Patents

Literature

86results about How to "Improve oil injection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

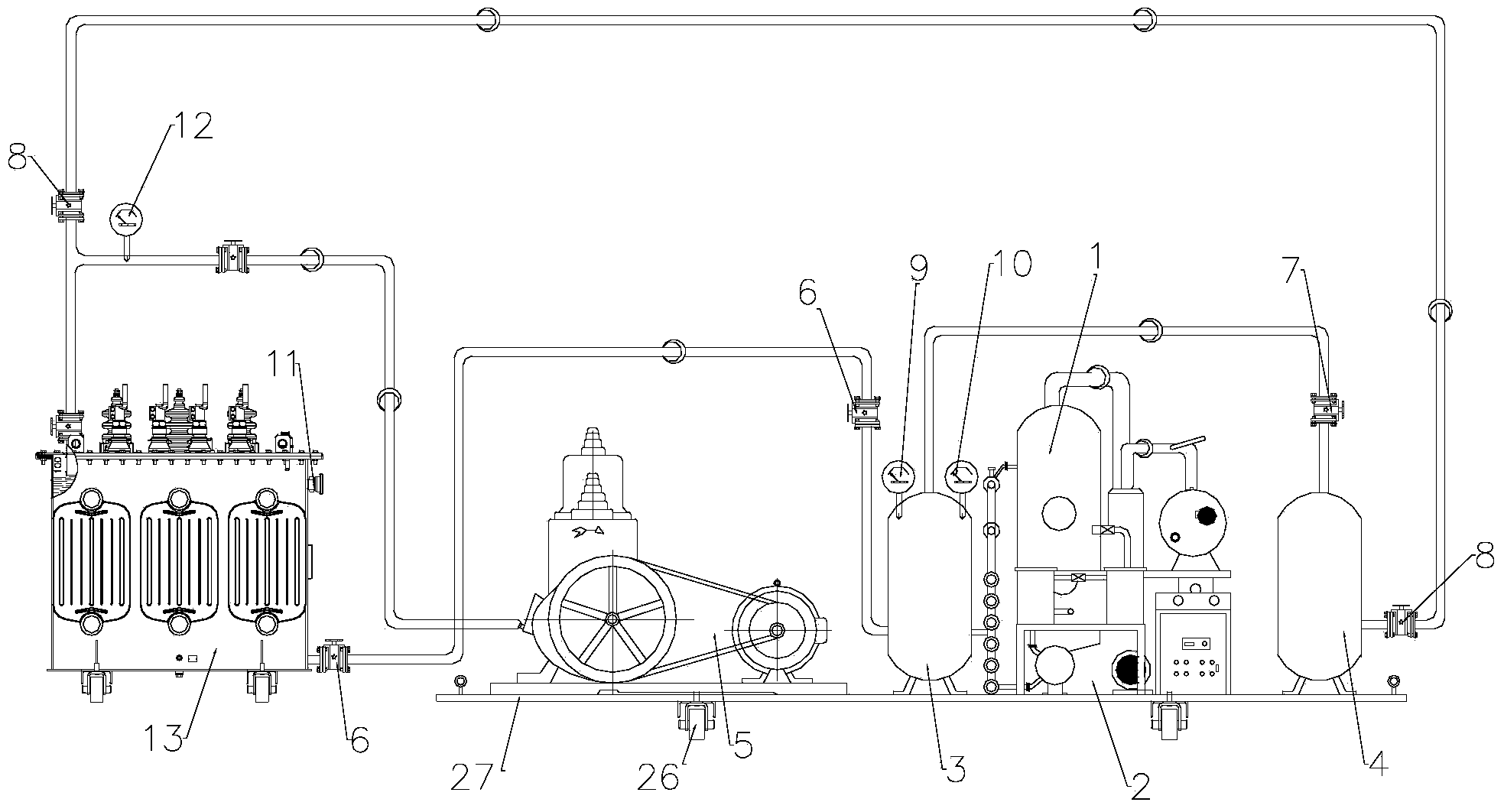

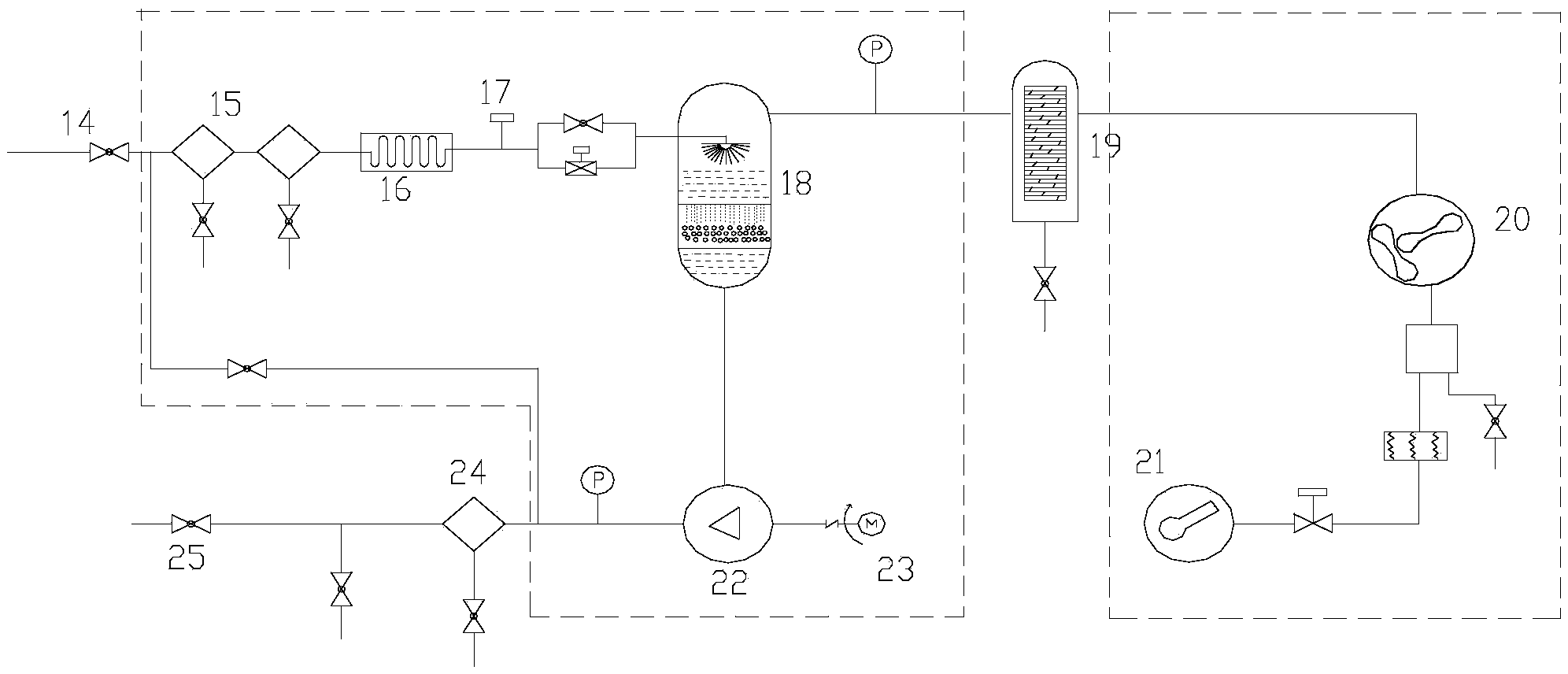

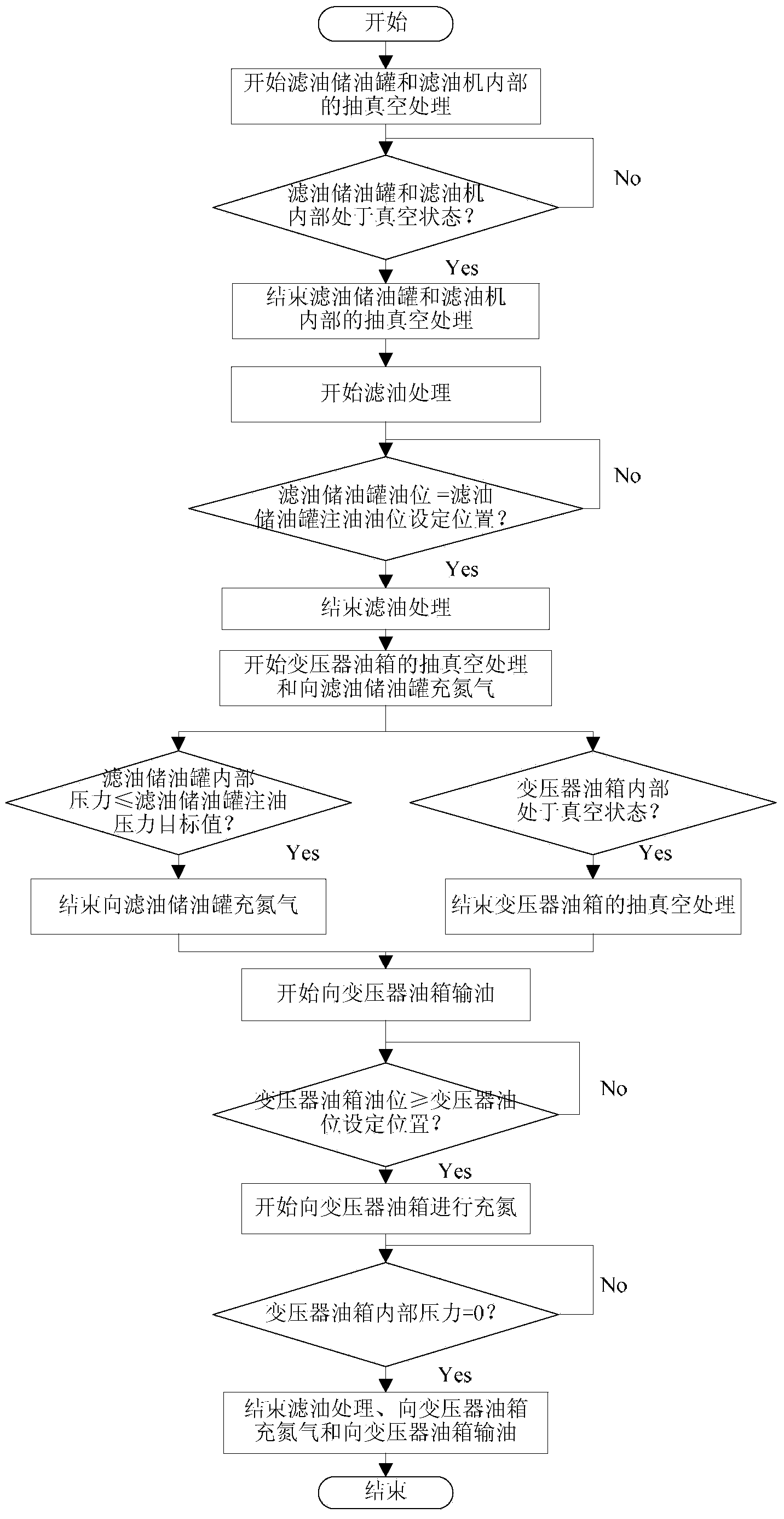

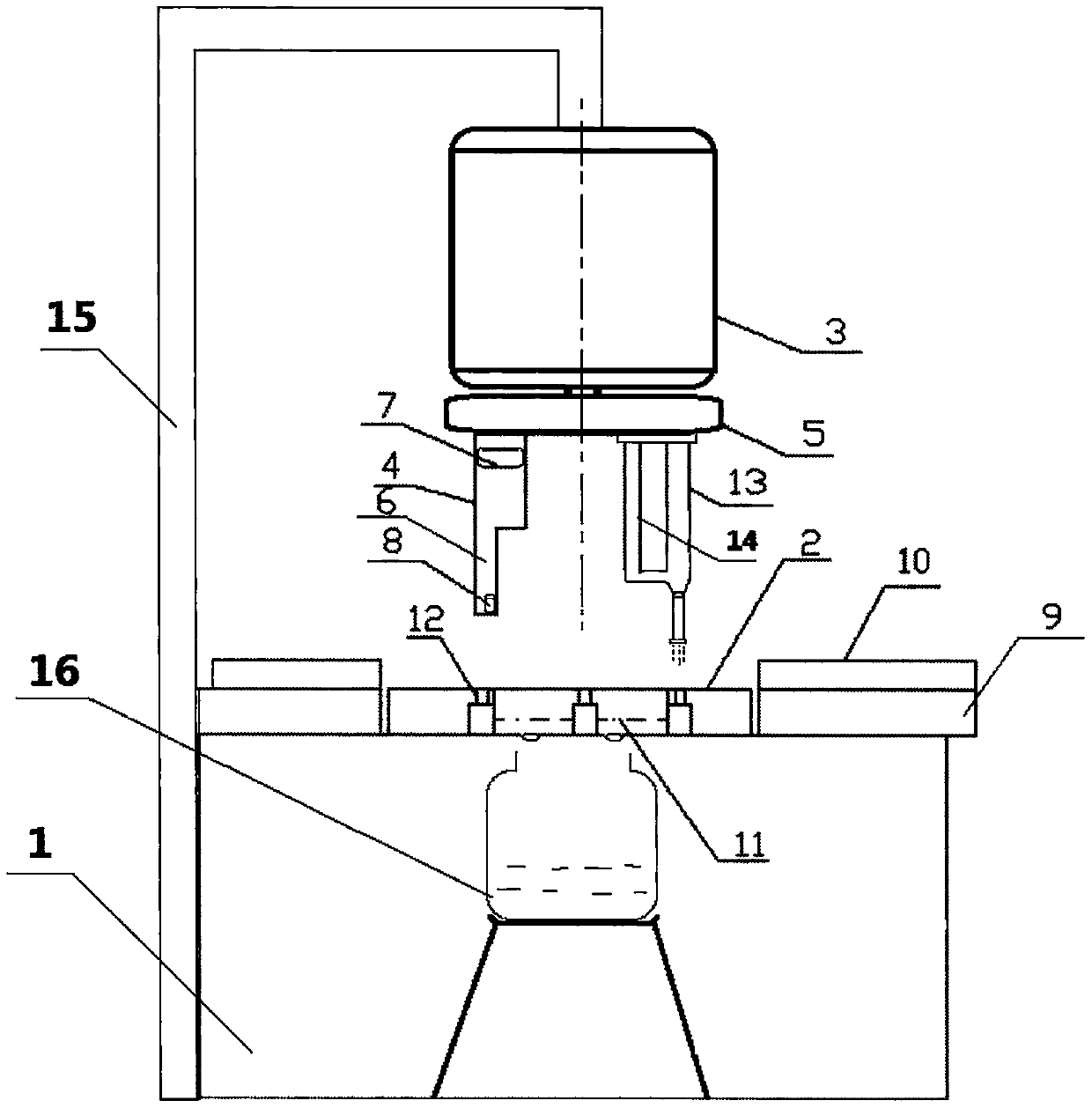

Transformer vacuum oiling device and oiling method thereof

ActiveCN103824679ARealize automatic oil fillingImprove insulation performanceTransformers/inductances coolingNitrogenFuel tank

The invention provides a transformer vacuum oiling device which is characterized in that a crude oil storage tank, an oil filter, a oil filtering and storing tank, a nitrogen tank and a main controller are included, and the transformer vacuum oiling device further comprises a filtered oil storage tank sensing device, a transformer oil tank sensing device, an oil storage tank oil outlet control device, an oil storage tank nitrogen filling control device, a transformer nitrogen filling control device and a vacuum device vacuumizing a transformer oil tank, wherein the sensing devices and the control devices are in signal connection with the main controller, the crude oil storage tank is connected with the oil filter and the filtered oil storage tank in sequence, and the vacuum device vacuumizing the transformer oil tank is directly connected with the transformer oil tank in a sealed mode. By means of the transformer vacuum oiling device, automatic transformer oiling can be achieved, the oiling speed is high, safety and reliability are achieved, on-site oiling can be achieved, moving is convenient, and cost is low. The invention further provides an oiling method, and on-site quick and automatic oiling can be achieved.

Owner:GUANGDONG CHAMPON ELECTRIC CO LTD

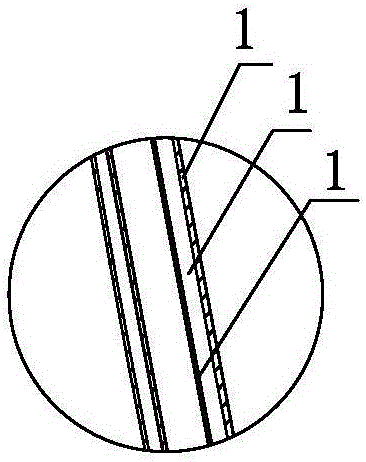

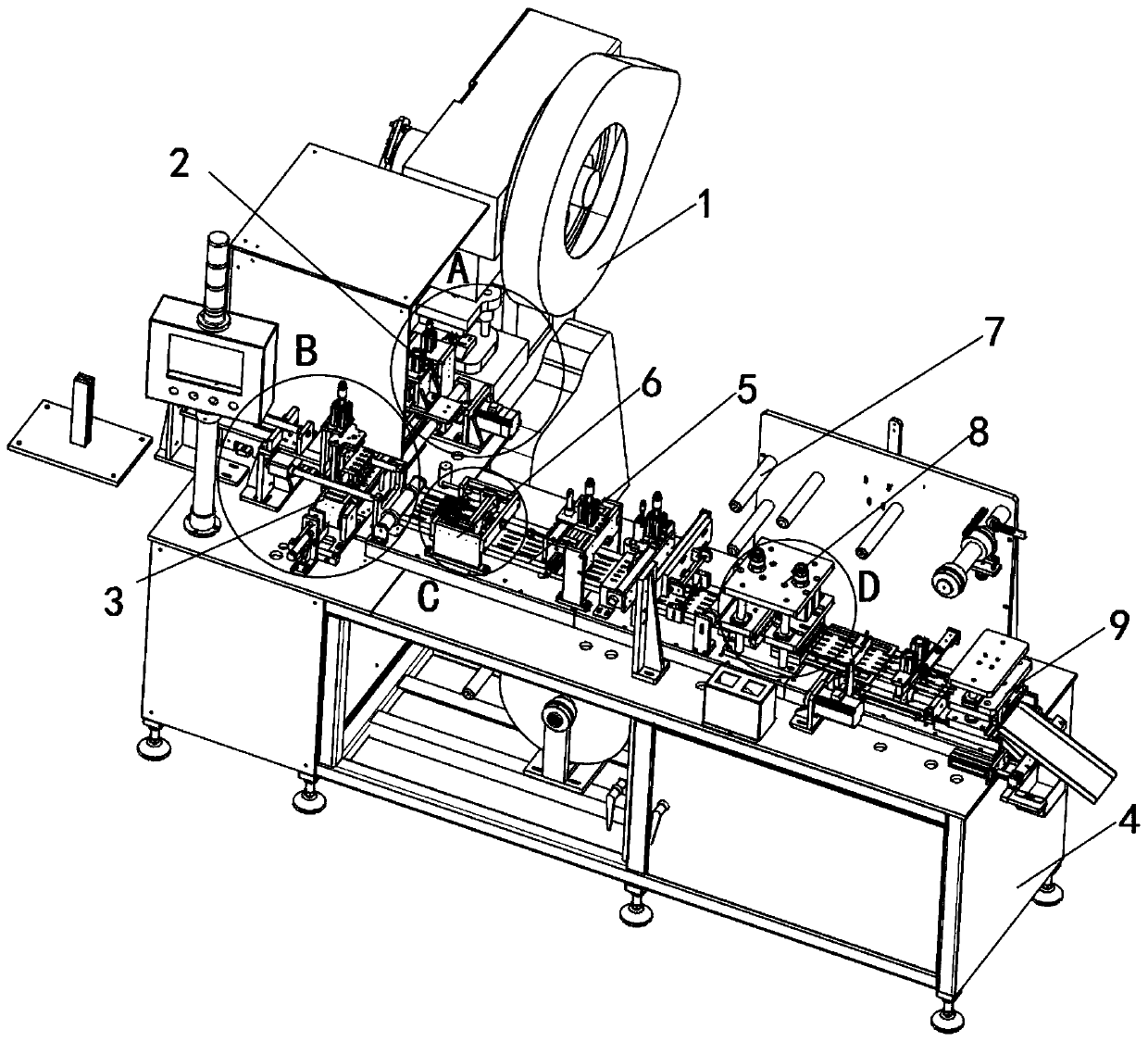

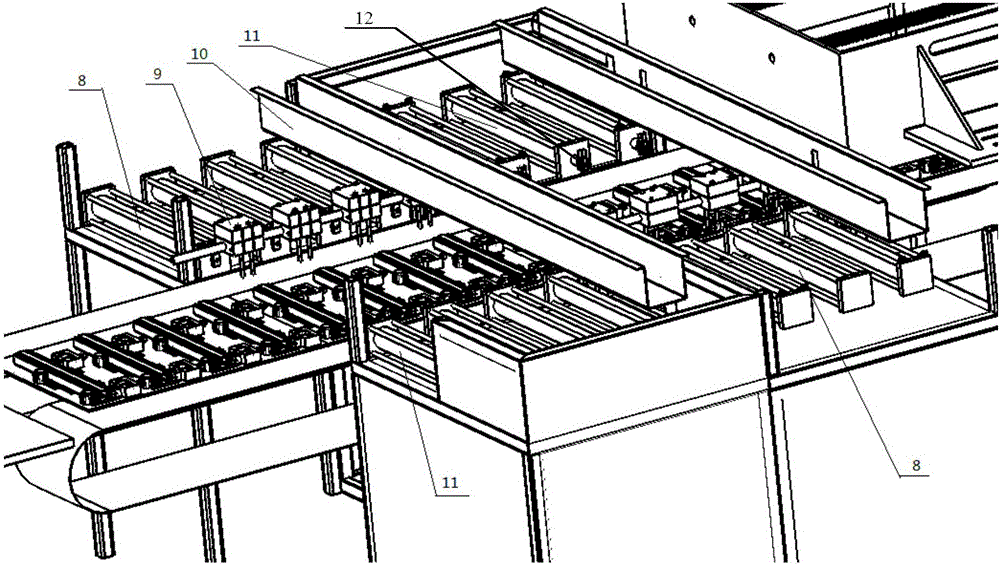

Automatic oil injection device of automobile seat slide rail

ActiveCN104998797AReduce scrap rateRealize the purpose of automatic oil injectionLiquid surface applicatorsCoatingsHydraulic cylinderSpray nozzle

The invention discloses an automatic oil injection device of an automobile seat slide rail. The automatic oil injection device comprises a conveying belt. An automobile slide rail device penetrates through the conveying belt. An air cylinder box is arranged in the middle of the conveying belt. The automobile slide rail device is provided with an automobile slide rail clamp. A plurality of sets of nozzle devices are arranged in the air cylinder box. Each set of nozzle devices are arranged on the two sides of the conveying belt. A plurality of fixed nozzle devices are arranged on one side of each set of nozzle devices, and a plurality of movable nozzle devices are arranged on the other side of each set of nozzle devices. The fixed nozzle devices and the movable nozzle devices of every two adjacent sets of nozzle devices are alternated. Each movable nozzle device is provided with a push rod. A hydraulic cylinder is arranged behind each push rod. Oil spraying nozzles are driven to move through the movement of the push rods, and the purpose of automatic oil injection is achieved. The structure is simple, operation is convenient and economic cost is saved. The needed labor cost is sharply reduced, the oil injection efficiency is improved, and the rejection rate of components is reduced; meanwhile, the oil injection flexibility and stability are improved.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

