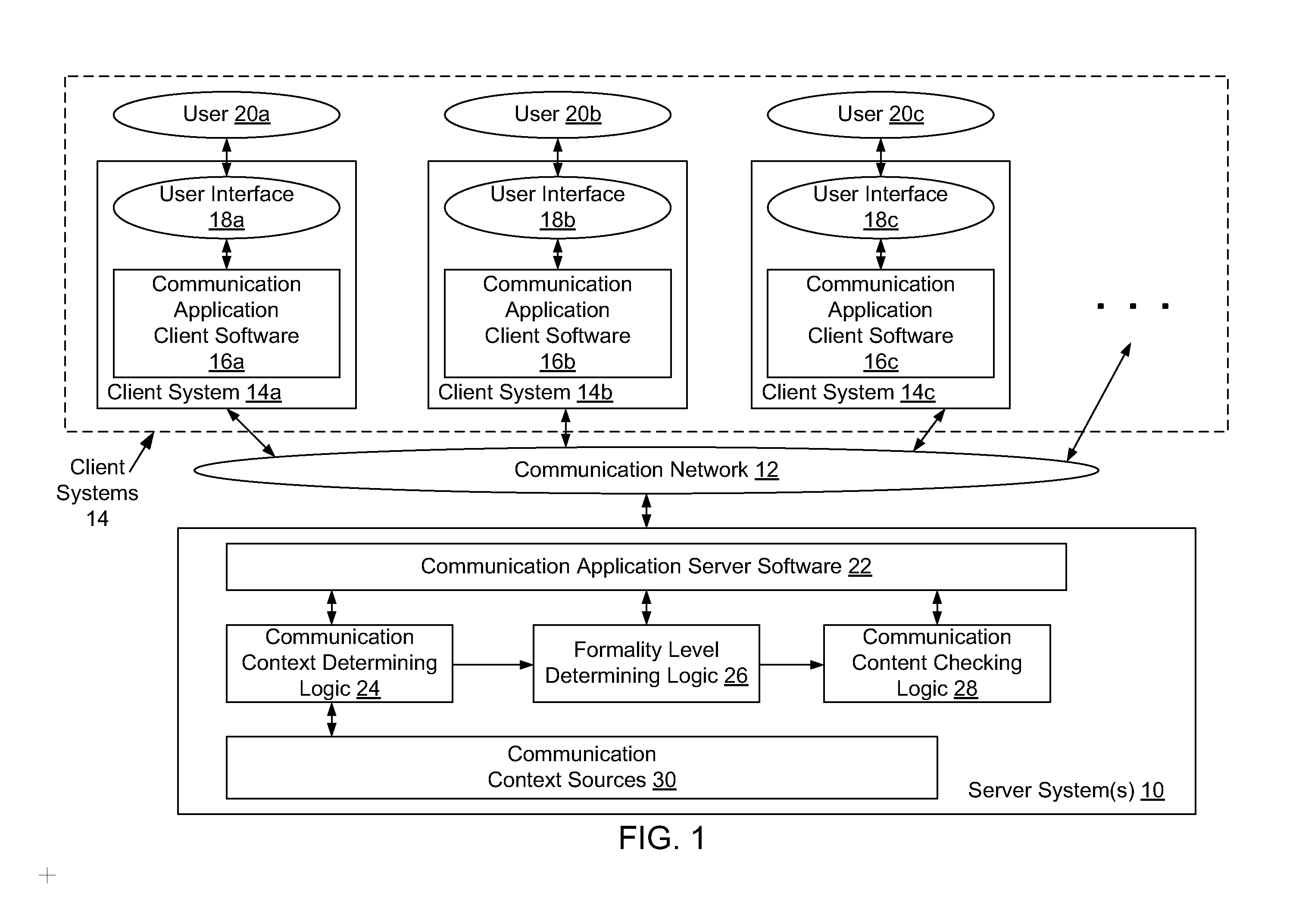

Method and system for providing communication context specific formality control

InactiveUS20080126481A1Reduce frustrationIncrease speedMultiple digital computer combinationsData switching networksProfessional relationshipGeolocation

A system for automatically providing different levels of formality controls in a communication is disclosed, in which a formality level is determined based on a current communication context. The formality level is used to enable an appropriate level of automatic checking of the communication contents. The determination of a formality level for a communication may be based on any specific context information regarding the participants and / or contents of a communication. including but not limited to the relative positions of participants within an organizational hierarchy (“organizational distance”), the professional relationships of the participants (e.g. service provider to client / customer), the frequency of communications between participants, the geographic locations of participants, the number of previous errors in the communication contents, configurable participant preferences, express communication settings by participants, etc. The determined formality level may be used to enable any specific type or level of automatic message contents checking, including but not limited to various types and levels of spell checking (e.g. location specific spell checking), grammar checking, acronym substitution, cultural filtering, etc. The disclosed system may determine organisational distances based on the contents of user directories, such as lightweight directory access protocol (LDAP) directories.

Owner:IBM CORP

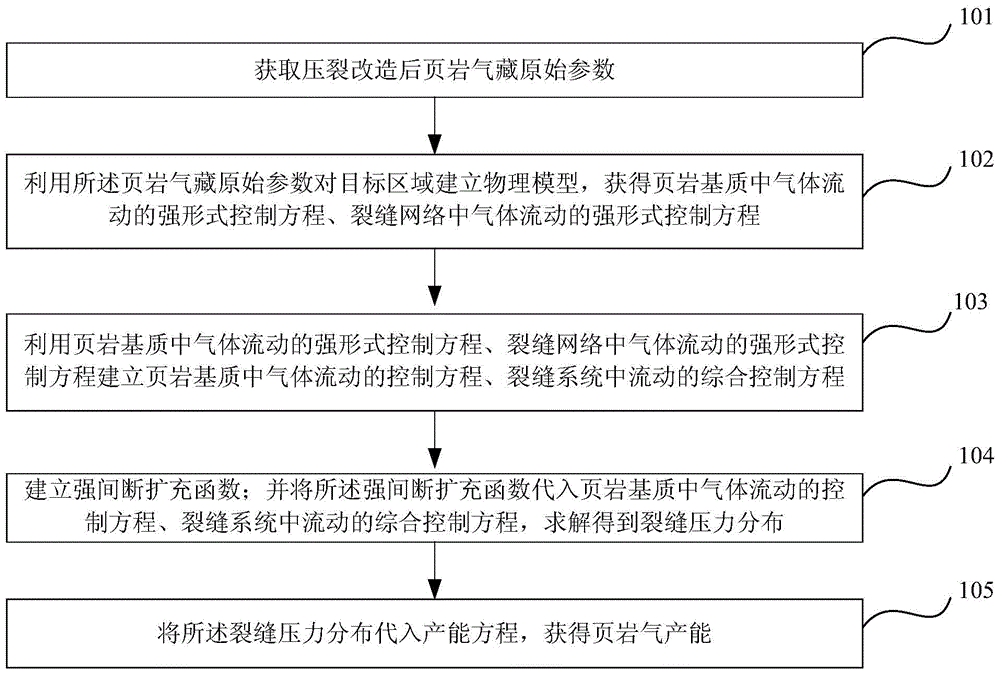

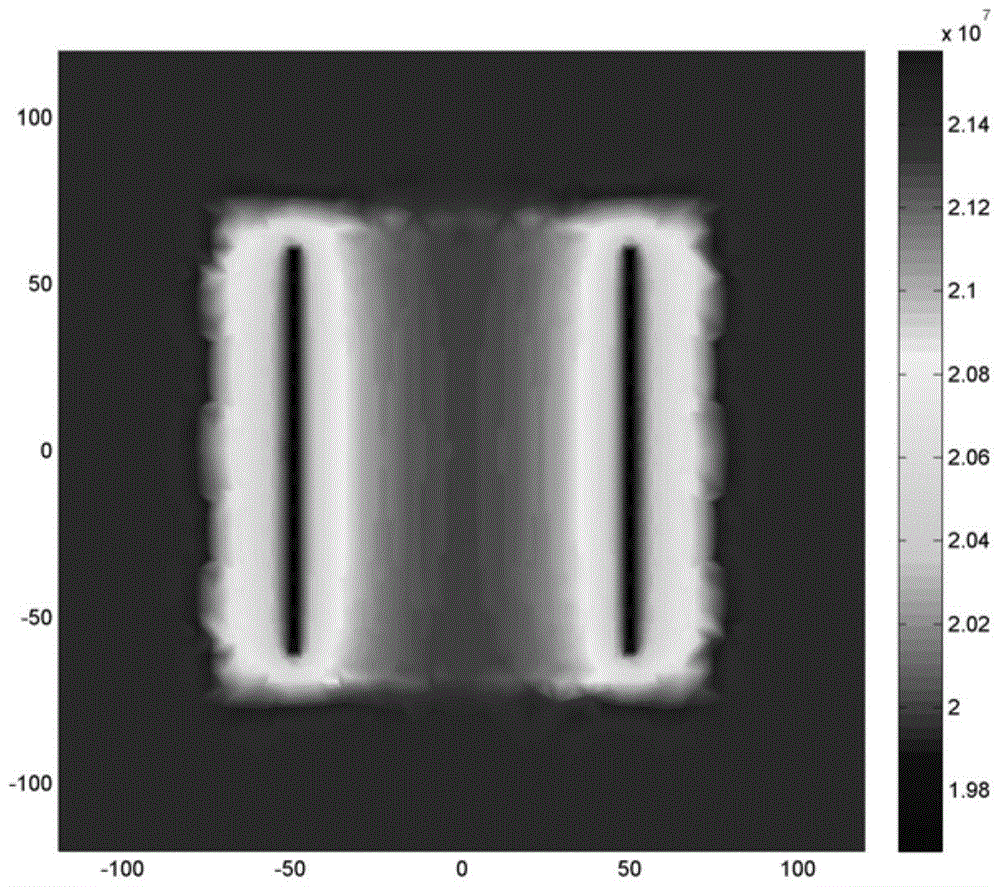

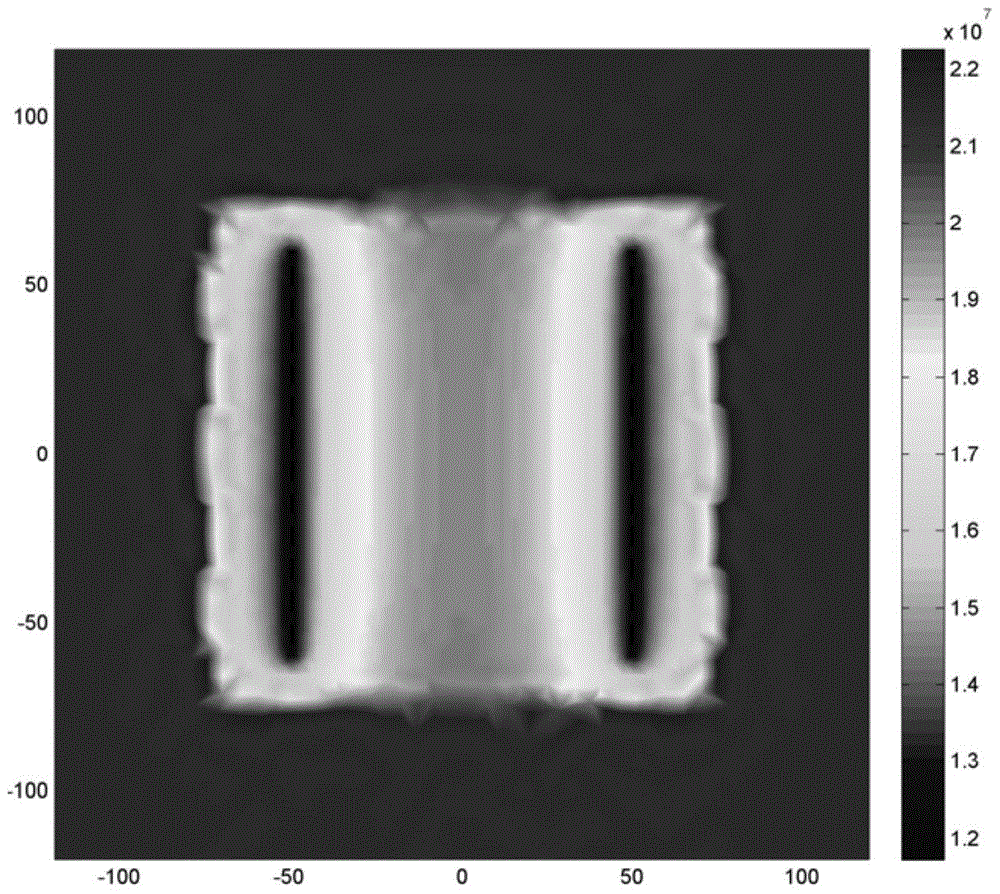

Method and apparatus for predicting multi-section fracturing productivity of shale gas reservoir horizontal well

ActiveCN105046006AReduce computing costAccurate predictionSpecial data processing applicationsPredictive methodsPhysical model

The invention relates to a method and an apparatus for predicting multi-section fracturing productivity of a shale gas reservoir horizontal well. The prediction method comprises: obtaining shale gas reservoir original parameters after fracturing modification; establishing a physical model for a target region by utilizing the shale gas reservoir original parameters, and obtaining a strong form control equation of gas flow in a shale matrix and a strong form control equation of gas flow in a fracture network; establishing a control equation for the gas flow in the shale matrix and a comprehensive control equation for the flow in a fracture system by utilizing the strong form control equation of the gas flow in the shale matrix and the strong form control equation of the gas flow in the fracture network; establishing a strong discontinuous expansion function; substituting the strong discontinuous expansion function to the control equation for the gas flow in the shale matrix and the comprehensive control equation for the flow in the fracture system to calculate fracture pressure distribution; and substituting the fracture pressure distribution into a productivity equation to obtain shale gas productivity.

