Petroleum paste filling device for electric cables

A technology of filling device and petroleum jelly, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc. It can solve problems such as filling blockage, poor insulation, petroleum jelly filling agglomeration, etc., and speed up filling , Prevent uneven filling and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

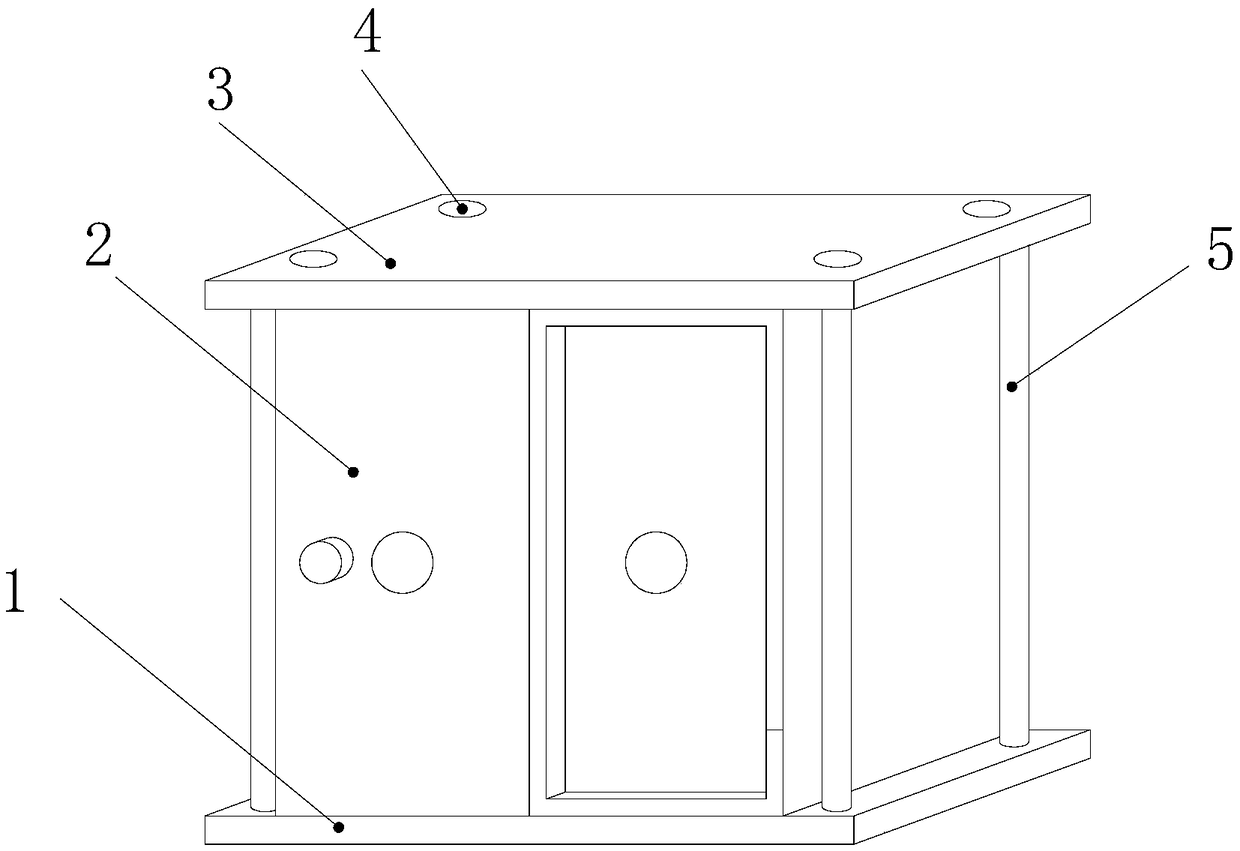

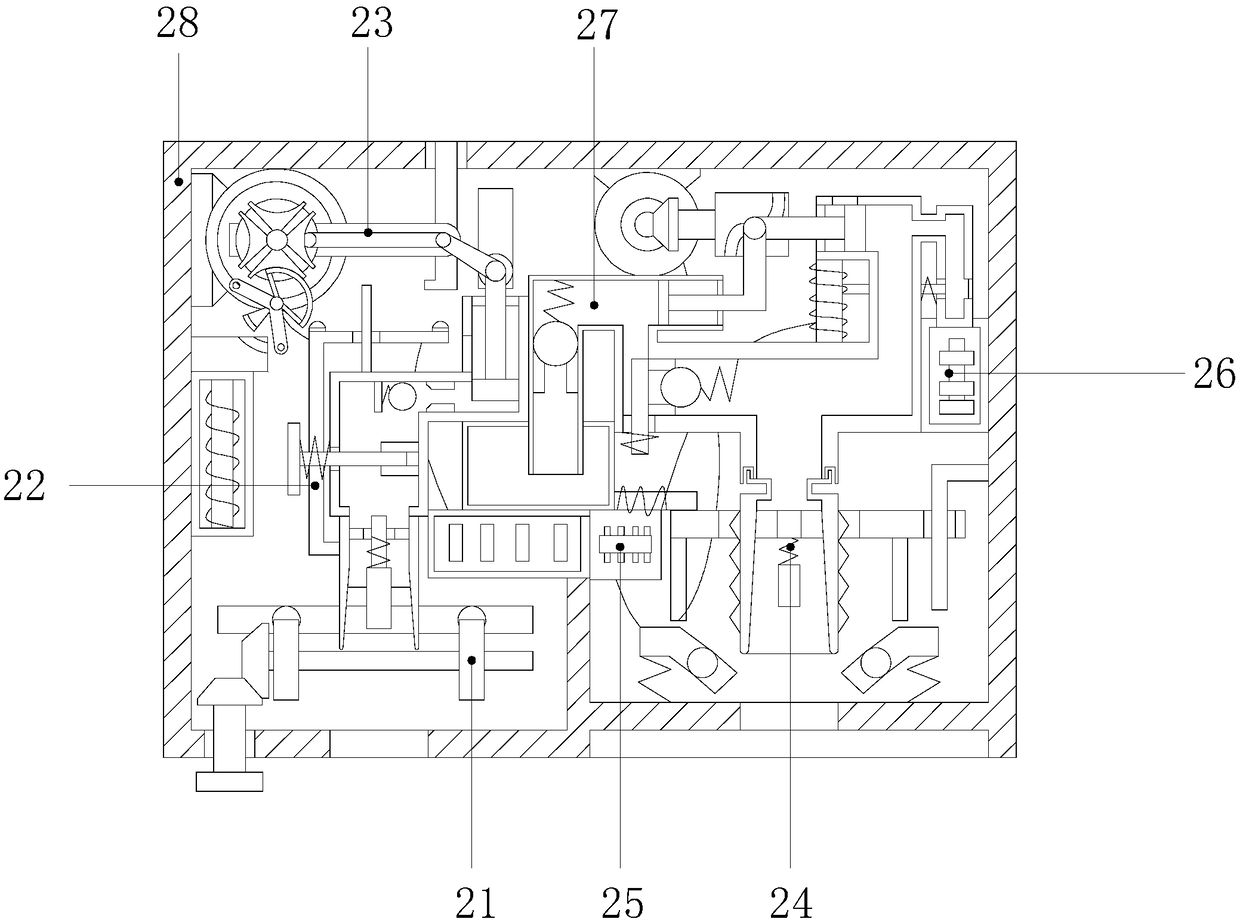

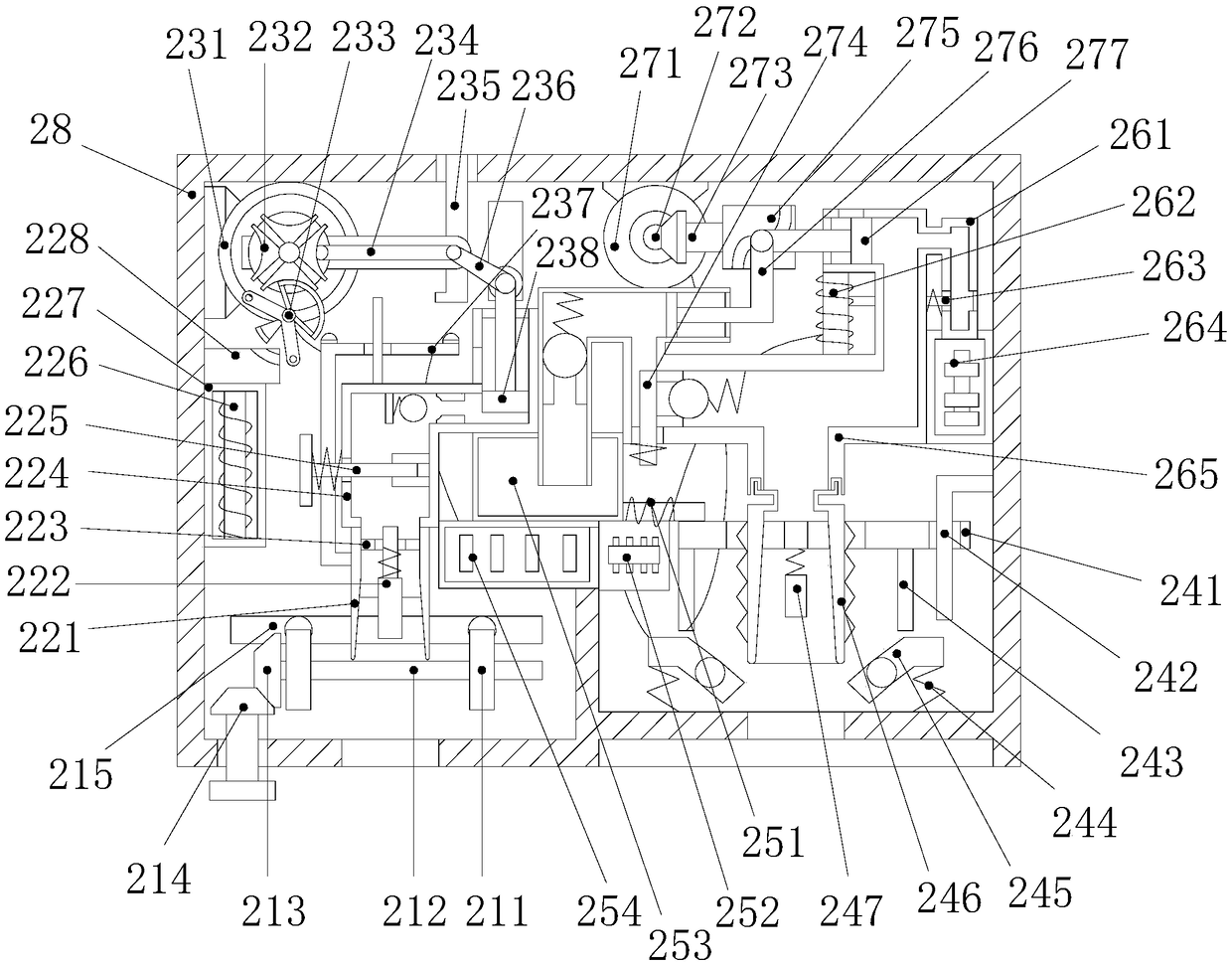

[0025] see Figure 1-Figure 5 , the present invention provides a petroleum jelly filling device for cables, the structure of which includes a bottom plate 1, a dust removal and dehumidification filling device 2, a mounting plate 3, a card slot 4, and a support column 5, and the plane where the bottom plate 1 is located and the plane where the mounting plate 3 is located are parallel to each other , the dust removal and dehumidification filling device 2 is arranged on the upper surface of the base plate 1, and is connected in a fixed manner, the installation plate 3 is provided with four card slots 4, and the support column 5 is vertically installed on the base plate 1 The upper surface of the four feet, the installation plate 3 is horizontally installed on the upper surface of the dust removal and dehumidification filling device 2, the support column 5 is embedded in the inside of the card slot 4, the support column 5 and the installation plate 3 The formed angle is 90 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com