Automatic oil injection device of automobile seat slide rail

A car seat slide rail and automatic oiling technology, which is applied to the device and coating of the surface coating liquid, can solve the problems that affect the product defective rate, easy fatigue, low labor rate, etc., to reduce labor costs, The effect of reducing scrap rate and saving economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

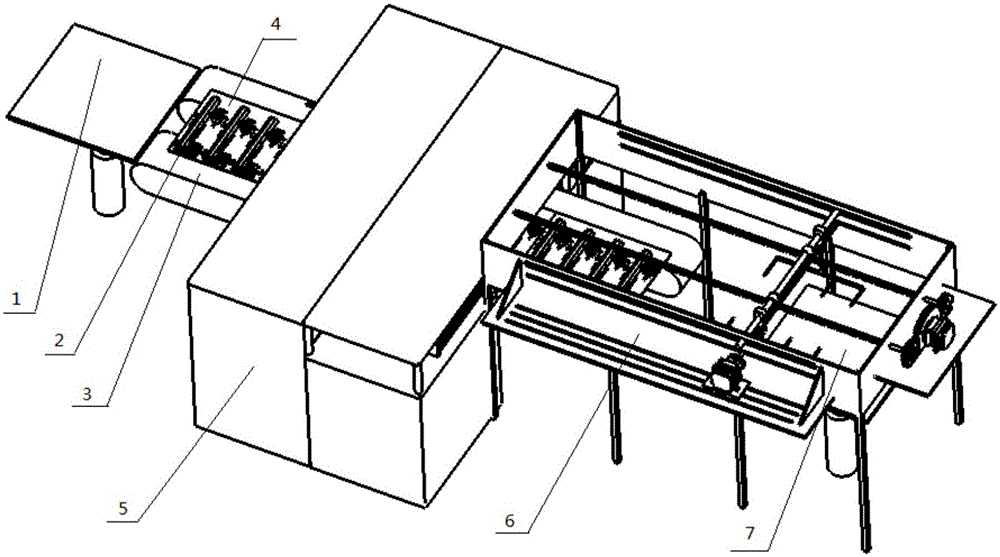

[0021] like figure 1 and 2 As shown, a kind of car seat slide rail automatic oiling device comprises a conveyor belt 3, a car slide rail device 2 runs through the conveyor belt 3, a cylinder box 5 is arranged in the middle of the conveyor belt 3, and a car slide rail device 2 is provided with Car slide rail fixture 4, described conveyer belt 3 is used for conveying car seat slide rail;

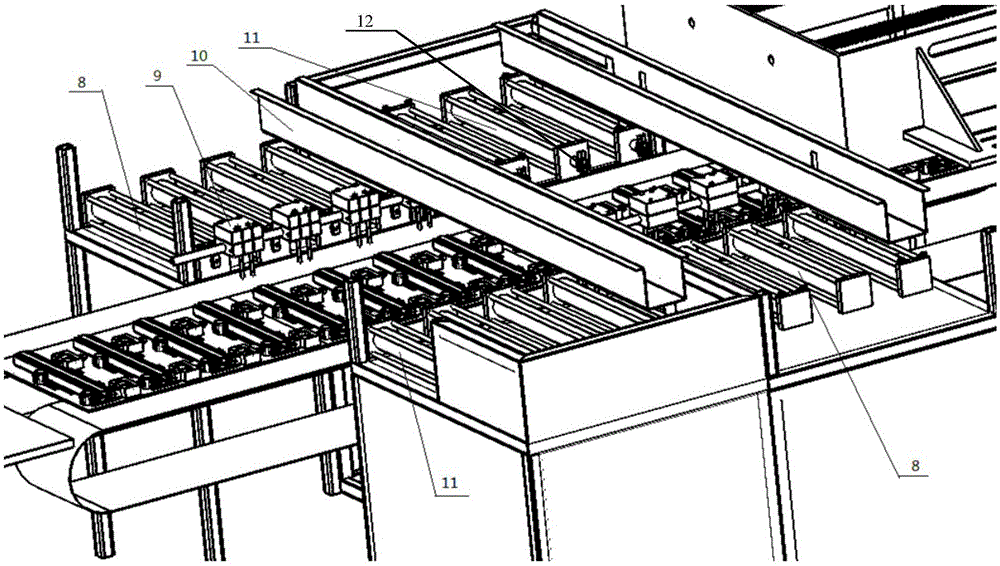

[0022] Several groups of nozzle devices are arranged in the cylinder box 5, and each group of nozzle devices is installed on both sides of the conveyor belt 3; one side of each group of nozzle devices is a plurality of fixed nozzle devices 9, and the other side is a plurality of mobile nozzle devices 11. The fixed nozzle devices 9 and the movable nozzle devices 11 of each adjacent two groups of nozzle devices alternate with each other, and each movable nozzle device 11 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com