Oil storage bin cover, atomizer and electronic cigarette

A technology of oil storage tanks and atomizers, which is applied in the direction of tobacco, etc., can solve the problems of burning out heating elements, inconvenient use and carrying, and easy to be stained with e-liquid, so as to prevent the leakage of e-liquid and accelerate the efficiency of oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

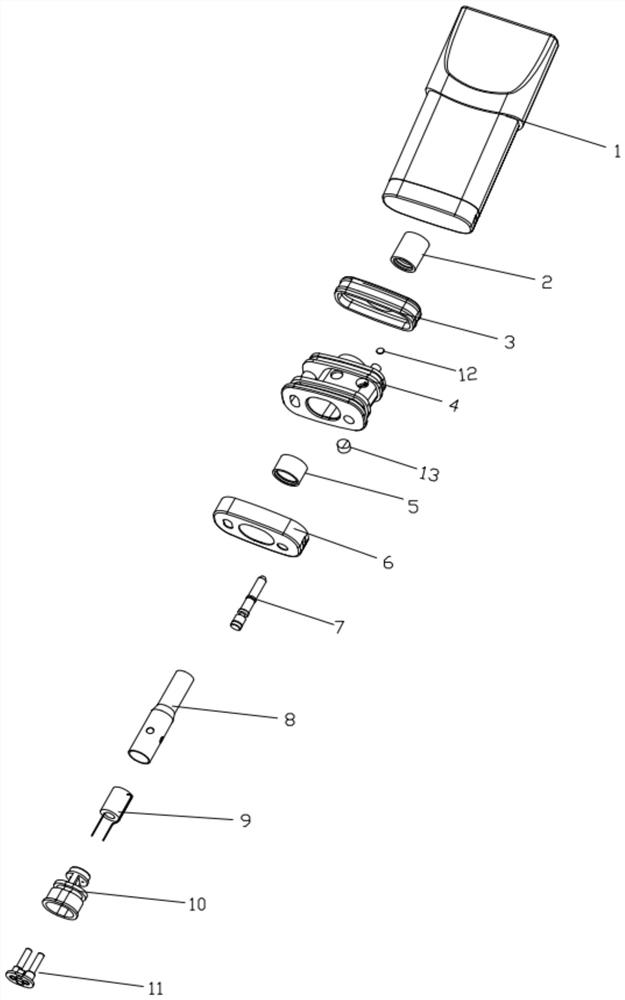

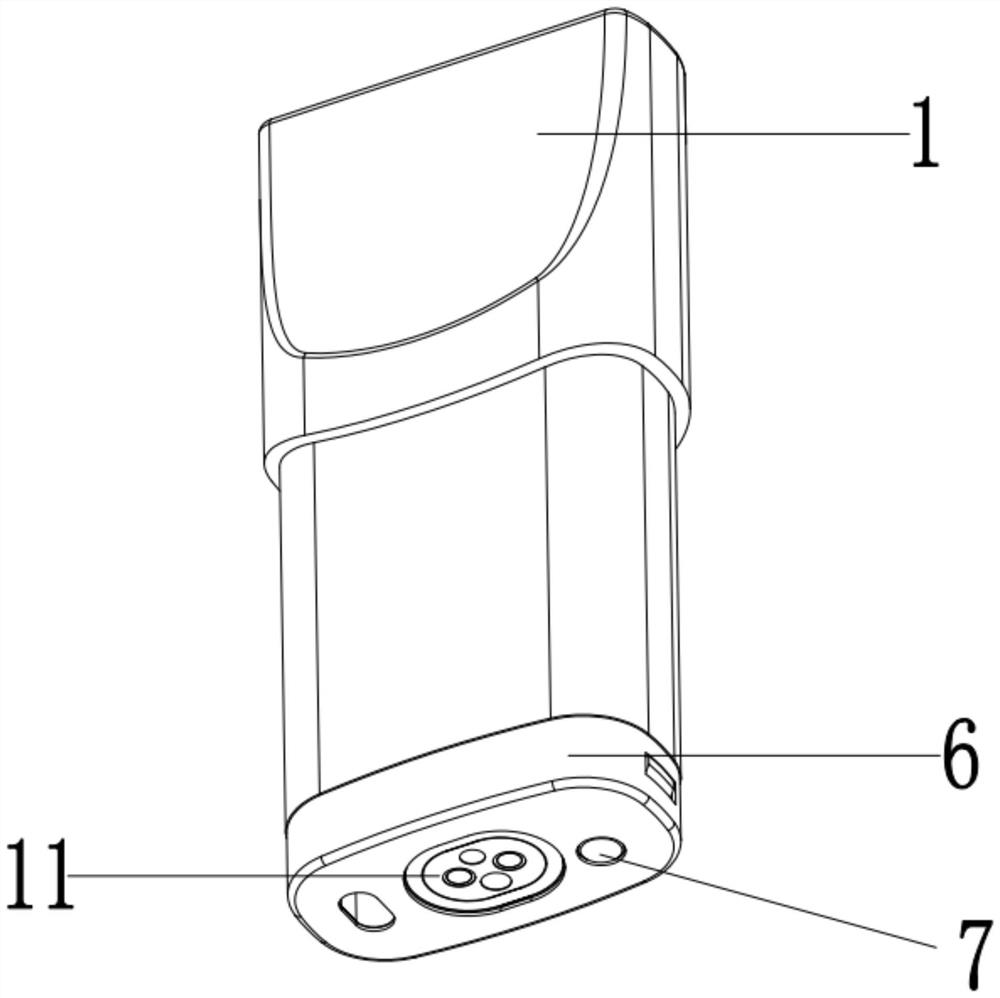

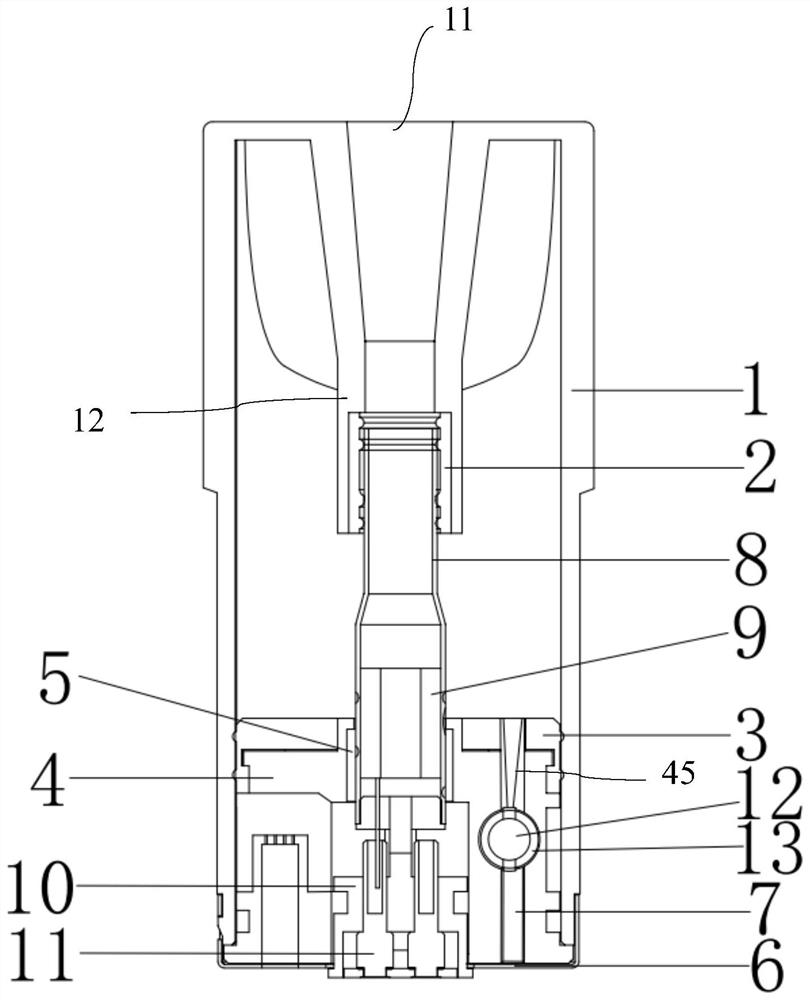

[0049] Specifically, as Figure 1-3 As shown, in order to solve the shortcomings of the prior art, in a specific embodiment of the present invention, the electronic cigarette includes an atomizer and an electric core assembly. The atomizer includes: oil storage tank 1, third seal 2, first seal 3, oil storage cover 4, second seal 5, oil tank cover 6, oil seal plug 7, limiter 8, heating Body 9, heating body fixing seat 10, pin fixing part 11, cotton suction part 12, filling plug 13.

[0050] Such as Figure 1-3 As shown, a mouthpiece 11 is provided at one end of the oil storage bin 1 , and a smoke pipe 12 protrudes from the mouthpiece 11 to the inside of the oil storage bin 1 , and the smoke generated after the e-liquid is heated flows out of the smoke pipe 12 .

[0051] Such as Figure 4 As shown, the oil storage tank cover 4 includes a hollow main body, the hollow part of the main body is used as an air channel 46, and the main body is provided with a space groove 41, an ai...

Embodiment 2

[0056] The difference from Embodiment 1 is that the air hole 18 is provided on the wall of the space groove 41 of the main body of the oil storage tank cover 4 , but the air inlet hole 15 and the air passage 46 are not designed, and the space groove 41 is only used in conjunction with the air hole 18 . The design of the air inlet 15 is not limited, as long as it communicates with the atomizing channel containing the heating element 9 .

Embodiment 3

[0058] The difference from Embodiment 1 is that the air inlet 15 is provided on the wall of the space groove 41 of the main body of the oil storage tank cover 4 , but the air hole 18 is not designed, and the space groove 41 is only used in conjunction with the air inlet 15 . The atomizer as a whole may not be designed with a vent hole, or a vent hole 18 may be designed on the wall of the oil storage tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com