Welding system for generating steel bars and steel belts

A welding system and steel strip technology, applied in the field of machinery, can solve the problems of low efficiency, high labor intensity, time-consuming and labor-intensive, etc., and achieve the effect of improving production efficiency and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It is only intended to describe the specific implementation of the present invention in detail, and does not impose any limitation on the present invention, and the scope of protection of the present invention shall be determined by the claims.

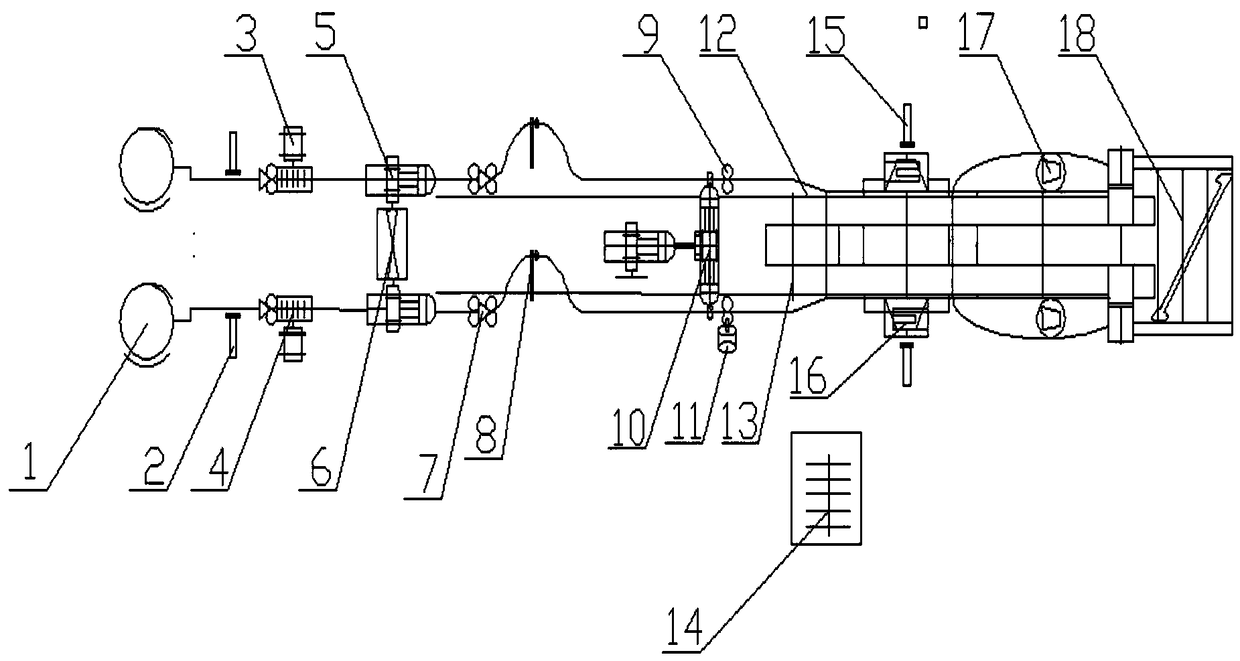

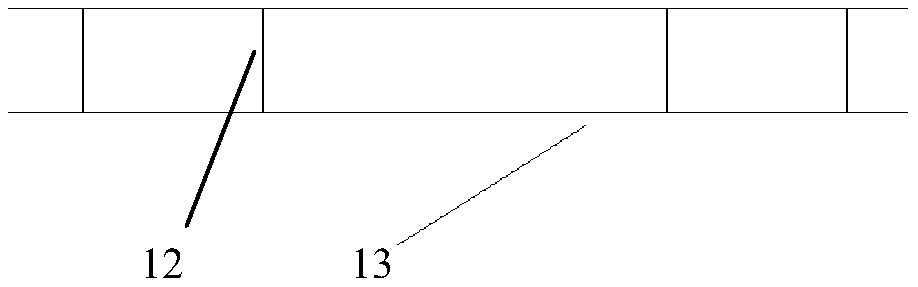

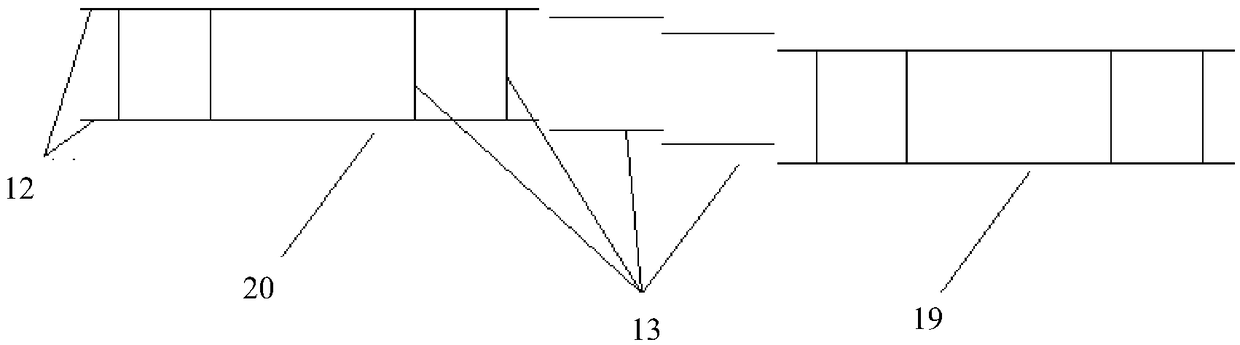

[0027] refer to figure 1 , the present invention proposes a welding system for generating steel strips, comprising:

[0028] Coil material straightening system 4, coil material butt welding device 5, roller conveying device 7, material storage buffer and feedback system 8, pull wire sensor, long material synchronous feeding device 10, short joint feeding device 14, resistance pressure welding welding system 16 and control system;

[0029] The coil straightening system 4 is connected with the coil butt welding device 5, the coil butt welding device 5 and the storage buffer and feedback system 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com