Round code-spurting device in coil strip

A coding and steel coil technology, applied in printing devices, power transmission devices, printing, etc., can solve problems such as harmful to the operator's body, burrs on characters, pollution of the environment, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

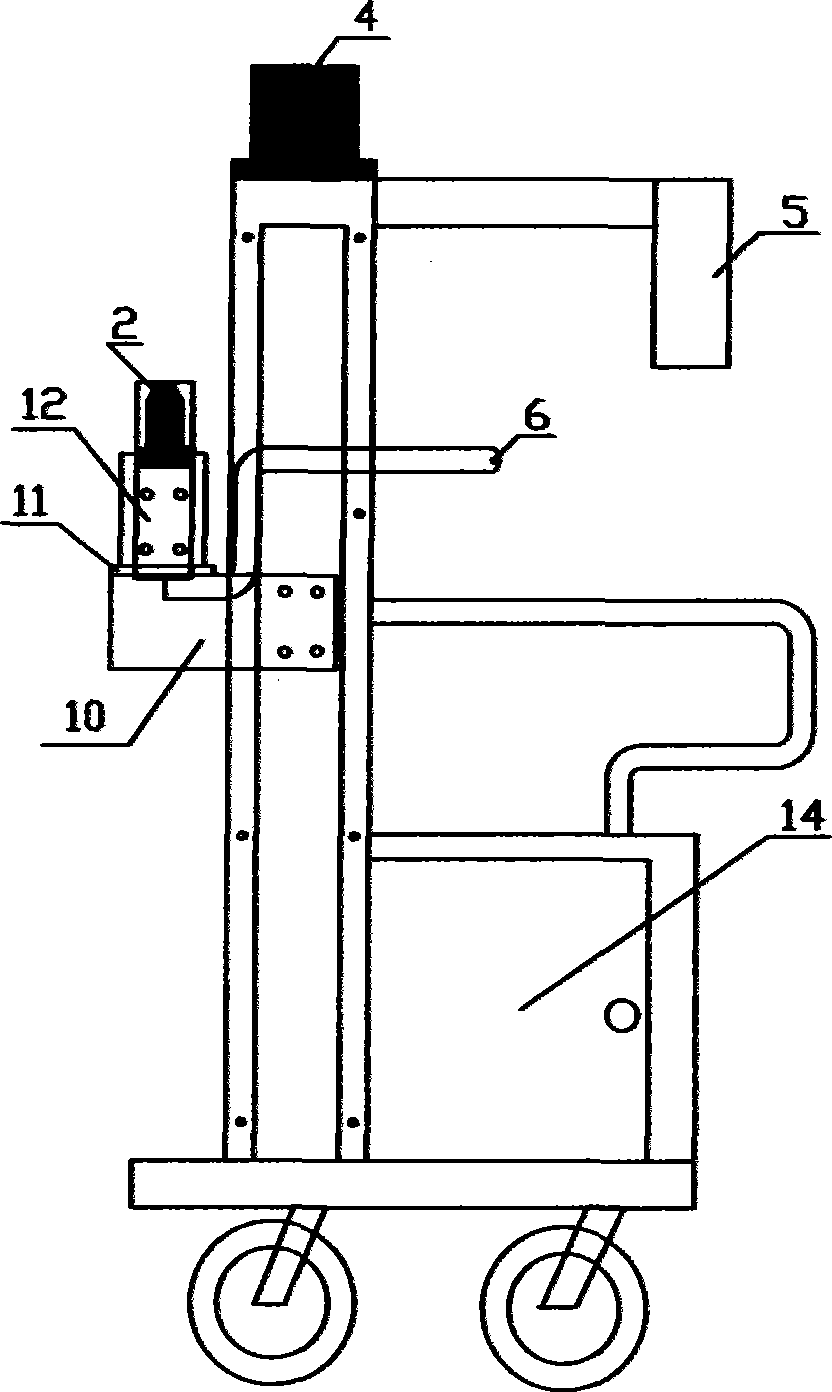

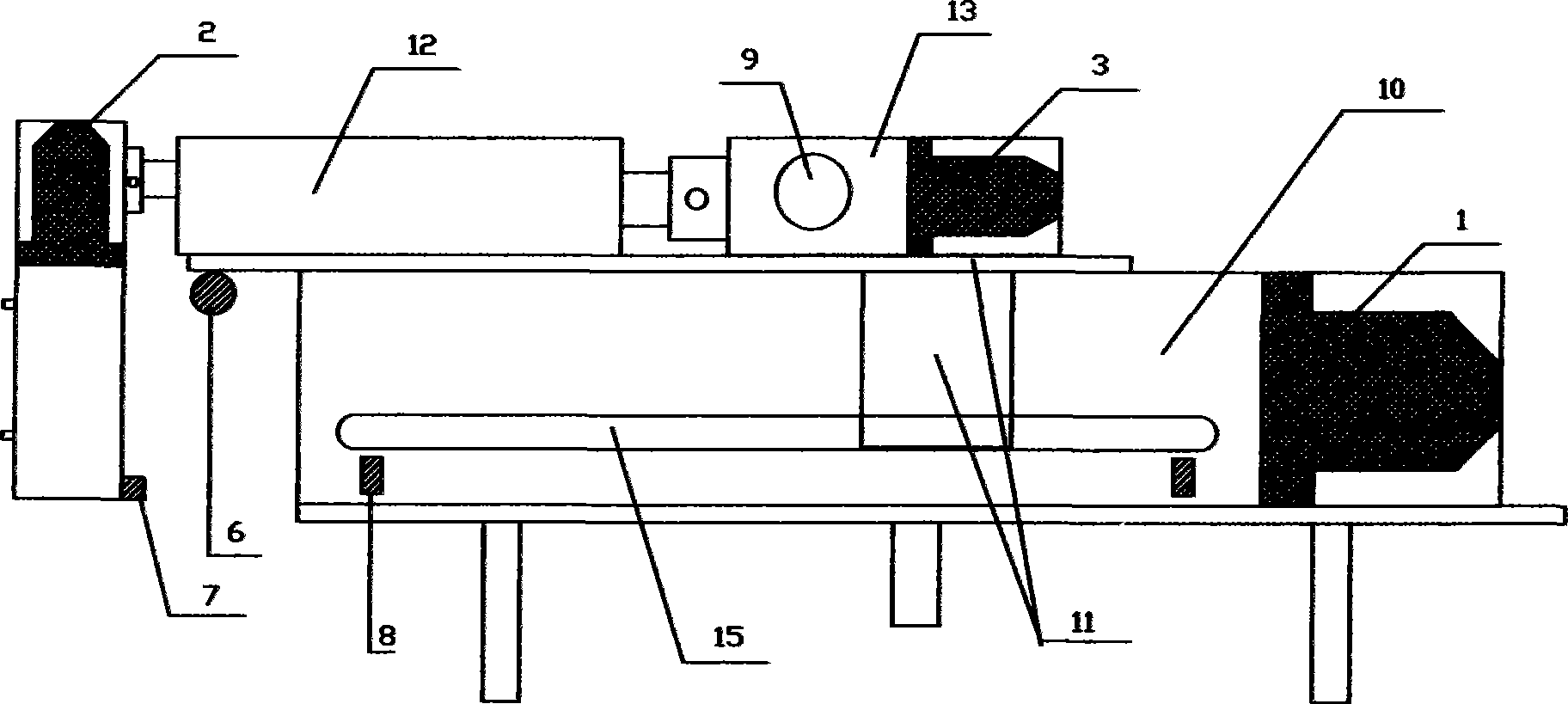

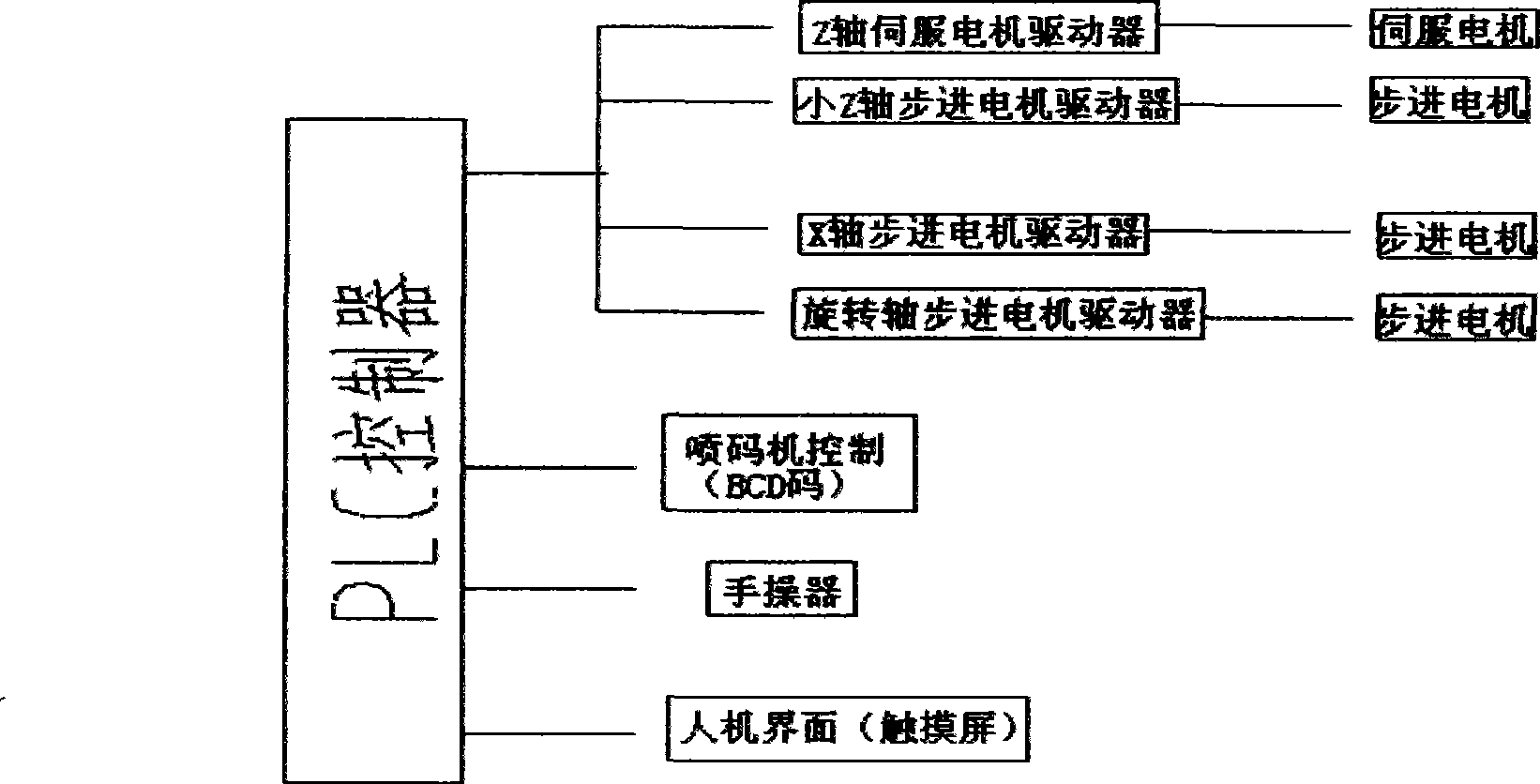

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Since the inner circle size of the steel coil is fixed at 760mm, the large character inkjet printer is non-contact inkjet printing, and the distance between the electric control nozzle and the surface of the object is: 20mm, the maximum length of the electronic control nozzle design of the present invention is (760 / 2-20=360mm ). Due to the different thickness and number of turns of the steel coil, the height of the center of the inner circle of the steel coil from the ground is inconsistent. The arm is automatically raised to the same height as the center of the inner circle of the steel coil. After the mechanical arm reaches the same height as the center of the inner circle of the steel coil, the horizontal telescopic axis-X axis of the mechanical arm is extended, and the nozzle is sent into the inner circle of the steel coil. The moving distance can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com