Lubricating oil filling machine

An oil injection machine and lubricating oil technology, which is applied in the direction of lubricating oil control valves, lubricating parts, engine lubrication, etc., can solve the problems of inconvenient oil injection, shorten the service life of equipment, and insufficient oil injection, so as to improve oil injection efficiency and reduce The effect of small workload and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

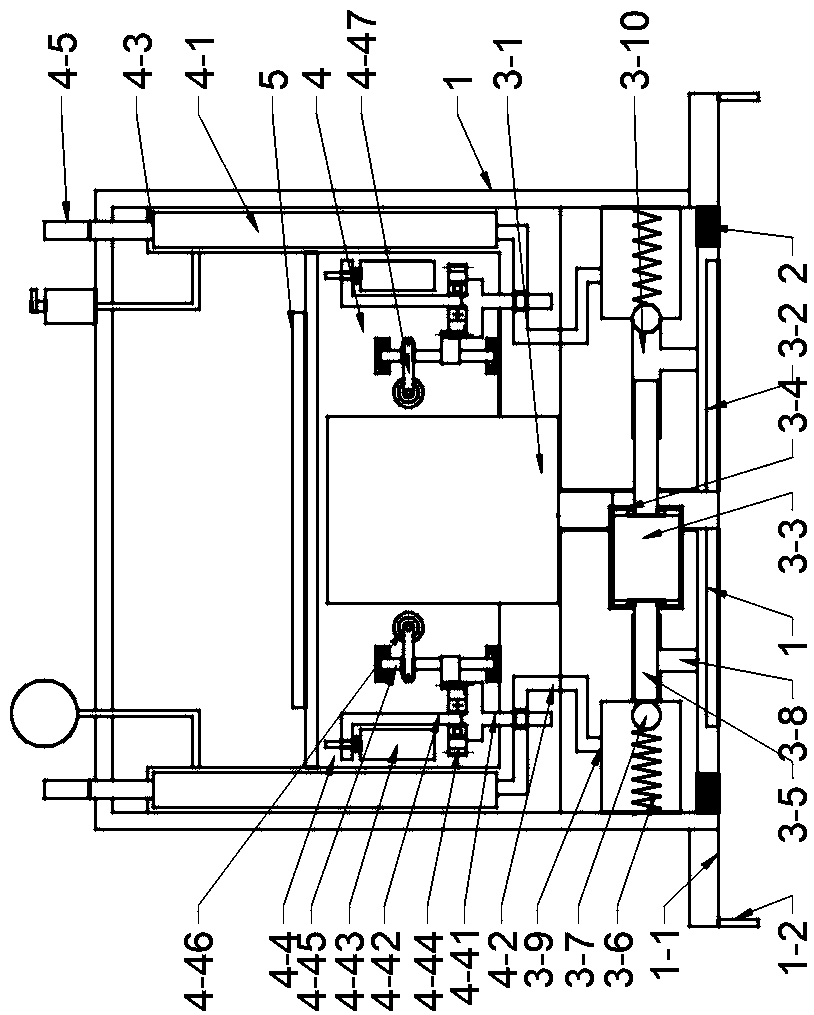

[0023] Such as figure 1 As shown, a lubricating oil injection machine includes a housing 1, a rubber oil pressure plate 2, an anti-tilt dustproof system, an oil pump device 3, an oil separator 4 and a control system 5; the oil pump device 3 is installed in the housing 1 The bottom of the housing 1 is installed with a rubber pressure oil plate 2, and the oil separator 4 and the control system 5 are installed in the housing 1; the oil pump device 3 includes a motor 3-1, a spiral oil scraper 3-2, and an eccentric wheel 3-3 , collar 3-4, plunger 3-5, spring 3-6, steel ball 3-7, oil inlet 3-8, oil outlet 3-9 and oil channel 3-10; the spiral oil scraper 3-2 is located at the bottom of the housing 1 and is fixedly connected with the output shaft of the motor 3-1; the oil inlet 3-8 is evenly distributed on the bottom surface of the housing 1 in the circumferential direction, and the oil inlet 3-8 is located on the spiral oil scraper 3- 2 within the radius of rotation; the oil outlet ...

