Control device for working machine

A technology for working machines and control devices, applied in mechanical equipment, transmission control, fluid pressure actuation devices, etc., can solve problems such as pressure loss, system energy efficiency cannot be fully improved, and driving force cannot be obtained immediately, and achieves improved The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The control device of the working machine in the present invention will be described below based on the embodiments shown in the accompanying drawings.

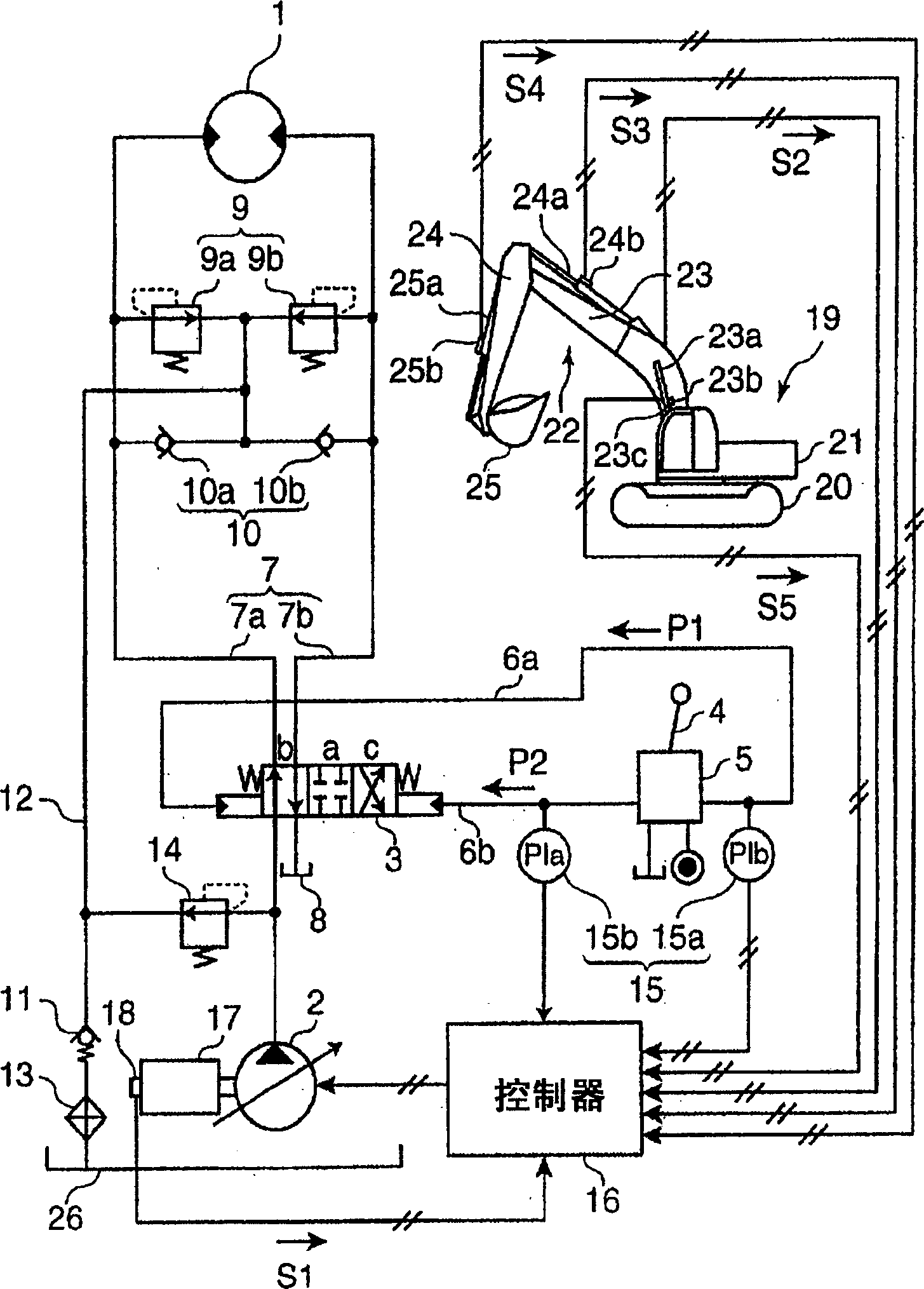

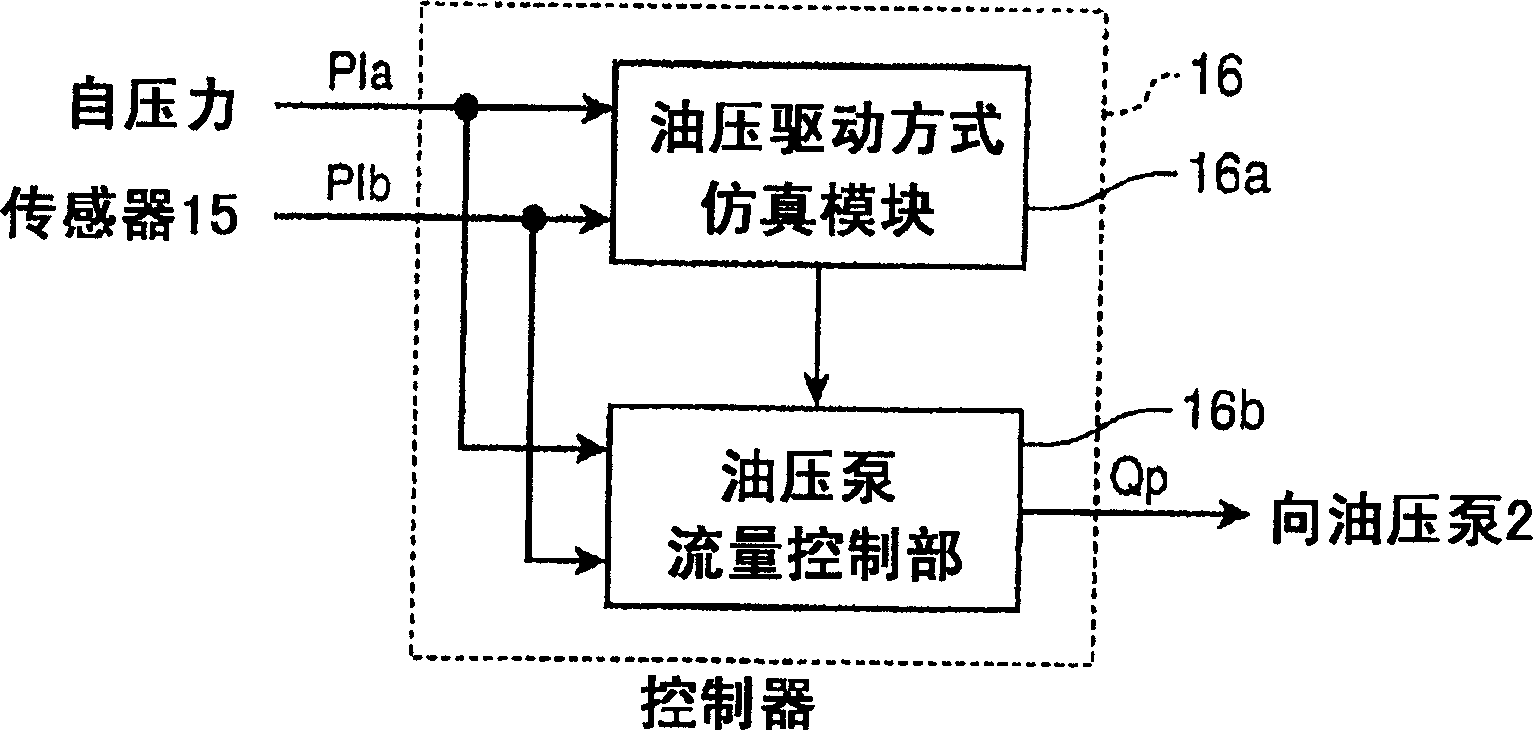

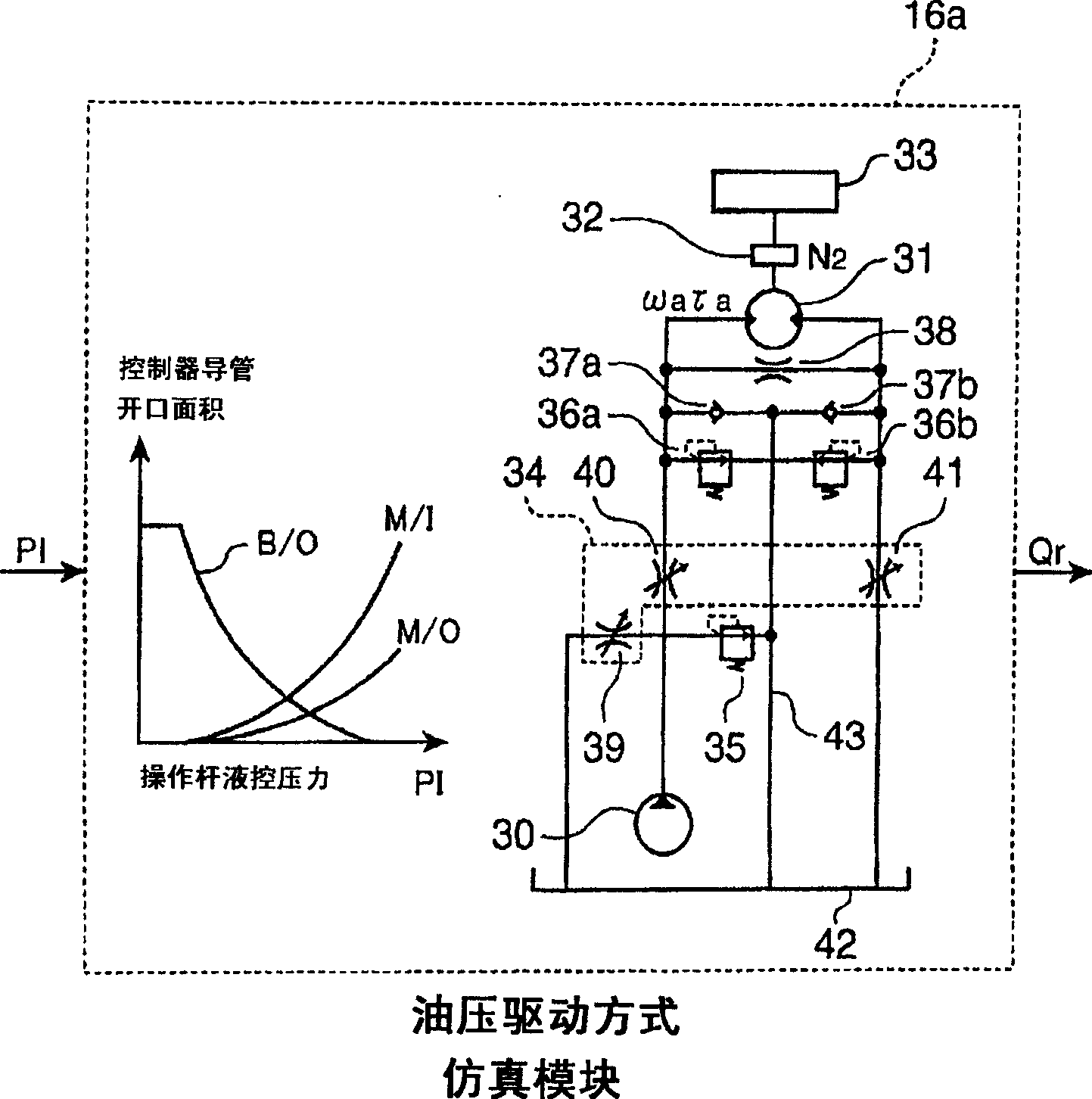

[0025] figure 1 The hydraulic circuit of the hydraulic control device as the control device in the present invention is shown.

[0026] In the figure, 1 is a hydraulic motor as an example of a hydraulic actuator; 2 is a variable capacity hydraulic pump that supplies working oil to the actuator 1.

[0027] 3 is a control valve for controlling the flow rate and direction of hydraulic oil supplied to the actuator 1 . When operating the operating lever 4 as the operating device, the hydraulic control pressure P1 (or P2) derived from the remote control valve 5 acts on the hydraulic control port of any one of the control valve 3 through the control pipeline 6a (or 6b), and the control valve 3 It changes from neutral position a to b or c.

[0028] When the control valve 3 is switched to position b, the pressurized oil from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com