Patents

Literature

32results about How to "Improve degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

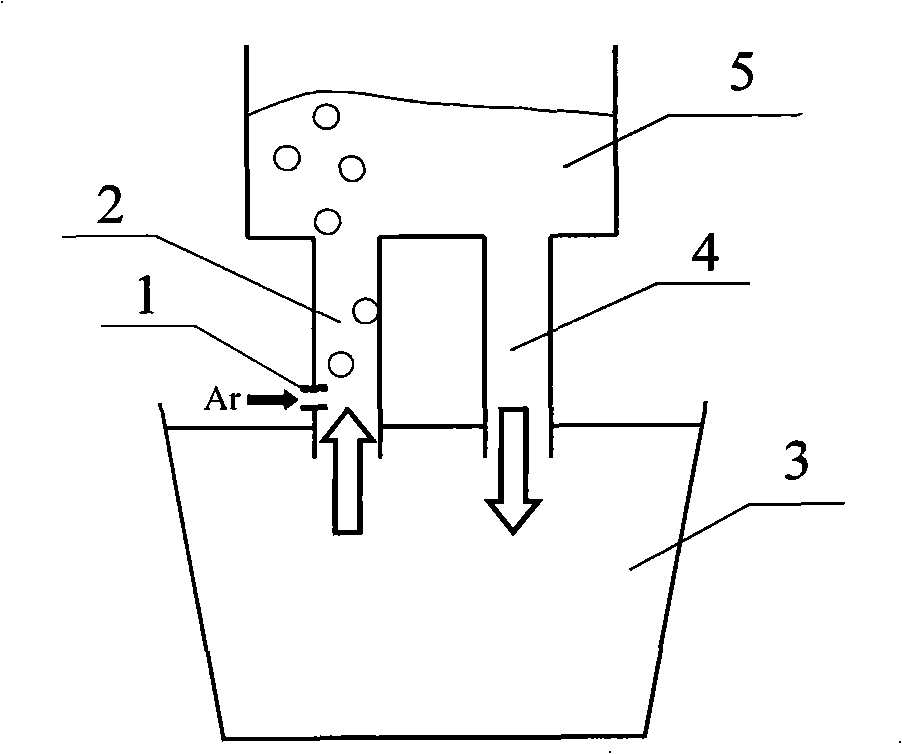

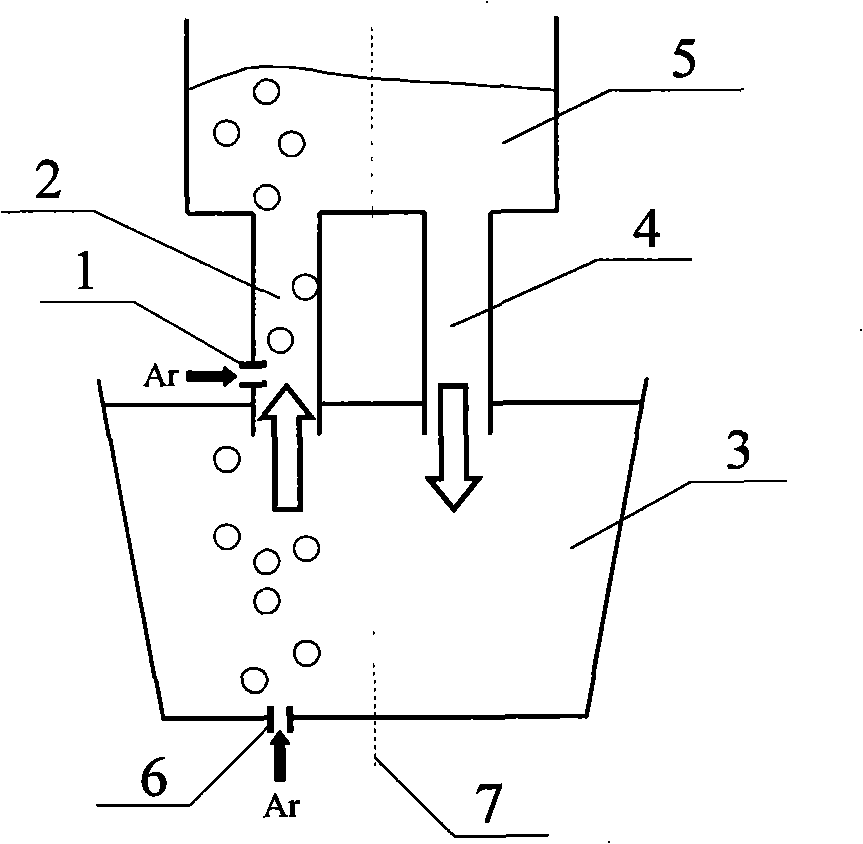

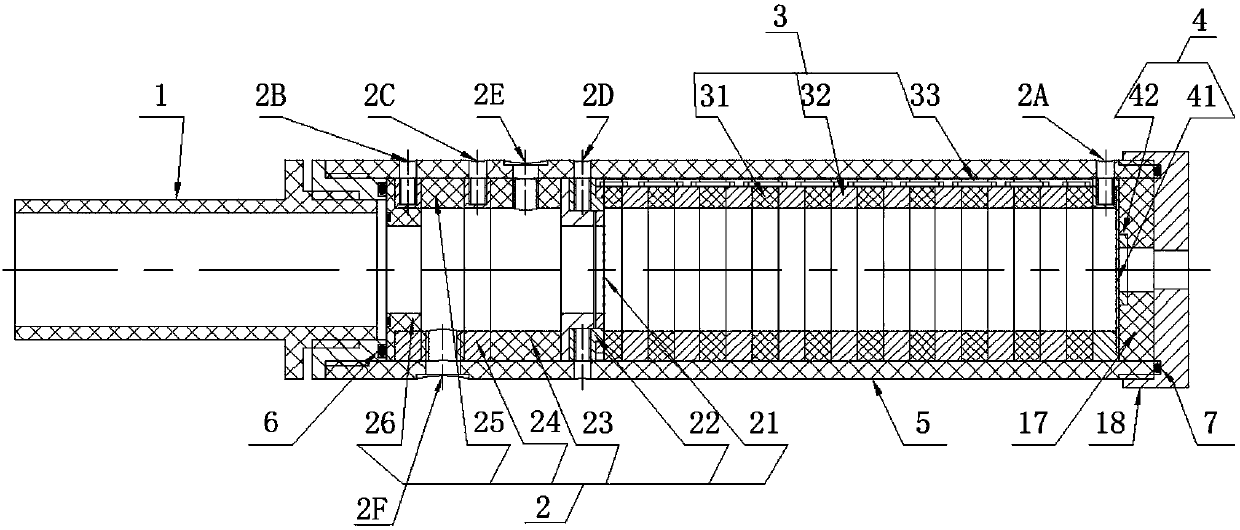

RH bottom blowing argon vacuum circulating degasser

The invention relates to an RH bottom argon blowing vacuum circulating degasser belonging to the technical field of metallurgy and comprising a steel ladle and a vacuum chamber, wherein the bottom wall of the steel ladle is provided with a nozzle or an air brick, and the nozzle or the air brick is connected with an argon blowing device and positioned at one side of the projection of an ascending tube of the vacuum chamber on the bottom wall of the steel ladle. The RH bottom argon blowing vacuum circulating degasser can effectively enhance the circular flow of the RH bottom argon blowing vacuum circulating degasser, increase the internal stirring of the RH vacuum circulating degassing steel ladle, shorten the blending time, accelerate the elimination of deoxidation type inclusions inside the RH vacuum circulating degassing steel ladle and enhance the degassing and the decarburization speed.

Owner:NORTHEASTERN UNIV

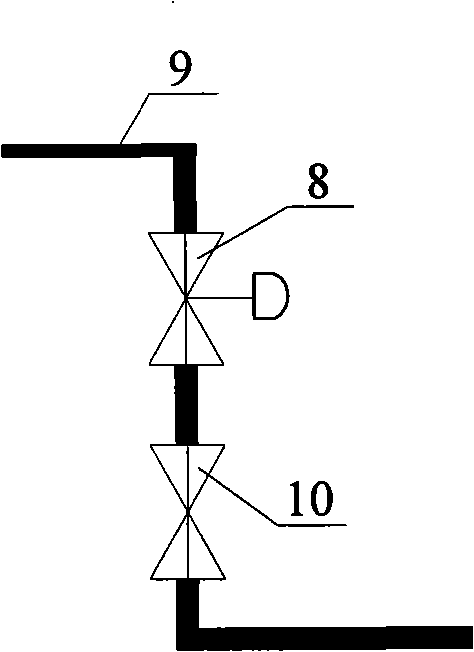

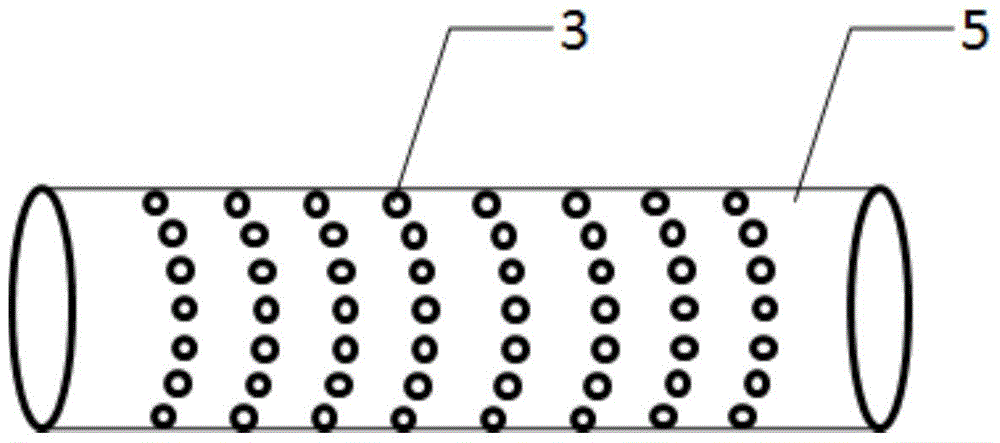

Ion migration tube

PendingCN108039312ASimple sealing structureReduce structural complexityElectron/ion optical arrangementsIon sources/gunsElectrical resistance and conductanceIonization

The invention discloses an ion migration tube. The ion migration tube comprises an ionization source device, an ion reaction device, an ion drifting device, an ion detection device and an outer tube,wherein the ion reaction device, the ion drifting device and the ion detection device are sequentially arranged in the outer tube; the ionization source device is connected with one end of the outer tube by threads, and is jacked against the ion reaction device; the outer casing is connected with the other end of the outer tube by threads, and is jacked against the ion detection device; the ion drifting device consists of insulation rings and electrode rings which are sequentially crossed and arranged; the two adjacent electrode rings are welded and connected together by a voltage division resistor; an ion migration zone is formed in an inner pore space of the insulation rings and electrode rings; the outer tube and the insulation rings of the ion migration tube are made of ceramic material with high heat conductivity. The ion migration tube has the beneficial effects that the sealing structure of the migration tube is improved; the heating rate is increased; the relaxation time is shortened when the positive and negative ion modes of the migration tube are switched; the technology is simplified; the uniformity and reliability of the migration tube are improved.

Owner:谱瑞科技(大连)有限公司

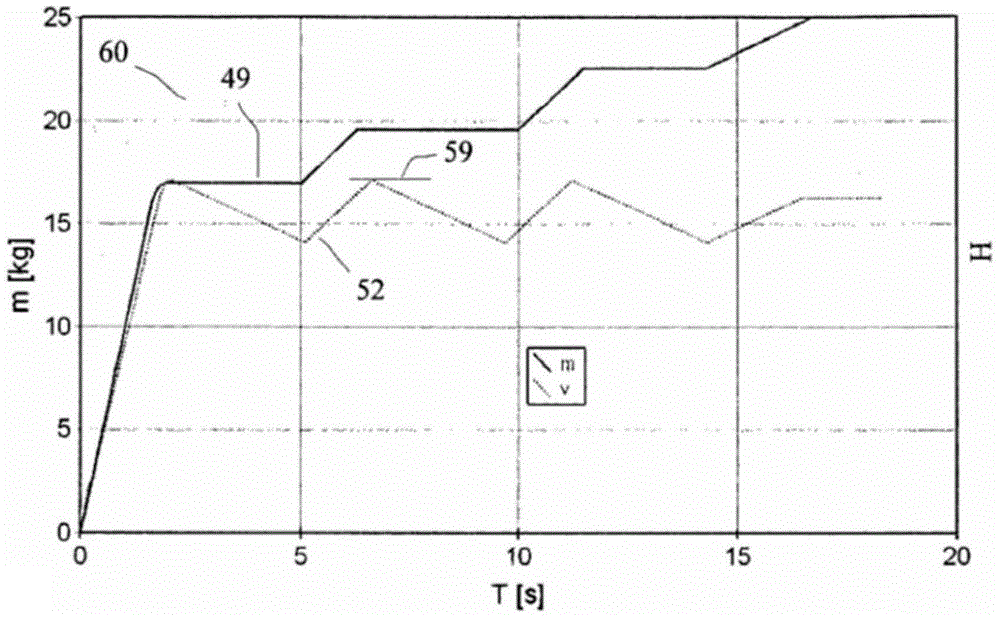

Packaging machine and method for filling pouches

ActiveCN104039653AVariable conveying speedConveying speed is variably controlledPackaging automatic controlSolid materialEngineeringPackaging machine

A packaging machine and method for filling bags with a supporting structure to which at least one filling box is fastened which includes a conveyor element and to which a weighing device and a filling spout are assigned. A control device is provided. The filling box is retained non-communicating with the supporting structure and the assigned filling box and is weighed separately by the assigned weighing device to discharge from the filling box a predefined quantity of intended fill product by way of differential weighing and to fill it into the bag through the tilling spout. The control device controls the strength of a volume flow into the bag over the time of the filling process so that the intended fill product is maintained at a high fill height while overflow is simultaneously prevented.

