Ultimate negative pressure waste oil catalytic cracking regeneration rectification complete set of acid-base free treatment

An acid-base treatment and negative pressure technology, which is applied in the field of extreme negative pressure waste oil catalytic cracking regeneration rectification acid-base treatment complete set of equipment, can solve the problems of short service life, harsh raw material requirements, low production efficiency, etc., to reduce production The effect of low cost, good quality of refined oil and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

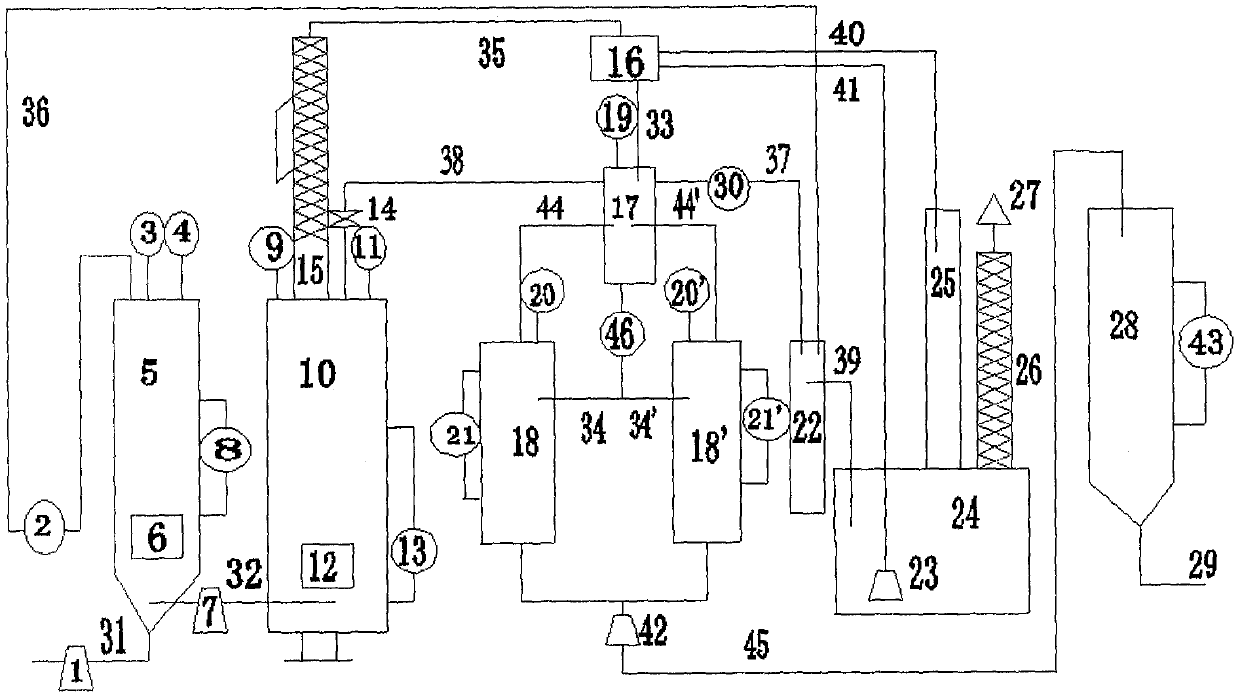

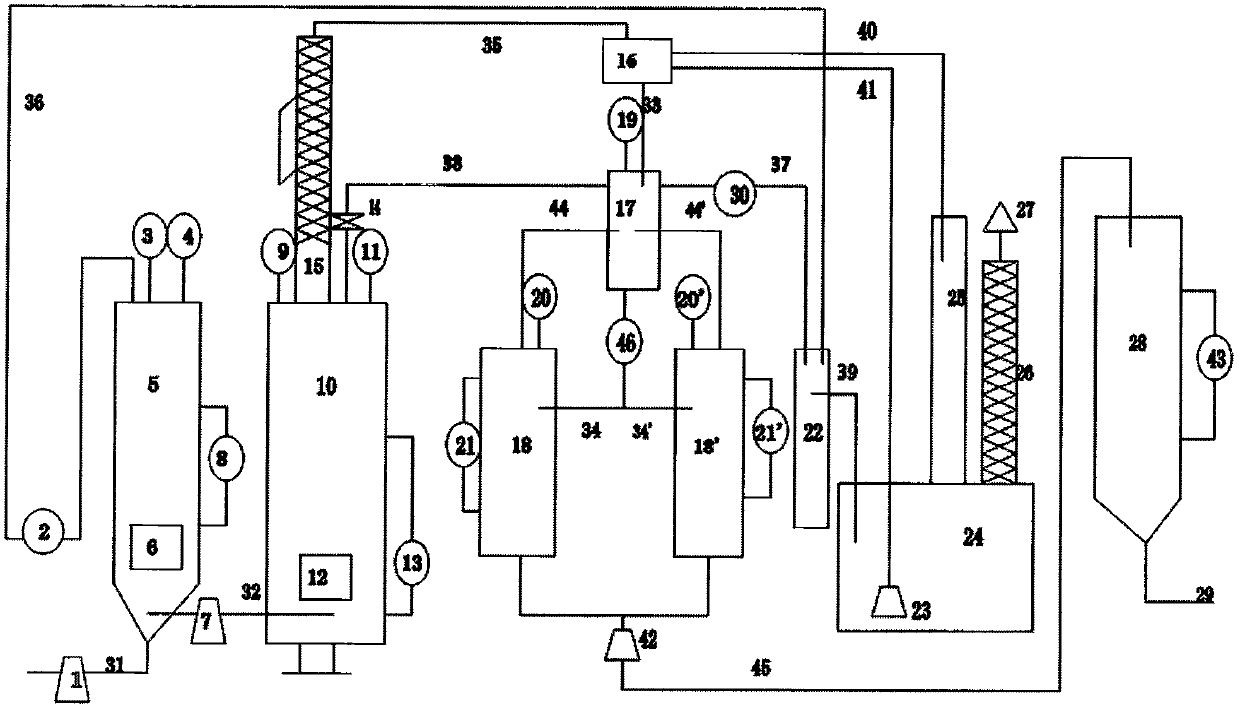

[0027] The specific structure and process of the device are as follows:

[0028] The external waste oil is pumped into the vacuum dehydration tank 5 through the oil inlet pipe 31 by the oil inlet pump 1, and the connected liquid level gauge 8 is observed to control the oil level to a suitable position. Preheating and dehydration in the vacuum dehydration tank 5 through the electromagnetic heater 6 keeps the ultimate vacuum in the vacuum dehydration tank and reduces the boiling point of water evaporation; figure 1 The medium vacuum dehydration tank 5 contains a vacuum pump 2, a thermocouple 3, a vacuum gauge 4, an electromagnetic heater 6, and a connected liquid level gauge 8; wherein the vacuum pump 2 extracts the water vapor generated after the waste oil in the vacuum dehydration tank 5 is heated, and Send into gas purification device 22 through pipeline 36; Wherein thermocouple 3 controls electromagnetic heater 6 to regulate the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com