Oil level detection alarming device during vacuum oil injection of transformer

A technology of oil level detection and alarm device, which is applied in the direction of measuring device, lubrication indicating device, liquid level indicator for physical variable measurement, etc., can solve the problems of wasting oil resources, polluting the environment, errors, etc., and achieves the reduction of labor intensity and accurate Control and realize the effect of automatic oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

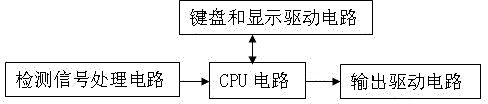

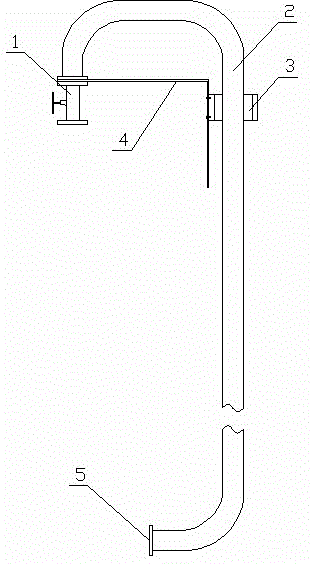

[0015] The key component in the present invention is the oil level detection and alarm device, and the oil level detection and alarm device includes a detection device 3, a detection position adjustment device and a display and control instrument, wherein the display and control instrument is an intelligent instrument, which is connected to the detection device 3 through a cable , its internal circuit mainly includes CPU circuit, keyboard and display drive circuit, detection signal processing circuit and output drive circuit. The output control circuit is used to control the power supply and alarm of the oil injection machine; the keyboard circuit in the keyboard and display drive circuit is used for parameter input (oil level parameters, control parameters, etc.), and the display drive circuit is used for display of various parameter data. The detection signal processing circuit is used to process the detection signal of the detection device, and send it to the CPU circuit for...

Embodiment 2

[0019] The difference between this implementation and Embodiment 1 is that the detection device adopts an ultrasonic detection component, and the ultrasonic detection component includes an ultrasonic transmitting device and an ultrasonic receiving device.

Embodiment 3

[0021] The difference between this implementation and Embodiment 1 is that the detection device adopts a capacitance detection component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com