Owner:HAVER & BOECKER

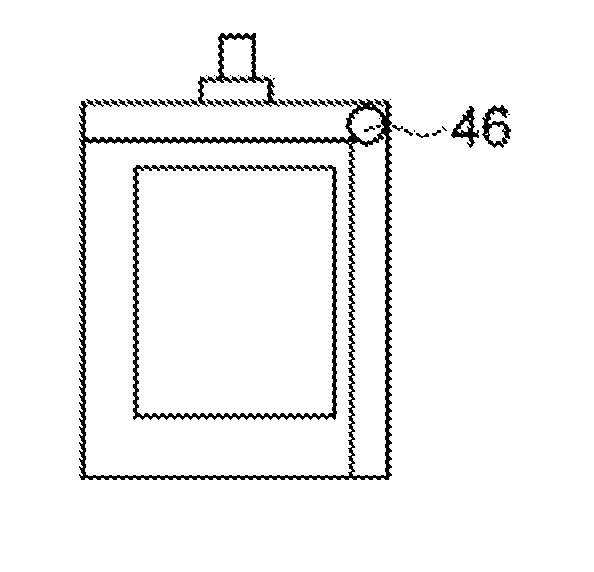

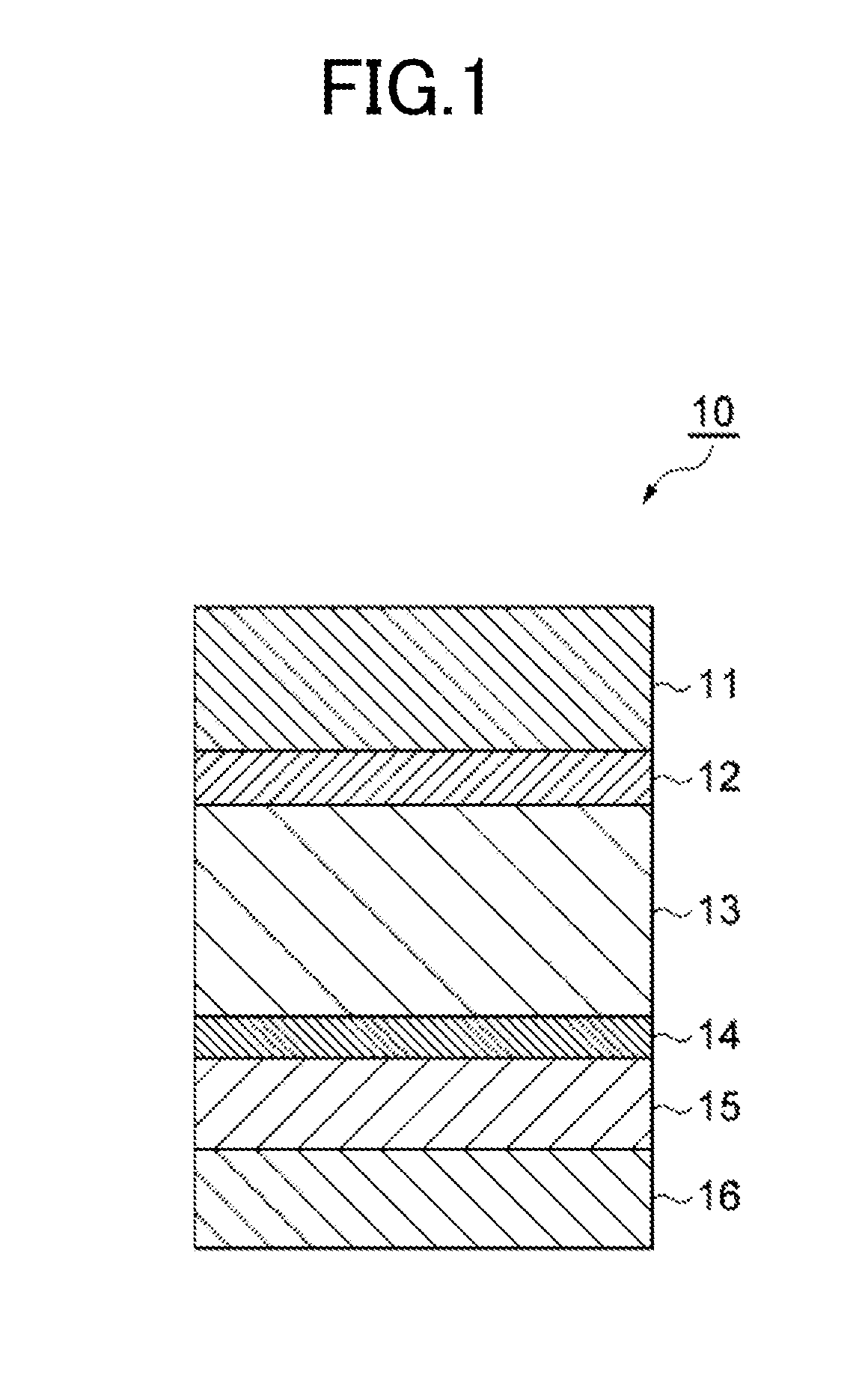

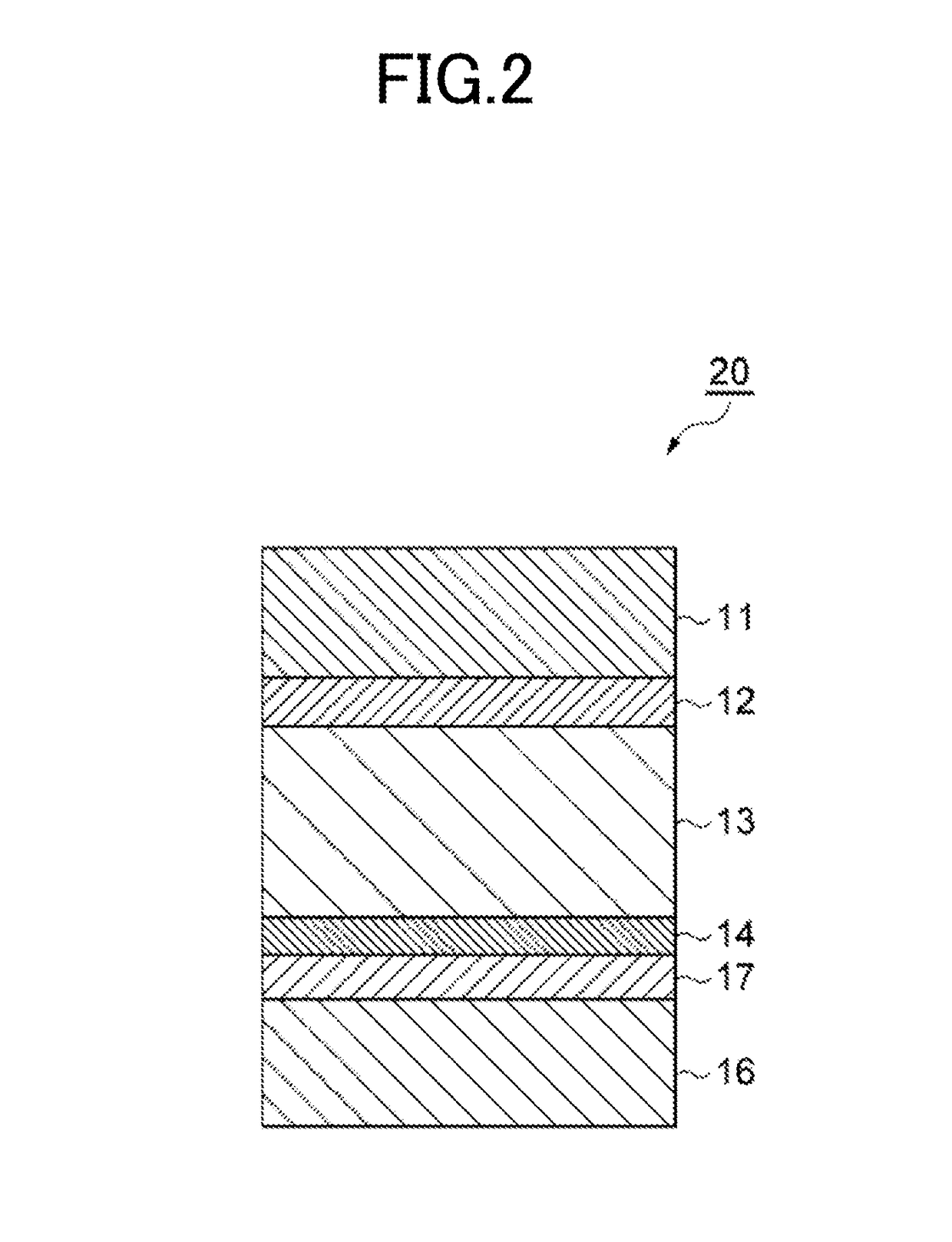

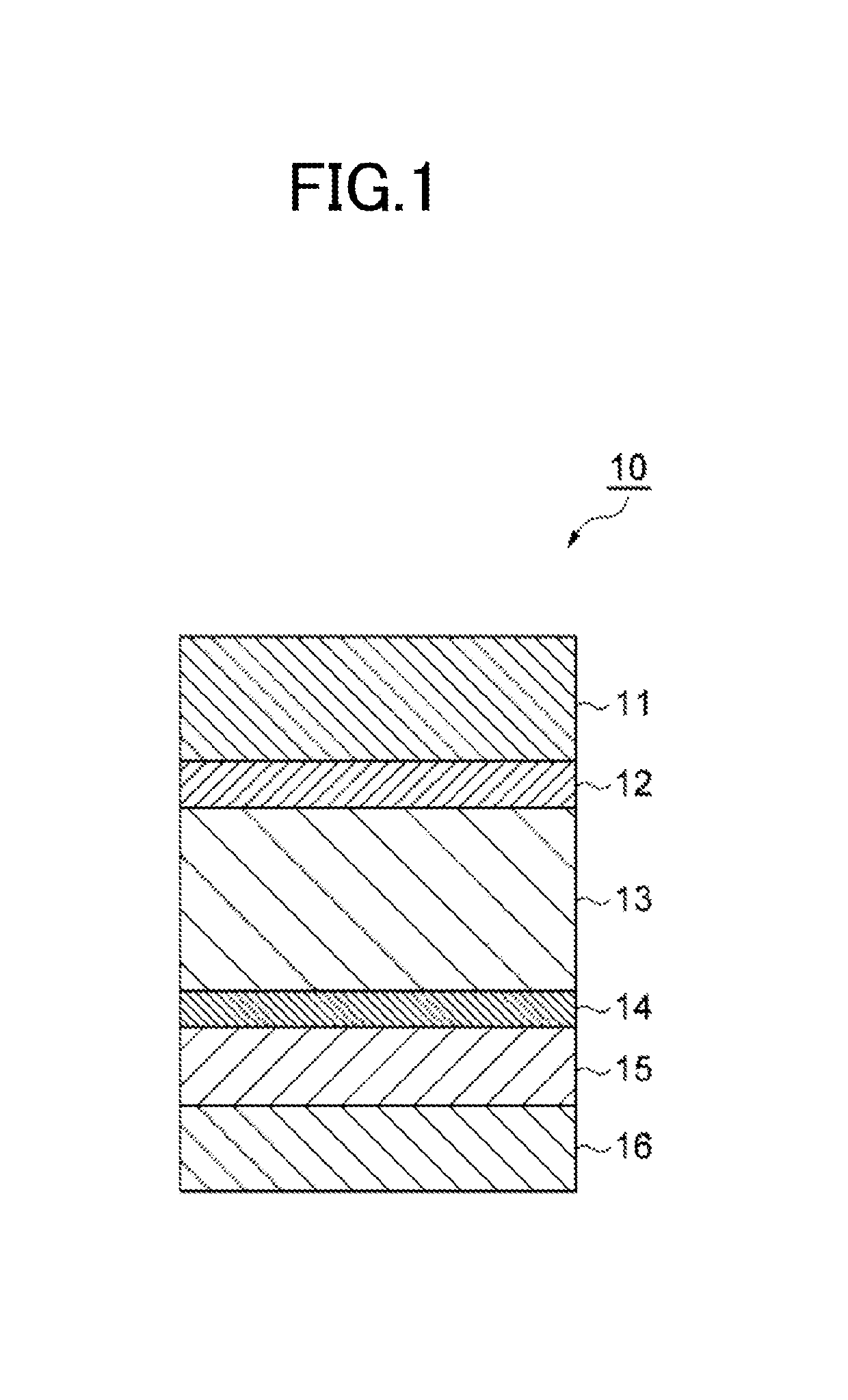

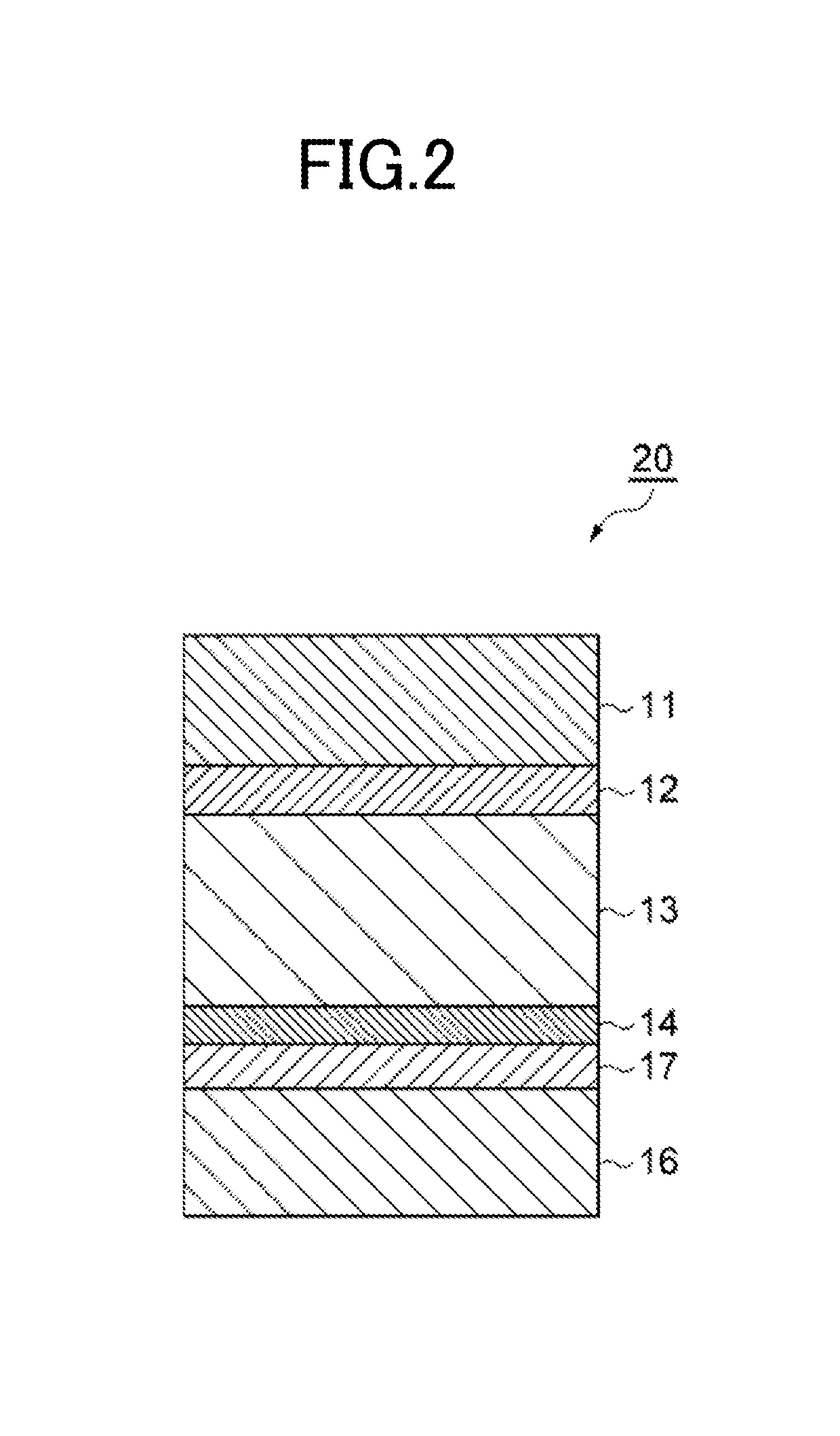

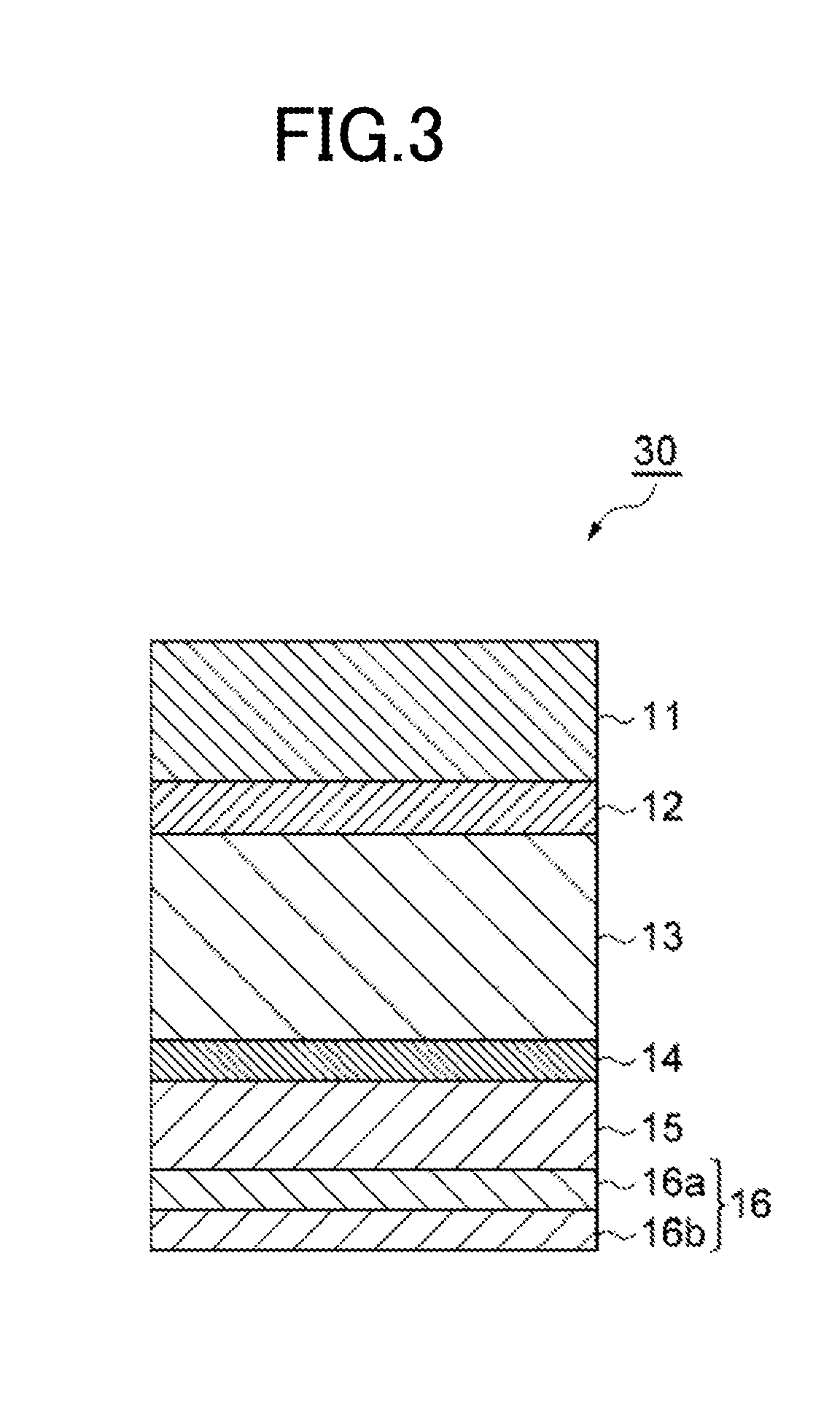

Packaging material for power storage device

ActiveUS20180076421A1Improve sealingMore sealSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsElastomerButene

A packaging material for a power storage device has a structure in which at least a base material layer, a first adhesive layer, a metal foil layer provided with an anti-corrosion treatment layer on one surface or both surfaces thereof, a second adhesive layer or an adhesive resin layer, and a sealant layer are laminated in this order. In the packaging material, the sealant layer includes a layer formed of a resin composition that contains 60 to 95 mass % propylene-ethylene random copolymer (A), and 5 to 40 mass % polyolefin elastomer (B) including 1-butene as a comonomer and having a melting point of 150° C. or less.

Owner:TOPPAN PRINTING CO LTD

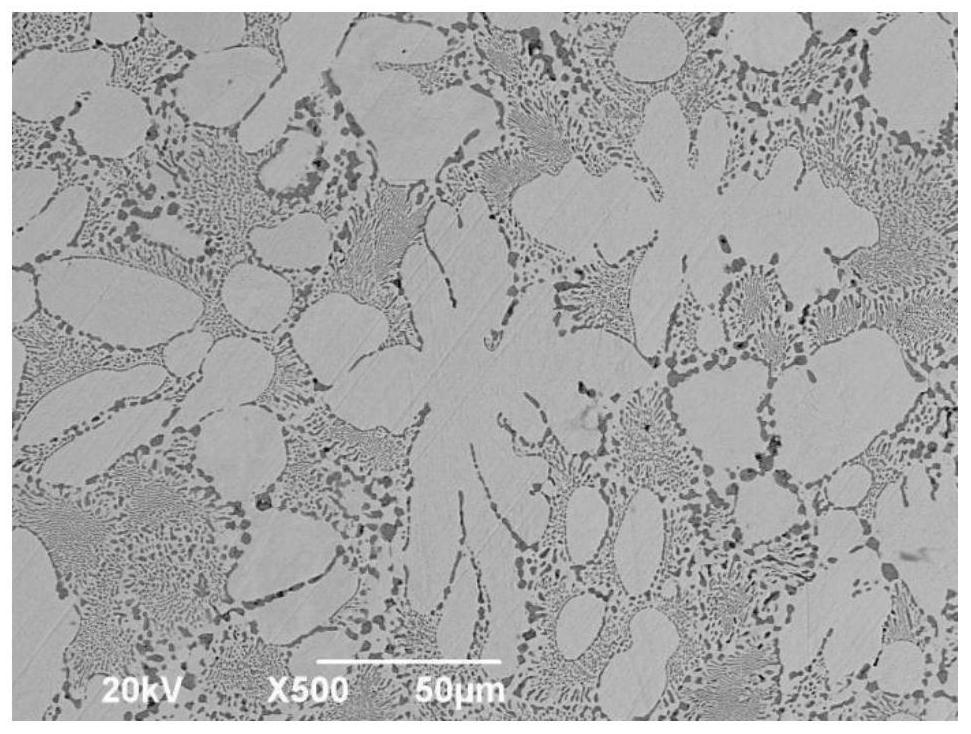

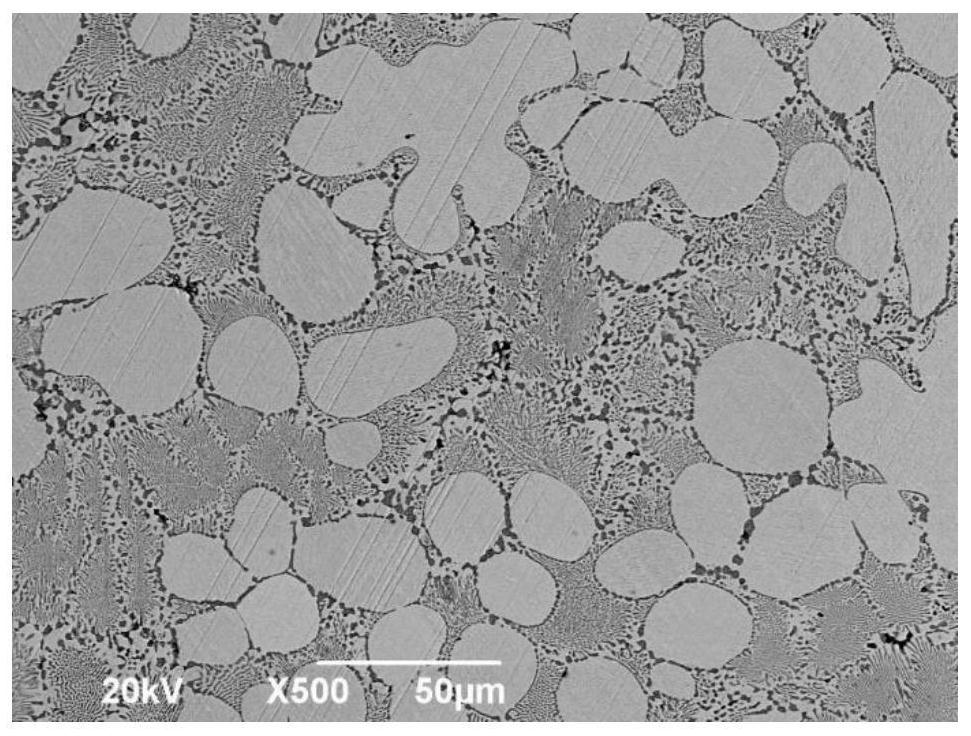

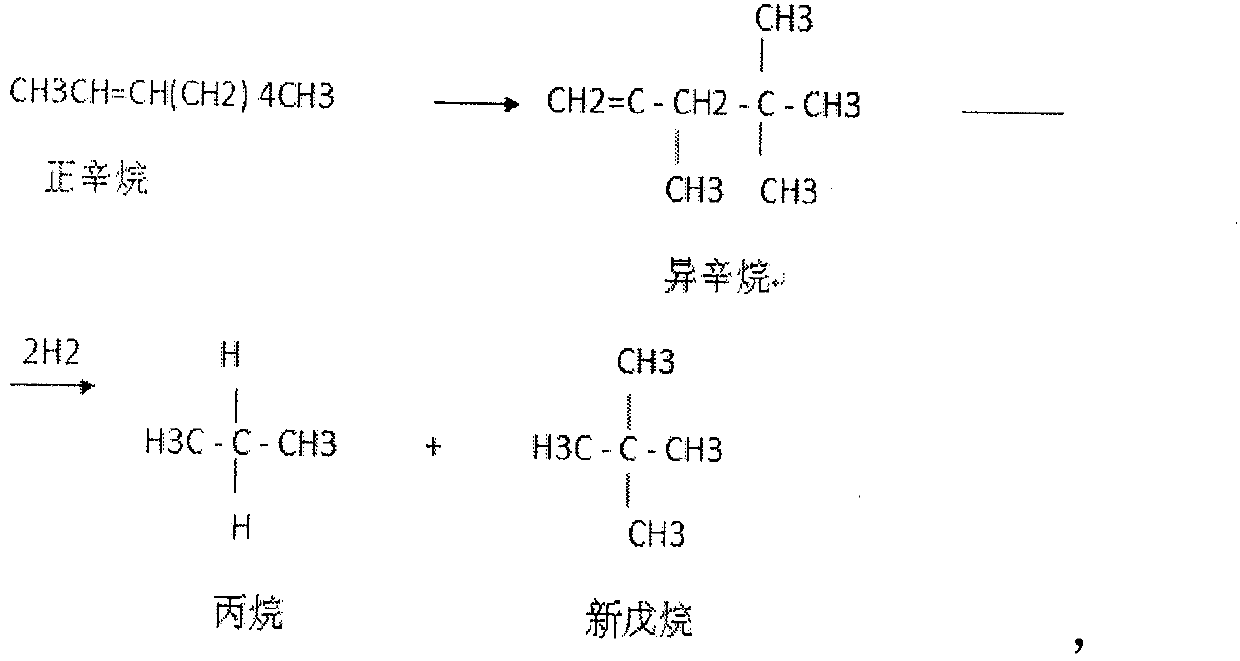

Zinc alloy and manufacturing method thereof

The invention discloses a zinc alloy and a manufacturing method thereof. The zinc alloy comprises the following elements: 4-7% of Al, 0.5-1.5% of Cu, 0.4-0.7% of Ti, 0.07-0.1% of B, 0.02-0.025% of Mg,0.1-1% of others, and the balance Zn. The method comprises the following steps: (1) pure aluminum is heated to a molten state, and is sprayed on the inner surface of a crucible; and a filter structure is fixed on the side surface of the inner surface; (2) zinc alloy raw materials are put in the crucible, and are vacuumized and heated until the raw materials are totally molten to obtain a molten pool; (3) a graphite stirring device is started; and a refining agent is continuously added to obtain a purified molten pool; (4) the purified molten pool is modified, and is cast and molded by a cooling extrusion process to obtain a zinc alloy ingot to be treated; and (5) the zinc alloy ingot to be treated is subjected to spheroidizing annealing to obtain the needed zinc alloy. The zinc alloy is high in purity, low in large-size dendritic segregation, uniform in overall grain size refining and low in primary structure multiple eutectic dendritic crystals.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

