Sand mulling and sieving device

A technology of sand screening and sand mixing, applied in foundry molding equipment, machinery for cleaning/processing mold materials, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

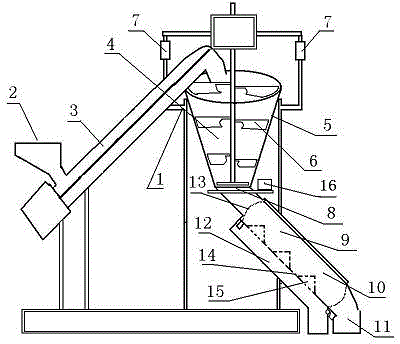

[0010] exist figure 1 Above, the sand mixing and screening device includes a bracket 1, a feed port 2, a screw conveyor 3, a sand mixer 4 and a vibrating screen 9, and the sand mixer 4 consists of a cylinder 5, a stirring spiral impeller 6, and an impeller lifting structure 7 , The discharge port 8 is formed, the cylinder body 5 is an inverted cone structure, the stirring spiral impeller 6 is close to the cylinder body 5 from top to bottom, the discharge port 8 is installed at the bottom of the cylinder body 5; and the discharge port 8 is set A program-controlled control mechanism 16; the vibrating screen 9 is composed of a sleeve 12, a semi-cylindrical structural screen 10, and a vibrating motor. The semi-cylindrical structural screen 10 extends into the sleeve 12 as a whole. Arc-closed cylinder plate 13 and straight screen 14, vibrating motors are installed at both ends of straight screen 14; one end of vibrating screen 9 is connected to the discharge port 8 of sand mixer 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com