Hoisting mechanism for dynamic compactor

A technology of lifting mechanism and dynamic tamping machine, which is applied in the direction of clockwork mechanism, infrastructure engineering, soil protection, etc. It can solve the problems of restricting the speed of the rammer falling by itself, heavy workload, unsafety, etc., and achieve reduction The effect of construction strength, high work efficiency, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

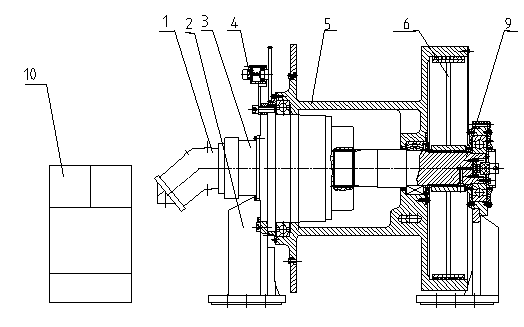

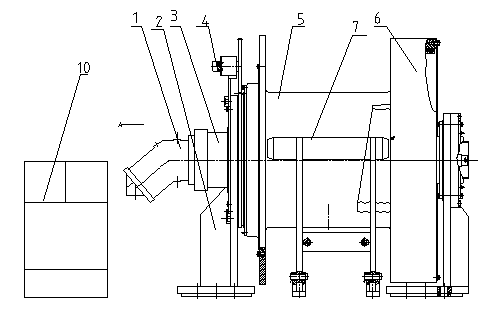

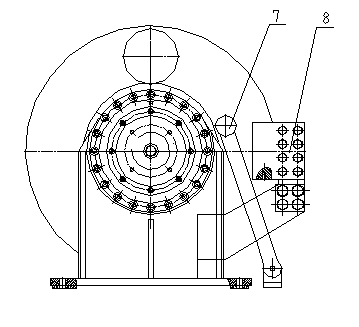

[0017] Such as Figure 1-3 Shown is a specific embodiment of the present invention, the lifting mechanism for a dynamic tamping machine includes a drive motor 1, a reducer 3, a reel 5, a brake 8, a main shaft 9, an encoder 4 and a control device 10, the main shaft 9 is set on the support seat 2, the drive motor 1, the reducer 3, and the main shaft 9 are connected in sequence, the reel 5 is wound with a steel wire rope and arranged on the main shaft 9, and the reel 5 is provided with a clutch device 6. A braking device 8 is provided outside the reel 5, and the encoder 4 is arranged on the top of the support base 2 and connected with the reel 5 through a set of gears to record the number of revolutions of the reel 5. The control device 10 is signal-connected with the encoder 4 to control the rotation direction of the reel 5, control the lifting and rapid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com