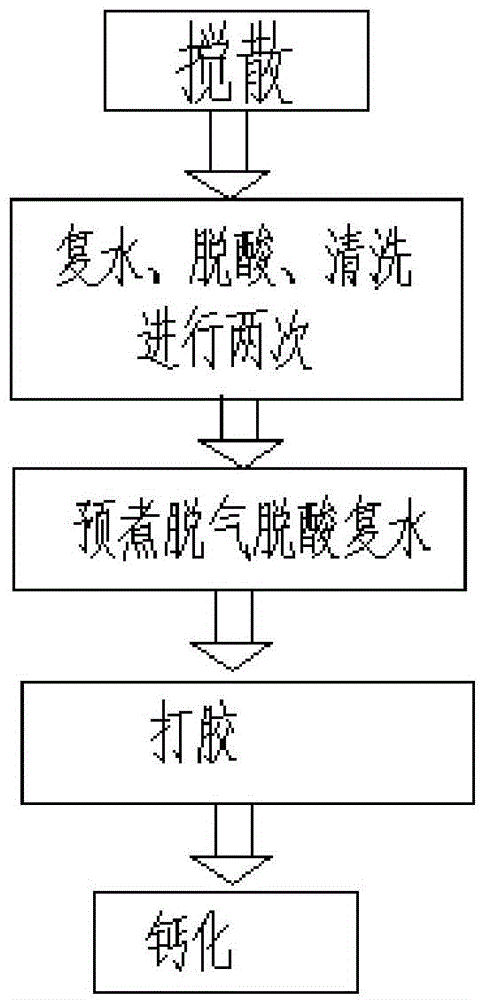

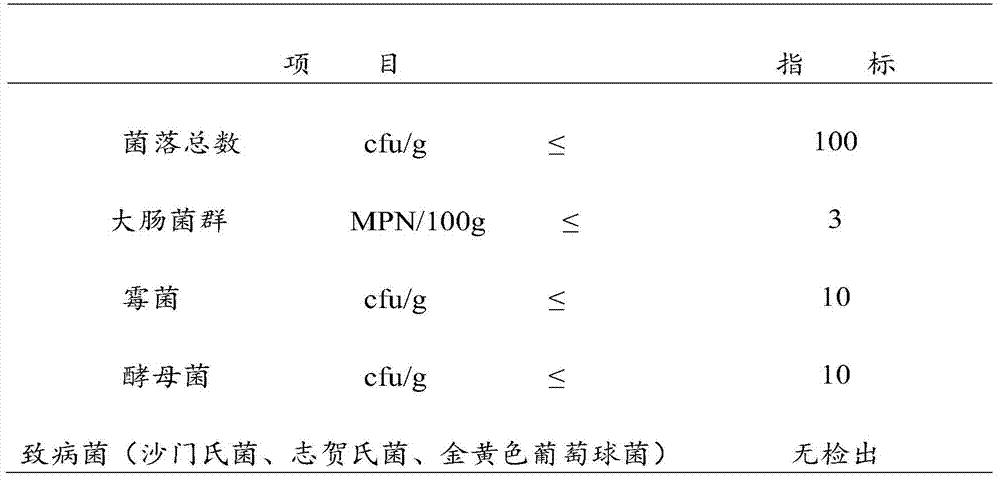

Vacuum coconut treatment process

InactiveCN104621498AQuality improvementShort processing timeFood preparationPulp and paper industryAir blower

The invention discloses a vacuum coconut treatment process. The process comprises the following steps: diffusing, precooking, degassing, deacidifying and rehydrating, gluing and calcifying. According to the process, the coconuts are subjected to vacuum treatment by adopting a vacuum treatment tank and are subjected to air blowing by adopting an air blower, so that the acids and unpleasant odors in the coconuts are eliminated under multiple effects of heating power, vacuum and blowing force, and the coconuts fully absorb water to swell. Therefore, the coconuts are saturated, and according to the process, the coconuts are subjected to normal pressure stirring or air blowing treatment instead of deacidifying, rehydrating and embrittling in the traditional technology, so that the quality of the coconuts is stable, the treatment time is short, the energy consumption is low, and the cost is greatly saved.

Owner:FUJIAN QUANZHOU XIDUODUO FOOD

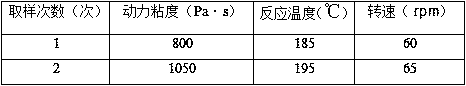

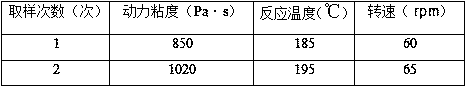

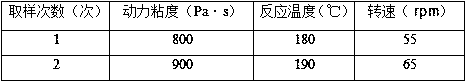

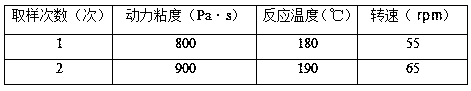

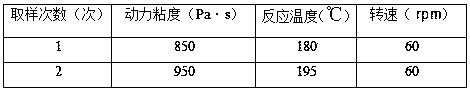

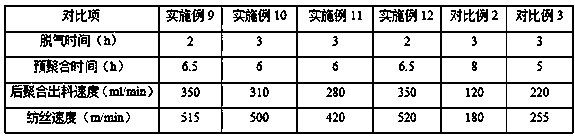

Process control method for PBO fiber production

ActiveCN107761185ARelieve pressureGuaranteed molar ratioMonocomponent synthetic polymer artificial filamentFiberThree stage

The invention discloses a process control method for PBO fiber production. PBO fiber is produced from polyphosphoric acid, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials by degassing, pre-polymerization, post-polymerization and spinning, the terephthalic acid is respectively poured into the three stages of raw material mixing, pre-polymerization and post-polymerization for production. In the production process, and the sum of molar amounts of the terephthalic acid injected in the three times is guaranteed to be equal to the molar amount of the4,6-diaminoresorcinol hydrochloride injected during the raw material mixing stage. According to the method, the polymerization production of the PBO fiber can be completed in the manner of multiple times of feeding of the TPA (terephthalic acid), the solution tressure of the TPA during the initial feeding is reduced, the process time of the mixing, the degassing, and the pre-polymerizing in the early stage can be shortened, and the performance of subsequent PBO fiber products can be improved.

Owner:CHENGDU XINCHEN NEW MATERIAL TECH CO LTD

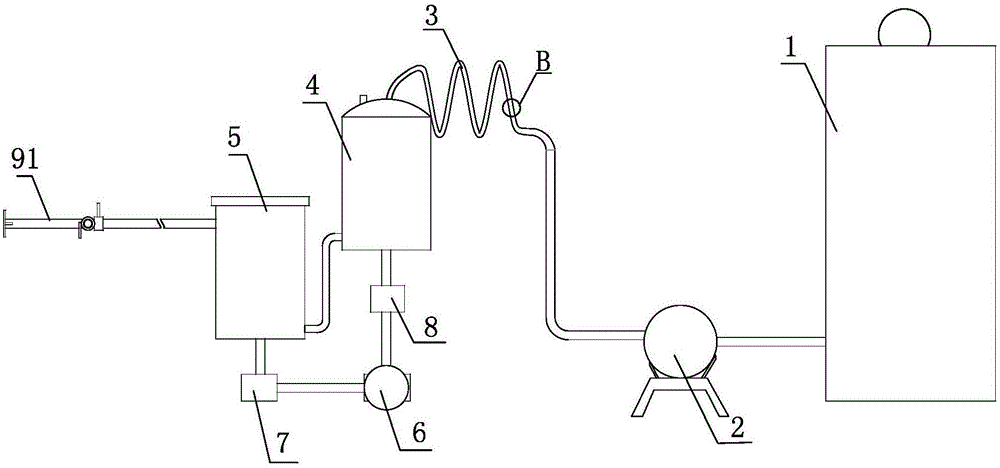

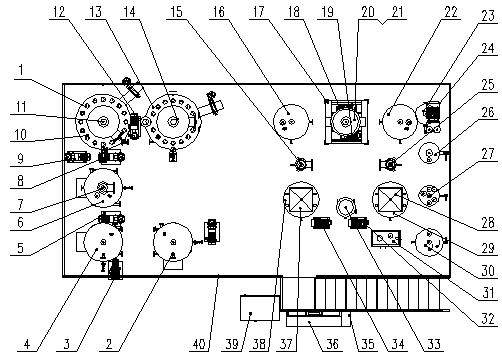

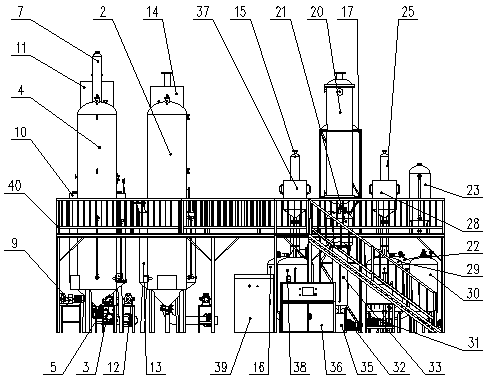

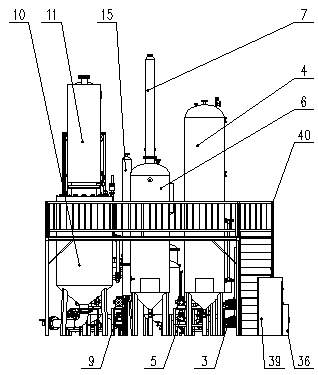

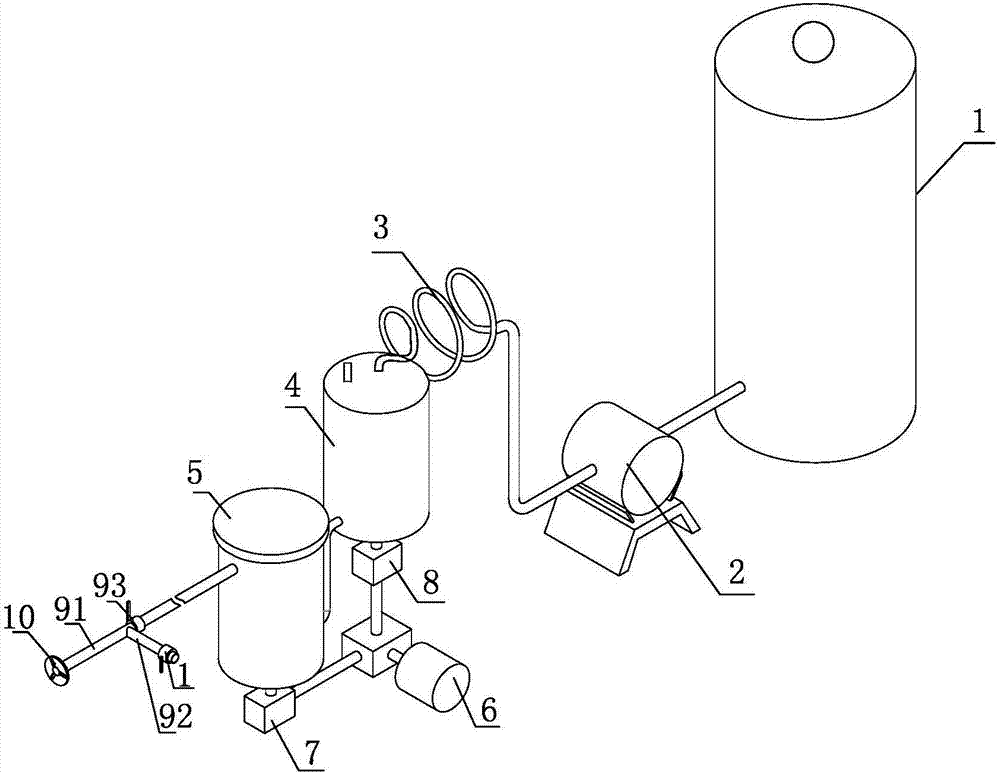

Oil-immersed transformer oiling device

InactiveCN106098318APrevent deterioration of insulationImprove securityTransformers/inductances coolingLiquid transferring devicesControl systemTransformer oil

The invention provides an oil-immersed transformer oiling device, belonging to the technical field of oiling devices. The oil-immersed transformer oiling device aims to solve the technical problems of degassing, impurity removal and oiling in the insulating oil for transformers. The oil-immersed transformer oiling device comprises an oil drum, an oil level detection mechanism, an oil pump, an oil filter, an oiling tube mechanism and a control system, wherein the oil level detection mechanism is installed in the oil drum; the upper end of the oil drum is provided with an alarm lamp; one end of the oil pump communicates with the oil drum, and the other end communicates with the oil filter; the oil filter comprises a heating mechanism, a degassing mechanism, an impurity removal mechanism and a power mechanism; the oiling tube mechanism comprises an oiling tube and an exhaust tube; and the outer end of the oiling tube is fixedly provided with an adjustable flange. The oil-immersed transformer oiling device effectively performs impurity removal, degassing treatment and oiling before oiling of the oil-immersed transformer insulating oil, prevents the insulating property of the insulating oil for transformers from degradation due to the influence of gases and impurities, and obviously enhances the safety performance of the insulating oil for transformers.

Owner:国网山东省电力公司茌平县供电公司 +1

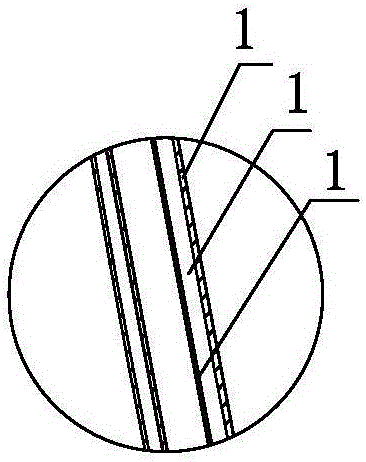

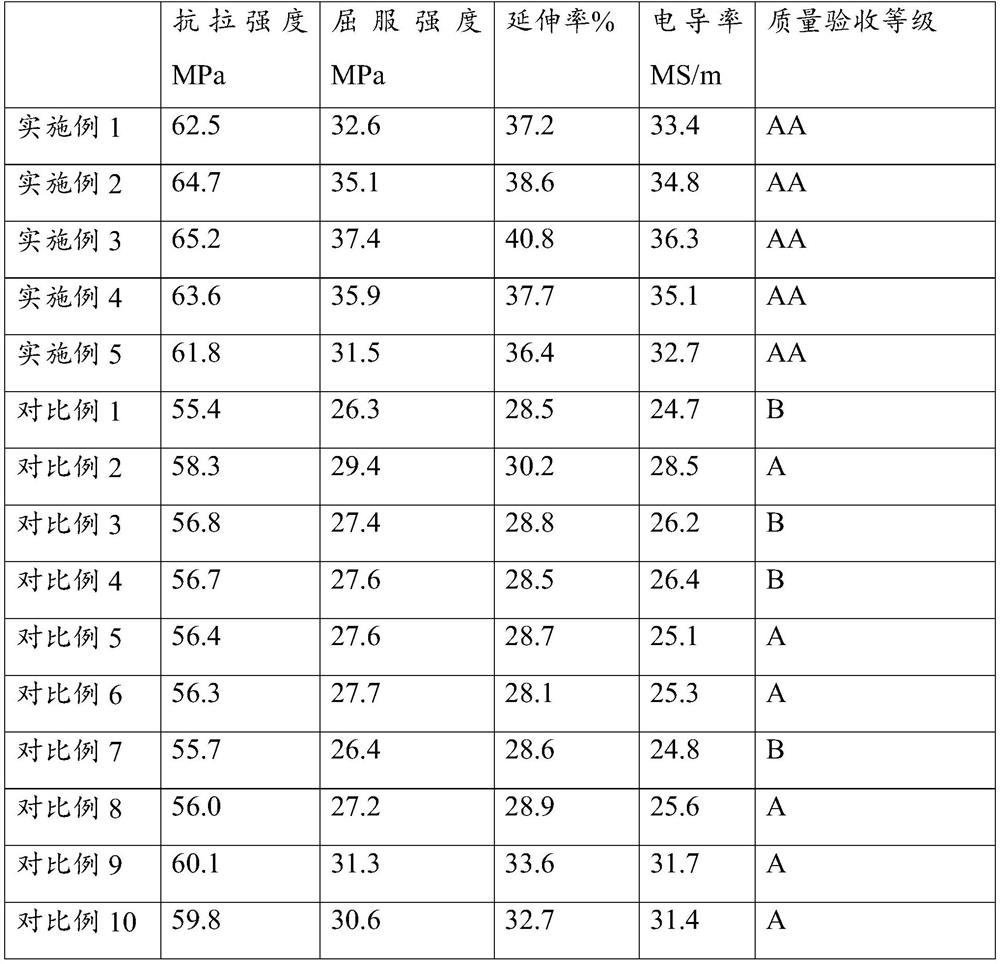

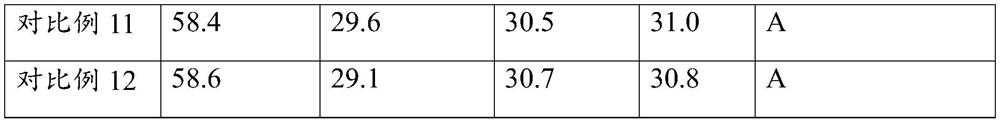

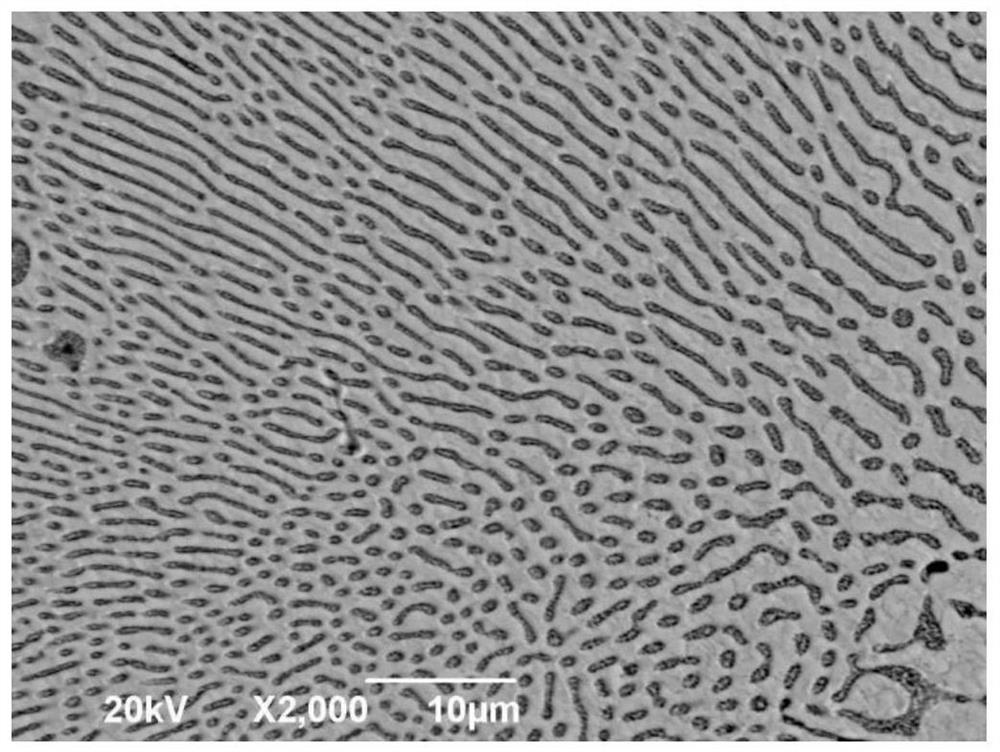

Preparation method of low-segregation-degree motor rotor microalloy aluminum of new energy automobile and microalloy aluminum prepared through preparation method