Owner:PETROCHINA CO LTD

Wrapping sheet

Owner:TOYODA GOSEI CO LTD

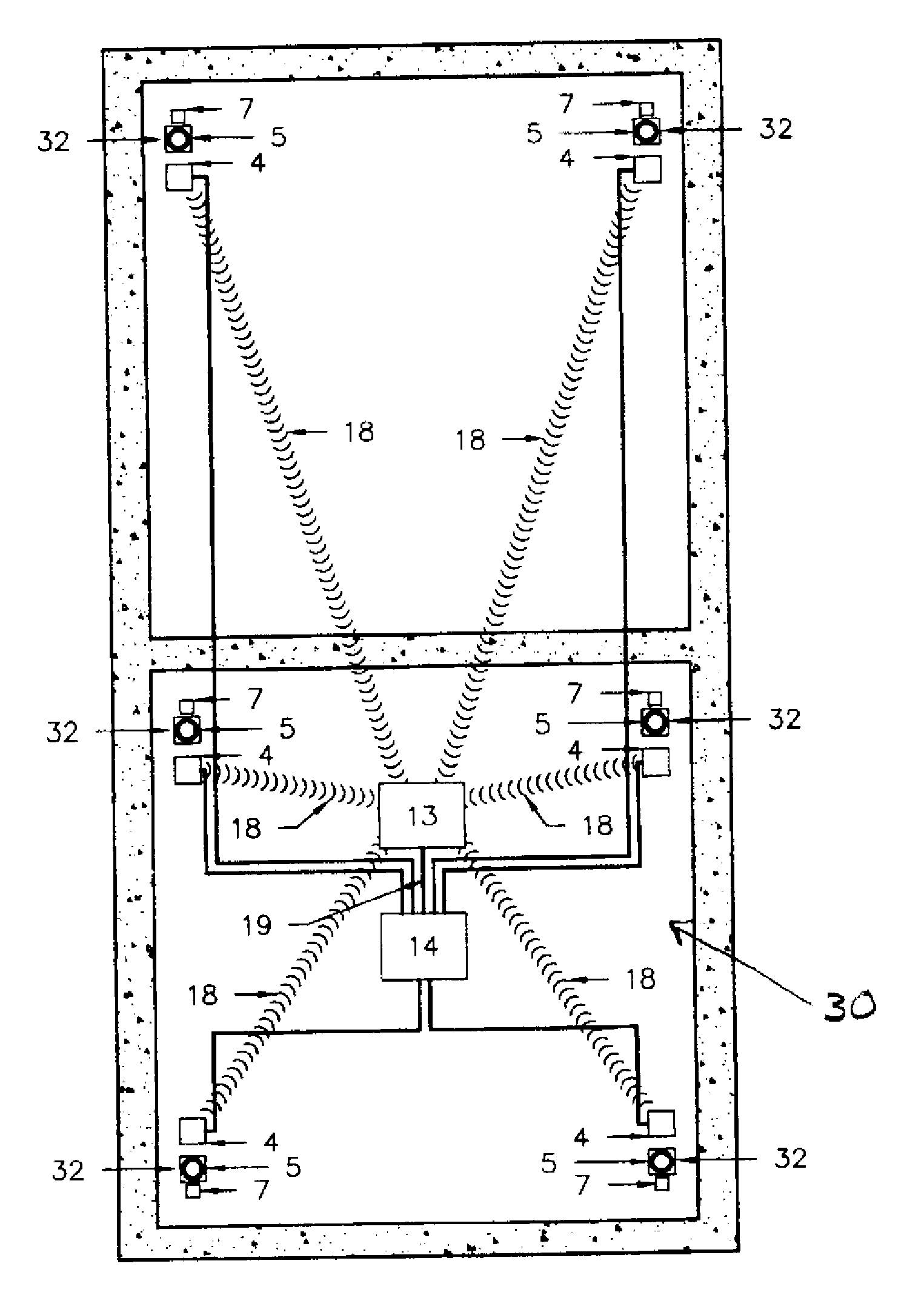

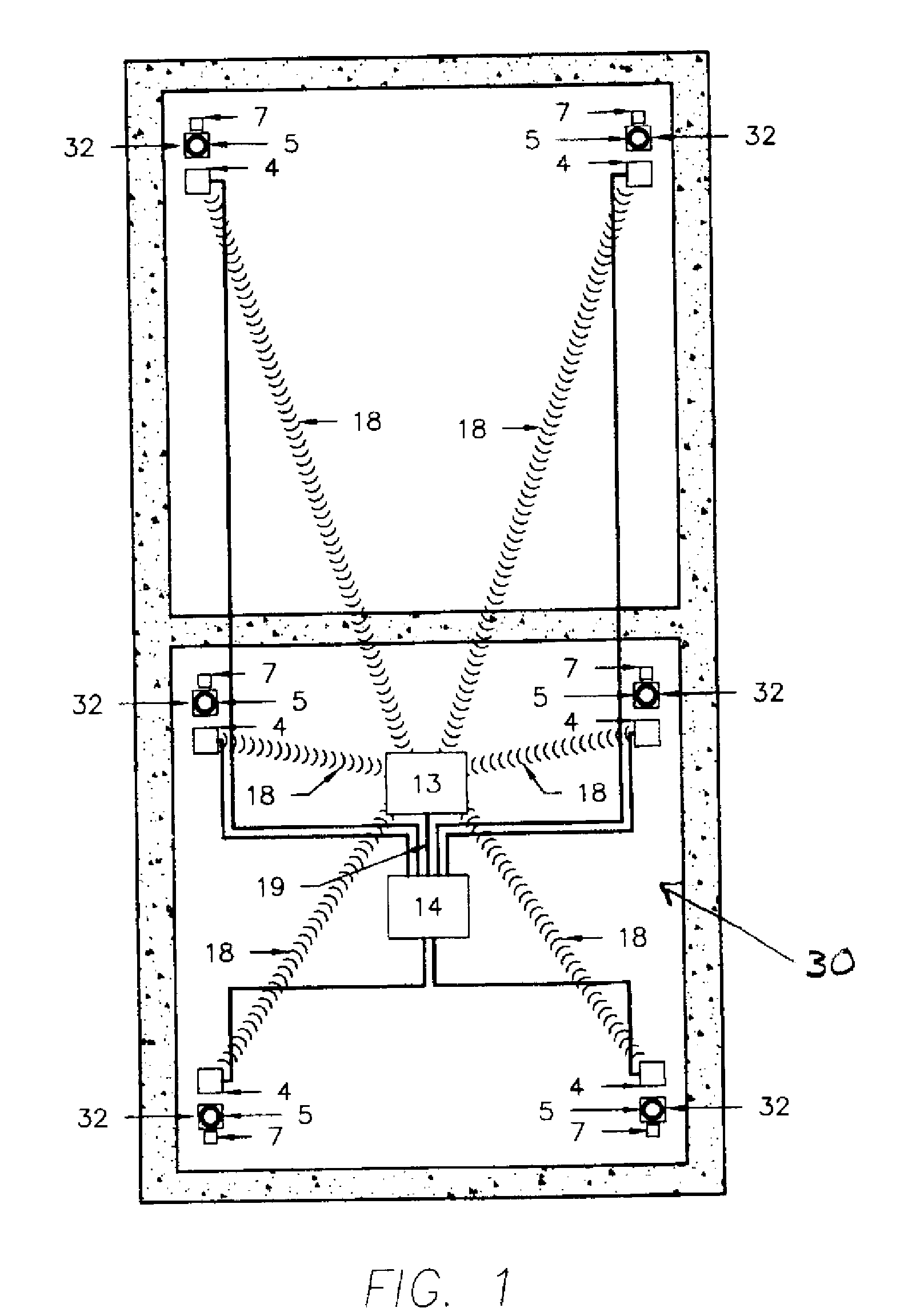

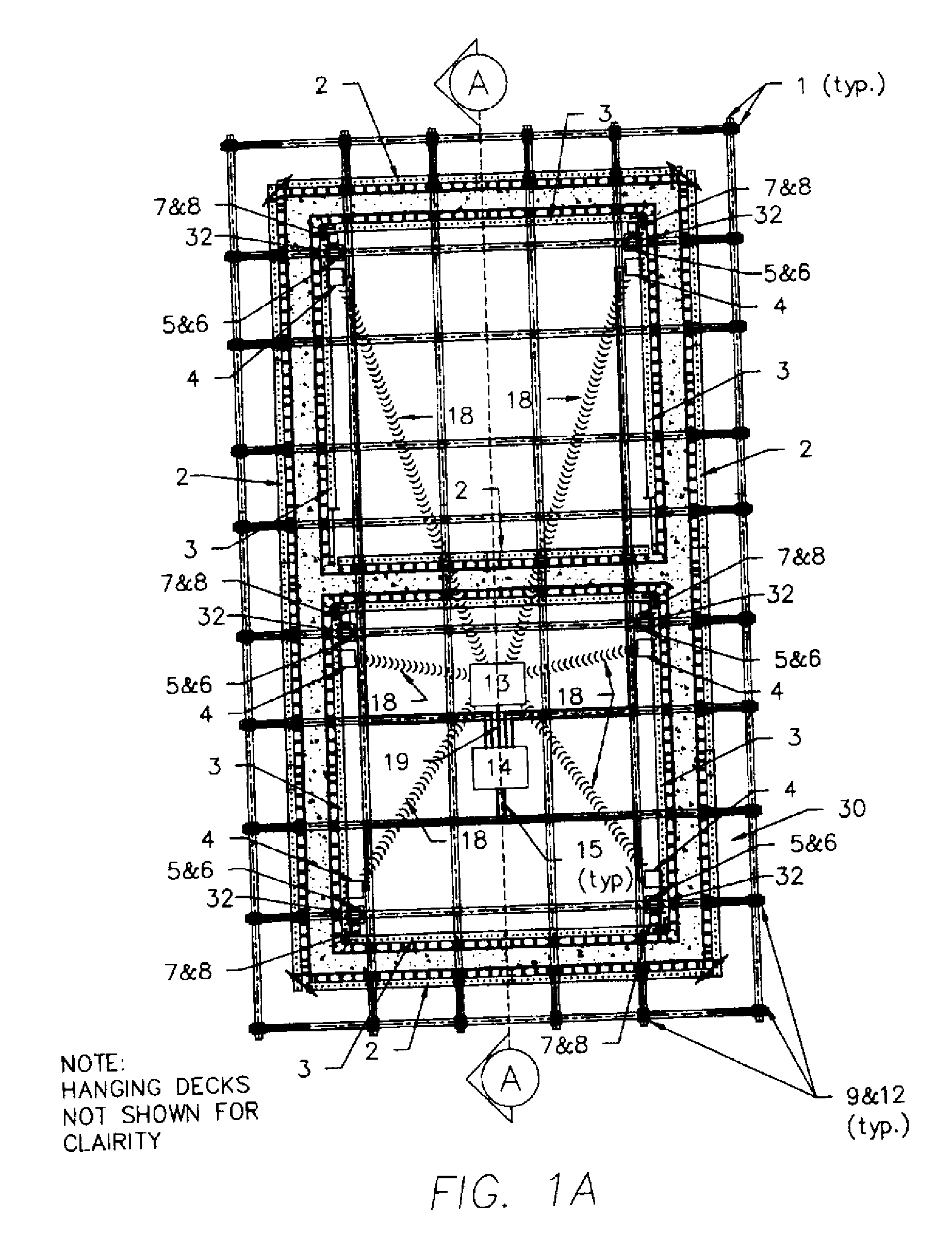

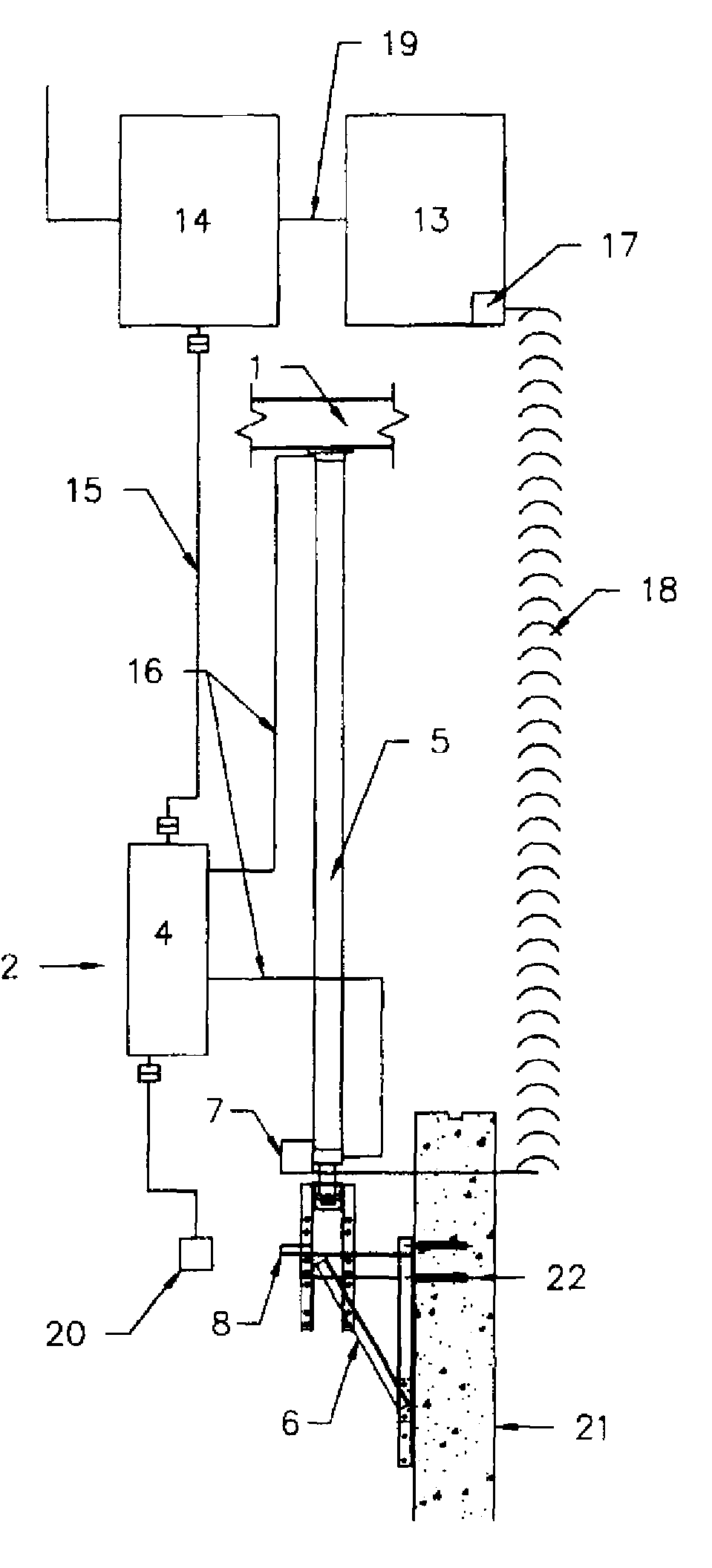

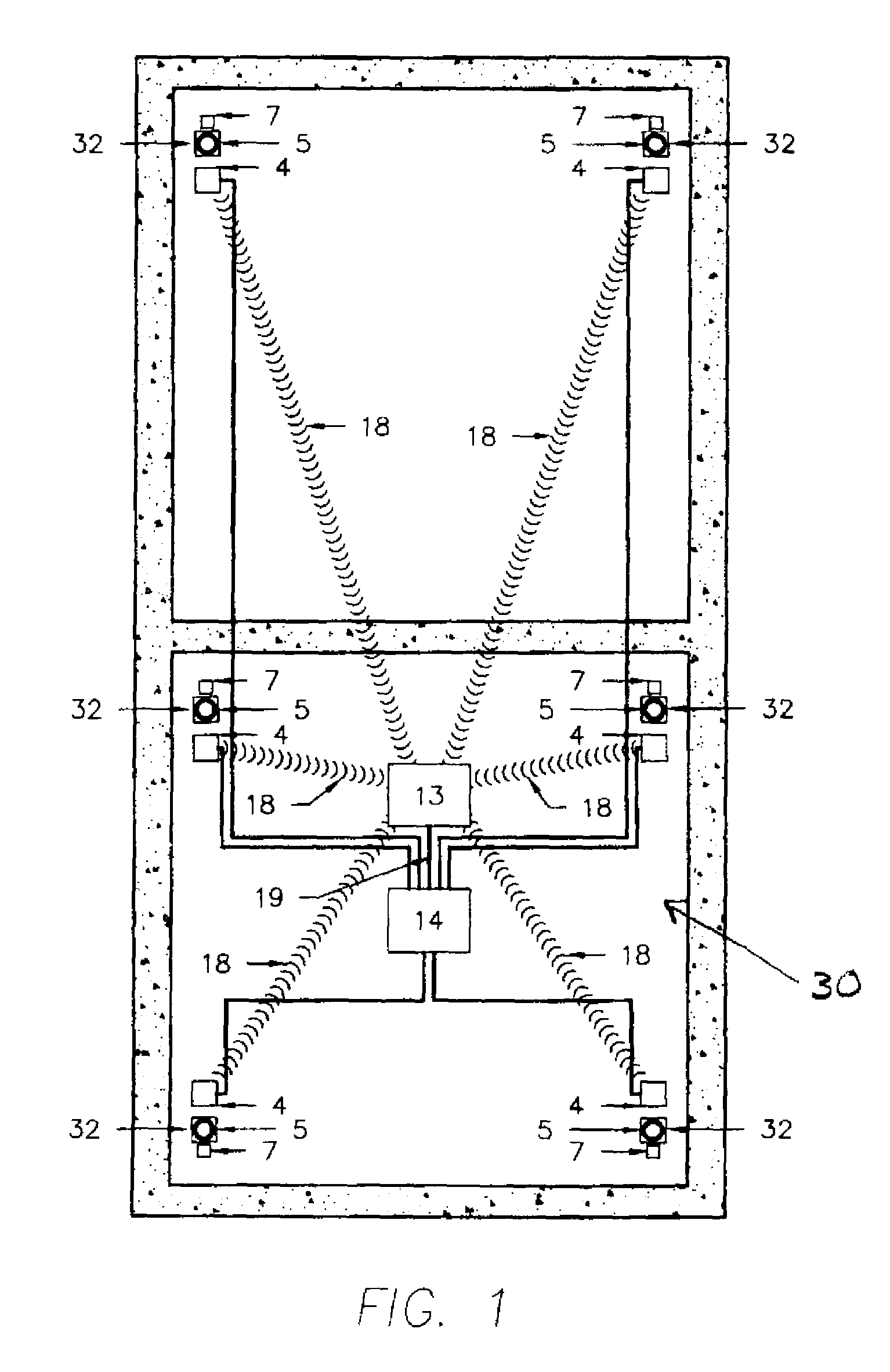

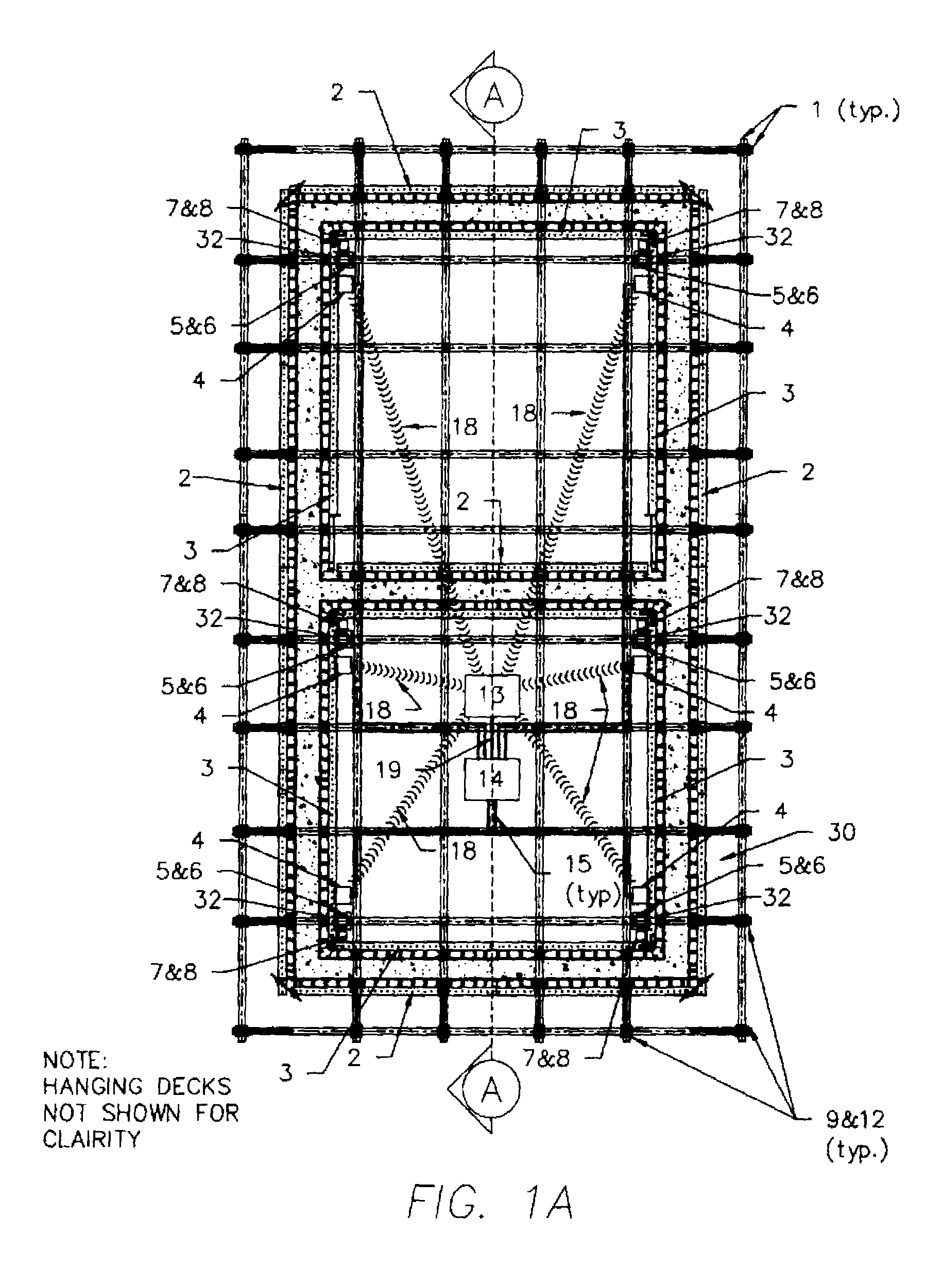

Self-Raising Form Control System and Method

ActiveUS20090041879A1Precise and even lifting of liftIncrease heightAssembly machinesFeeding apparatusMeasurement deviceControl system

A self-raising form control system and method is provided that that may be used to form elevator shafts and other vertical building structures. The apparatus includes one or more form elements for defining an area to receive a formable material, such as concrete. Each element is attached to the form structure. A lift apparatus is provided for lifting the form elements. The lift apparatus comprises a measurement device for measuring the position of said lift apparatus relative to a fixed point. The lift apparatus is connected to the form structure. A control unit is provided for controlling the lift apparatus. The control unit is signal connected to the measurement device and is signal connected to the lift apparatus.

Owner:FORMING CONCEPTS INC

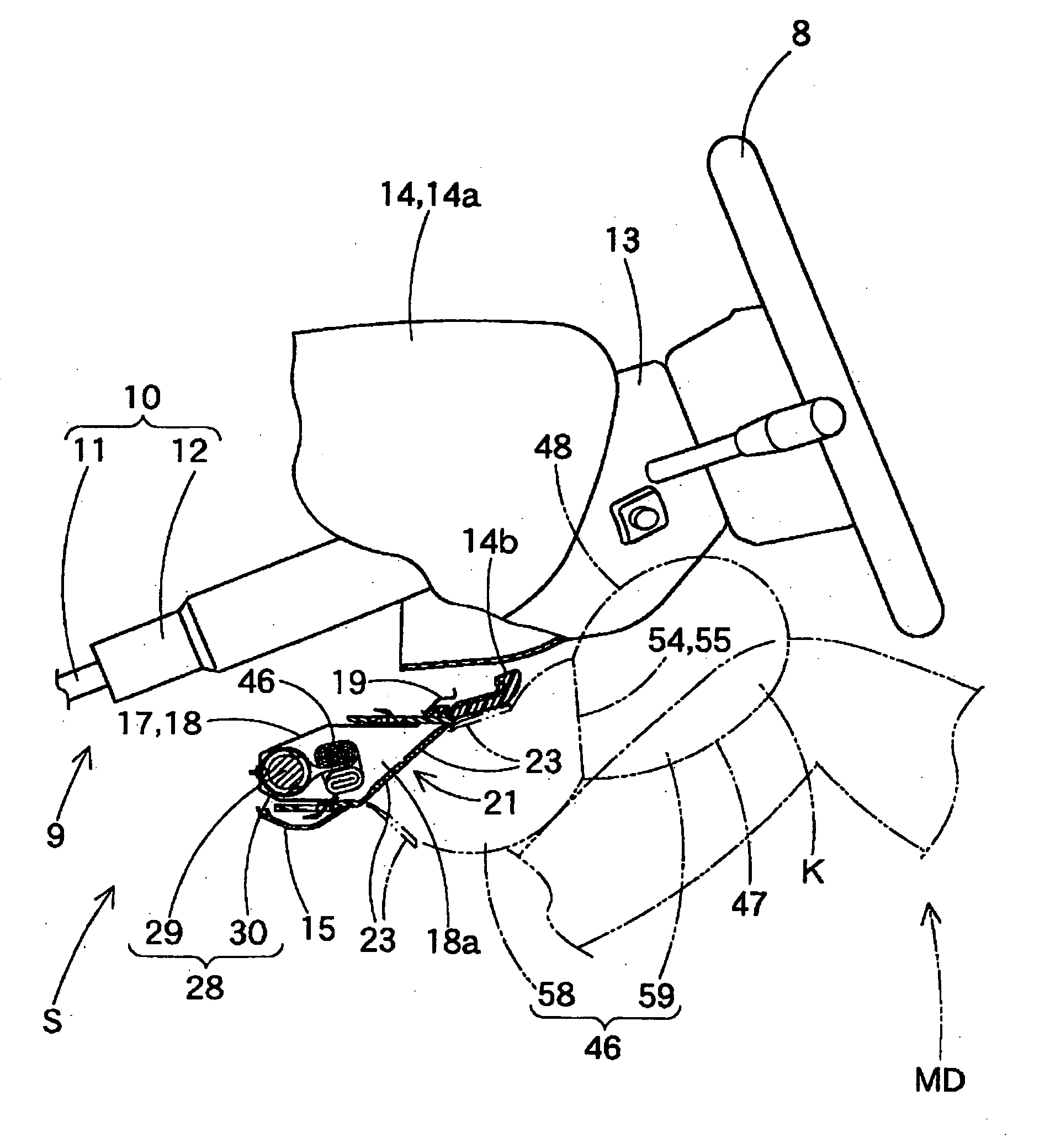

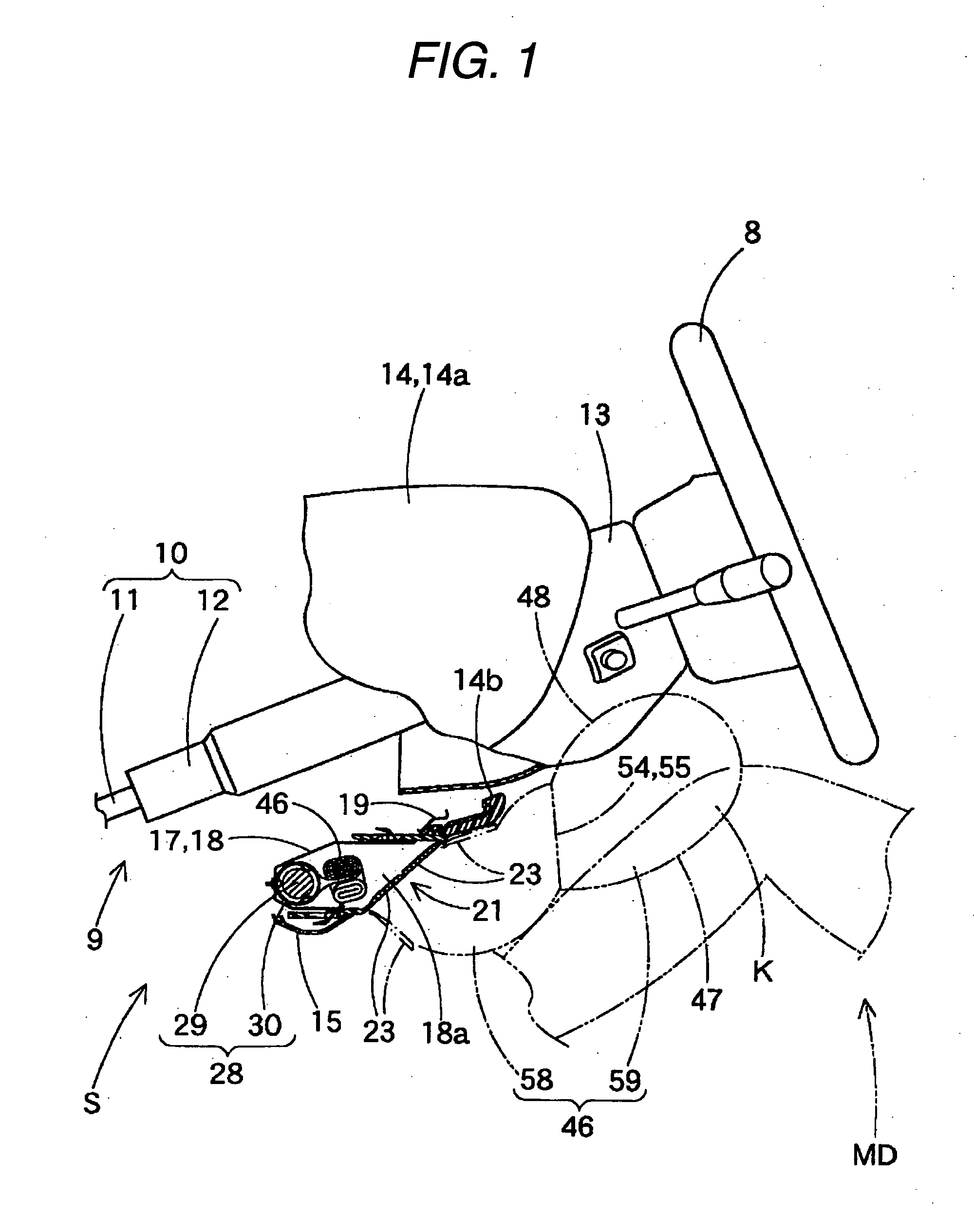

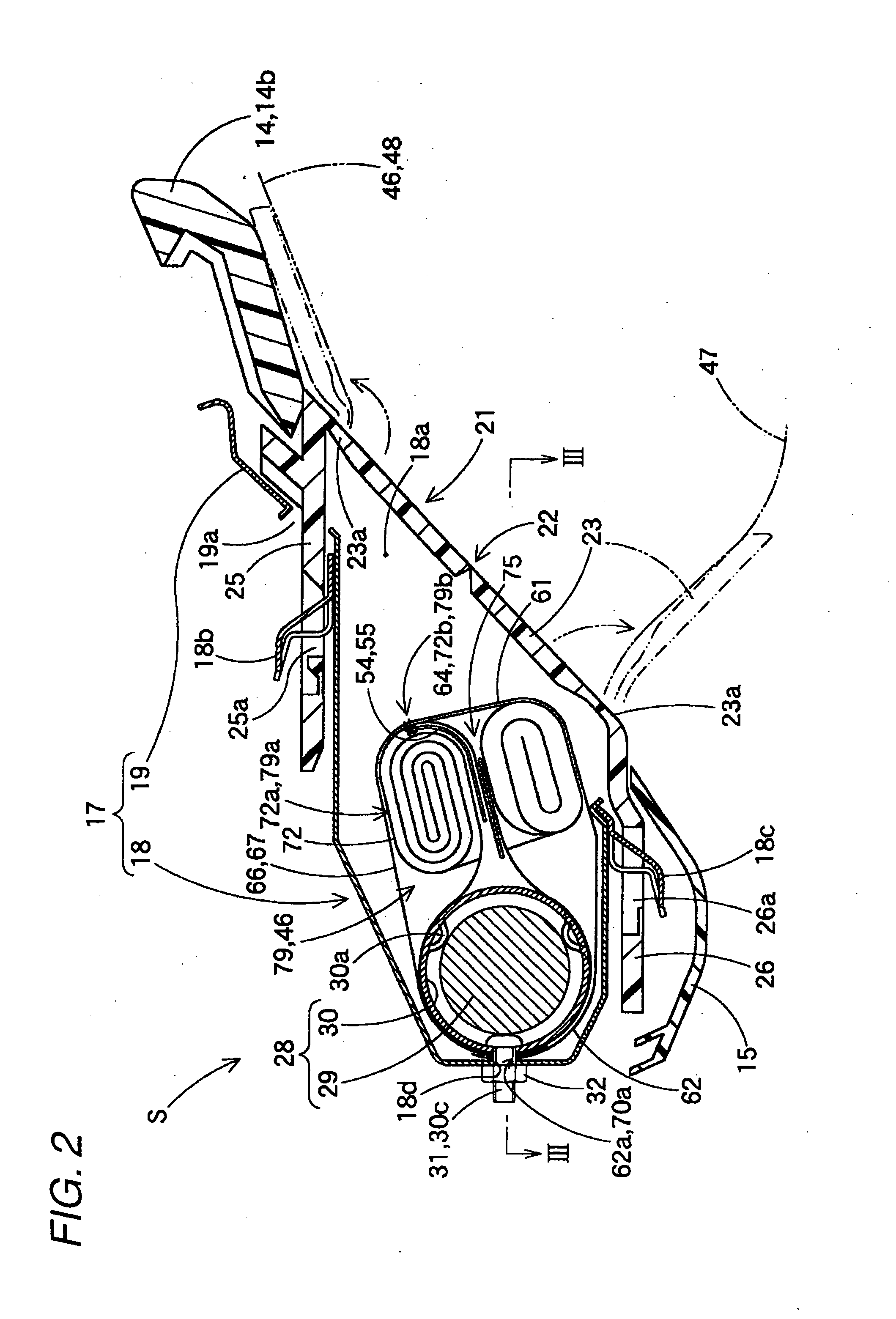

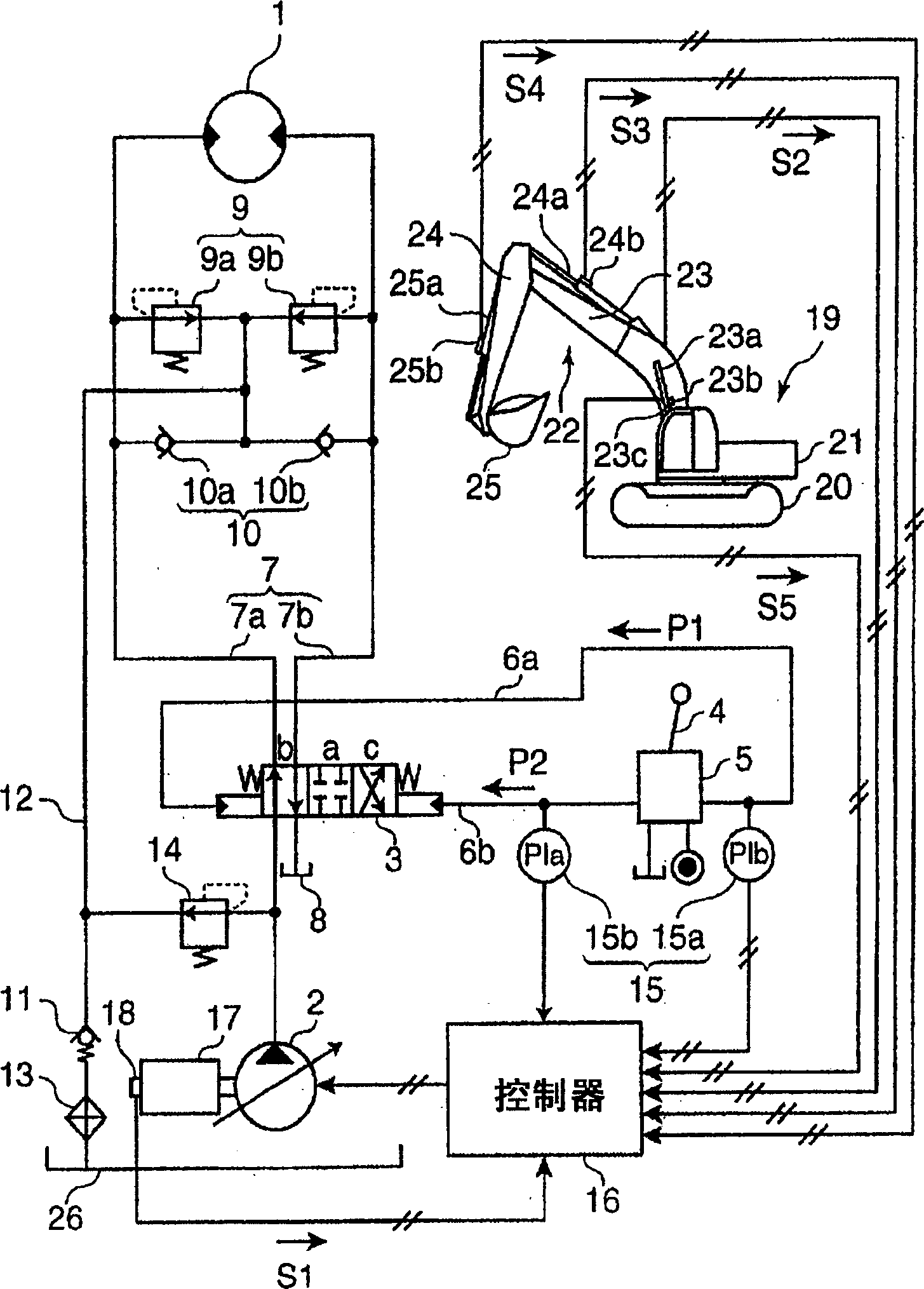

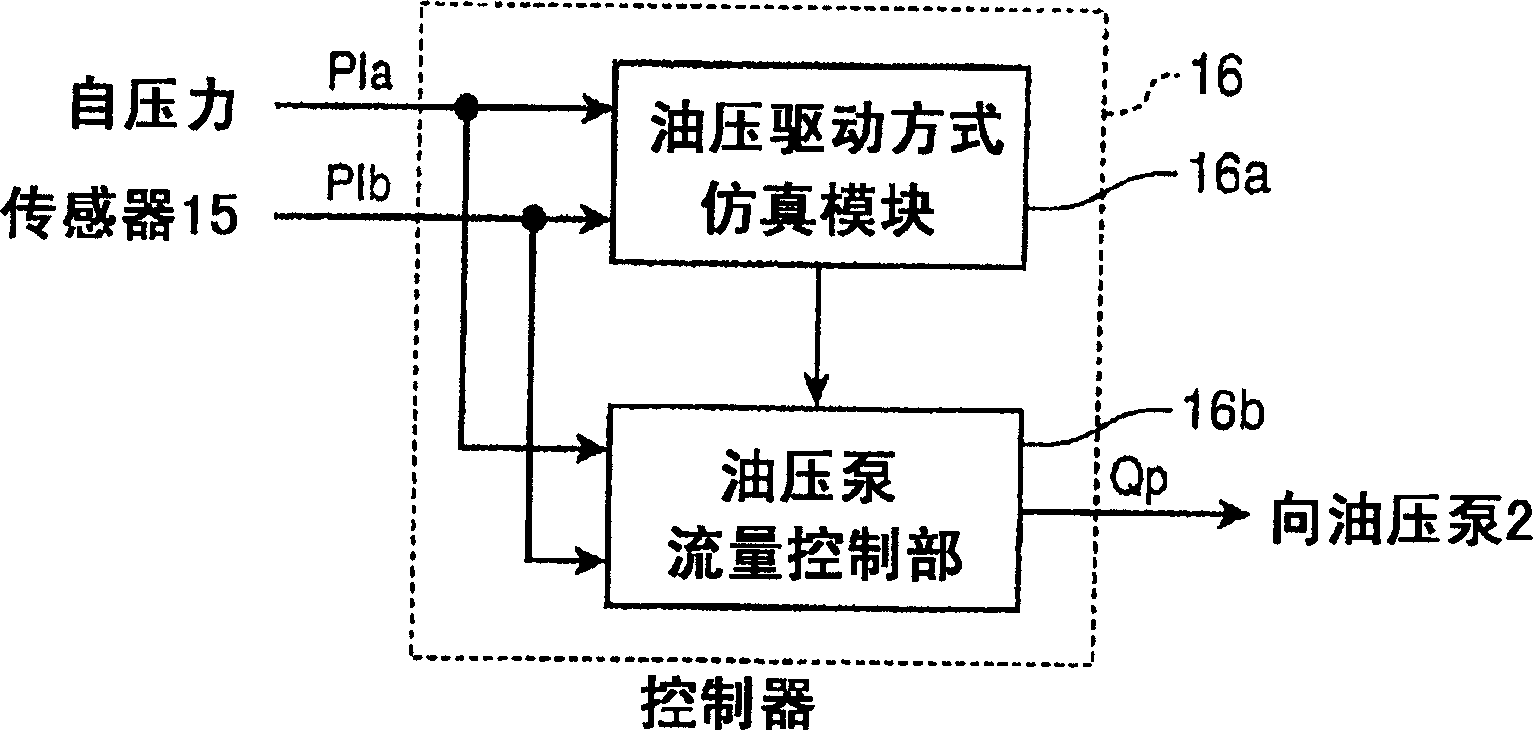

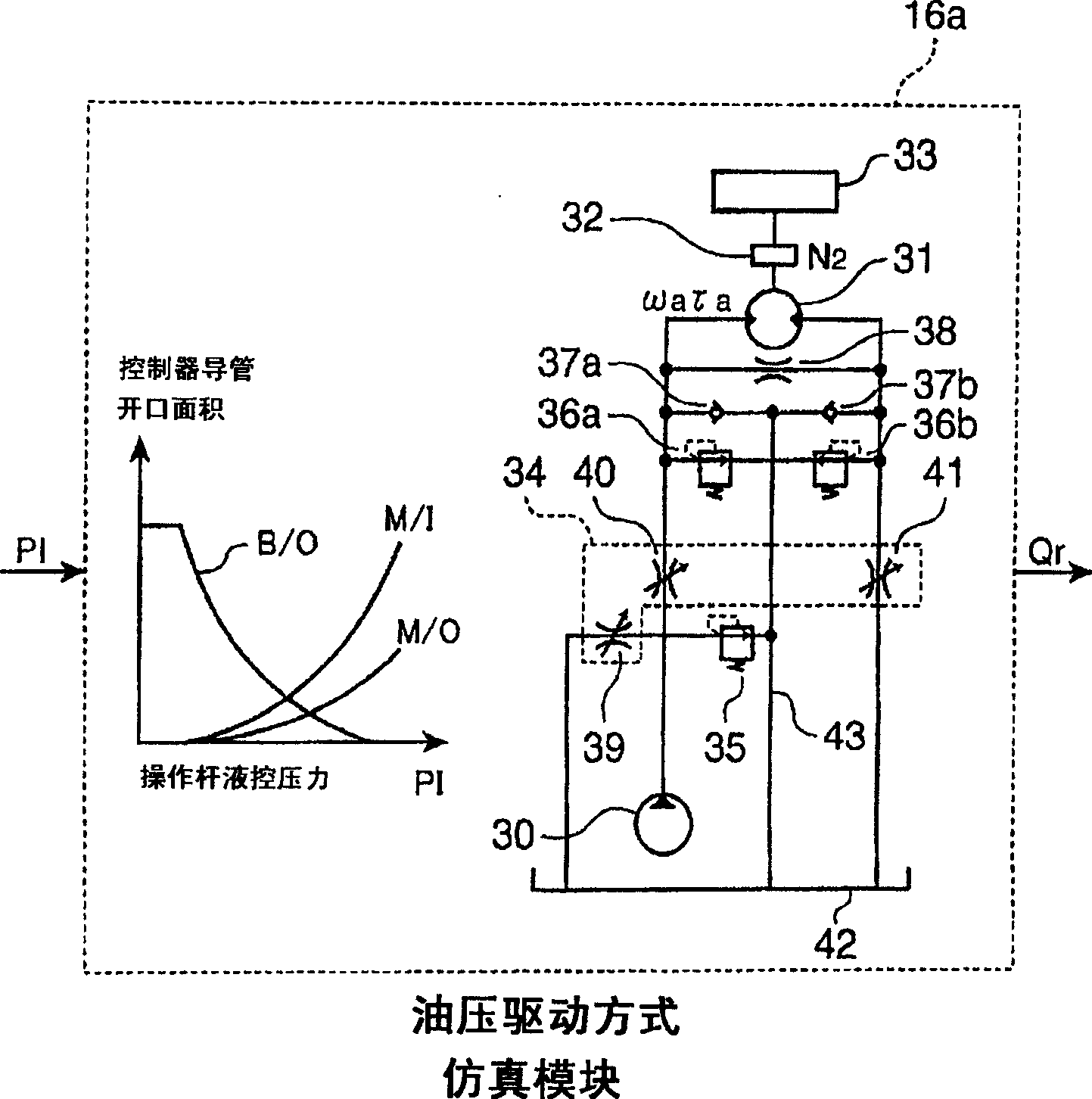

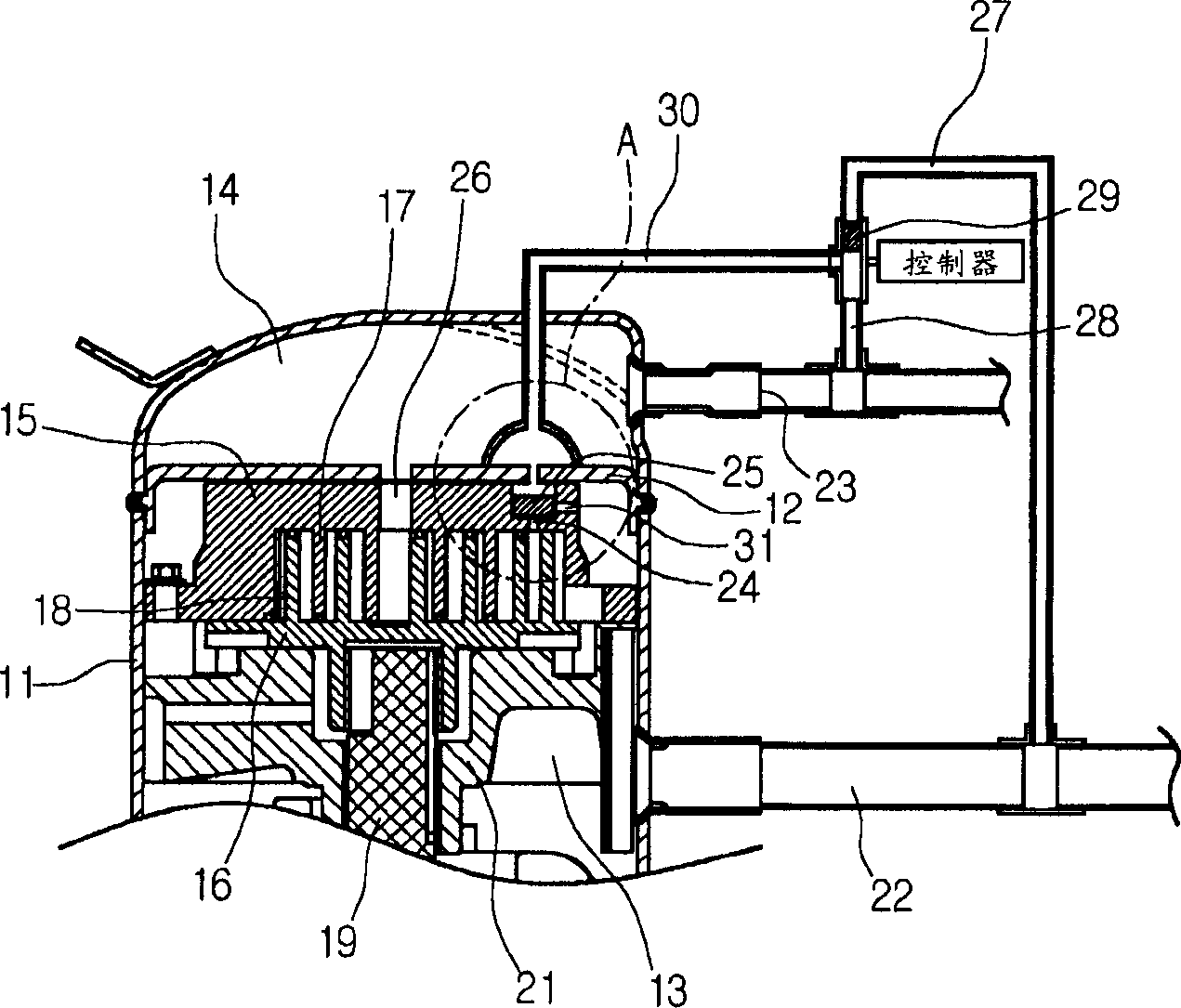

Control device for working machine

A control device for a working machine according to the present invention comprises a capacity variable pump for supplying working oil, a controller for controlling the discharge amount of the pump, a control valve for controlling the working oil discharged from the pump, a hydraulic actuator operated by the working oil from the control valve, an operating lever for operating the hydraulic actuator, and a relief valve to be operated when the pressure of the working oil is a relief pressure or more. The controller has a dynamic emulation model of a hydraulic driving device, and is constituted to estimate the pressure oil flow rate passing through the relief valve from the emulation model according to the operation amount of the operating lever, and to control the pump flow rate of the pump so that the relief flow rate estimation value gets close to zero. According to this, relief loss can be precisely reduced without generating a response delay or pressure loss, and the power can be saved.

