Silicon rubber insulation braided wire and process thereof

A silicone rubber insulation and wire processing technology, applied in the direction of insulated cables, insulated conductors, circuits, etc., can solve the problems of easy leakage point electric shock, poor insulation effect, short circuit and other problems, improve strength and high temperature resistance, avoid insulation less effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the scope of protection.

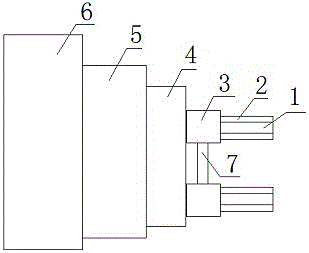

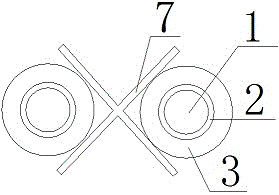

[0027] A silicone rubber insulated braided wire, comprising several metal conductor layers 1, insulation layers 3, heat insulation layers 5, and fiber braid layers 6, the metal conductor layers 1 are coated with a tin layer 2, and the tin layer 2 is externally connected to the insulation layer 3. The plurality of metal conductor layers 1 externally connected to the tin layer 2 and the insulating layer 3 constitute a cable core 4, the cable core 4 is externally connected to a heat insulating layer 5, the heat insulating layer 5 is externally connected to a fiber braiding layer 5, and the externally connected tin A grid 7 is provided between the layer 2 and the metal conductor layer 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com