The invention discloses a preparation method of low-segregation-degree motor rotor microalloy aluminum of a new energy automobile, which comprises the following steps: (1) preheating a mixture of titanium, boron, silicon, iron, copper, magnesium, zinc and aluminum, charging into a furnace for smelting, paving a layer of covering agent on the surface, and heating to 670-800 DEG C; (2) adding a refining agent for refining, performing standing and slag removal to obtain refined melt A; (3) heating the refined melt A to 800-900 DEG C, firstly adding lanthanum, preserving heat for 15-30 minutes, then adding ytterbium, stirring, paving a covering agent, preserving heat for 10-60 minutes, and then cooling; (4) when the temperature is reduced to 670-800 DEG C, adding a refining agent for refining, standing, covering and slagging off to obtain refined melt B; and (5) spraying coating on the inner side of a casting mold, pouring the refined melt B into the casting mold, performing centrifugal casting for 20-40 s, and taking the microalloy aluminum out. According to the method, by adding lanthanum and ytterbium, pinholes are eliminated, and the mechanical property of the microalloy aluminum is improved; and through the regulation and control of each preparation step, the cooling time is shortened, migration and aggregation of TiAl3 and TiB2 are reduced, and segregation is reduced.

Owner:SHANDONG BOYUAN PRECISION MASCH CO LTD

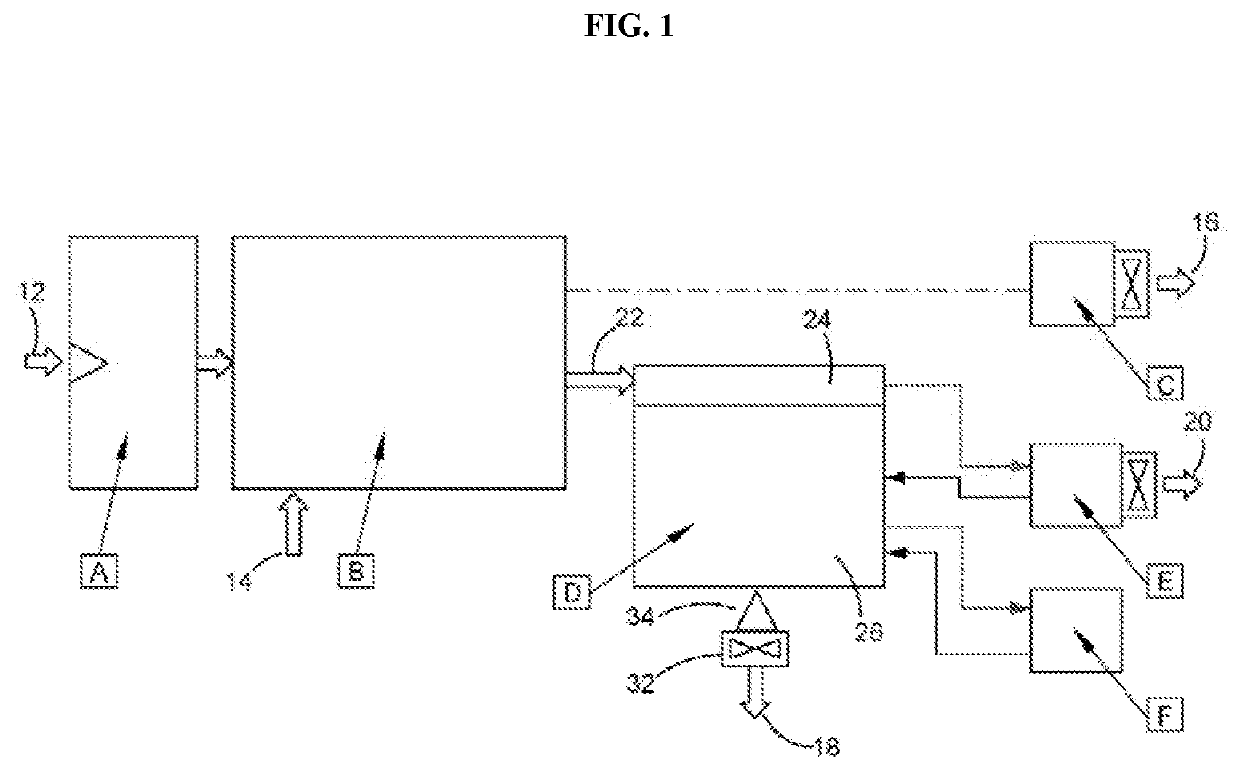

Method and Apparatus for Gas Destruction

ActiveUS20190360689A1Improve degassingEasy to operateGas treatmentExhaust apparatusCombustionTurbocharger

A method for the destruction of a target gas, the method including: a) compressing at a first pressure a mixture of air and target gas to produce a compressed target gas mixture; b) destroying the target gas by combusting the compressed target gas mixture with diesel fuel in a forced-induction internal combustion engine, at a combustion pressure greater than the first pressure in the turbocharger, to produce an oxidised exhaust gas, the combustion occurring while maintaining a load on the diesel engine with a load bank; and c) processing the oxidised exhaust gas to produce a vent gas for venting to atmosphere where the vent gas includes substantially no target gas.

Owner:MEBROM RES & DEV PTY LTD

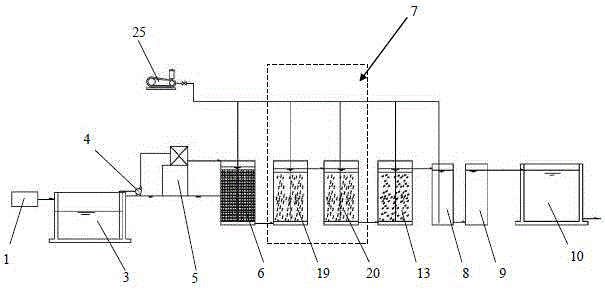

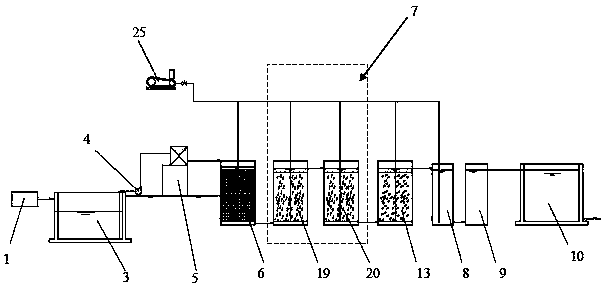

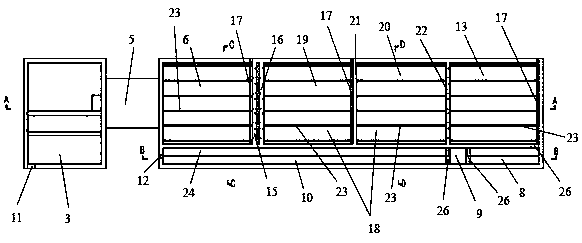

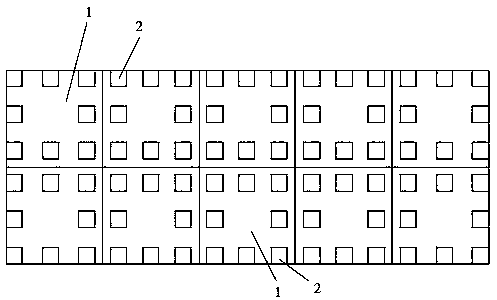

Factorized circulating water high-density three-dimensional ecological breeding system

ActiveCN105981667AReduce loadEasy to handleClimate change adaptationAgricultural fishingHigh densityWater flow

The invention provides a factorized circulating water high-density three-dimensional ecological breeding system which comprises a plurality of breeding tanks, a breeding circulating water treating system communicated with the breeding tanks, and three-dimensional spraying aquaculture columns arranged on the upper portions of the breeding tanks. The factorized circulating water high-density three-dimensional ecological breeding system is characterized in that the breeding circulating water treating system comprises a water collection tank, a water pump, a microfilter, a decarburization area, a nitration area, a degassing area, an ultraviolet sterilizing area and a temperature adjusting and tempering tank sequentially along a water flow direction, the water collection tank is communicated with the breeding tanks through sewage inlets, and the temperature adjusting and tempering tank is communicated with the three-dimensional spraying aquaculture columns through a clean water outlet and the water pump; a biological filtering area or a low-speed nitration area are arranged between the nitration area and the degassing area; a mud blocking slot is formed between the decarburization area and the nitration area, a plurality of mud-blocking water-passing holes are formed in a wall of the decarburization area on one side of the mud blocking slot, a plurality of nitration water incoming holes are formed in a wall of the nitration area on the other side of the mud blocking slot, and bottom height of the mud-blocking water-passing holes is greater than height of a mud discharging pipe in the decarburization area. The factorized circulating water high-density three-dimensional ecological breeding system is low in investment, high in space utilization rate, healthy and efficient.