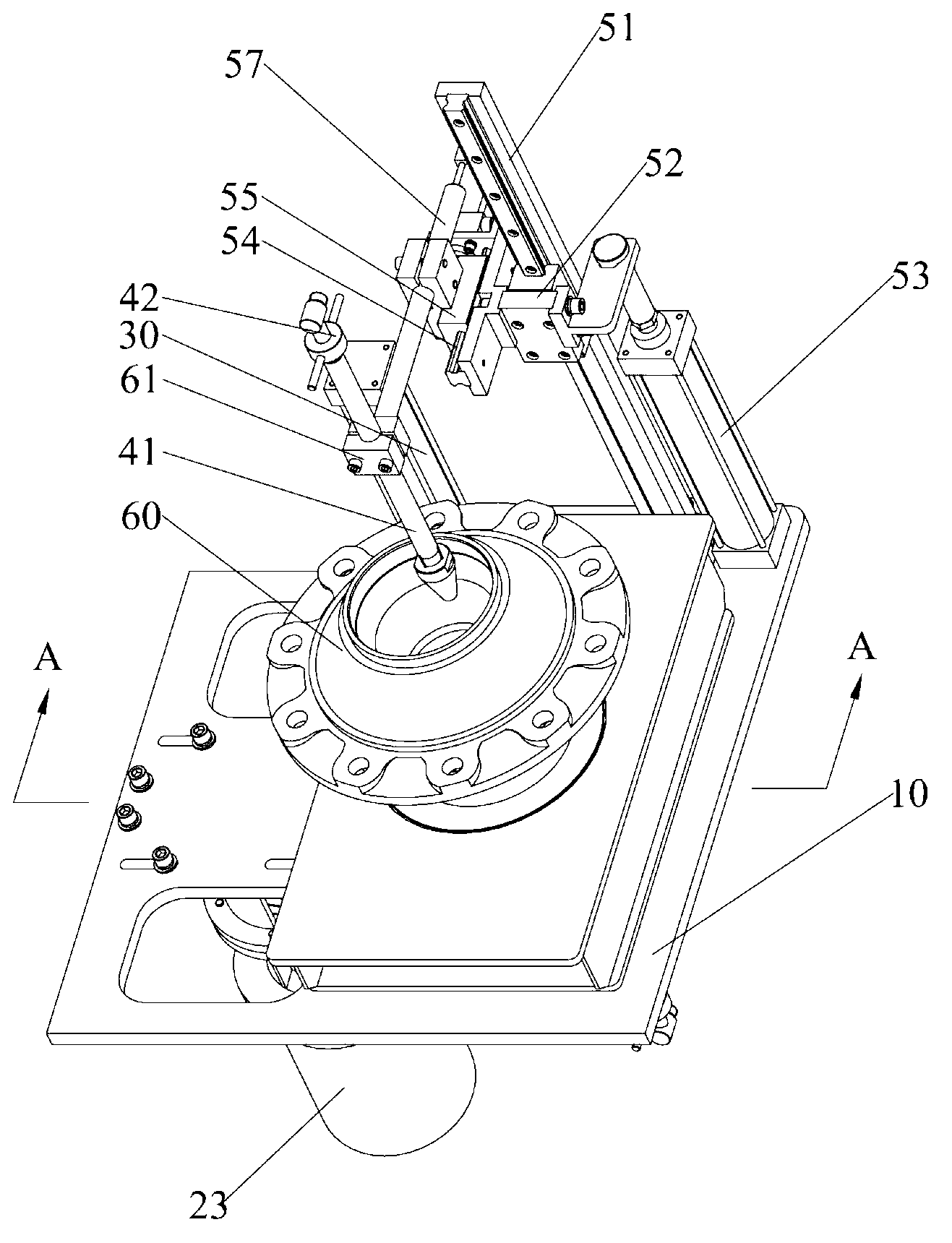

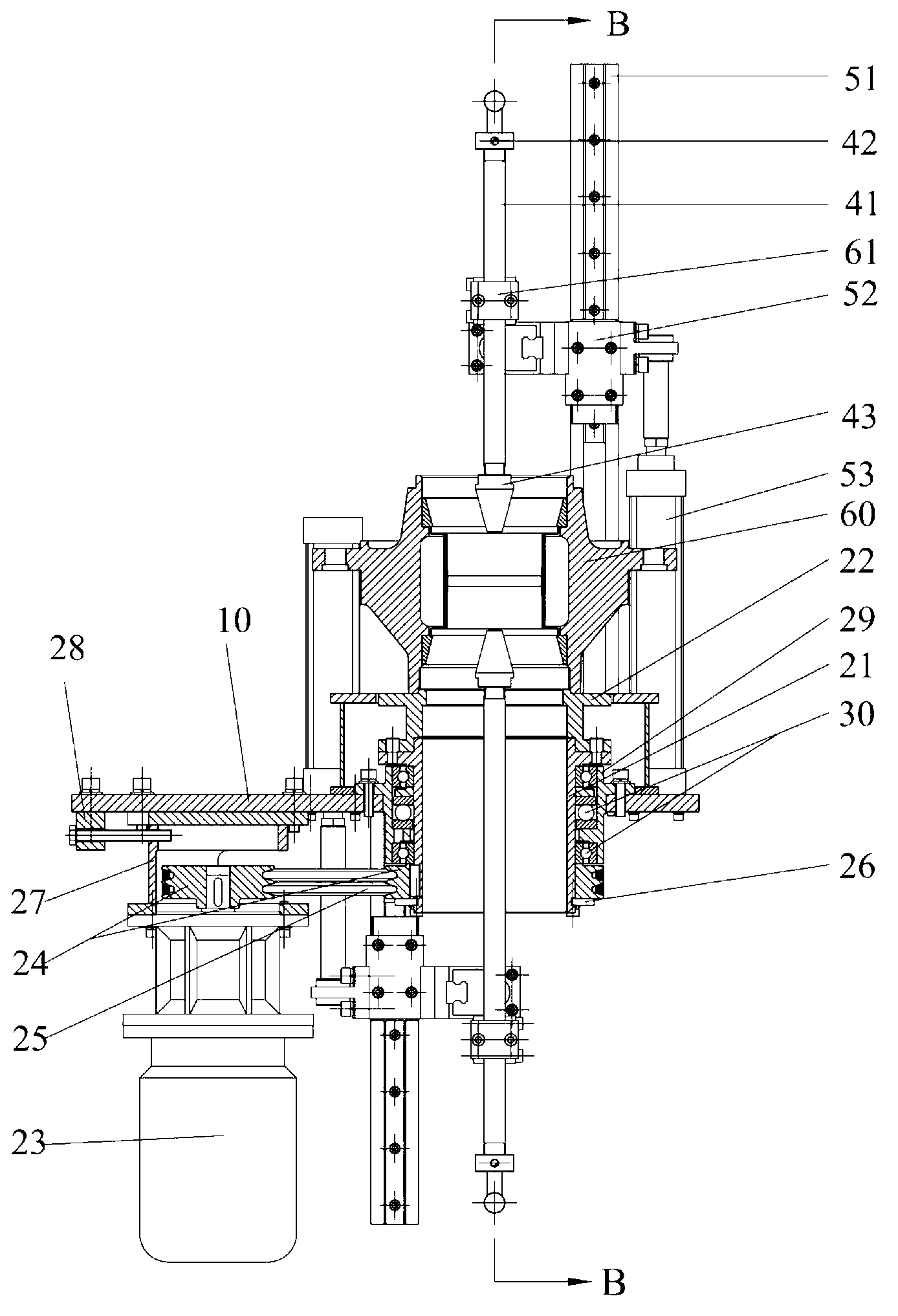

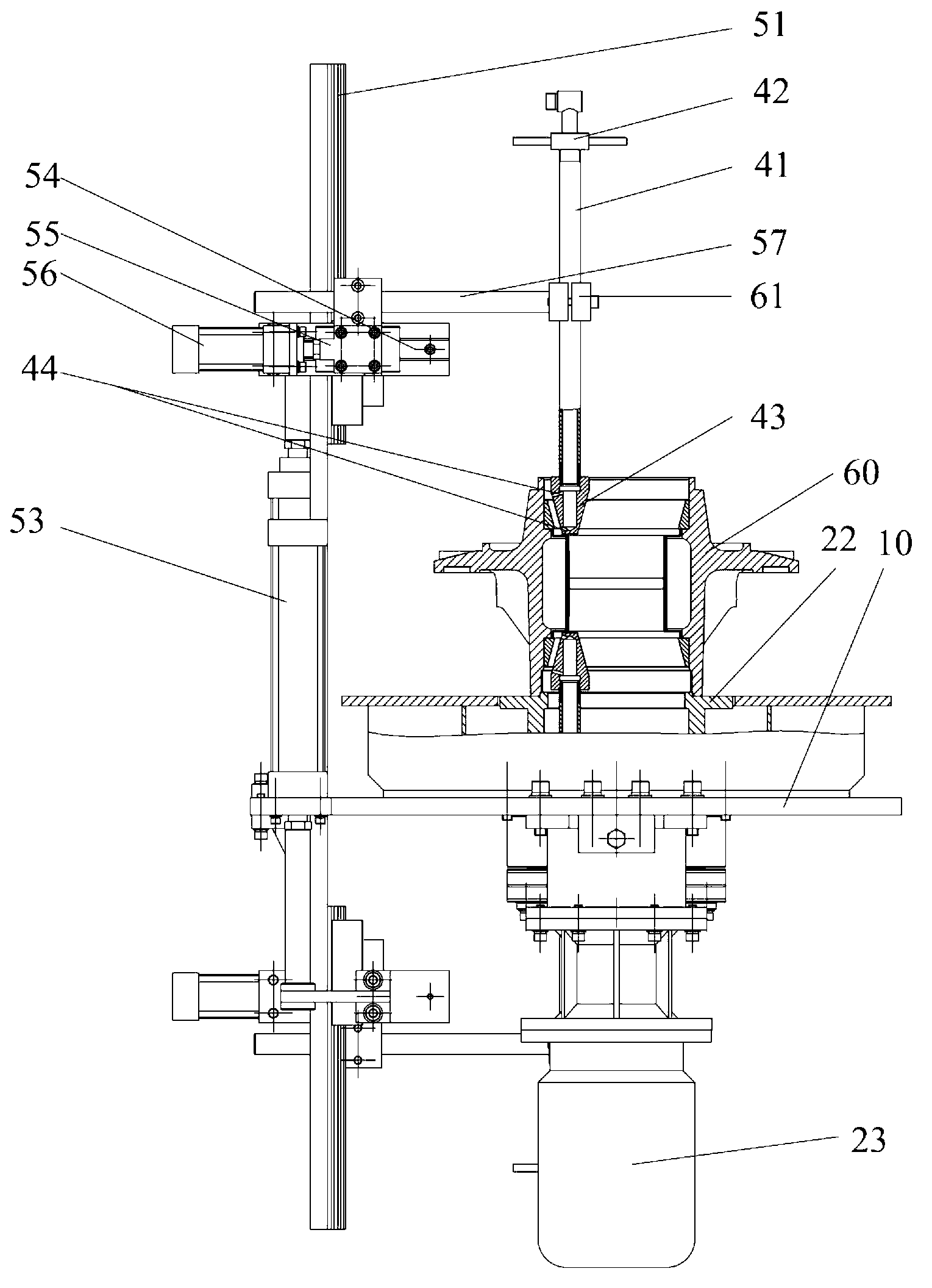

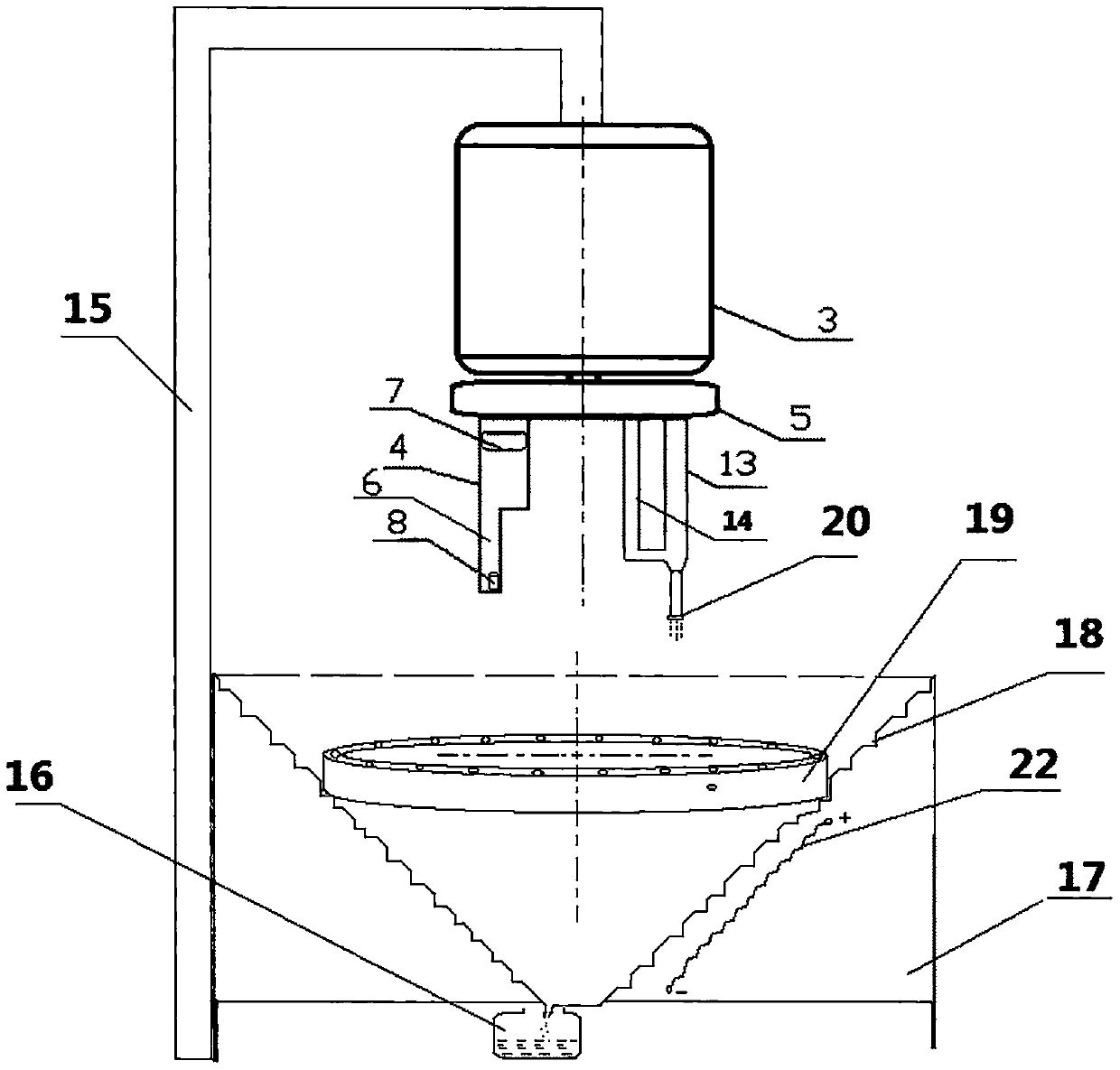

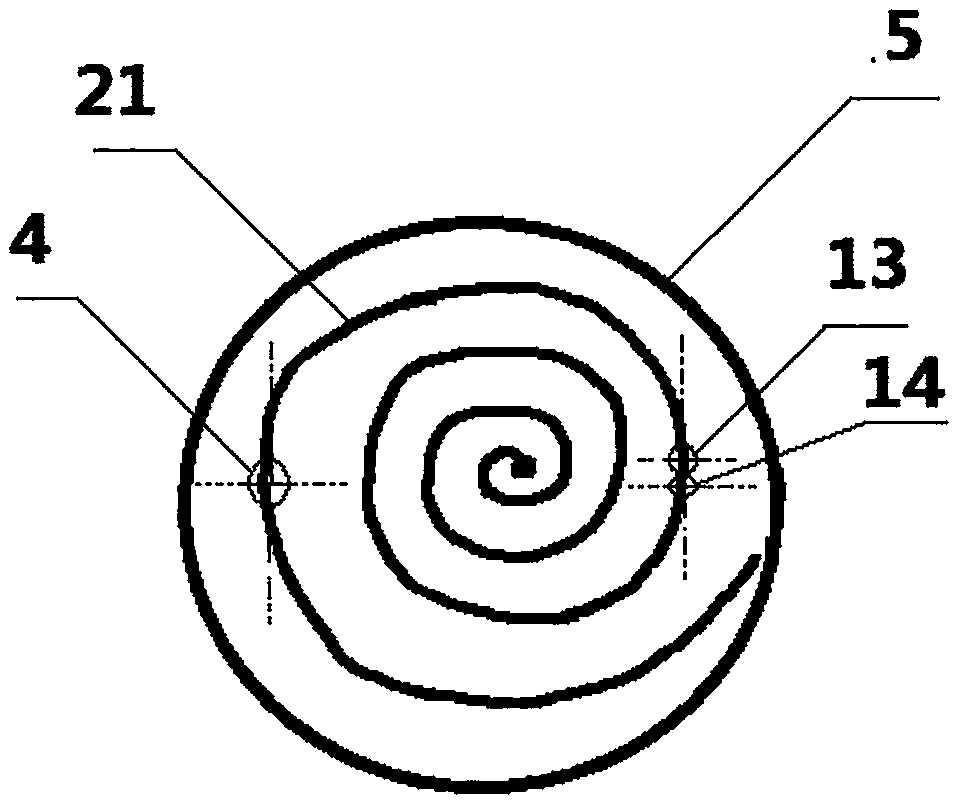

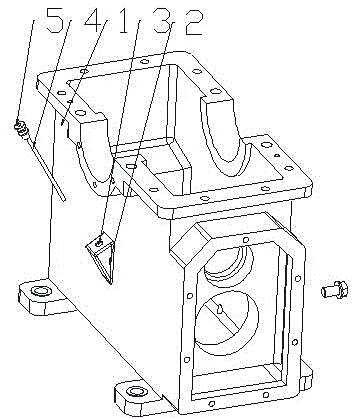

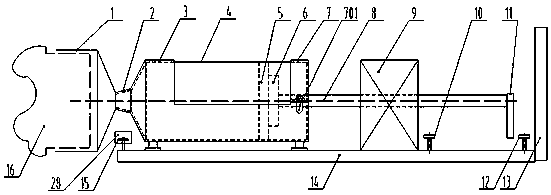

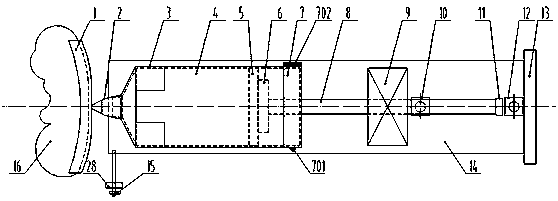

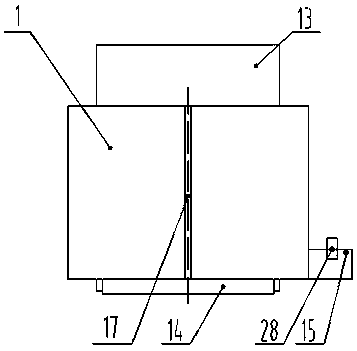

Automatic hub oiling machine

ActiveCN103062606AImprove oil injection efficiencyQuality improvementEngine lubricationEngineeringProduction quality

The invention relates to an automatic hub oiling machine. The automatic hub oiling machine comprises a frame, a rotating mechanism mounted on the frame and an oiling device, the oiling device comprises an oiling pipe and a positioning device for driving the oiling pipe to enter a hub, the positioning device comprises a first guide rail, a first slide seat, a second guide rail, a second slide seat and a connecting rod, the first slide seat slides vertically on the first guide rail, the second guide rail is arranged on the first slide seat, the second slide seat slides bilaterally on the second guide rail, and two ends of the connecting rod are connected with the second slide seat and the oiling pipe respectively. The automatic hub oiling machine is capable of uniformly filling lubricating grease on the hub and capable of oiling at two bearing positions in the hub simultaneously, manual operation slowness and oiling not in place are avoided, and production efficiency and production quality are improved.

Owner:GUANGDONG FUWA HEAVY IND

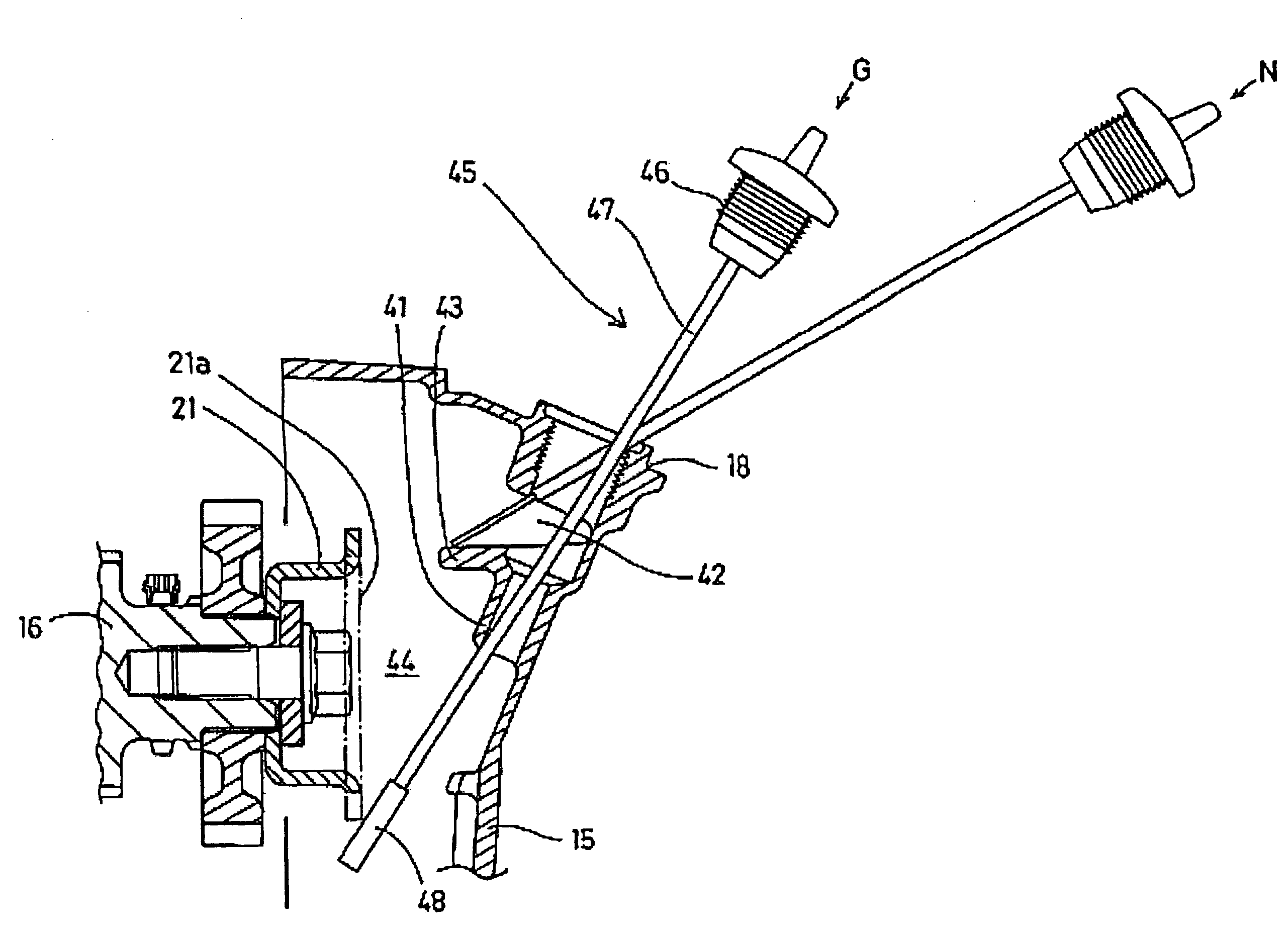

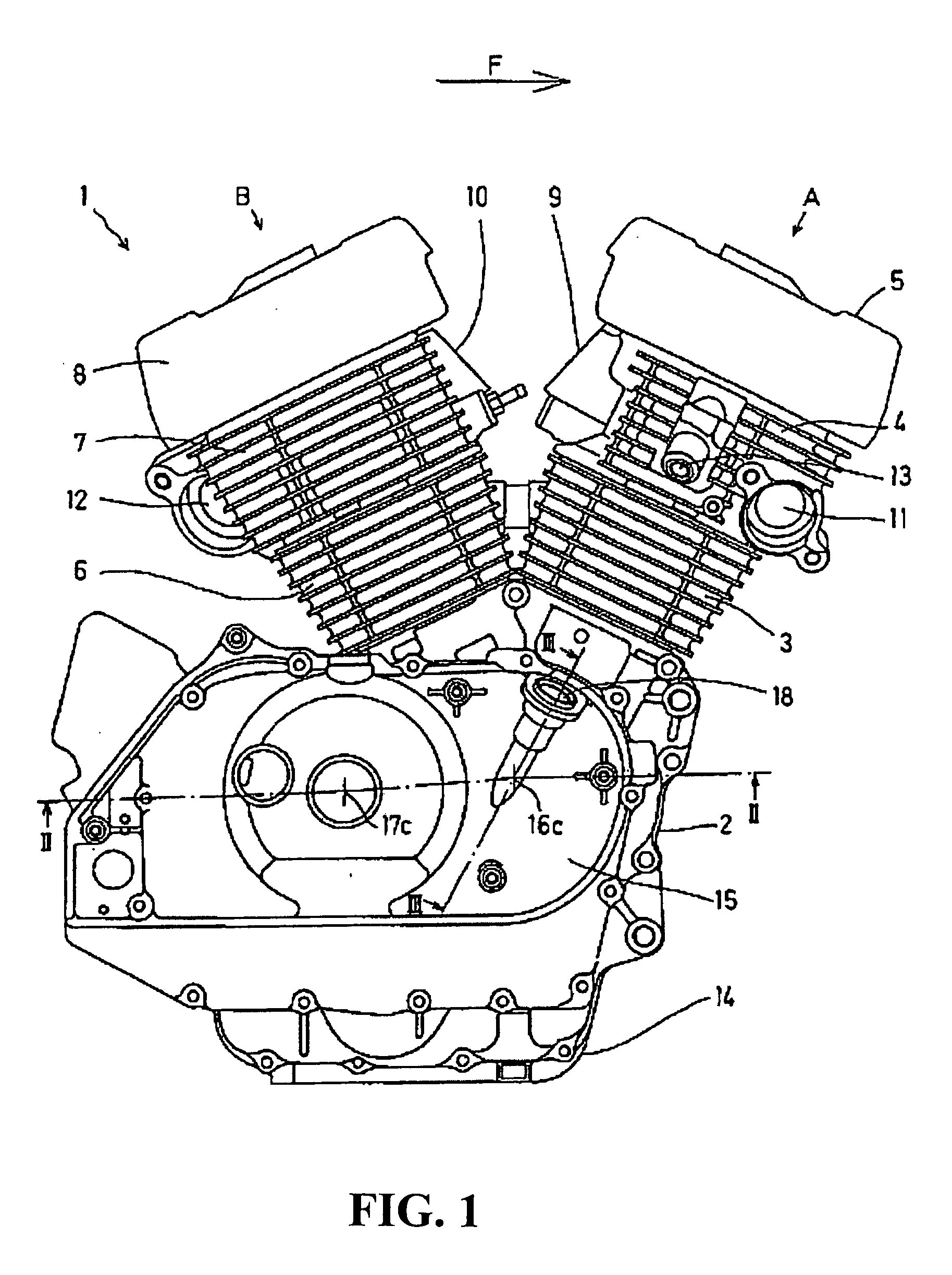

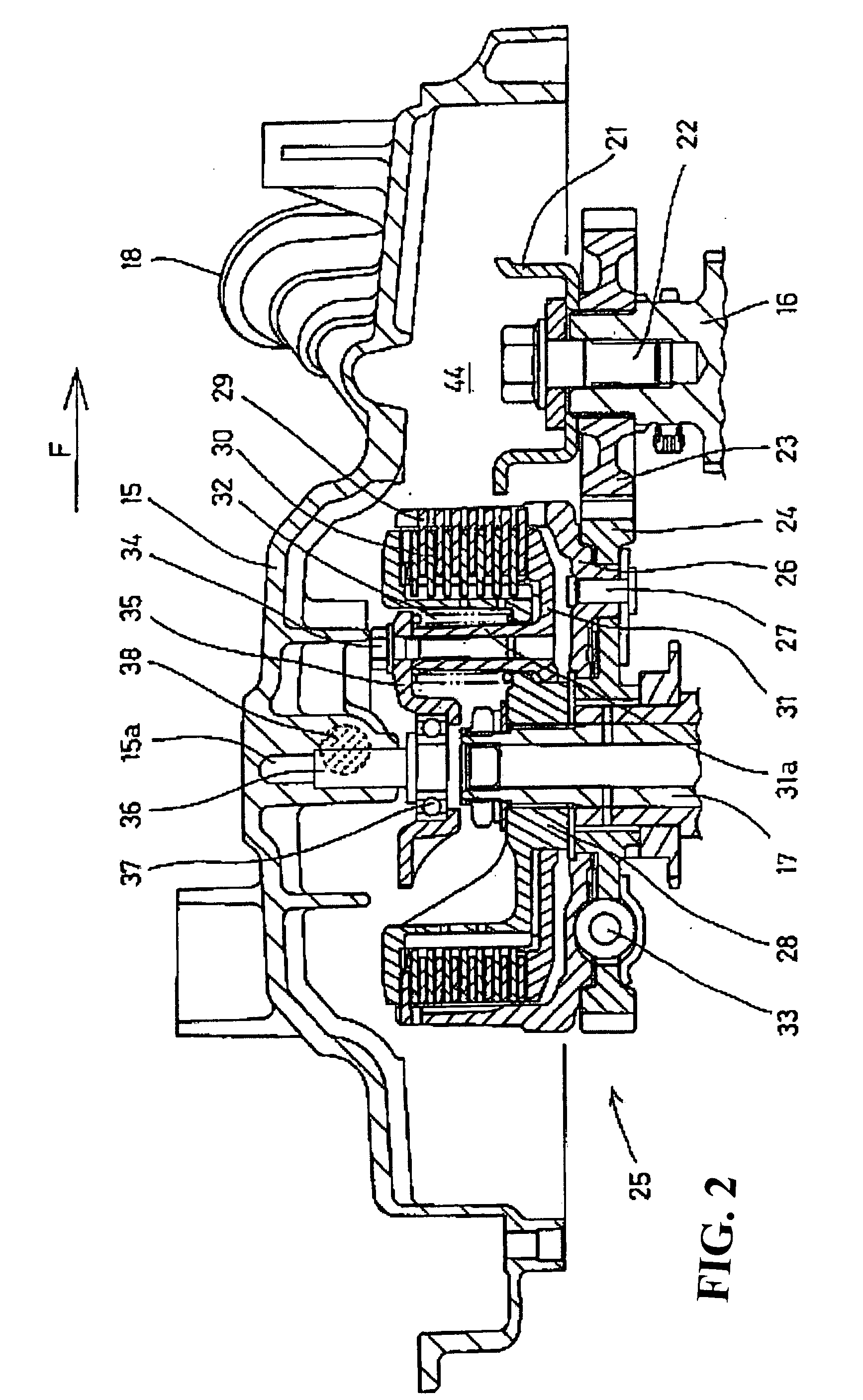

Oil filling structure of internal combustion engine

InactiveUS20080028630A1Enhance workability of fillingImprove workabilityLevel indicators by dip membersLubricant conduit arrangementsExternal combustion engineEngineering

In an internal combustion engine, an oil-filler-port / oil-level-gauge attachment hole is formed on a side of the internal combustion engine. An oil-level-gauge for measuring the amount of oil in the inside of the internal combustion engine extends within the oil-filler-port. The oil-level-gauge is formed integral with a cap for the oil-filler-port. A guide cylinder portion for guiding the gauge deep inside the oil-level-gauge attachment hole is provided to extend therein. A side outflow hole where the filled oil detours around the guide cylinder portion and directly flows down to the inside is formed on the way of the guide cylinder portion. A guide wall for preventing the gauge from entering the side outflow hole is formed on a lower portion of the side outflow hole.