Owner:KOBELCO CONSTR MASCH CO LTD

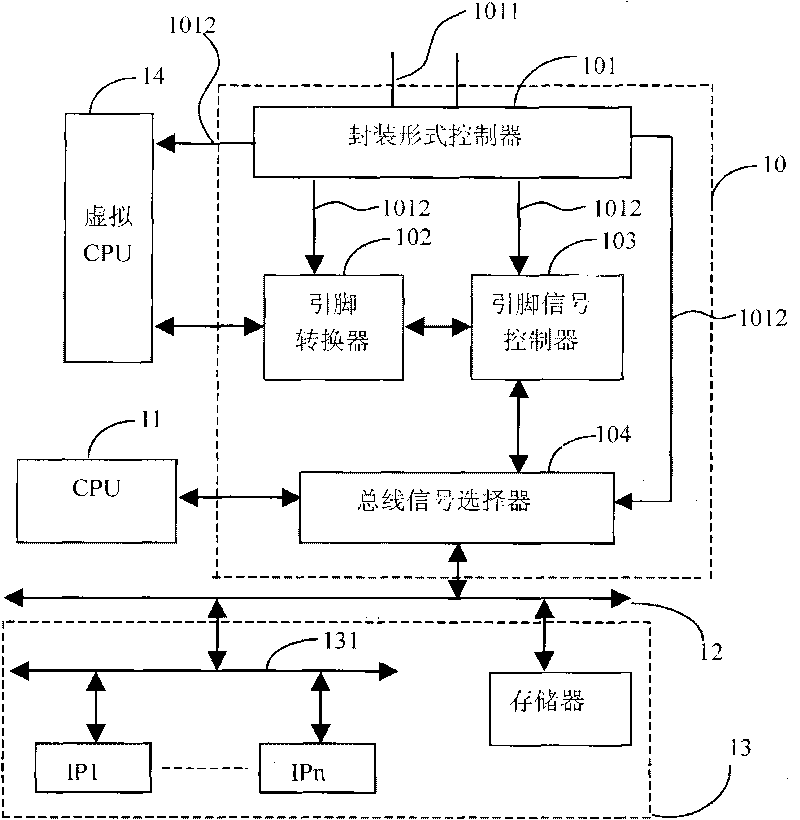

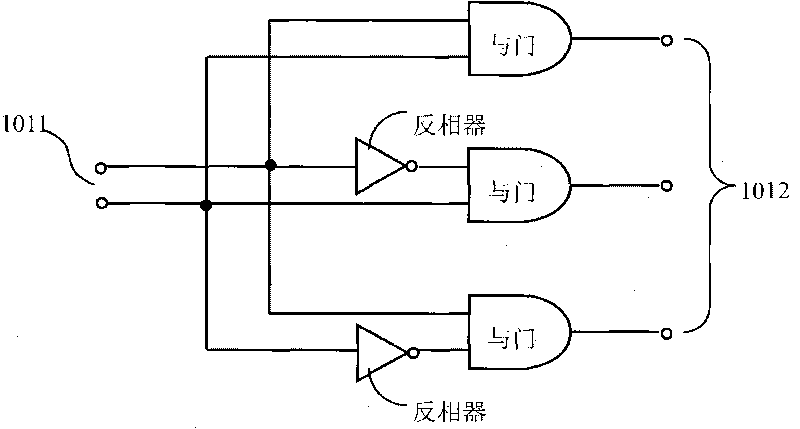

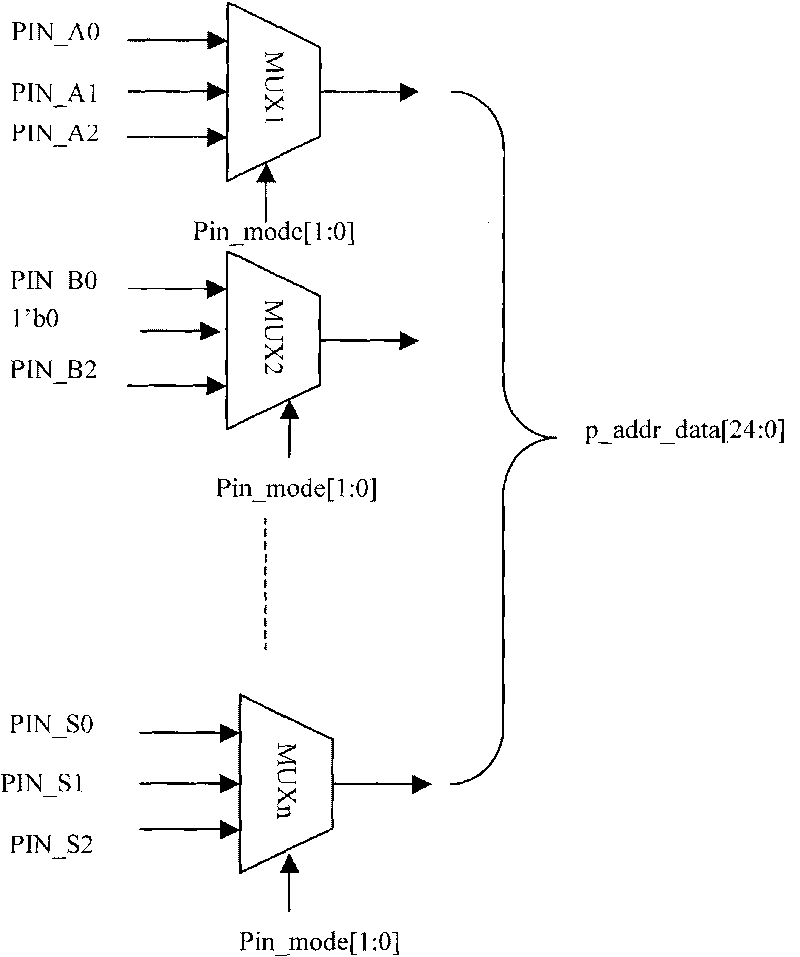

Configurable on-chip testing module supporting encapsulation of different pins of chip

ActiveCN101706552AImprove general performanceWide range of testsElectronic circuit testingComputer moduleTest procedures

The invention discloses a configurable on-chip testing module supporting the encapsulation of a chip through different pins, which consists of an encapsulation form controller (101), a pin converter (102), a pin signal controller (103) and a bus signal selector (104). The testing module can support the encapsulation form of the multifunctional chip that the different pins are adopted for different pieces of application. The configurable on-chip testing module supporting the encapsulation of the chip through the different pins is characterized in that: 1, the testing module is strong in universality and wide in testing range and can almost test all other functional modules except an internal CPU; 2, the testing module is less logical and can ignore influence on the area of the chip, thus the production cost of the chip is not increased; and 3, a virtual CPU (an excitation controller) adopted in testing is arranged outside the chip, thus the development on testing programs is more flexible and more relevant.

Owner:苏州国芯科技股份有限公司

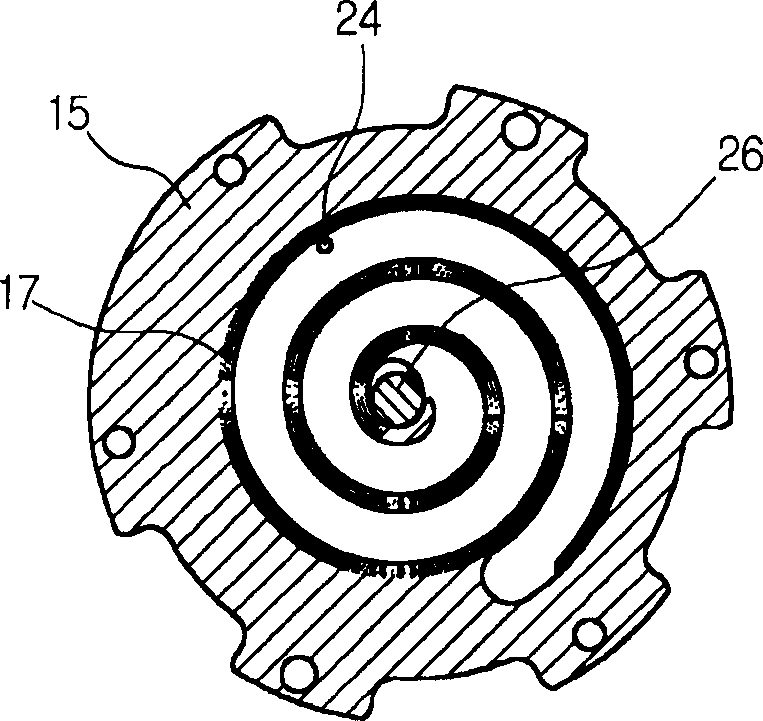

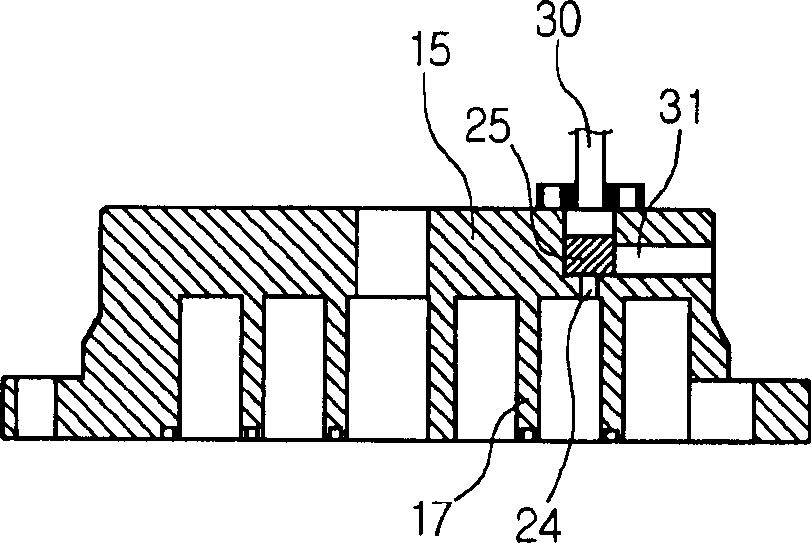

Variable capacity scroll compressor

InactiveCN1576603AControl action stateChange the amount of compressionRotary piston pumpsRotary piston liquid enginesDischarge pressureMechanical engineering

Owner:LG ELECTRONICS INC

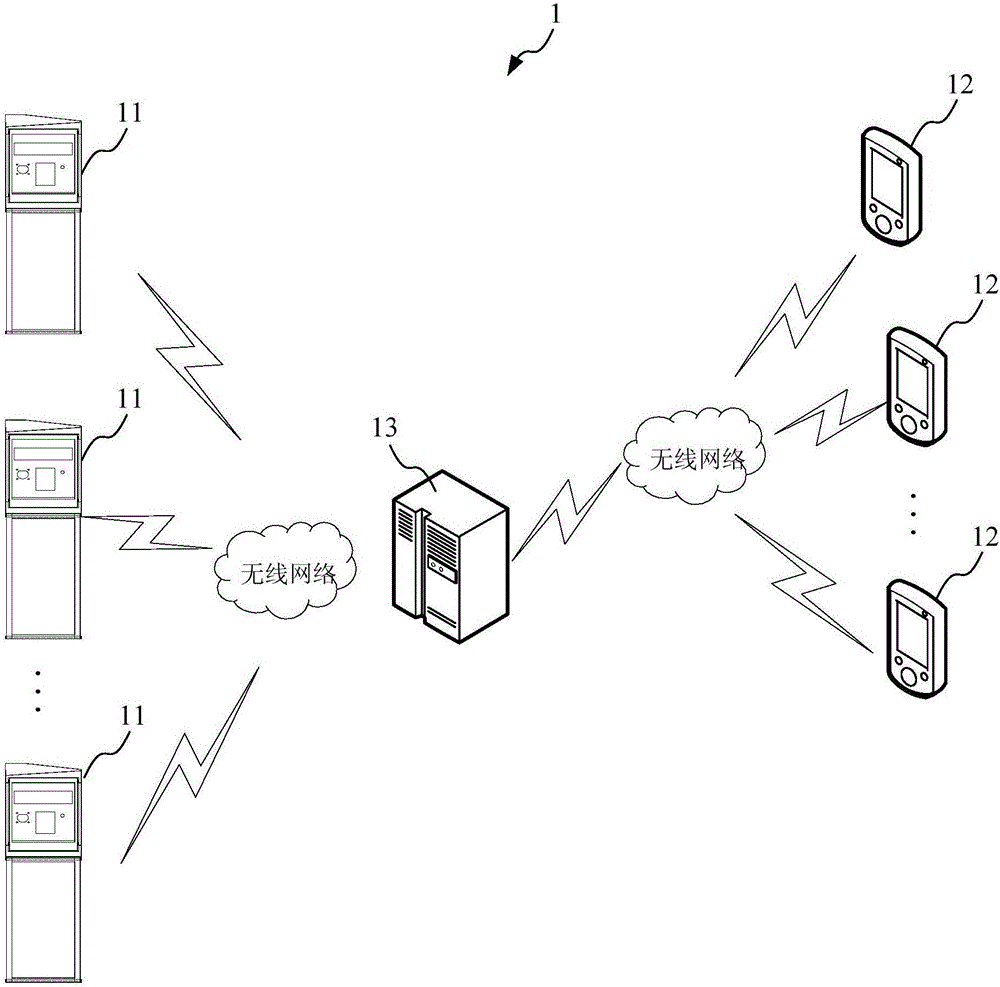

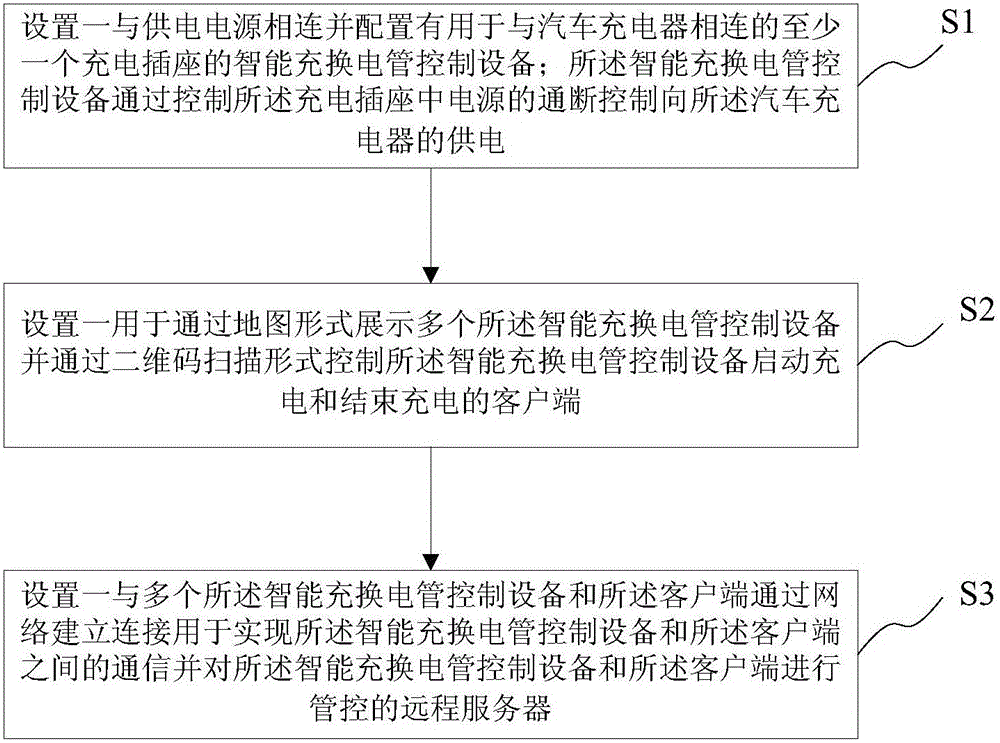

Intelligent electric charging manage control method and system

ActiveCN105844802AIncrease profitEfficient managementElectric vehicle charging technologyApparatus for hiring articlesElectricityCharge control

The invention provides an intelligent electric charging manage control method and system, and applies to the electric vehicle charging manage and control; the system comprises the following elements: intelligent charging control equipment connected with a power supply and configured with at least one charging socket used for connecting with vehicle chargers, wherein the intelligent charging control equipment controls the power on / off in the charging sockets so as to control the power supplied to the vehicle chargers; a client end using a mapping mode to display many intelligent charging control equipment and using a two dimension code scanning mode to control the intelligent charging control equipment to start and stop charging; a remote server connected with the intelligent charging control equipment and client ends through the network and used for realizing communication between the intelligent charging control equipment and the client end, and managing and controlling the intelligent charging control equipment and the client ends. The intelligent electric charging manage control method and system can control the power supply to connect / disconnect with the vehicle chargers, and can provide charging management and control services for vehicle chargers of different types and models.

Owner:SHANGHAI LECHONG NEW ENERGY EQUIP CO LTD

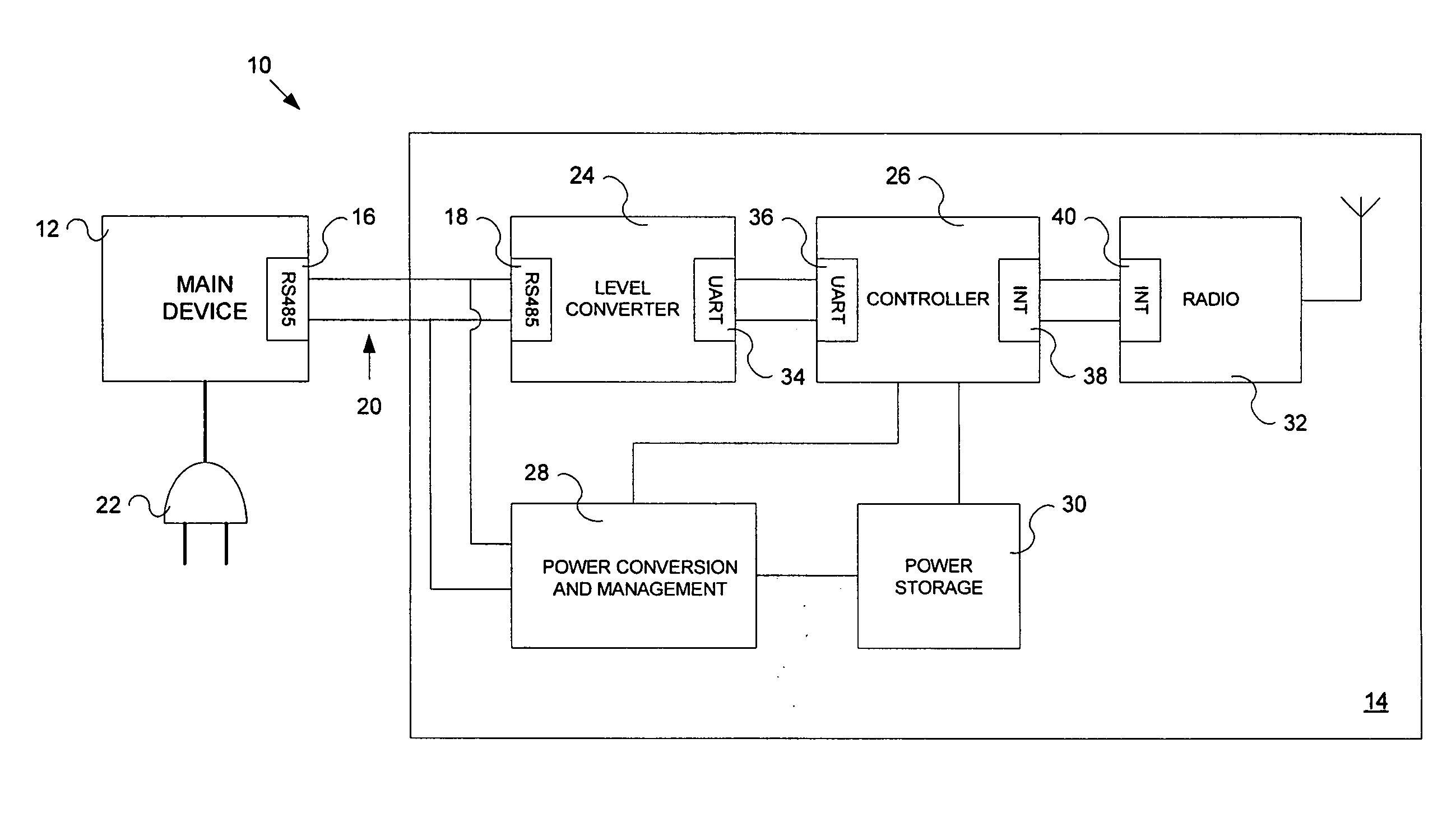

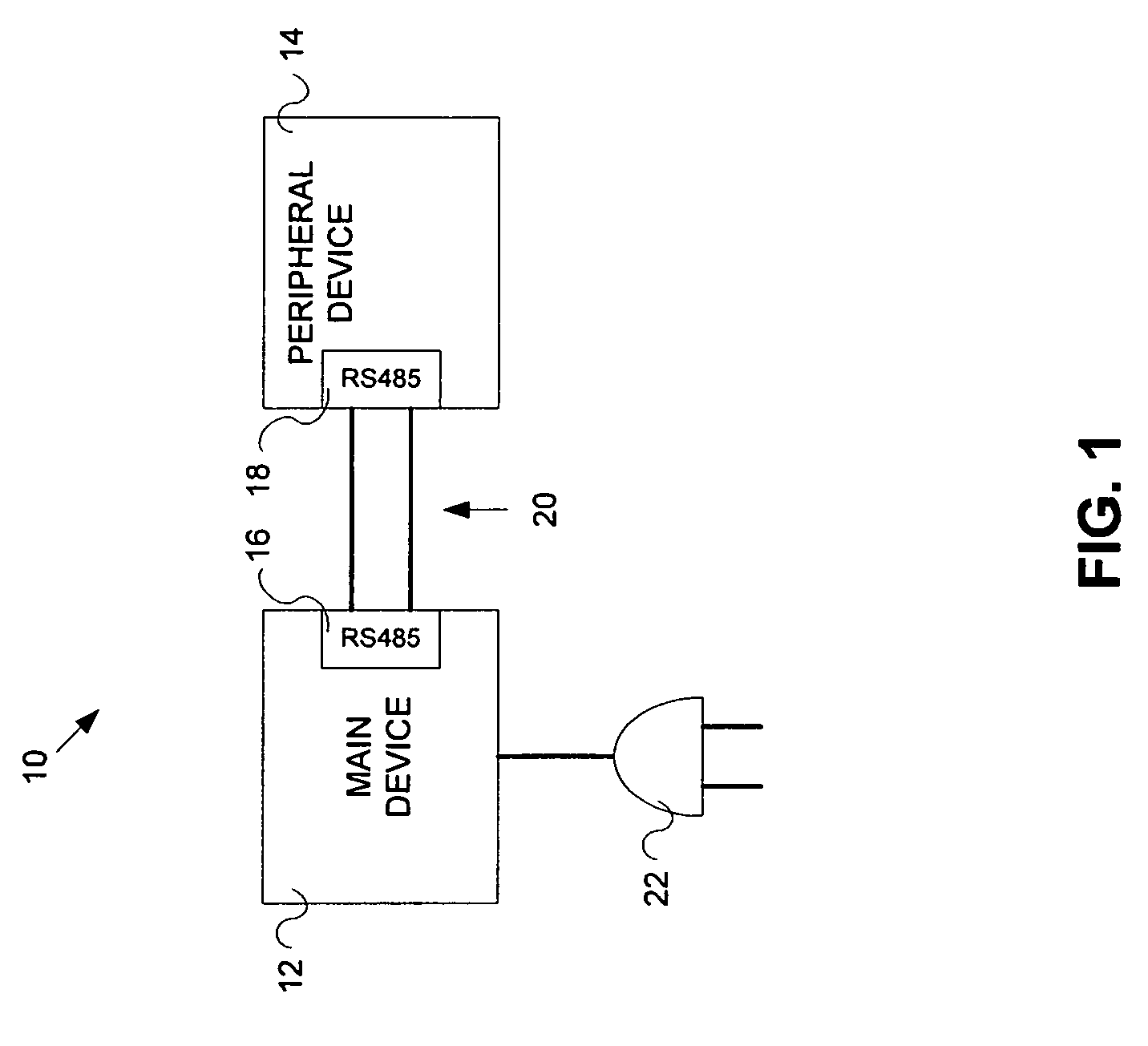

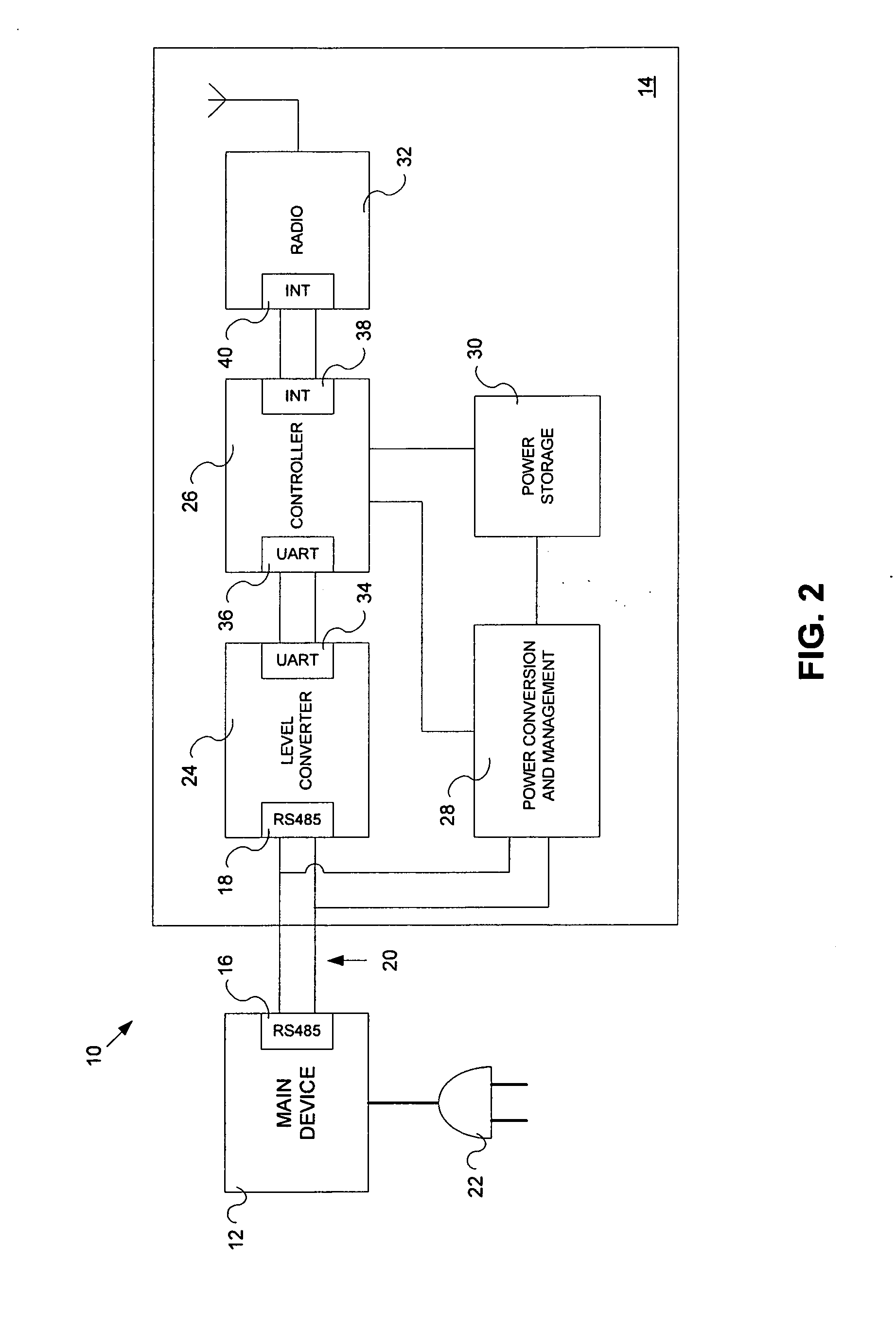

Method and system for powering a device using a data communications signal line

ActiveUS20070168596A1Suitable for storageDigital data processing detailsData switching current supplyElectricitySignal on

A system and method for transferring power using a data communications signal line. The data communications signal line is in a high impedance powerless state when idle. A main device is electrically coupled to the data communications signal line. The main device generates and transmits a signal on the data communications signal line. The signal includes power generation and non-power generation characters. A peripheral device is electrically coupled to the data communications signal line. The peripheral device has a functional unit arranged to perform a desired function for the peripheral device. A power conversion module is electrically coupled to the data communications signal line and receives the signal. The power conversion module converts power from the received signal to a form suitable for storage. A controller is in electrical communication with the functional unit and the power conversion module. The controller receives the power generation and non-power generation characters, strips the power generation characters from the signal and transmits the non-power generation characters to the functional unit.