Owner:GUANGZHOU CHANG CHI MECHANICAL & ELECTRICAL EQUIP CO LTD

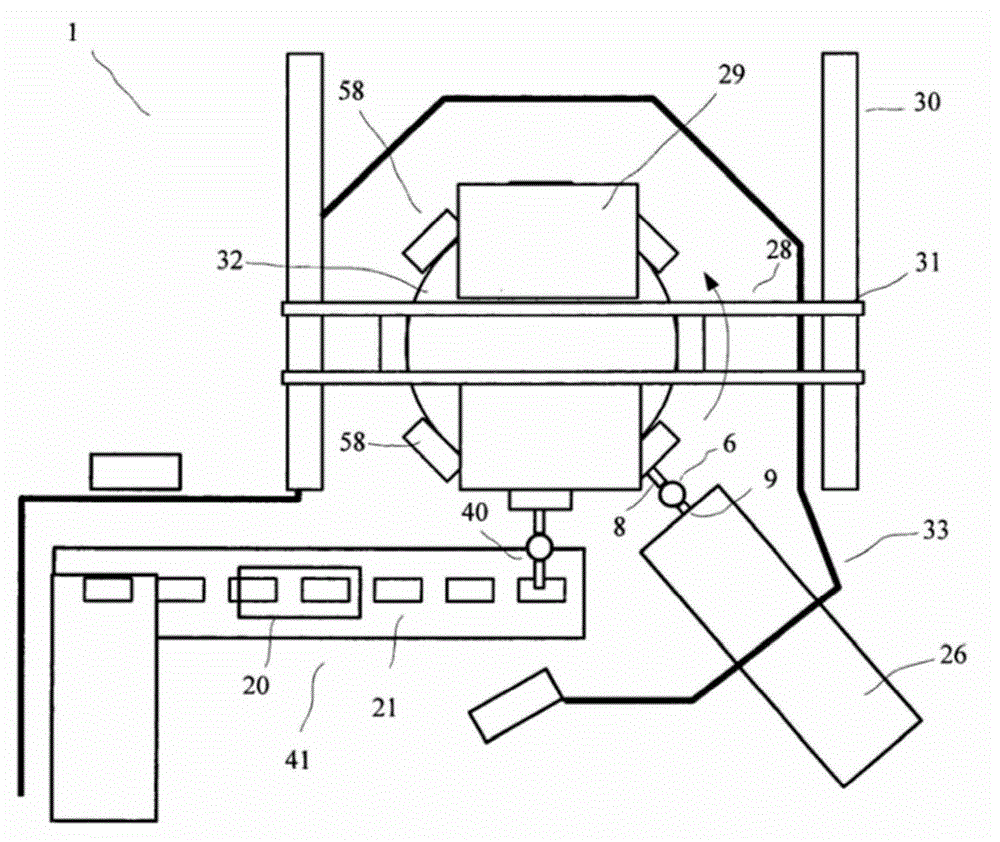

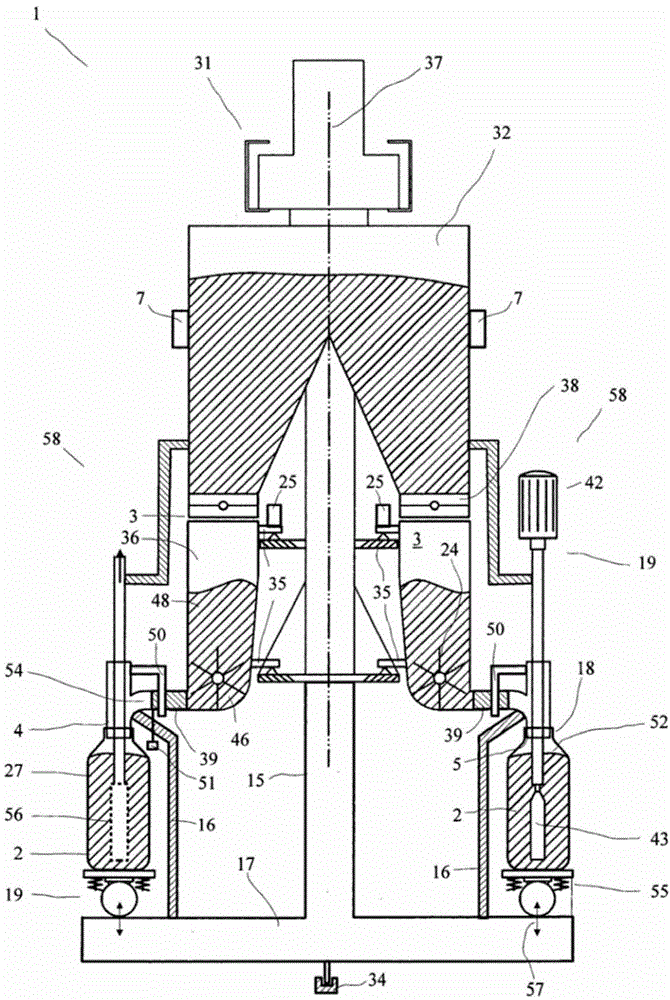

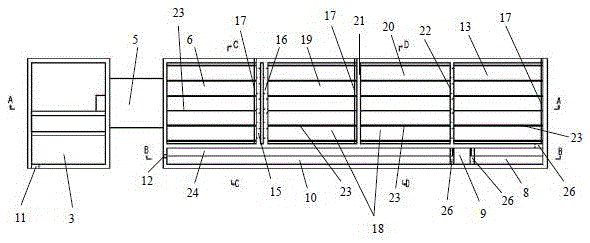

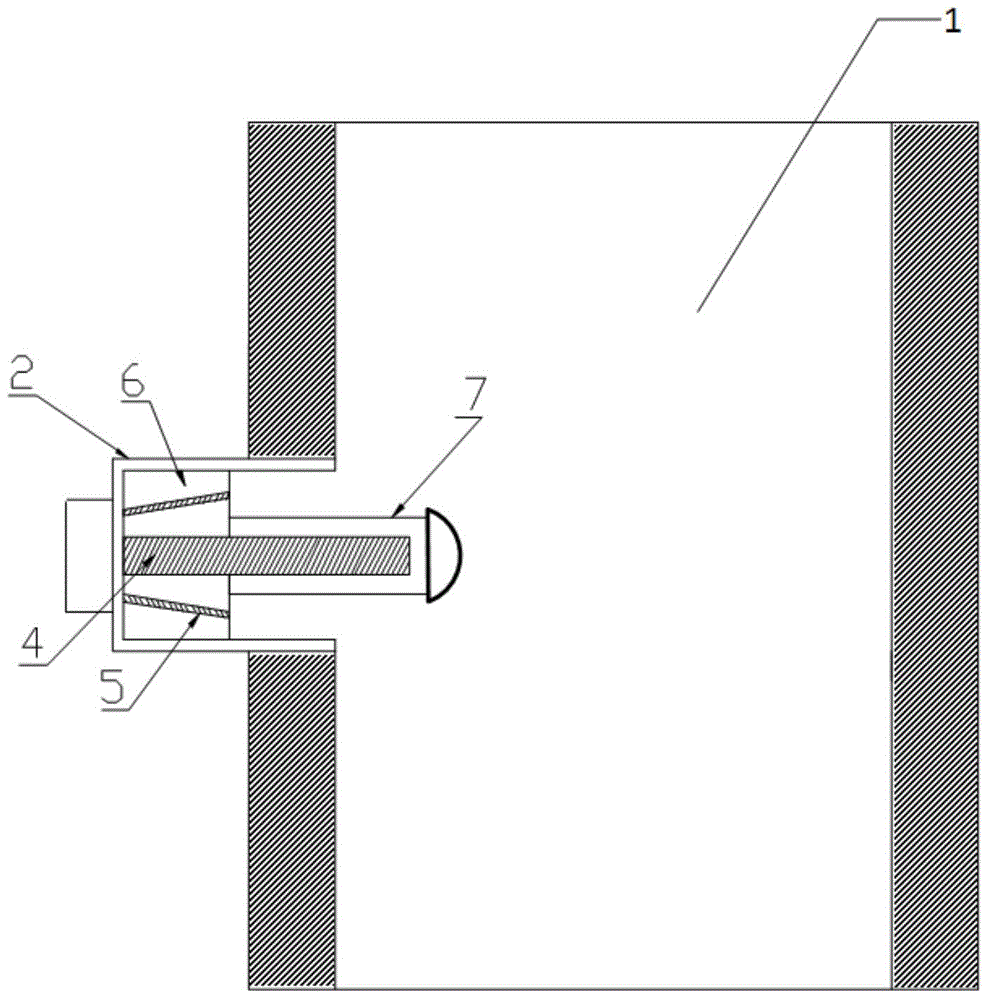

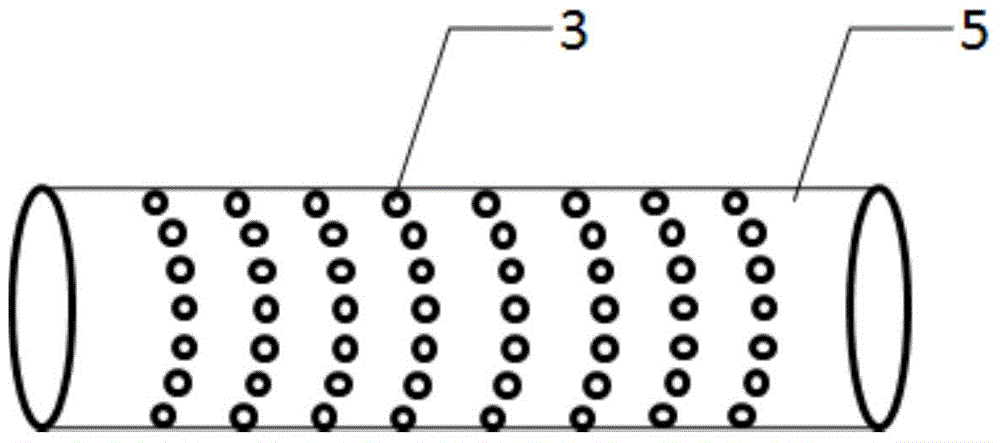

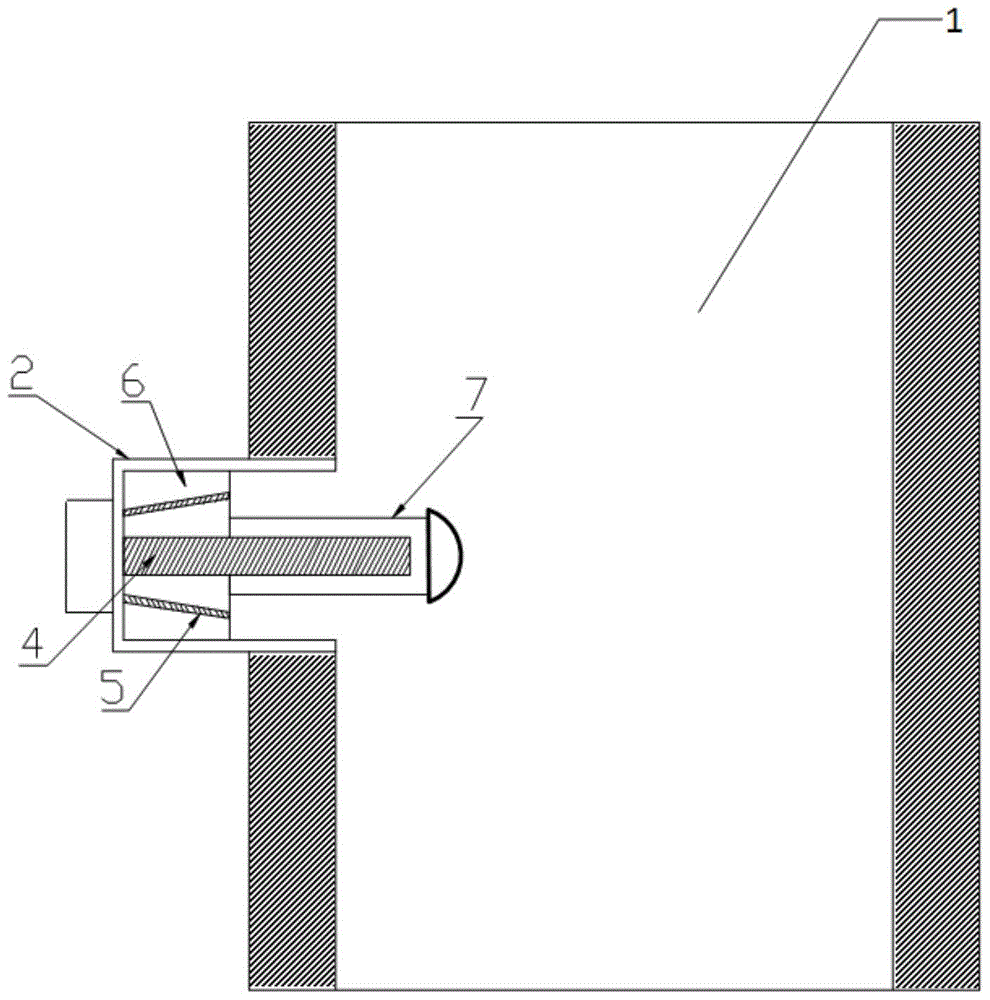

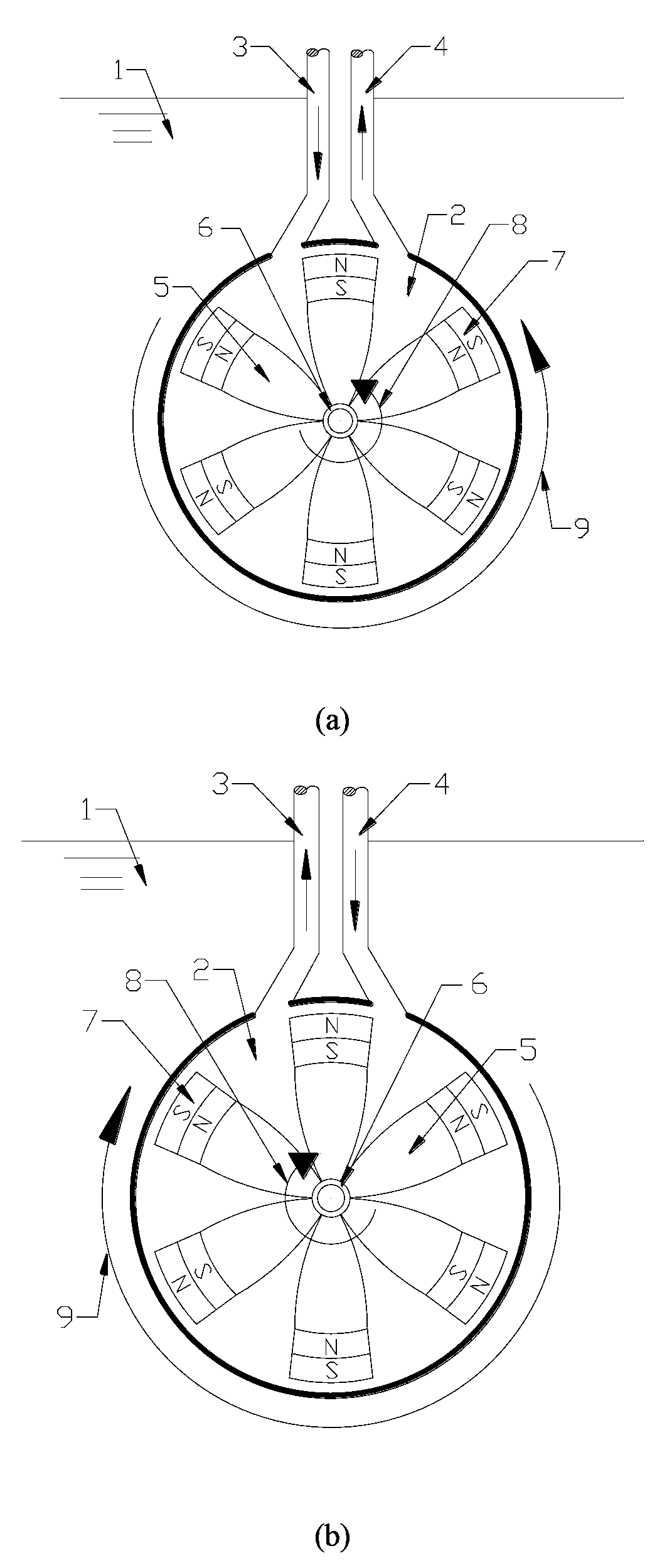

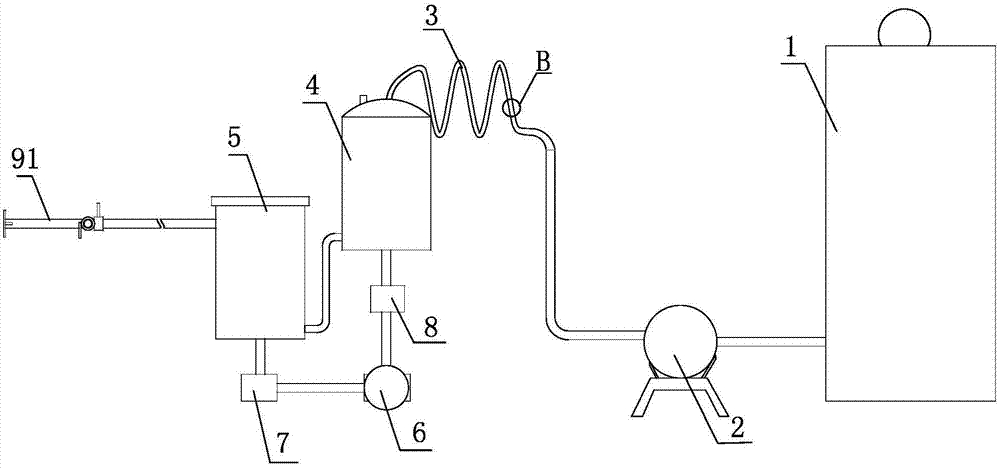

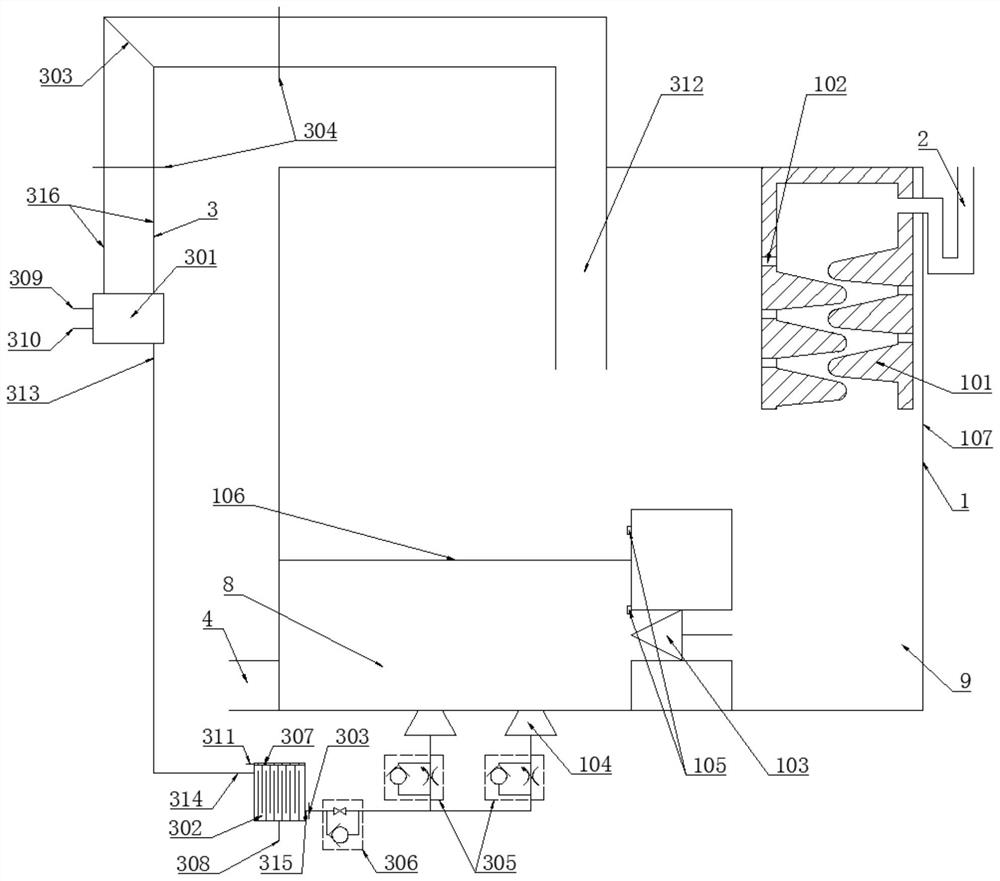

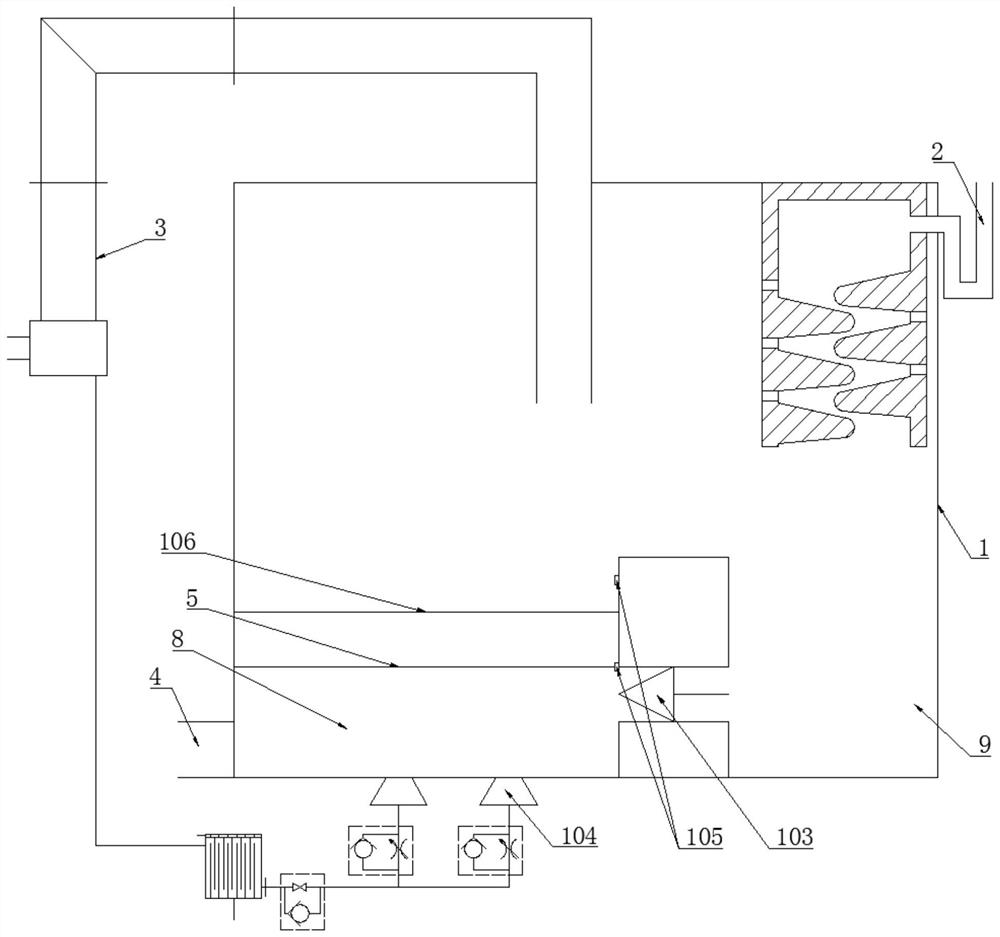

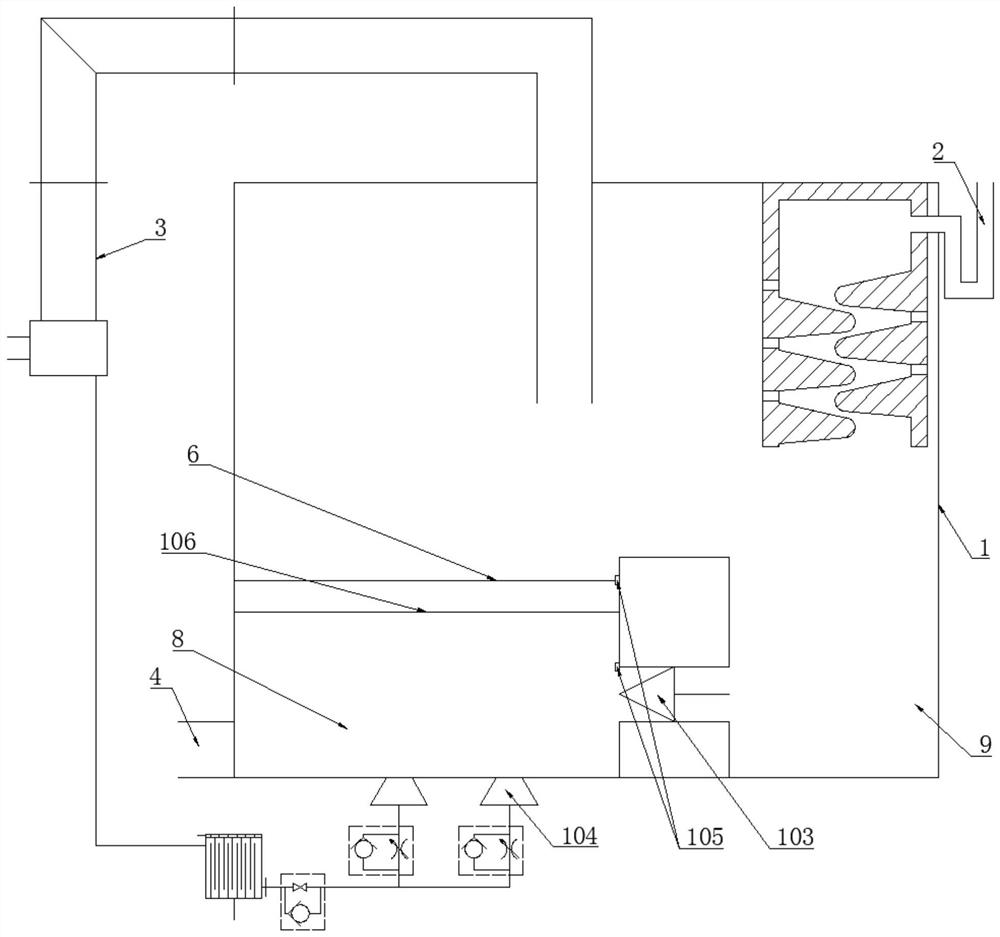

Ultrasonic metallurgical device for RH refining furnace

The invention discloses an ultrasonic metallurgical device for an RH refining furnace, which comprises an outer frame (2) connected with a riser (1) of the RH refining furnace, wherein an ultrasonic generator (6) and an ultrasonic working head (7) for inputting ultrasonic generated by the ultrasonic generator (6) into the riser (1) are arranged in the outer frame (2); an argon blowing pipe (4) communicated with the riser (1), a surrounding argon blowing pipe (4) and a plurality of argon sealing pipes (5) for hermetic seal are also arranged in the outer frame (2); and the argon blowing pipe (4) and the argon sealing pipes (5) are connected with an argon source after penetrating through the outer frame (2). The metallurgical device can enhance the molten steel circulation efficiency of the RH refining furnace and improve the degassing and inclusion removal effects.

Owner:SHANDONG IRON & STEEL CO LTD

Packaging material for power storage device

ActiveUS10305069B2Improve sealingMore sealAutomatic/semiautomatic turning machinesSmall-sized cells cases/jacketsElastomerPolyolefin

A packaging material for a power storage device has a structure in which at least a base material layer, a first adhesive layer, a metal foil layer provided with an anti-corrosion treatment layer on one surface or both surfaces thereof, a second adhesive layer or an adhesive resin layer, and a sealant layer are laminated in this order. In the packaging material, the sealant layer includes a layer formed of a resin composition that contains 60 to 95 mass % propylene-ethylene random copolymer (A), and 5 to 40 mass % polyolefin elastomer (B) including 1-butene as a comonomer and having a melting point of 150° C. or less.