Owner:HONDA MOTOR CO LTD

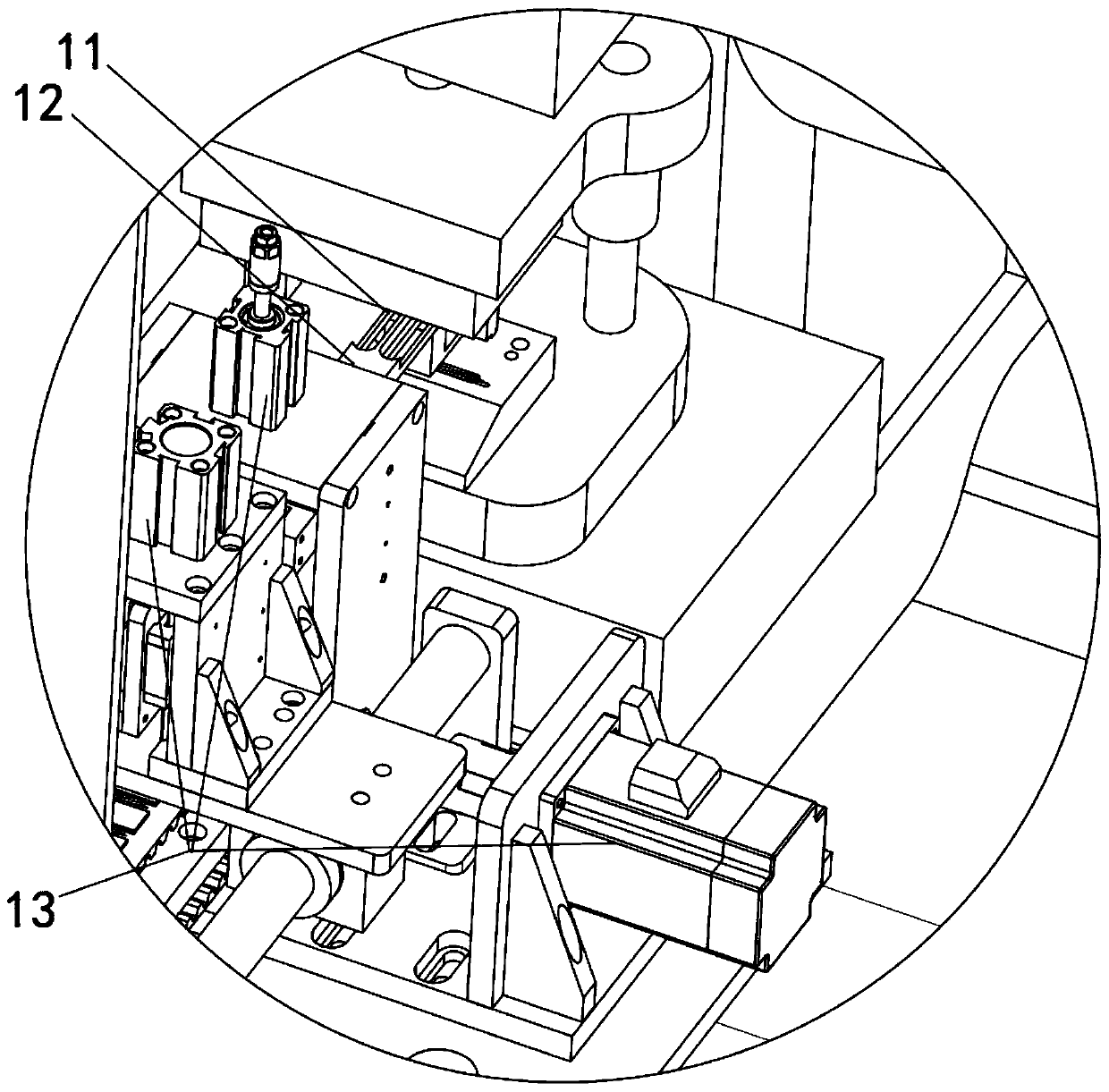

Bearing greasing device and clearing method adopted before greasing operation of bearing greasing device

ActiveCN107906354AImprove oil injection effectImprove oil injection efficiencyLubricant transferCleaning using gasesEngineeringStart up

The invention discloses a bearing greasing device which comprises a workbench, wherein a tooling plate is arranged at the middle of the workbench and used for the mounting of a bearing; a greasing machine is arranged above the tooling plate; a rotating disc is arranged at the upper end of a greasing head of the greasing machine; through the rotation of the rotating disc, the greasing head is further driven to perform circular motion; a greasing brush is arranged at the lower end of the greasing head; and grease in the greasing machine flows into the greasing brush through the greasing head. According to the bearing greasing device disclosed by the invention, the greasing brush is driven by the arranged rotating disc to perform circular motion, and the greasing brush gets in touch with eachroller on a bearing through the rotation, thereby achieving the greasing effect; the greasing processing can be fully automated and the manual operation of a worker is not needed; the greasing efficiency is high; and the precision can be guaranteed. The invention further discloses a clearing method adopted before greasing of the bearing. When the bearing is heated, the temperature of the bearingis increased to 280 DEG C through a started-up heating device, thereby melting the grease; then, the molten grease is cleared from the bearing through the pressurized jet operation of a jet pipe and aclearing pipe; and accordingly, the purpose of quickly clearing the grease is fulfilled, the speed is high, and the efficiency is high.

Owner:李子木

Air conditioner oiling device

InactiveCN104389763ASimple structureEasy to operatePositive displacement pump componentsPositive-displacement liquid enginesDifferential pressureFuel tank

The invention discloses an air conditioner oiling device, and belongs to the technical field of air conditioners. The air conditioner oiling device is designed for solving the problems that an existing air conditioner oiling device wastes time and labor in oiling, is low in oiling efficiency and the like. The air conditioner oiling device comprises an oiling tank, wherein the oiling tank is connected with an oil tank through an oil pipe, the oiling tank is connected with an exhaust port end of an air condition compressor through a first connection pipe, the oiling tank is connected with an air inlet end of the air condition compressor through a second connection pipe, a pressure increasing valve is arranged on the first connection pipe, and an oil discharge valve is arranged on the second connection pipe. The air conditioner oiling device uses differential pressure to achieve an oiling mode of automatically injecting lubricating oil into the air condition compressor, is simple in structure and convenient to operate, improves oiling efficiency, and saves time and labor.

Owner:GREE ELECTRIC APPLIANCES INC

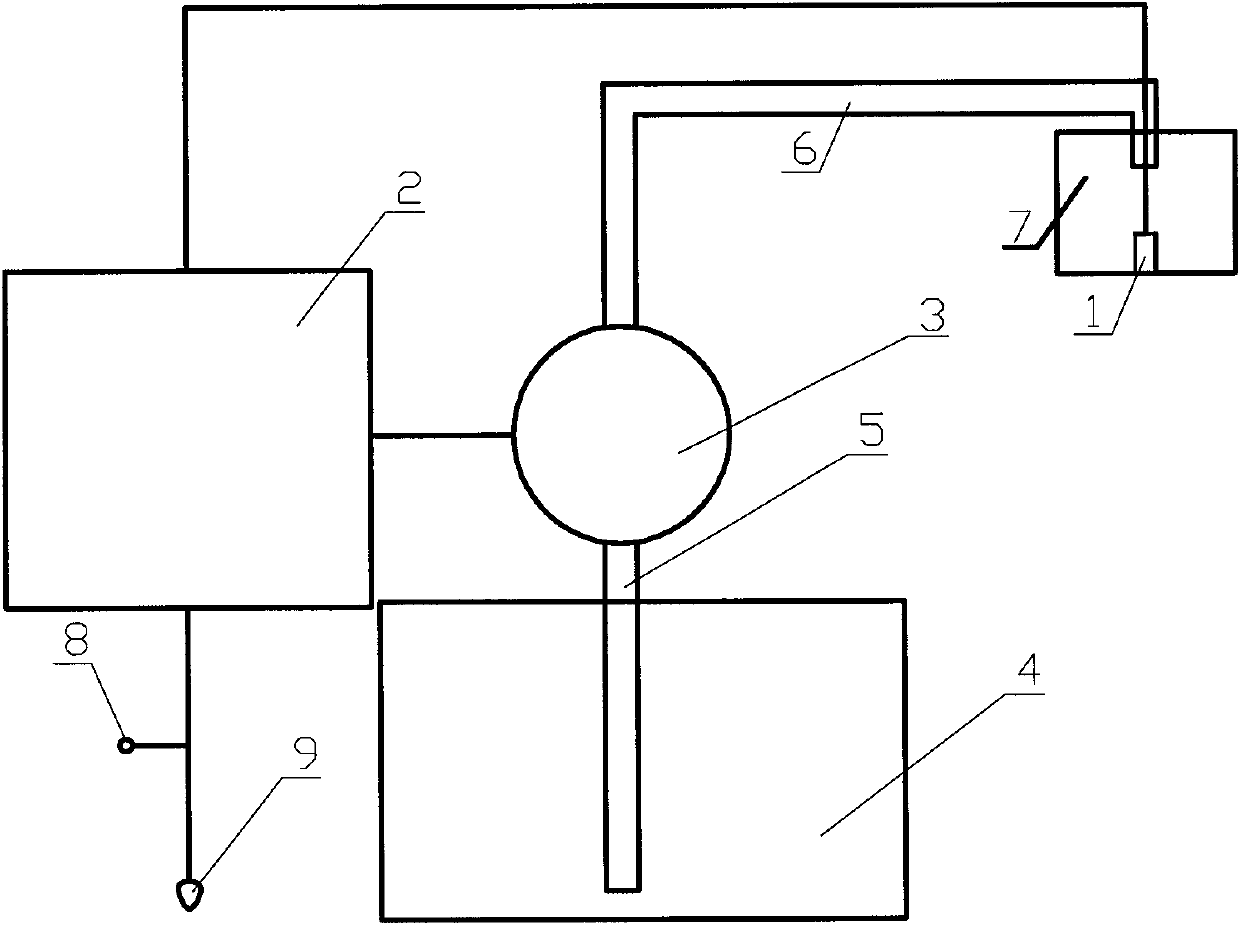

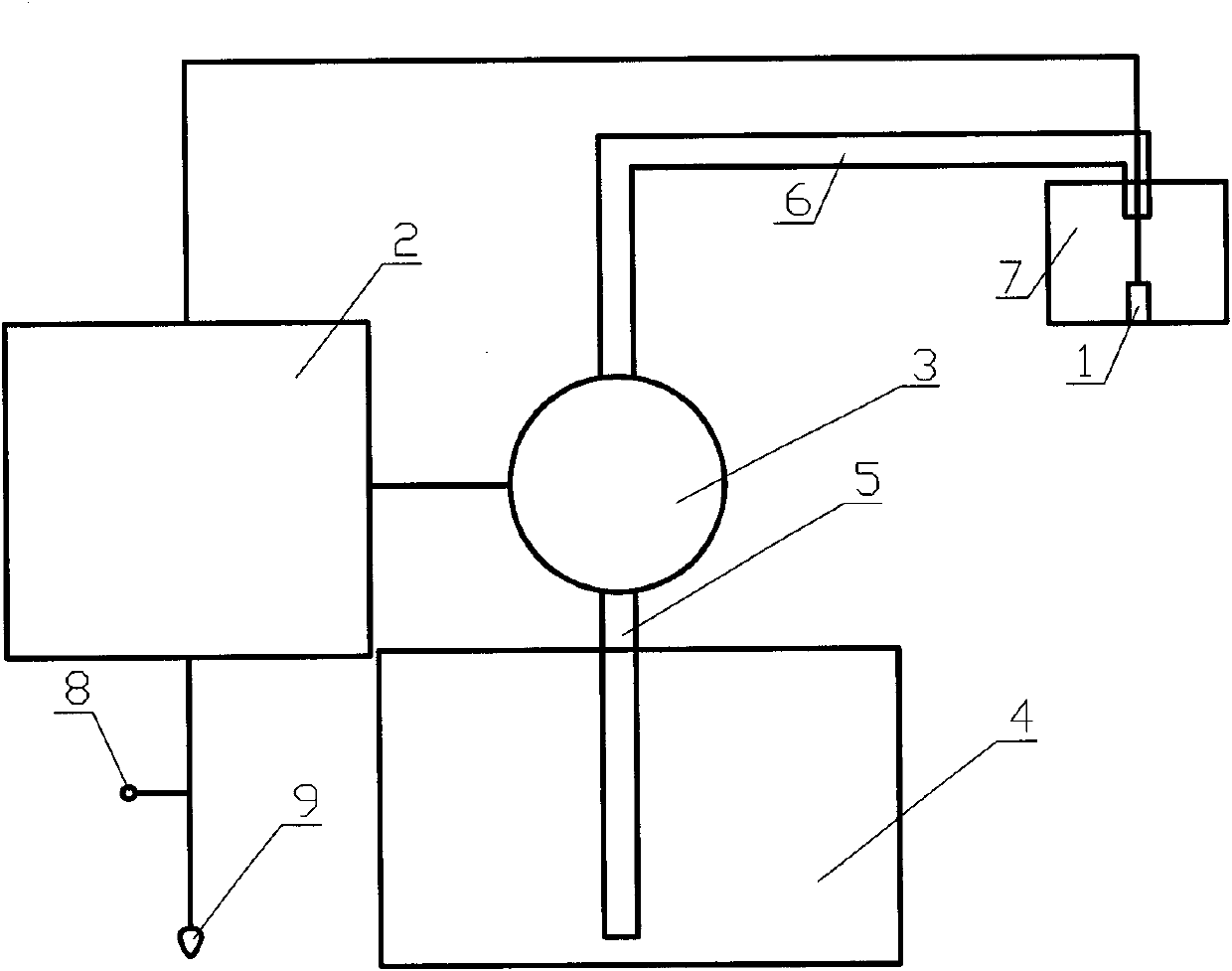

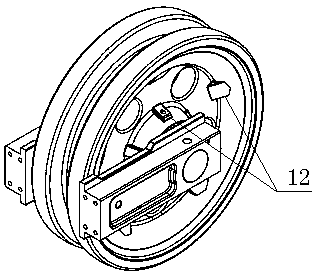

Oiling machine for lubricating fuel tank at wheel rim of motor train unit

InactiveCN101769414ARealize automatic oil filling operationReduce labor intensityRail lubricationRail wetting/lubricationFuel tankEngineering

The invention relates to an oiling machine for a lubricating fuel tank at the wheel rim of a motor train unit, relating to a device for refueling the lubricating fuel tank at the wheel rim of the motor train unit. The oiling machine comprises a sensor, a controller, an oil pump and an oil storage tank; remaining oil amount in the lubricating fuel tank at the wheel rim of the motor train unit is detected by the sensor, the detected signal is sent to the controller by the sensor, the received sensor signal is treated by the controller to control the oil pump to work according to the treating condition of the sensor signal, and the oil storage tank is used for storing wheel rim lubricating oil. The invention can realize the automatic oiling work for the lubricating fuel tank at the wheel rim of the motor train unit, the labor intensity of a manipulator is reduced, and the oiling efficiency is improved.

Owner:米铮

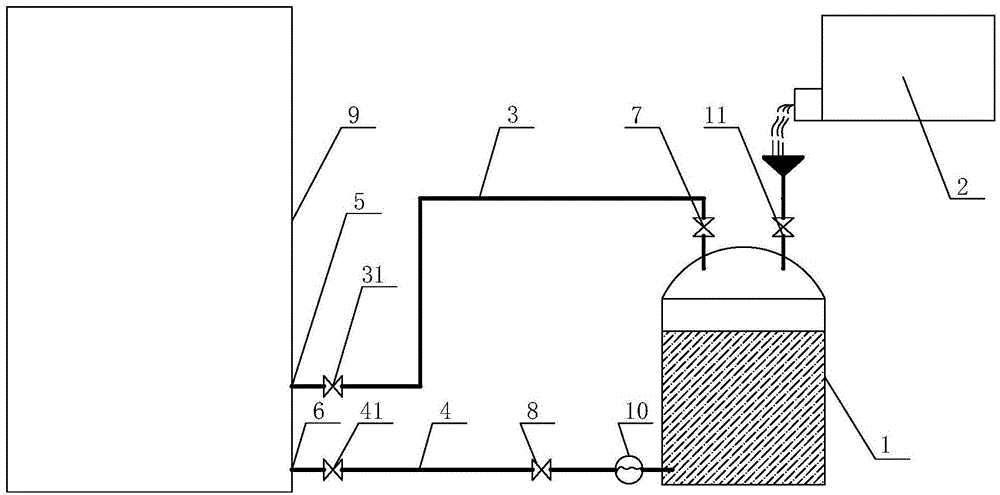

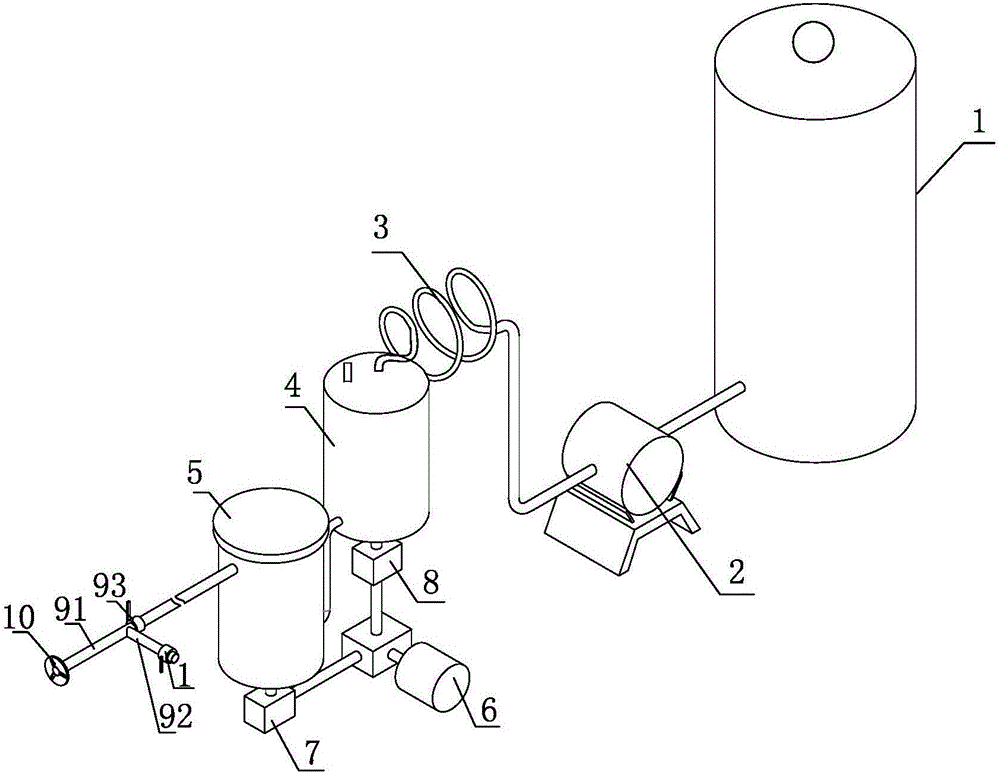

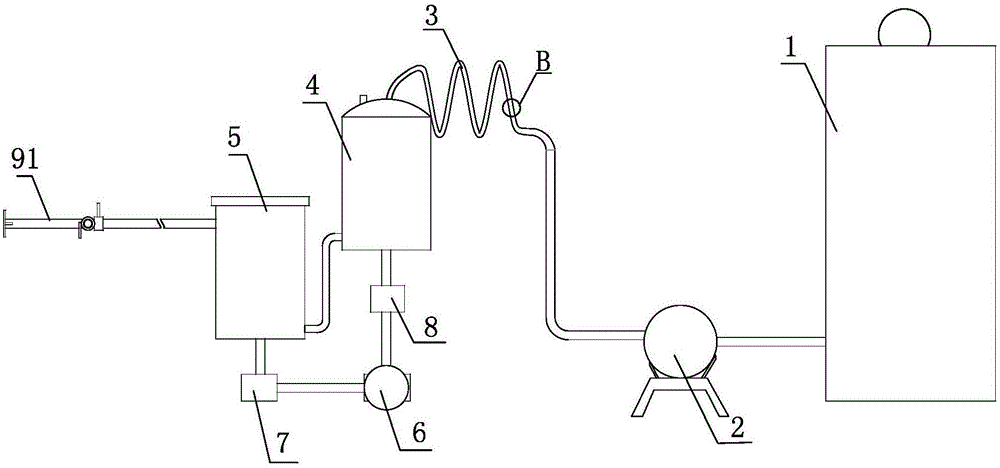

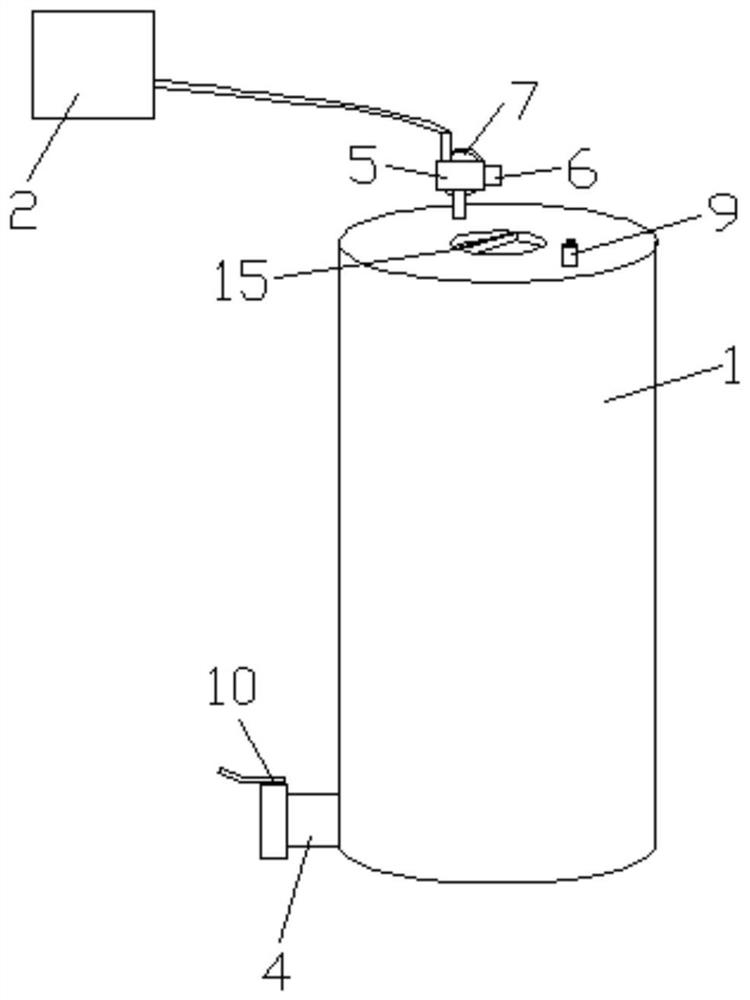

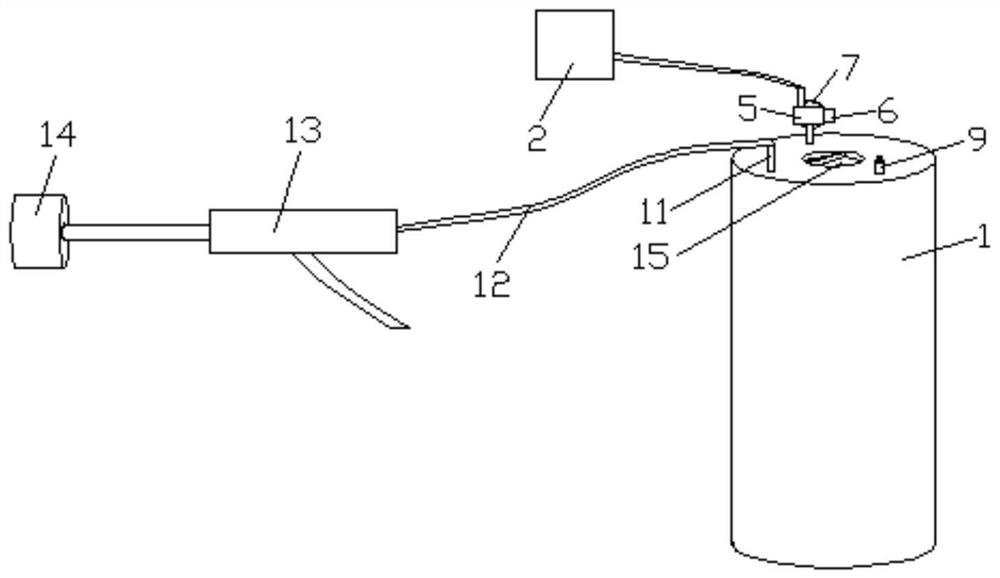

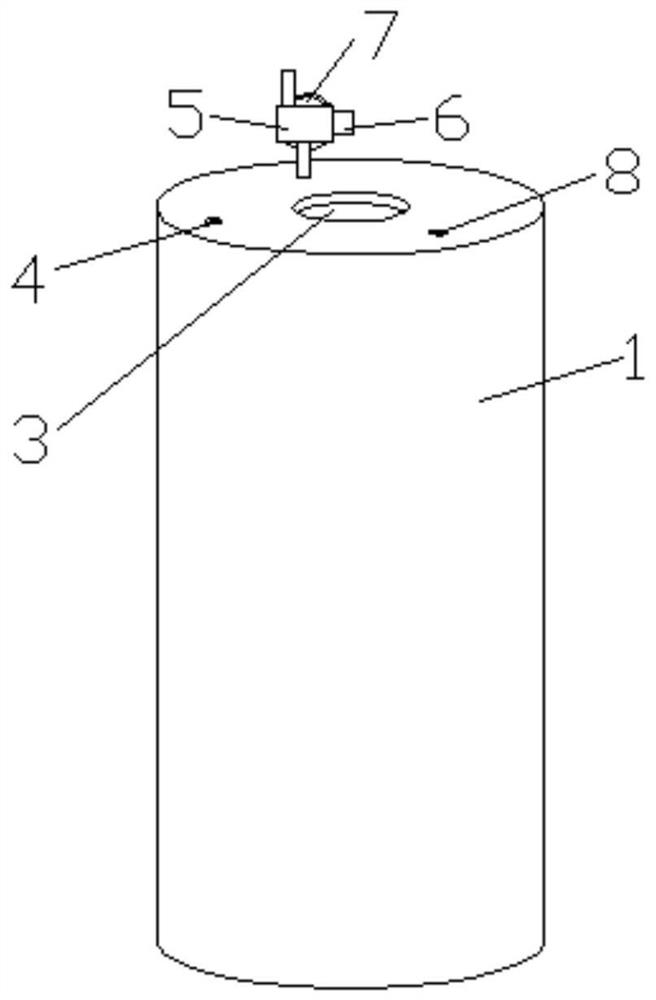

Oil-immersed transformer oiling device

InactiveCN106098318APrevent deterioration of insulationImprove securityTransformers/inductances coolingLiquid transferring devicesControl systemTransformer oil