Owner:SENSORMATIC ELECTRONICS CORP

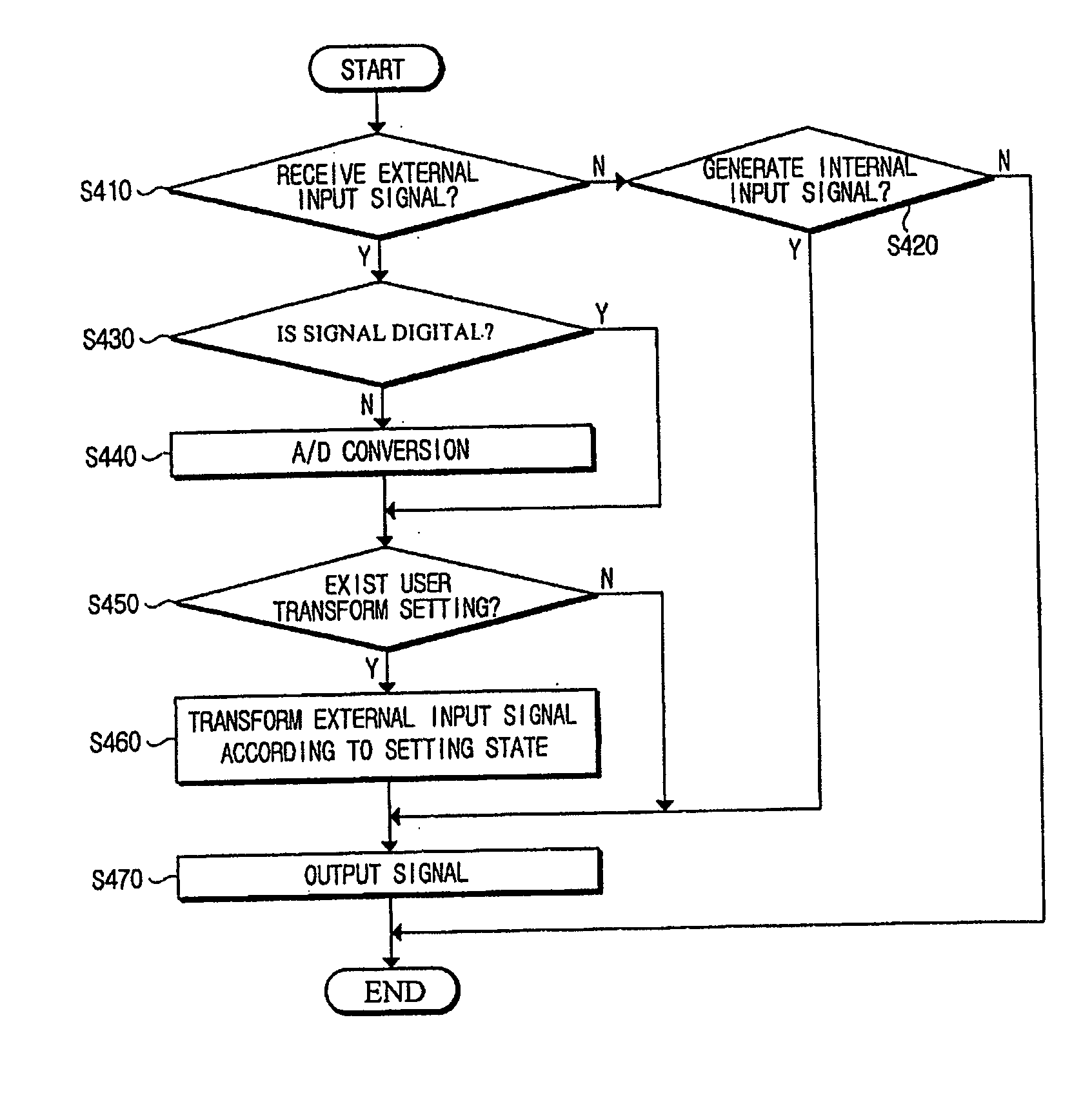

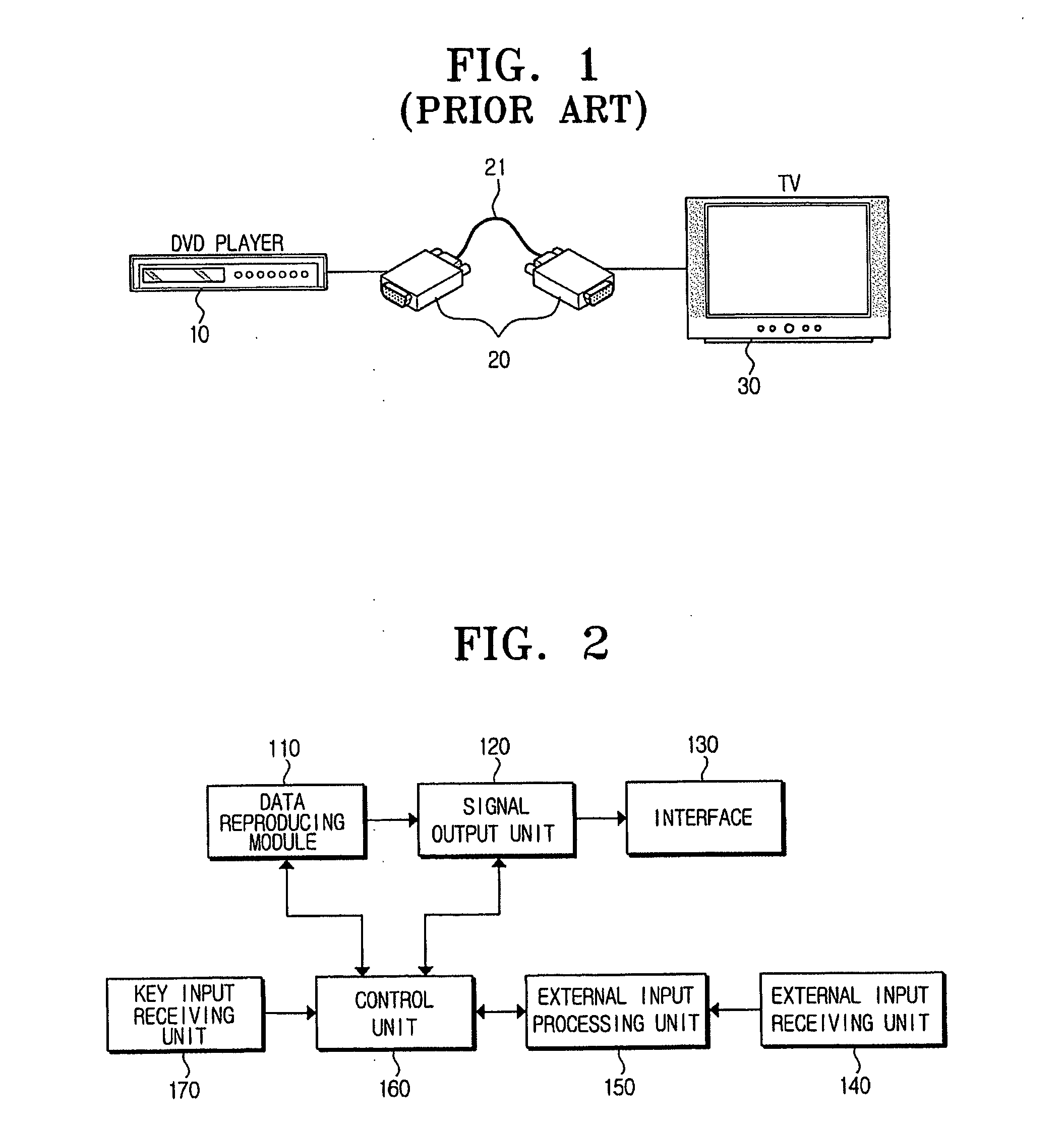

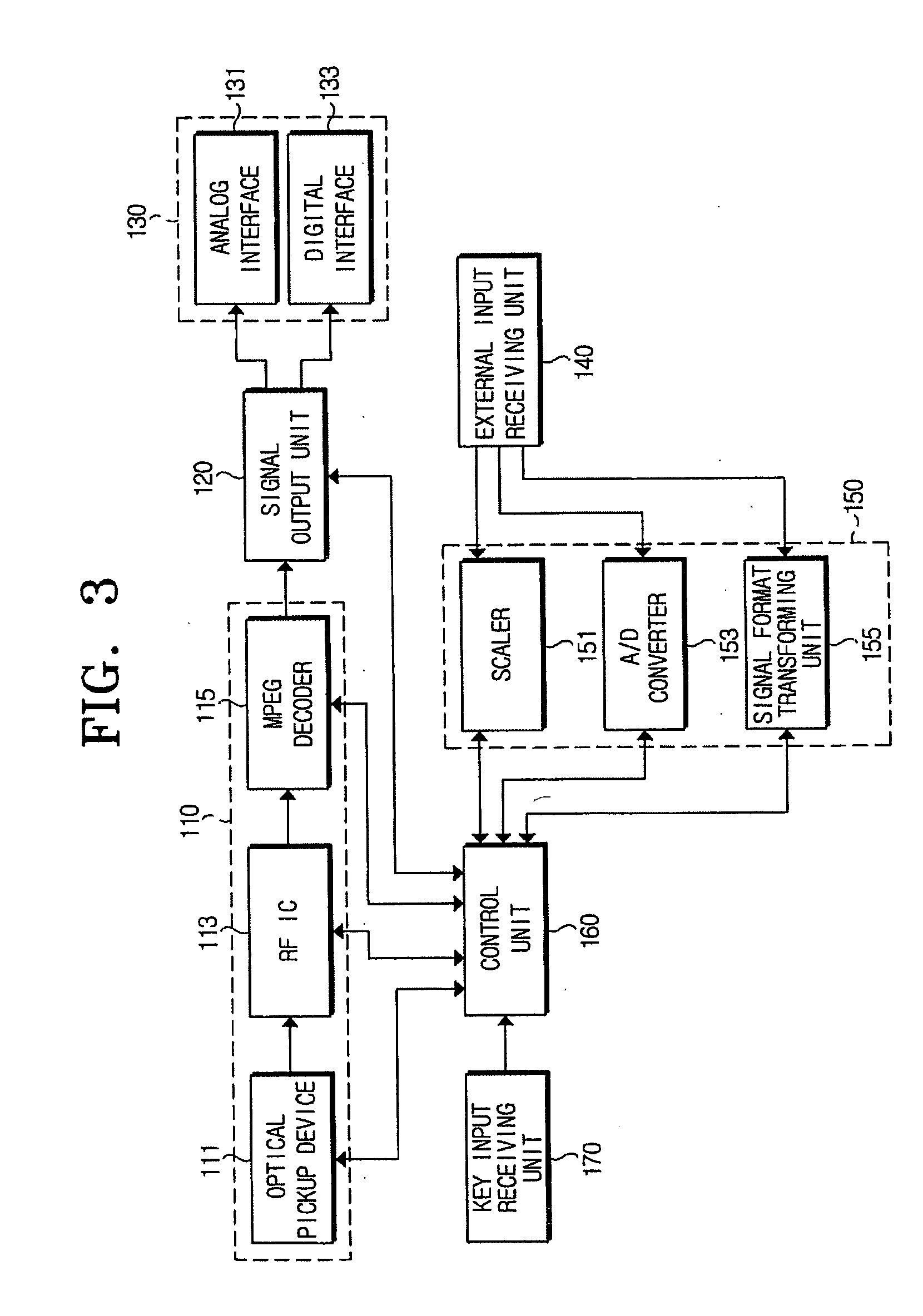

Data reproducing apparatus for transforming external input signal and method thereof

ActiveUS20050283551A1Television system detailsAnalogue secracy/subscription systemsDisplay deviceComputer science

A DVD reproducing device is capable of being connected to a certain external electronic device. The DVD reproducing device includes an external input receiving unit connected with the external electronic device to receive an external input signal from the external electronic device. A key input receiving unit receives a user selection signal for selecting whether or not the external input signal is transformed. An external signal processing unit transforms the external input signal into a certain form according to a user selection signal. A control unit controls the external signal processing unit such that when an external input signal is received through the external input receiving unit, a received signal is transformed into a signal form predetermined by a user selection signal; and a signal output unit outputs the external input signal transformed at the external signal processing unit, whereby a signal inputted from the external electronic device is transformed into an optimal form to be displayed on the video display device.

Owner:SAMSUNG ELECTRONICS CO LTD

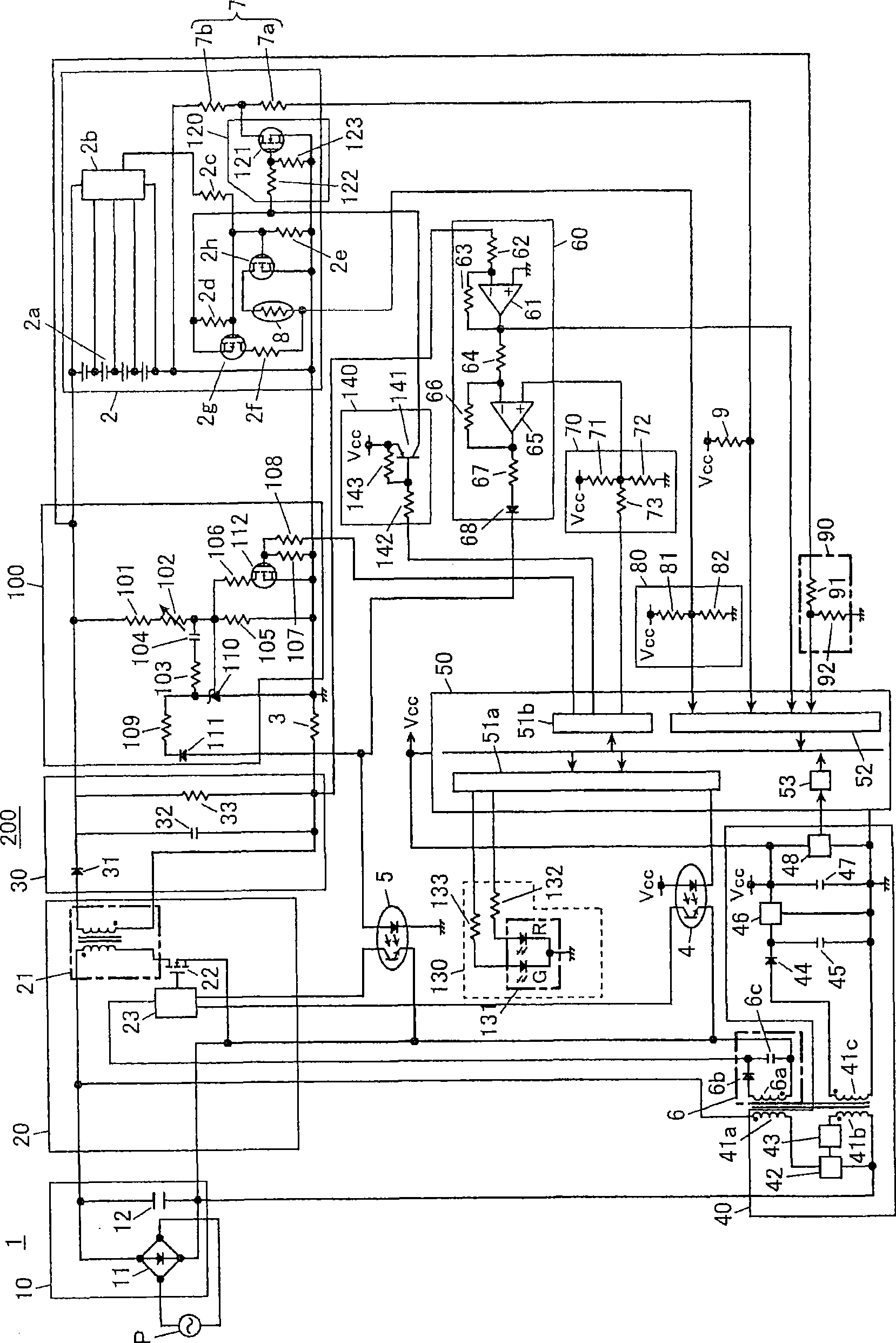

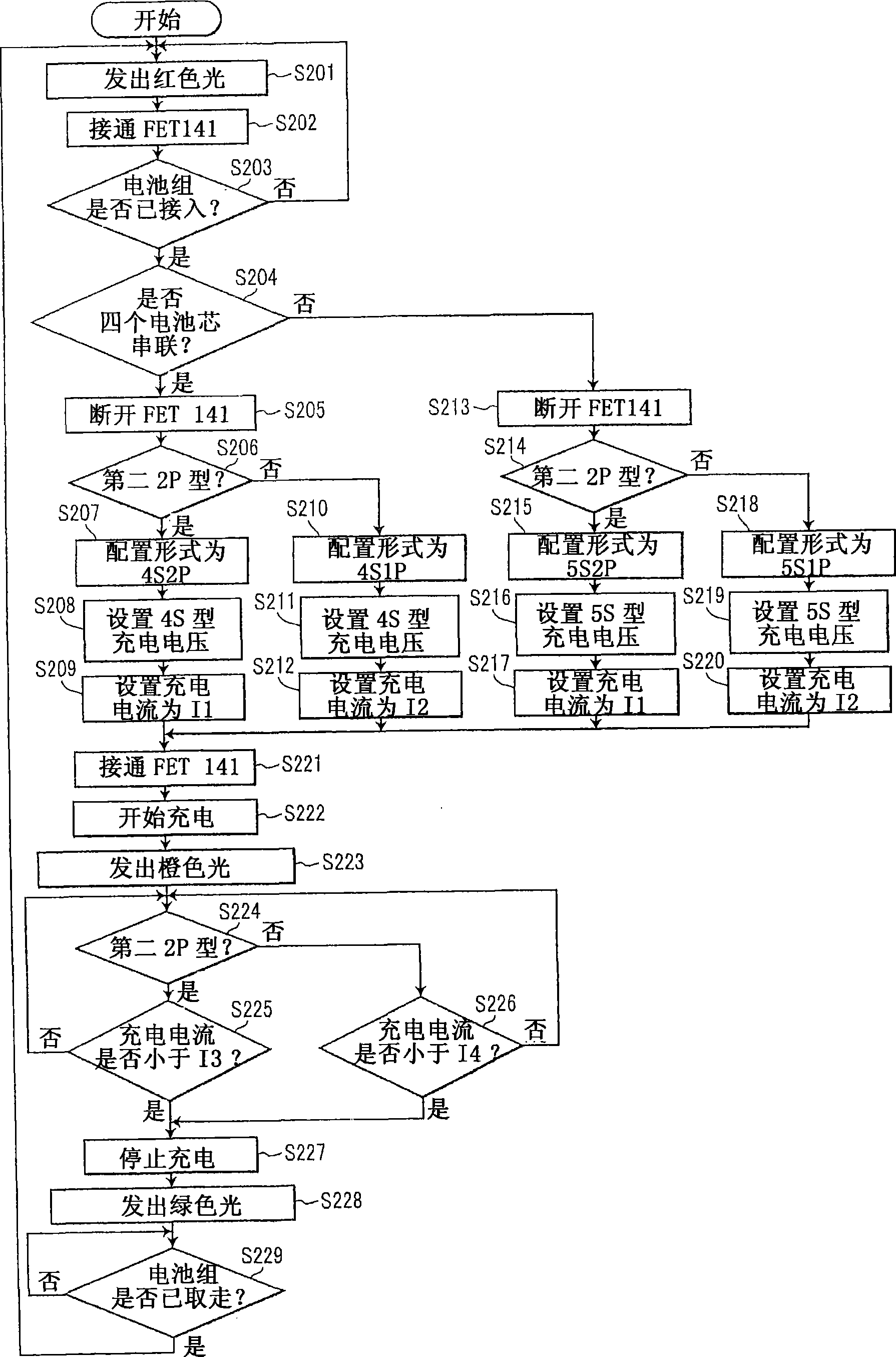

Charging system for charging battery pack

A charging system has a battery pack and a charging device. The battery pack has a battery cell and a plurality of identifiers that identify a configuration of the battery cell. The charging device has a charging unit, a signal transmission unit, a reading unit, and a control unit. The charging unit charges the battery pack. The signal transmission unit transmits a first signal and a second signal to the battery pack separately to read the plurality of identifiers when the battery pack is attached to the charging unit. The reading unit reads the plurality of identifiers according to the first and second signals to determine the configuration of the battery cell. The control unit controls the charging unit according to the configuration of the battery cell.