Owner:TOPPAN PRINTING CO LTD

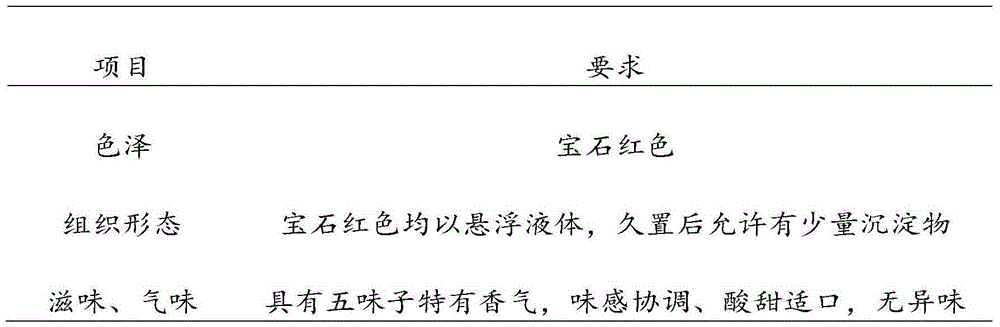

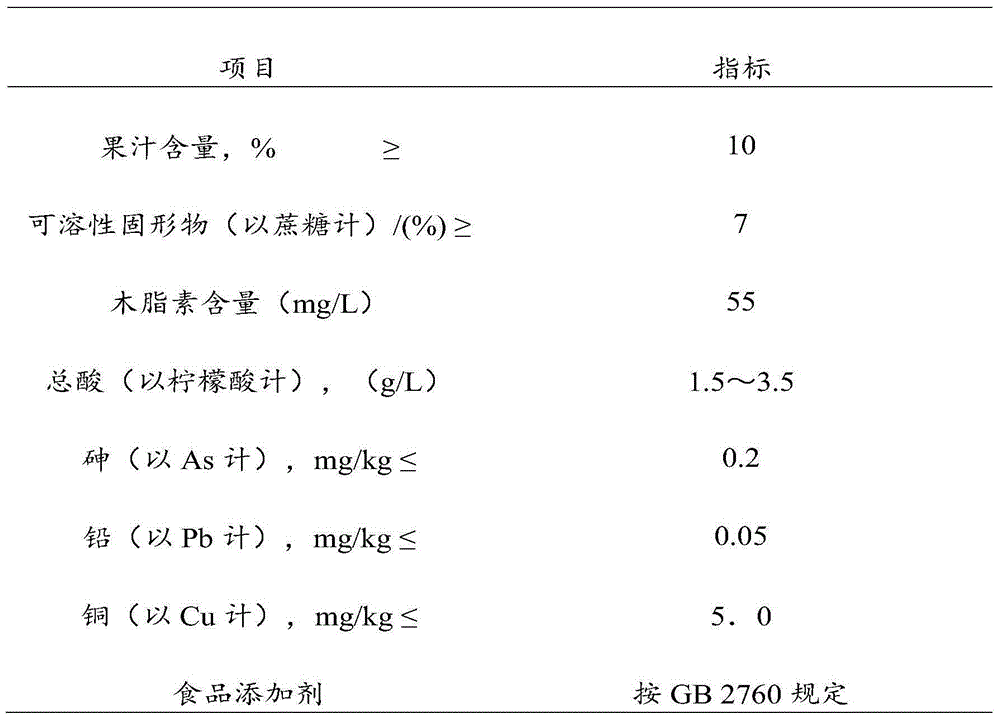

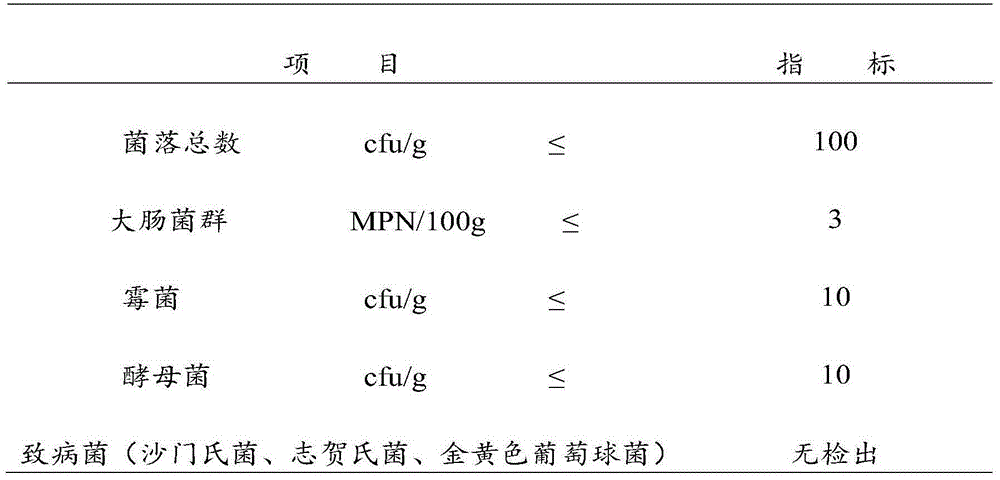

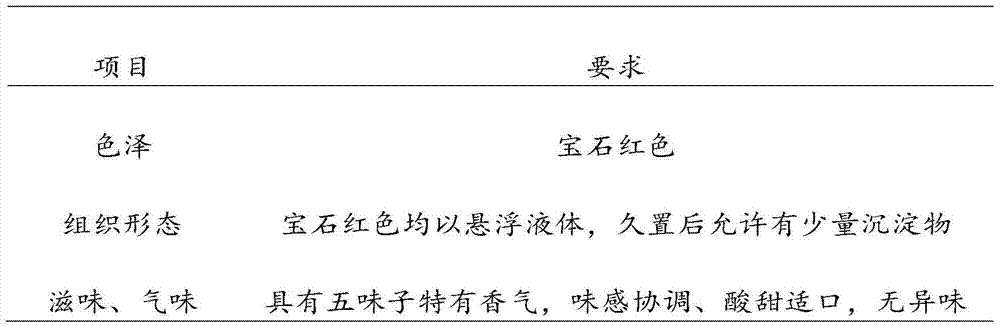

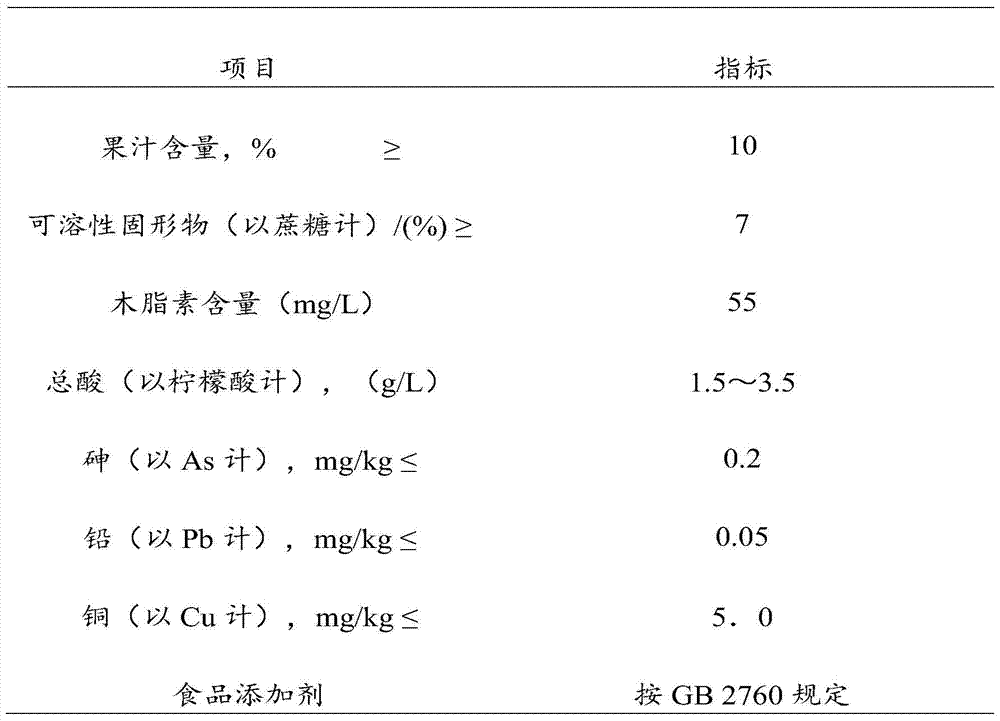

Entire schisandra chinensis suspended beverage and preparation method thereof

The invention provides an entire schisandra chinensis suspended beverage and a preparation method thereof. The suspended beverage is mainly prepared from raw materials as follows: 5-6 g / L of entire schisandra chinensis fruit powder, 70-110 g / L of sugar, 0.2-0.3 g / L of citric acid and 1.8-2.2 g / L of a stabilizer. The preparation method comprises steps as follows: all the raw materials and auxiliary materials are added to water according to the formula, blended, homogenized, degassed, sterilized and bottled, and the entire schisandra chinensis suspended beverage is prepared. The entire schisandra chinensis suspended beverage proves to be non-toxic through animal experiments, is safe to drink, and has an anti-fatigue function, tranquilizing and nerve soothing functions, an alcoholic liver injury inhibitive function and other kinds of health-care efficacy; the entire schisandra chinensis suspended beverage has the aroma specific to schisandra chinensis, is coordinated in taste, palatably sour and sweet, uniform and stable, does not have any peculiar smell and has a bright ruby red color.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Refining agent for aluminum or aluminum alloy smelting and application thereof

InactiveCN112458312AAvoid introducingAvoid problems such as difficult storageMaterials scienceAluminium alloy

The invention provides a refining agent for aluminum or aluminum alloy smelting and application thereof. The refining agent comprises NaCl, KCl, mNaF.AlF3 with the weight percentage of 10%-30%, Na2SiF6 with the weight percentage of 10%-30%, C2Cl6 with the weight percentage of 2%-8%, KNO3 with the weight percentage of 25%-45%, graphite powder with the weight percentage of 3%-8% and scandium with the weight percentage of 1%-5%, wherein the total weight percentage of NaCl and KCl is 10%-25%, scandium exists in the refining agent in the form of scandium salt which is a halogen-containing compound,and m in mNaF.AlF3 is 2.1-3.0. When the refining agent is applied to aluminum or aluminum alloy refining, the degassing and solid inclusion removing capacity of the refining agent can be remarkably improved through the synergistic effect of all the components in the refining agent.

Owner:CHINA ENFI ENGINEERING CORPORATION

Complete rectifying device for regeneration of waste oil

PendingCN107815328ANot easy to scaleExtended service lifeTreatment with plural serial stages onlyCooling towerFiltration

The invention provides a complete rectifying device for regeneration of waste oil, and relates to an oil purifier. According to the complete rectifying device for regeneration of the waste oil, a pretreatment tank, a reaction kettle, a fractionating tower, a distillation tower, a catalytic tower, a reboiling tower, a rectifying tower, a cooling tower, a gas-liquid separator, a semi-finished product tank, a desulfurizing tower, a light oil storage tank, a distillation vacuum pump unit, a filtration vacuum pump unit, a steam-water separator, a buffer tank, a filter tank, a fire isolating tank, an oil spill tank, a pneumatic valve box, a console and a power cabinet are sequentially installed on the ground and a mounting rack of the device, wherein vertical electric heating tubes are arrangedin the reaction kettle, the distillation tower, the catalytic tower, the reboiling tower and the rectifying tower. The device has a scientific and reasonable structure, and the defects in an existingpyrolysis rectifying system for regeneration of the waste oil can be overcome; the vertical electric heating tubes do not scale and get damaged easily, so that types of oil are adjusted and controlledat will, the effect of distillation of the waste oil is improved significantly, and the production cost of waste oil regeneration is reduced; therefore, the device has a promotion value.

Owner:CHONGQING FANGSHENG CLEANING EQUIP CO LTD

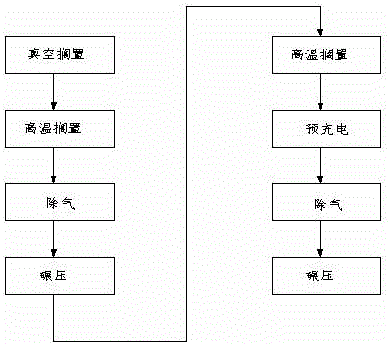

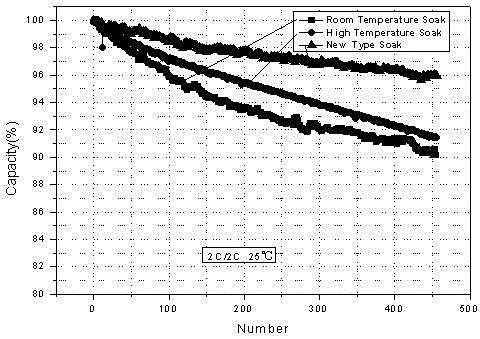

A kind of impregnation method of high-pressure negative electrode power battery

ActiveCN104659399BImprove the ability to absorb electrolyteExtend your lifeElectrode manufacturing processesFinal product manufactureNegative powerEngineering

The invention provides a method for soaking a high-pressure negative electrode power battery. The method comprises the following steps: A. Vacuum shelving: place the battery core that has just been injected with electrolyte but has not been sealed once in a vacuum box, and the battery core is 60- Placed at an angle of 90 degrees, the vacuum degree of the vacuum box is controlled at -0.085MPa~-0.09MPa, and the shelf time is 10 minutes to 15 minutes; B, high temperature shelf; C, degassing; D, rolling; E, secondary high temperature shelf; F. Pre-charging: On the charging device, use 0.007C, 0.01C, 0.1C, and 0.2C to pre-charge the batteries after step E. The charging upper limit voltages are 3.17V, 3.17V, and 3.17V respectively. , 3.47V, the charging time is 50 minutes, 70 minutes, 120 minutes, and 300 minutes respectively; G, degassing; H, secondary rolling: the battery cell after the completion of step G is subjected to secondary rolling according to step D After pressing, the impregnation process of the high-pressure negative electrode power battery is completed. The method makes it easy to infiltrate the low-porosity negative electrode sheet generally, and the liquid loss of the electric core is low.

Owner:WANXIANG 123 CO LTD

A kind of zinc alloy and its manufacturing method

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

A factory-like circulating water high-density three-dimensional ecological breeding system

ActiveCN105981667BReduce loadEasy to handleClimate change adaptationAgricultural fishingHigh densityWater flow

The invention provides a factorized circulating water high-density three-dimensional ecological breeding system which comprises a plurality of breeding tanks, a breeding circulating water treating system communicated with the breeding tanks, and three-dimensional spraying aquaculture columns arranged on the upper portions of the breeding tanks. The factorized circulating water high-density three-dimensional ecological breeding system is characterized in that the breeding circulating water treating system comprises a water collection tank, a water pump, a microfilter, a decarburization area, a nitration area, a degassing area, an ultraviolet sterilizing area and a temperature adjusting and tempering tank sequentially along a water flow direction, the water collection tank is communicated with the breeding tanks through sewage inlets, and the temperature adjusting and tempering tank is communicated with the three-dimensional spraying aquaculture columns through a clean water outlet and the water pump; a biological filtering area or a low-speed nitration area are arranged between the nitration area and the degassing area; a mud blocking slot is formed between the decarburization area and the nitration area, a plurality of mud-blocking water-passing holes are formed in a wall of the decarburization area on one side of the mud blocking slot, a plurality of nitration water incoming holes are formed in a wall of the nitration area on the other side of the mud blocking slot, and bottom height of the mud-blocking water-passing holes is greater than height of a mud discharging pipe in the decarburization area. The factorized circulating water high-density three-dimensional ecological breeding system is low in investment, high in space utilization rate, healthy and efficient.

Owner:GUANGZHOU CHANG CHI MECHANICAL & ELECTRICAL EQUIP CO LTD

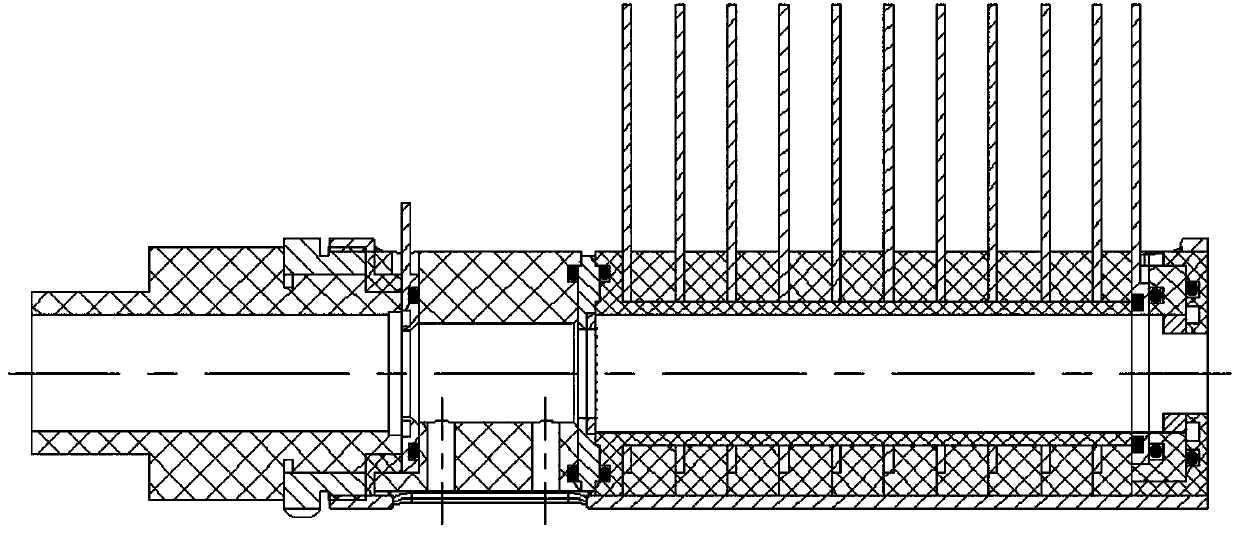

A kind of ultrasonic metallurgy device used in rh refining furnace

The invention discloses an ultrasonic metallurgical device for an RH refining furnace, which comprises an outer frame (2) connected with a riser (1) of the RH refining furnace, wherein an ultrasonic generator (6) and an ultrasonic working head (7) for inputting ultrasonic generated by the ultrasonic generator (6) into the riser (1) are arranged in the outer frame (2); an argon blowing pipe (4) communicated with the riser (1), a surrounding argon blowing pipe (4) and a plurality of argon sealing pipes (5) for hermetic seal are also arranged in the outer frame (2); and the argon blowing pipe (4) and the argon sealing pipes (5) are connected with an argon source after penetrating through the outer frame (2). The metallurgical device can enhance the molten steel circulation efficiency of the RH refining furnace and improve the degassing and inclusion removal effects.