Embodiment approach 2

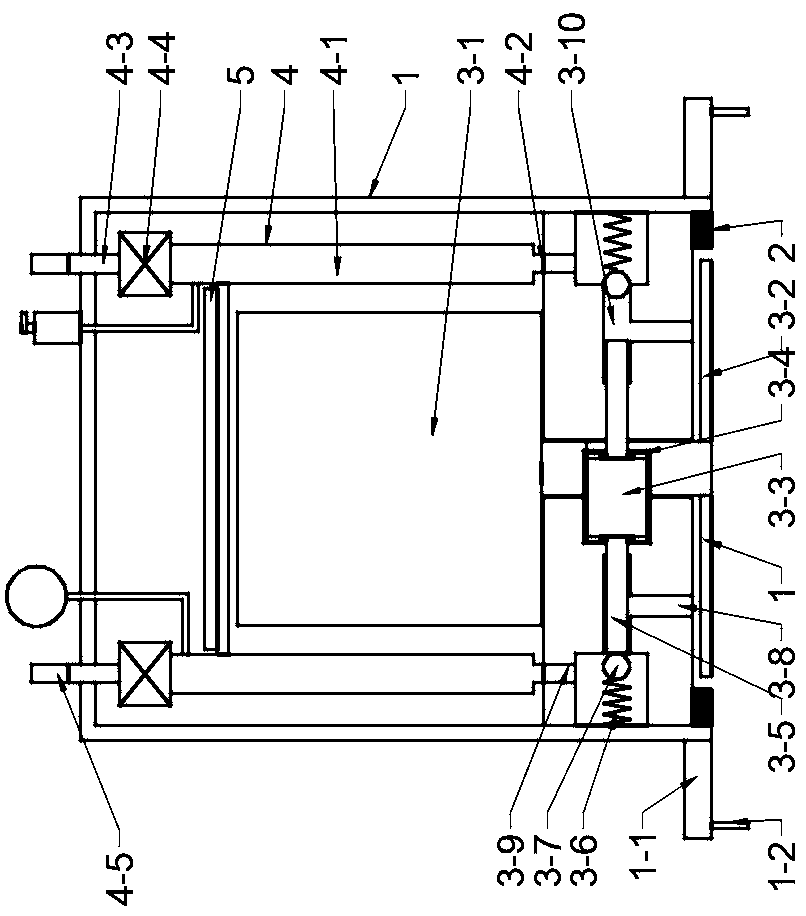

[0037] Such as image 3 As shown, the electromagnetic valve 4 directly adopts an electromagnetic valve.

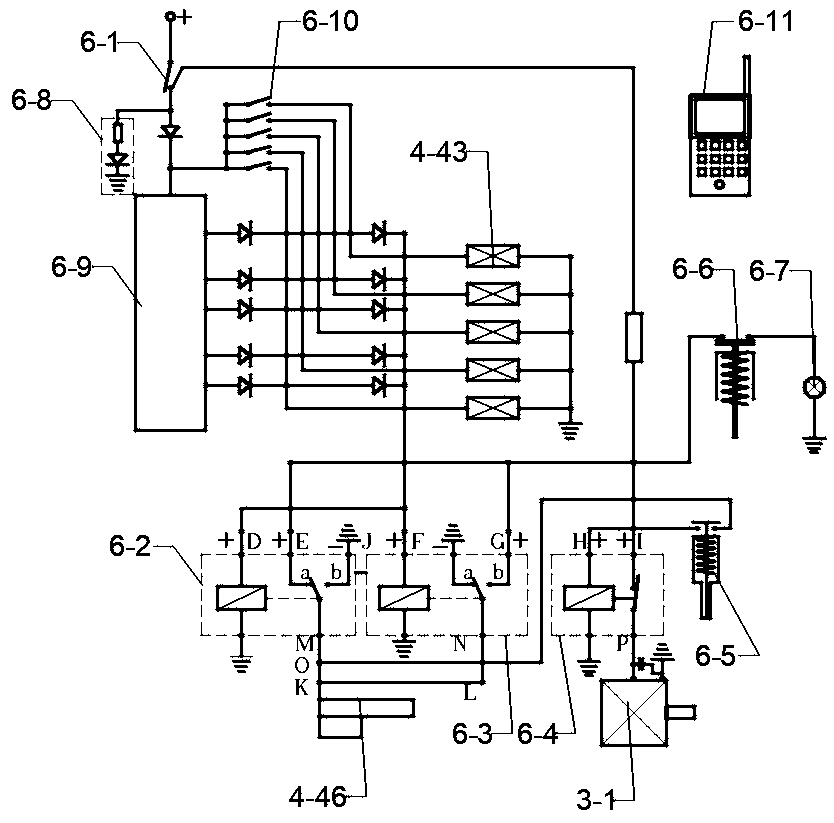

[0038] Such as Figure 4 As shown, the control system 5 includes a power switch 5-1, a solenoid valve switch 5-2, an oil pump relay 5-3, a pressure controller 5-4, a remote control chip 5-5, a position sensor 5-6, and an alarm 5-7, power indicator light 5-8 and remote controller 5-9; the main circuit of the control system 5 is connected to the power supply, and is provided with a power switch 5-1; the main circuit connects four branch circuits, all the way connected to the power indicator light 5 -8; the other road is connected to the remote controller chip 5-5, and the remote controller chip 5-5 and the remote controller 5-9 realize wireless signal transmission; the third route is a plurality of solenoid valve switches 5-2 and corresponding solenoid valve valves 4- 4 in series and then in parallel, then in series with the pressure controller 5-4, the pressure controller...

Embodiment approach 3

[0044] Such as Figure 5 As shown, the electric push rod 4-46 in Embodiment 1 is replaced by a motor 4-48, the front end of the output shaft of the motor 4-48 is equipped with a power output gear 4-49, and the upper part of the disc shift fork 4-45 is equipped with a transmission Gear 4-50, output gear 4-49 meshes with transmission gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com