Owner:HITACHI KOKI CO LTD

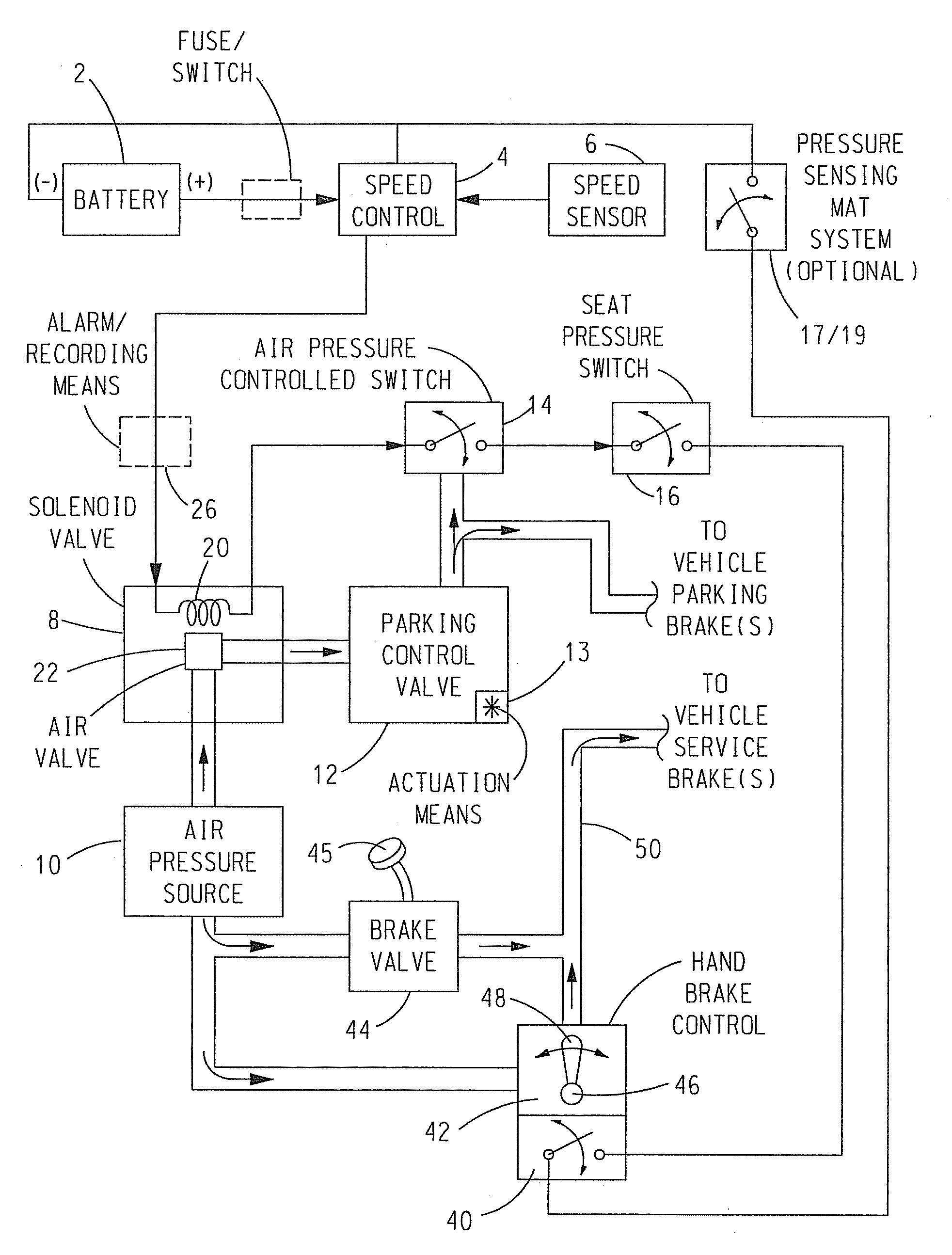

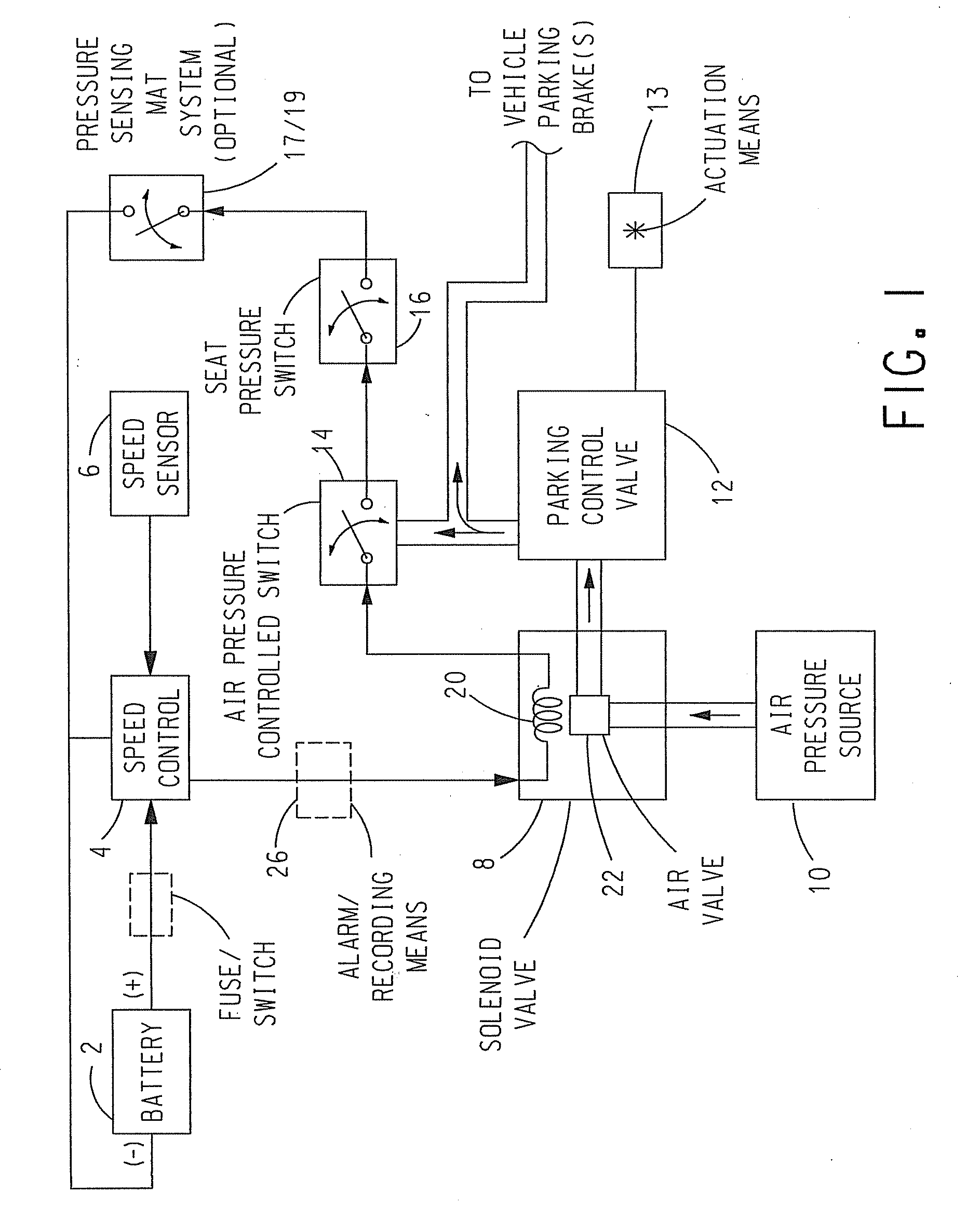

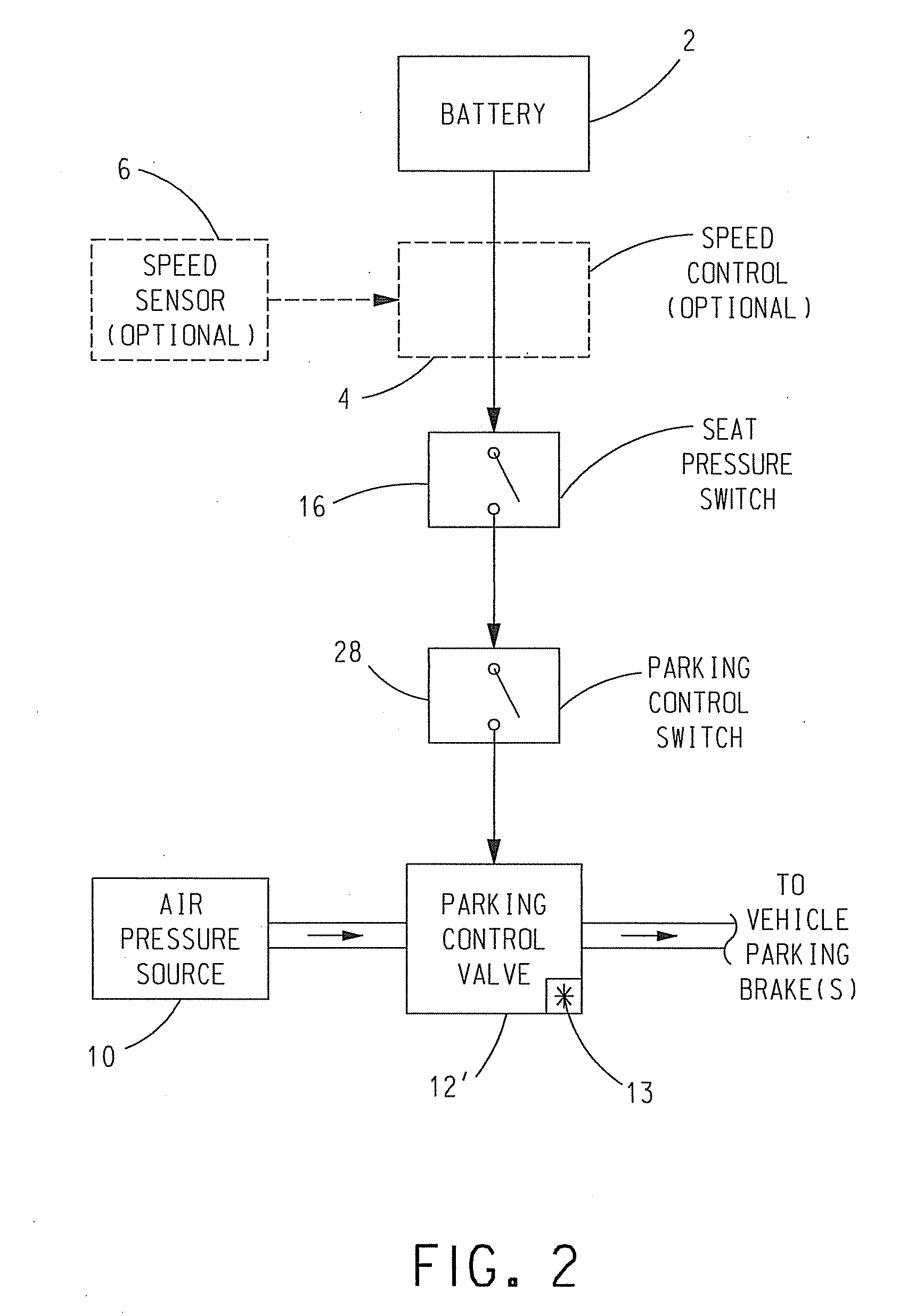

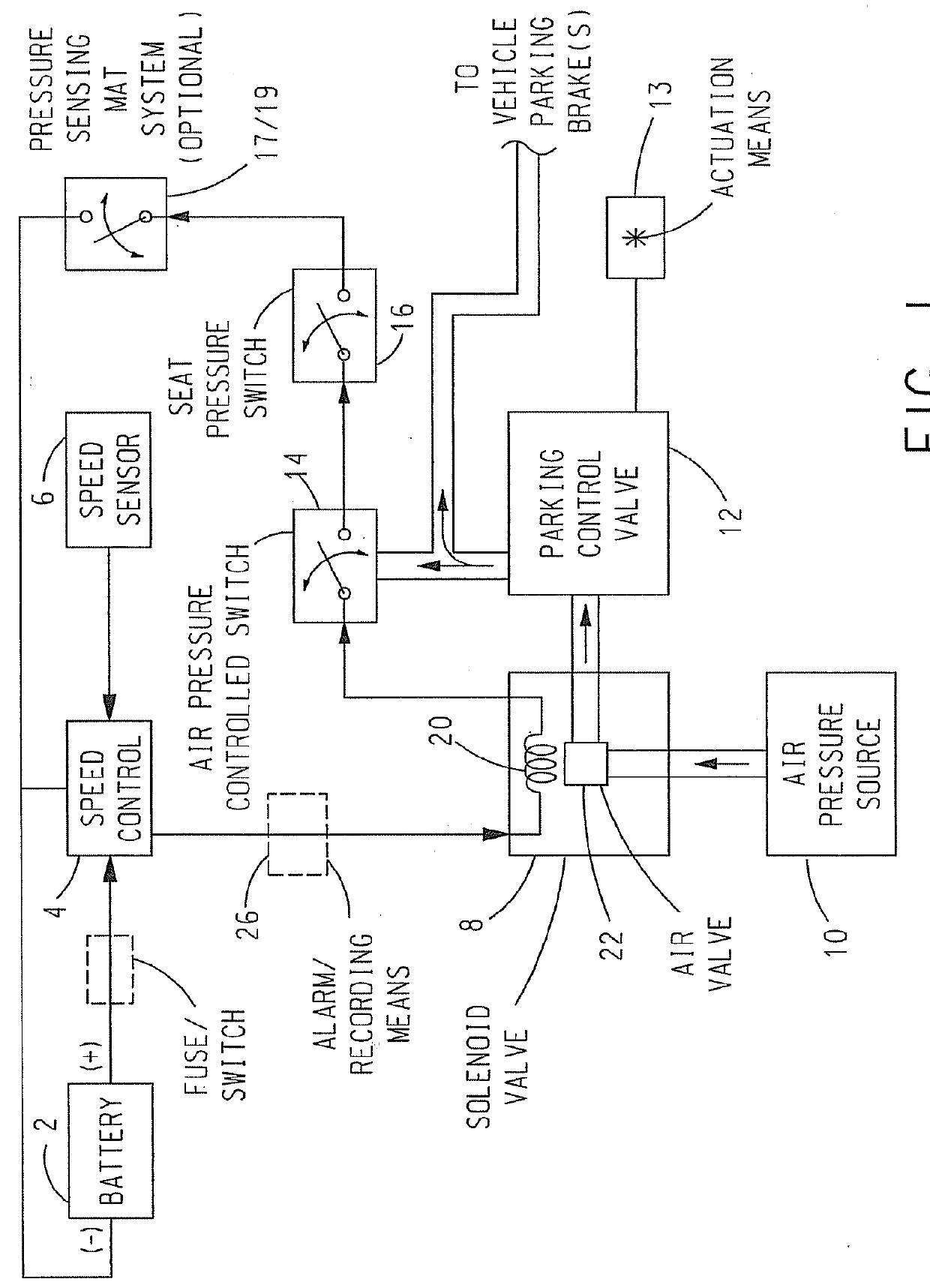

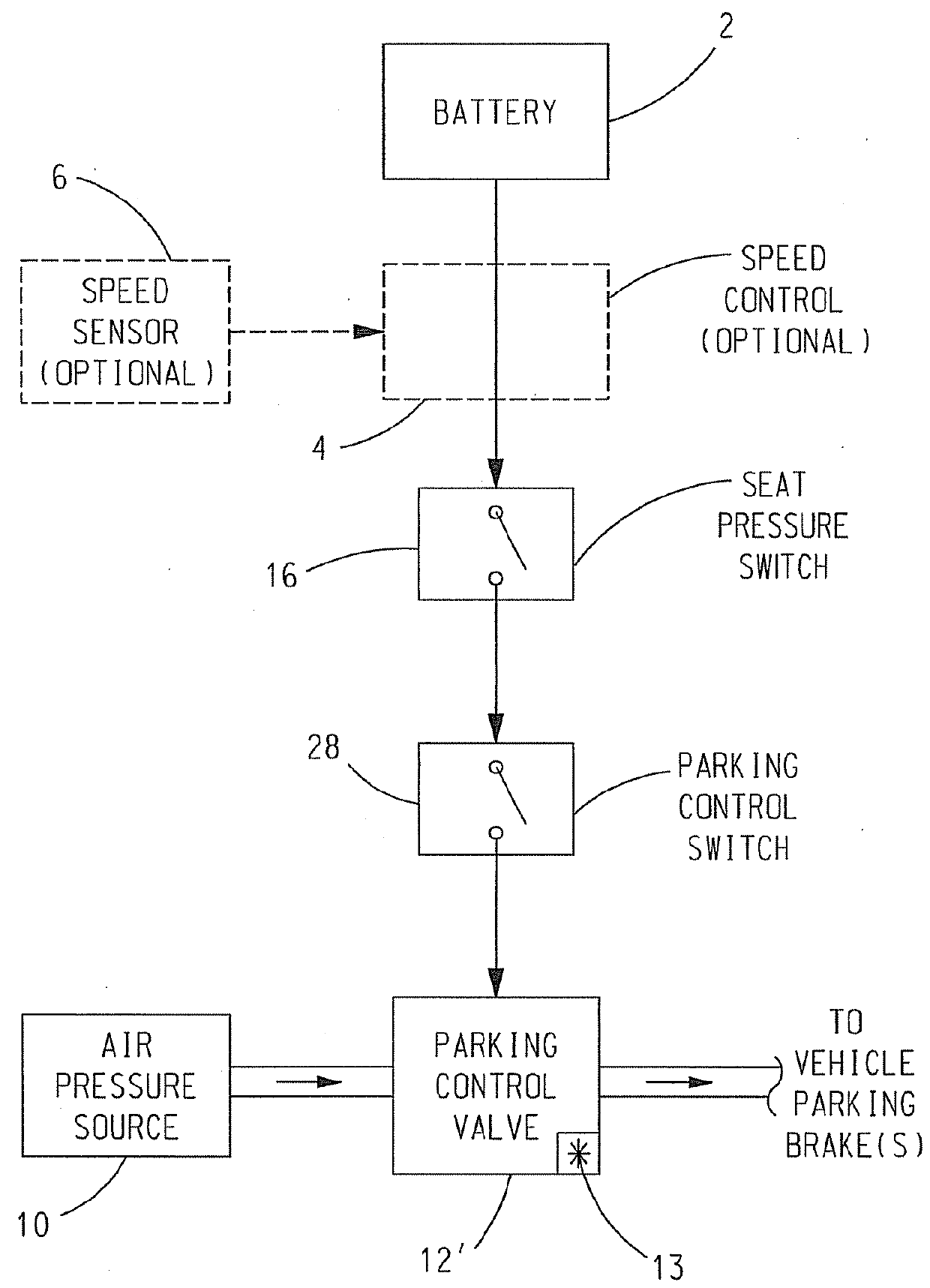

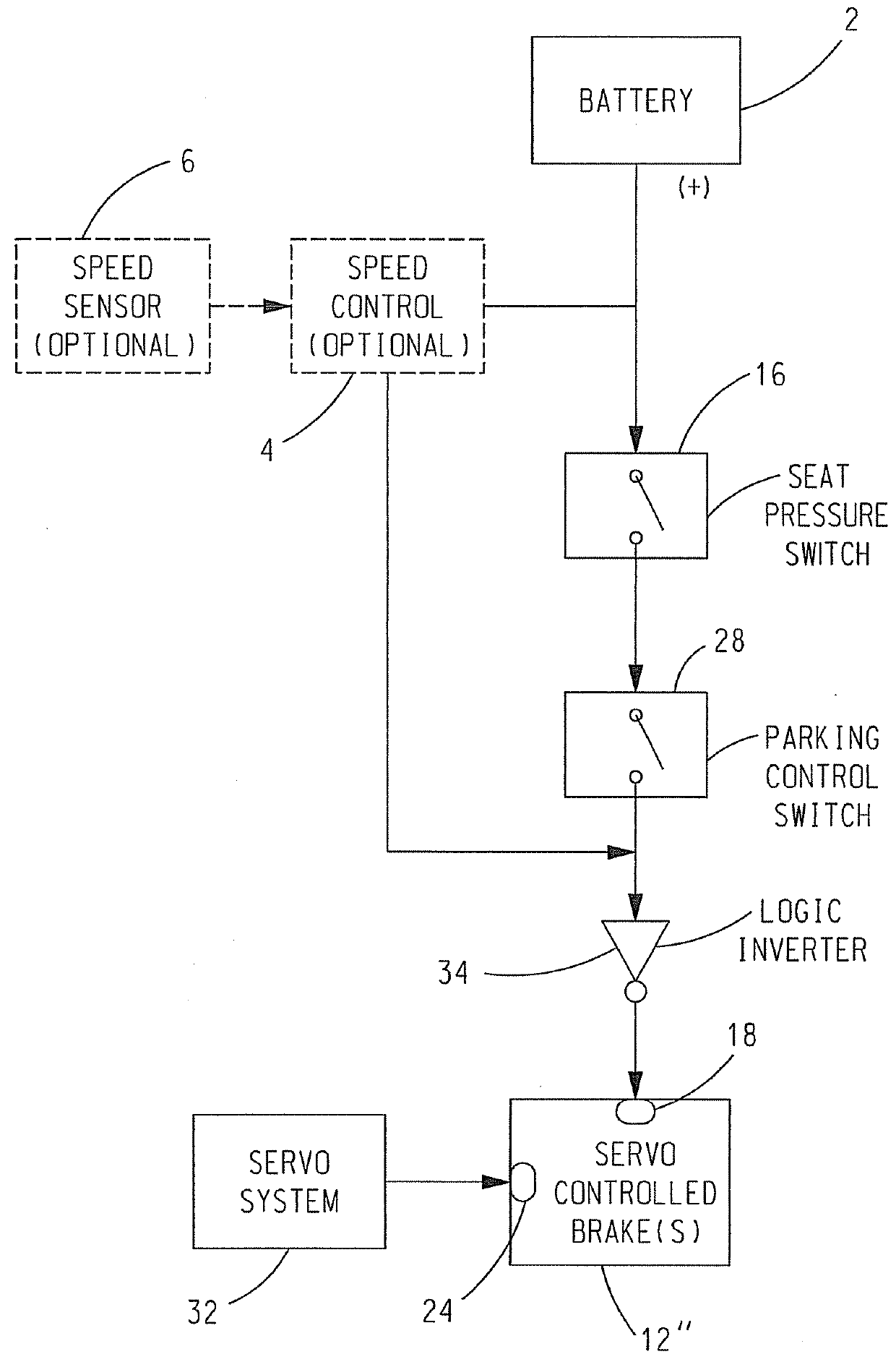

Anti-rollaway device for trucks and equipment with fluid and electrically actuated brakes

A vehicle anti-rollaway device includes a first switch responsive to the presence and absence of an operator at a predetermined location in the vehicle for controlling the on / off state of parking brake of the vehicle in the form of either a servo controlled parking brake or a fluid controlled parking brake. The device can also include a speed control responsive to a speed of the vehicle for controlling the on / off state of the parking brake as a function of the speed of the vehicle. The device can also include a second switch operative for controlling the response of the parking brake to the state of the first switch.

Owner:ACCARDI THOMAS

Device for laser-optical eye surgery

A device for laser-optical eye surgery includes a source (10) of pulsed femtosecond laser radiation and also optical components (12, 14, 16) for guiding the las er radiation and focusing the same ontoa treatment location on or in the eye (28), the optical components including a plurality of lenses (18, 20) arranged in succession in the beam path of the laser radiation. In accordance with the invention, at least one (18) of the lenses is arranged so as to be adjustable relative to other lens es in the direction of the beam path. In particular, the adjustable lens is a first diverging lens of beam-expansion optics (12). An actuating arrangement (24) is assigned to the adjustable lens for its adjustment, for the control of which arrangement a control unit (26) is provided which is set up toaccess measured data concerning the topography of a surface of the eye and to control the actuating arrangement in a manner depending on the measured surface topography. The laser device enables the abandonment of a contact lens to be placed onto the eye.

Owner:ALCON INC

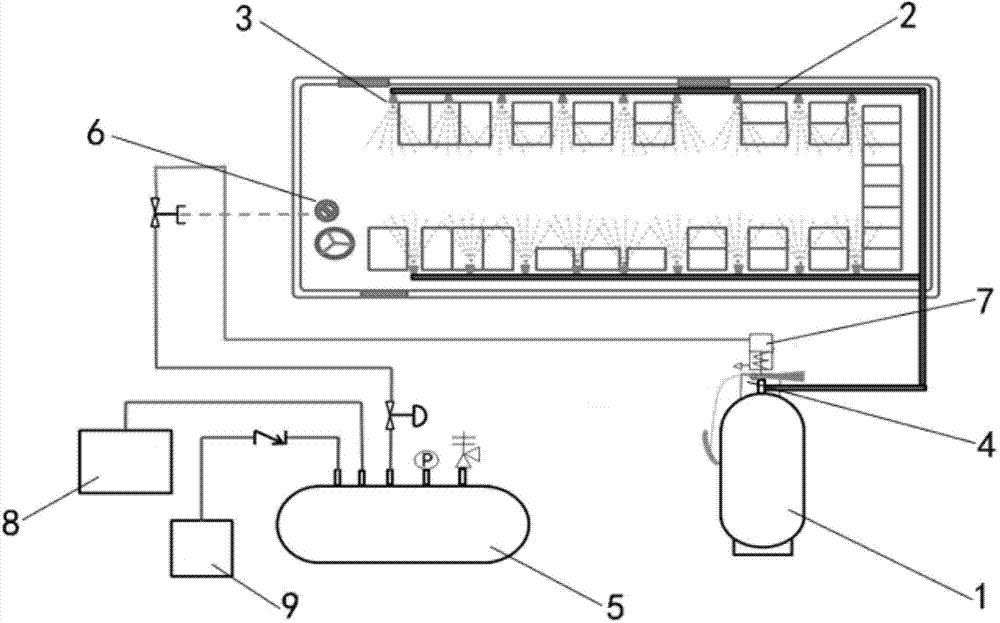

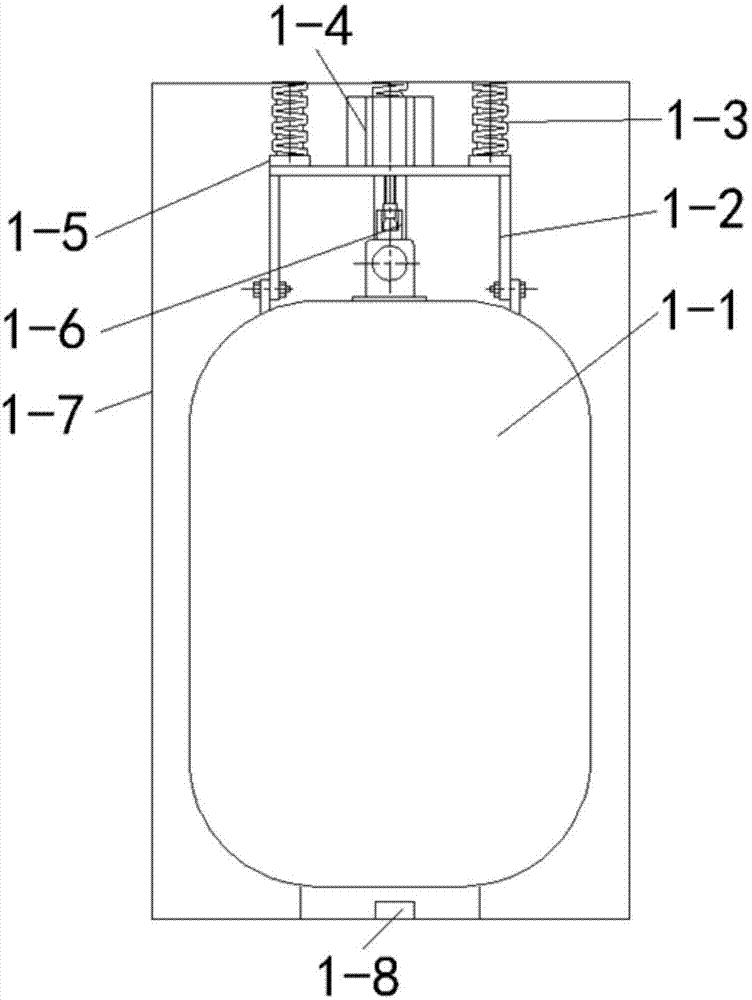

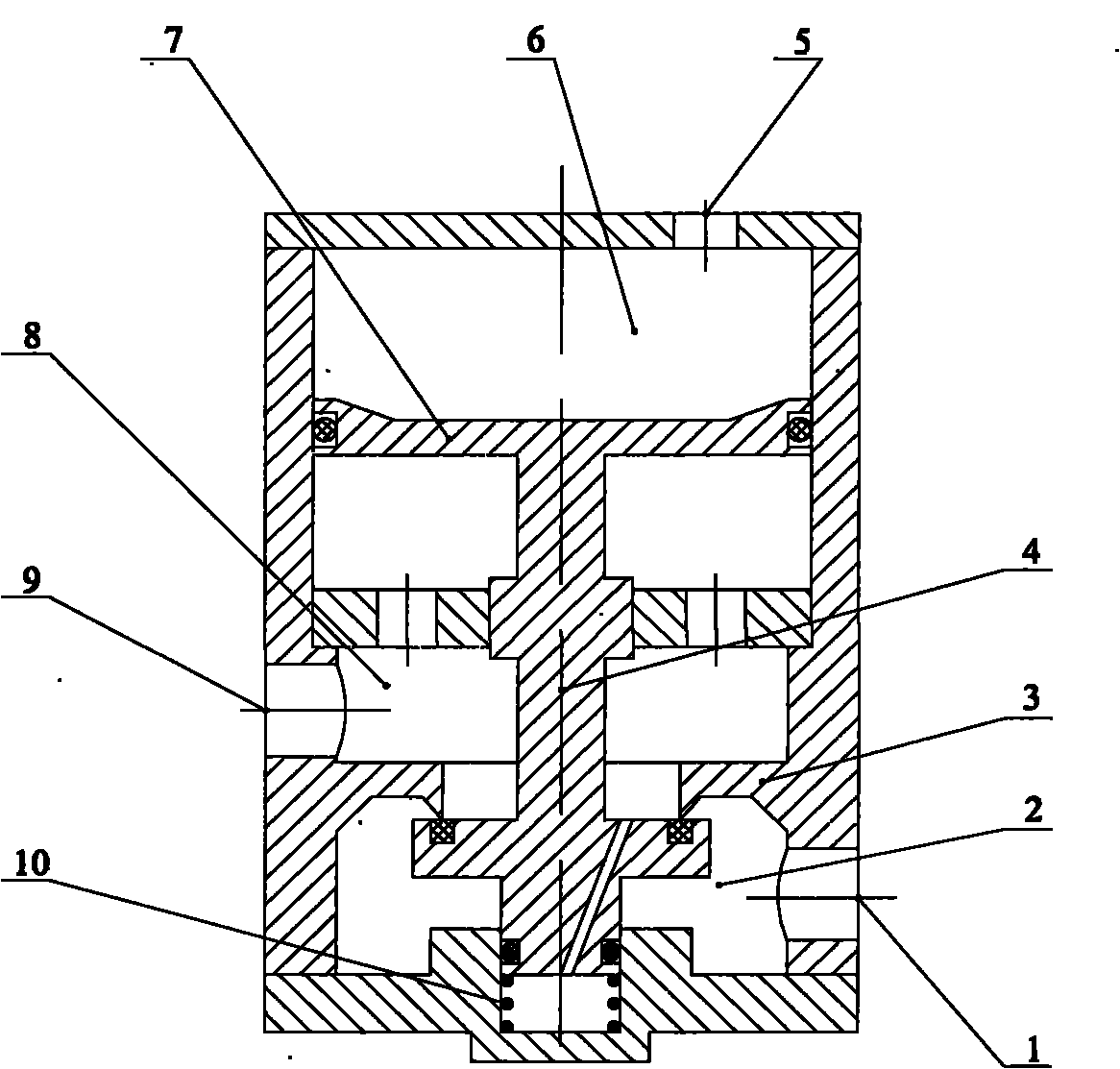

Fire extinguishing system of public bus

The invention relates to a fire extinguishing system of a public bus. The fire extinguishing system comprises a fire extinguisher, a fire extinguishing pipeline and a plurality of spraying heads. The fire extinguisher is placed at the rear side of a bus body, and is connected with the fire extinguishing pipeline, and the fire extinguishing pipeline is laid at the two sides inside the bus body; a plurality of spraying heads which spray the interior of the bus body are arranged on the fire extinguishing pipeline at intervals, and a pneumatic control switch, a manual control switch and an electric control switch which are used for controlling a valve of the fire extinguisher to be turned on or off are arranged on the fire extinguisher. Power own by the bus and manual control are utilized for controlling the fire extinguisher in three modes. Through a large quantity of tests and a large amount of demonstration, the response time of the fire extinguishing system is not more than 3 seconds, solid and liquid fire disasters in various types of public transport vehicles can be controlled within 10 seconds and completely extinguished within 30 seconds, an oil tank is protected and prevented from exploding, and the evacuation time is gained for passengers.

Owner:王卫国 +1

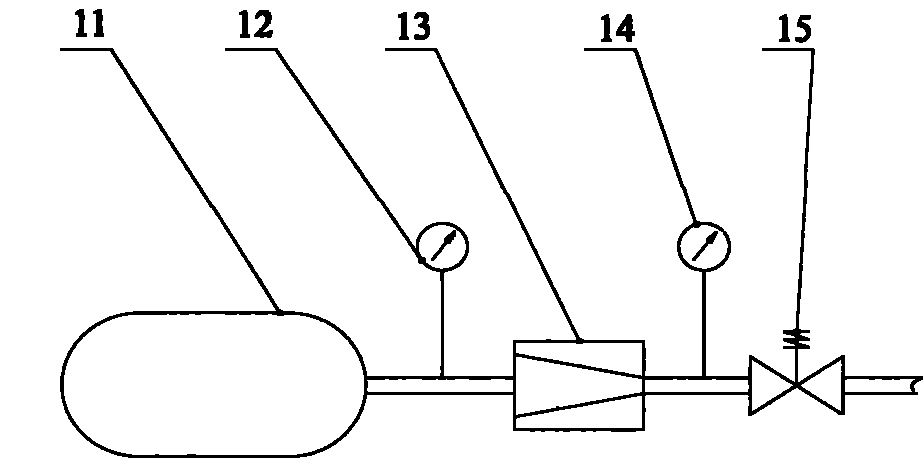

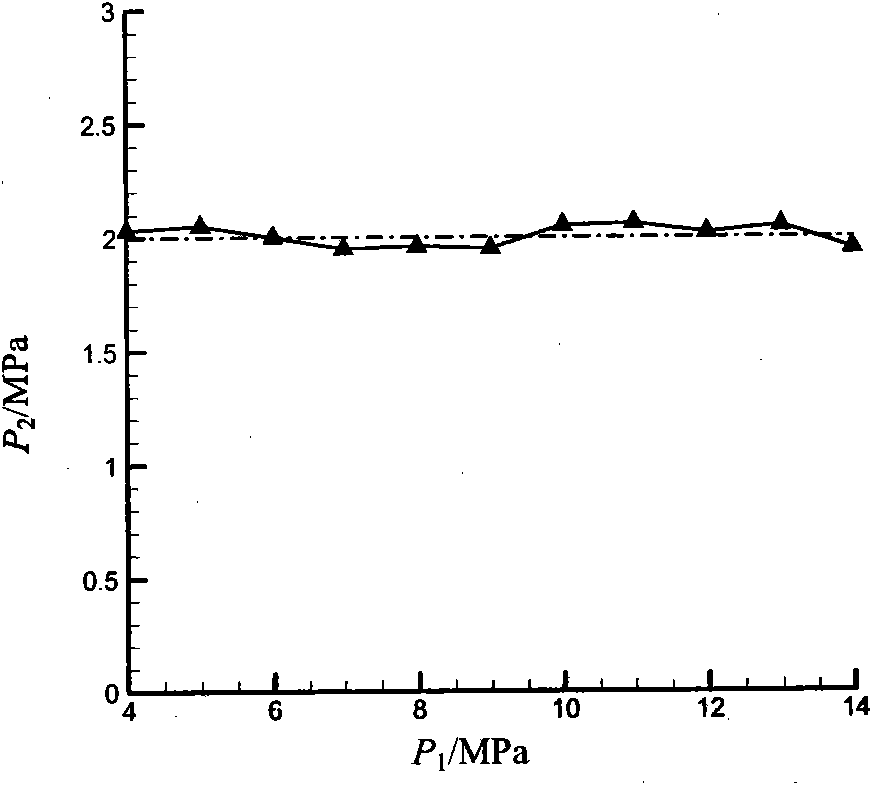

Quantitative feed electric control pressure reductor, characteristic test system for pressure reductor and automatic test method

InactiveCN101769824AFully automatedImprove securityInternal-combustion engine testingRocket engine plantsAutomatic test equipmentData acquisition

The invention relates to a quantitative feed electric control pressure reductor, a characteristic test system for the pressure reductor and an automatic test method. The quantitative feed electric control pressure reductor comprises a quantitative air charging device and a quantitative air discharging device, and the quantitative air charging device and the quantitative air discharging device respectively control the movement of a valve core with an air charging magnet coil and an air discharging magnet coil in an pulse mode to quantitatively charge or discharge air to a control cavity, thereby the outlet pressure of the quantitative feed electric control pressure reductor is regulated to a setting value; the quantitative feed electric control pressure reductor, a measured pressure reductor, a sensor device, a control valve, a data acquisition and control circuit and like are connected in series to form the characteristic test system for the pressure reductor, the outlet pressure of the quantitative feed electric control pressure reductor is used as the inlet pressure of the measured pressure reductor, the sensor and a collection card are used as a data acquisition device, the automatic performance of the characteristic test of the measured pressure reductor is realized by computer process control, and the test data is displayed and recorded in real time.