Owner:SHANDONG IRON & STEEL CO LTD

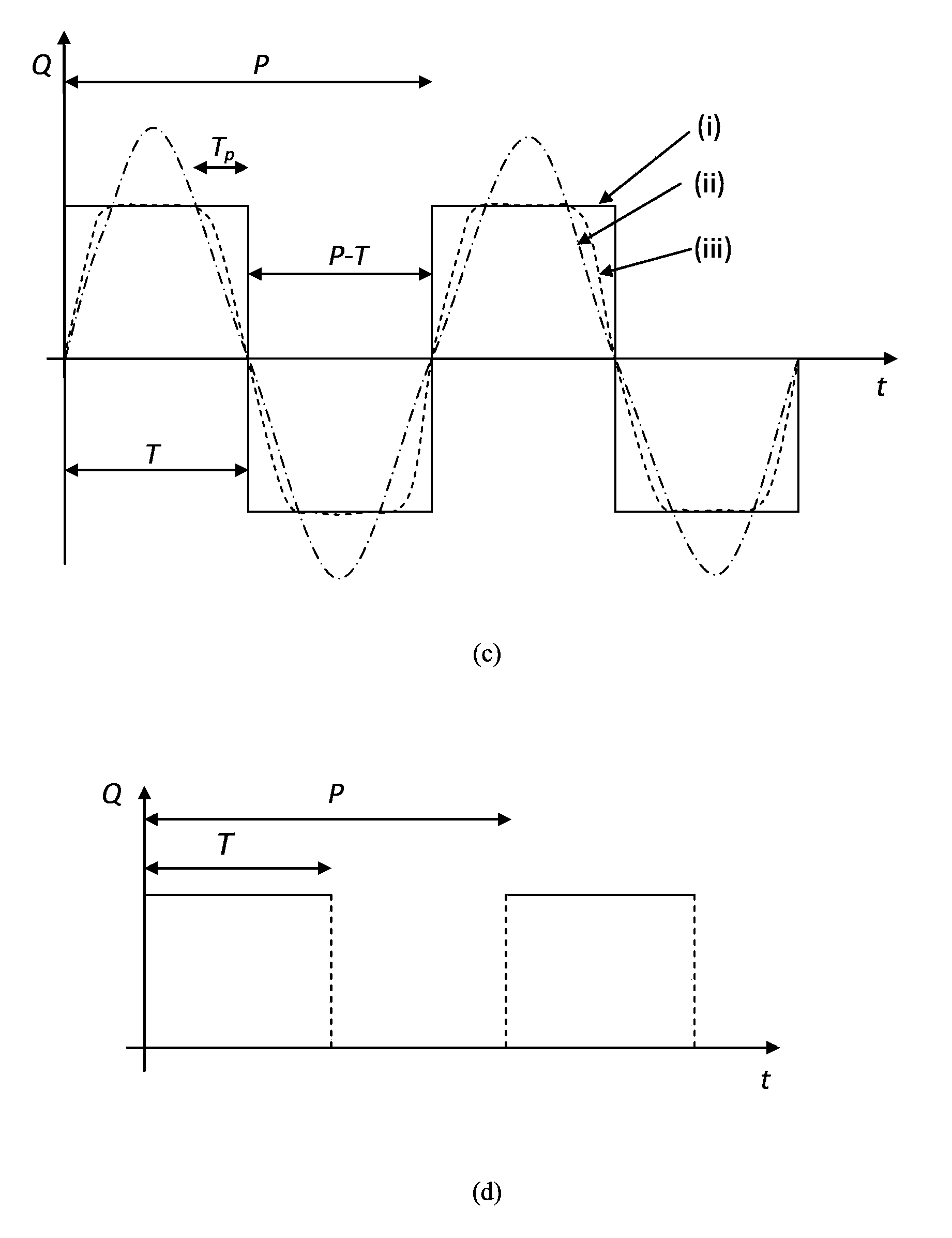

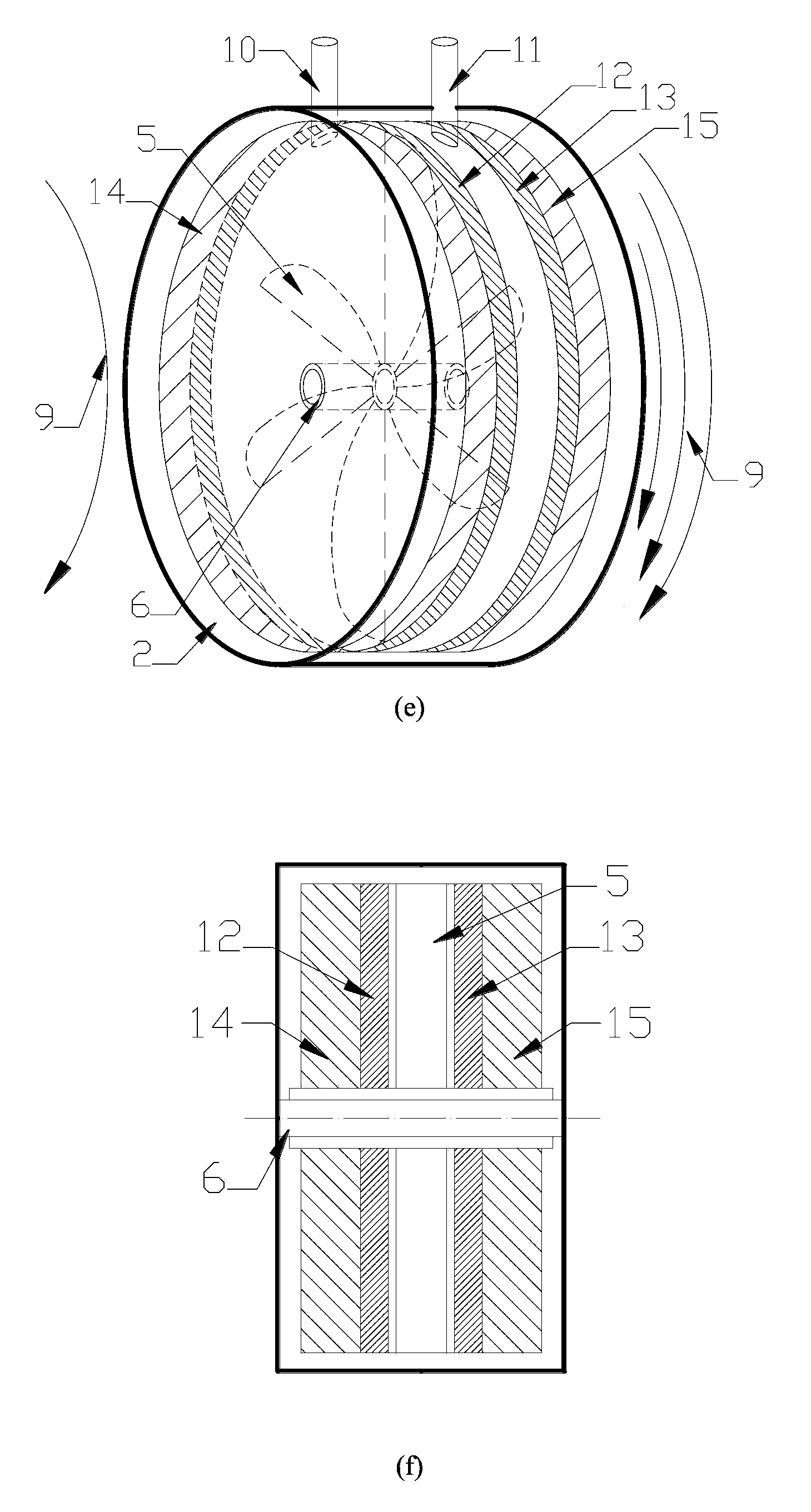

Method for generating electromagnetic force with temporal and spatial variation in conducting liquid by adopting fluid driving

ActiveCN102664511BEasy to implementReliable means of implementationDynamo-electric machinesChemical industrySemiconductor materials

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS +1

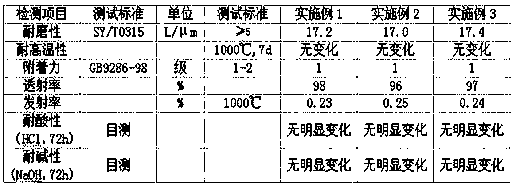

Sr-contained panel solar aluminum alloy plating layer and preparation method thereof

InactiveCN107675049AGood dimensional stabilityQuality improvementMolten spray coatingUltimate tensile strengthWear resistance

The invention discloses a Sr-contained panel solar aluminum alloy plating layer and a preparation method thereof. The plating layer material is prepared by the following raw materials in percentage bymass including 0.3%-0.5% of Sr, 2%-3% of Ti, 10%-20% of Zn, 8%-10% of Si, 0.65%-0.75% of La, 0.1%-0.6% of Ce, 0.2%-0.3% of Zr, and the balance aluminum. The plating layer material is simple in preparation method, excellent in bonding with a basal body and not easy to fall; and the prepared aluminum alloy plating layer is beautiful, excellent in corrosion resistance and wear resistance, high in strength and ductility and high in heat absorption and heat transfer capacity.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