The invention provides an oil-immersed transformer oiling device, belonging to the technical field of oiling devices. The oil-immersed transformer oiling device aims to solve the technical problems of degassing, impurity removal and oiling in the insulating oil for transformers. The oil-immersed transformer oiling device comprises an oil drum, an oil level detection mechanism, an oil pump, an oil filter, an oiling tube mechanism and a control system, wherein the oil level detection mechanism is installed in the oil drum; the upper end of the oil drum is provided with an alarm lamp; one end of the oil pump communicates with the oil drum, and the other end communicates with the oil filter; the oil filter comprises a heating mechanism, a degassing mechanism, an impurity removal mechanism and a power mechanism; the oiling tube mechanism comprises an oiling tube and an exhaust tube; and the outer end of the oiling tube is fixedly provided with an adjustable flange. The oil-immersed transformer oiling device effectively performs impurity removal, degassing treatment and oiling before oiling of the oil-immersed transformer insulating oil, prevents the insulating property of the insulating oil for transformers from degradation due to the influence of gases and impurities, and obviously enhances the safety performance of the insulating oil for transformers.

Owner:国网山东省电力公司茌平县供电公司 +1

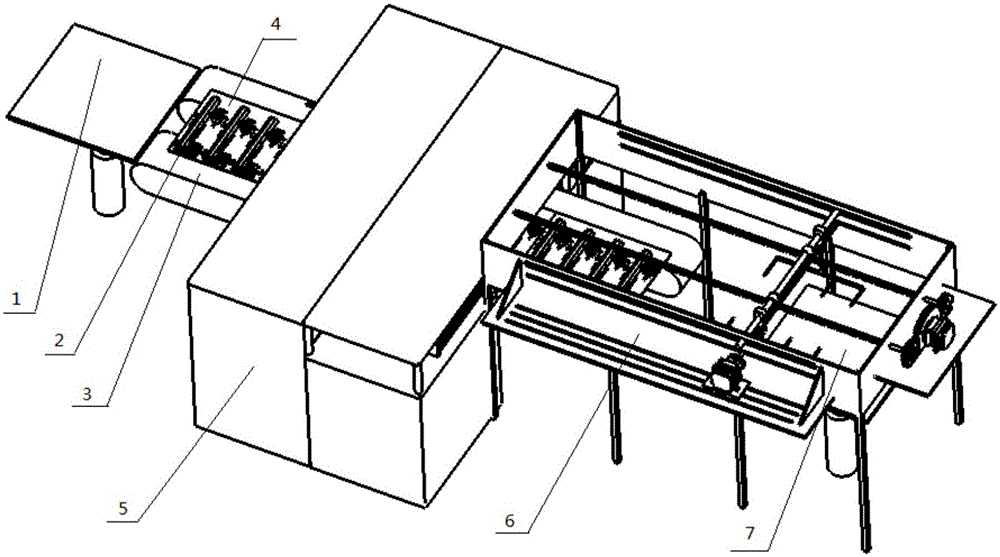

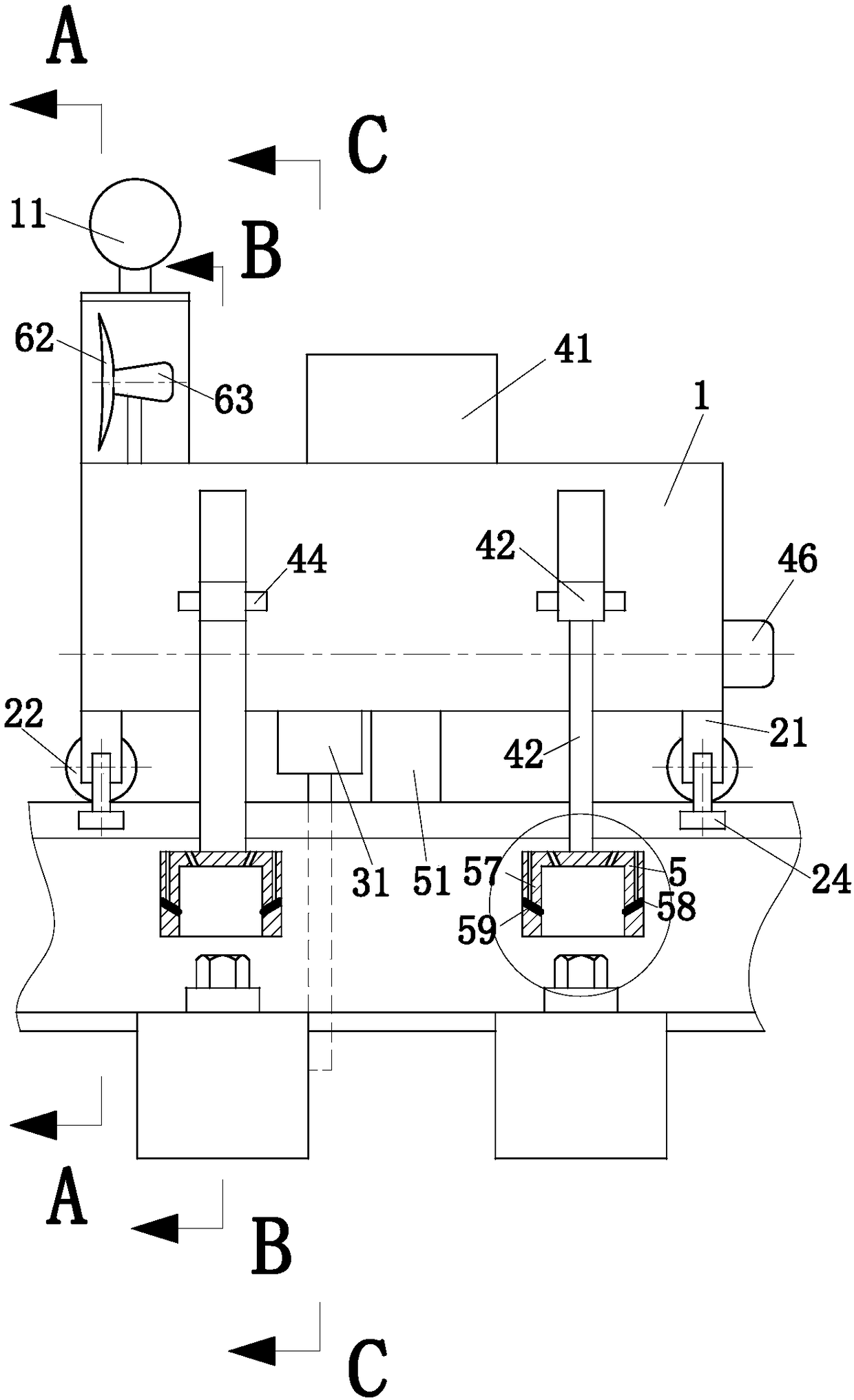

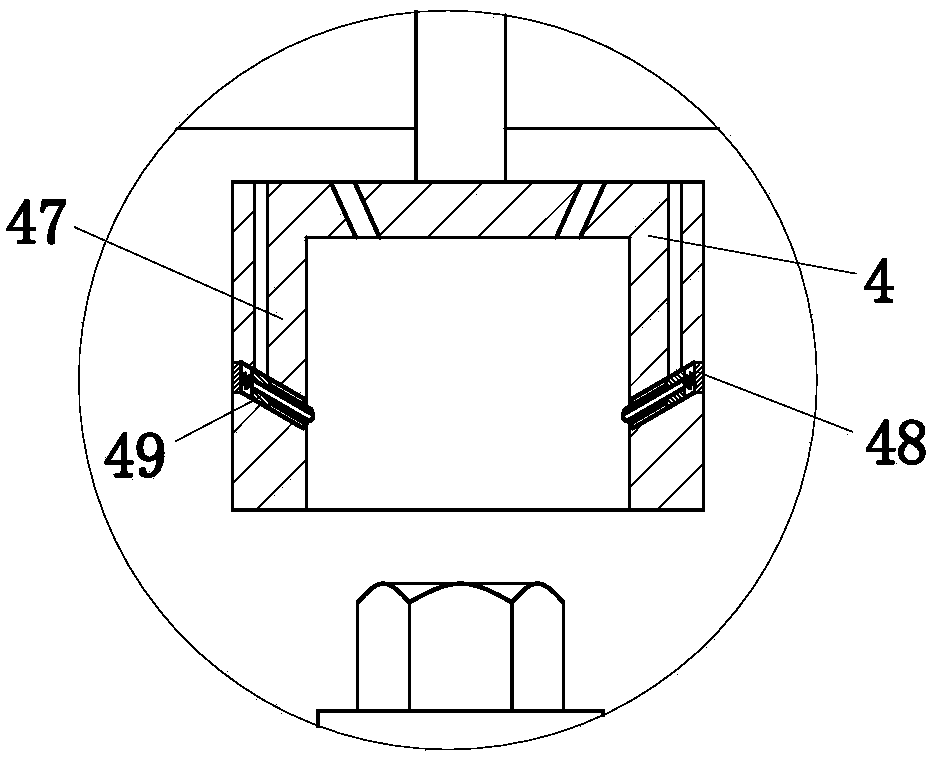

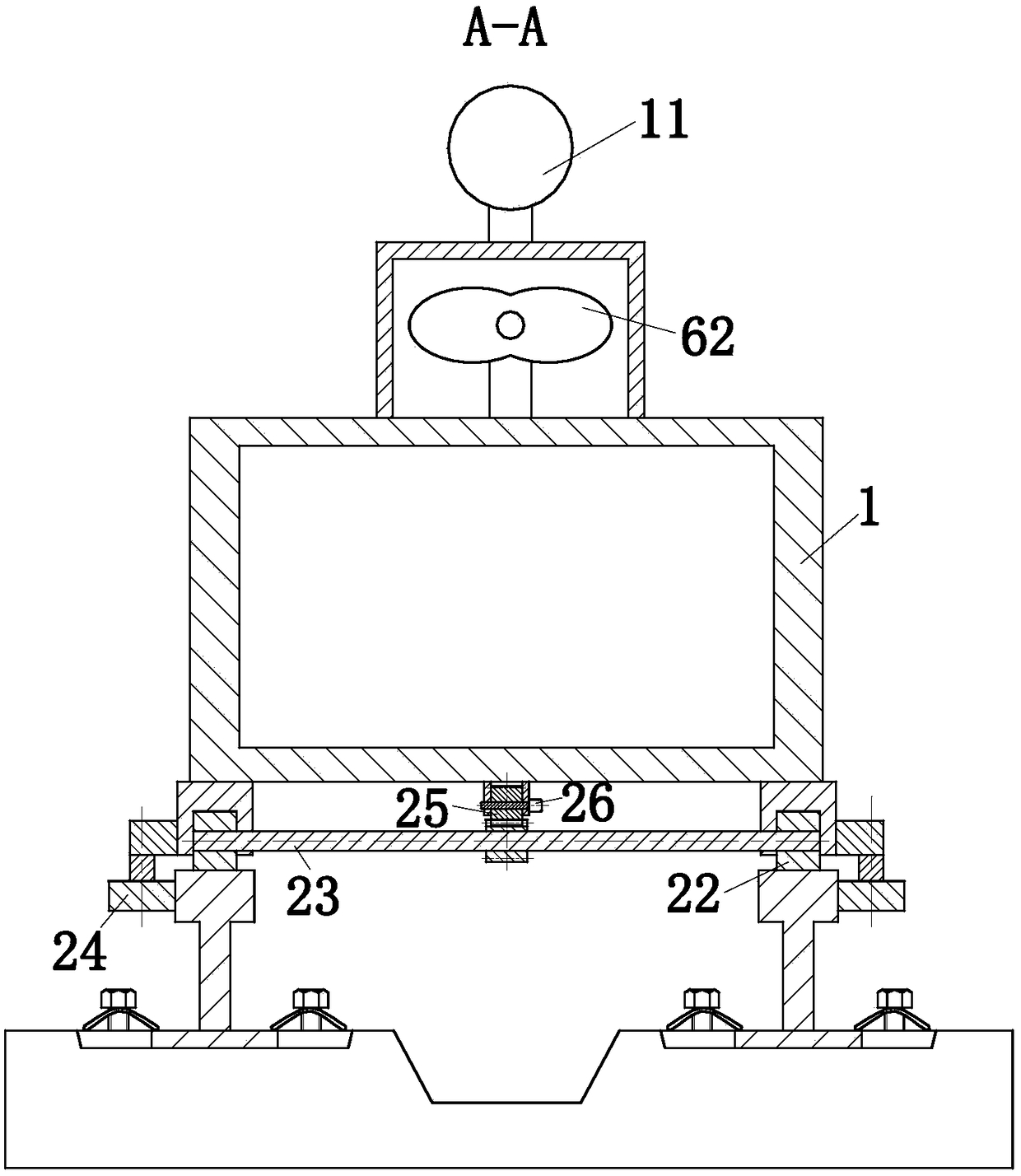

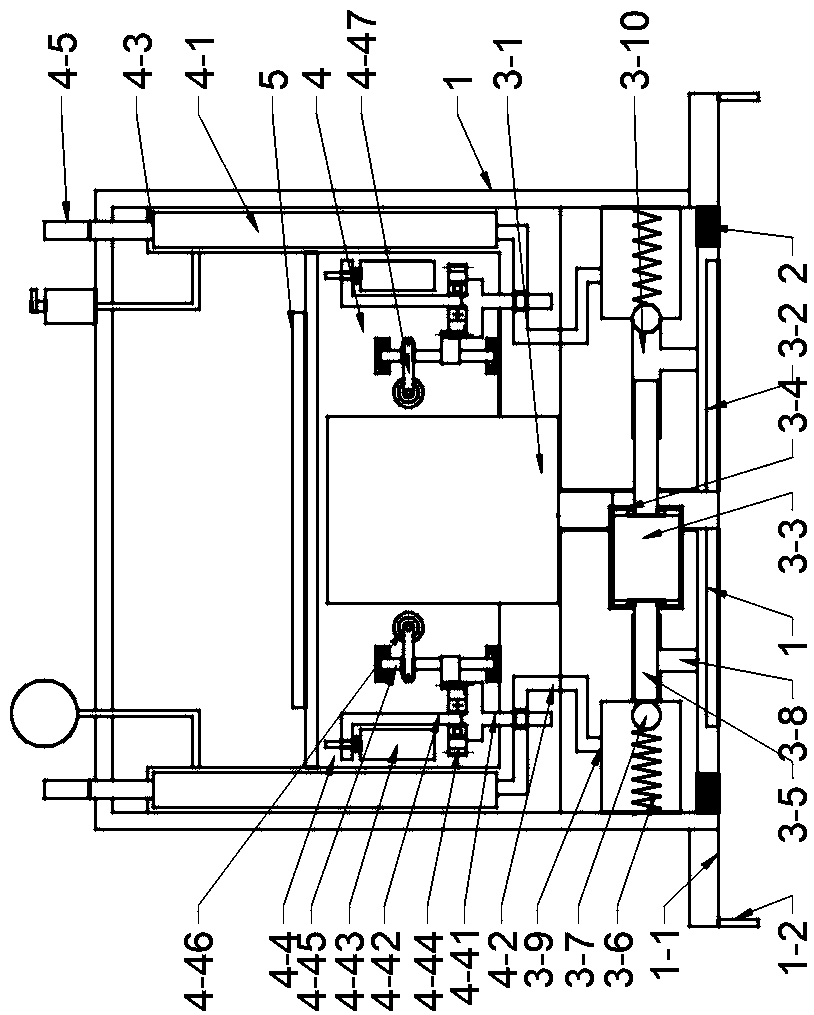

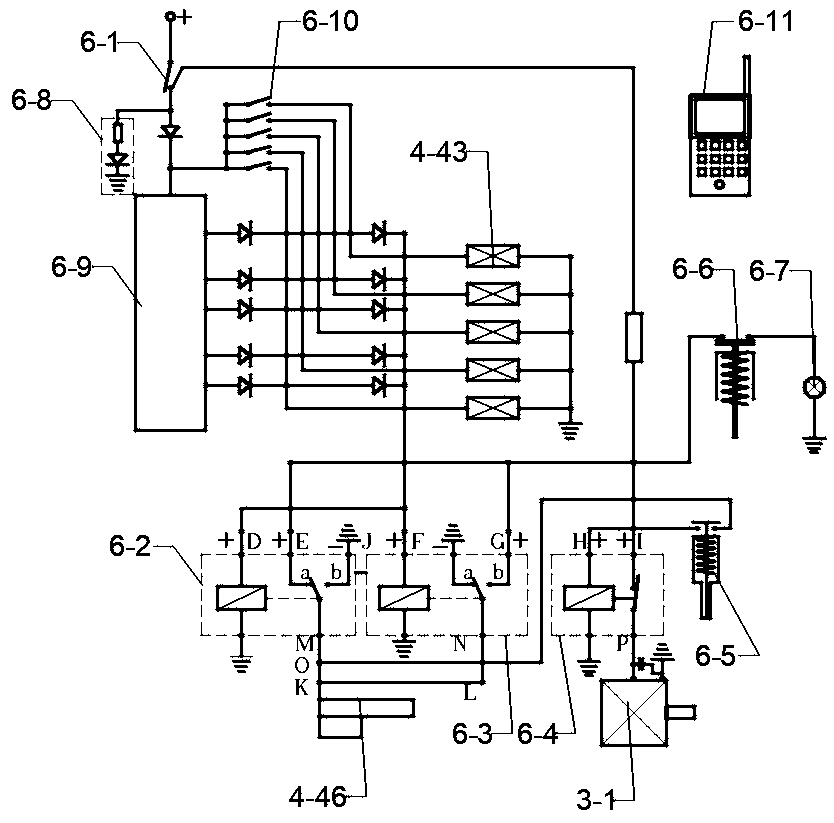

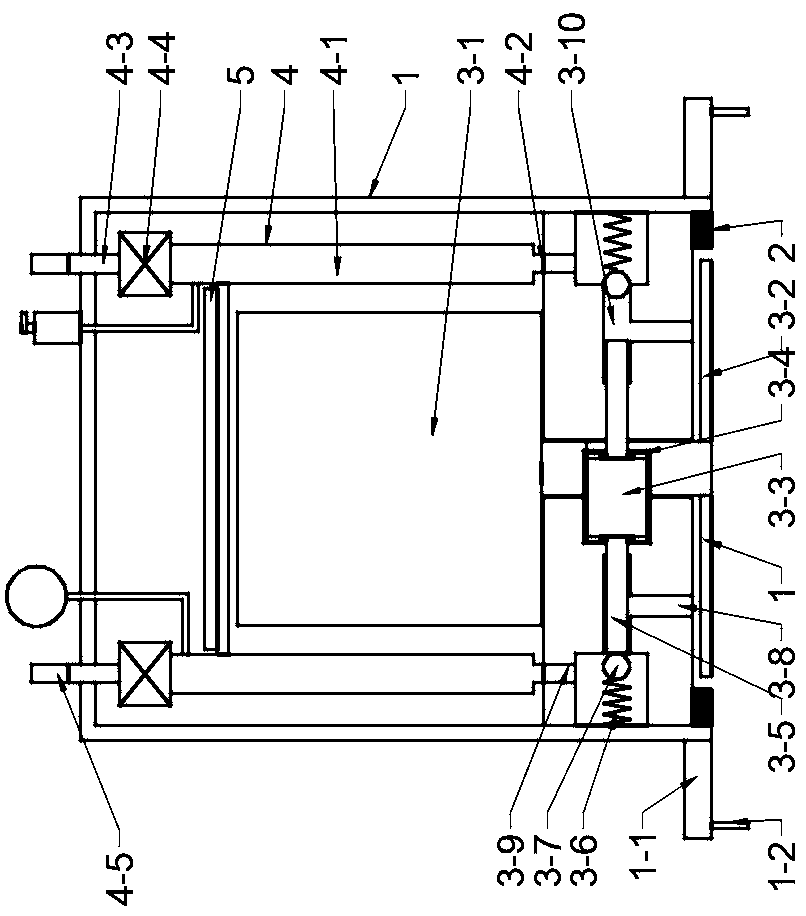

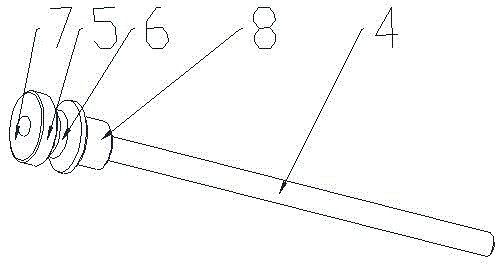

Oiling equipment for railway tiepre-embedded sleeve

ActiveCN108131550AImprove oil injection efficiencyAchieve cleanupEngine lubricationEngineeringPre embedding

The invention belongs to the technical field of railway maintenance, andparticularly relates to oiling equipment for a railway tie pre-embedded sleeve. The equipment comprises a box body, a walking module, a positioning module,oiling modules, a cleaning module and a power generation module, andLED lampsare arranged at the top of the box body; the walking module is located below the box body, and the walking module is used for driving the box body to walk on a steel rail; the positioning module is located at the bottom of the box body, the positioning module is used for positioning the equipment; the number of oiling modules is at least two,the oiling modulesare symmetrically installed on the left and right in the box body, and the oiling modulesare used for filling the pre-embedded sleevewith grease; the cleaning module is used for cleaningoiling devices and blowing off debris near tie bolts to facilitate oil injection; the power generation module is located on the box body, and the power generation module is used for converting wind and solar energy into electrical energy to power the equipment. The equipment can achieve the cleaning of the sides of ties before oiling, have protection effects during the oiling, and prevent the grease from pollutingsurrounding environments.

