Packaging machine and method for filling pouches

A packaging machine and filling bag technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of insufficient weight, and achieve the effect of accelerating the filling process, degassing, and efficient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

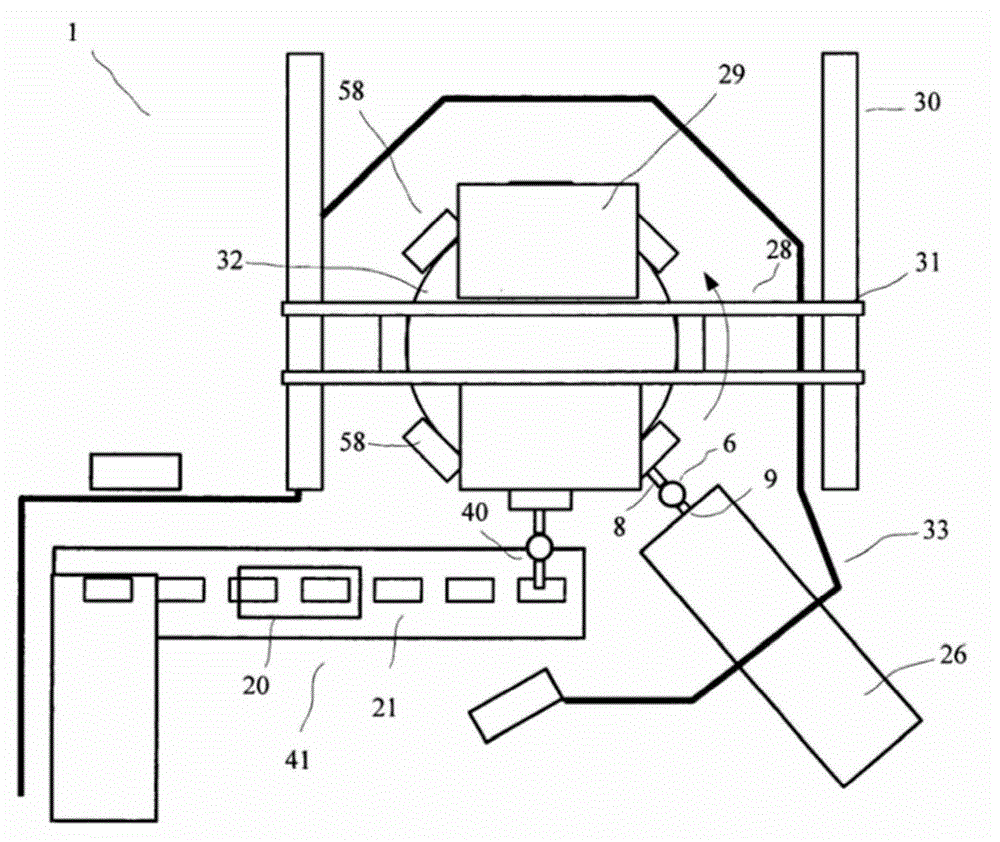

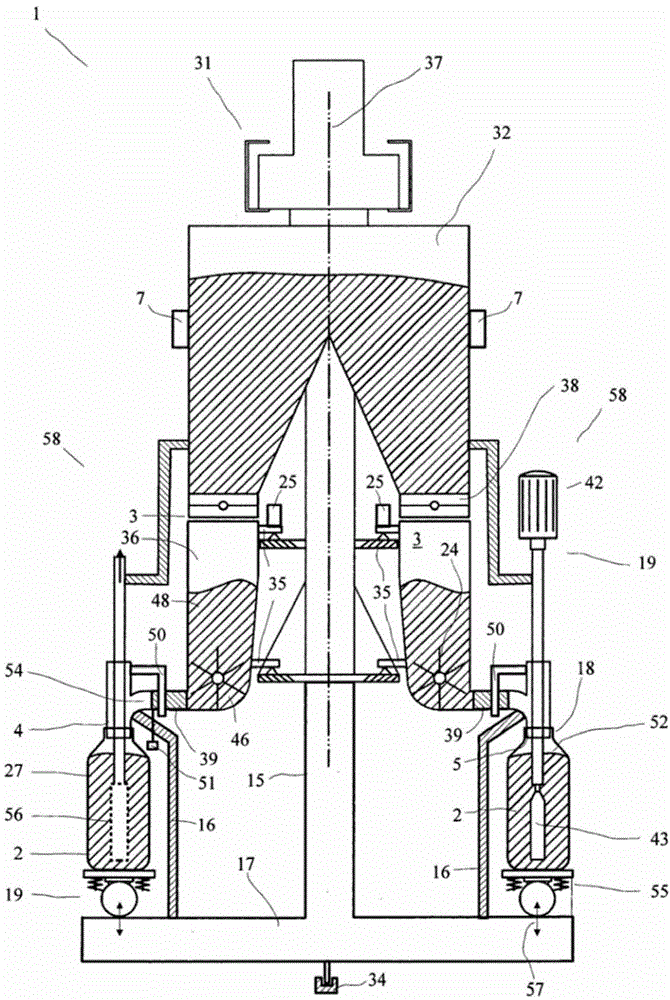

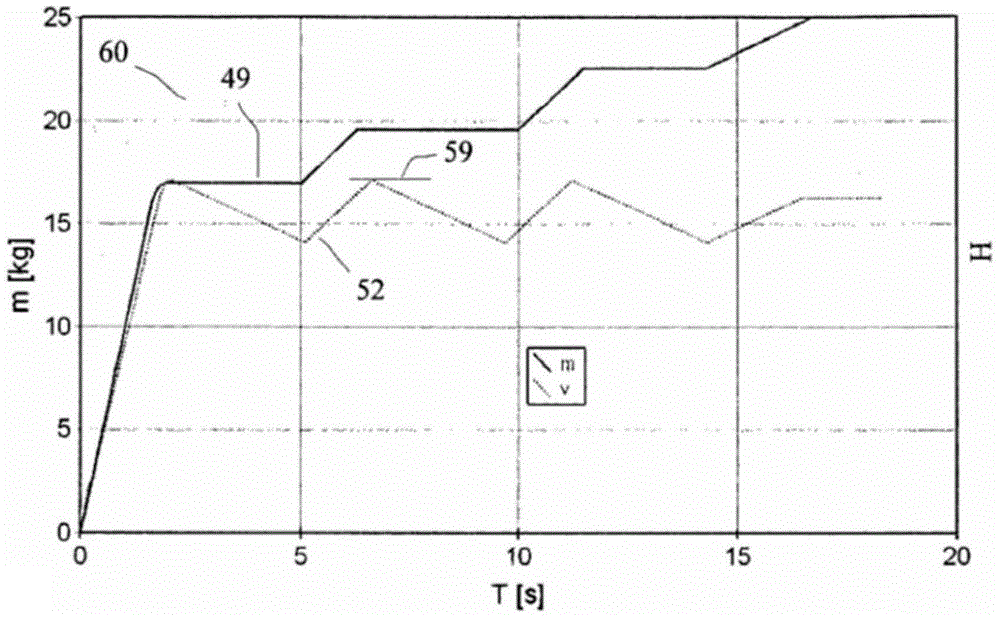

[0043] Embodiments of the rotary packaging machine 1 according to the present invention will be discussed below with reference to the accompanying drawings, which are described in figure 1 is shown in a schematic top view.

[0044] In this case, the packaging machine 1 is designed to be pivotable and is used for filling the open-mouth bags 2 , the packaging machine 1 having a plurality of filling units 58 . Each filling unit 58 includes a filling box 3 , each of which is associated here with a filling spout 4 . Approximately 2 to 16 filling nozzles 4 can be provided on the packaging machine shown. In principle, further filling units can also be mounted on the rotary packaging machine 1 . A stationary packaging machine, for example in the form of a single-spout packaging machine or a combined packaging machine, is also possible and preferred.

[0045] In this example, the packaging machine 1 is turned counterclockwise in the direction of rotation 28 . The rotary packaging m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com