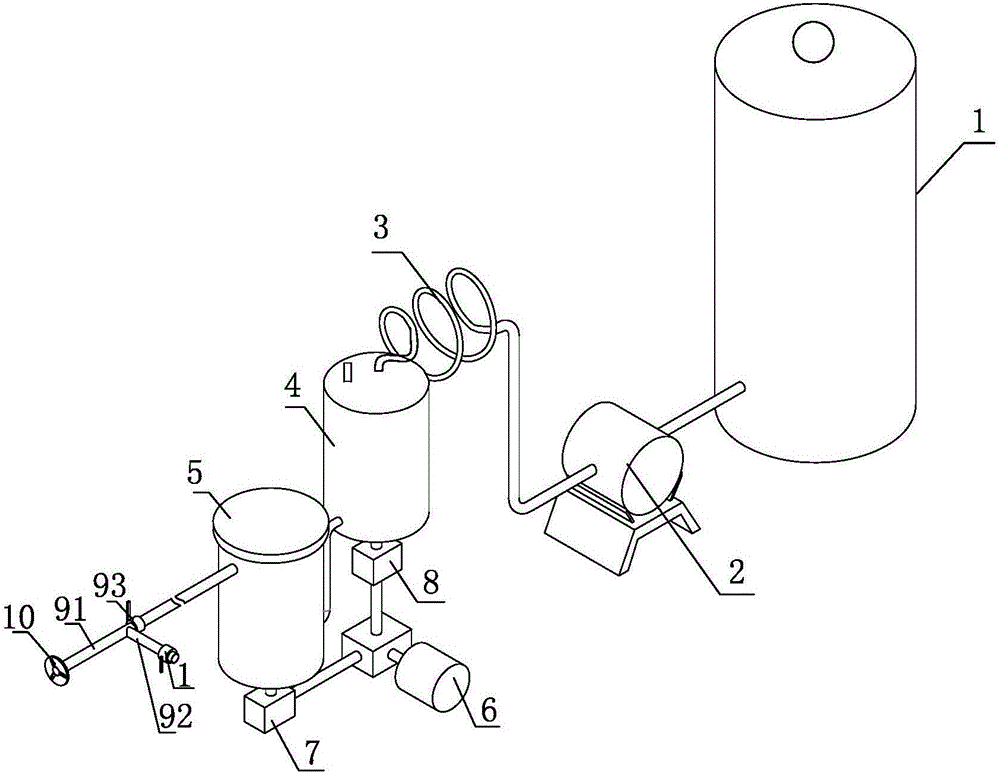

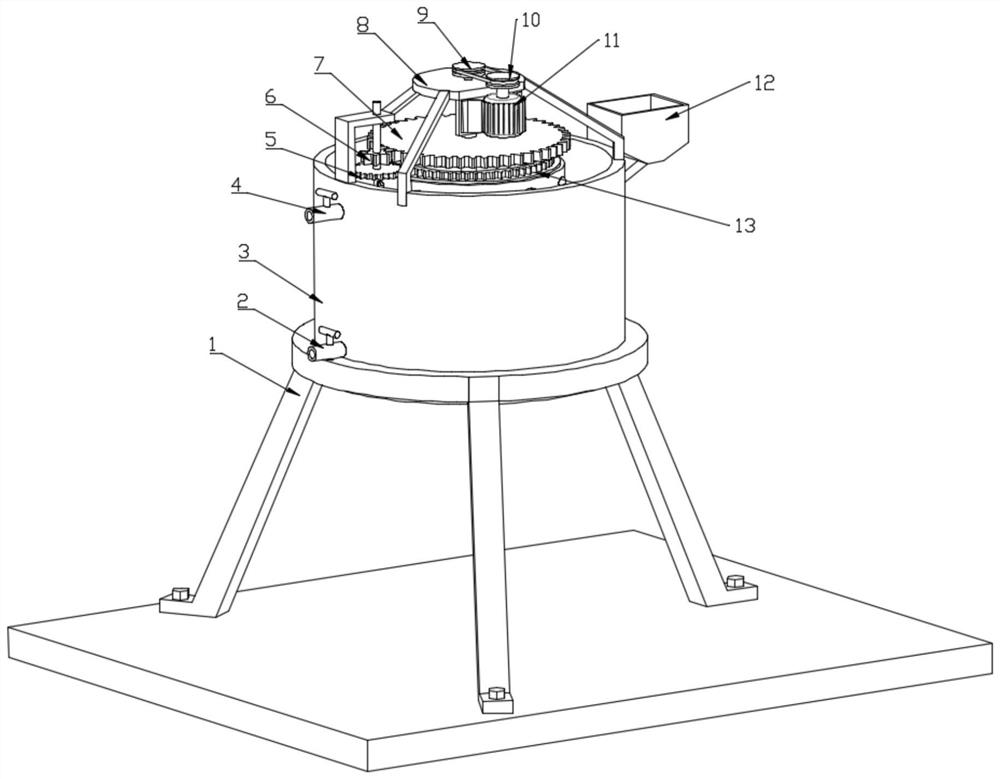

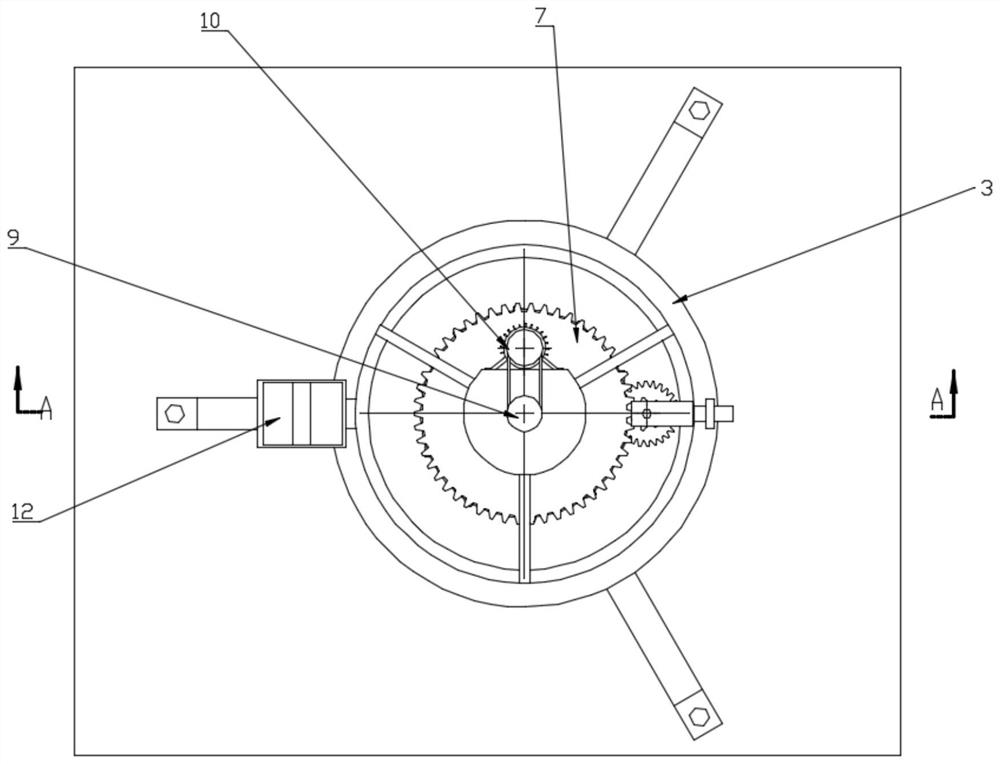

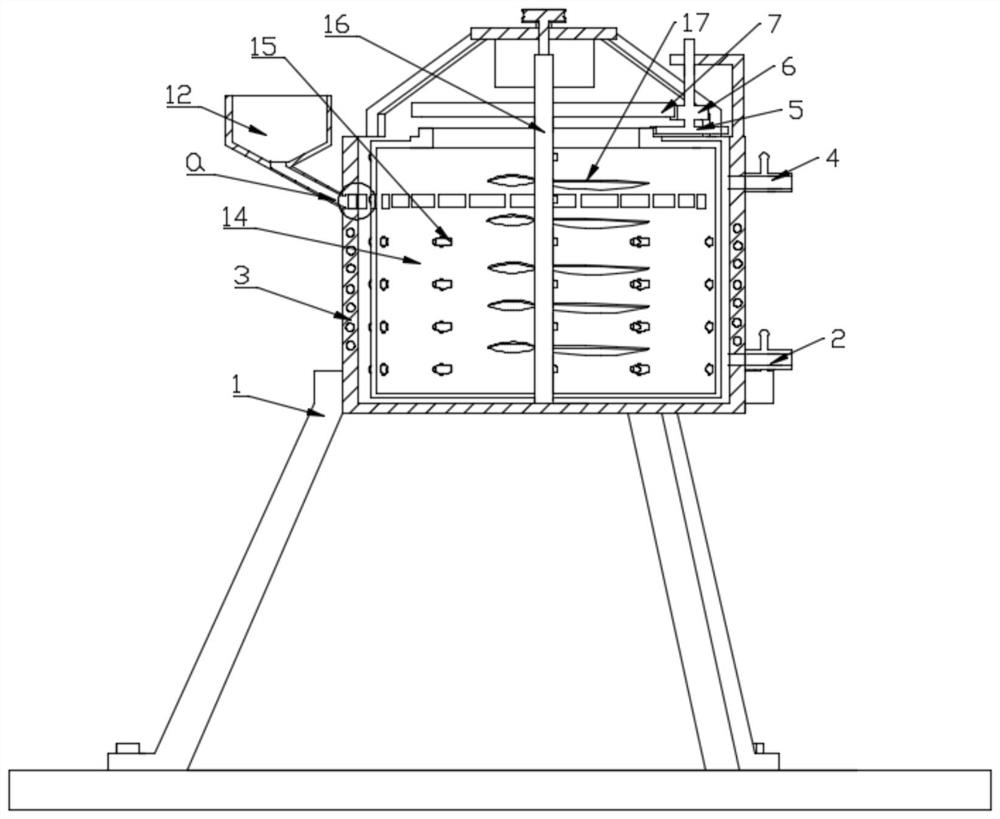

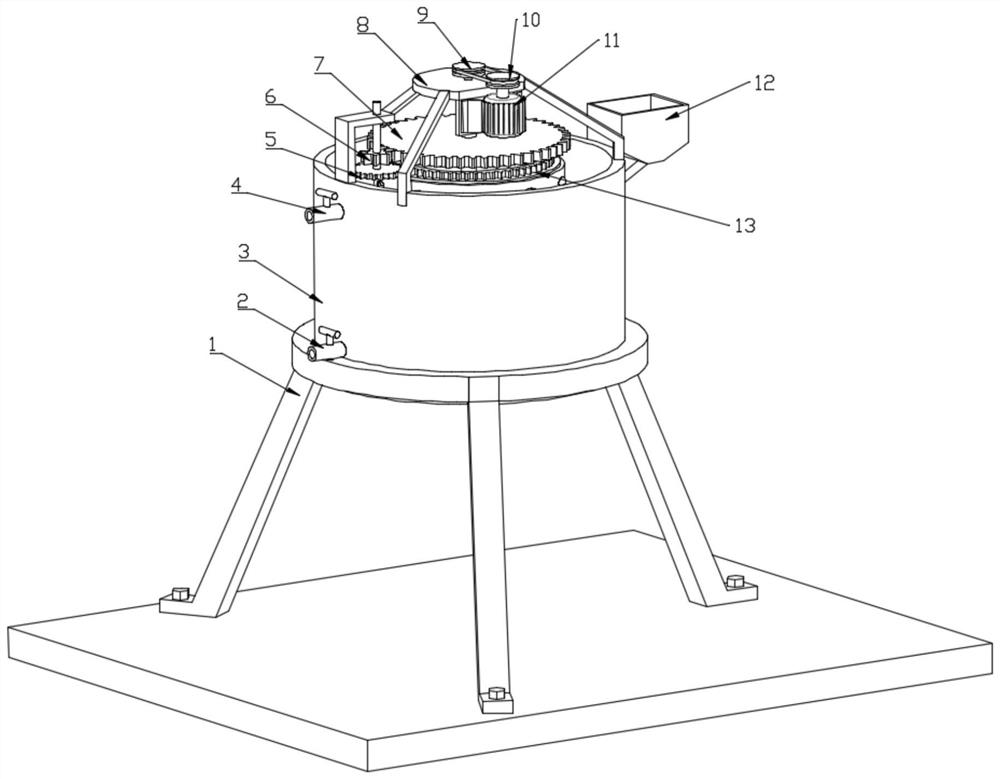

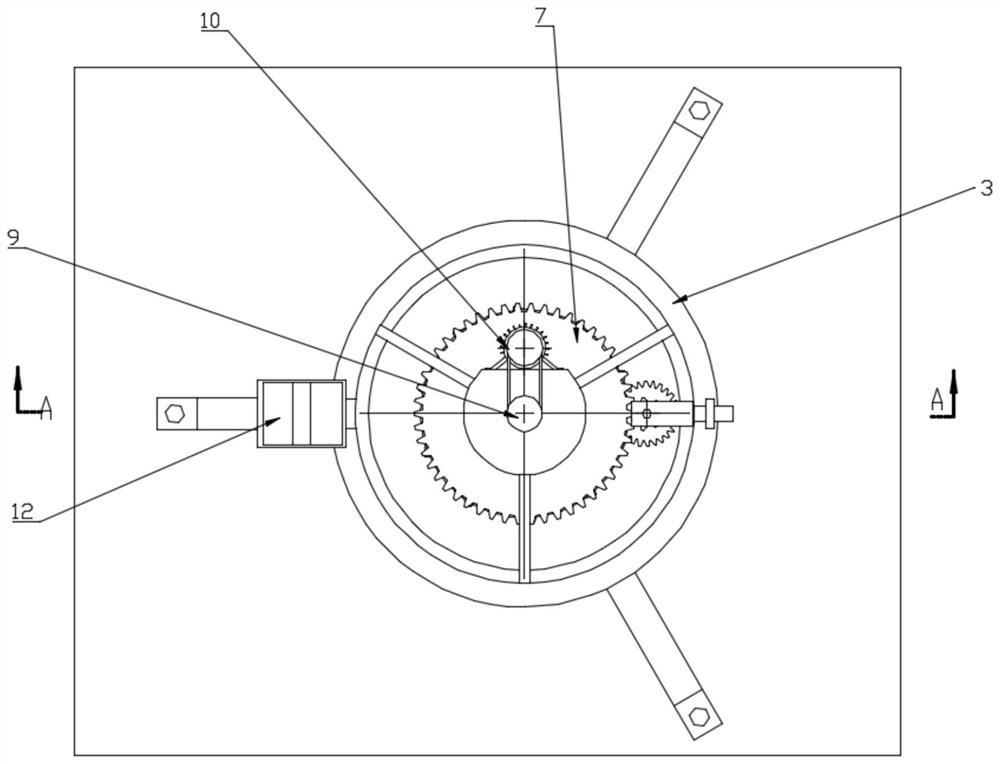

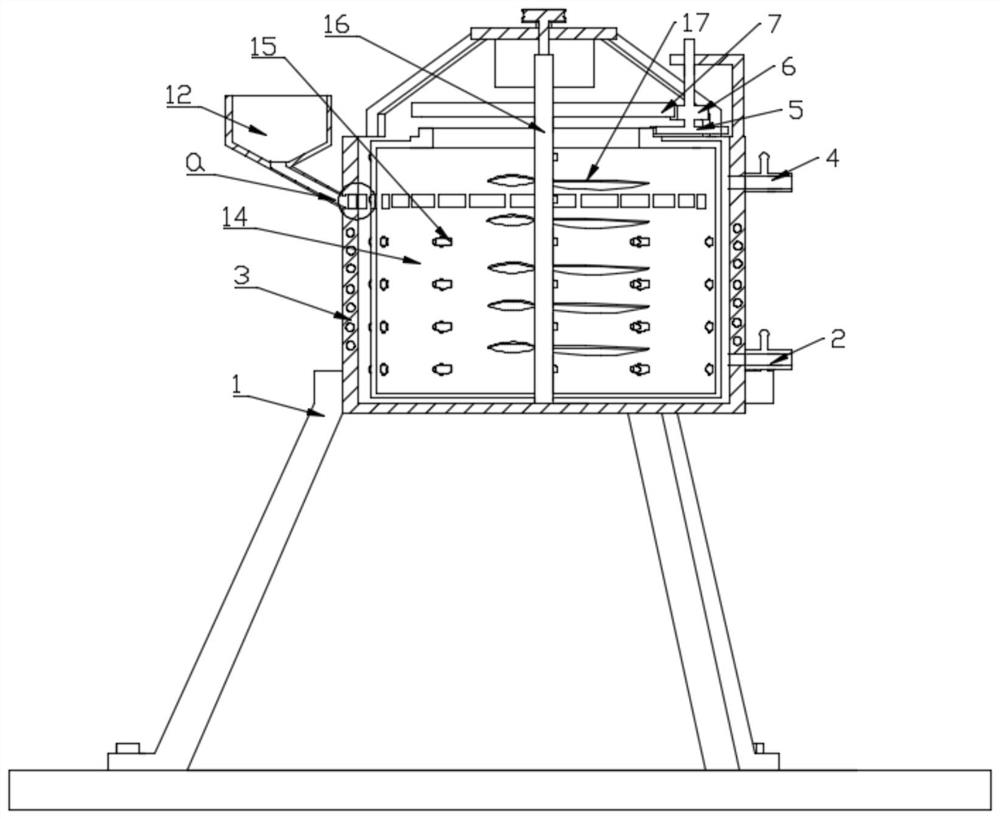

Preparation equipment and method of modified polyurethane material

ActiveCN114307939AAccelerate mixing and dissolvingDehydration fastChemical/physical/physico-chemical moving reactorsFan bladeMaterials science

The invention relates to the field of polyurethane materials, and discloses a preparation device and method of a modified polyurethane material, the preparation device of the modified polyurethane material comprises: an outer cylinder having a barrel-shaped structure; the heating piece is used for heating. And at least one reaction liquid injection port is arranged. The temperature sensor is used for sensing the temperature in the outer cylinder. And the discharge outlet is communicated with the bottom of the outer cylinder. The embedded barrel is coaxially and rotatably arranged in the outer barrel, and a plurality of through holes are formed in the embedded barrel. The rotating shaft is coaxially and rotatably arranged in the embedded barrel, a transmission structure is arranged between the embedded barrel and the rotating shaft, and a plurality of fan blades are fixedly arranged on the rotating shaft. At least one raw material hopper is arranged. And the driving part is mounted on the outer cylinder through a mounting frame and is connected with the rotating shaft. And the controller is electrically connected with the driving piece, the temperature sensor and the heating piece. The fan blades are matched with the through holes in the direction, and the embedded barrel is matched with the fan blades, so that mixing dissolution, dehydration and degassing can be accelerated.

Owner:JIANGSU WELLCARE HOUSEHOLD ARTICLES

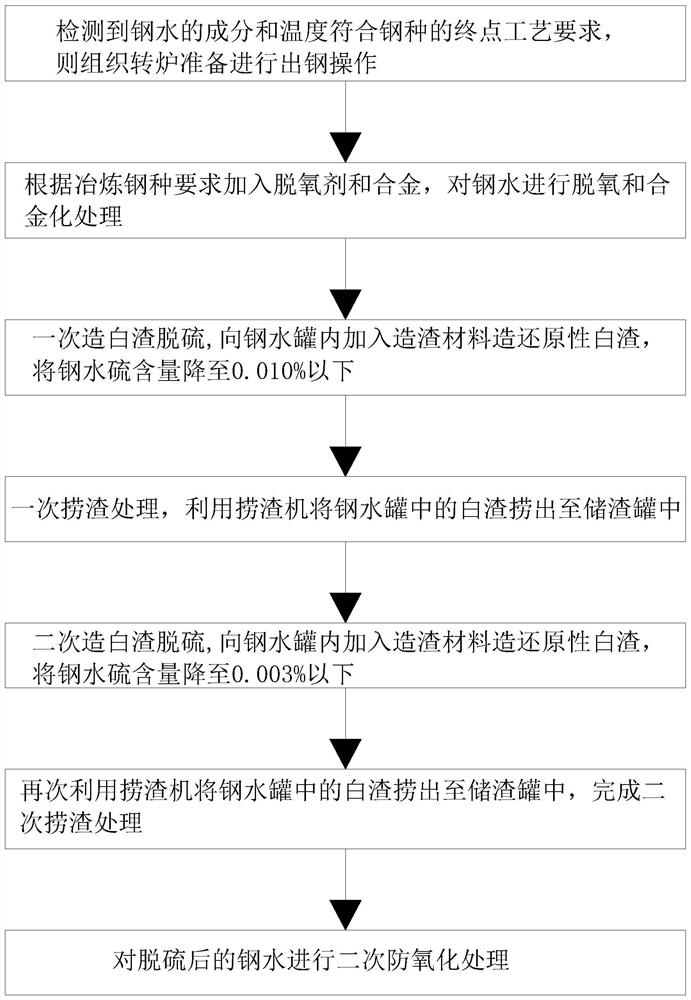

Deep desulfurization method for LF furnace

ActiveCN114657323AImprove deep desulfurizationImprove degassingProcess efficiency improvementSulfur contentLadle furnace

The invention discloses a deep desulfurization method for an LF (ladle furnace), which relates to the technical field of steelmaking and refining and comprises the following steps: adding a deoxidizer and an alloy before tapping according to the requirements of smelted steel grades, deoxidizing and alloying molten steel, and carrying out primary white slag desulfurization; the sulfur content of the molten steel is reduced to 0.010% or below, white slag in the molten steel tank is fished out into a slag storage tank through a slag fishing machine, secondary white slag desulfurization is carried out, the sulfur content of the molten steel is reduced to 0.003% or below, and secondary anti-oxidation treatment is carried out on the desulfurized molten steel; according to the method, the slag making material reducing white slag is added in the tapping process, the sulfur content of the molten steel can be reduced to 0.010% or below in the primary white slag making process, the sulfur content of the molten steel can be reduced to 0.003% or below by adding the slag making material again for secondary white slag making after the slag is dredged by the slag dredger, the cleanliness of a finished product of the molten steel is higher, and the quality of the molten steel is improved. And it can be guaranteed that the LF can achieve the purpose of smelting extremely-low-sulfur steel.

Owner:YANGCHUN NEW STEEL CO LTD

An oil-immersed transformer oil injection device

InactiveCN106098318BPrevent deterioration of insulationImprove securityTransformers/inductances coolingLiquid transferring devicesControl systemTransformer oil

The invention provides an oil-immersed transformer oiling device, belonging to the technical field of oiling devices. The oil-immersed transformer oiling device aims to solve the technical problems of degassing, impurity removal and oiling in the insulating oil for transformers. The oil-immersed transformer oiling device comprises an oil drum, an oil level detection mechanism, an oil pump, an oil filter, an oiling tube mechanism and a control system, wherein the oil level detection mechanism is installed in the oil drum; the upper end of the oil drum is provided with an alarm lamp; one end of the oil pump communicates with the oil drum, and the other end communicates with the oil filter; the oil filter comprises a heating mechanism, a degassing mechanism, an impurity removal mechanism and a power mechanism; the oiling tube mechanism comprises an oiling tube and an exhaust tube; and the outer end of the oiling tube is fixedly provided with an adjustable flange. The oil-immersed transformer oiling device effectively performs impurity removal, degassing treatment and oiling before oiling of the oil-immersed transformer insulating oil, prevents the insulating property of the insulating oil for transformers from degradation due to the influence of gases and impurities, and obviously enhances the safety performance of the insulating oil for transformers.

Owner:国网山东省电力公司茌平县供电公司 +1

A process control method for pbo fiber production

ActiveCN107761185BRelieve pressureGuaranteed molar ratioMonocomponent synthetic polymer artificial filamentFiberThree stage

The invention discloses a process control method for PBO fiber production. PBO fiber is produced from polyphosphoric acid, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials by degassing, pre-polymerization, post-polymerization and spinning, the terephthalic acid is respectively poured into the three stages of raw material mixing, pre-polymerization and post-polymerization for production. In the production process, and the sum of molar amounts of the terephthalic acid injected in the three times is guaranteed to be equal to the molar amount of the4,6-diaminoresorcinol hydrochloride injected during the raw material mixing stage. According to the method, the polymerization production of the PBO fiber can be completed in the manner of multiple times of feeding of the TPA (terephthalic acid), the solution tressure of the TPA during the initial feeding is reduced, the process time of the mixing, the degassing, and the pre-polymerizing in the early stage can be shortened, and the performance of subsequent PBO fiber products can be improved.

Owner:CHENGDU XINCHEN NEW MATERIAL TECH CO LTD

A kind of preparation equipment and method of modified polyurethane material

ActiveCN114307939BAccelerate mixing and dissolvingDehydration fastChemical/physical/physico-chemical moving reactorsEngineeringFan blade

The invention relates to the field of polyurethane materials, and discloses a preparation equipment and a method for modified polyurethane materials. The preparation equipment for modified polyurethane materials comprises: an outer cylinder, which is a cylindrical structure. The heating element is used for heating. At least one reaction liquid injection port is provided. The temperature sensor is used to sense the temperature inside the outer cylinder. The discharge port is communicated and provided at the bottom of the outer cylinder. The inner barrel is coaxially rotated and arranged inside the outer barrel, and the inner barrel is provided with a plurality of through holes. The rotating shaft is coaxially arranged inside the embedded barrel, a transmission structure is arranged between the embedded barrel and the rotating shaft, and a plurality of fan blades are fixedly arranged on the rotating shaft. There is at least one raw material hopper. The driving part is mounted on the outer cylinder through the mounting bracket and is connected with the rotating shaft. The controller is electrically connected with the driving element, the temperature sensor and the heating element. The present invention can accelerate mixing, dissolving, dehydration and degassing through the coordination of the fan blade and the through-hole direction, and the in-line barrel cooperates with the fan blade.

Owner:JIANGSU WELLCARE HOUSEHOLD ARTICLES

A kind of schisandra fruit suspension beverage and preparation method thereof

The invention provides an entire schisandra chinensis suspended beverage and a preparation method thereof. The suspended beverage is mainly prepared from raw materials as follows: 5-6 g / L of entire schisandra chinensis fruit powder, 70-110 g / L of sugar, 0.2-0.3 g / L of citric acid and 1.8-2.2 g / L of a stabilizer. The preparation method comprises steps as follows: all the raw materials and auxiliary materials are added to water according to the formula, blended, homogenized, degassed, sterilized and bottled, and the entire schisandra chinensis suspended beverage is prepared. The entire schisandra chinensis suspended beverage proves to be non-toxic through animal experiments, is safe to drink, and has an anti-fatigue function, tranquilizing and nerve soothing functions, an alcoholic liver injury inhibitive function and other kinds of health-care efficacy; the entire schisandra chinensis suspended beverage has the aroma specific to schisandra chinensis, is coordinated in taste, palatably sour and sweet, uniform and stable, does not have any peculiar smell and has a bright ruby red color.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

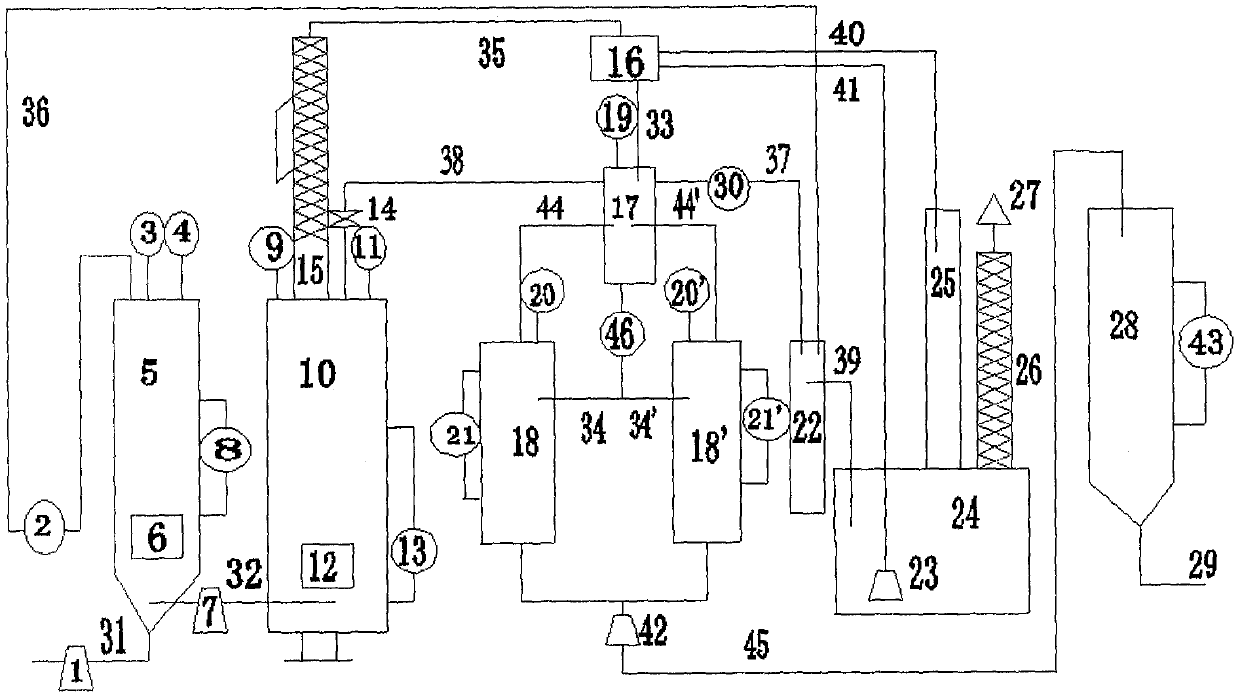

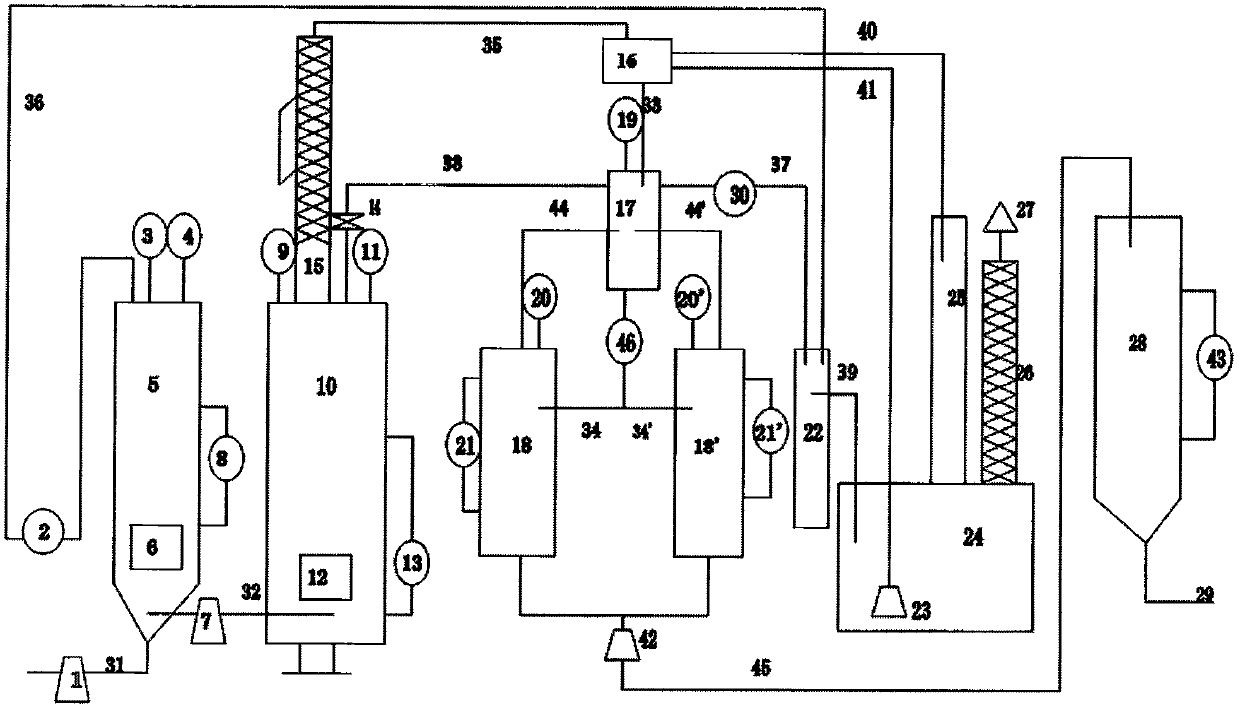

Ultimate negative pressure waste oil catalytic cracking regeneration rectification complete set of acid-base free treatment

ActiveCN108165306BDehydration fastImprove degassingTreatment with plural serial stages onlyFiltrationWaste oil

The invention provides a complete apparatus capable of performing extreme negative pressure catalytic cracking regeneration rectification on waste oil without acid-alkali treatment. The complete apparatus comprises an oil inlet pump (1), a vacuum dehydration tank (5), a reaction kettle (10), an oil gas catalysis tower (15), an oil gas cooling device (16), a gas-liquid separation device (17), a first finished product oil storage tank (18), a second finished product oil storage tank (19) and a filtration tank (28), wherein the first finished product oil storage tank (18) and the second finishedproduct oil storage tank (19) are identical and are mutually spare to each other. According to the present invention, the complete apparatus integrates waste oil cracking, rectification, catalysis, gasification separation and other processes, has the simple and reasonable structure, significantly improves the dewatering, degassing, decolorization, desulfurization, cracking and rectification effecton waste oil, has the oil output rate of 95%, has advantages of continuous production and production cost reducing, wherein the obtained finished product oil has the good quality, and meets the national standard, and has promotion value.

Owner:唐山宸午流体科技有限公司

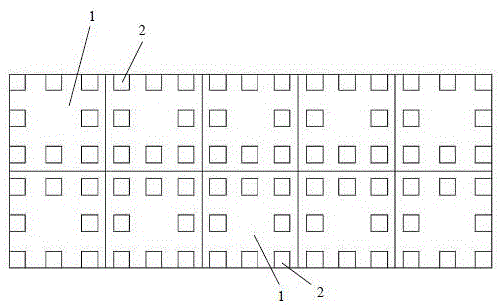

A vacuum degassing device

Owner:佛山市三水凤铝铝业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com