Owner:北京旧宫旭德天普机械厂 +1

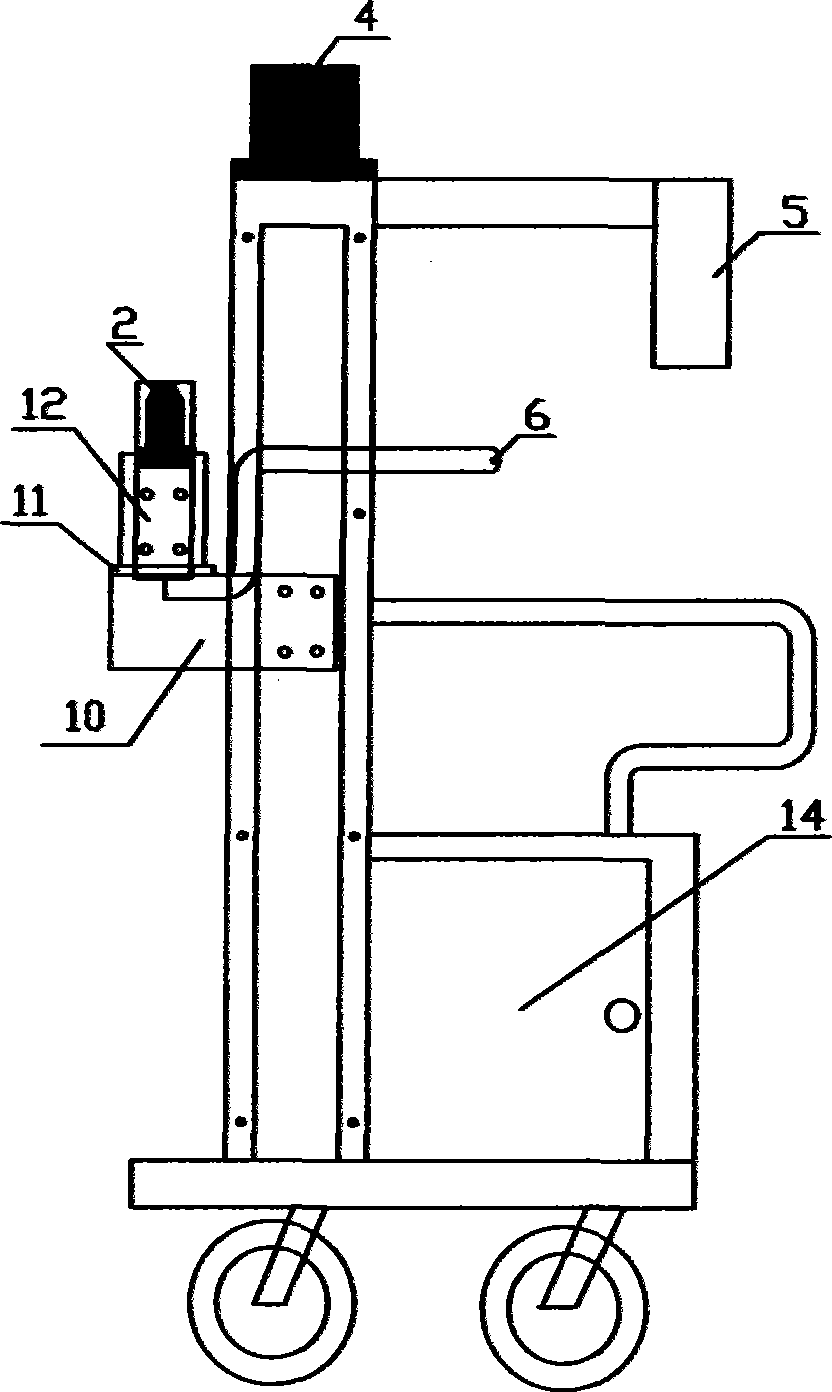

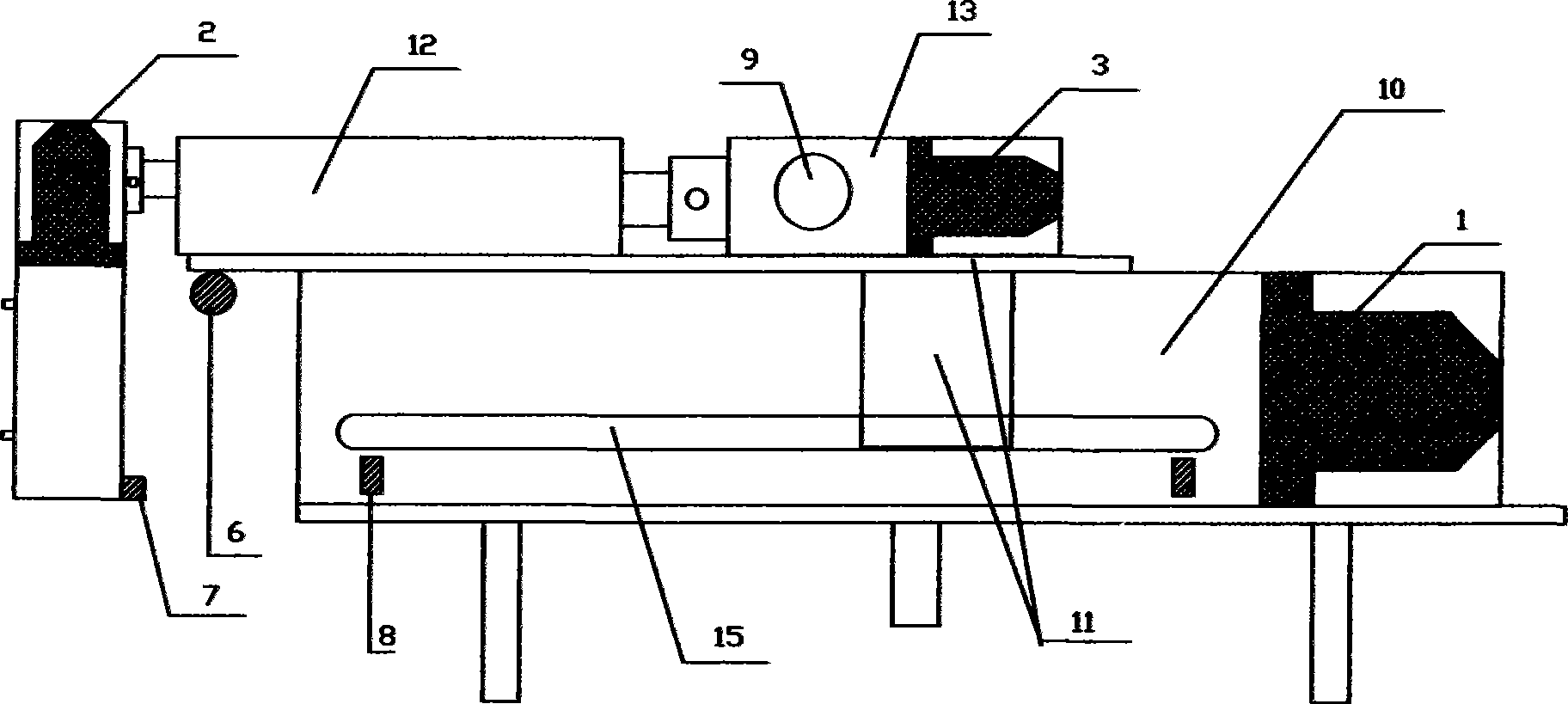

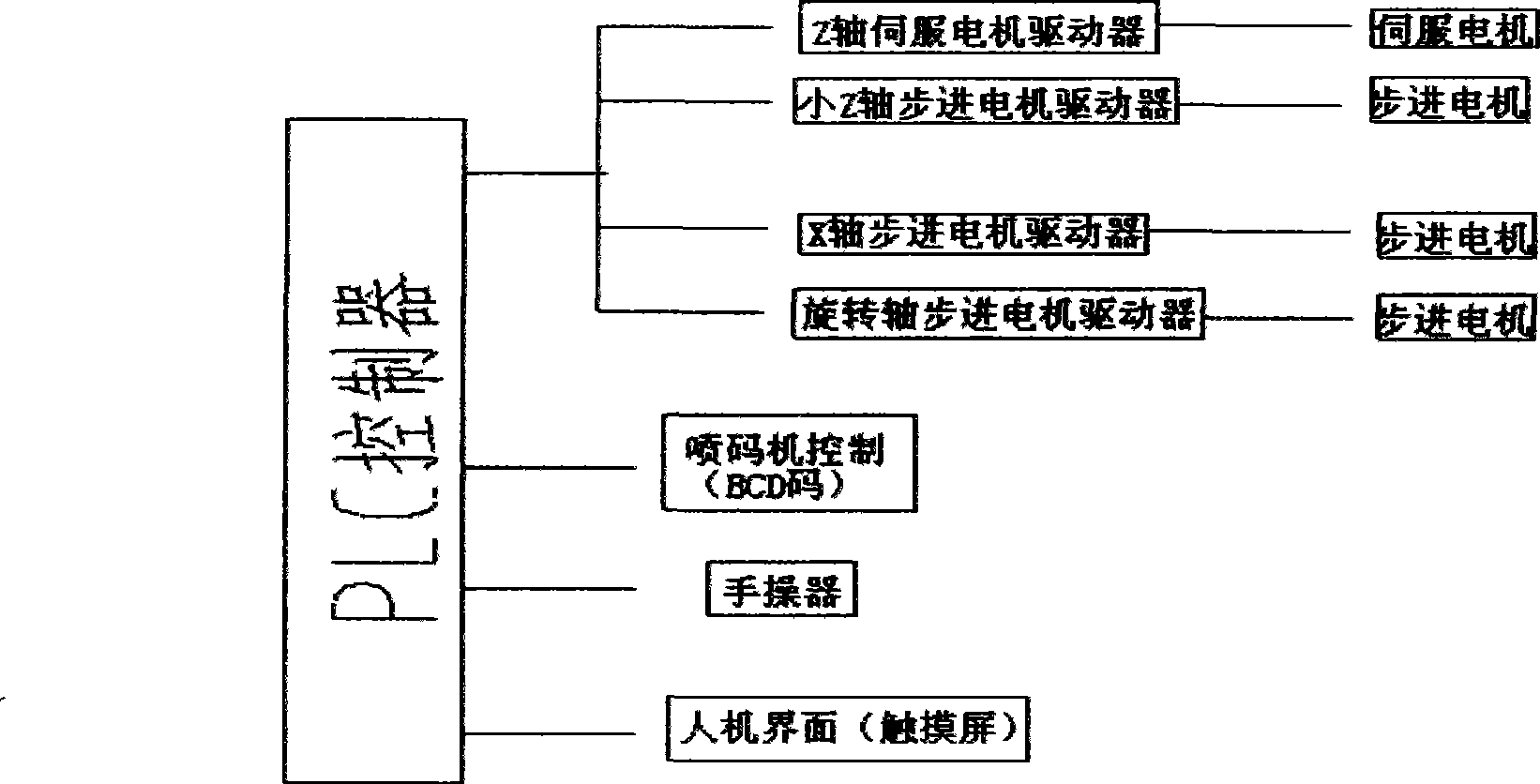

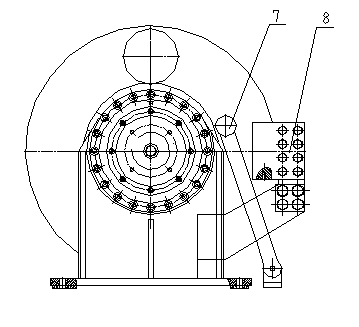

Round code-spurting device in coil strip

InactiveCN101386234AImprove printing effectImprove adsorption capacityTypewritersPower drive mechanismsHigh absorptionElectric machinery

The invention relates to a code spraying device for an inner circle of a steel roll, which consists of a wheelbarrow, a control device and an electric control nozzle. The control device is arranged on the wheelbarrow; PLC is adopted by the control device. The invention is characterized in that a longitudinal track is arranged on the wheelbarrow; a manipulator is arranged on the longitudinal track; the electric control nozzle is arranged on the end of the manipulator; a motor with a large Z shaft is arranged on the upper end of the longitudinal track; the motor with a large Z shaft controls the manipulator to move up and down on the longitudinal track. As the mode that adopts PLC to control the manipulator is adopted by the invention for controlling the rising, lowering, advancing, backing off and the rotary spraying in the inner circle of the steel roll of the electric control nozzle for leading the spraying starting point of the invention to be freely set in 360 degrees in the arc of the inner circle of the steel roll; the locating precision is high and the property is stable; if special ink and a thinner are adopted in the electric control nozzle, the ink has a high absorption capacity and is hard to be erased. The code spraying device can realize to automatically finish the code spraying operation of the inner circle of the steel roll, improve the working efficiency and remarkably improve the code spraying effect of the inner circle of the steel roll.

Owner:武钢集团有限公司

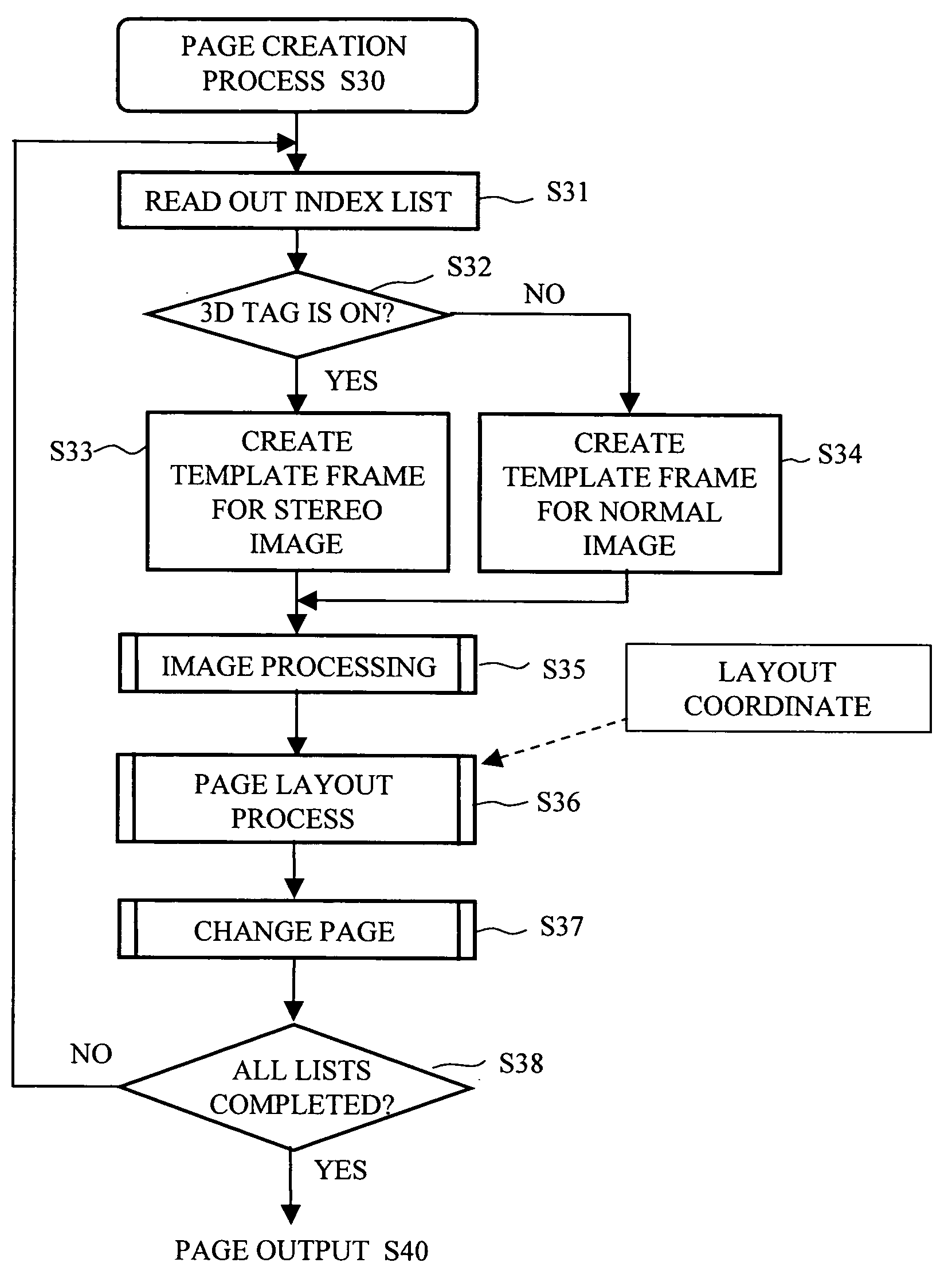

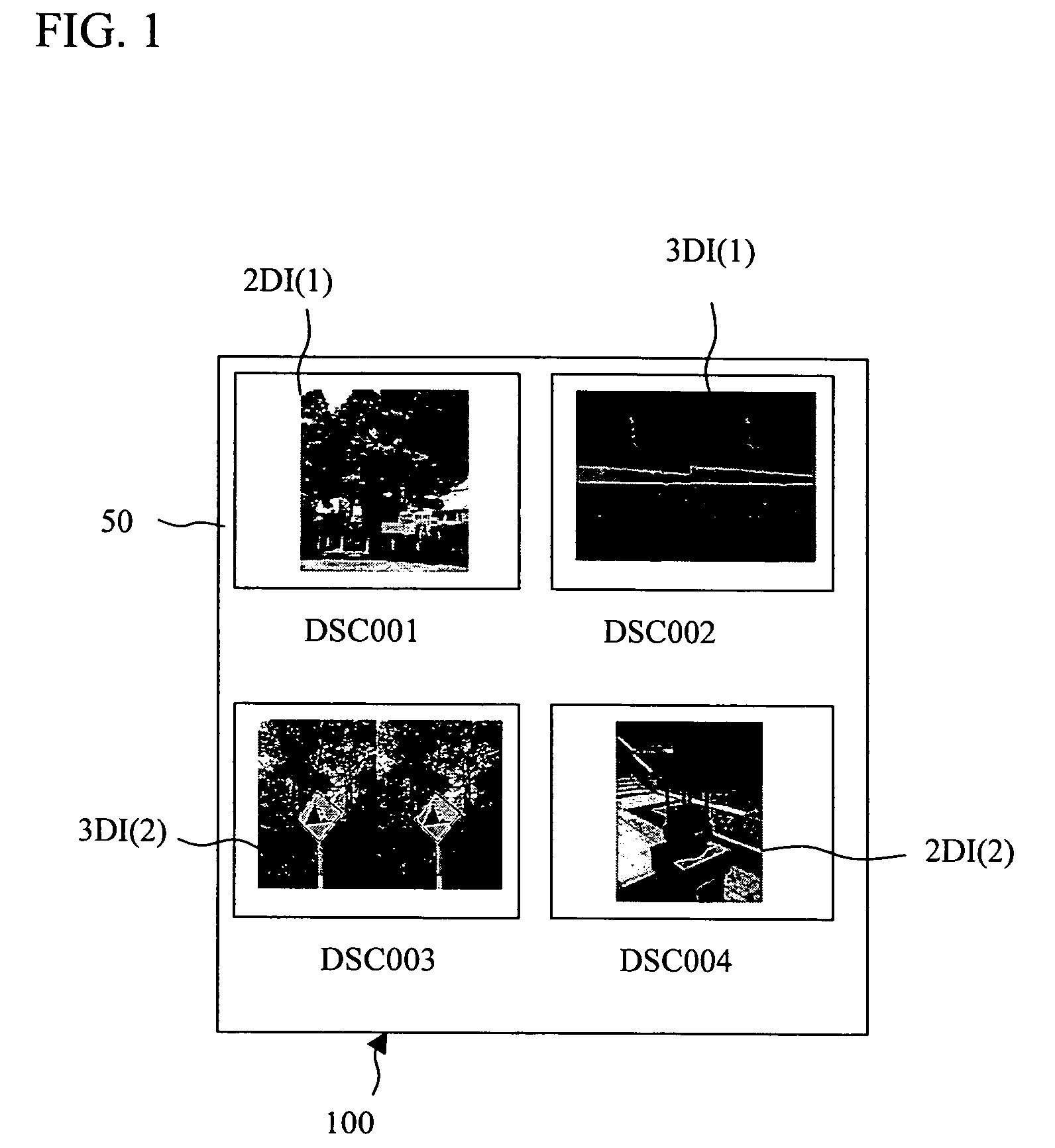

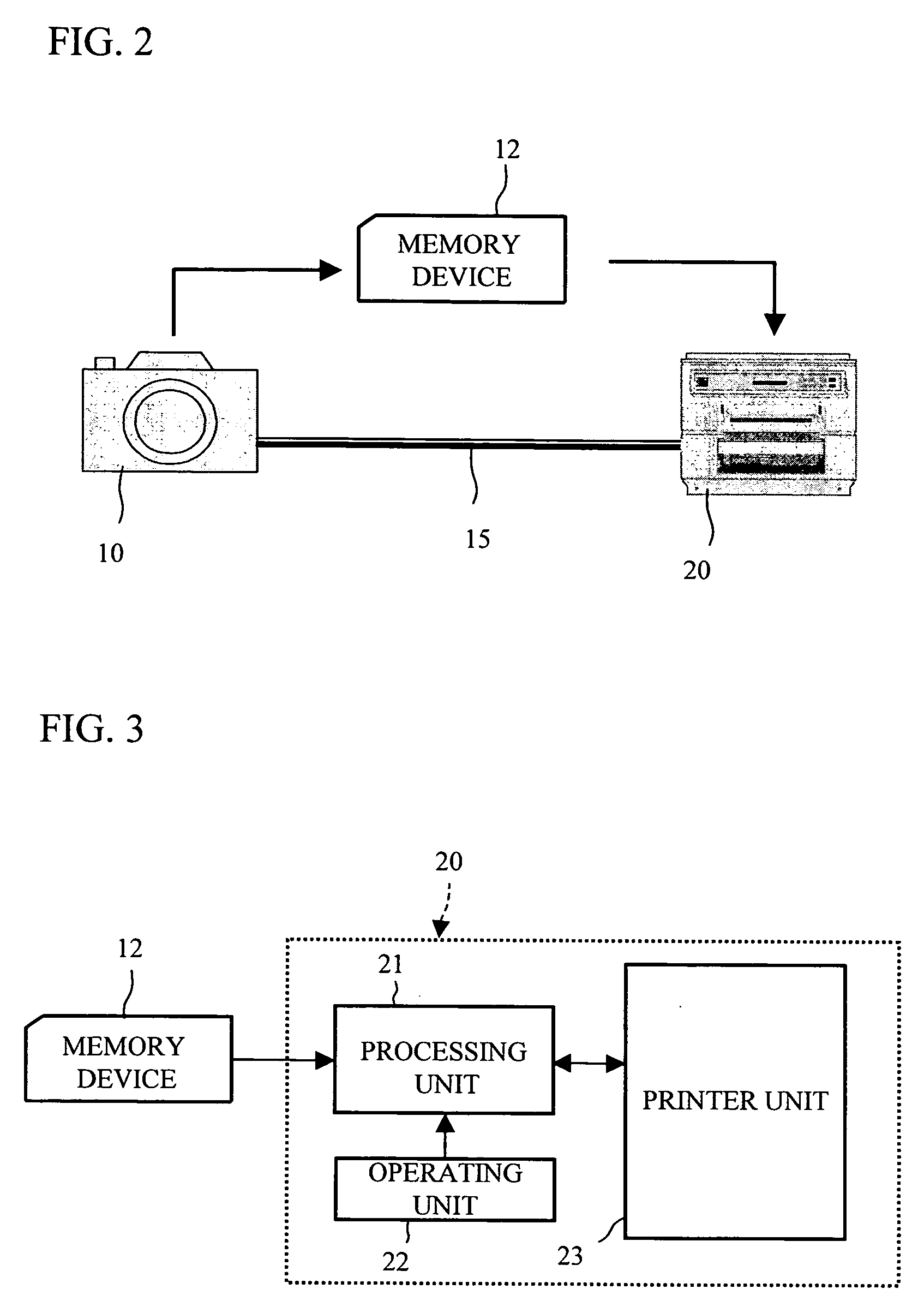

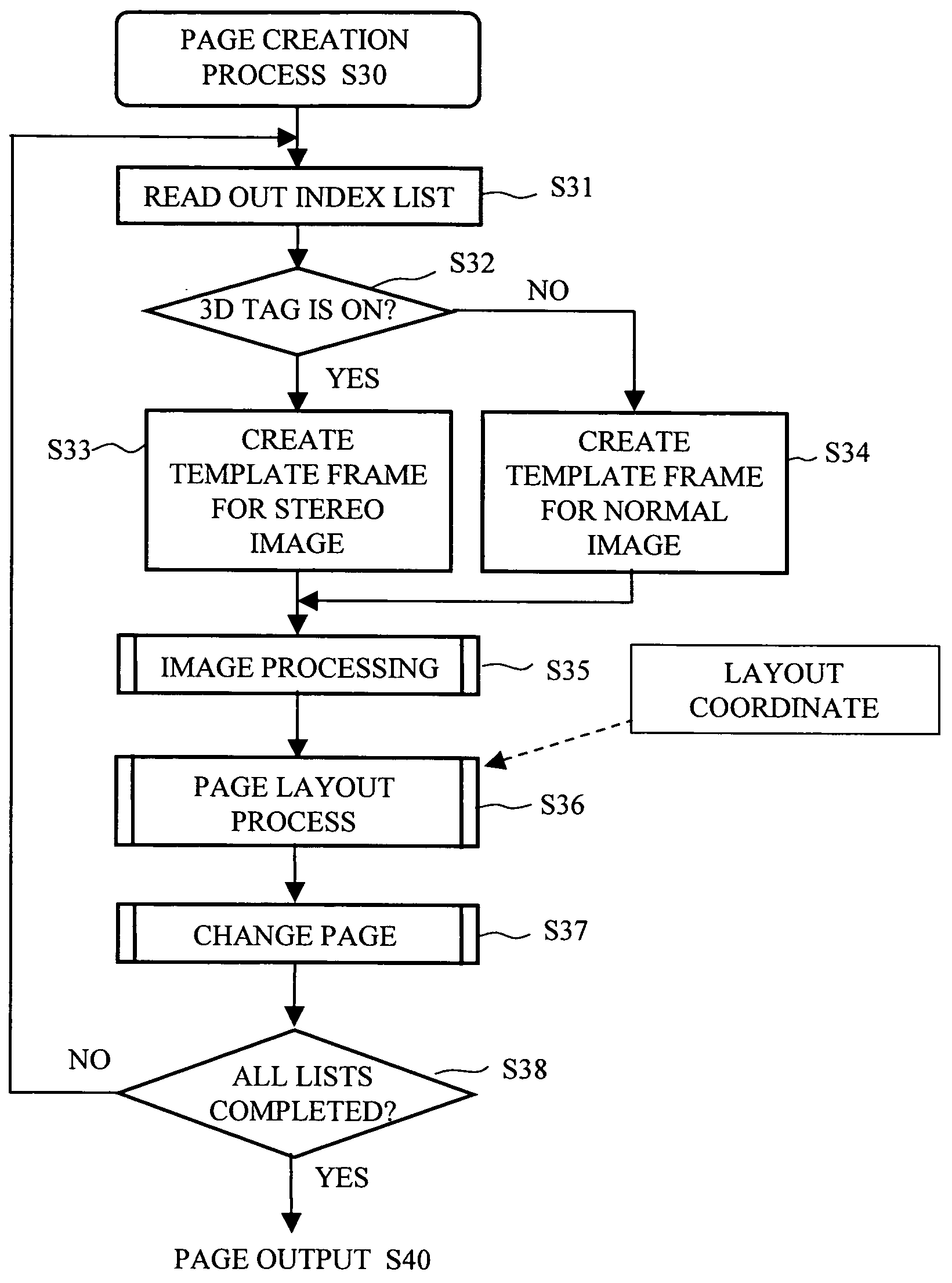

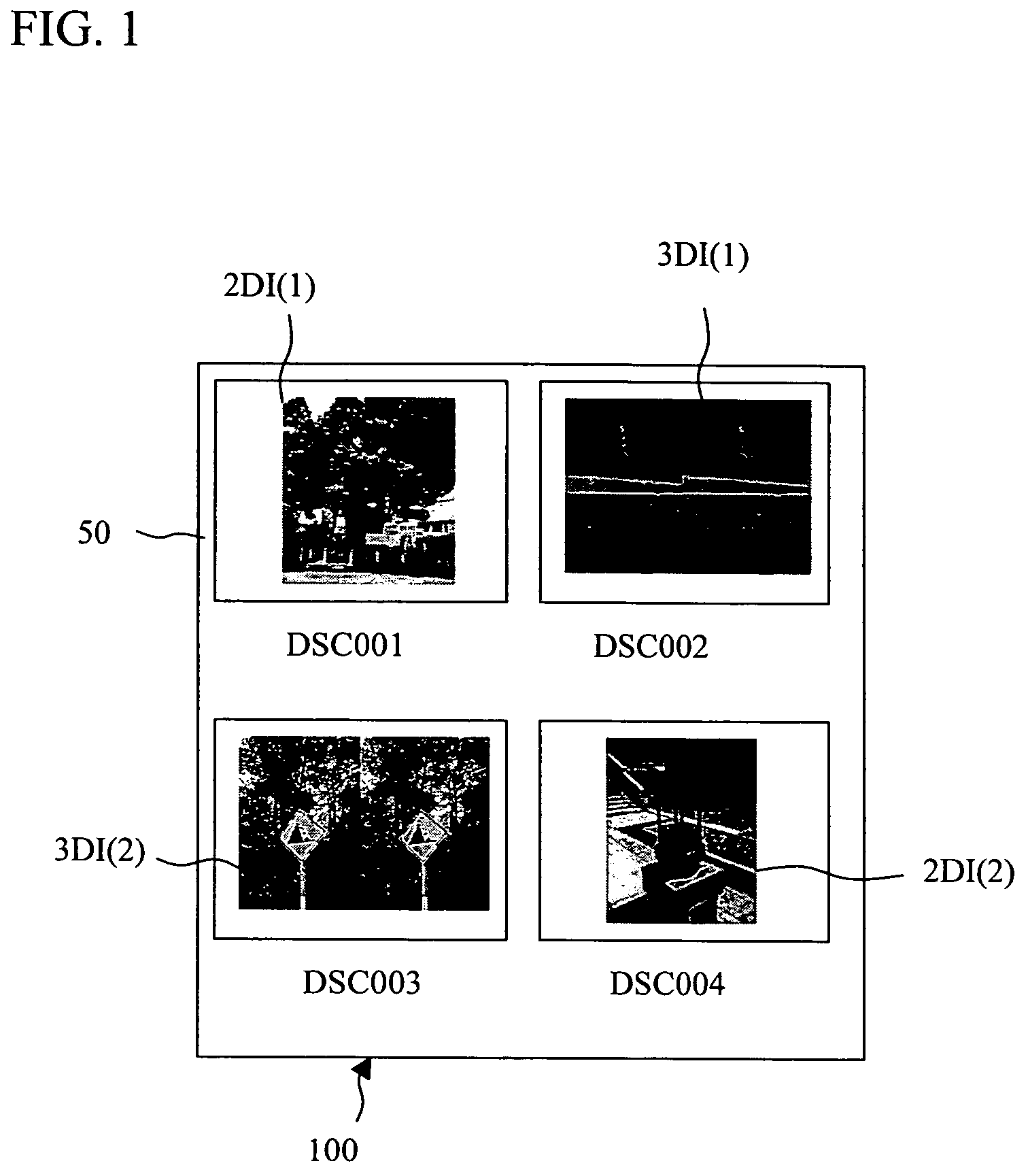

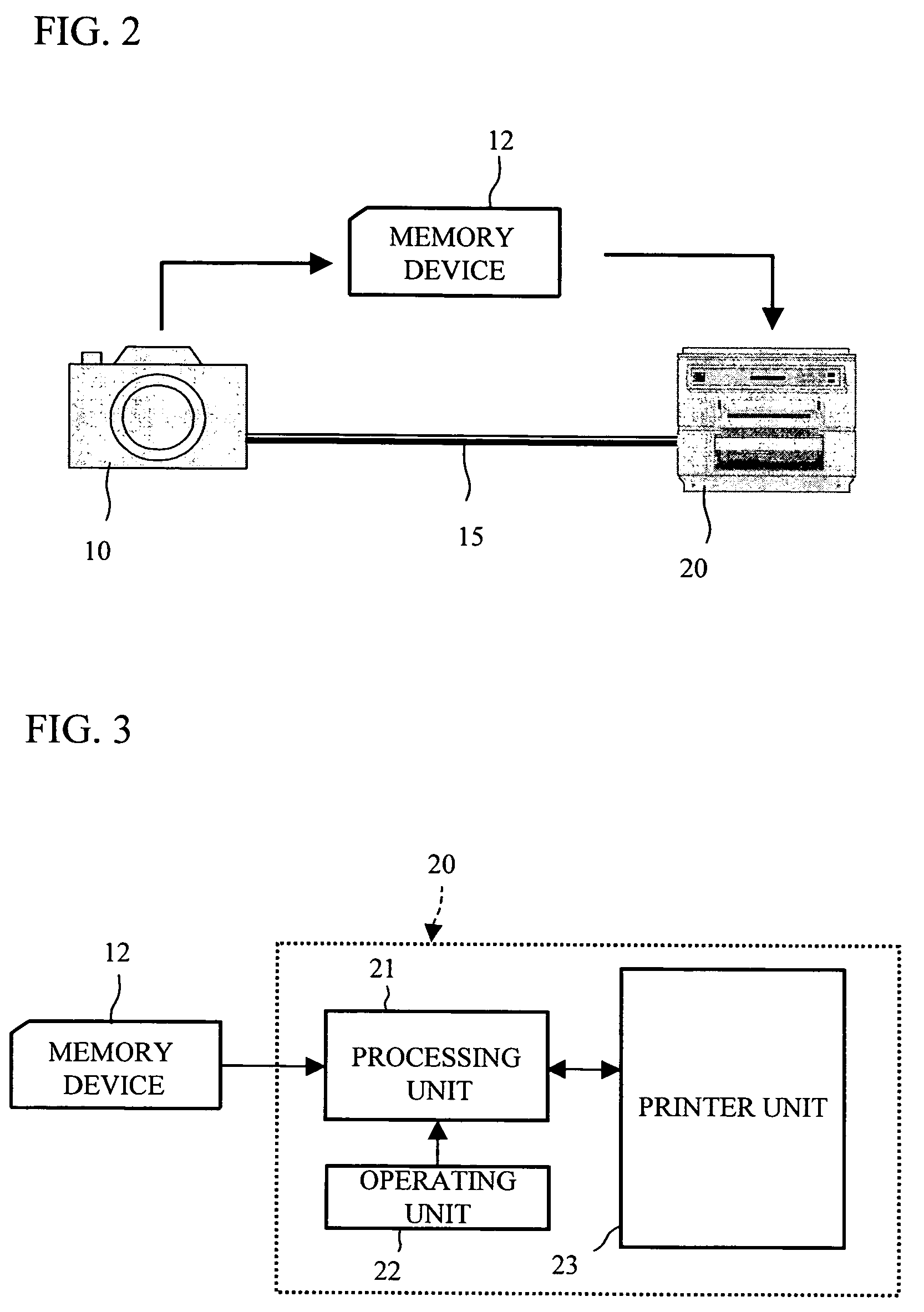

Image output control apparatus, image output control method, image output control program and printer

InactiveUS20050238224A1Easy to distinguishTelevision system detailsDigitally marking record carriersDisplay deviceStereo image

An image output control apparatus is capable of outputting normal images and stereo images from an output unit to a display device or a printer so that the normal images and the stereo images may be distinguishable. The image output control apparatus includes an image type determining unit that determines whether an image to be output is a stereo image or a normal image, the stereo image being composed of a pair of a left-eye image and a right-eye image, and an output form control unit that controls an image output form to distinguish a first image output form from a second image output form, the first image output form being used for outputting the stereo image, and the second image output form being used for outputting the normal image, according to the determination of the image type determining unit.