Owner:贵阳渝冠技术服务中心

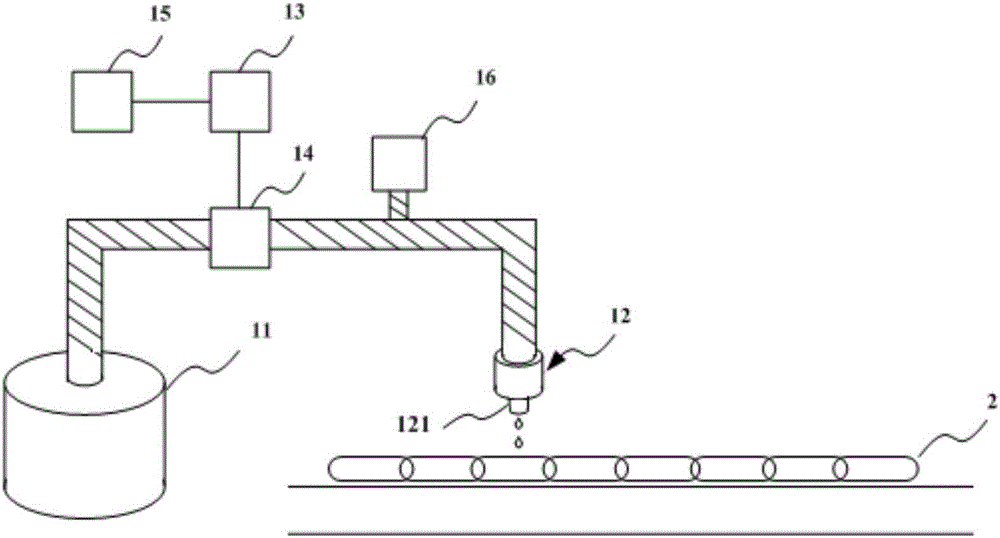

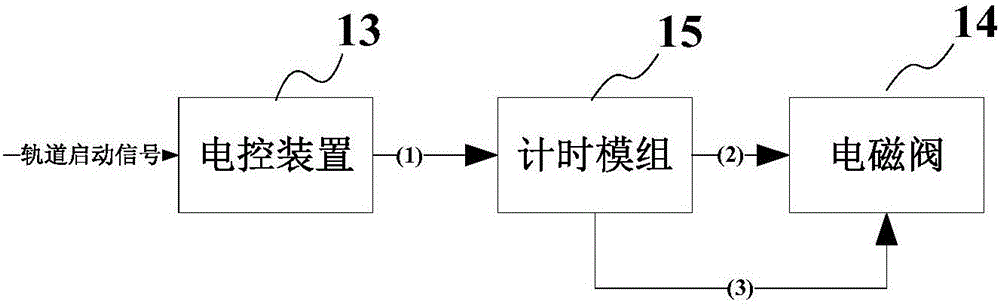

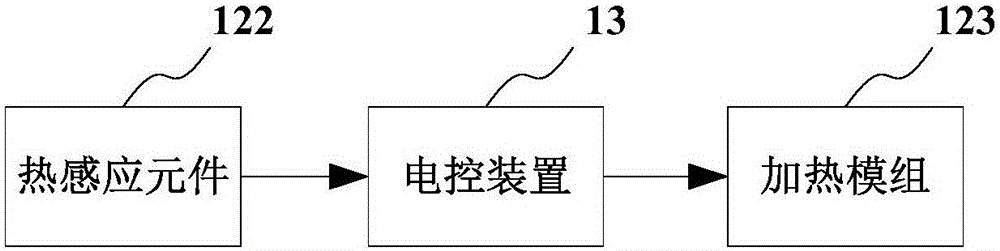

Equipment lubricating system

InactiveCN106764363ASimplify routine maintenanceImprove oil injection efficiencyCleaningGearing detailsStart signalEngineering

The invention provides an equipment lubricating system which comprises at least one lubricating agent container, at least one nozzle assembly, an electric control device and a timing module. The lubricating agent container is used for storing lubricating agents. At least one nozzle assembly communicates with the lubricating agent container for the lubricating agents to flow towards the nozzle assembly from the lubricating agent container. The electric control device receives a rail starting signal. An electromagnetic valve is arranged between the lubricating agent container and a nozzle and is electrically connected with the electric control device. The timing module is electrically connected with the electromagnetic valve and the electric control device. When the electric control device receives the rail starting signal, the timing module starts to conduct timing and generate a timing value, when the timing value reaches the first preset threshold value, the electromagnetic valve is opened so that the lubricating agents in the lubricating agent container can be sprayed out through the nozzle assembly, when the timing value reaches the second preset threshold value, the electromagnetic valve is closed, the nozzle assembly is stopped from spraying the lubricating agents, and the timing module conducts timing again. According to the equipment lubricating system, the lubricating agents are quantitatively injected to equipment rails periodically, and the oil injection efficiency is high.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

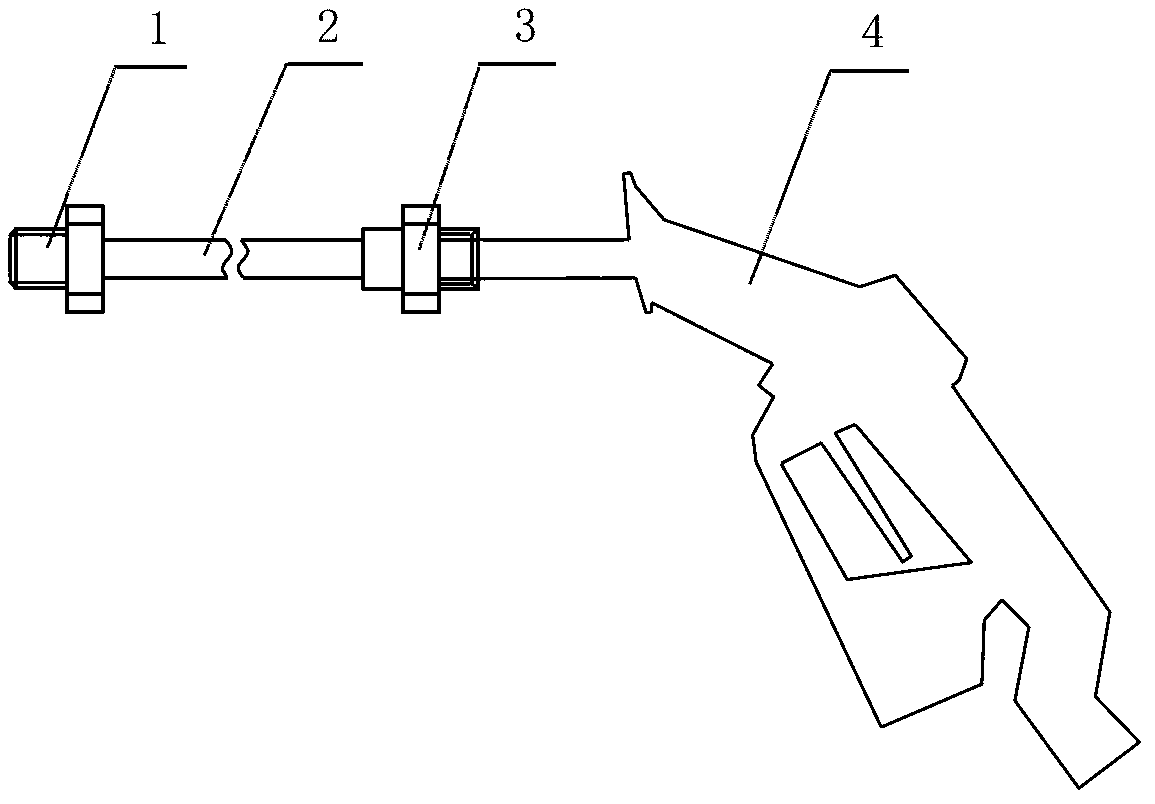

Oiling device for oil gun for mines

InactiveCN103267213AEasy to assemble and disassembleShorten the lengthManual lubricationEngineeringPetroleum engineering

The invention relates to oiling devices for oil guns, particularly to an oiling device for an oil gun for mines. The oiling device comprises the oil gun, an oil gun nozzle is connected with one end of a hose through an oil gun joint, the other end of the hose is connected with a hose joint, the oil gun nozzle is provided with an outer thread and in firm threaded connection with the oil gun joint through the outer thread, the oil gun joint can be a quick joint, an inner thread is machined at the position where the oil gun joint and the oil gun nozzle are connected, and a seal ring is arranged in the quick joint. The oiling device for the oil gun is convenient to operate, high in oiling efficiency and capable of oiling equipment which is difficult to be oiled and guaranteeing operation of the equipment.

Owner:SHANDONG HUALIAN MINING

Lubricating grease filling machine for building machinery

InactiveCN102644839AReduce repetitive processesHigh degree of automationLubricating pumpsConduits/junctionsLubricationPiston

The invention relates to a device for filling lubricating grease into a mechanical system, and provides a lubricating grease filling machine for multi-station building machinery, which has a simple structure and high automation degree, improves the injection efficiency, reduces the injection cost and can easily and safely completes the lubrication maintenance work of each part of a machine. The lubricating grease filling machine comprises a base, a manifold block support, a manifold block, a piston-type valve core, a compression ball, a spring and an oil storage hopper, wherein the manifold block support is arranged on the base, the manifold block is detachably fixed on the manifold block support, the manifold block is provided with an oil inlet hole, an oil outlet hole and an air pressurizing chamber, the oil inlet hole is communicated with the air pressurizing chamber, the air pressurizing chamber is communicated with the oil outlet hole, the piston-type valve core is driven by a drive device to move vertically and is arranged on the air pressurizing chamber of the manifold block, the compression ball is arranged between the air pressurizing chamber and the oil outlet hole, the spring is arranged inside the oil outlet hole, one end of the spring is pushed against the ball, the other end of the spring is pushed against a spring arrangement boss, and the oil storage hopper is arranged on the manifold block support and above the oil inlet hole of the manifold block.

Owner:李历强

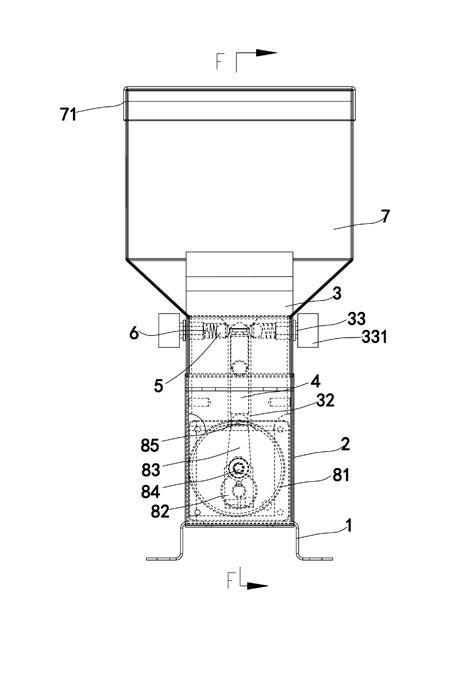

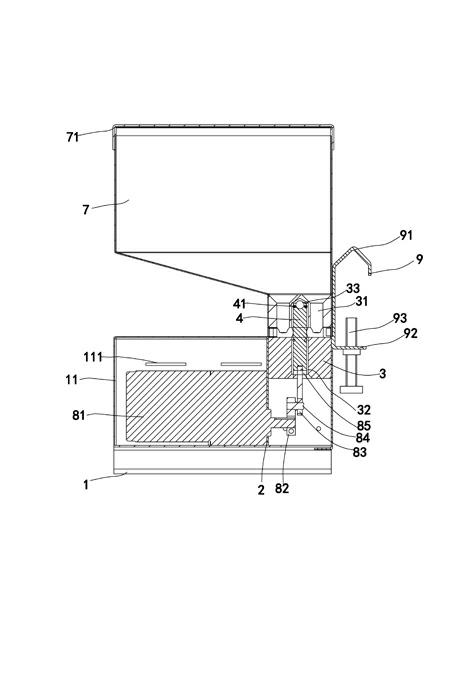

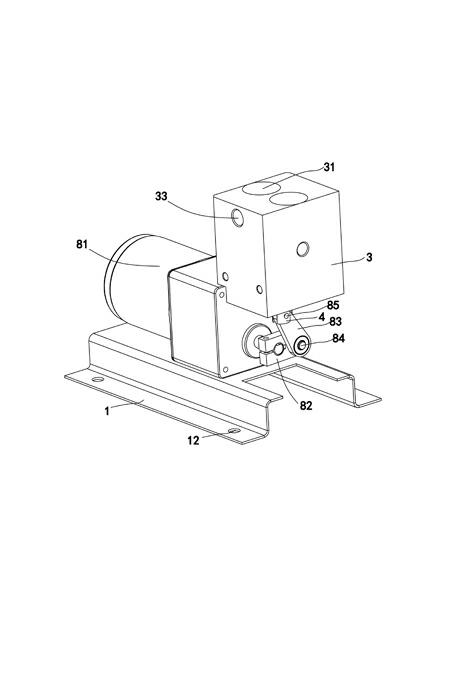

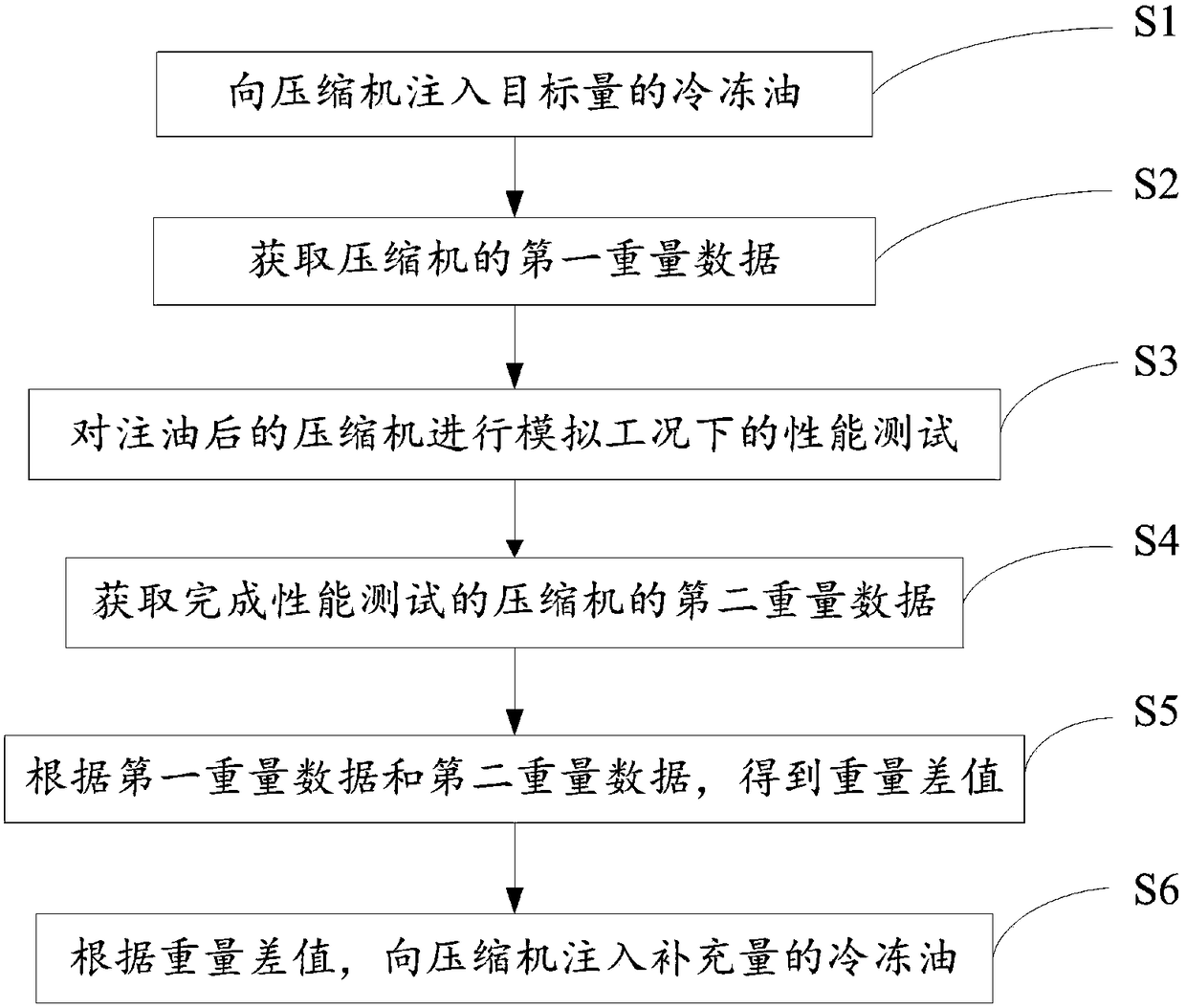

Precision oil-injecting method for automobile conditioner compressors

InactiveCN108105070AMake up for the defect of insufficient oil storageReduce manual operationsPump testingPositive displacement pump componentsAutomobile air conditioningWeight difference

The invention discloses a precision oil-injecting method for automobile conditioner compressors, comprising: injecting a target amount of refrigerant oil into a compressor according to a standard value, wherein the target amount is the standard value; acquiring first weight data of the compressor; subjecting the compressor with the injected oil to a performance test under simulated conditions; acquiring second weight data of the compressor subjected to the performance test; acquiring a weight difference according to the first weight data and the second weight data; injecting a supplementary amount of refrigerant oil into the compressor according to the weight difference, wherein the supplementary amount is the weight difference. The precision oil-injecting method for automobile conditionercompressors has the advantages that oil is supplementarily injected according to the actual conditions, acquired through a weighing apparatus, a code scanning apparatus and a data processing apparatus, of refrigerant oil left by the different compressors in a performance test system, the precision of ex-factory compressors is enabled to meet the oil injection standard, performance of the compressors is improved, and their service lives are extended.

Owner:JIANGSU YINHE TONGZHI NEW ENERGY TECHNOLOGY CO LTD

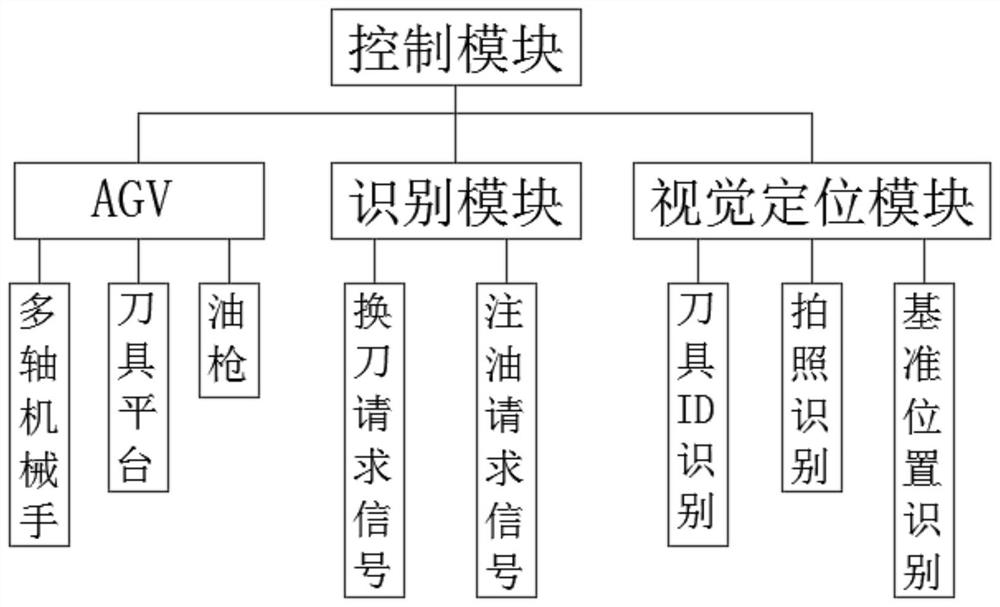

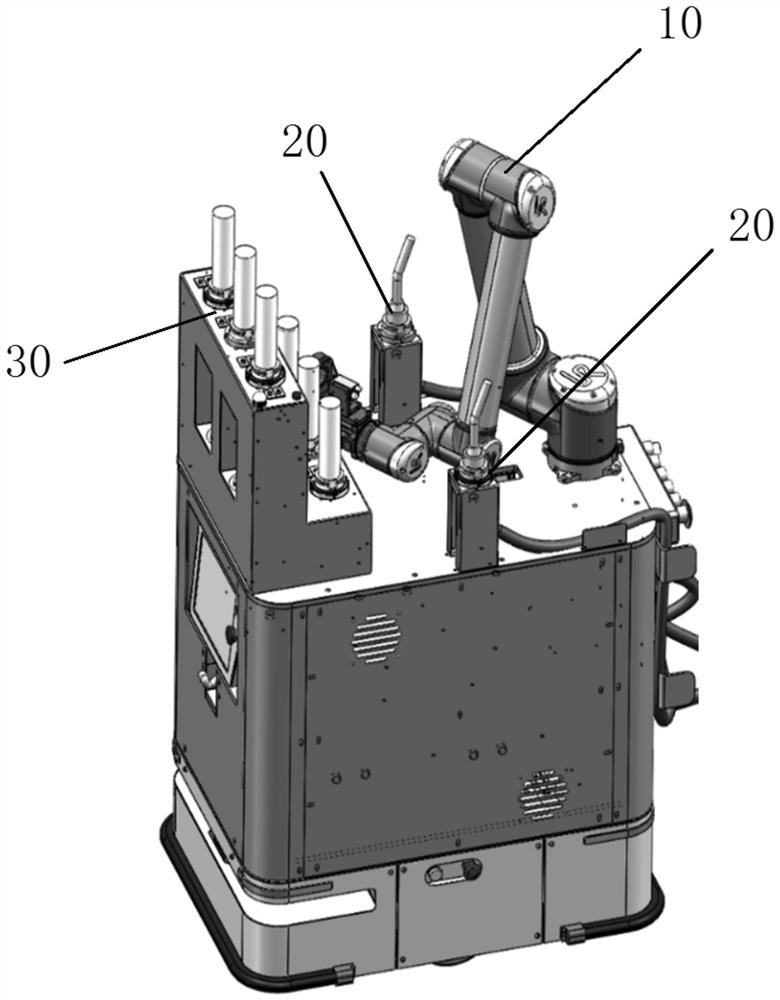

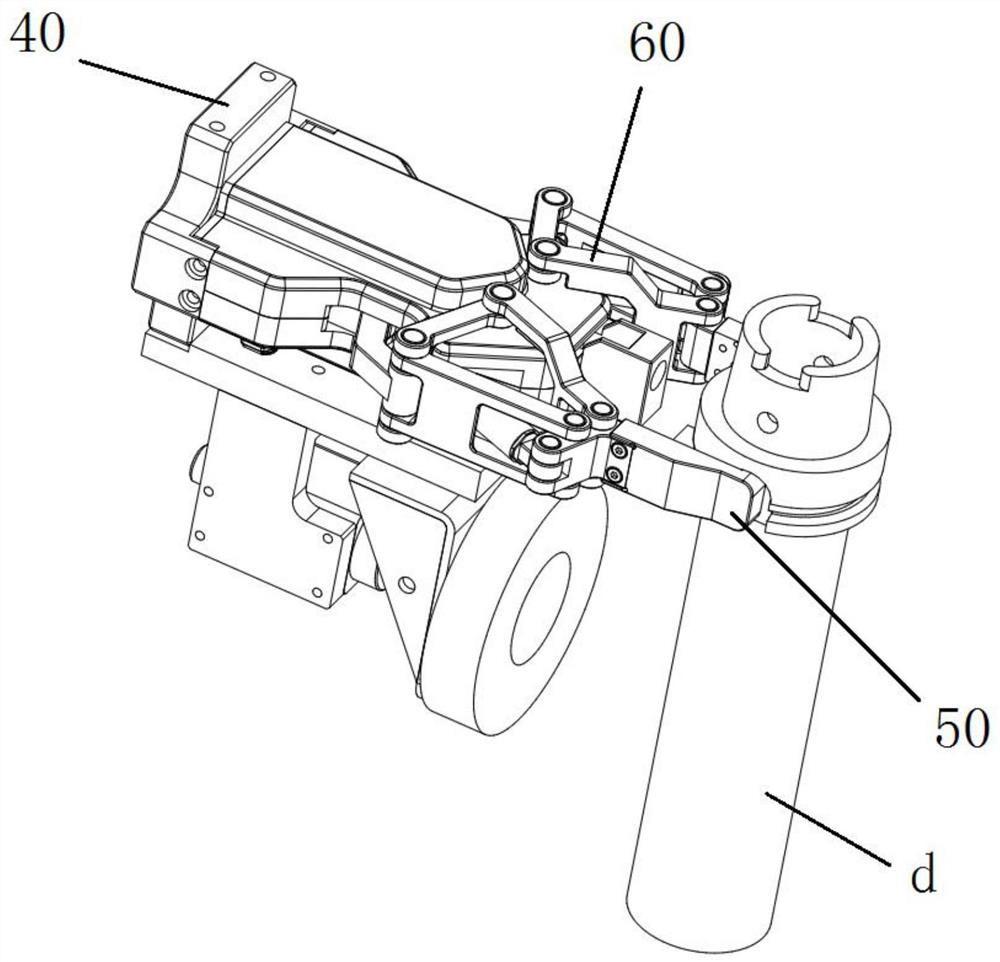

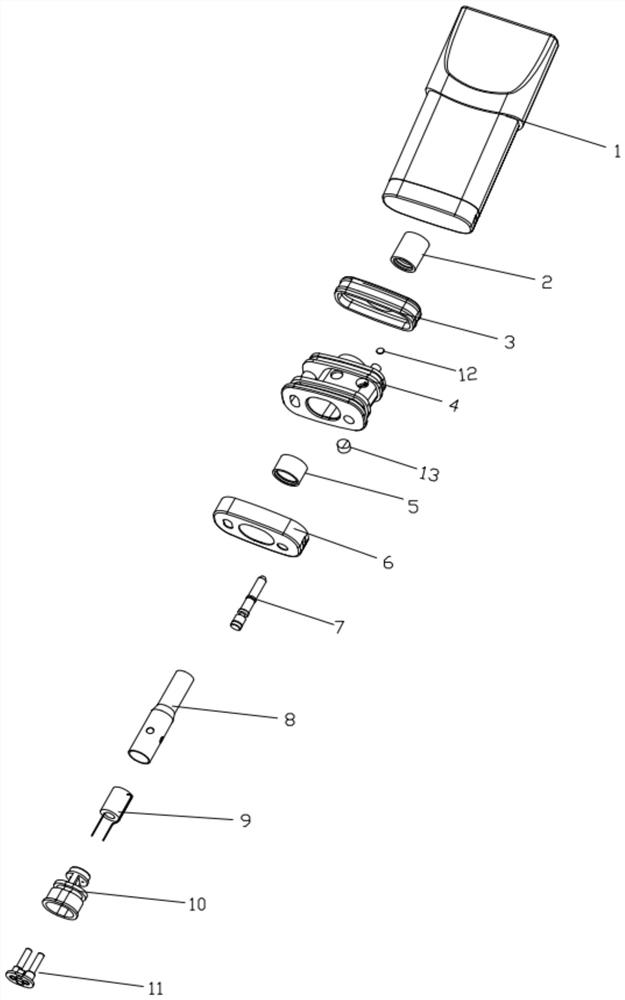

Automatic tool changing and oiling system and automatic tool changing and oiling method

ActiveCN112705984AImprove replacement efficiencyImprove oil injection efficiencyElectric/hybrid propulsionPositioning apparatusProcess engineeringManipulator

The invention provides an automatic tool changing and oiling system and an automatic tool changing and oiling method which are used for automatically conducting tool changing or oiling operation according to a signal source station, and the automatic tool changing and oiling system comprises an AGV, a recognition module for recognizing a tool changing and / or oiling signal source and a control module. The AGV is provided with a multi-axis manipulator, an oil gun and a tool platform; the recognition module is connected with the control module and converts the tool changing or oiling signal source to a first instruction and a second instruction; and the control module is connected with the AGV and sets a running path of the AGV according to the first instruction, and controls the multi-axis manipulator to conduct tool changing or oil oiling operation according to the second instruction after the AGV reaches the signal source. The automatic tool changing and oiling system and an automatic tool changing and oiling method have the advantages of high automation degree, high tool replacement efficiency and rapid oiling.

