Automatic oiling machine

A fuel dispenser and automatic technology, applied in the directions of engine components, engine lubrication, mechanical equipment, etc., can solve the problems of poor working environment, uncontrollable speed of grease injection, difficult implementation, etc. Solve the effect of low coating efficiency and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

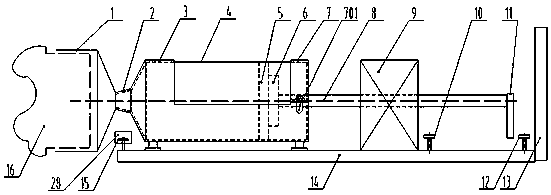

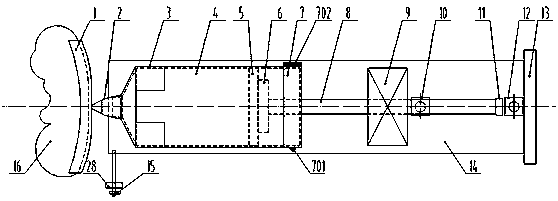

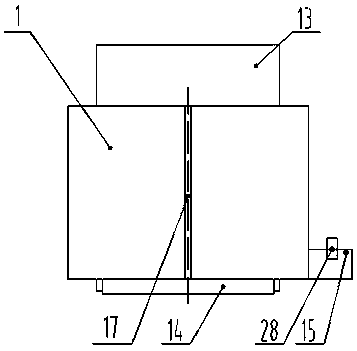

[0031] In order to clearly illustrate the technical features of this solution, the present invention will be further described below through non-limiting examples and in conjunction with the accompanying drawings.

[0032] The front, back, left, and right directions in the present invention are described based on the front, back, left, and right directions shown in the accompanying drawings. For ease of description, only parts related to the embodiments of the present invention are shown.

[0033]An automatic fuel dispenser, comprising a controller, a frame 14, an oil applicator 1 and an oil storage tank 4, the oil storage tank 4 has a structure similar to a glass glue tank, and is a package of lubricating oil, which has a rigid The tank body has a movable piston-type tank bottom 5 at the rear end, and a conical oil outlet nozzle 26 at the front end to push the tank bottom 5, and the lubricating oil 27 can be squeezed out from the conical oil outlet nozzle 26, and the lubricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com