Owner:FUJIFILM BUSINESS INNOVATION CORP

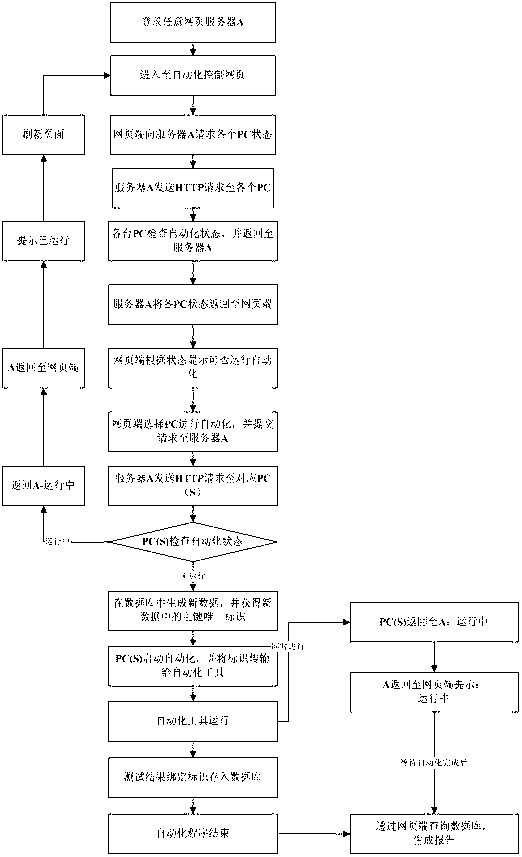

Parallel remote automated testing method

ActiveCN102999424ABrowsing is simple but fastSoftware testing/debuggingTransmissionPersonal computerWeb page

The invention discloses a parallel remote automated testing method. The parallel remote automated testing method is characterized in that a form control automated tool of a web page server is adopted, and testing results are stored by utilizing a database; a platform structure comprises a plurality of PC (personal computer) terminals, and the web page server is established at each automated testing PC terminal; the web page server of each PC terminal is provided with a public database; the web page servers only control the starting of the automated tool and detect whether the automated tool runs; the automated tool stores the testing results into the database according to an unique identification distributed by the web page server; and a web page terminal extracts the report content according to the unique identification, and a testing report is generated through inquiry statistics. According to the invention, multiple PCs are controlled, can be controlled by a console, and run synchronously without mutual interference, and write-in reports are mutually individual in carrying out automation.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Self-raising form control system and method

ActiveUS8020271B2Precise and even lifting of liftWell formedAutomatic control devicesAssembly machinesMeasurement deviceControl system

A self-raising form control system and method is provided that that may be used to form elevator shafts and other vertical building structures. The apparatus includes one or more form elements for defining an area to receive a formable material, such as concrete. Each element is attached to the form structure. A lift apparatus is provided for lifting the form elements. The lift apparatus comprises a measurement device for measuring the position of said lift apparatus relative to a fixed point. The lift apparatus is connected to the form structure. A control unit is provided for controlling the lift apparatus. The control unit is signal connected to the measurement device and is signal connected to the lift apparatus.

Owner:FORMING CONCEPTS INC

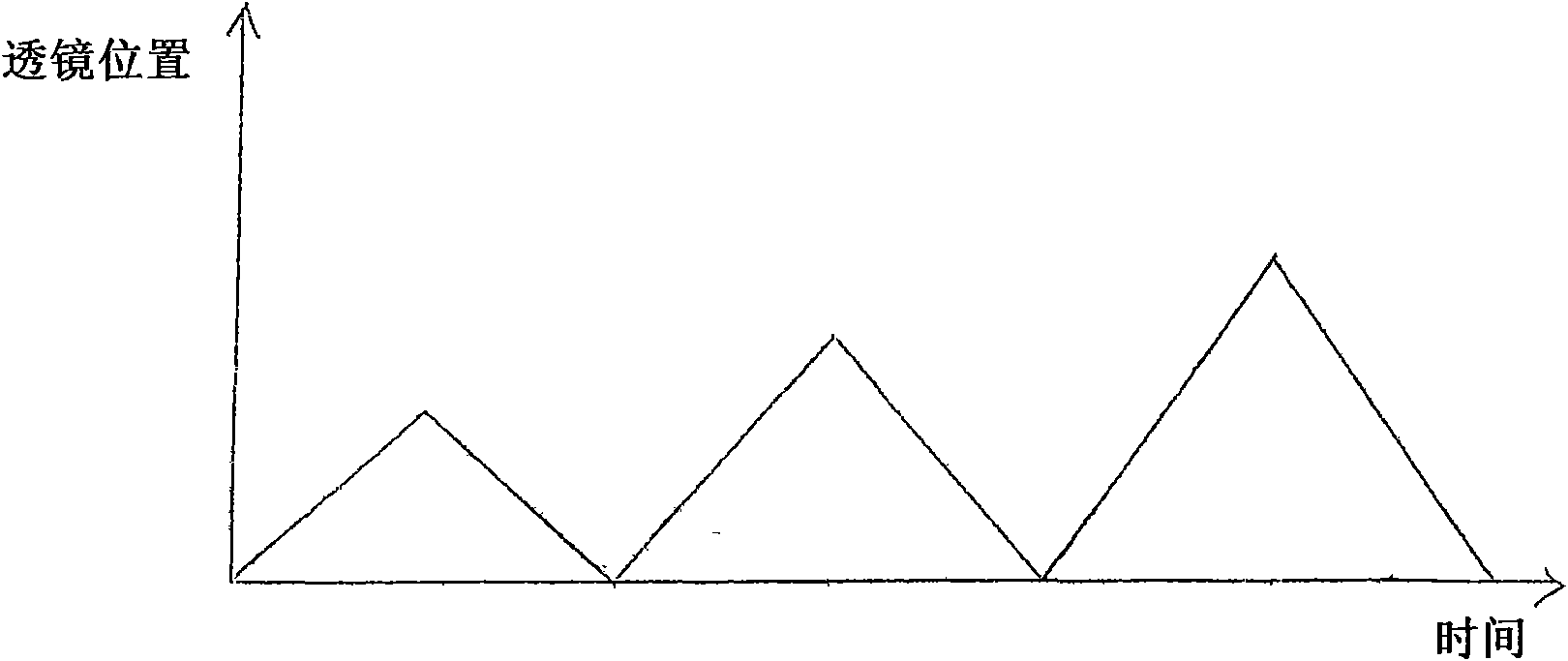

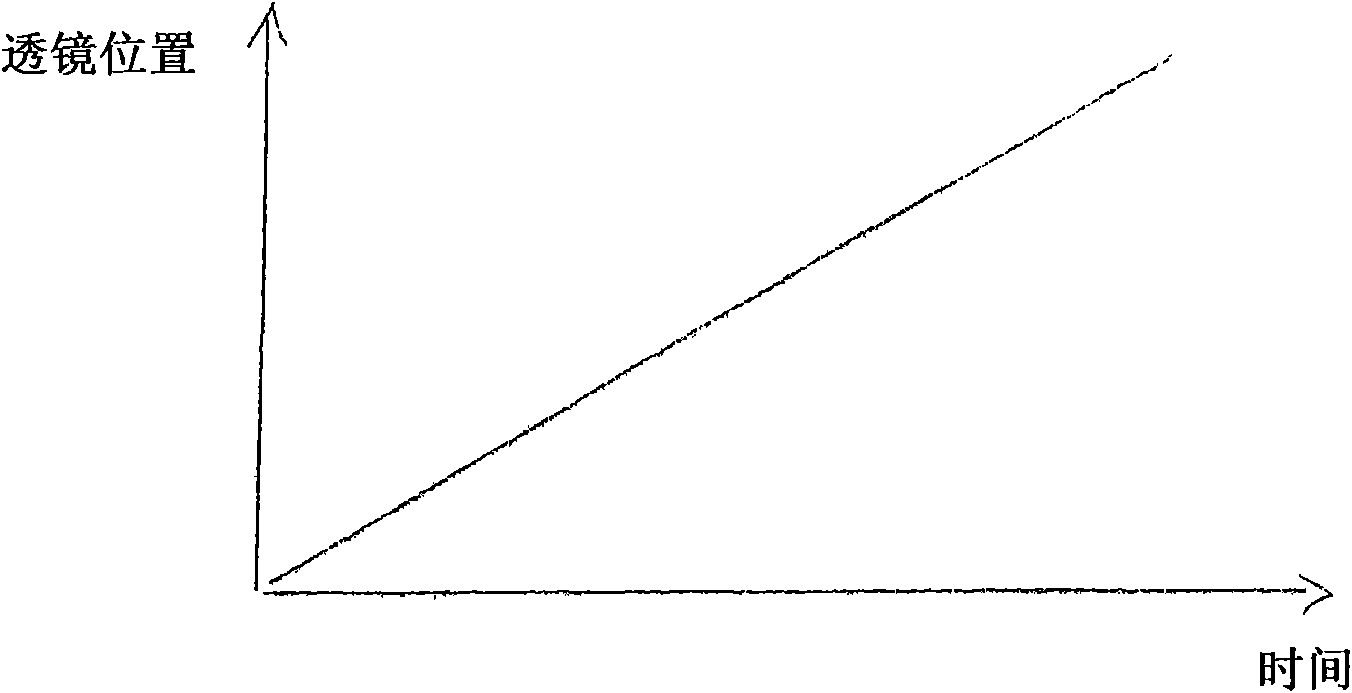

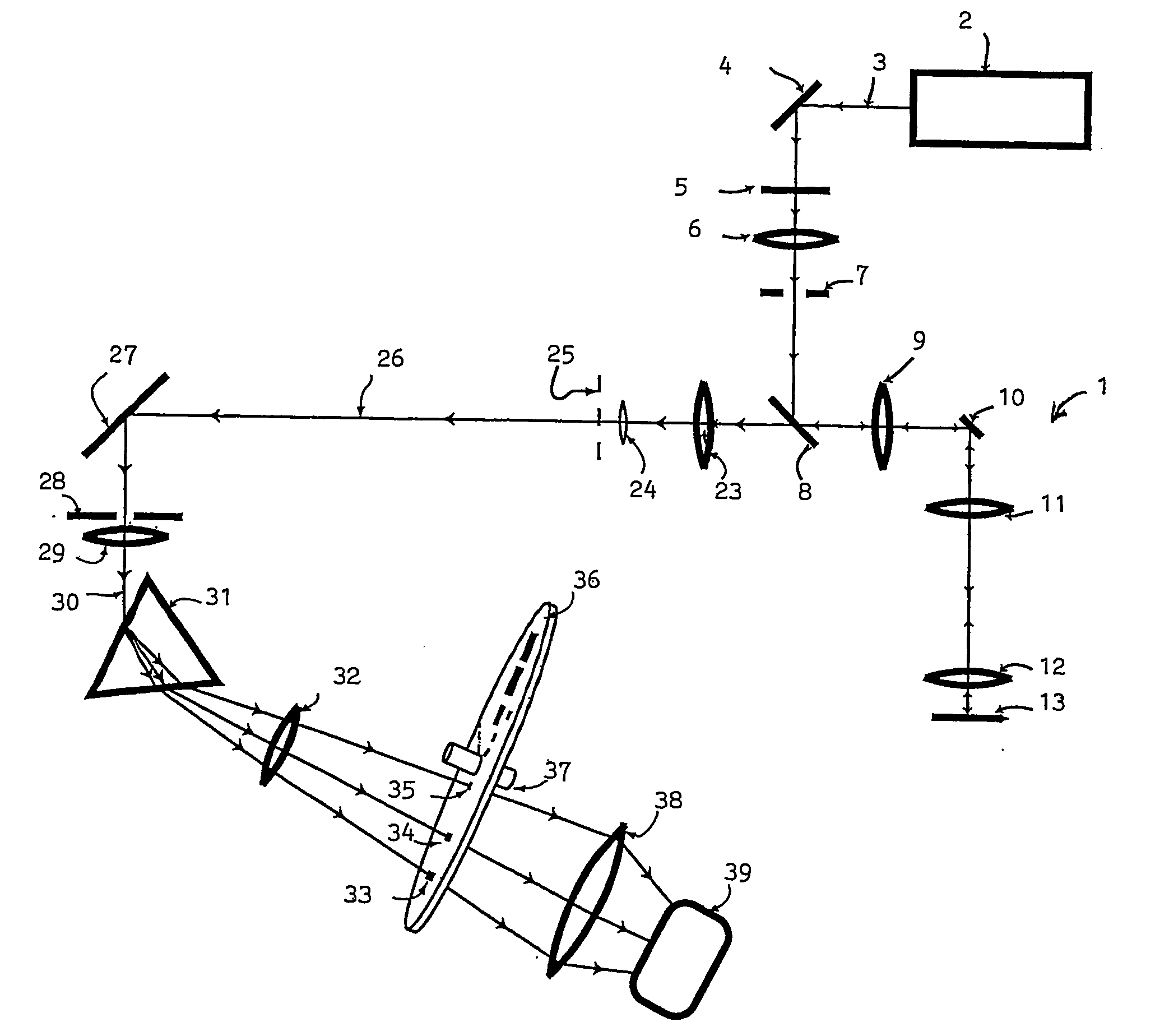

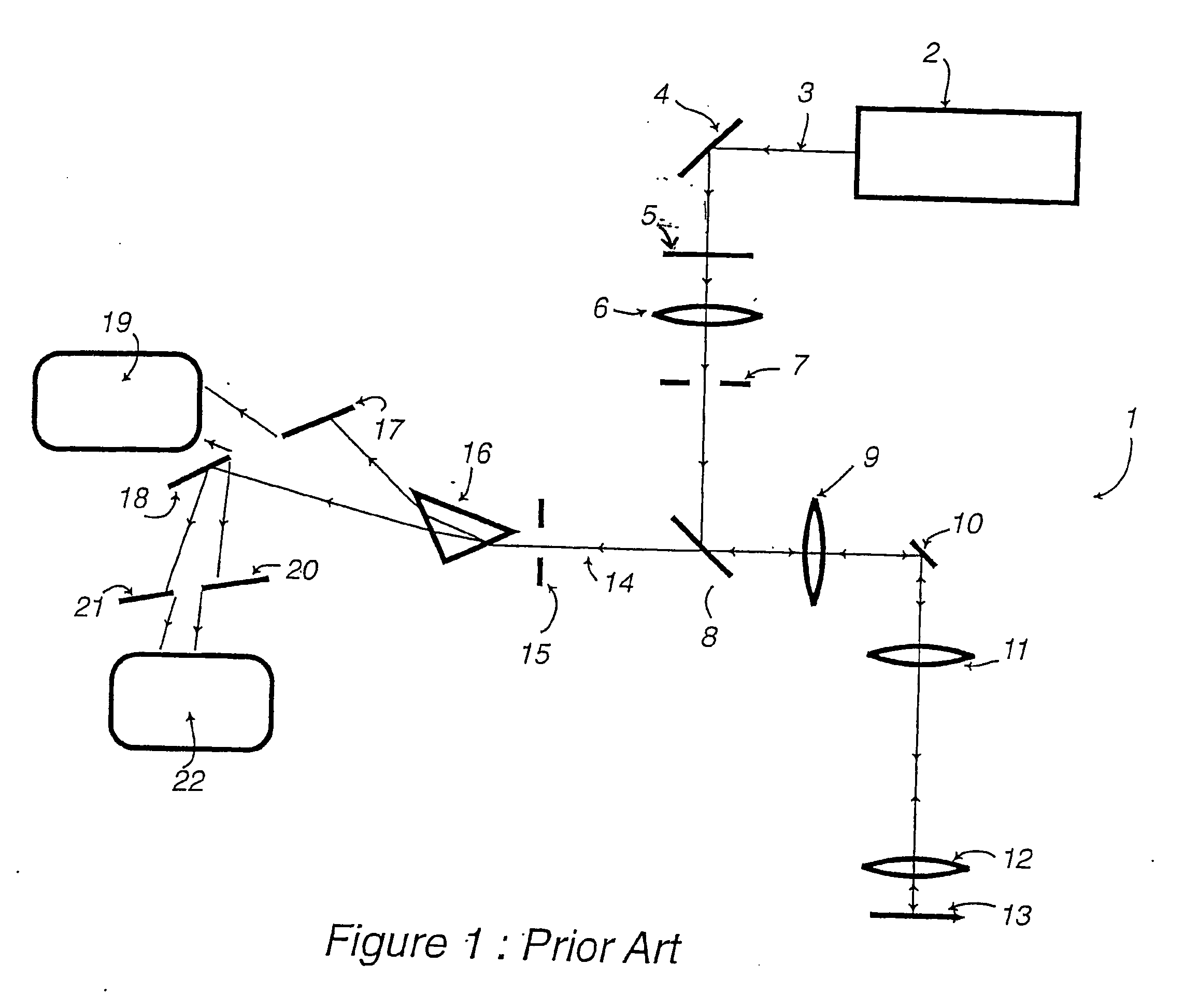

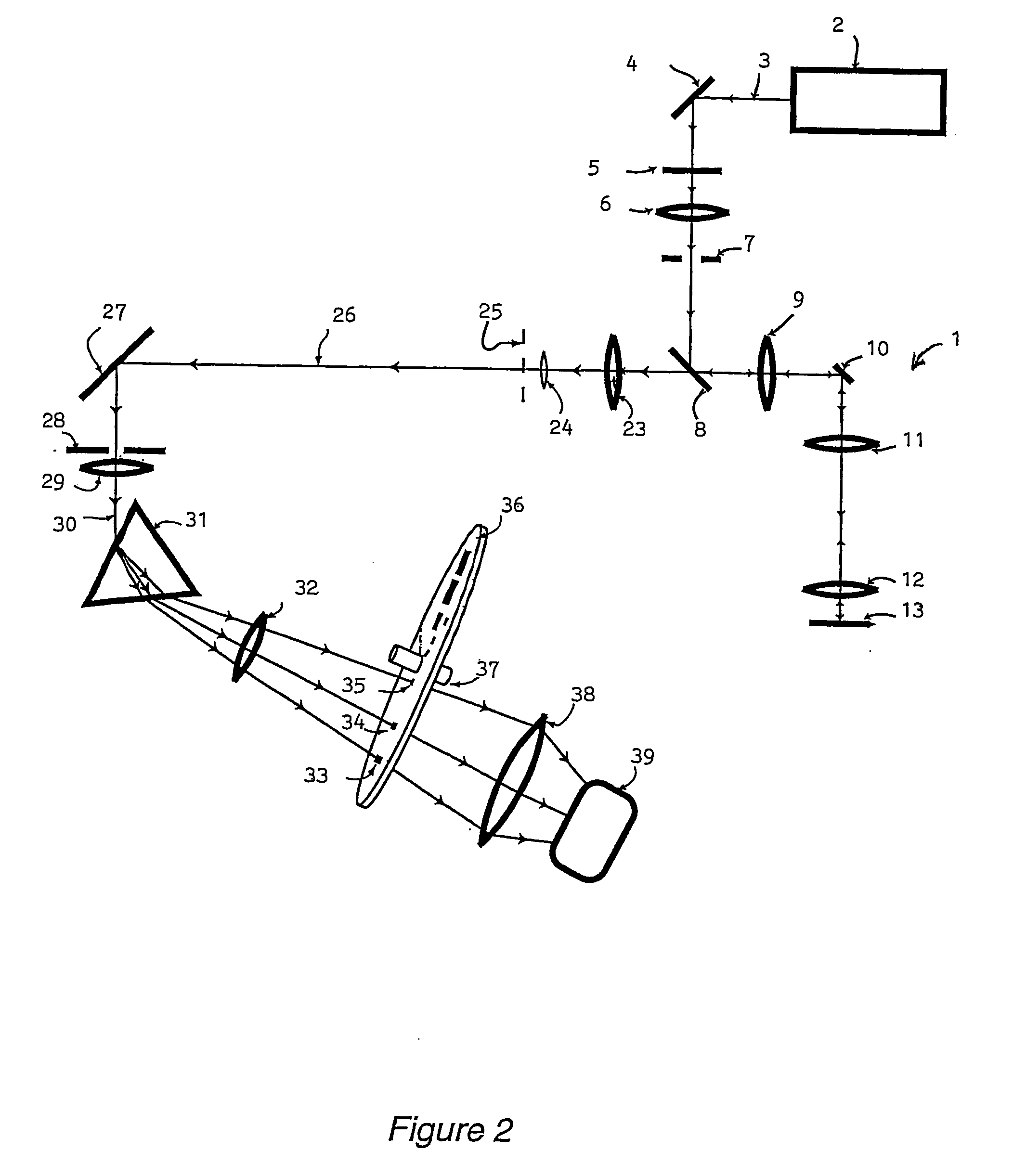

Spectral discrimination apparatus and method

InactiveUS20090021819A1Economic controlProduced cheaplyRadiation pyrometrySpectrum investigationCamFormal control

There is provided spectral discrimination apparatus for use in a scanning optical microscope, the spectral discrimination apparatus comprising dispersive means (31) and frequency selective means including a rotatable disc (36) or discs. The discs are formed with apertures or spiral slots which, on rotation of the disc or discs, controls the frequency of light transmitted by the apparatus. The apparatus includes a detector (39) for receiving light from the frequency selective means. The, or each, rotatable disc (36) is positioned at an aperture plane after the dispersive means (31), although this is not essential if the rotatable disc has its outer periphery shaped to provide a cam surface engaged by a cam follower. There is also provided a method of spectral discrimination in a scanning optical microscope, comprising dispersing the light and passing the light through frequency selective means in which the form of rotating discs controls the frequency of transmitted light.

Owner:MEDICAL RESEARCH COUNCIL

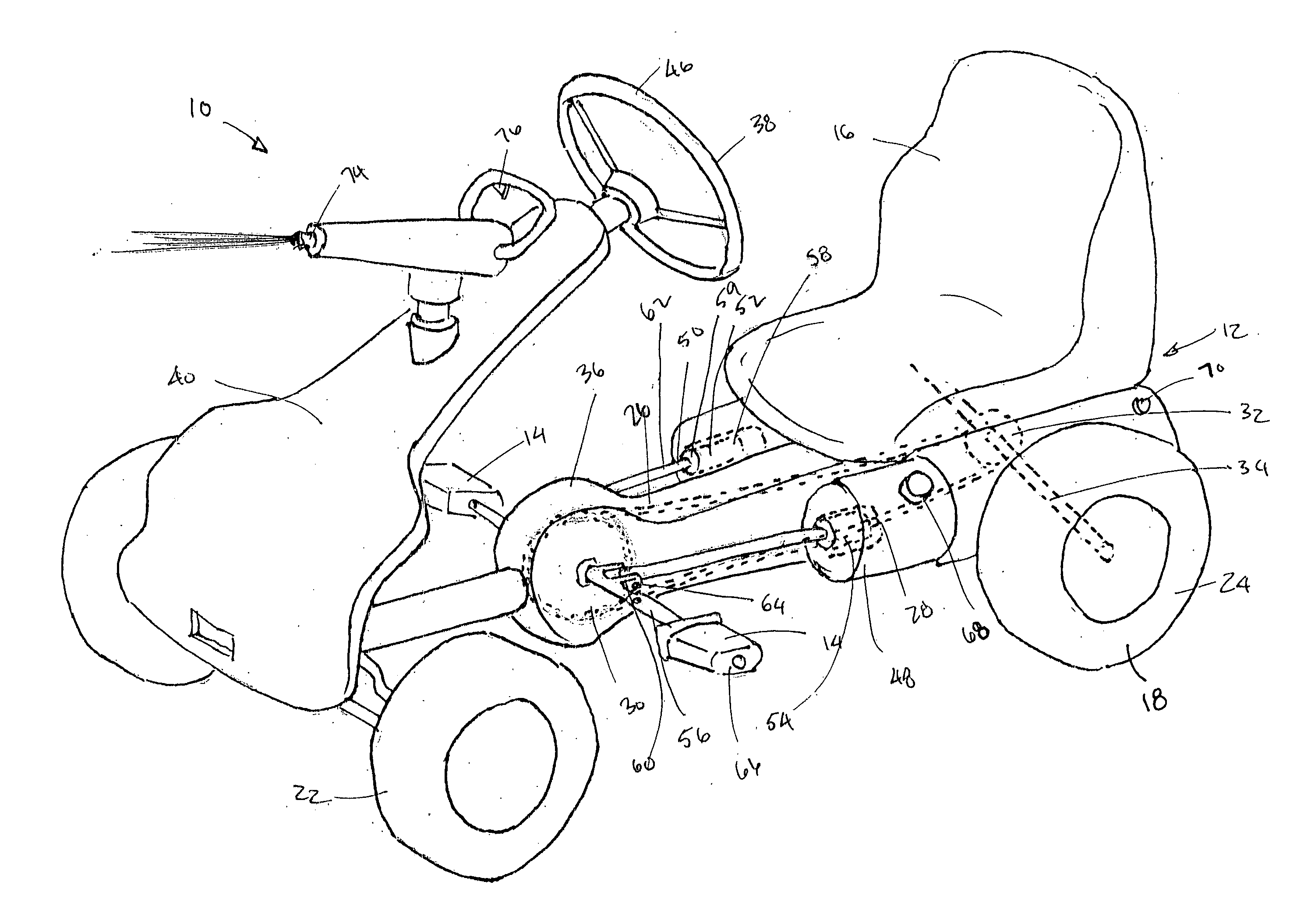

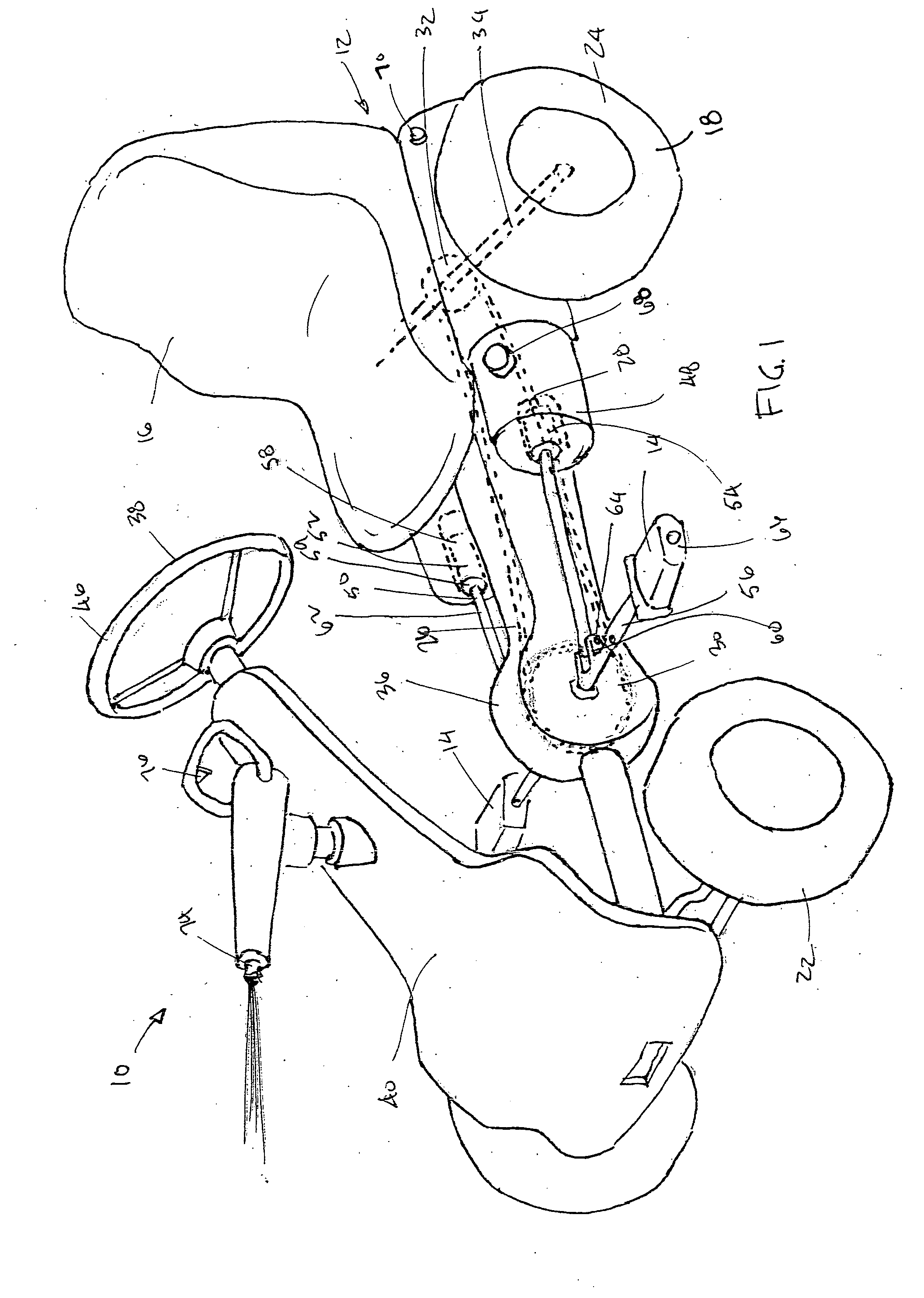

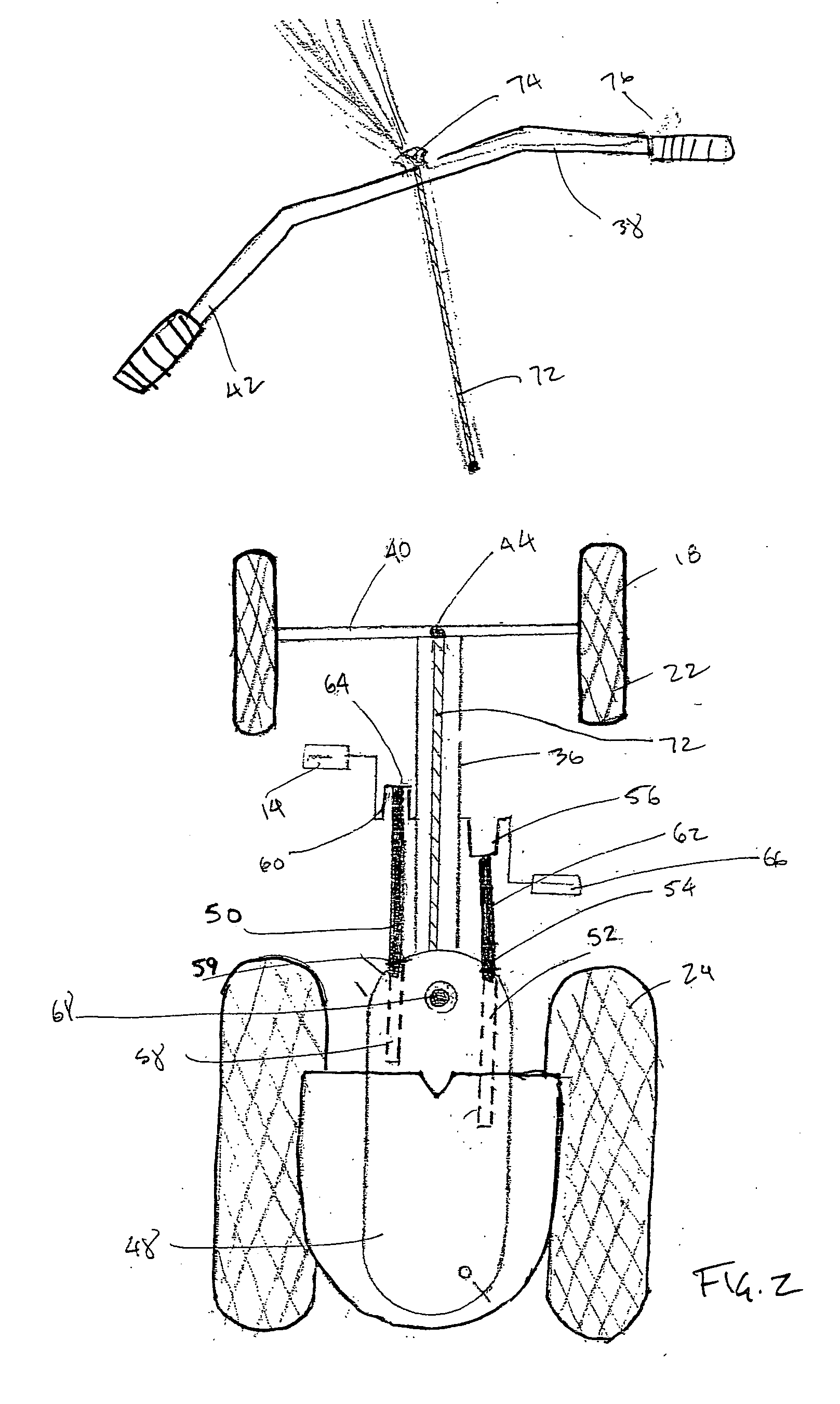

Pedal-operated fluid dispensing apparatus

InactiveUS20050242133A1Easy to operateSeed and root treatmentCycle equipmentsEngineeringSafety valve

A fluid dispensing apparatus integrated within a pedal operated vehicle such as bicycles, tricycles, three-wheelers, four-wheelers and paddleboats is provided comprising a means for storing a fluid, such as water, a means for pressurizing said stored fluid, a means for controlling the release of said pressurized fluid in the form of one or more jets. In the preferred embodiment, the fluid is stored within one or more tanks or reservoirs, which tanks include a pump mechanism for pressurizing the tanks and the fluid stored therein. The pump mechanism includes pistons which are connected to the pedal cranks of the vehicle such that operation of the pedals so as to propel the vehicle simultaneously serves to reciprocate the pistons of the pump mechanism, thereby pressurizing the fluid tanks. Connected to the fluid storage tanks is at least one conduit or hose which is connected at its opposite end to a nozzle for dispensing the fluid. A trigger is incorporated with said nozzle so as to allow the user to alternatively release the pressurized fluid or stop the flow of said fluid. The nozzle may be incorporated on the handlebars or steering mechanism of the vehicle such that the fluid is released in the direction the vehicle is facing. A safety valve is also provided for the storage tanks to prevent the generation of dangerous pressure level.