Owner:DONGFENG MOTOR CO LTD

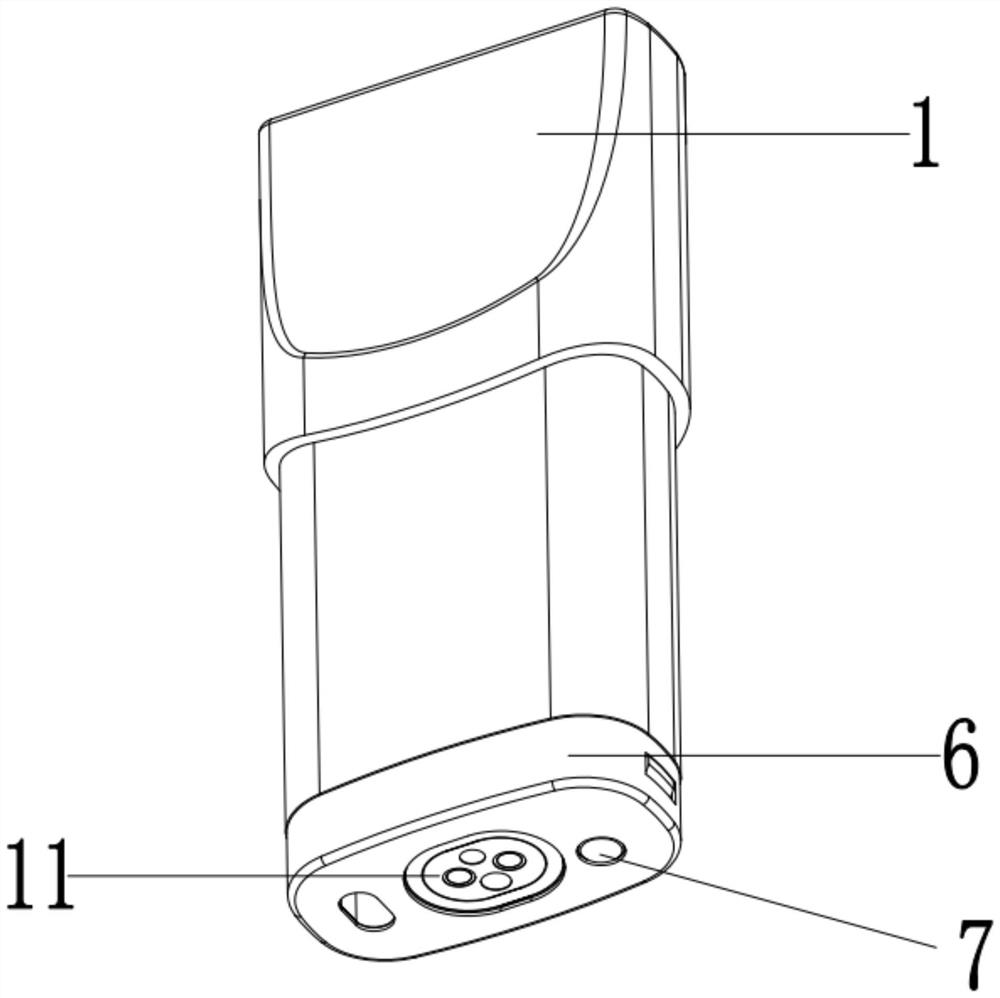

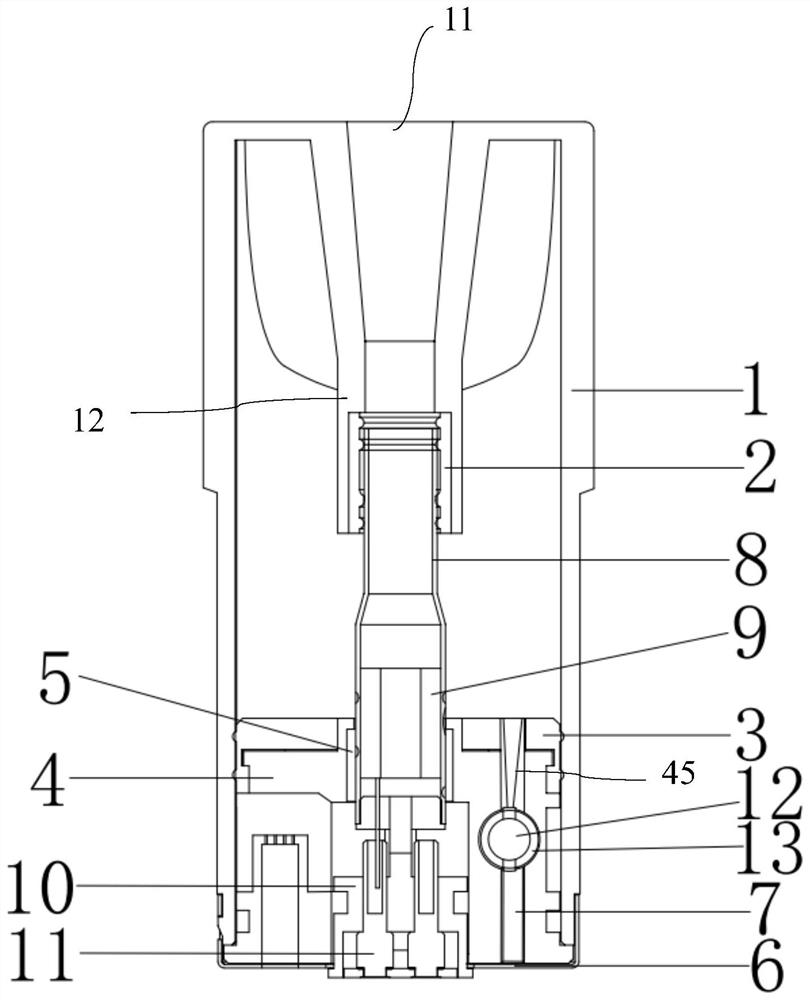

Oil storage bin cover, atomizer and electronic cigarette

The invention discloses an oil storage bin cover, an atomizer and an electronic cigarette, the oil storage bin cover comprises a main body, a space groove for air flow circulation is formed in the peripheral wall of the main body, and an air inlet hole for air inflow to achieve atomization and / or a vent hole for tobacco tar ventilation are / is formed in the groove wall of the space groove. According to the oil storage bin cover, the space groove is designed, the space groove can form a space in the atomizer, air flow can enter the atomization channel only after passing through the space, tobacco tar condensed in the atomization channel is left in the atomization channel and at most flows into the space formed by the space groove, and leakage is avoided; in addition, a vent hole is formed in the space groove, air can be exhausted during oil injection, the oil injection efficiency is improved, air can be supplemented during smoking so that tobacco tar can enter the heating body from the oil storage bin more rapidly, and meanwhile the space groove can prevent the tobacco tar overflowing from the vent hole from leaking outwards.

Owner:SHENZHEN EIGATE TECH CO LTD

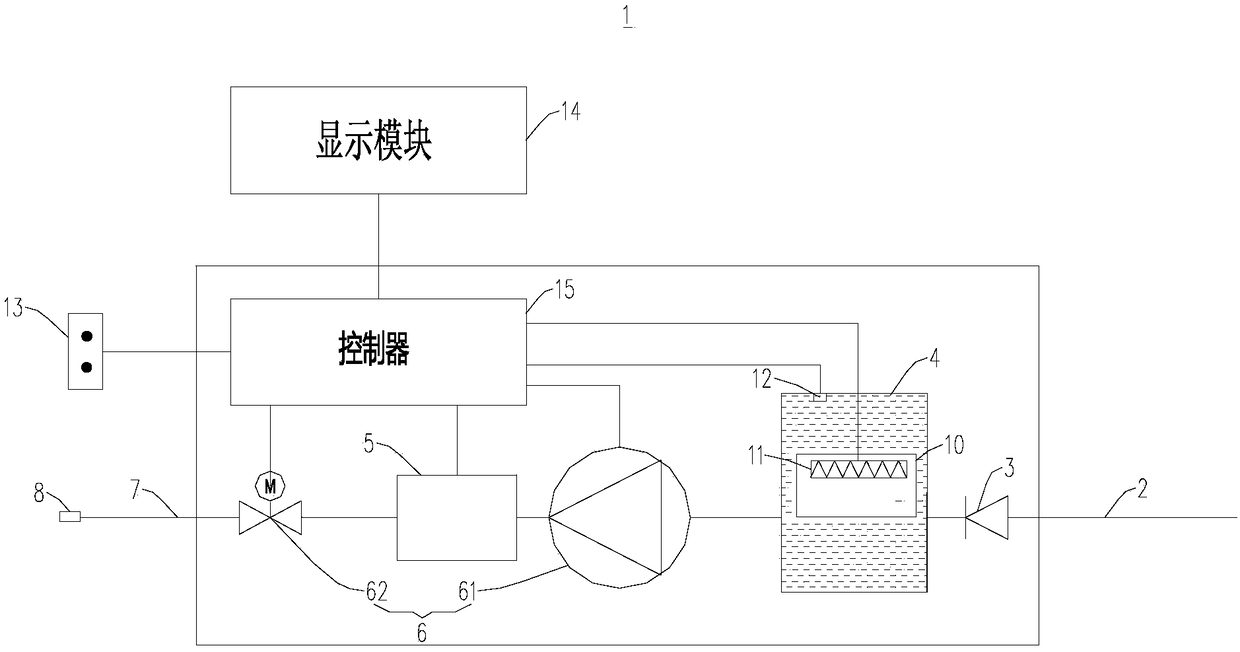

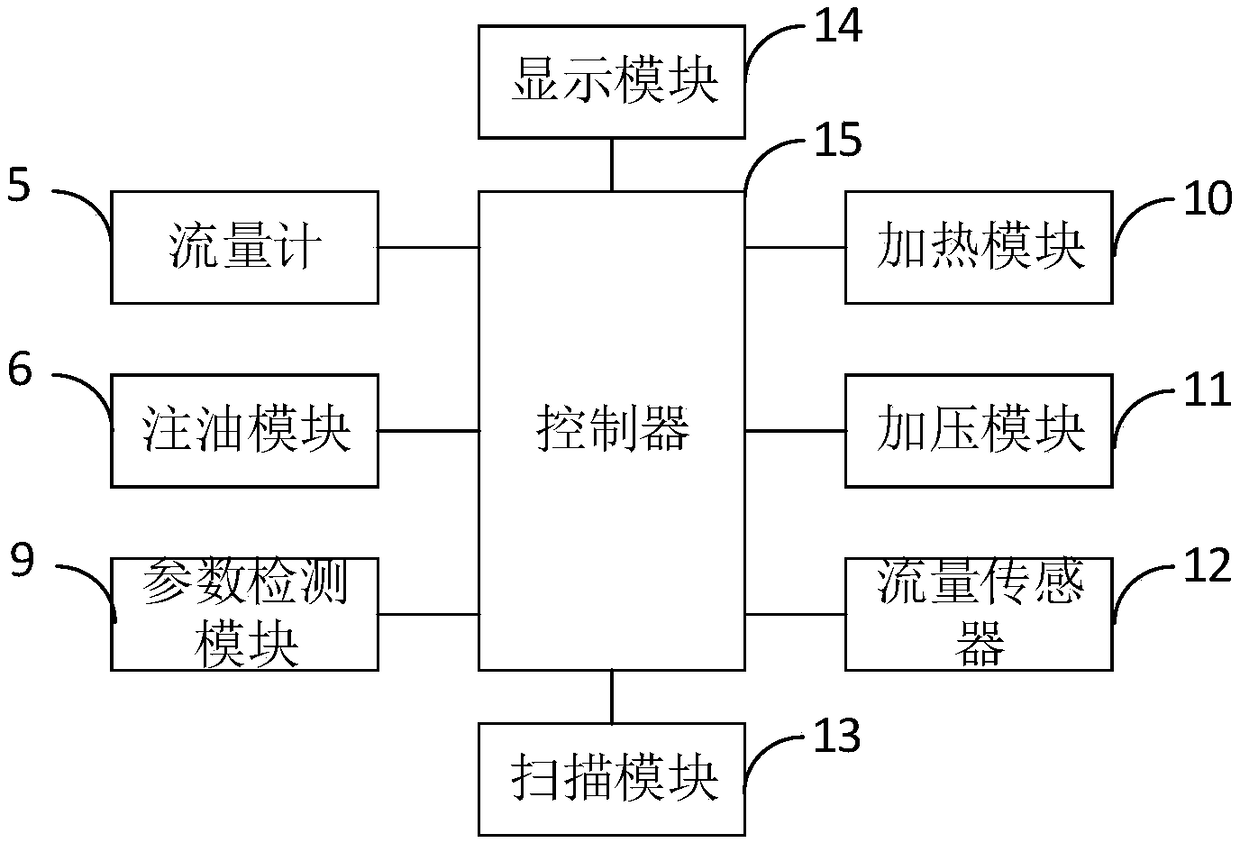

Oil injection system, method and device

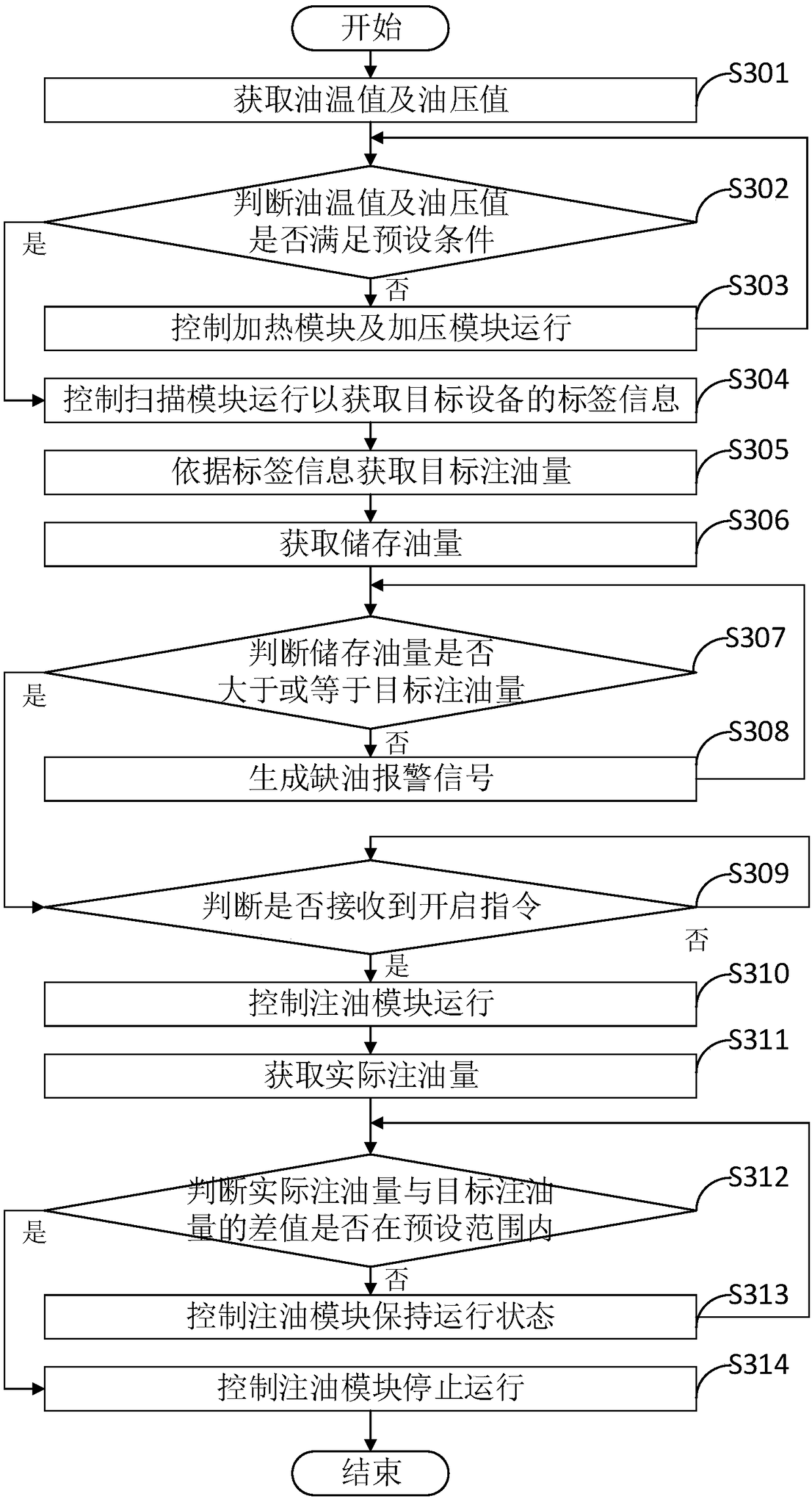

PendingCN109114408AImprove oil injection efficiencyGuaranteed accuracyLubrication elementsElectricityOil temperature

The invention provides an oil injection system, method and device, and relates to the field of mechanical automation control. The oil injection system comprises a parameter detecting module, a scanning module, an oil injection module, a flowmeter and a controller. The controller is electrically connected with the parameter detecting module, the scanning module, the oil injection module and the flowmeter correspondingly, and the controller is used for controlling the scanning module to operate to obtain label information of a target device when an oil temperature value and an oil pressure valuemeet the preset conditions, obtaining a target oil injection amount according to the label information, controlling the oil injection module to operate when receiving an opening instruction, and thencontrolling the oiling injection module according to the target oil injection amount and an actual oil injection amount. Product information is obtained through the scanning module, the target oil injection amount is obtained according to the product information, and at the same time, the actual oil injection amount is tracked to ensure that the actual oil injection amount is close to or the sameas the target oil injection amount; and meanwhile, the whole process is completely automatic, the oil injection efficiency is improved, and the accuracy of oil injection is guaranteed.

Owner:NINGBO AUX ELECTRIC +1

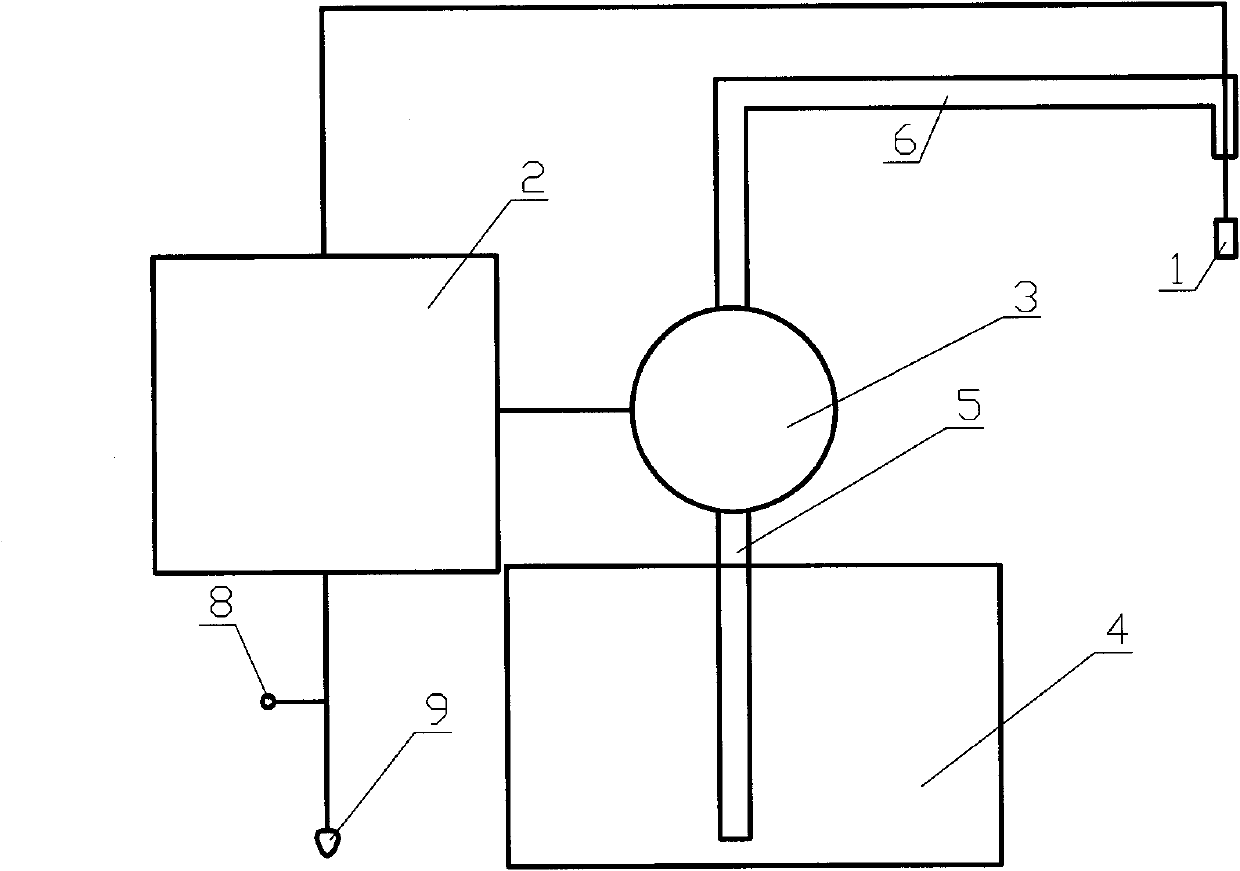

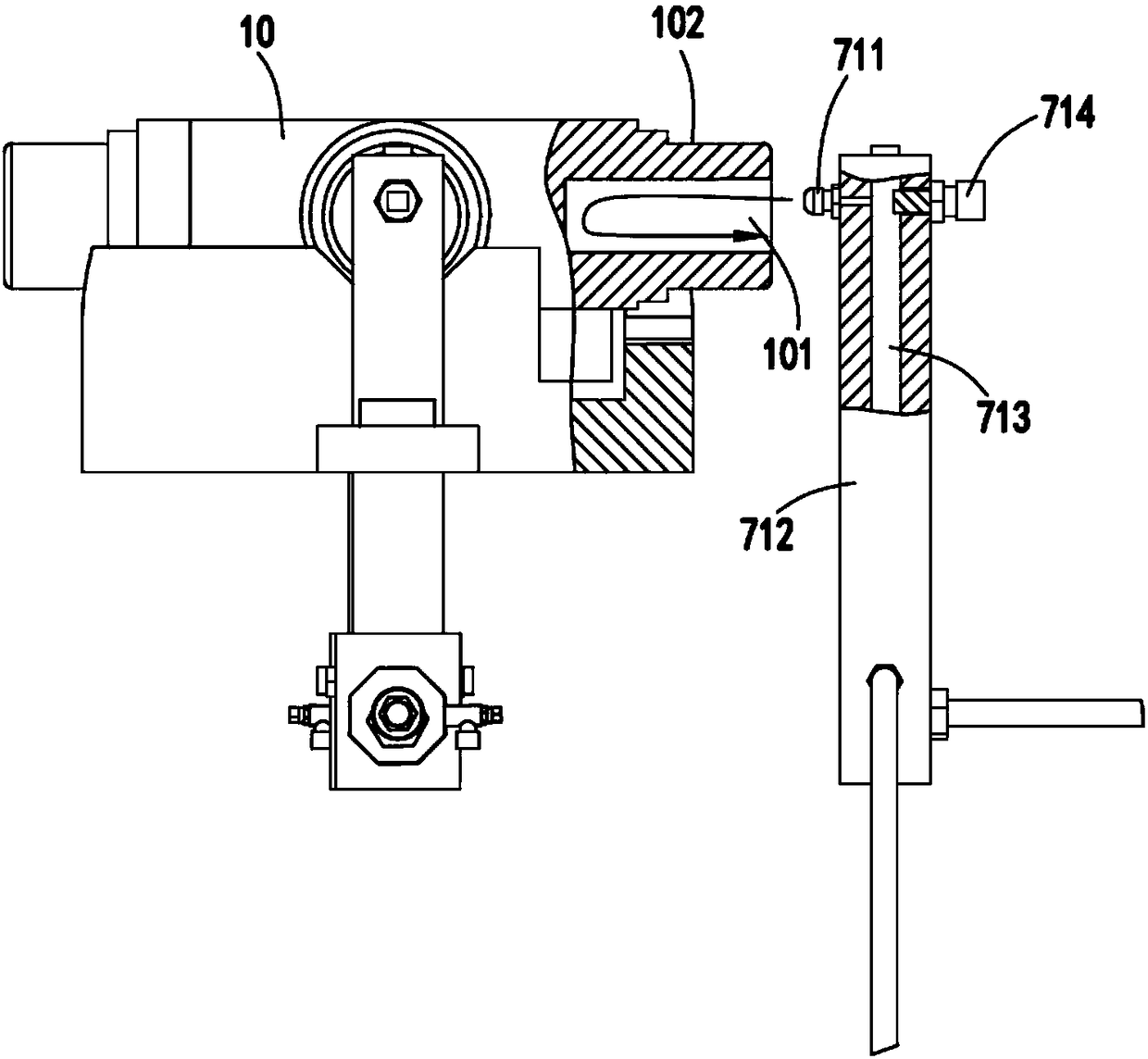

Vacuumizing oil injection system and method of hydraulic spring operating mechanism

