Multi-head oil injection positioning device, oil injection equipment and oil injection method

A technology of positioning device and oil filling equipment, which is applied to distribution devices, special distribution devices, liquid distribution, conveying or transfer devices, etc. The effect of low filling cost and improved oil filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

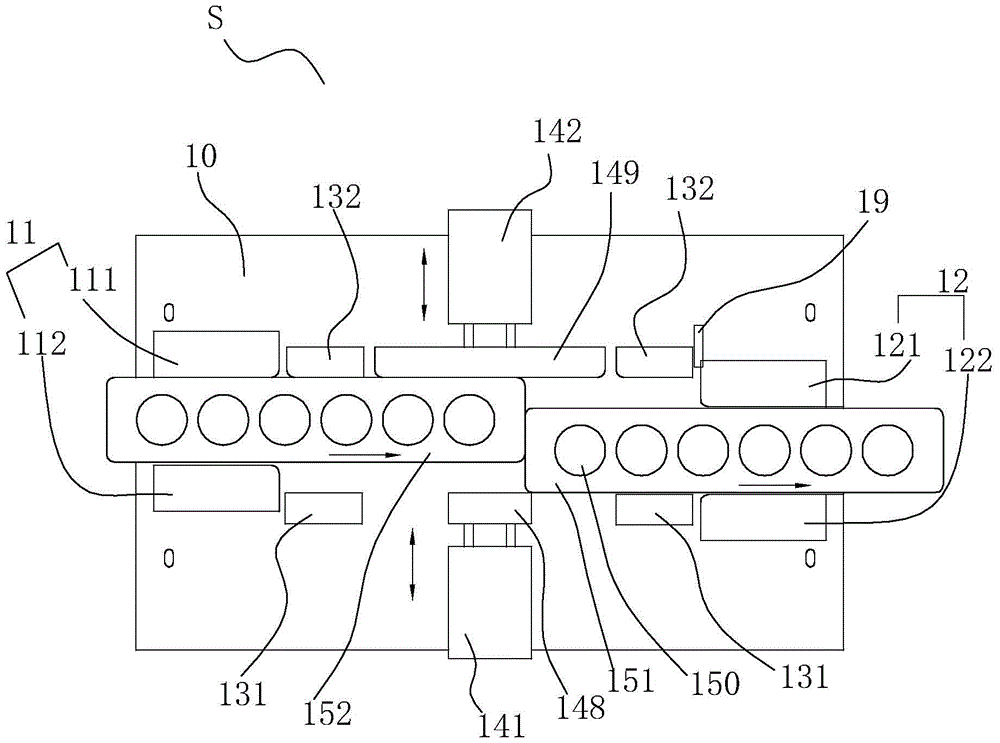

[0056] Such as figure 1As shown, the multi-head oil injection positioning device S of the present invention includes a bottom plate 10; it also includes a feed stopper group 11 and a discharge stopper group 12 arranged on the bottom plate, and also includes a set of feed stoppers 11 and a discharge stopper The front baffle 131 and the back baffle 132 between the block groups 12, and the front cylinder 141 positioned at the front side of the front baffle 131 and the rear cylinder 142 positioned at the rear side of the rear baffle 132 (its movable end is provided with a push plate 149) The jig seat 151 that has been filled with oil moves to the front baffle plate 131 under the forward push of the rear cylinder 142, and the rear cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com