Transformer vacuum oiling device and oiling method thereof

A technology for oil injection equipment and transformer oil tank, which is applied in the field of transformer oil injection, can solve the problems of development obstacles of small and medium-sized transformer manufacturers, unfavorable development of transformers, and inability to move, and achieves the effect of ensuring the quality of insulating oil, fast oil injection, and increasing equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

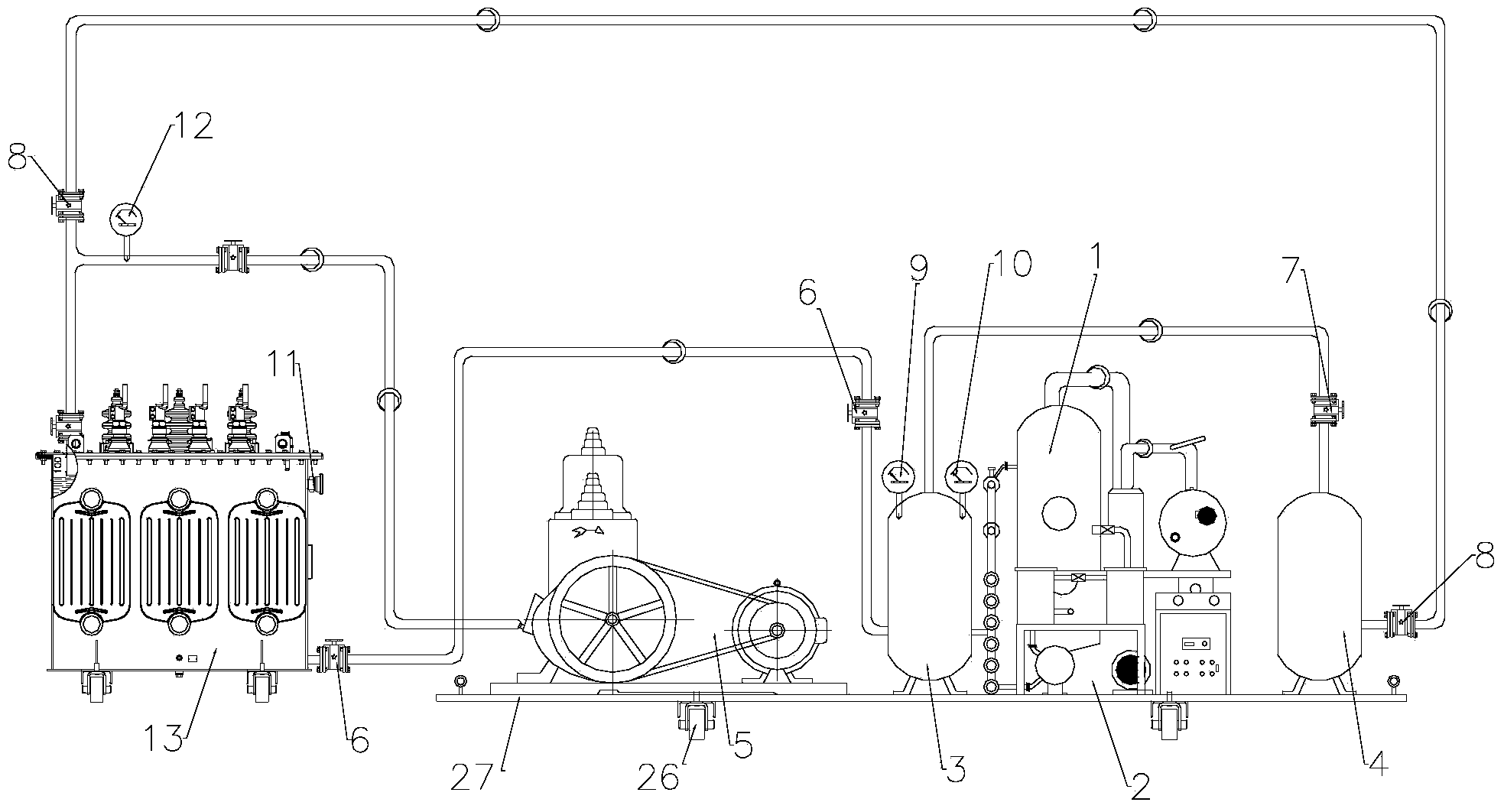