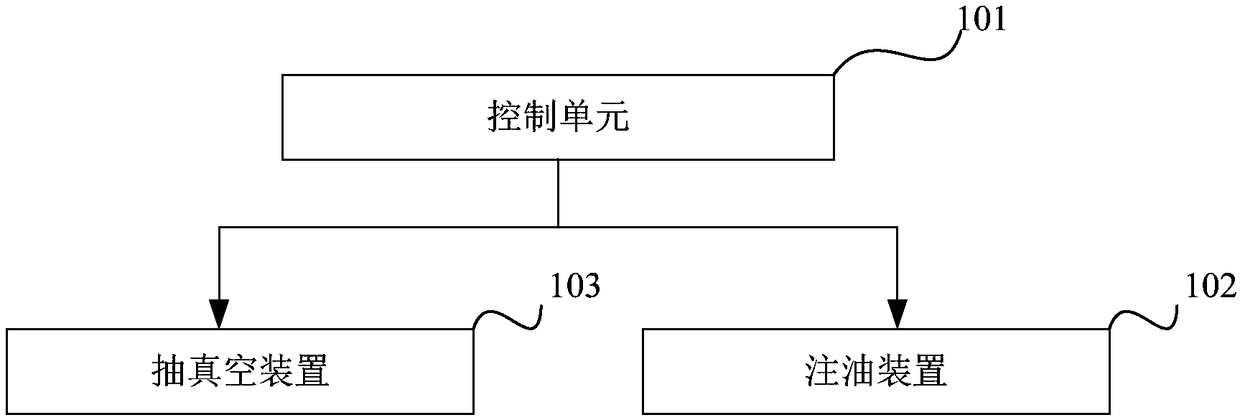

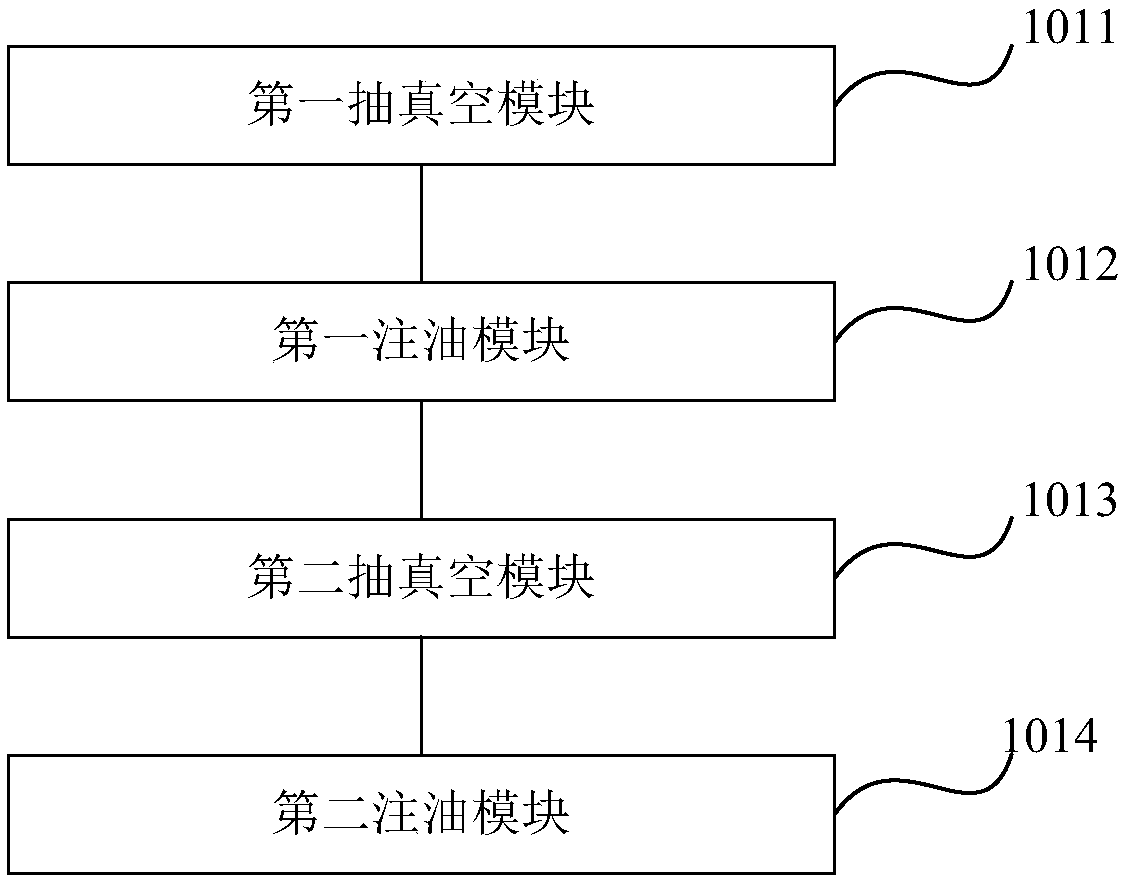

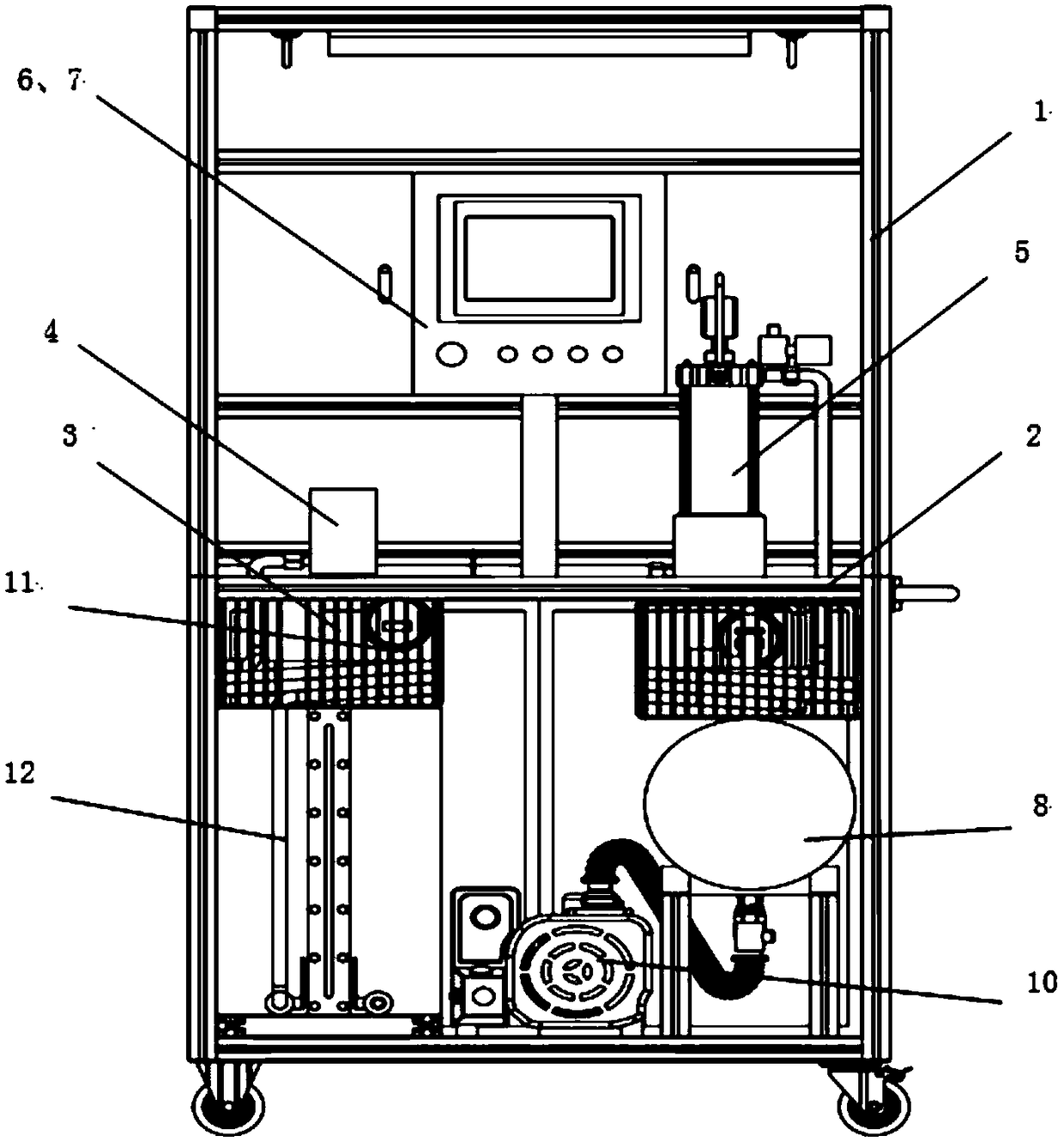

ActiveCN109110721APrevent not to suppressAvoid the problem of splitting and closing energy storageLiquid transferring devicesControl signalInjection device

The embodiment of the invention discloses a vacuumizing oil injection system and method of a hydraulic spring operating mechanism. The vacuumizing oil injection system of the hydraulic spring operating mechanism comprises a control unit, an oil injection device and a vacuumizing device, wherein the vacuumizing device is used for vacuumizing an inner cavity of the hydraulic spring operating mechanism; the oil injection device is used for injecting oil into the inner cavity of the hydraulic spring operating mechanism; and the control unit is used for obtaining vacuumizing data of the vacuumizingdevice and oil injection data of the oil injection device, generates a control signal according to the vacuumizing data or the oil injection data and determines whether or not the vacuumizing deviceneeds to conduct vacuumizing operation and whether or not the oil injection device needs to conduct oil injection operation according to the control signal.

Owner:西安西电高压开关操动机构有限责任公司 +2

Lubricating oil filling machine

InactiveCN108953961AReduce workloadControl oil injectionVehicle componentsSafety/regulatory devicesControl systemSteel ball

The invention relates to a lubricating oil filling machine. An oil pump device is mounted at the bottom of a shell. The bottom of the shell is provided with a rubber oil pressing pan. Oil distributorsand a control system are mounted in the shell. A spiral oil scraping plate of the oil pump device is fixedly connected with an output shaft of a motor. Oil inlets are located within the rotating radius of the spiral oil scraping plate. Oil outlets communicate with the oil inlets through pipes to form an oil channel. Springs and steel balls are arranged in the oil channel. A plunger is arranged inthe oil channel. The outer end of the plunger is provided with an eccentric wheel. The eccentric wheel is in gearing-down connection with the output shaft of the motor. The plunger does reciprocatingmotion in the oil channel under the action of the eccentric wheel and a clamp ring to push the steel balls to squeeze out grease. Oil storage cavities of the oil distributors are connected with the corresponding oil inlets and the corresponding oil outlets. The oil inlets are arranged corresponding to the oil outlets of the oil pump device. The oil outlets are connected with oil filling hoses tofill oil to oil filling points one by one. The lubricating oil filling machine can control the oil filling volume, improve the oil filling efficiency and avoid waste and is operated through a remote controller, is safe and sanitary and facilitates replacing of an oil drum.

Owner:丰县王领农机服务专业合作社

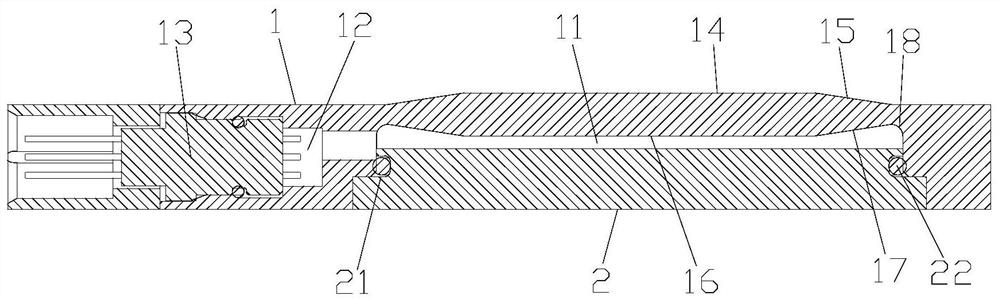

Oil injection device for gearbox

InactiveCN104482190AImprove oil injection efficiencyImprove oil injection accuracyGearboxesGear lubrication/coolingInjection devicePiston

The invention relates to an oil injection device for a gearbox. The oil injection device comprises a gearbox body, and the side wall of the gearbox body is fixedly connected with a projection having the triangular cross section. The upper surface of the projection is provided with an oil inlet hole communicated with the inside of the gearbox body, the projection is provided with an oil injector injecting oil relative to the oil inlet hole, the oil injector is composed of an oil injection rod and a monitor, an oil storage bin is arranged in the oil injection rod, a piston push rod used for injecting lubricating oil in the oil storage bin into the gearbox body and sucking the lubricating oil into the oil storage bin is arranged in the oil storage bin, the bottom of the oil injection rod is fixedly connected with an oil level sensor, an output end of the oil level sensor is electrically connected with the monitor, and an annular alarm LED is fixedly connected with the upper surface of the monitor. The oil level monitor and a piston type oil injector are arranged on the oil injection device for the gearbox, so that oil injection efficiency is greatly improved and oil injection accuracy is improved.

Owner:张立

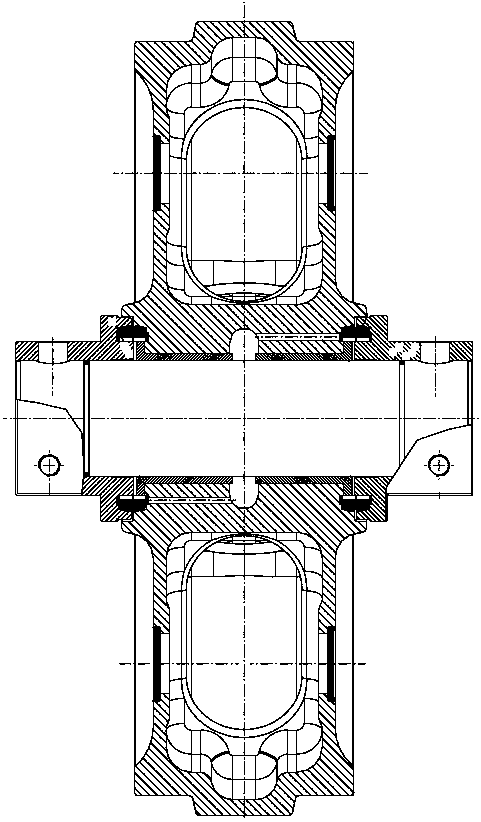

Idle wheel for excavator for large scale mine

PendingCN107933719AAvoid crackingPlay a reinforcing roleEndless track vehiclesRadial surfaceEngineering

Provided is an idle wheel for an excavator for a large scale mine. The wheel includes a wheel body, a shaft, shaft seats and a shaft sleeve; the shaft sleeve is installed in a center hole of the wheelbody, and the shaft penetrates through the shaft sleeve and is matched with the shaft sleeve in a rolling mode; two ends of the shaft are symmetrically provided with two shaft seats, and each shaft seat is fixed to the shaft through a pin; a partition plate is disposed between the shaft sleeve and the wheel body, and the shaft and the wheel body are sealed by a seal assembly; a radial direction surface of the wheel body is designed as a structure shaped like a Chinese character 'ji', so that the radial direction surface constitutes two track surfaces symmetrical along the center surface of the wheel body, and each track surface is an arc surface, so that forces imposed on the wheel body are more uniform. The idle wheel is simple and reliable in structure, and is particularly suitable forthe use of large and ultra large crawler-type construction machinery.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

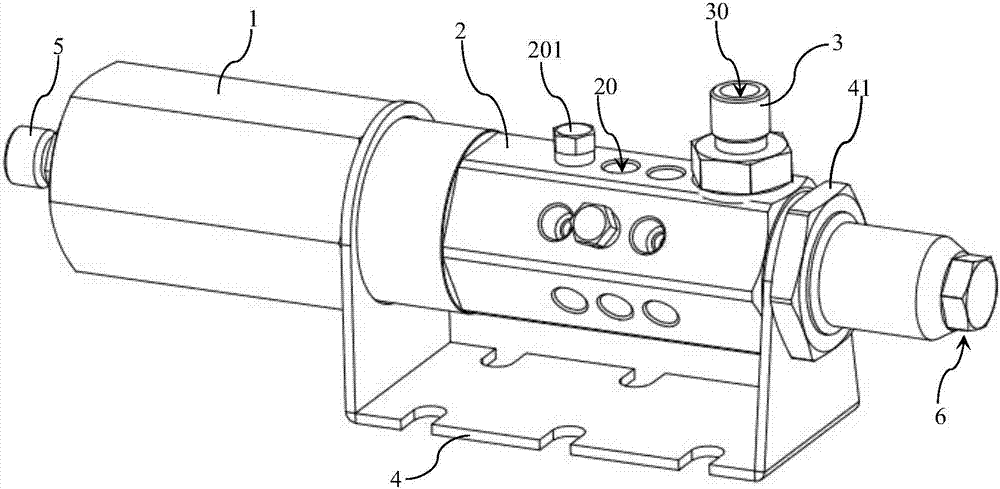

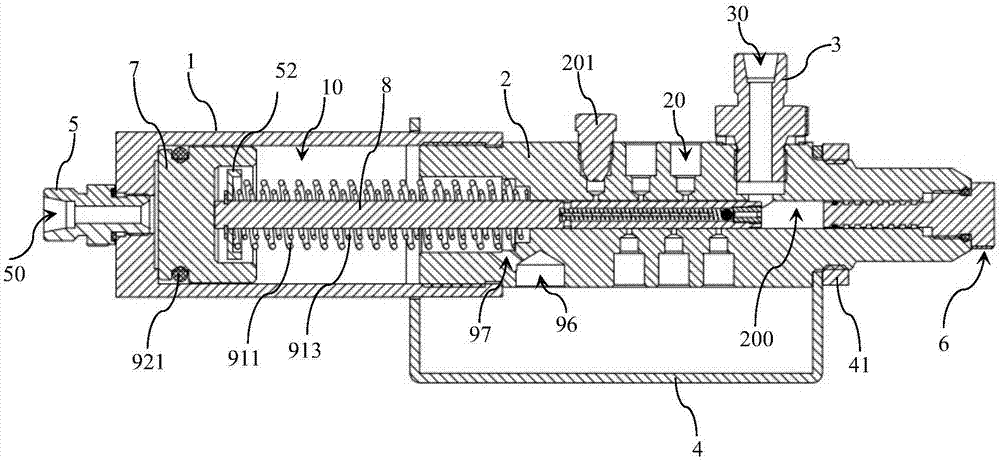

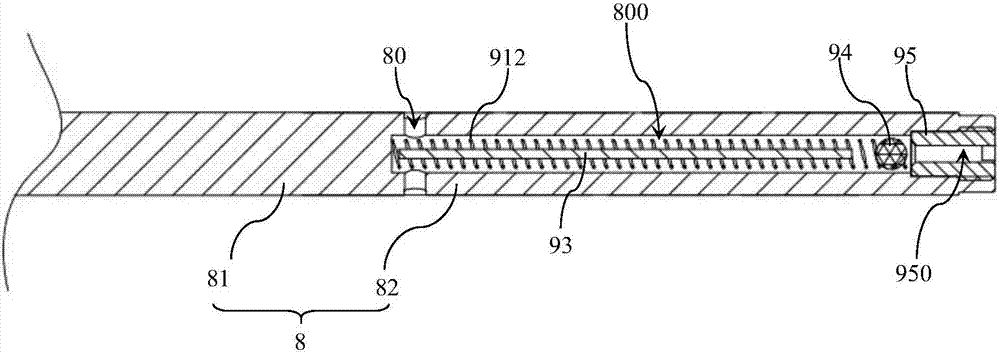

Multi-point oil injection pump

ActiveCN107061969AImprove oil injection efficiencyImprove stabilityBearing componentsLubricating pumpsBodies oilEngineering

The invention provides a multi-point oil injection pump which comprises a valve body provided with a valve element channel, a valve element partially contained in the valve element channel, an oil inlet connector communicating with the valve element channel, an adjustment plug blocking the free end of the valve element channel, a cylinder connected with the valve body, an air inlet connector communicating with the cylinder, a piston located in the cylinder and connected with the valve element in an abutting mode and a first spring connected between the piston and the valve body and arranged outside the valve element in a sleeving mode. The valve body is provided with an air exhaust hole communicating with the cylinder and provided with a plurality of valve body oil outlets sequentially distributed in the longitudinal extension direction of the valve body. The valve element is provided with a valve element inner cavity which communicates with a plurality of valve element oil outlets annularly distributed in the valve element inner cavity. The valve element is pushed through inflation to move so as to enable the valve element oil outlets to sequentially communicate with the valve body oil outlets located in different positions, so that the valve element oil outlets and the different valve body oil outlets form a plurality of oil supply passages, oil injection efficiency and stability are improved, and oil injection cost is reduced.

Owner:无锡卓能环境科技有限公司

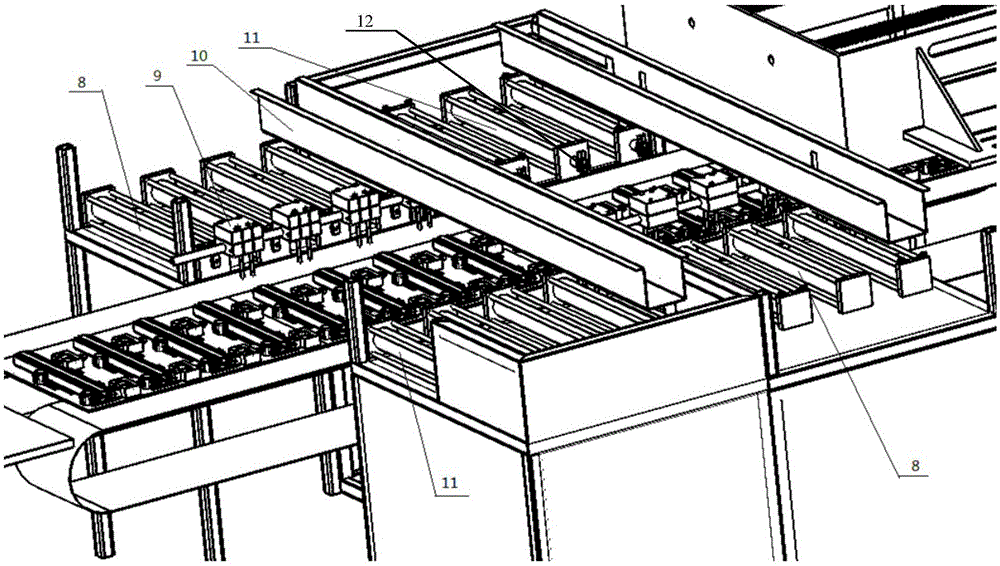

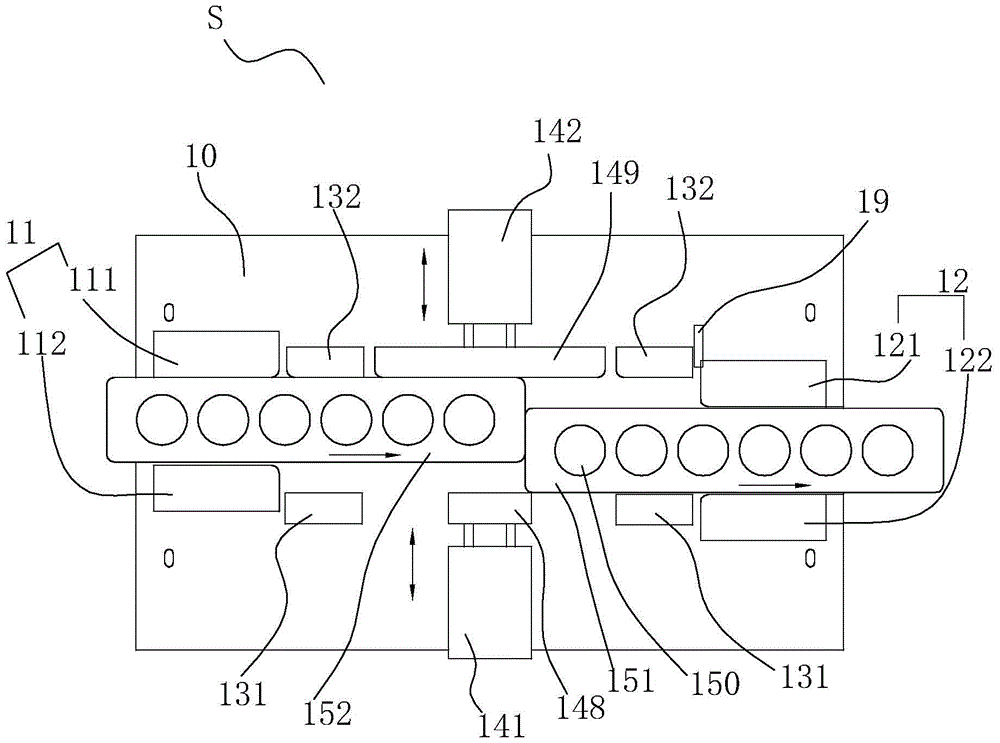

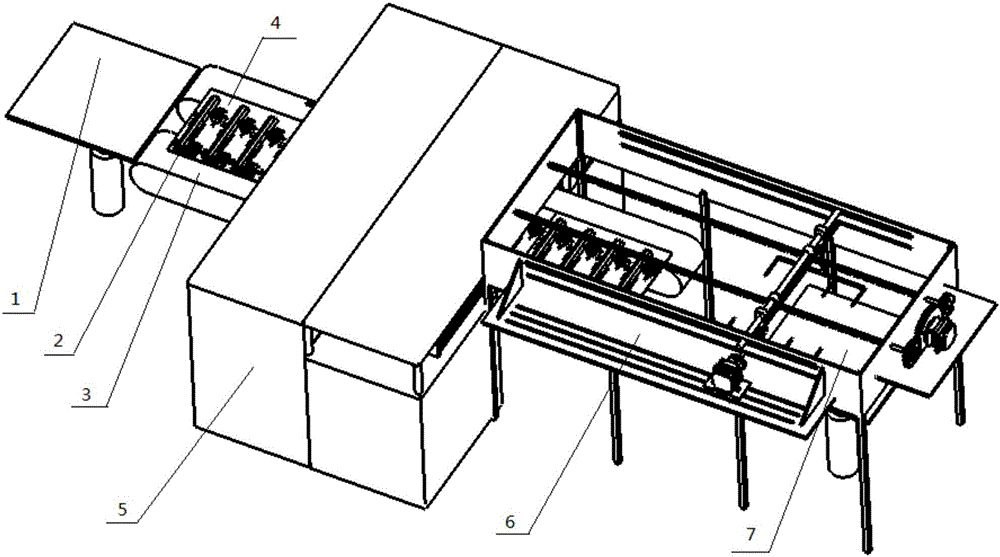

Multi-head oil injection positioning device, oil injection equipment and oil injection method

ActiveCN104591071BReduce operating proceduresImprove oil injection efficiencyLiquid transferring devicesMarine engineeringInjection equipment

The invention discloses a multi-head oiling and locating device, oiling equipment and an oiling method. The multi-head oiling and locating device comprises a feeding stopper group and a discharging stopper group which are arranged on a bottom plate, a front baffle plate and a rear baffle plate which are arranged between the feeding stopper group and the discharging stopper group, a front air cylinder located on the front side of the front baffle plate, and a rear air cylinder located on the rear side of the rear baffle plate. An oiled fixture seat is forwards pushed by the rear air cylinder so as to move to the front baffle plate, and the rear air cylinder retreats backwards; a new fixture seat is propelled to an oiling station located between the front air cylinder and the rear air cylinder from the middle of the feeding stopper group; the oiled fixture seat is moved out of the middle of the discharging stopper group under the drive of the new fixture seat; when the new fixture seat is propelled to the inner end face of the discharging stopper group, the front air cylinder backwards pushes the new fixture seat to the rear baffle plate. According to the locating device provided by the invention, after the oiled fixture seat is staggered, the oiled fixture seat is pushed by a fixture seat to be filled to the other side from one side, and the oiled fixture seat is synchronously pushed, so that the operation procedure is reduced, and the oiling efficiency is improved.

