Oil-immersed transformer oiling device

A technology of oil-immersed transformer and oil injection device, which is applied in the direction of transformer/inductor cooling, distribution device, special distribution device, etc., which can solve the problems affecting the insulation performance of insulating oil, internal discharge, and deterioration of oil insulation performance, so as to improve High oil injection efficiency, high impurity removal efficiency, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

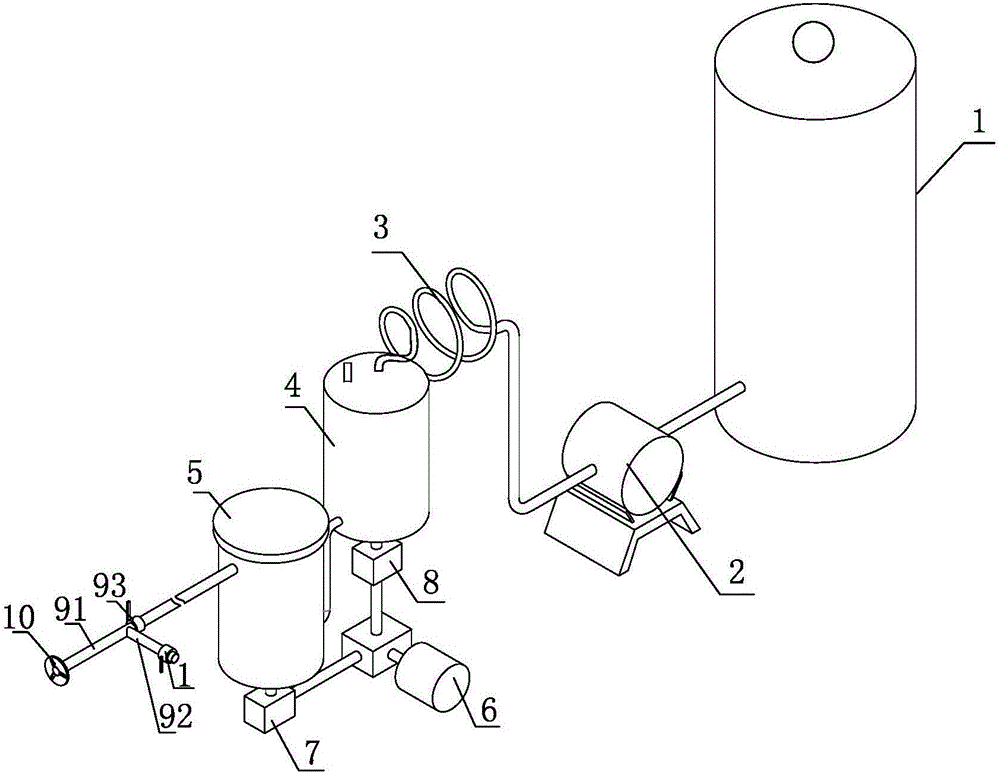

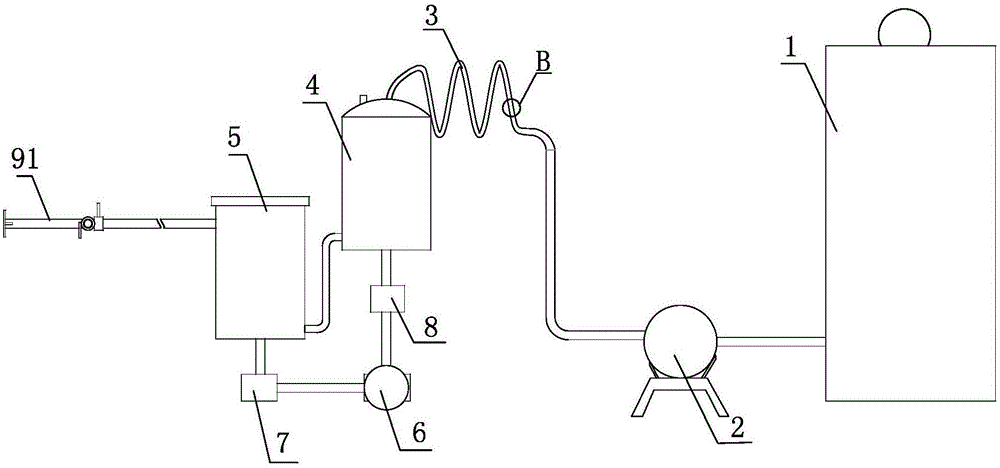

[0033] Such as Figures 1 to 8 As shown, an oil-immersed transformer oil injection device includes an oil barrel 1, an oil level detection mechanism, an oil well pump 2, an oil filter, an oil injection pipe mechanism and a control system;

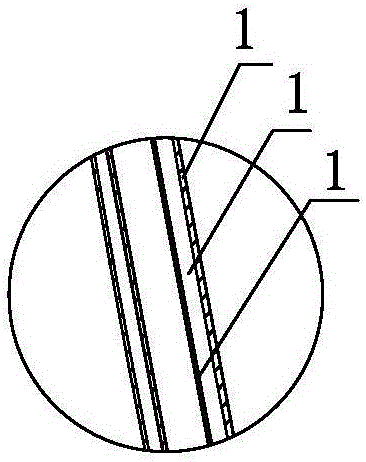

[0034] The oil level detection mechanism is used to detect the oil level in the oil drum 1 to prevent the oil pump 2 from sucking the impurities at the bottom of the oil drum 1 into the transformer, and the top of the oil drum 1 is provided with a warning light 16; The oil level detection mechanism includes a floating ball 11, a wireless signal transmitting module 12, a counterweight 13, a sleeve 14 and a slide rod 15, the floating ball 11 adopts a hollow shell sealing structure, and the top of the floating ball 11 is provided with Hanging ring, the density of the floating ball 11 is less than that of the oil body; the counterweight 13 is fixed on the bottom inside the floating ball 11; the wireless signal transmitting module 12 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com