Owner:WARD WILLIAM A

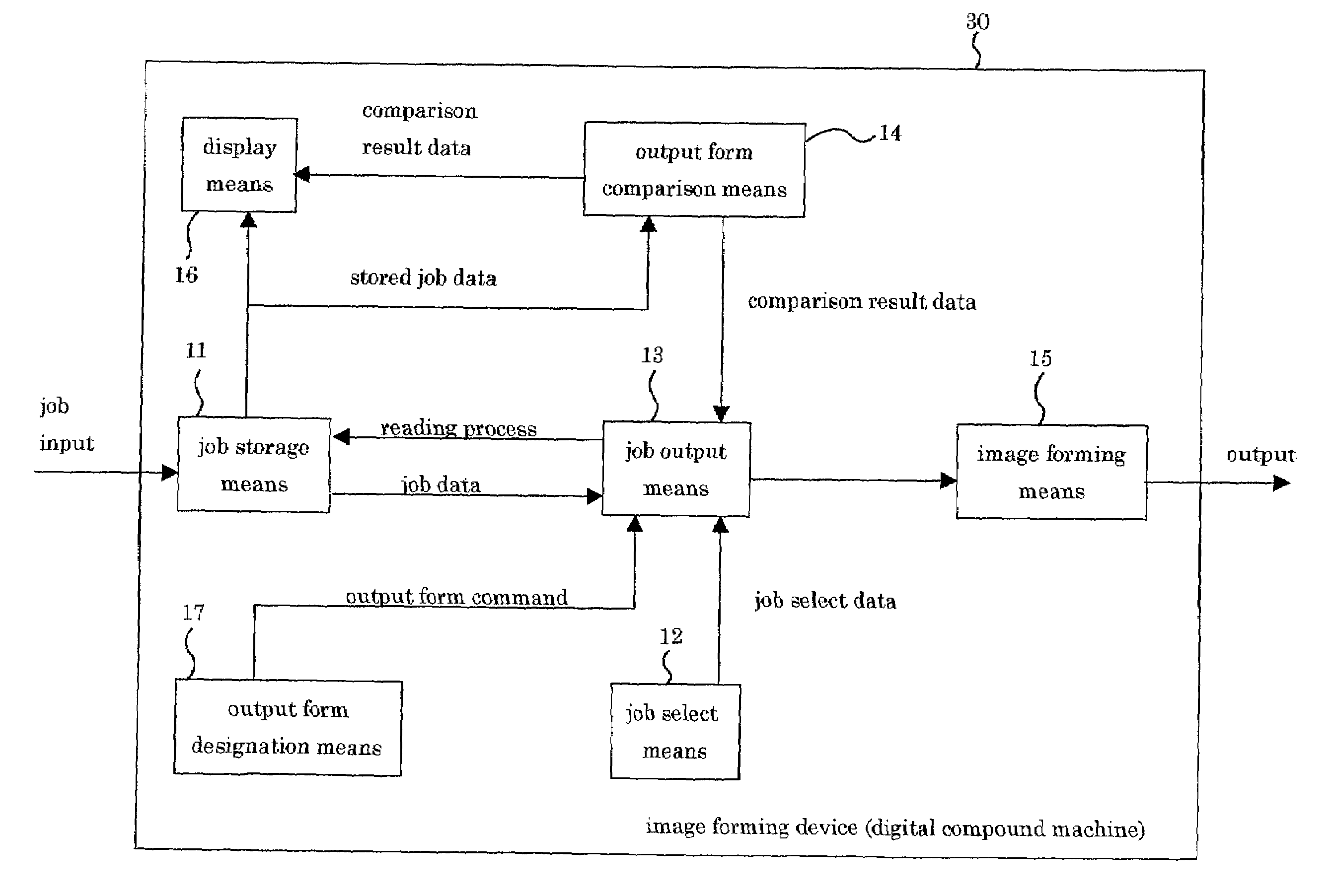

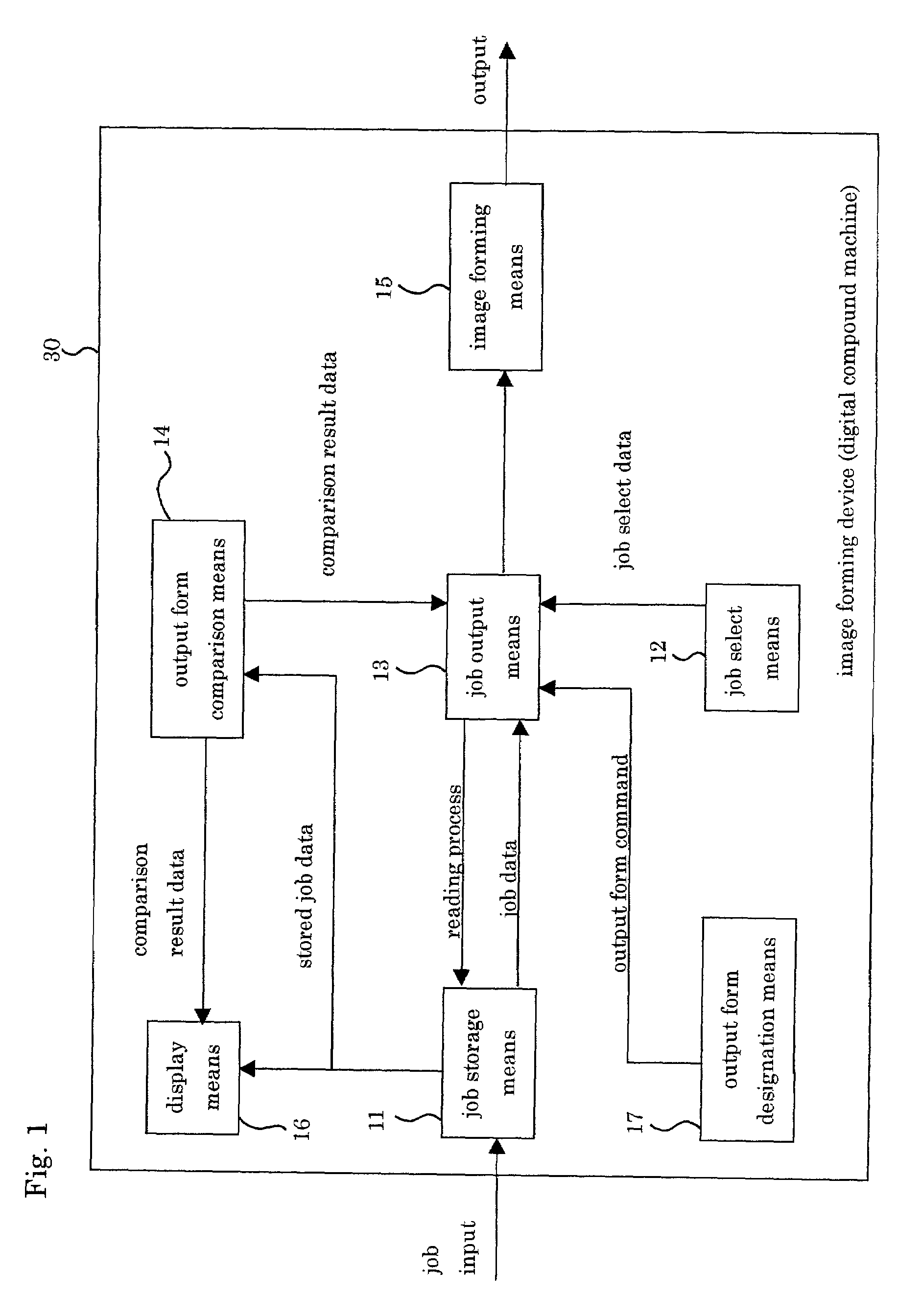

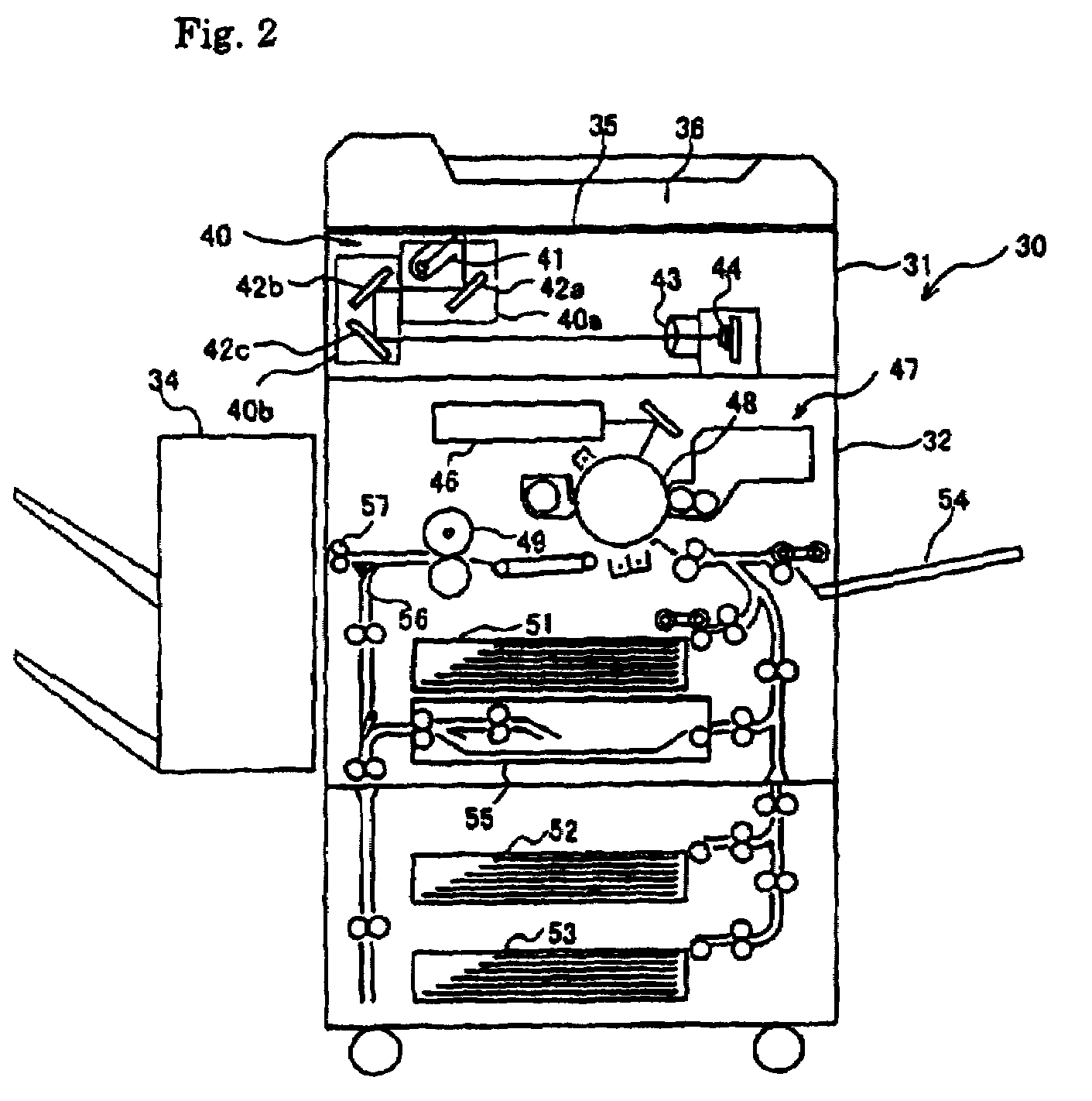

Image forming device for image output form control

InactiveUS7133150B2Easy to understandEasy to operateDigitally marking record carriersDigital computer detailsImage formationComputer science

Owner:SHARP KK

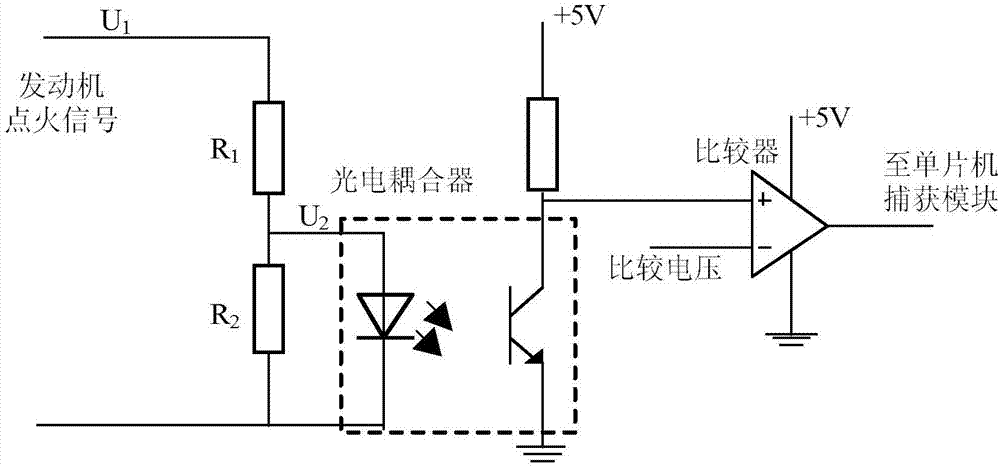

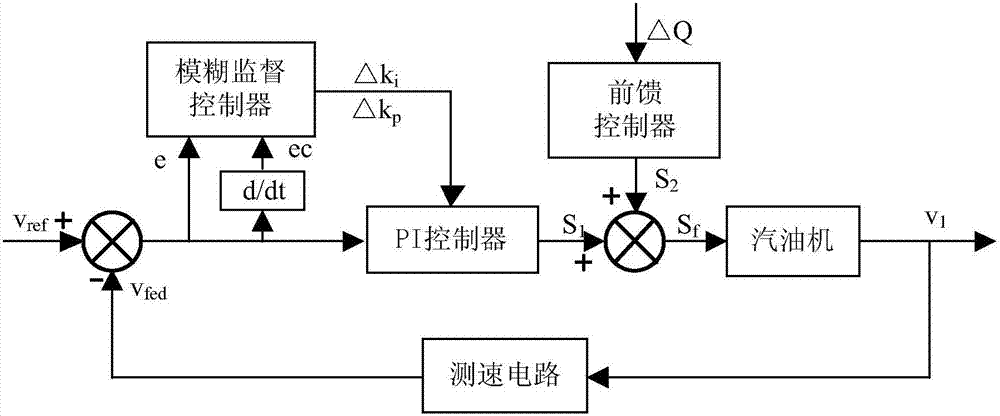

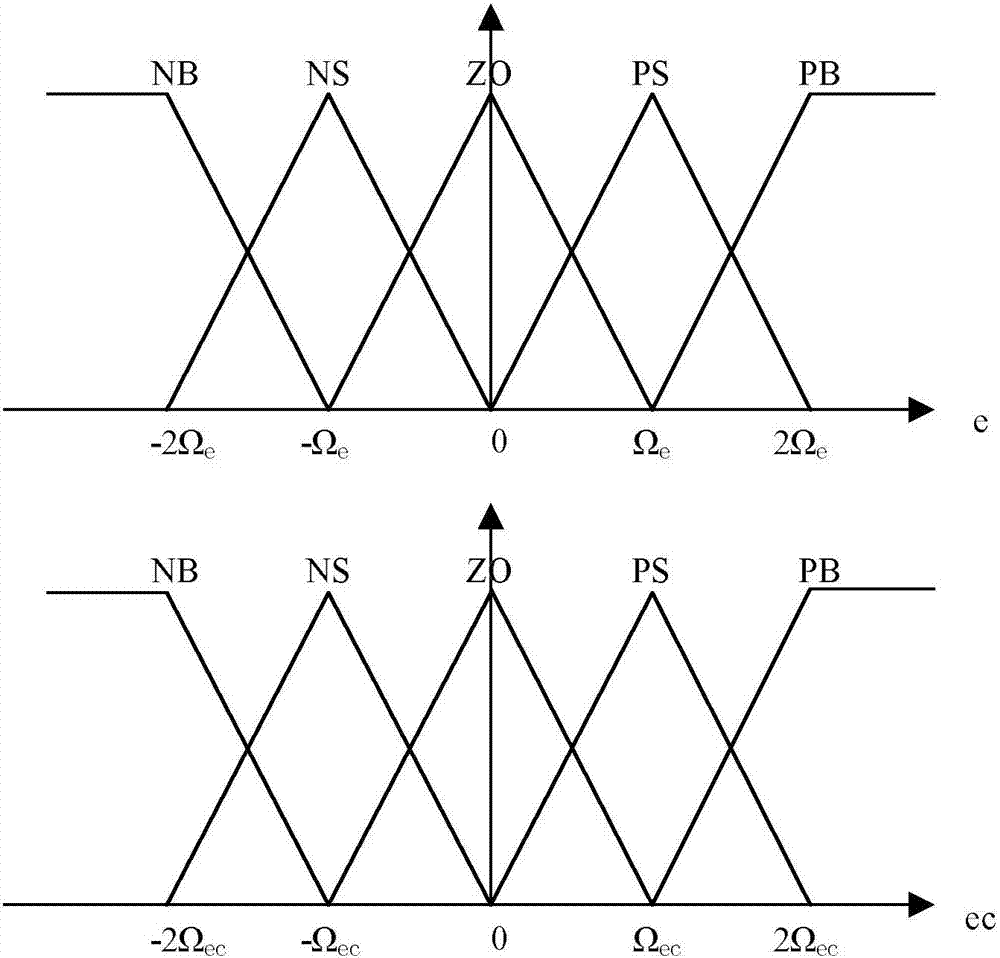

Servo control method for gasoline engine speed in hydraulic system of legged robot

ActiveCN106870181AStable speedReduce speed fluctuationElectrical controlSpeed sensing governorsLegged robotGasoline

The invention provides a servo control method for the gasoline engine speed in a hydraulic system of a legged robot. The servo control method comprises the following steps: (1) calculating the engine speed error e and the engine speed error change rate ec; (2), after the fuzzy logic calculation of e and ec, outputting the proportionality coefficient increment delta kp and the integral coefficient increment delta ki; (3) calculating the proportionality coefficient and the integral coefficient according to the following formulas correspondingly: kp = kp0 + delta kp and ki = ki0 + delta ki; (4) calculating the accelerator opening degree according to the following formula: S1 = S1_old + kp*ec + ki*e; (5) calculating the accelerator opening degree change caused by the hydraulic oil flow rate change according to the following formula: S2 = kQ*detal Q; and (6) calculating the final accelerator opening degree Sf = S1 + S2, wherein the rotation of a steering engine is controlled through the accelerator opening degree in the PWM form, the air inlet volume is controlled by controlling the opening degree of an engine throttle valve through an accelerator cable, and finally the engine speed is controlled. The servo control method provided by the invention has the advantages that the feedforward control is adopted, so that the stable engine speed can be guaranteed well under the circumstance that the flow rate changes suddenly; parameters are modified online by adoption of fuzzy self-tuning, so that the different control requirements can be met; and accordingly, the hydraulic system can have the good dynamic property and static property.

Owner:SHANDONG UNIV

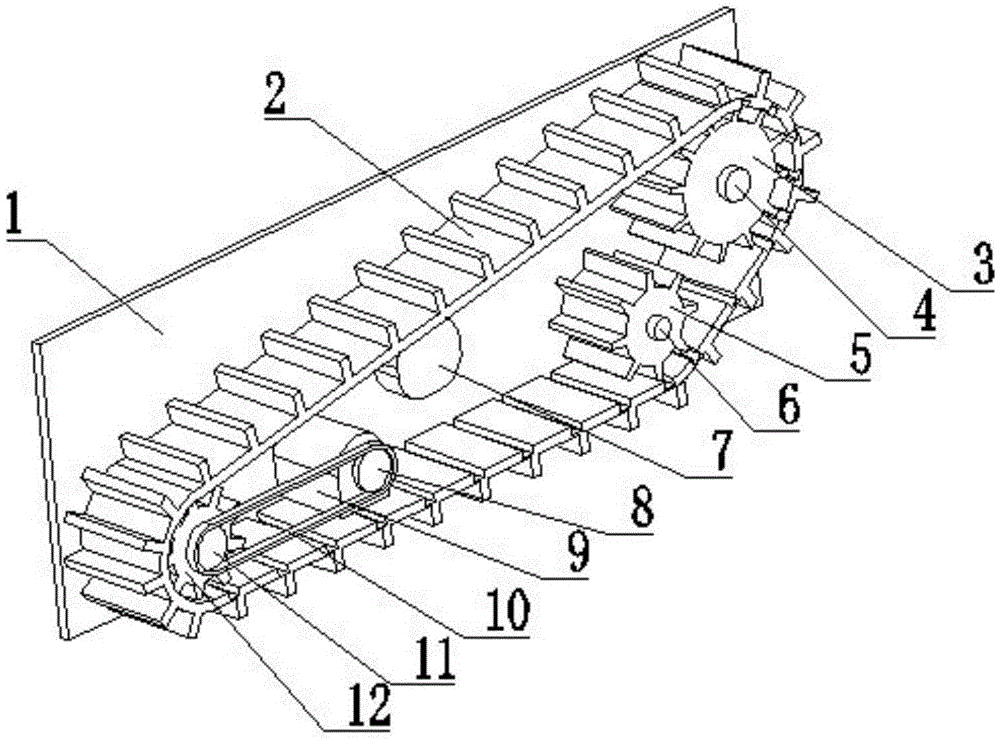

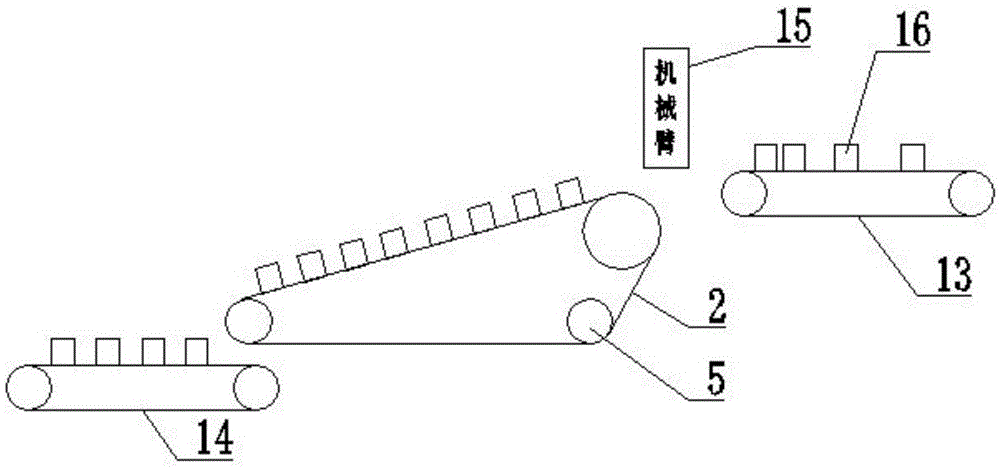

Counting type conveying control equipment

InactiveCN105540157AControl delivery speedControllable conveying speedControl devices for conveyorsPackaging automatic controlDrive wheelEngineering

The invention discloses counting type conveying control equipment which comprises baffles, a conveyor belt, a first driven wheel, a second driven wheel, an FXN-MR, a servo motor, a driving chain wheel, a chain and a driven chain wheel, wherein the baffles are installed on a working platform; a first driven wheel shaft, a second driven wheel shaft, the FXN-MR and the servo motor are fixedly installed on the baffles; the conveyor belt is composed of a base band and a transverse partition plate; the baffles are installed on the two side surfaces of the conveyor belt respectively; an interval is formed between the conveyor belt and each baffle; the first driven wheel is installed on the first driven wheel shaft and is provided with a rotary pair; and the second driven wheel is installed on the second driven wheel shaft and is provided with a rotary pair. According to the counting type conveying control equipment disclosed by the invention, with the adoption of the nylon conveyor belt with the transverse partition plate, uniform large-inclination conveying of goods can be realized; meanwhile, as the conveyor belt moves controlled by a PLC counting manner, the conveying speed of the goods can be controlled; and as being controlled by a PLC module, the whole process is smooth and reliable and is rapid in operation speed.

Owner:王嫣俐

Image output control apparatus, image output control method, image output control program and printer

InactiveUS7570385B2Easy to distinguishTelevision system detailsDigitally marking record carriersDisplay deviceImage type

An image output control apparatus is capable of outputting normal images and stereo images from an output unit to a display device or a printer so that the normal images and the stereo images may be distinguishable. The image output control apparatus includes an image type determining unit that determines whether an image to be output is a stereo image or a normal image, the stereo image being composed of a pair of a left-eye image and a right-eye image, and an output form control unit that controls an image output form to distinguish a first image output form from a second image output form, the first image output form being used for outputting the stereo image, and the second image output form being used for outputting the normal image, according to the determination of the image type determining unit.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Anti-rollaway device for trucks and equipment with fluid and electrically actuated brakes

Owner:ACCARDI THOMAS

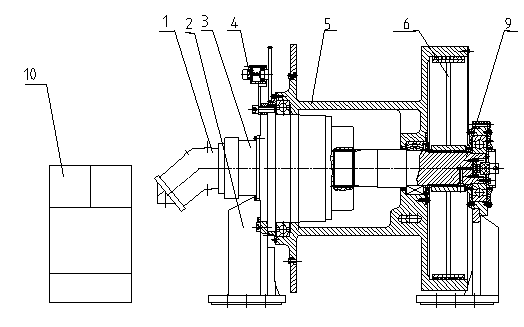

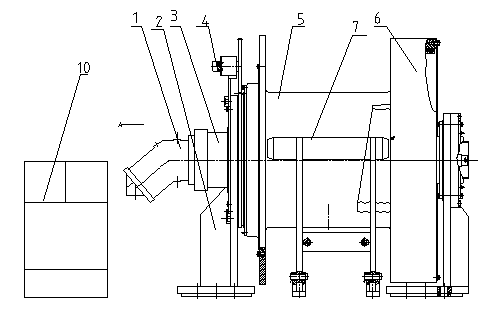

Hoisting mechanism for dynamic compactor

InactiveCN103696412AAvoid entanglementAvoid the phenomenon of tangled ropeWinding mechanismsSoil preservationControl systemEngineering

The invention discloses a hoisting mechanism for a dynamic compactor. The hoisting mechanism comprises a driving motor (1), a speed reducer (3), a reel (5), a brake (8), a spindle (9), an encoder (4) and a control device (10). The hoisting mechanism has the advantages that the hoisting mechanism is simple in structure, an internal expansion clutch is arranged in the reel, and the reel can be driven to rotate, so that the purpose of hoisting a rammer can be achieved; the hoisting mechanism is provided with the calipers brake, a rope pressing roller and the encoder, so that continuous falling of a steel wire rope can be controlled timely after the rammer falls to the ground, and steel wire rope twining and disorder phenomena due to the fact that the steel wire rope is excessively released can be prevented; the falling rammer can be quickly controlled by a control system and the encoder, accordingly, a working procedure for hooking and hoisting an existing rammer again in current construction procedures after the existing rammer is unhooked can be omitted, the construction intensity can be reduced, and potential safety hazards can be eliminated; the hoisting mechanism is compact in structure, convenient to use, high in work efficiency and suitable for large-scale popularization and application, and is safe and reliable.

Owner:TAIAN XINCHUANG ENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com