Owner:SHENZHEN HANGSEN STAR TECH

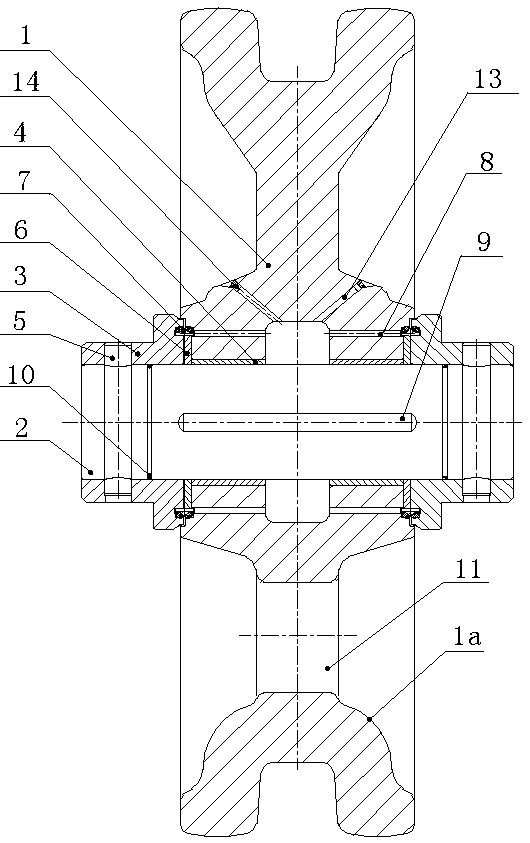

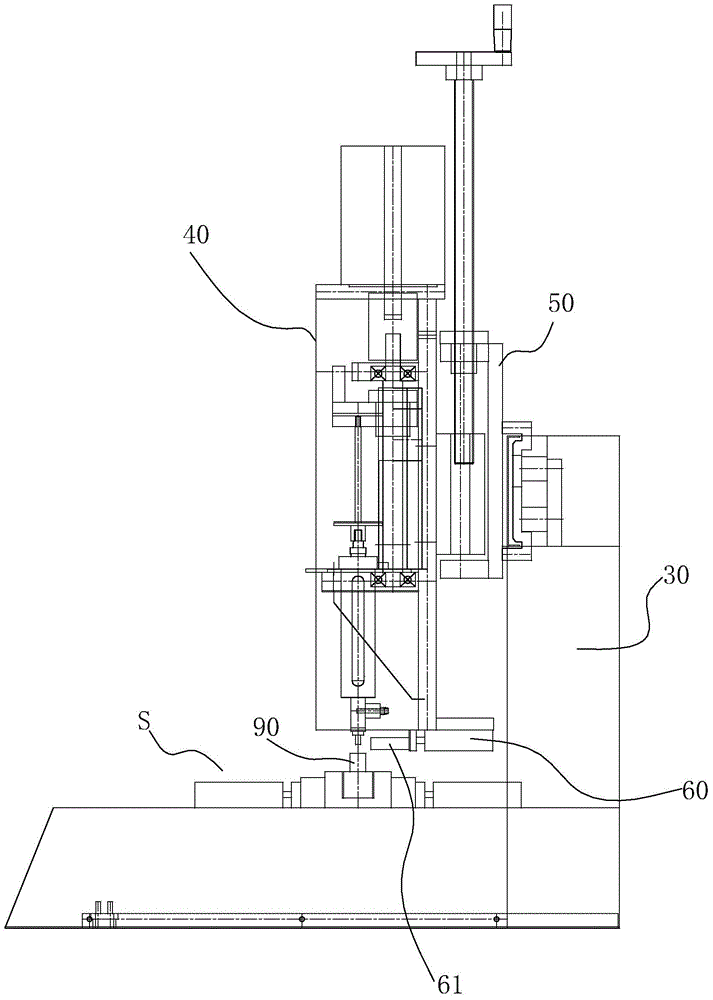

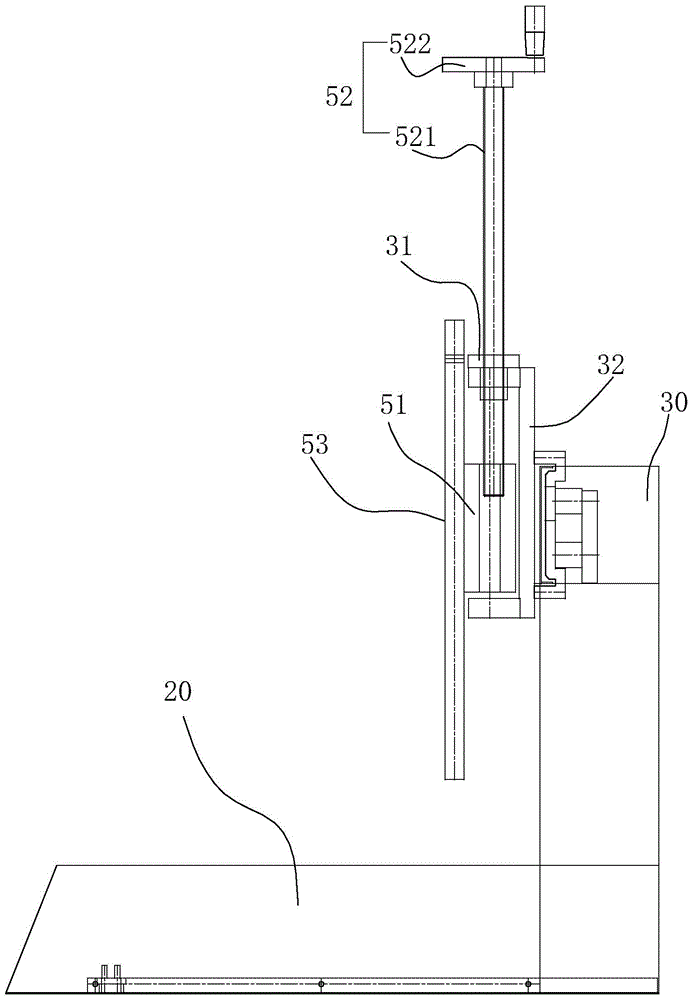

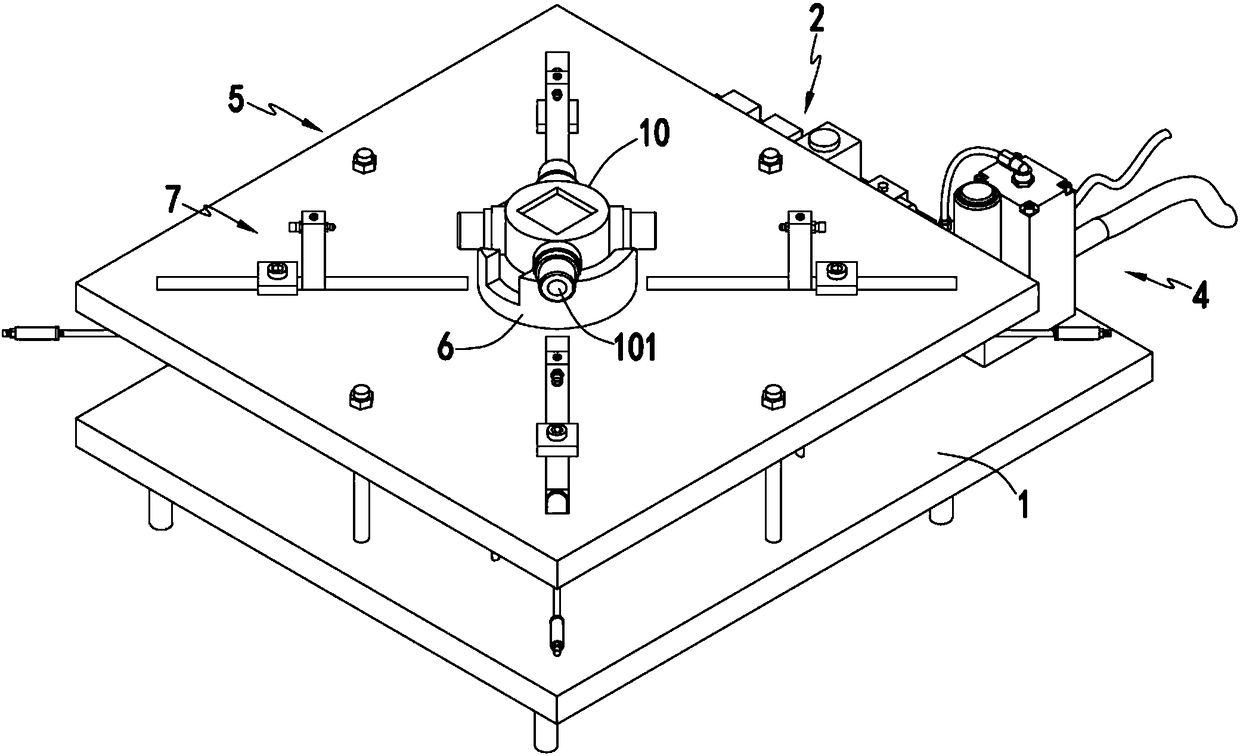

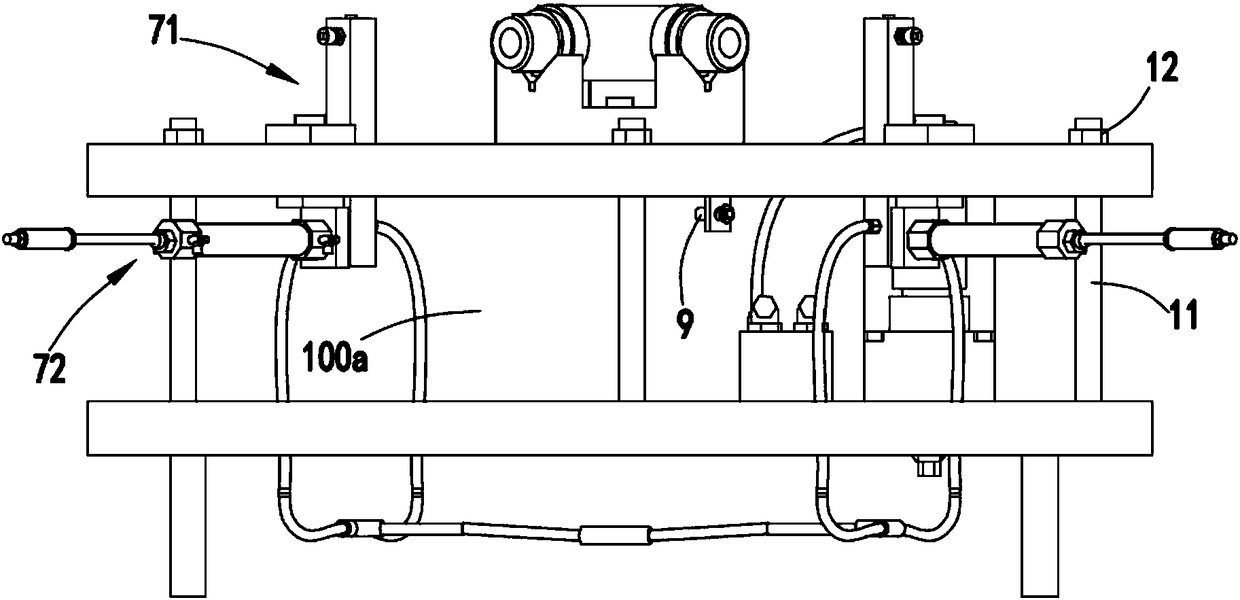

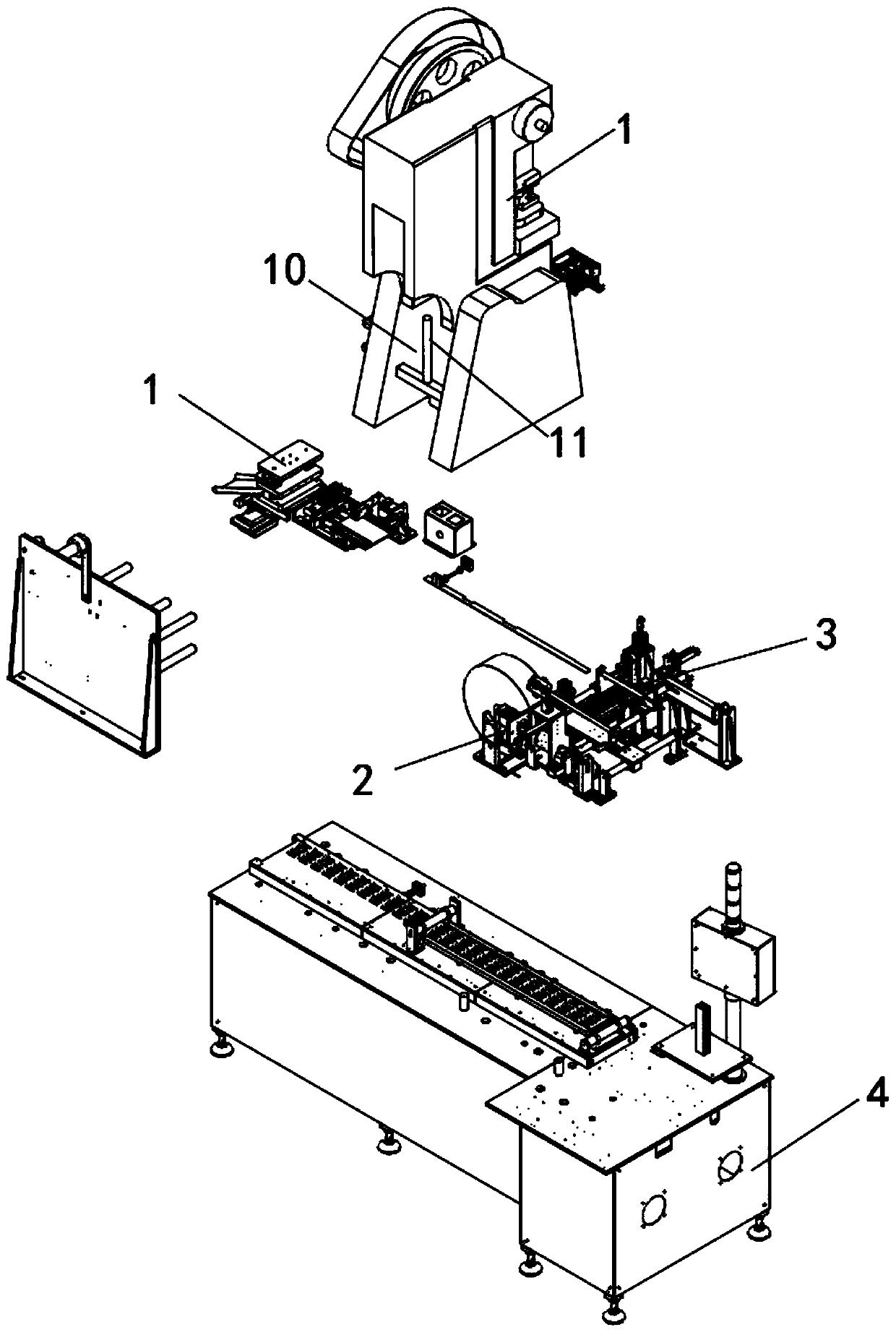

Candan universal joint synchronization oil injection equipment and method thereof

PendingCN108302314AQuick oil injectionSame lengthYielding couplingConduits/junctionsInjection equipmentUniversal joint

The invention relates to candan universal joint synchronization oil injection equipment and a method thereof. The candan universal joint synchronization oil injection equipment comprises a base, an electric control device installed on the base, an air inlet control device and an oil feeding device, a guide supporting unit is arranged above the base and is provided with a positioning clamp for positioning a candan universal joint, and oil injection devices corresponding to the oil injection hole in a one-to-one manner are arranged on the periphery of the positioning clamp along the circumferential route; the multiple oil injection devices are controlled by the air inlet control device to synchronously move towards the center position of the candan universal joint in the radial directions ofthe oil injection holes corresponding to the oil injection devices in position, oil is injected from the oil injection devices to the oil injection holes through control of an oil supply device afterthe oil injection devices are moved to the specific positions, and the oil inlet control device controls the oil injection devices to reset after oil injection is finished. The candan universal jointsynchronization oil injection equipment and the method solve the problems that multiple holes need to be subject to oil injection one by one in the candan universal joint oil injection process, the oil injection efficiency is low, oil amount in all holes is difficult to balance, oil injection into blind holes are prone to being brought out after oil injection resetting is carried out, the oil amount in the blind hole is insufficient, and consequently the product using effect is influenced.

Owner:ZHEJIANG QIDIE AUTOMOBILE PARTS CO LTD

Gearbox oil filler

PendingCN112879545AQuick oil injectionSimple structureLubricant transferGear lubrication/coolingInjection equipmentStorage tank

The invention relates to a gearbox oil filler. The gearbox oil filler comprises an oil storage tank and gas injection equipment used for injecting gas into the oil storage tank, an oil filling port which is through inside and outside is formed in the top of the oil storage tank, and the oil storage tank is further provided with an oil outlet which is through inside and outside. The gas injection equipment communicates with the top of the oil storage tank through a pipeline. The gearbox oil filler has the advantages that the structure is simple, operation is simple and convenient, the oil injection efficiency is greatly improved, manpower is saved, and cost is reduced.

Owner:BEIJING AUS JOURNEY AUTO SALES & SERVICE

Finishing processing device for compressor bearing machining and working method

ActiveCN109773609AFully polishedGood polishingEdge grinding machinesGrinding carriagesMotor driveEngineering

Owner:MAANSHAN YUEMEI METAL PROD TECH IND

Method for oil injection of liquid immersed type distribution transformer

InactiveCN105140014AGuaranteed performanceEasy to operateTransformers/inductances coolingInductances/transformers/magnets manufactureVacuum pumpingDistribution transformer

The invention discloses a method for oil injection of a liquid immersed type distribution transformer. The method comprises the following steps: the first step of finishing assembly of a transformer which is to undergo oil injection, and carrying the transformer to a presoaking liquid area; the second step of immersing a transformer body in the first step in oil in the presence of air; the third step of carrying the transformer in the second step to the vacuum environment, performing vacuum-pumping treatment on a transformer oil tank on the required process conditions, maintaining the vacuum for a period of time when the vacuum degree reaches a set value; the fourth step of carrying the transformer in the third step to an injection area, and performing supplemented injection to the vacuumized oil tank in the air until the liquid fills the oil tank. According to the method for oil injection, first in the air the transformer oil tank is filled with oil, then the transformer is placed in a vacuum tank or a pouring tank to be vacuumized, finally liquid supplementing is performed, so that the air in the oil tank can be discharged thoroughly, and the performance of the transformer is guaranteed. According to the method for oil injection, the operation process is also greatly simplified, and the oil injection efficiency is improved.

Owner:JIANGSU HONGYUAN ELECTRIC +3

Automatic oil filling device for automobile seat sliding rails

The invention discloses an automatic grease filling device for slide rails of automobile seats, which comprises: a transmission device; a slide rail fixing device, the slide rail fixing device is installed on the transmission device, and a A slide rail clamp for clamping the slide rail; an oil filling tank, in which multiple groups of nozzle devices are arranged, and the nozzle devices include at least one fixed nozzle device for oiling the outer rail of the slide rail and at least one for injecting oil into the outer rail of the slide rail The moving nozzle device for oiling the inner rail of the slide rail, in the same group of nozzle devices, the fixed nozzle device and the corresponding moving nozzle device are respectively located on both sides of the transmission device; among the adjacent two groups of nozzle devices, the fixed nozzle device of one group The nozzle device and the moving nozzle device of another group of nozzle devices are arranged alternately on the same side of the conveying device; the moving nozzle device is correspondingly provided with a reciprocating push mechanism. The invention can improve the oil injection efficiency of the car seat slide rail, thereby improving the production efficiency.

Owner:HOHAI UNIV CHANGZHOU

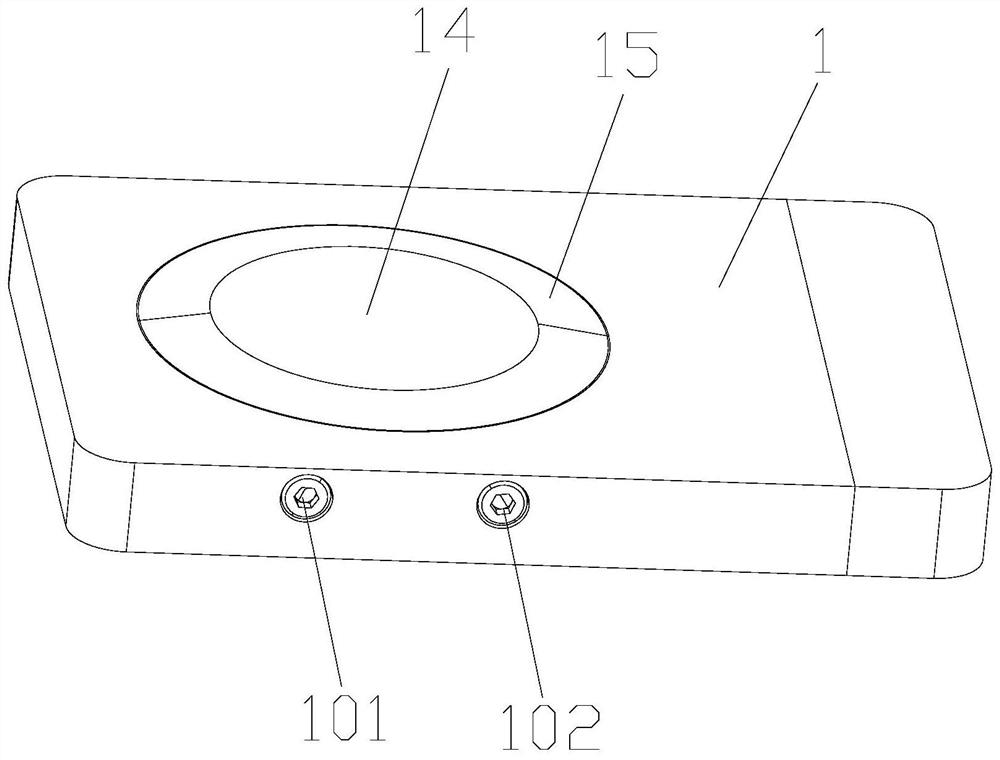

Weighing pressure sensor with high oil injection efficiency and oil injection method

PendingCN112857656AIncrease rangeHigh sensitivityFluid pressure measurement using ohmic-resistance variationPhysicsEngineering

The invention relates to a weighing pressure sensor with high oil injection efficiency and an oil injection method. The weighing pressure sensor comprises a shell, the shell is internally provided with a cavity, the cavity is filled with liquid, one side of the shell is provided with an opening, the opening is provided with a bottom cover, one side of the shell is provided with a first through hole, the first through hole is internally provided with a connector, the connector is provided with a diffused silicon sensor, the cavity wall of the other side, opposite to the bottom cover, of the shell is provided with an outward first protrusion and an inward second protrusion, a first inclined plane is formed between the highest point and the lowest point of the first protrusion, a second inclined plane is formed between the highest point and the lowest point of the second protrusion, and an inner chamfer is arranged at the joint of the second inclined surface and the side wall of the cavity. The pressure sensor is provided with the first inclined surface, the second inclined surface and the inner chamfer, so that the measuring range and the sensitivity are greatly improved. And moreover, the oil injection efficiency is high, oil injection is uniform, and no bubble is generated.

Owner:山东重心电子科技有限公司

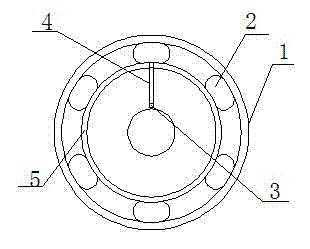

Oil filler point bearing

InactiveCN103591146AImprove oil injection efficiencyShorten the timeBearing componentsMachine repairPetroleum engineering

The invention relates to the technical field of bearing, and in particular to an oil filler point bearing. An oil filler point bearing includes a bearing and a roller. The bearing is provided with a roller, an oil filler point and an annular oil duct. The oil filler point and the annular oil duct are connected by an oil filler channel. According to the oil filler point bearing, for lubricating oil filling, the oil filling process can be carried out by aiming at the oil filler point on the bearing, and does not require removal of the bearing, so as to improve the working efficiency of oil filling, shorten the mechanical repair time and realize good usage effect.

Owner:CHANGZHOU JIANGNAN SPEED REDUCER

Automatic oiling machine

PendingCN109973798AApply evenlyStable and reliable applicationConduits/junctionsOil canOil distribution

The invention discloses an automatic oiling machine. The machine comprises a controller, a rack, an oil applying device and an oil storage tank; the rear end of the oil storage tank is provided with amovable piston type tank bottom, the tank bottom is pushed, lubricating oil can be extruded from a conical oil outlet nozzle in the front end, a lubricating oil pushing mechanism and an oil storage tank support are arranged on the rack, an adapting pipe is arranged on the front end of the oil storage tank support, the oil applying device is connected with the front end of the adapting pipe, the oil storage tank is placed on an oil storage tank support, the conical oil outlet nozzle of the front end of the oil storage tank is inserted into the adapting pipe, the tank bottom on the rear end ofthe oil storage tank is in abut joint with a pushing disc, the pushing disc is connected with the work end of a lubricating oil pushing mechanism, during use, an oil distribution cavity in the oil applying device is aligned with the part, required to be charged with the lubricating oil, of a mechanical device, the lubricating oil pushing mechanism is started, the lubricating oil can be extruded into the oil distribution cavity, the lubricating oil can be automatically injected into the portion, required to be lubricated, of the machine, during filling, the manual lubricating repeated procedureis reduced, the automation degree is high, and the problems that the work is tedious, dirty, tired and dangerous can be solved.

Owner:SHANDONG GURUN ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com