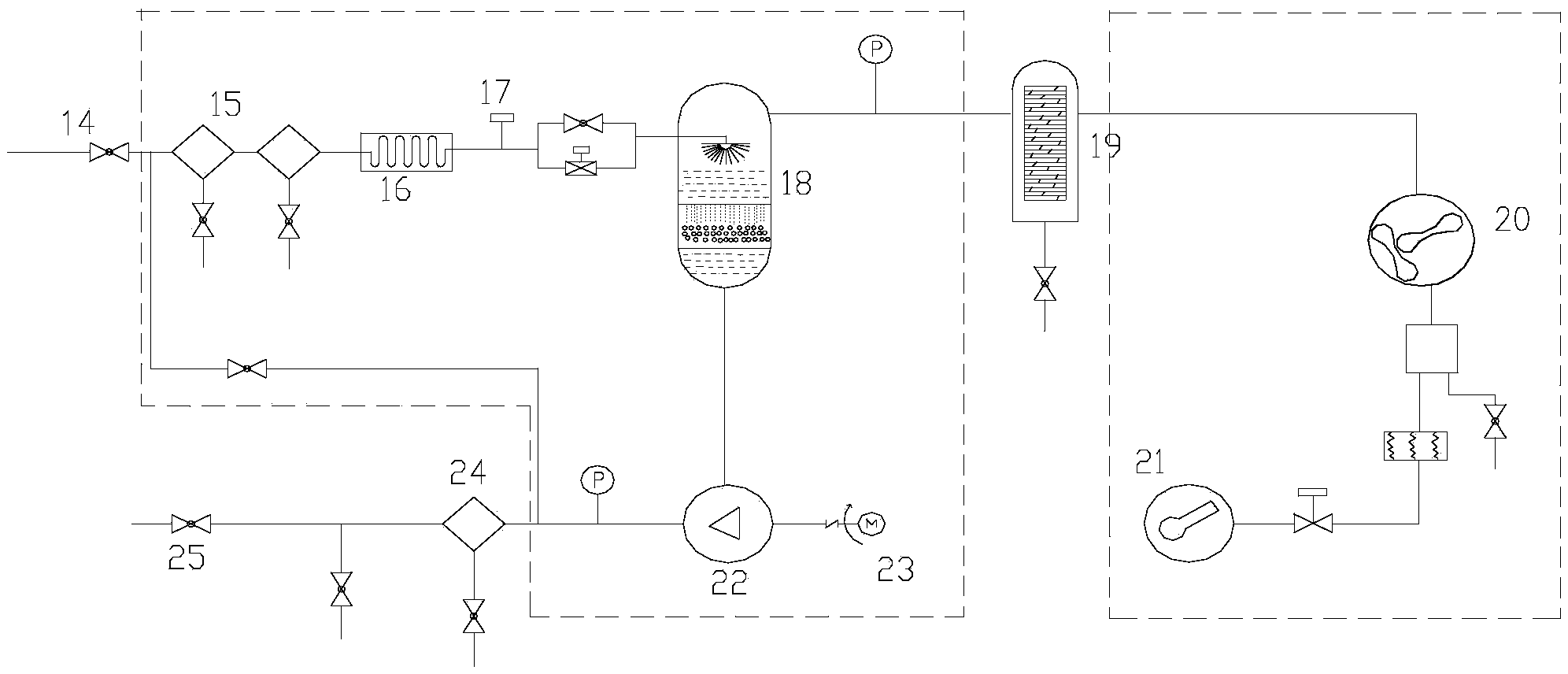

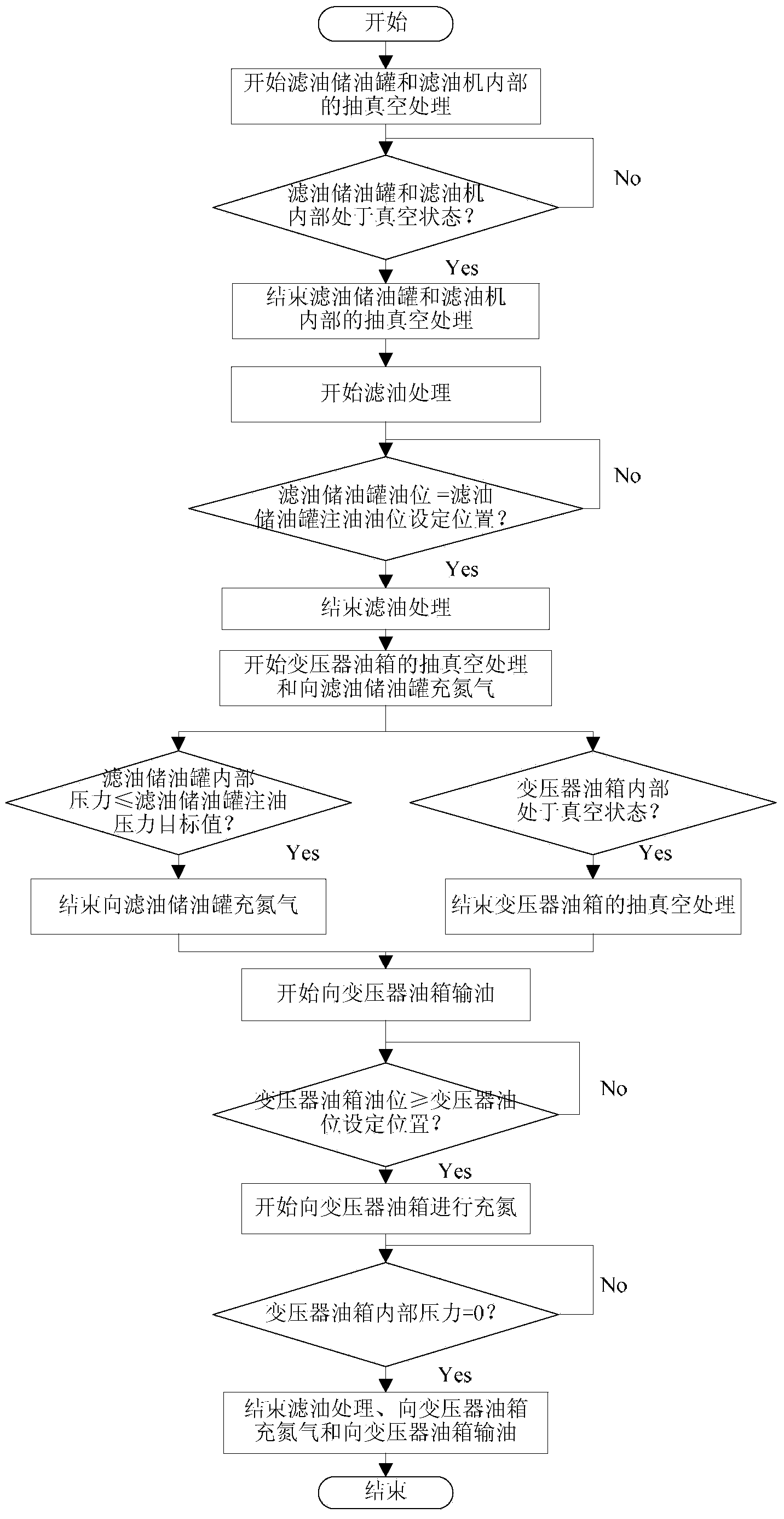

[0042] This embodiment describes a transformer vacuum oiling equipment, its structure is as follows figure 1 shown. The equipment includes a crude oil storage tank 1, an oil filter unit 2, an oil filter storage tank 3, a nitrogen tank 4 and a main controller, as well as a sensor device for the oil filter storage tank and a transformer oil tank sensor device connected to the main controller for signals , oil storage tank oil output control device 6, oil storage tank nitrogen filling control device 7, transformer nitrogen filling control device 8 and vacuum device. The equipment in this embodiment uses sensing technology to detect the internal pressure and oil level of the oil filter oil storage tank and transformer, and the main controller controls the oil filling according to the detection results, thereby realizing automatic oil filling.

[0043] The crude oil storage tank 1 is connected to the oil filter unit 2 and the filtered oil storage tank 3 in sequence. The crude oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com